Axial Stress-Strain Performance of Recycled Aggregate Concrete Reinforced with Macro-Polypropylene Fibres

Abstract

1. Background

2. Significance

3. Experimental Scheme

3.1. Materials and Preparation of Samples

3.2. Test Plan

4. Results and Discussion

4.1. General Behaviour

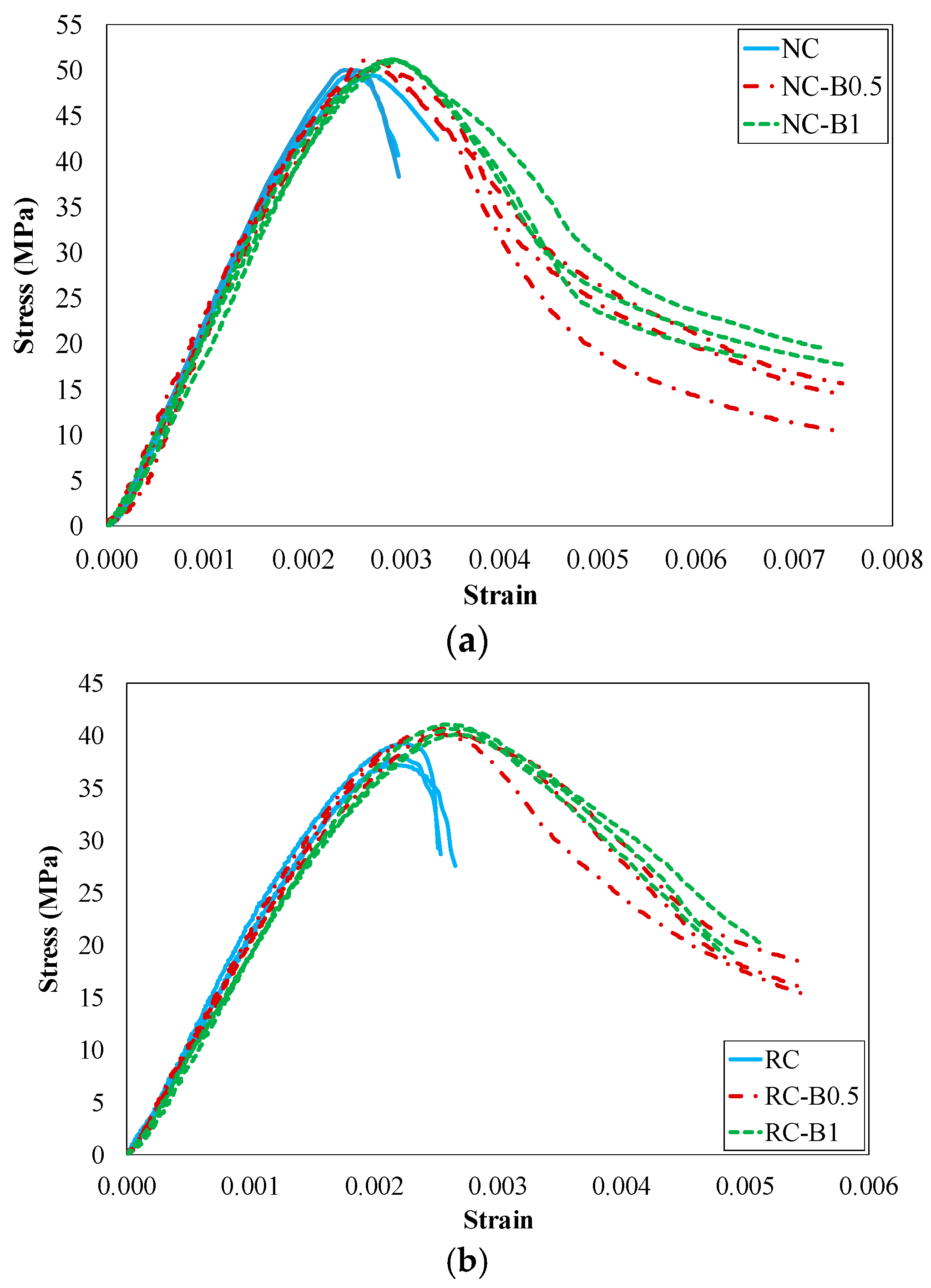

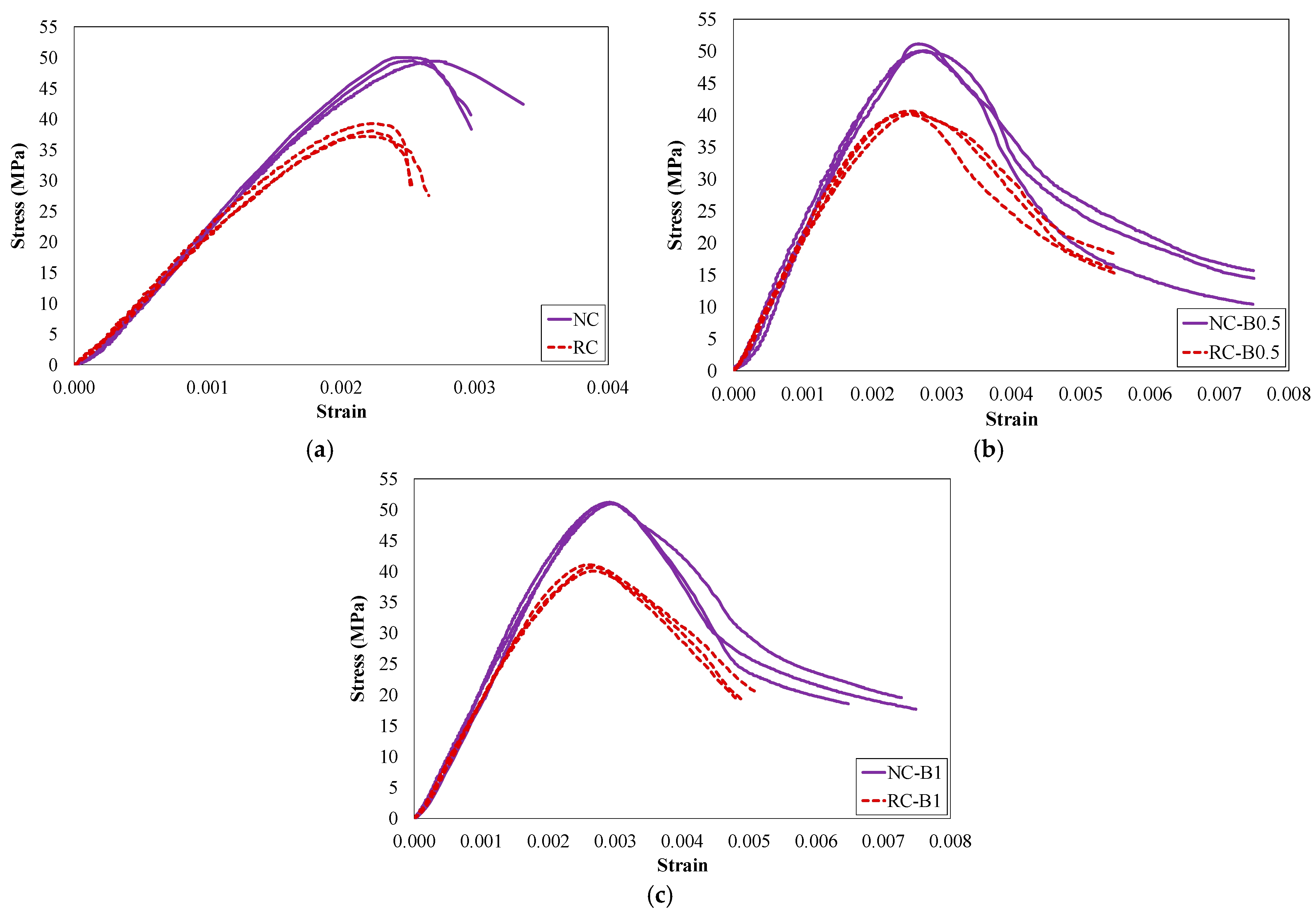

4.2. Axial Stress-Strain Behaviour

4.3. Stress-Strain Properties

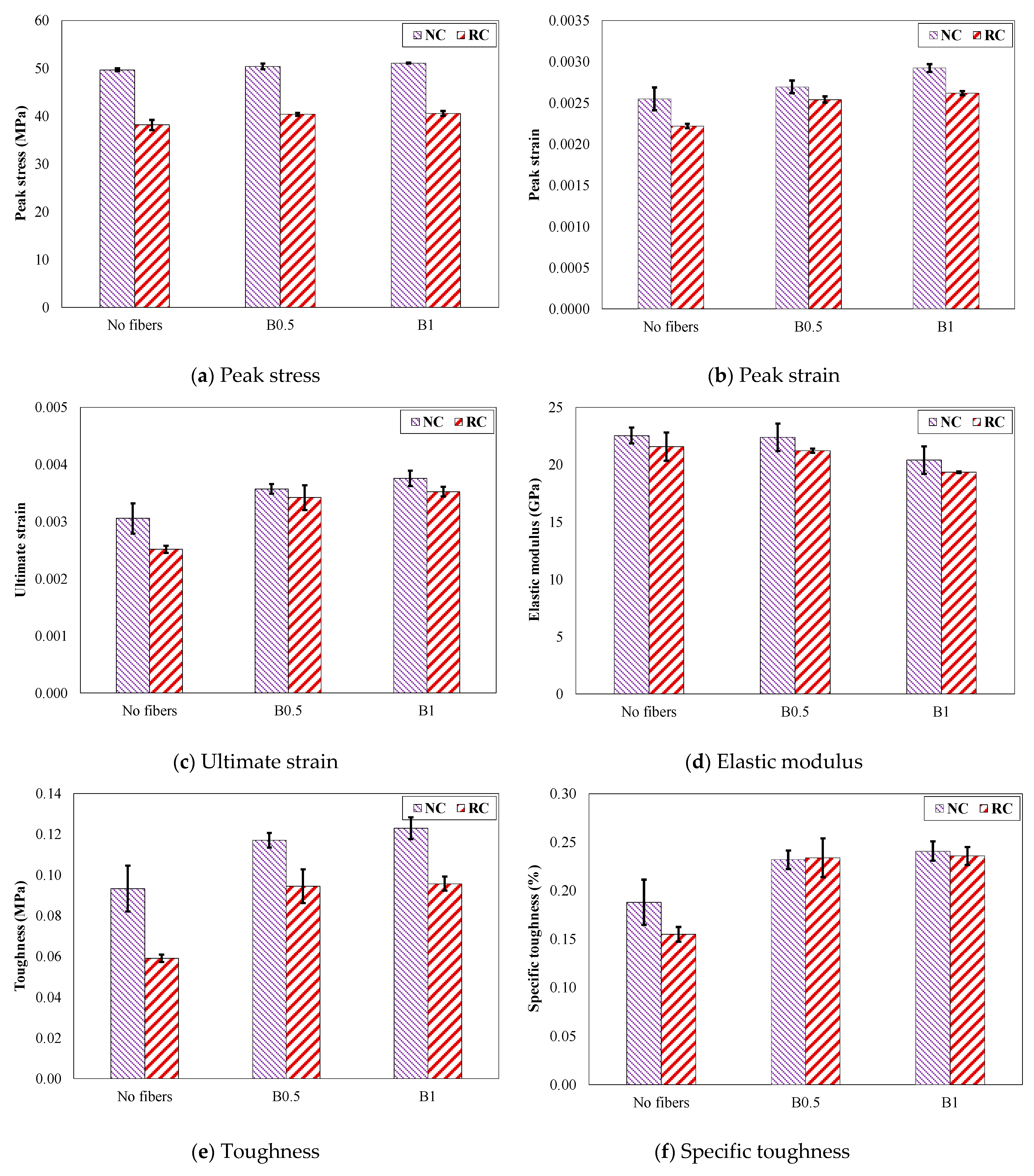

4.3.1. Peak Stress

4.3.2. Peak Strain

4.3.3. Ultimate Strain

4.3.4. Elastic Modulus

4.3.5. Toughness

4.3.6. Specific Toughness

4.4. Analytical Modelling

4.5. Effect of Fibre Type on the Axial Stress-Strain Behaviour

5. Summary and Conclusions

- Increases in energy dissipation capacity (i.e., area under the curve), peak stress, and peak strain of samples are noticed with an increase in fibre dosage, indicating the positive effect of fibre addition on the stress-strain performance of concrete. Strength enhancement due to the addition of fibres is also noticed to be higher for RC samples than for NC samples.

- An increase of 3 and 6% in the peak stress is observed for the NC-B1 and RC-B1 samples, respectively. The fibre addition reduces the wing-crack growth rate by resisting the development of micro-cracks and results in the improved mechanical performance of concrete samples.

- NC samples show a peak strain of 0.0025, which reduces to 0.0022 for RC samples. However, an increased peak strain of concrete samples is noticed with an increase in fibre dosage. NC-B1 and RC-B1 samples show peak strain 15 and 18% higher than NC and RC samples, respectively. The peak strain of all the FRC samples is higher than the NC samples.

- NC samples show an ultimate strain of 0.0031, which reduces to 0.0025 for RC samples. However, an increased ultimate strain of concrete samples is observed with an increase in fibre dosage. NC-B1 and RC-B1 samples show an ultimate strain 23 and 40% higher than NC and RC samples, respectively. The ultimate strain of all the FRC samples is higher than the NC samples.

- NC samples have a modulus of elasticity of 23 GPa, which decreases to 22 GPa for RC samples. Decreased modulus of elasticity of concrete samples is also noticed with an increase in fibre dosage, which is due to the influence of the fibre addition on the compaction/consolidation of concrete samples. The elastic modulus of all the concrete samples is lower than the NC samples.

- NC samples show the specific toughness of 0.19%, which reduces to 0.15% for RC samples. However, increased specific toughness of concrete samples is observed with an increase in fibre dosage. NC-B1 and RC-B1 samples show specific toughness 28 and 52% higher than NC and RC samples, respectively. The specific toughness of all the BFNAC and BFRAC samples is higher than the NC samples. Hence, the negative effect of CRA on the properties of concrete samples can be minimised by adding BarChip macro-polypropylene fibres.

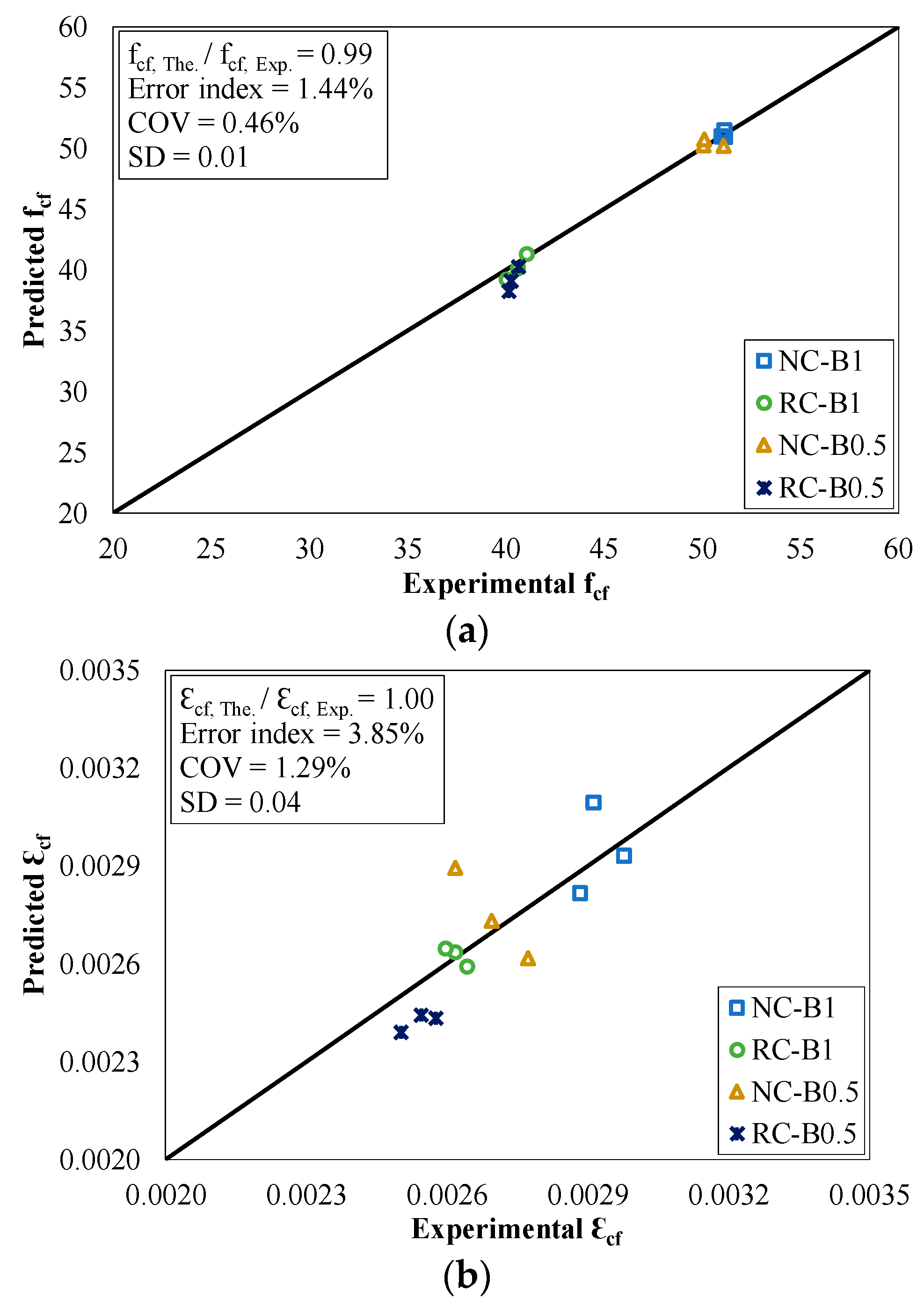

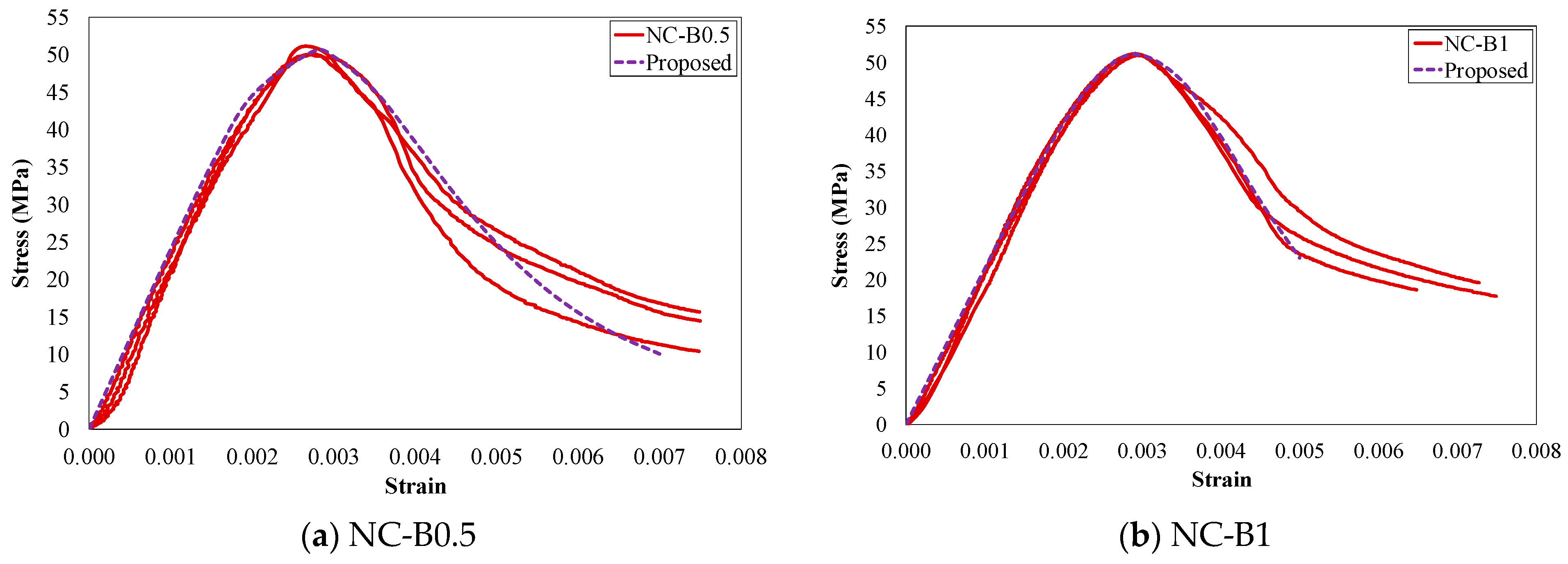

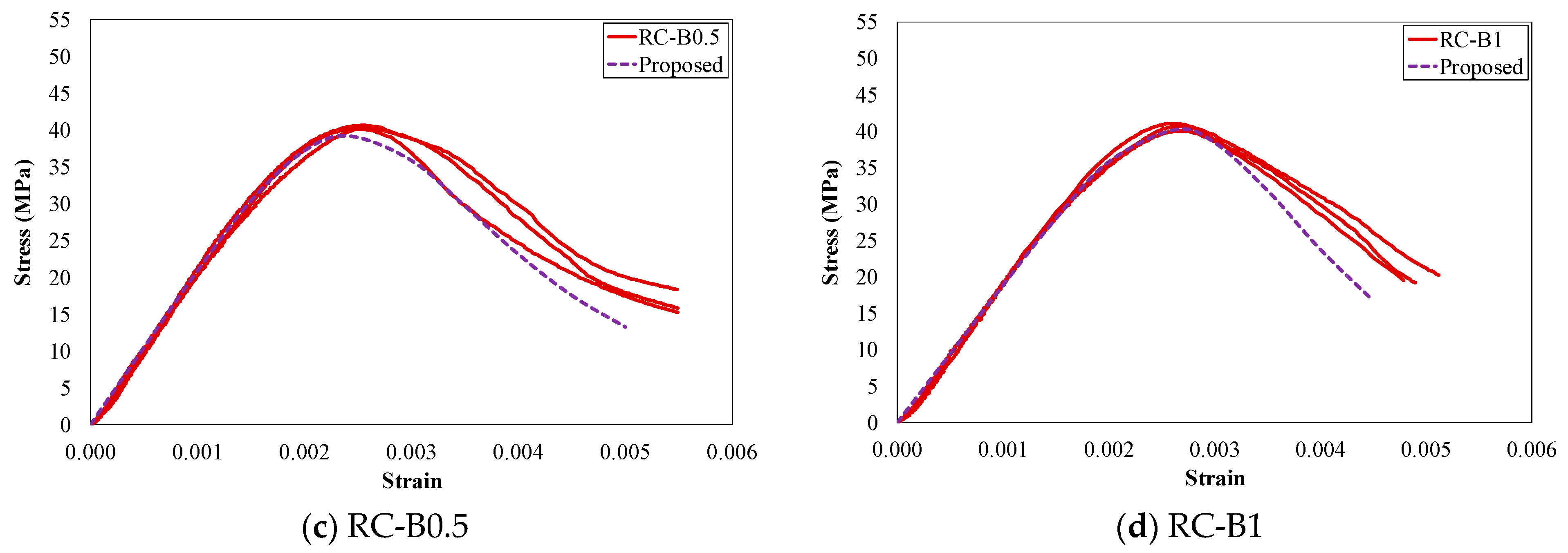

- The applicability of the stress-strain model developed by Kazmi et al. [5] for macro-synthetic and steel fibre-reinforced NAC and RAC to BFNAC and BFRAC is examined in this study. The predicted values of peak stress and peak strain are close to the measured results of BFNAC and BFRAC samples by an error index of 1 and 4%, respectively. The experimental stress-strain curves are also quite close to the predicted curves. Therefore, the Kazmi et al. [5] model can effectively predict the axial stress-strain behaviour of BFNAC and BFRAC samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Patnaikuni, I.; Wang, J.; Wang, Q. Development of a unified model to predict the axial stress–strain behavior of recycled aggregate concrete confined through spiral reinforcement. Eng. Struct. 2020, 218, 110851. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Kazmi, S.M.S.; Munir, M.J.; Zhou, Y.; Xing, F. Effect of compression casting method on the compressive strength, elastic modulus and microstructure of rubber concrete. J. Clean. Prod. 2020, 264, 121746. [Google Scholar] [CrossRef]

- Fu, Q.; Niu, D.; Li, D.; Wang, Y.; Zhang, J.; Huang, D. Impact characterization and modelling of basalt‒polypropylene fibre-reinforced concrete containing mineral admixtures. Cem. Concr. Compos. 2018, 93, 246–259. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Monteiro, P.J.M. The effect of steel and polypropylene fibers on the chloride diffusivity and drying shrinkage of high-strength concrete. Compos. Part B Eng. 2018, 139, 84–96. [Google Scholar] [CrossRef]

- Banyhussan, Q.S.; Yıldırım, G.; Bayraktar, E.; Demirhan, S.; Şahmaran, M. Deflection-hardening hybrid fiber reinforced concrete: The effect of aggregate content. Constr. Build. Mater. 2016, 125, 41–52. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Axial stress-strain behavior of macro-synthetic fiber reinforced recycled aggregate concrete. Cem. Concr. Compos. 2019, 97, 341–356. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I. Effect of macro-synthetic fibers on the fracture energy and mechanical behavior of recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 857–868. [Google Scholar] [CrossRef]

- Mudadu, A.; Tiberti, G.; Germano, F.; Plizzari, G.A.; Morbi, A. The effect of fiber orientation on the post-cracking behavior of steel fiber reinforced concrete under bending and uniaxial tensile tests. Cem. Concr. Compos. 2018, 93, 274–288. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Shui, Z.; Rao, S.; Wang, X.; Sun, M.; Jiang, C. Steel fibre content and interconnection induced electrochemical corrosion of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Compos. 2018, 94, 191–200. [Google Scholar] [CrossRef]

- Teng, S.; Afroughsabet, V.; Ostertag, C.P. Flexural behavior and durability properties of high performance hybrid-fiber-reinforced concrete. Constr. Build. Mater. 2018, 182, 504–515. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yurtseven, A.; Ozgur Yaman, I. Workability of hybrid fiber reinforced self-compacting concrete. Build. Environ. 2005, 40, 1672–1677. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yaman, I.O. Hybrid fiber reinforced self-compacting concrete with a high-volume coarse fly ash. Constr. Build. Mater. 2007, 21, 150–156. [Google Scholar] [CrossRef]

- Neves, R.D.; Almeida, J.C.O.F.D. Compressive behaviour of steel fibre reinforced concrete. Struct. Concr. 2005, 6, 1–8. [Google Scholar] [CrossRef]

- Amin, A.; Foster, S.J.; Gilbert, R.I.; Kaufmann, W. Material characterisation of macro synthetic fibre reinforced concrete. Cem. Concr. Compos. 2017, 84, 124–133. [Google Scholar] [CrossRef]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Sadrinejad, I.; Madandoust, R.; Ranjbar, M.M. The mechanical and durability properties of concrete containing hybrid synthetic fibers. Constr. Build. Mater. 2018, 178, 72–82. [Google Scholar] [CrossRef]

- Drzymała, T.; Jackiewicz-Rek, W.; Gałaj, J.; Šukys, R. Assessment of mechanical properties of high strength concrete (HSC) after exposure to high temperature. J. Civ. Eng. Manag. 2018, 24, 138–144. [Google Scholar] [CrossRef]

- Rudnik, E.; Drzymała, T. Thermal behavior of polypropylene fiber-reinforced concrete at elevated temperatures. J. Therm. Anal. Calorim. 2018, 131, 1005–1015. [Google Scholar] [CrossRef]

- Jackiewicz-Rek, W.; Drzymała, T.; Kuś, A.; Tomaszewski, M. Durability of high performance concrete (HPC) subject to fire temperature impact. Arch. Civ. Eng. 2016, 62, 73–93. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W. Production of sustainable and structural fiber reinforced recycled aggregate concrete with improved fracture properties: A review. J. Clean. Prod. 2021, 279, 123832. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I. Mechanical and post-cracking performance of recycled aggregate concrete incorporating synthetic fibers. IOP Conf. Ser. Mater. Sci. Eng. 2020, 829, 012003. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.; Li, T.; Liu, B.; Li, B.; Zhou, Y. The mechanical properties of tailing recycled aggregate concrete and its resistance to the coupled deterioration of sulfate attack and wetting–drying cycles. Structures 2020, 27, 2208–2216. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Maurya, K.K.; Samanta, A.K. Investigation on UPVC confined RC columns with Recycled Aggregate Concrete using C&D waste. Structures 2020, 23, 279–288. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of different aggregate treatment techniques on the freeze-thaw and sulfate resistance of recycled aggregate concrete. Cold Reg. Sci. Technol. 2020, 178, 103126. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of recycled aggregate treatment techniques on the durability of concrete: A comparative evaluation. Constr. Build. Mater. 2020, 264, 120284. [Google Scholar] [CrossRef]

- Tam, V.W.Y. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- Kisku, N.; Rajhans, P.; Panda, S.K.; Pandey, V.; Nayak, S. Microstructural investigation of recycled aggregate concrete produced by adopting equal mortar volume method along with two stage mixing approach. Structures 2020, 24, 742–753. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F. Application of waste tire rubber and recycled aggregates in concrete products: A new compression casting approach. Resour. Conserv. Recycl. 2021, 167, 105353. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of fly ash as cement replacement on the properties of recycled aggregate concrete. J. Mater. Civ. Eng. 2007, 19, 709–717. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S.; Etxeberria, M. Influence of recycled aggregates on long term mechanical properties and pore size distribution of concrete. Cem. Concr. Compos. 2011, 33, 286–291. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Kazmi, S.M.S.; Munir, M.J.; Park, C. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates–Comparative assessment of assorted techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Lin, X.; Ahmad, M.R. Investigation of thermal performance of concrete incorporating different types of recycled coarse aggregates. Constr. Build. Mater. 2020, 270, 121433. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Properties of concrete prepared with PVA-impregnated recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 649–654. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Klama, J.; Zawal, D.; Krupa, D. Modification of recycled concrete aggregate by calcium carbonate biodeposition. Constr. Build. Mater. 2012, 34, 145–150. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M. Compressive behavior of steel fiber reinforced recycled coarse aggregate concrete designed with equivalent cubic compressive strength. Constr. Build. Mater. 2017, 141, 235–244. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L. Flexural performance and evaluation method of steel fiber reinforced recycled coarse aggregate concrete. Constr. Build. Mater. 2018, 159, 126–136. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Toledo Filho, R.D. Compressive stress–strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Anike, E.E.; Saidani, M.; Olubanwo, A.O.; Tyrer, M.; Ganjian, E. Effect of mix design methods on the mechanical properties of steel fibre-reinforced concrete prepared with recycled aggregates from precast waste. Structures 2020, 27, 664–672. [Google Scholar] [CrossRef]

- Haido, J.H. Flexural behavior of basalt fiber reinforced concrete beams: Finite element simulation with new constitutive relationships. Structures 2020, 27, 1876–1889. [Google Scholar] [CrossRef]

- Kang, W.-H.; Ramesh, R.B.; Mirza, O.; Senaratne, S.; Tam, V.; Wigg, D. Reliability based design of RC beams with recycled aggregate and steel fibres. Structures 2017, 11, 135–145. [Google Scholar] [CrossRef]

- Akça, K.R.; Çakır, Ö.; İpek, M. Properties of polypropylene fiber reinforced concrete using recycled aggregates. Constr. Build. Mater. 2015, 98, 620–630. [Google Scholar] [CrossRef]

- Lee, J.-H.; Cho, B.; Choi, E.; Kim, Y.-H. Experimental study of the reinforcement effect of macro-type high strength polypropylene on the flexural capacity of concrete. Constr. Build. Mater. 2016, 126, 967–975. [Google Scholar] [CrossRef]

- Patel, P.A.; Desai, A.K.; Desai, J.A. Evaluation of engineering properties for polypropylene fibre reinforced concrete. Int. J. Adv. Eng. Technol. 2012, 3, 42–45. [Google Scholar]

- Kazmi, S.M.S. Improvement of the Mechanical and Durability Performance of Recycled Aggregate Concrete; RMIT University: Melbourne, Australia, 2020. [Google Scholar]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Li, C.; Zhao, X.; Jiang, G. Influence of Barchip fiber length on early-age behavior and cracking resistance of concrete internally cured with super absorbent polymers. Constr. Build. Mater. 2019, 214, 219–231. [Google Scholar] [CrossRef]

- Common Wealth Scientific Industrial Research Organization. Guide for Specification of Recycled Concrete Aggregate for Concrete Production (H155-2002); Standards Australia: Sydney, Australia, 2002. [Google Scholar]

- AS 2758.1:2014. Aggregates and Rock for Engineering Purposes: Part 1. Concrete Aggregates; Standards Australia: Sydney, Australia, 2014. [Google Scholar]

- ASTM C192:2016. Standard practice for making and curing concrete test specimens in the laboratory. In American Society of Testing and Materials; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Influence of different treatment methods on the mechanical behavior of recycled aggregate concrete: A comparative study. Cem. Concr. Compos. 2019, 104, 103398. [Google Scholar] [CrossRef]

- Munir, M.J.; Wu, Y.-F.; Kazmi, S.M.S.; Patnaikuni, I.; Zhou, Y.; Xing, F. Stress-strain behavior of spirally confined recycled aggregate concrete: An approach towards sustainable design. Resour. Conserv. Recycl. 2019, 146, 127–139. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Stress strain performance of steel spiral confined recycled aggregate concrete. Cem. Concr. Compos. 2020, 108, 103535. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Patnaikuni, I. Influence of concrete strength on the stress-strain behavior of spirally confined recycled aggregate concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 829, 012004. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, Y.-F. Compression behavior of concrete columns confined by high strength steel wire. Constr. Build. Mater. 2014, 54, 443–453. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Stress–strain curves for steel-fiber reinforced concrete under compression. Cem. Concr. Compos. 1999, 21, 383–390. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, K.; Akbarnezhad, A. Variability of stress-strain relationship for recycled aggregate concrete under uniaxial compression loading. J. Clean. Prod. 2018, 181, 753–771. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Lin, X. Axial stress-strain performance of steel spiral confined acetic acid immersed and mechanically rubbed recycled aggregate concrete. J. Build. Eng. 2020, 34, 101891. [Google Scholar] [CrossRef]

- Chaboki, H.R.; Ghalehnovi, M.; Karimipour, A.; de Brito, J. Experimental study on the flexural behaviour and ductility ratio of steel fibres coarse recycled aggregate concrete beams. Constr. Build. Mater. 2018, 186, 400–422. [Google Scholar] [CrossRef]

- Li, V.C. A simplified micromechanical model of compressive strength of fiber-reinforced cementitious composites. Cem. Concr. Compos. 1992, 14, 131–141. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S.; Wan, H.-W. Properties of concrete prepared with low-grade recycled aggregates. Constr. Build. Mater. 2012, 36, 881–889. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Chen, Y.F.; Ji, H. Residual stress-strain relationship for thermal insulation concrete with recycled aggregate after high temperature exposure. Constr. Build. Mater. 2016, 129, 37–47. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Counto, U.J. The effect of the elastic modulus of the aggregate on the elastic modulus, creep and creep recovery of concrete. Mag. Concr. Res. 1964, 16, 129–138. [Google Scholar] [CrossRef]

- Suksawang, N.; Wtaife, S.; Alsabbagh, A. Evaluation of elastic modulus of fiber-reinforced concrete. ACI Mater. J. 2018, 115, 239–249. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Baradaran-Nasiri, A. Residual properties of concrete containing recycled refractory brick aggregate at elevated temperatures. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Taerwe, L.R. Influence of steel fibers on strain-softening of high-strength concrete. Mater. J. 1993, 89, 54–60. [Google Scholar]

- Poon, C.S.; Shui, Z.H.; Lam, L. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. Cem. Concr. Res. 2004, 34, 2215–2222. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Canbaz, M. Effect of different fibers on the mechanical properties of concrete containing fly ash. Constr. Build. Mater. 2007, 21, 1486–1491. [Google Scholar] [CrossRef]

| Base Material | Modified Olefin |

|---|---|

| Surface texture | Continuously embossed |

| Young modulus (GPa) | 10 |

| Eq. diameter (mm) | 0.65 |

| Specific gravity | 0.91 |

| Length (mm) | 48 |

| Tensile strength (MPa) | 640 |

| Type of CA | Water Absorption (%) | Bulk Density (kg/m3) | Specific Gravity |

|---|---|---|---|

| CNA | 2.06 | 1512 | 2.53 |

| CRA | 7.61 | 1413 | 2.32 |

| Group | CNA (kg/m3) | CRA (kg/m3) | Sand (kg/m3) | Water (kg/m3) | Fibres (%) | Cement (kg/m3) | Additional Water (kg/m3) | Slump (mm) |

|---|---|---|---|---|---|---|---|---|

| NC | 822 | - | 709 | 185 | - | 451 | 17 | 50 |

| NC-B0.5 | 822 | - | 0.5 | 17 | 30 | |||

| NC-B1 | 822 | - | 1.0 | 17 | 10 | |||

| RC | - | 822 | - | 63 | 60 | |||

| RC-B0.5 | - | 822 | 0.5 | 63 | 40 | |||

| RC-B1 | - | 822 | 1.0 | 63 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Lin, X.; Ahmad, M.R. Axial Stress-Strain Performance of Recycled Aggregate Concrete Reinforced with Macro-Polypropylene Fibres. Sustainability 2021, 13, 5741. https://doi.org/10.3390/su13105741

Munir MJ, Kazmi SMS, Wu Y-F, Lin X, Ahmad MR. Axial Stress-Strain Performance of Recycled Aggregate Concrete Reinforced with Macro-Polypropylene Fibres. Sustainability. 2021; 13(10):5741. https://doi.org/10.3390/su13105741

Chicago/Turabian StyleMunir, Muhammad Junaid, Syed Minhaj Saleem Kazmi, Yu-Fei Wu, Xiaoshan Lin, and Muhammad Riaz Ahmad. 2021. "Axial Stress-Strain Performance of Recycled Aggregate Concrete Reinforced with Macro-Polypropylene Fibres" Sustainability 13, no. 10: 5741. https://doi.org/10.3390/su13105741

APA StyleMunir, M. J., Kazmi, S. M. S., Wu, Y.-F., Lin, X., & Ahmad, M. R. (2021). Axial Stress-Strain Performance of Recycled Aggregate Concrete Reinforced with Macro-Polypropylene Fibres. Sustainability, 13(10), 5741. https://doi.org/10.3390/su13105741