Environmental Design Guidelines for Circular Building Components: The Case of the Circular Building Structure

Abstract

1. Introduction

2. Methods

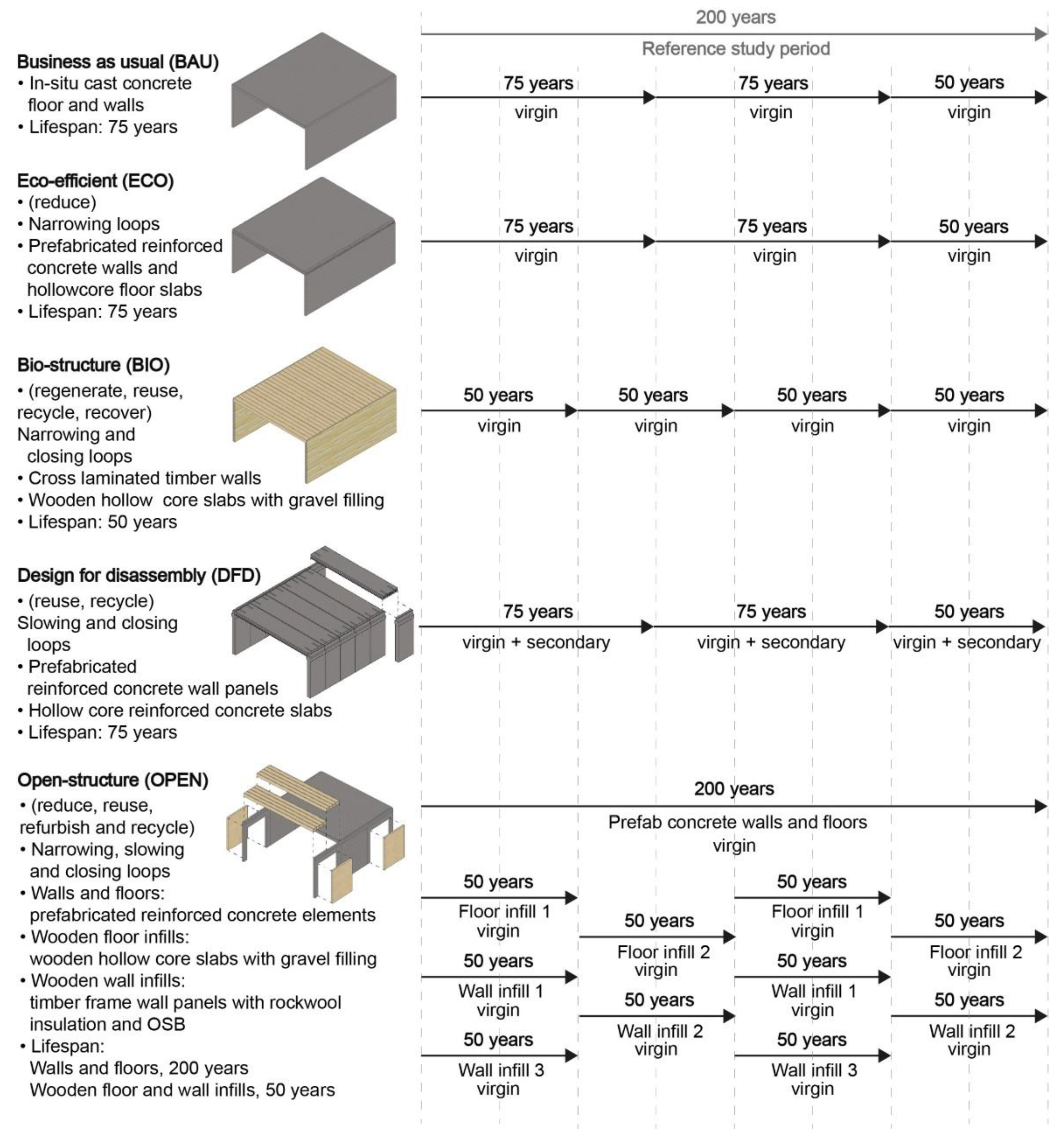

2.1. Design Variants for the Circular Structure

2.2. Method for the Life Cycle Assessment

2.3. Method for the Material Flow Analysis

2.4. Method for the Sensitivity Analysis

2.5. Method for Developing Design Guidelines

2.6. Method for Expert Sessions

3. Results

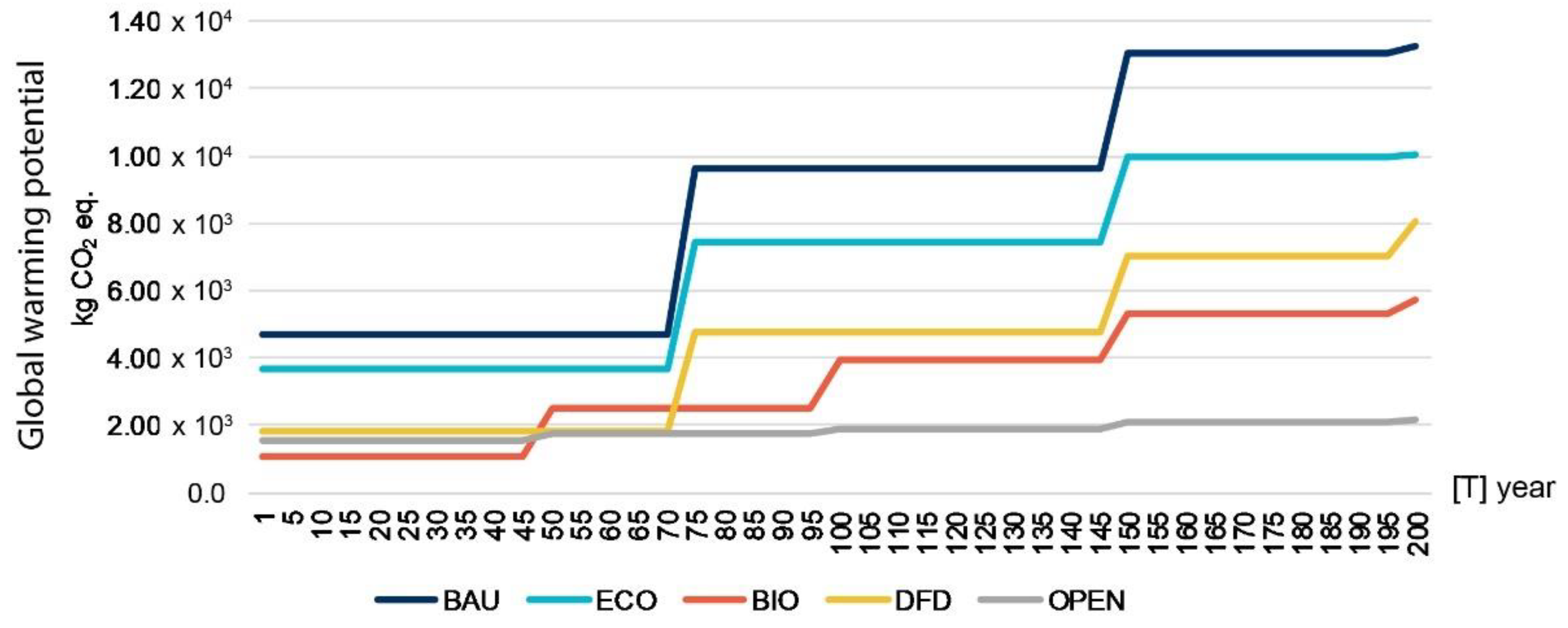

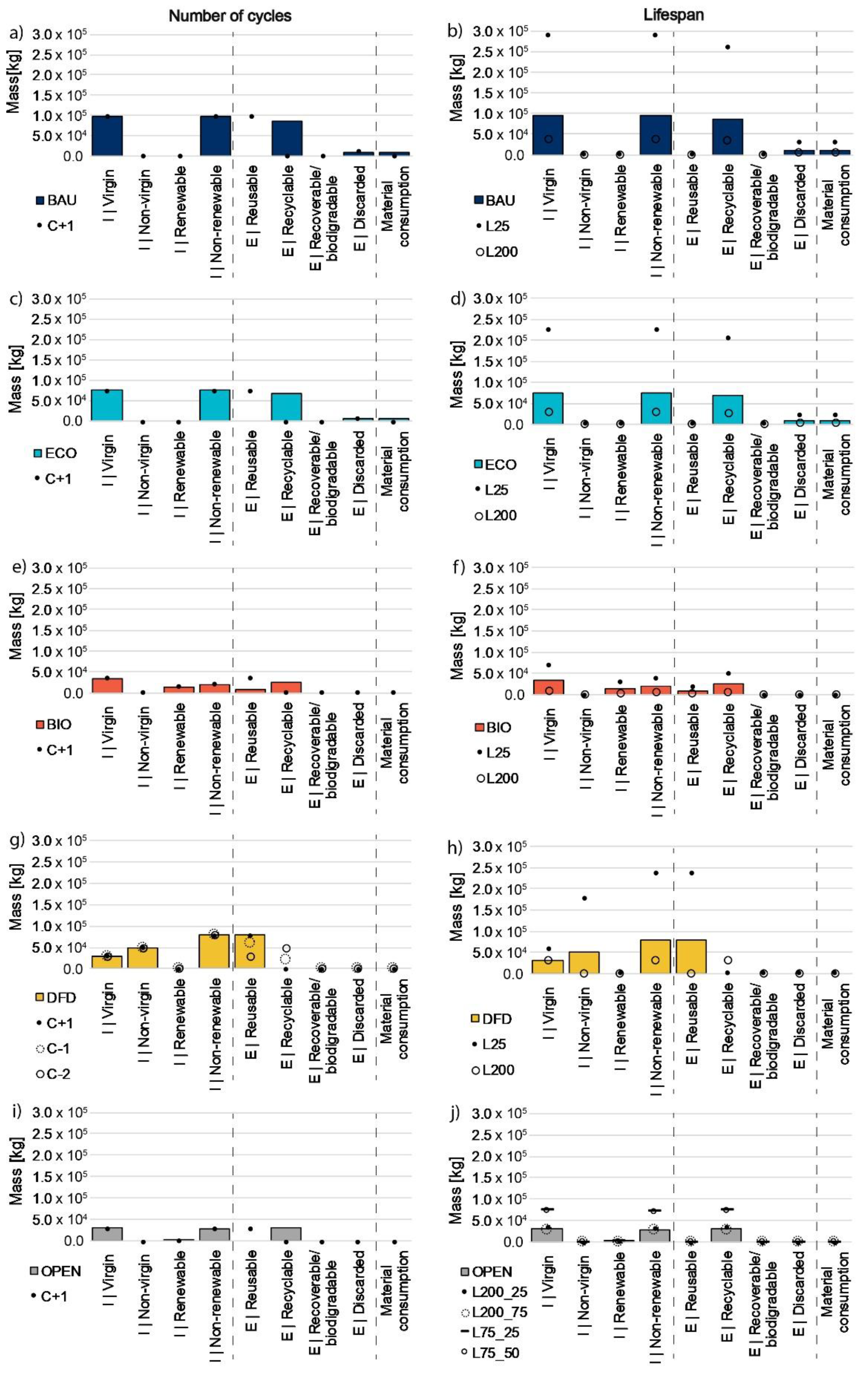

3.1. Results of the Life Cycle Assessment and Material Flow Analysis

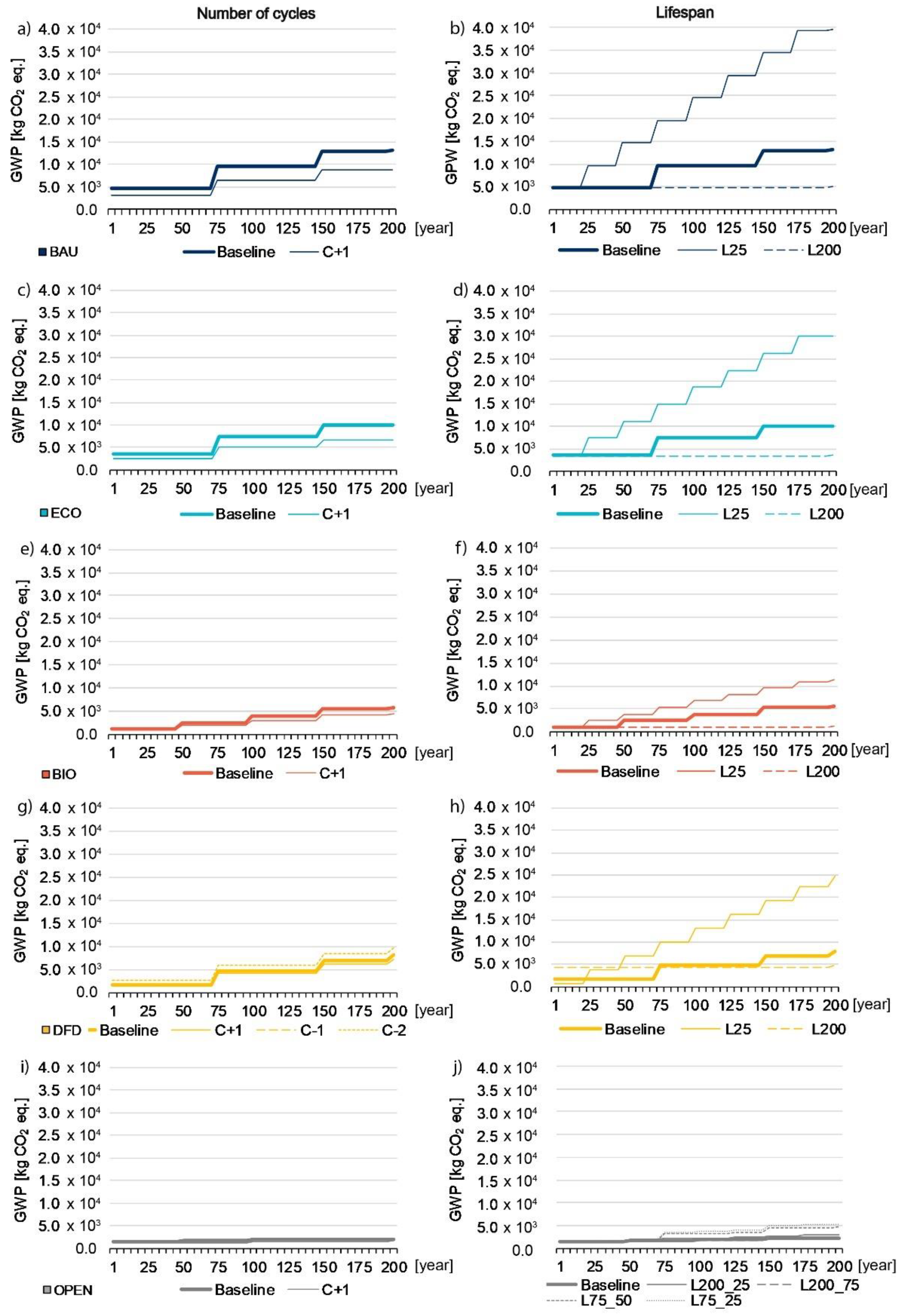

3.2. Results of the Sensitivity Analysis

3.3. Environmental Design Guidelines for Circular Building Structure

3.3.1. Score-Card

3.3.2. Rules-of-Thumb

3.3.3. Nine Environmental Design Rules for Circular Building Components

3.4. Results of the Expert Sessions

4. Discussion and Conclusions

- (1)

- The industry focus for structures is now often on material substitution (e.g., light-weight structures, bio-based alternatives such as CLT, design for disassembly and durability) and limited to consider only one cycle at a time, independently of one another. The findings of this paper suggest that this focus alone does not lead to optimum long-term environmental performance. Instead, for components with a long functional–technical lifespan, the design guidelines entail facilitating a combination of circular design options: a resource-efficient design, longer use through adaptable design, substituting high-impact materials with low-impact biomaterials and facilitating multiple cycles before final disposal.

- (2)

- The LCA and MFA approaches used in this study are currently not included in the LCA standards or practice tools. Implementation of the method is not straightforward as it would require changing the LCA scope, the calculation method, and the datasets of the different LCA databases used by the building industry.

- (3)

- It is stressed that the variants in this study are not proven concepts, but concept ideas about ideal circular solutions. As a result, the circularity facilitated in the technical design for the design variants spans over chains of cycles that happen at different points in time and in some cases far into the future. Some of the major challenges of facilitating circularity arise because building projects consist of multiple processes, functions and stakeholders that are subject to change over time [21] and do not necessarily run in sequence but in parallel. The long life of building components and materials increases the uncertainty of the circularity. Furthermore, the structural variant with the best environmental performance might not be the most viable variant for the building industry. Hence, to guarantee the circularity would require a completely different approach in the building industry, including new market mechanisms, business models, supply-chain dynamics and multidisciplinary stakeholder co-creation throughout the value chain. Furthermore, circularity calls for moving away from the current short-term “one-off” independent project focus to a long-term project-transcending approach, where buildings are perceived as a composite of components, parts and materials with different and multiple use- and life cycles in a CE (i.e., to consider materials in different cycles).

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abergel, T.; Dulac, J.; Hamilton, I.; Jordan, M.; Pradeep, A.; International Energy Agency. Global Status Report for Buildings and Constructi on towards a Zero-Emissions, Efficient and Resilient Buildings and Constructi on Sector; United Nations Environment Programme: Nairobi, Kenya, 2019. [Google Scholar]

- Circle Economy. The Circularity Gap Report-Closing the Circularity Gap in a 9% World; Circle Economy: Amsterdam, The Netherlands, 2019. [Google Scholar]

- International Resource Panel. Assessing Global Resource Use: A Systems Approach to Resource Efficiency and Pollution Reduction (a Report of the International Resource Panel); United Nations Environment Programme: Nairoby, Kenya, 2017. [Google Scholar]

- Remondis Shortage of Raw Materials. Available online: https://www.remondis-sustainability.com/en/sharing/shortage-of-raw-materials/ (accessed on 16 November 2020).

- Danish Technological Institute. Materialer i den Cirkulære Økonomi: Gips; Danish Technological Institute: Taastrup, Denmark, 2019. [Google Scholar]

- GAB Report Sand Scarcity in the Construction Industry. Available online: https://www.gabreport.com/sand-scarcity-in-the-construction-industry (accessed on 9 November 2020).

- Gallego-Schmid, A.; Chen, H.M.; Sharmina, M.; Mendoza, J.M.F. Links between circular economy and climate change mitigation in the built environment. J. Clean. Prod. 2020, 260, 121115. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A. Policy trends for the sustainability assessment of construction materials: A review. Sustain. Cities Soc. 2017, 35, 280–288. [Google Scholar] [CrossRef]

- DBEIS and NS. Monthly Statistics of Building Materials and Components; DBEIS and NS: London, UK, 2019. [Google Scholar]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circularity in the Built Environment: Case Studies; Ellen MacArthur Foundation: Cowes, UK, 2016. [Google Scholar]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Blomsma, F.; Kjaer, L.; Pigosso, D.; McAloone, T.; Lloyd, S. Exploring Circular Strategy Combinations-Towards Understanding the Role of PSS. Procedia CIRP 2018, 69, 752–757. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and drivers in a circular economy: The case of the built environment. Procedia CIRP 2019, 80, 619–624. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2020, 1–21. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment—What does the evidence say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef]

- Mestre, A.; Cooper, T. Circular Product Design. A Multiple Loops Life Cycle Design Approach for the Circular Economy. Des. J. 2017, 20, S1620–S1635. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.; Gruner, R.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Geldermans, R.J. Design for Change and Circularity-Accommodating Circular Material & Product Flows in Construction. Energy Procedia 2016, 96, 301–311. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Principles for Buildings Design; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Cheshire, D. Building Revolutions Applying the Circular Economy to the Built Environement; RIBA Publishing: Newcastle upon Tyne, UK, 2016. [Google Scholar]

- Brad, G.; Ciarimboli, N. Design for Disassembly in the Built Environment: A Guide to Closed-Loop Design and Building; Pennsylvania State University: University Park, PA, USA, 2005. [Google Scholar]

- Ness, D.A.; Xing, K. Toward a Resource-Efficient Built Environment: A Literature Review and Conceptual Model. J. Ind. Ecol. 2017, 21, 572–592. [Google Scholar] [CrossRef]

- EN 15978. European Committee for Standardisation. Sustainability of Construction Works-Assessment of Environmental Performance of Buildings-Calculation Method; European Committee for Standardisation: Brussels, Belgium, 2011. [Google Scholar]

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- ISO 14044. Environmental Management-Life Cycle Assessment-Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 21931-1. Sustainability in Building Construction Framework for Methods of Assessment of the Environmental Performance of Construction Works Part 1: Buildings; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- Heeren, N.; Hellweg, S. Tracking Construction Material over Space and Time: Prospective and Geo-referenced Modeling of Building Stocks and Construction Material Flows. J. Ind. Ecol. 2019, 23, 253–267. [Google Scholar] [CrossRef]

- Tingley, D.D.; Arbabi, H. The importance of understanding the material metabolism of the built environment. In Proceedings of the World Sustainable Built Environment Conference 2017, Hong Kong, China, 5–7 June 2017; pp. 888–894. [Google Scholar]

- Pomponi, F.; Moncaster, A. Circular Economy Research in the Built Environment: A Theoretical Contribution. In International Conference on Sustainable Ecological Engineering Design for Society; Leeds Beckett University: Leeds, UK, 2016. [Google Scholar]

- De Wolf, C. Low Carbon Pathways for Structural Design: Embodied Life Cycle Impacts of Building Structures. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2017. [Google Scholar]

- Malmqvist, T.; Nehasilova, M.; Moncaster, A.; Birgisdottir, H.; Nygaard, F. Design and construction strategies for reducing embodied impacts from buildings—Case study analysis. Energy Build. 2018, 166, 35–47. [Google Scholar] [CrossRef]

- De Koeijer, B.; Wever, R.; Henseler, J. Realizing Product-Packaging Combinations in Circular Systems: Shaping the Research Agenda. Packag. Technol. Sci. 2017, 30, 443–460. [Google Scholar] [CrossRef]

- Hellweg, S.; Mila i Canals, L. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- Marsh, R. LCA profiles for building components: Strategies for the early design process. Build. Res. Inf. 2016, 44, 358–375. [Google Scholar] [CrossRef]

- Meex, E.; Hollberg, A.; Knapen, E.; Hildebrand, L.; Verbeeck, G. Requirements for applying LCA-based environmental impact assessment tools in the early stages of building design. Build. Environ. 2018, 133, 228–236. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Andersen, C.E.; Kanafani, K.; Zimmermann, R.K.; Rasmussen, F.N.; Birgisdóttir, H. Comparison of GHG emissions from circular and conventional building components. Build. Cities 2020, 1, 379. [Google Scholar] [CrossRef]

- Birgisdottir, H.; Kanafani, K.; Zimmermann, R.K.; Andersen, C.M.E.; Hatic, D.; Elmbæk, M.; Kamper, M.; Falbe-Hansen, M.; Sack-Nielsen, T. Dialogværktøj: Cirkulær Værdiskabelse i den Eksisterende Bygningsmasse (Dialog Tool: Circular Value Creation in the Existing Building Mass); Aalborg University: Copenhagen, Denmark, 2019. [Google Scholar]

- Birgisdottir, H.; Houlihan-Wiberg, A.; Malmqvist, T.; Moncaster, A.; Rasmussen, F.N. IEA EBC ANNEX 57-Subtask 4: Case Studies and Recommendations for the Reduction of Embodied Energy and Embodied Greenhouse Gas Emissions from Buildings; Institute for Building Environment and Energy Conservation: Tokyo, Japan, 2016; ISBN 978-4-909107-08-4. [Google Scholar]

- Hollberg, A.; Lützkendorf, T.; Habert, G. Using a budget approach for decision-support in the design process. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012026. [Google Scholar] [CrossRef]

- Kanafani, K.; Zimmermann, R.K.; Birgisdottir, H.; Rasmussen, F.N. LCA i Tidlig Bygningsdesign: Introduktion til Metoden og Eksempler på Miljøprofiler (LCA in Early Building Design: Introduction to the Method and Examples of Environmental Profiles); Aalborg University: Copenhagen, Denmark, 2019. [Google Scholar]

- Eberhardt, L.C.M.; van Stijn, A.; Nygaard Rasmussen, F.; Birkved, M.; Birgisdottir, H. Development of a life cycle assessment allocation approach for circular economy in the built environment. Sustainability 2020, 12, 9579. [Google Scholar] [CrossRef]

- Van Stijn, A.; Eberhardt, L.C.M.; Wouterszoon Jansen, B.; Meijer, A. Design guidelines for circular building components based on LCA and MFA. J. Clean. Prod. 2020. submitted. [Google Scholar]

- Van Stijn, A.; Eberhardt, L.C.M.; Wouterszoon Jansen, B.; Meijer, A. A Circular Economy Life Cycle Assessment (CE-LCA) model for Buildings and Building Components. Resour. Conserv. Recycl. 2020. submitted. [Google Scholar]

- Van Stijn, A.; Gruis, V. Towards a circular built environment: An integral design tool for circular building components. Smart Sustain. Built Environ. 2019. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Rønholt, J.; Birgisdottir, H.; Birkved, M. Circular Economy potential within the building stock-mapping the embodied greenhouse gas emissions of four Danish examples. Build. Eng. 2020, 33, 101845. [Google Scholar] [CrossRef]

- Rønholt, J.; Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H.; Niki, B. Tracing the environmental impact origin within the existing building portfolio of prevailing building typologies. In Proceedings of the Submitted to 1st Nordic Conference on Zero Emission and Plus Energy Buildings, Trondheim, Norway, 6–7 November 2019; p. 012065. [Google Scholar]

- Partners Circle House. Circle House; KLS PurePrint: Hvidovre, Denmark, 2018; ISBN 978-87-998670-7-3. [Google Scholar]

- Van Stijn, A.; Gruis, V.H. Circular Housing Retrofit Strategies and Solutions: Towards Modular, Mass-Customised and “Cyclable” Retrofit Products. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012035. [Google Scholar] [CrossRef]

- Lignatur, LIGNATUR Element. Available online: https://www.lignatur.ch/en/product/lignatur-element (accessed on 15 October 2020).

- Copenhagen Cleantech Cluster. CLEAN Report: Kortlægning af Genbrugsmarkeder for Byggematerialer [Mapping of Recycling Markets for Building Materials]; Copenhagen Cleantech Cluster: Copenhagen, Denmark, 2014. [Google Scholar]

- Jensen, N.J.J. Beregningssoftware Giver CO2-Besparelser [Calculation Software Results in CO2 Savings]. Available online: http://www.dagensbyggeri.dk/artikel/93549-beregningssoftware-giver-co2-besparelser (accessed on 12 May 2021).

- Eberhardt, L.; Birgisdottir, H.; Birkved, M. Comparing life cycle assessment modelling of linear vs. circular building components. IOP Conf. Ser. Earth Environ. Sci. 2020, 225, 012039. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. A novel selective disassembly sequence planning method for adaptive reuse of buildings. J. Clean. Prod. 2018, 183, 998–1010. [Google Scholar] [CrossRef]

- Kohler, N. From the design of green buildings to resilience management of building stocks. Build. Res. Inf. 2017. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. Capital project planning for a circular economy. Constr. Manag. Econ. 2018, 36, 303–312. [Google Scholar] [CrossRef]

- Aagaard, N.-J.; Brandt, E.; Aggerholm, S.; Haugbølle, K. Levetider af Bygningsdele ved Vurdering af Bæredygtighed og Totaløkonomi; Aalborg University: Copenhagen, Denmark, 2013. [Google Scholar]

- Habraken, N.J. Supports: An Alternative to Mass Housing; Urban International Press: London, UK, 1972. [Google Scholar]

- Brand, S. How Buildings Learn: What Happens after They’re Built; Viking Press: New York, NY, USA, 1994. [Google Scholar]

- Ecoinvent Ecoinvent 3.4–Ecoinvent. Available online: https://www.ecoinvent.org/database/older-versions/ecoinvent-34/ecoinvent-34.html (accessed on 4 September 2020).

- Hauschild, M.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment-Theory and Practice; Springer International Publishing: Cham, Switzerland, 2018; ISBN 9783319564746. [Google Scholar]

- Ecochain Environmental Cost Indicator (ECI)—Overview. Available online: https://ecochain.com/knowledge/environmental-cost-indicator-eci/ (accessed on 16 October 2020).

- Vogtländer, J.G.; Baetens, B.; Bijma, A.; Brandjes, E.; Lindeijer, E.; Sergers, M.; Witte, F. LCA-Based Assessment of Sustainability: The Eco-Costs/Value Ratio EVR; Delft University of Technology: Delft, The Netherlands, 2010; ISBN 1090312059. [Google Scholar]

- Dahlsrud, A. How corporate social responsibility is defined: An analysis of 37 definitions. Corp. Soc. Responsib. Environ. Manag. 2008, 15, 1–13. [Google Scholar] [CrossRef]

- Haney, W.; Russel, M.; Gulek, C.; Fierros, E. Drawing on Education: Using Student Drawings to Promote Middle School Improvement. Sch. Middle 1998, 7, 38–43. [Google Scholar]

- Chau, C.K.; Xu, J.M.; Leung, T.M.; Ng, W.Y. Evaluation of the impacts of end-of-life management strategies for deconstruction of a high-rise concrete framed office building. Appl. Energy 2017, 185, 1595–1603. [Google Scholar] [CrossRef]

- Diyamandoglu, V.; Fortuna, L.M. Deconstruction of wood-framed houses: Material recovery and environmental impact. Resour. Conserv. Recycl. 2015, 100, 21–30. [Google Scholar] [CrossRef]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What gets measured, gets done: Development of a Circular Economy measurement scale for building industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef]

| Sensitivity Scenarios | Abbreviation | BAU | ECO | BIO | DFD | OPEN | |

|---|---|---|---|---|---|---|---|

| Number of cycles | −2 cycles | C-2 | x | ||||

| −1 cycle | C-1 | x | |||||

| +1 cycle | C + 1 | x | x | x | x | x | |

| Lifespan | 25 years | L25 | x 1 | x 1 | x 1 | x 2 | |

| 75 years | L75_50 | x 1 | |||||

| L75_25 | x 1 | ||||||

| 200 years | L200 | x 1 | x 1 | x 1 | x 2 | ||

| L200_25 | x 1 | ||||||

| L200_75 | x 1 | ||||||

| Impact Category | Unit | Design Variants | ||||

|---|---|---|---|---|---|---|

| BAU | ECO | BIO | DFD | OPEN | ||

| GWP | kg CO2 eq. | 1.32 × 104 | 1.01 × 104 (24%) | 5.69 × 103 (57%) | 8.08 × 103 (39%) | 2.15 × 103 (84%) |

| ODP | kg CFC-11 eq. | 6.50 × 10−4 | 4.50 × 10−4 (31%) | 7.90 × 10−4 (−22%) | 9.5 × 10−4 (−46%) | 1.60 × 10−4 (75%) |

| POCP | kg C2H4 eq. | 1.36 | 9.98 × 10−1 (27%) | 1.97 (−44%) | 1.19 (12%) | 4.47 × 10−1 (65%) |

| AP | kg SO2 eq. | 3.16 × 10 | 2.32 × 10 (27%) | 3.08 × 10 (3%) | 2.34 × 10 (26%) | 7.81 (64%) |

| EP | kg PO43− eq. | 1.05 × 10 | 7.77 (26%) | 1.23 × 10 (−17%) | 7.00 (33%) | 2.78 (74%) |

| ADPe | kg Sb eq. | 1.38 × 10−2 | 1.02 × 10−2 (26%) | 1.79 × 10−2 (−30%) | 1.85 × 10−2 (−34%) | 4.21 × 10−3 (69%) |

| ADPf | MJ | 7.70 × 104 | 5.52 × 104 (28%) | 7.55 × 104 (2%) | 8.81 × 104 (−14%) | 1.78 × 104 (77%) |

| FETP | kg 1,4-DB eq. | 2.39 × 103 | 1.40 × 103 (41%) | 1.72 × 103 (28%) | 1.53 × 103 (36%) | 4.68 × 102 (80%) |

| HTP | kg 1,4-DB eq. | 2.96 × 103 | 1.98 × 103 (33%) | 2.68 × 103 (9%) | 3.40 × 103 (−15%) | 7.25 × 102 (76%) |

| MAETP | kg 1,4-DB eq. | 5.45 × 106 | 3.75 × 106 (31%) | 5.05 × 106 (7%) | 3.70 × 106 (32%) | 1.35 × 106 (75%) |

| TETP | kg 1,4-DB eq. | 8.10 × 10 | 6.26 × 10 (23%) | 1.95 × 10 (76%) | 3.24 × 10 (60%) | 1.16 × 10 (86%) |

| Import|Total material | kg | 1.93 × 105 | 1.51 × 105 (22%) | 6.87 × 104 (64%) | 1.58 × 105 (18%) | 5.92 × 104 (69%) |

| Import|Virgin | kg | 9.63 × 104 | 7.53 × 104 (22%) | 3.43 × 104 (64%) | 2.97 × 104 (69%) | 2.93 × 104 (70%) |

| Import|Non-virgin | kg | 0.00 | 0.00 (0%) | 0.00 (0%) | 4.95 × 104 (100%) | 0.00 (0%) |

| Import|Renewable | kg | 0.00 | 0.00 (0%) | 1.47 × 104 (100%) | 0.00 (0%) | 1.25 × 103 (100%) |

| Import|Non-renewable | kg | 9.63 × 104 | 7.53 × 104 (22%) | 1.97 × 104 (80%) | 7.92 × 104 (18%) | 2.86 × 104 (70%) |

| Export|Reusable | kg | 0.00 | 0.00 × 10 (0%) | 8.84 × 103 (100%) | 7.92 × 104 (100%) | 0.00 (0%) |

| Export|Recyclable | kg | 8.69 × 104 | 6.79 × 104 (22%) | 2.55 × 104 (71%) | 0.00 (100%) | 2.98 × 104 (66%) |

| Export|Recoverable/biodegradable | kg | 0.00 | 0.00 (0%) | 0.00 (0%) | 0.00 (0%) | 0.00 (0%) |

| Export|Disposed | kg | 9.45 × 103 | 7.40 × 103 (22%) | 0.00 (100%) | 0.00 (100%) | 0.00 (100%) |

| Material consumption | kg | 9.45 × 103 | 7.40 × 103 (22%) | 0.00 (100%) | 0.00 (100%) | 0.00 (100%) |

| Percentage Savings | BAU | ECO | BIO | DFD | OPEN | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BAU baseline | BAU C+1 | BAU L25 1 | BAU L200 1 | ECO baseline | ECO C+1 | ECO L25 1 | ECO L200 1 | BIO baseline | BIO C+1 | BIO L25 1 | BIO L200 1 | DFD baseline | DFD C+1 | DFD C-1 | DFD C-2 | DFD L25 2 | DFD L200 2 | OPEN baseline | OPEN C+1 | OPEN L200_25 1 | OPEN L200_75 1 | OPEN L75_25 1 | OPEN L75_50 1 | ||

| LCA | GWP | 0% | 33% | −200% | 63% | 24% | 49% | −128% | 72% | 57% | 67% | 14% | 89% | 39% | 46% | 36% | 27% | −87% | 64% | 84% | 87% | 78% | 86% | 65% | 61% |

| ODP | 0% | 31% | −200% | 63% | 30% | 52% | −108% | 74% | −21% | 9% | −142% | 70% | −46% | −28% | −54% | −60% | −484% | 59% | 76% | 82% | 62% | 80% | 57% | 48% | |

| POCP | 0% | 31% | −200% | 63% | 27% | 50% | −120% | 73% | −44% | −11% | −189% | 64% | 12% | 22% | 9% | 1% | −191% | 54% | 65% | 75% | 41% | 73% | 43% | 27% | |

| AP | 0% | 32% | −200% | 63% | 27% | 50% | −120% | 73% | 3% | 25% | −95% | 76% | 26% | 34% | 24% | 16% | −142% | 61% | 75% | 82% | 61% | 80% | 56% | 46% | |

| EP | 0% | 32% | −200% | 63% | 26% | 50% | −121% | 72% | −17% | 10% | −135% | 71% | 33% | 41% | 32% | 24% | −95% | 57% | 74% | 80% | 58% | 79% | 53% | 42% | |

| ADPe | 0% | 30% | −200% | 63% | 26% | 48% | −121% | 72% | −30% | 2% | −160% | 67% | −34% | −19% | −41% | −49% | −381% | 39% | 69% | 77% | 51% | 76% | 46% | 33% | |

| ADPf | 0% | 31% | −200% | 63% | 28% | 51% | −115% | 73% | 2% | 26% | −96% | 75% | −14% | −1% | −20% | −27% | −326% | 56% | 77% | 83% | 64% | 81% | 57% | 49% | |

| FAETP | 0% | 32% | −200% | 63% | 41% | 60% | −76% | 78% | 28% | 44% | −44% | 82% | 36% | 43% | 39% | 32% | −65% | 54% | 80% | 85% | 70% | 84% | 64% | 56% | |

| HTP | 0% | 29% | −200% | 63% | 33% | 52% | −100% | 75% | 9% | 31% | −81% | 77% | −15% | −3% | −16% | −23% | −254% | 29% | 76% | 81% | 62% | 80% | 54% | 45% | |

| MAETP | 0% | 31% | −200% | 63% | 31% | 53% | −106% | 74% | 7% | 29% | −85% | 77% | 32% | 39% | 32% | 24% | −86% | 52% | 75% | 81% | 61% | 80% | 55% | 45% | |

| TETP | 0% | 33% | −200% | 63% | 23% | 48% | −132% | 71% | 76% | 81% | 52% | 94% | 60% | 64% | 59% | 49% | 17% | 63% | 86% | 88% | 82% | 87% | 67% | 64% | |

| Av. saving LCA | 0% | 31% | −200% | 63% | 29% | 51% | −113% | 73% | 6% | 29% | −87% | 77% | 12% | 22% | 9% | 1% | −190% | 53% | 76% | 82% | 63% | 80% | 56% | 47% | |

| MFA | Import|Total material | 0% | 0% | −200% | 63% | 22% | 22% | −135% | 71% | 64% | 64% | 29% | 91% | 18% | 18% | 18% | 18% | −146% | 69% | 69% | 69% | 64% | 71% | 20% | 25% |

| Import|Virgin | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 63% | 63% | 63% | 63% | 75% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | |

| Import|Non-renewable | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 43% | 43% | 43% | 43% | 0% | 0% | 0% | 0% | 0% | 0% | 4% | 4% | 7% | 3% | 3% | 2% | |

| Export|Composted | 0% | 100% | 0% | 0% | 0% | 100% | 0% | 0% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | |

| recovered or discarded (i.e., lost) | |||||||||||||||||||||||||

| Material consumption | 0% | 100% | −200% | 63% | 22% | 100% | −135% | 71% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | |

| Av. saving MFA | 0% | 40% | −80% | 25% | 9% | 44% | −54% | 28% | 61% | 61% | 54% | 67% | 56% | 56% | 56% | 56% | 26% | 54% | 55% | 55% | 54% | 55% | 45% | 45% | |

| Av. saving LCA + MFA | 0% | 36% | −140% | 44% | 19% | 48% | −84% | 51% | 34% | 45% | −17% | 72% | 34% | 39% | 33% | 29% | −82% | 54% | 65% | 68% | 59% | 68% | 50% | 46% | |

| Av. saving GWP + MFA | 0% | 36% | −140% | 44% | 16% | 47% | −91% | 50% | 59% | 64% | 34% | 78% | 47% | 51% | 46% | 42% | −31% | 59% | 69% | 71% | 66% | 70% | 55% | 53% | |

| Av. rank LCA + MFA | 20 | 14 | 24 | 12 | 19 | 9 | 23 | 7 | 16 | 11 | 21 | 1 | 15 | 13 | 17 | 18 | 22 | 6 | 4 | 2 | 5 | 3 | 8 | 10 | |

| Av. rank GWP + MFA | 21 | 18 | 24 | 16 | 20 | 14 | 23 | 12 | 7 | 6 | 19 | 1 | 13 | 11 | 15 | 17 | 22 | 8 | 4 | 2 | 5 | 3 | 9 | 10 | |

| Ranking | Variant/Scenario | Applied Design Principle | ||||

|---|---|---|---|---|---|---|

| LCA + MFA | GWP + MFA | Technical Model | Industrial Model | Business Model | ||

| ‘Pure’ circular pathays | 1 | 1 | OPEN baseline | Adaptable (50 years between adaptations), durable materials, standard sized parts, multiple cycles (reuse, recycling), very long lifespan (200 years) | Maintenance, updates, reuse by client, recycling by third party | Sale, maintenance and update service |

| 2 | 3 | DFD baseline | Standard sized parts, durable materials, demountable parts, reusable parts, multiple cycles (reuse, recycle) | Reuse by provider or client, recycling by third party | Sale with takeback, or sale and re-sale | |

| 3 | 2 | BIO baseline | Biomaterials, multiple cycles (reuse, recycle, recover), long lifespan (50 years) | Open-loop recycling and incineration by third party | Sale | |

| 4 | 4 | ECO baseline | Lean design, long lifespan (75 years) | Open-loop recycling and landfill by third party | Sale | |

| 5 | 5 | BAU baseline | Linear design, long lifespan (75 years) | Open-loop recycling and landfill by third party | Sale | |

| All variants and scenarios | 1 | 1 | BIO L200 1 | Biomaterials, multiple cycles (reuse, recycle, recover), very long lifespan (200 years) | Open-loop recycling and incineration by third party | Sale |

| 2 | 2 | OPEN C+1 | Adaptable (50 years between adaptations), durable materials, standard sized parts, multiple cycles (reuse, recycling), very long lifespan (200 years for the concrete structure), 1 additional cycle (reuse) | Maintenance, updates, reuse by client, recycling by third party | Sale, maintenance and update service | |

| 3 | 3 | OPEN L200_75 1 | Adaptable (75 years between adaptations), durable materials, standard sized parts, multiple cycles (reuse, recycling), very long lifespan (200 years for the concrete structure) | Maintenance, updates, reuse by client, recycling by third party | Sale, maintenance and update service | |

| 4 | 4 | OPEN baseline | Adaptable (50 years between adaptations), durable materials, standard sized parts, multiple cycles (reuse, recycling), very long lifespan (200 years for the concrete structure) | Maintenance, updates, reuse by client, recycling by third party | Sale, maintenance and update service | |

| 5 | 5 | OPEN L200_25 1 | Adaptable (25 years between adaptations), durable materials, standard sized parts, multiple cycles (reuse, recycling), very long lifespan (200 years for the concrete structure) | Maintenance, updates, reuse by client, recycling by third party | Sale, maintenance and update service | |

| 6 | 8 | DFD L200 2 | Standard sized parts, durable materials, demountable parts, reusable parts, multiple cycles (reuse, recycle), very long lifespan (200 years) | Reuse by provider or client, recycling by third party | Sale with takeback, or sale and re-sale | |

| 7 | 12 | ECO L200 1 | Lean design, long lifespan (200 years) | Open-loop recycling and landfill by third party | Sale | |

| 8 | 9 | OPEN L75_25 1 | Adaptable (25 years between adaptations), durable materials, standard sized parts, multiple cycles (reuse, recycling), long lifespan (75 years for the concrete structure) | Maintenance, updates, reuse by client, recycling by third party | Sale, maintenance and update service | |

| 9 | 14 | ECO C+1 | Lean design, 1 additional cycle (reuse) | Local reuse, open-loop recycling and landfill by third party | Sale | |

| 10 | 10 | OPEN L75_50 1 | Adaptable (59 years between adaptations), durable materials, standard sized parts, multiple cycles (reuse, recycling), long lifespan (75 years for the concrete structure) | Maintenance, updates, reuse by client, recycling by third party | Sale, maintenance and update service | |

| 11 | 6 | BIO C+1 | Biomaterials, multiple cycles (reuse, recycle, recover), 1 additional cycle (reuse) | Local reuse, open-loop recycling and incineration by third party | Sale | |

| 12 | 16 | BAU L200 1 | Linear design, very long lifespan (200 years) | Open-loop recycling and landfill by third party | Sale | |

| 13 | 11 | DFD C+1 | Standard sized parts, durable materials, demountable parts, reusable parts, multiple cycles (reuse, recycle), 1 additional cycle (reuse) | Reuse by provider or client, recycling by third party | Sale with takeback, or sale and re-sale | |

| 14 | 18 | BAU C+1 | Linear design + 1 additional cycle (reuse) | Local reuse, open-loop recycling and landfill by third party | Sale | |

| 15 | 13 | DFD baseline | Standard sized parts, durable materials, demountable parts, reusable parts, multiple cycles (reuse, recycle) | Reuse by provider or client, recycling by third party | Sale with takeback, or sale and re-sale | |

| 16 | 7 | BIO baseline | Biomaterials, multiple cycles (reuse, recycle, recover), long lifespan (50 years) | Open-loop recycling and incineration by third party | Sale | |

| 17 | 15 | DFD C-1 | Standard sized parts, durable materials, demountable parts, reusable parts, multiple cycles (reuse, recycle), 1 less cycle (reuse) | Reuse by provider or client, recycling by third party | Sale with takeback, or sale and re-sale | |

| 18 | 17 | DFD C-2 | Standard sized parts, durable materials, demountable parts, reusable parts, multiple cycles (reuse, recycle), 2 less cycles (reuse) | Reuse by provider or client, recycling by third party | Sale with takeback, or sale and re-sale | |

| 19 | 20 | ECO baseline | Lean design, long lifespan (75 years) | Open-loop recycling and landfill by third party | Sale | |

| 20 | 21 | BAU baseline | Linear design, long lifespan (75 years) | Open-loop recycling and landfill by third party | Sale | |

| 21 | 19 | BIO L25 1 | Biomaterials, multiple cycles (reuse, recycle, recover), short lifepan (25 years) | Open-loop recycling and incineration by third party | Sale | |

| 22 | 22 | DFD L25 2 | Standard sized parts, durable materials, demountable parts, reusable parts, multiple cycles (reuse, recycle), short lifespan (25 years) | Reuse by provider or client, recycling by third party | Sale with takeback, or sale and re-sale | |

| 23 | 23 | ECO L25 1 | Lean design, short lifespan (25 years) | Open-loop recycling and landfill by third party | Sale | |

| 24 | 24 | BAU L25 1 | Linear design, short lifespan (25 years) | Open-loop recycling and landfill by third party | Sale | |

| LCA | MFA | Underlying Comparisons | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Savings Based on Average of All Impacts | Savings Based on GWP | Total Import | Percentage Virgin | Percentage Non-Renewable | Percentage Recycled and Reused | Material Consumption | Number of Underlying Comparisons | Variant/Scenario of Reference | Variant/scenario Compared with Reference | ||

| Adding one cycle (virgin material) | Min. | 24% | 21% | 0% | 0% | 0% | 0% | 0% | 4 | Baseline of the BAU, BIO, ECO and OPEN | C+1 of BAU, ECO, BIO and OPEN |

| Av. | 28% | 28% | 0% | 0% | 0% | 5% | 50% | ||||

| Max. | 31% | 33% | 0% | 0% | 0% | 11% | 100% | ||||

| Lean design | Av. | 29% | 24% | 22% | 0% | 0% | 0% | 22% | 1 | BAU baseline | ECO baseline |

| Biomaterials | Av. | 6% | 57% | 64% | 0% | 43% | 11% | 100% | 1 | BAU baseline | BIO baseline |

| Life extending design, functional lifespan extension from 75 to 200 years (virgin material) | Min. | 63% | 63% | 63% | 0% | 0% | 0% | 0% | 3 | Baseline of BAU, BIO and ECO | L200 of BAU, BIO and ECO |

| Av. | 67% | 67% | 67% | 0% | 0% | 0% | 42% | ||||

| Max. | 75% | 75% | 75% | 0% | 0% | 0% | 63% | ||||

| Reducing the functional lifespan from 75 to 25 years (virgin material) | Min. | −200% | −200% | −200% | 0% | 0% | 0% | −200% | 3 | Baseline of BAU, BIO and ECO | L25 of BAU, BIO and ECO |

| Av. | −166% | −166% | −167% | 0% | 0% | 0% | −133% | ||||

| Max. | −100% | −100% | −100% | 0% | 0% | 0% | 0% | ||||

| Modularity | Av. | 12% | 39% | 18% | 63% | 0% | 11% | 100% | 1 | BAU baseline | DFD baseline |

| Removing one reuse cycle (virgin material) | Min. | −46% | −49% | 0% | 0% | 0% | −10% | 0% | 4 | C+1 of BAU, ECO, BIO and OPEN | Baseline of BAU, ECO, BIO and OPEN |

| Av. | −39% | −39% | 0% | 0% | 0% | −5% | 50% | ||||

| Max. | −31% | −27% | 0% | 0% | 0% | 0% | 100% | ||||

| Removing one recycling cycle (virgin material) | Av. | −3% | −4% | 0% | 0% | 0% | 0% | 0% | 1 | DFD C-1 | DFD baseline |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malabi Eberhardt, L.C.; van Stijn, A.; Kristensen Stranddorf, L.; Birkved, M.; Birgisdottir, H. Environmental Design Guidelines for Circular Building Components: The Case of the Circular Building Structure. Sustainability 2021, 13, 5621. https://doi.org/10.3390/su13105621

Malabi Eberhardt LC, van Stijn A, Kristensen Stranddorf L, Birkved M, Birgisdottir H. Environmental Design Guidelines for Circular Building Components: The Case of the Circular Building Structure. Sustainability. 2021; 13(10):5621. https://doi.org/10.3390/su13105621

Chicago/Turabian StyleMalabi Eberhardt, Leonora Charlotte, Anne van Stijn, Liv Kristensen Stranddorf, Morten Birkved, and Harpa Birgisdottir. 2021. "Environmental Design Guidelines for Circular Building Components: The Case of the Circular Building Structure" Sustainability 13, no. 10: 5621. https://doi.org/10.3390/su13105621

APA StyleMalabi Eberhardt, L. C., van Stijn, A., Kristensen Stranddorf, L., Birkved, M., & Birgisdottir, H. (2021). Environmental Design Guidelines for Circular Building Components: The Case of the Circular Building Structure. Sustainability, 13(10), 5621. https://doi.org/10.3390/su13105621