Forecasting of Disassembly Waste Generation under Uncertainties Using Digital Twinning-Based Hidden Markov Model

Abstract

1. Introduction

2. Problem Description and Modeling

2.1. DG-HMM Modeling

2.2. Performance Measures

3. Theoretical Methods

3.1. Data Pretreatment

3.2. Baum–Welch Algorithm

4. Model Verification

4.1. Parameter Setting

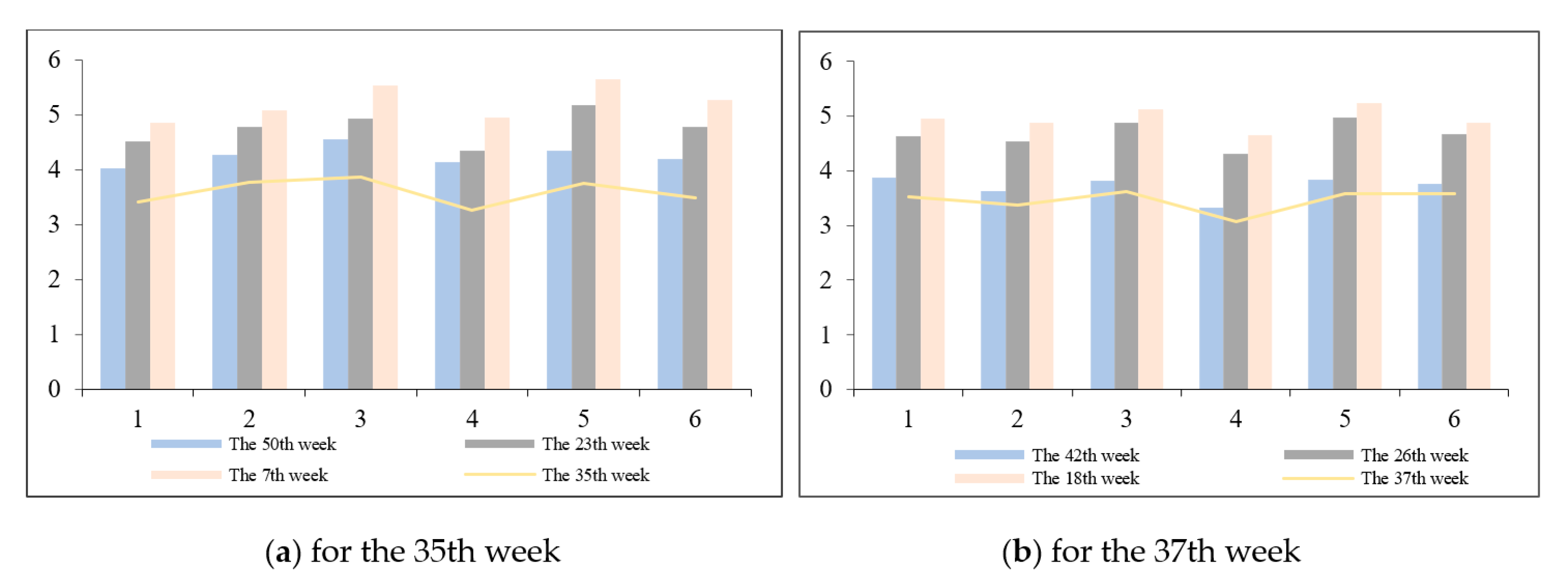

4.2. Disassembly Waste Generation Prediction

4.2.1. Computational Complexity Analysis

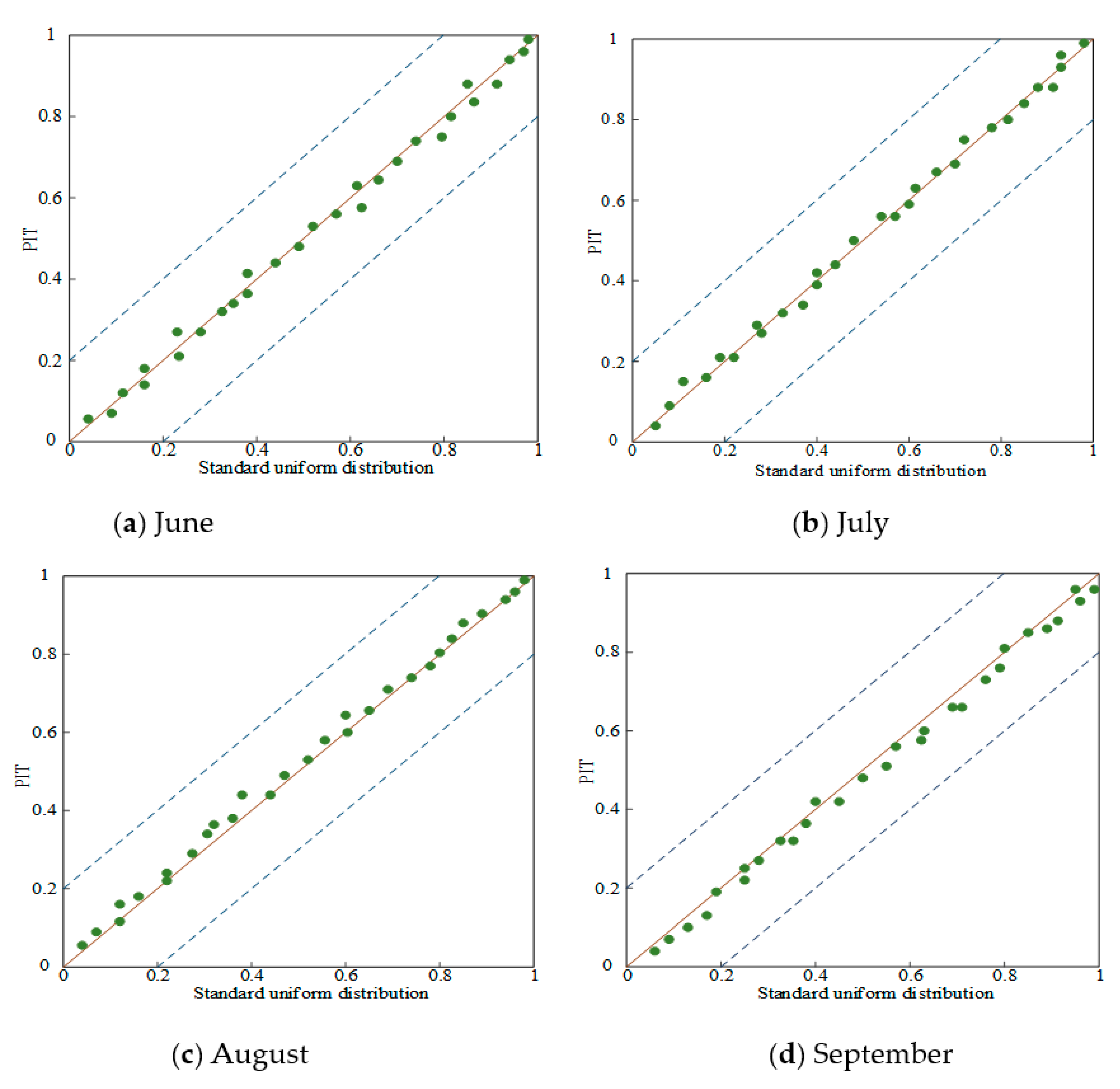

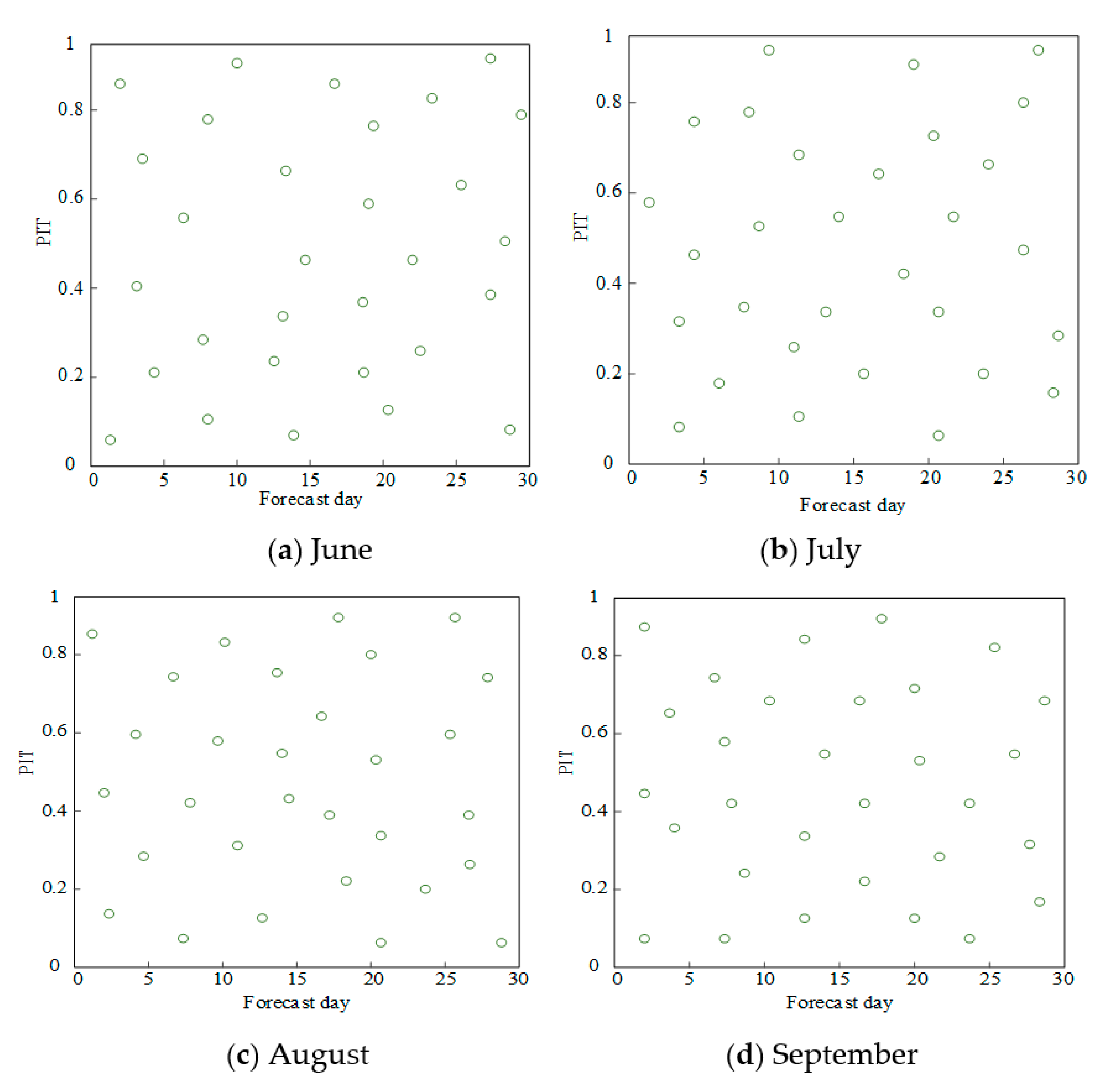

4.2.2. Prediction Reliability Analysis

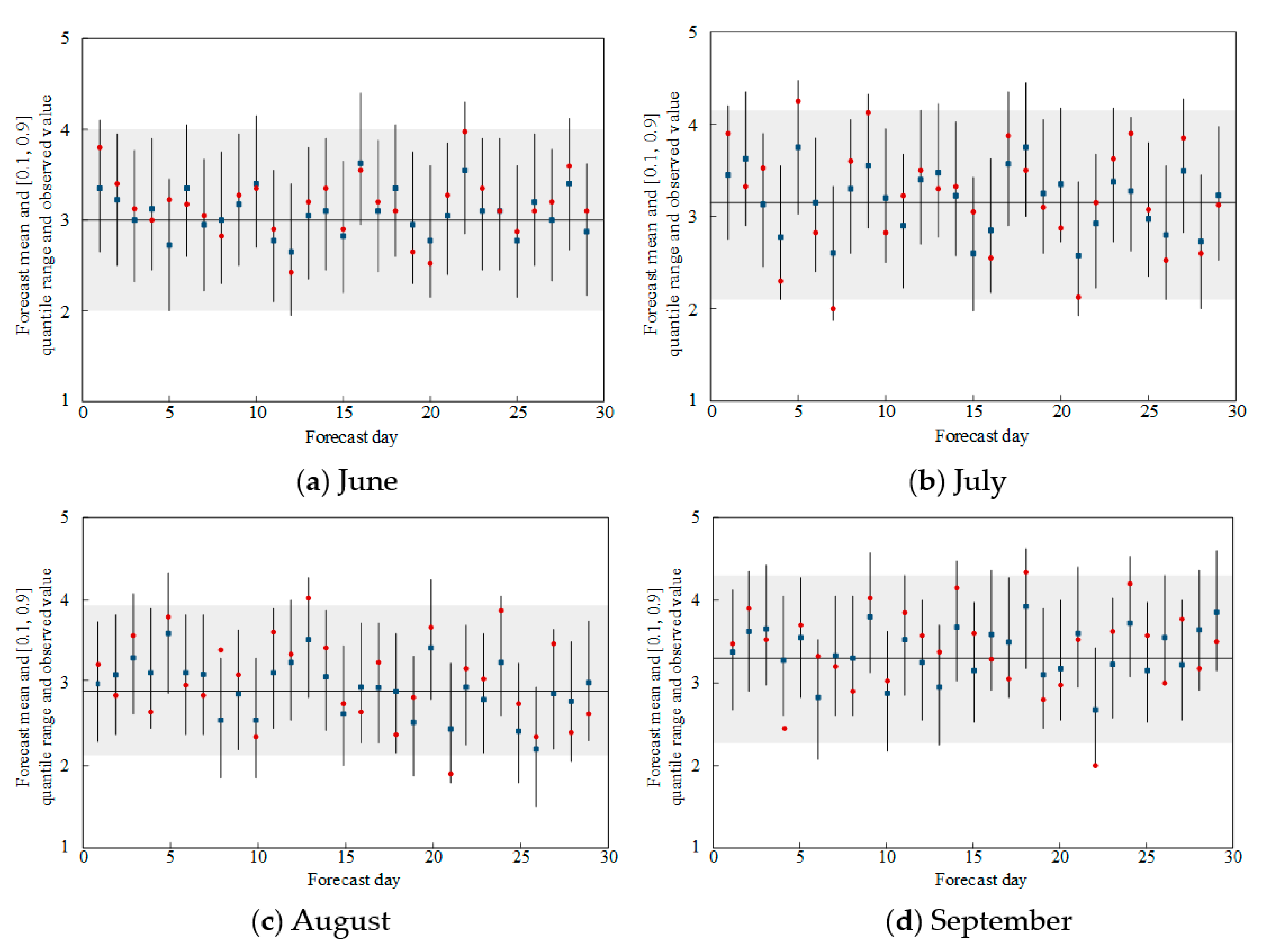

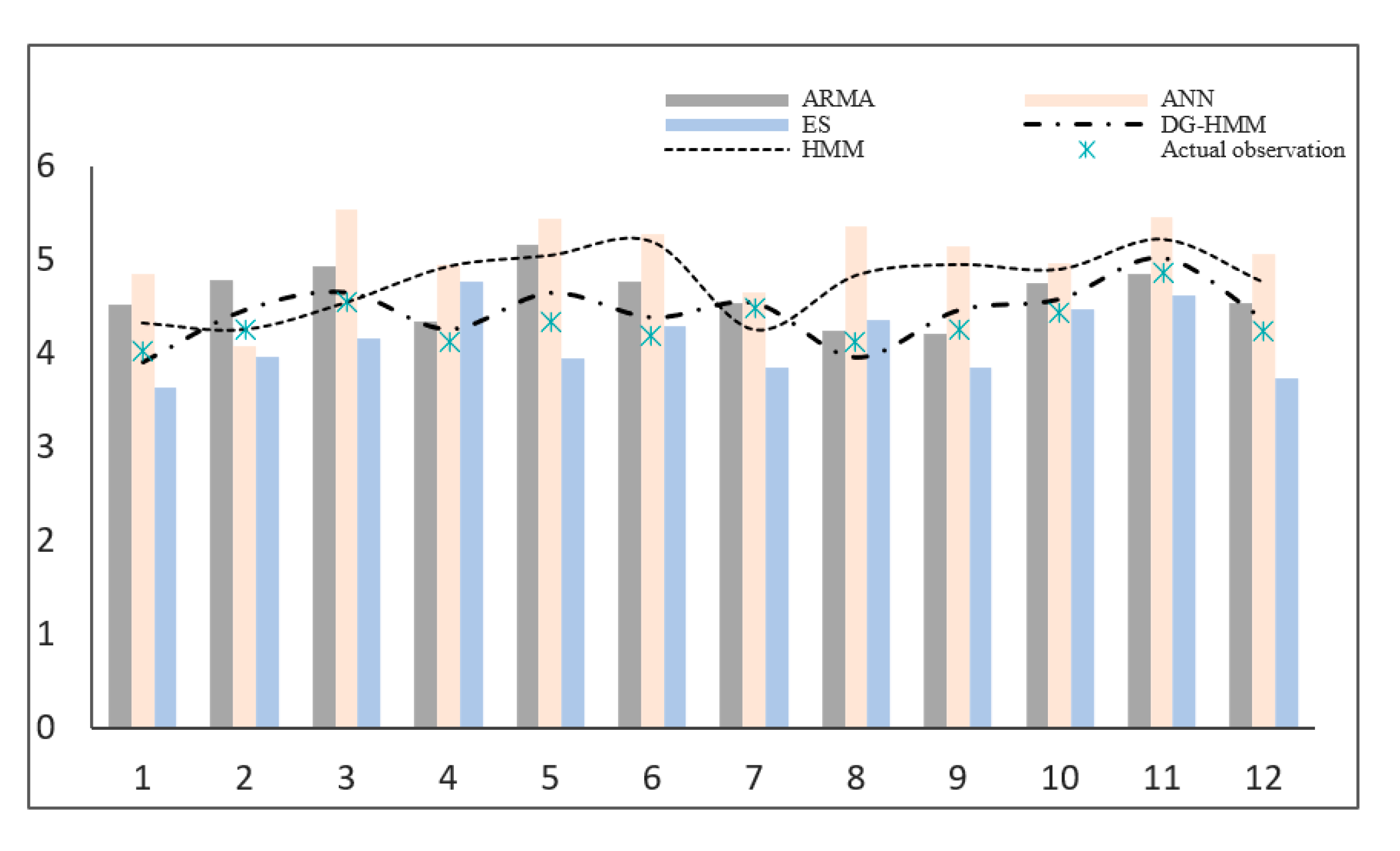

4.2.3. Comparison Plots of the Forecast and Observed Value

4.3. Comparative Analysis

5. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bovea, M.D.; Perez, B.V.; Ibanez, F.V.; Quemades, B.P. Disassembly properties and material characterisation of household small waste electric and electronic equipment. Waste Manag. 2016, 53, 225–236. [Google Scholar] [CrossRef]

- Jin, T.; Chen, M. Assessing the economics of processing end-of-life vehicles through manual dismantling. Waste Manag. 2016, 12, 384–395. [Google Scholar]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery: A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef]

- Shao, J.; Huang, S.; Lemus, A.I.; Unal, E. Circular business models generation for automobile remanufacturing industry in China barriers and opportunities. J. Manuf. Technol. Manag. 2020, 31, 542–571. [Google Scholar] [CrossRef]

- Tian, G.D.; Ren, Y.P.; Feng, Y.X.; Zhou, M.C.; Zhang, H.; Tan, J. Modeling and planning for dual-objective selective disassembly using and or graph and discrete artificial bee colony. IEEE Trans. Ind. Inform. 2019, 15, 2456–2468. [Google Scholar] [CrossRef]

- Zhang, C.L.; Chen, M. Designing and verifying a disassembly line approach to cope with the upsurge of end-of-life vehicles in China. Waste Manag. 2018, 76, 697–707. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Pan, X.; Chen, X.; Mao, J.; Pang, J.; Xue, B. Modeling of waste flow in industrial symbiosis system at city-region level: A case study of Jinchang, China. Sustainability 2021, 13, 466. [Google Scholar] [CrossRef]

- Bai, Y.; Ochuodho, T.O.; Yang, J. Impact of land use and climate change on water-related ecosystem services in Kentucky, USA. Ecol. Indic. 2019, 102, 51–64. [Google Scholar] [CrossRef]

- Grant, S.B.; Saphores, J.D.; Feldman, D.L.; Hamilton, A.J.; Fletcher, T.D.; Cook, P.L.; Marusic, I. Taking the “waste” out of “wastewater” for human water security and ecosystem sustainability. Science 2012, 337, 681–686. [Google Scholar] [CrossRef] [PubMed]

- Navarro, E.J.; Diamadopoulos, E.; Ginestar, D. Time series analysis and forecasting techniques for municipal solid waste management. Resour. Conserv. Recycl. 2002, 35, 201–214. [Google Scholar] [CrossRef]

- Chen, H.W.; Chang, N.B. Prediction analysis of solid waste generation based on grey fuzzy dynamic modeling. Resour. Conserv. Recycl. 2000, 29, 1–18. [Google Scholar] [CrossRef]

- Roubík, H.; Mazancová, J.; Rydval, J.; Kvasnička, R. Uncovering the dynamic complexity of the development of small-scale biogas technology through causal loops. Renew. Energy 2020, 149, 235–243. [Google Scholar] [CrossRef]

- Setzler, H.; Saydam, C.; Park, S. EMS call volume predictions: A comparative study. Comput. Oper. Res. 2009, 36, 1843–1851. [Google Scholar] [CrossRef]

- Karpušenkaitė, A.; Ruzgas, T.; Denafas, G. Time-series-based hybrid mathematical modelling method adapted to forecast automotive and medical waste generation: Case study of Lithuania. Waste Manag. Res. 2018, 36, 454–462. [Google Scholar] [CrossRef]

- Box, G.E.; Tiao, G.C. Intervention analysis with applications to economic and environmental problems. J. Am. Stat. Assoc. 1975, 70, 70–79. [Google Scholar] [CrossRef]

- Giannouli, M.; Haan, P.; Keller, M.; Samaras, Z. Waste from road transport: Development of a model to predict waste from end-of-life and operation phases of road vehicles in Europe. J. Clean. Prod. 2007, 15, 1169–1182. [Google Scholar] [CrossRef]

- Chen, Y.; Cai, G.; Zheng, L.; Zhang, Y.; Qi, X.; Ke, S.; Gao, L.; Bai, R.; Liu, G. Modeling waste generation and end-of-life management of wind power development in Guangdong, China until 2050. Resour. Conserv. Recycl. 2021, 169, 105533. [Google Scholar] [CrossRef]

- Althaf, S.; Babbitt, C.W.; Chen, R. Forecasting electronic waste flows for effective circular economy planning. Resour. Conserv. Recycl. 2019, 151, 104362. [Google Scholar] [CrossRef]

- Denafas, G.; Ruzgas, T.; Martuzevičius, D.; Shmarin, S.; Hoffmann, M.; Mykhaylenko, V.; Ludwig, C. Seasonal variation of municipal solid waste generation and composition in four east European cities. Resour. Conserv. Recycl. 2014, 89, 22–30. [Google Scholar] [CrossRef]

- Tian, G.D.; Zhou, M.C.; Li, P. Disassembly sequence planning considering fuzzy component quality and varying operational cost. IEEE Trans. Autom. Sci. Eng. 2017, 81, 1–13. [Google Scholar] [CrossRef]

- Xiao, F.; Ai, Q. Data-driven multi-hidden Markov model-based power quality disturbance prediction that incorporates weather conditions. IEEE Trans. Power Syst. 2019, 34, 402–412. [Google Scholar] [CrossRef]

- Peeters, J.R.; Bracqguene, E.; Nelen, D.; Ueberschaar, M.; Van-Acker, K.; Duflou, J.R. Forecasting the recycling potential based on waste analysis: A case study for recycling Nd-Fe-B magnets from hard disk drives. J. Clean. Prod. 2018, 175, 96–108. [Google Scholar] [CrossRef]

- Karpušenkaitė, A.; Ruzgas, T.; Denafas, G. Forecasting medical waste generation using short and extra short data sets: Case study of Lithuania. Waste Manag. Res. 2016, 34, 378–387. [Google Scholar] [CrossRef] [PubMed]

- Abdoli, M.A.; Falahnezhad, M.; Behboudian, S. Multivariate econometric approach for solid waste generation modeling: Impact of climate factors. Environ. Eng. Sci. 2011, 28, 627–633. [Google Scholar] [CrossRef]

- Kannangara, M.; Dua, R.; Ahmadi, L.; Bensebaa, F. Modeling and prediction of regional municipal solid waste generation and diversion in Canada using machine learning approaches. Waste Manag. 2018, 74, 3–15. [Google Scholar] [CrossRef]

- Intharathirat, R.; Abdul, S.P.; Kumar, S.; Untong, A. Forecasting of municipal solid waste quantity in a developing country using multivariate Grey models. Waste Manag. 2015, 39, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, A.; Singh, A. A hybrid multi-criteria decision making method approach for selecting a sustainable location of health-care waste disposal facility. J. Clean. Prod. 2016, 139, 1001–1010. [Google Scholar] [CrossRef]

- Noori, R.; Abdoli, M.A.; Farokhnia, A.; Abbasi, M. Results uncertainty of solid waste generation forecasting by hybrid of wavelet transform-ANFIS and wavelet transform-neural network. Expert Syst. Appl. 2009, 36, 9991–9999. [Google Scholar] [CrossRef]

- Aldieri, L.; Vinci, C.P. Climate change and knowledge spillovers for cleaner production: New insights. J. Clean. Prod. 2020, 271, 122729. [Google Scholar] [CrossRef]

- Anonymous. Studies from Maejo University yield new data on biofuel (a biorefinery approach for the production of bioethanol from alkaline-pretreated, enzymatically hydrolyzed nicotiana tabacum stalks as feedstock for the bio-based industry). Biotech Week 2021, 20, 996. Available online: link.gale.com/apps/doc/A648765269/AONE?u=nuslib&sid=AONE&xid=1f24d3f7 (accessed on 11 May 2021).

- Tsai, F.M.; Bui, T.; Tseng, M.; Wu, K. A causal municipal solid waste management model for sustainable cities in Vietnam under uncertainty: A comparison. Resour. Conserv. Recycl. 2020, 154, 104599. [Google Scholar] [CrossRef]

- Roubík, H.; Mazancová, J.; Phung, L.D.; Banout, J. Current approach to manure management for small-scale Southeast Asian farmers-using Vietnamese biogas and non-biogas farms as an example. Renew. Energy 2018, 115, 362–370. [Google Scholar] [CrossRef]

- Ahamed, A.; Vallam, P.; Iyer, N.S.; Veksha, A.; Bobacka, J.; Lisak, G. Life cycle assessment of plastic grocery bags and their alternatives in cities with confined waste management structure: A Singapore case study. J. Clean. Prod. 2021, 278, 123956. [Google Scholar] [CrossRef]

- Bai, R.; Sutanto, M. The practice and challenges of solid waste management in Singapore. Waste Manag. 2002, 22, 557–567. [Google Scholar] [CrossRef]

- Xiong, C.; Yang, D.; Ma, J.; Chen, X.; Zhang, L. Measuring and enhancing the transfer ability of hidden Markov models for dynamic travel behavioral analysis. Transportation 2018, 47, 585–605. [Google Scholar] [CrossRef]

- Jiang, P.; Liu, X. Hidden Markov model for municipal waste generation forecasting under uncertainties. Eur. J. Oper. Res. 2016, 250, 639–651. [Google Scholar] [CrossRef]

- Collin, B.E.; Bruce, E.A.; Susan, M.S. Comparison of Gaussian process modeling software. Eur. J. Oper. Res. 2018, 266, 179–192. [Google Scholar]

- Sheng, H.M.; Xiao, J.; Wang, P. Lithium iron phosphate battery electric vehicle state-of-charge estimation based on evolutionary Gaussian mixture regression. IEEE Trans. Ind. Electron. 2016, 64, 544–551. [Google Scholar] [CrossRef]

- Diedrich, A.; Charoensuk, W.; Brychta, R.J.; Ertl, A.C.; Shiavi, R. Analysis of raw microneurographic recordings based on wavelet de-noising technique and classification algorithm: Wavelet analysis in microneurography. IEEE Trans. Biomed. Eng. 2003, 50, 41–50. [Google Scholar] [CrossRef] [PubMed]

- Bouzida, A.; Touhami, O.; Ibtiouen, R.; Belouchrani, A.; Fadel, M.; Rezzoug, A. Fault diagnosis in industrial induction machines through discrete wavelet transform. IEEE Trans. Ind. Electron. 2011, 58, 4385–4395. [Google Scholar] [CrossRef]

- Thomas, C.; John, C.; Ramazan, G. Long-run wavelet-based correlation for financial time series. Eur. J. Oper. Res. 2018, 271, 676–696. [Google Scholar]

- Baum, L.E.; Petrie, T.; Soules, G.; Weiss, N. A maximization technique occurring in the statistical analysis of probabilistic functions of Markov chains. Ann. Math. Stat. 1970, 41, 164–171. [Google Scholar] [CrossRef]

- Bot, R.I.; Csetnek, E.R.; Vuong, P.T. The forward-backward-forward method from continuous and discrete perspective for pseudo-monotone variational inequalities in Hilbert spaces. Eur. J. Oper. Res. 2020, 287, 49–60. [Google Scholar] [CrossRef]

- Juan, F.; Rendon, S.; Lilian, M.M. Structural combination of seasonal exponential smoothing forecasts applied to load forecasting. Eur. J. Oper. Res. 2019, 275, 916–924. [Google Scholar]

- Sakdirat, K.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.; Nee, A.Y. Digital twin-driven product design framework. Int. J. Prod. Res. 2018, 57, 3935–3953. [Google Scholar] [CrossRef]

| Comparison Model | Parameters Setting |

|---|---|

| ANN | Learning rate 0.1; the transfer function of hidden layer is tansig; the wrong target is 0.0001; the maximum number of iterations is 10,000; the hidden node is 3; the output node is 1. |

| SVM | Radial basis function is used as the best kernel function. In the coarse grid search, the parameters of the gamma function and the penalty parameters are set to the range [2−8, 28]. The steps of coarse grid search and fine grid search are set to 1 and 0.2, respectively. |

| ARIMA | The most suitable ARIMA model parameters are (1, 1, 1). |

| ES | Using a multiplicative algorithm to predict the amount of waste generated during disassembly. |

| Monday | Tuesday | Wednesday | Thursday | Friday | Saturday | |

|---|---|---|---|---|---|---|

| Sample size | 53 | 53 | 52 | 52 | 52 | 52 |

| Normal(Mean/SD) | 3.532/2.753 | 3.364/2.517 | 3.826/2.964 | 2.963/1.857 | 4.178/3.135 | 3.584/2.822 |

| Most extreme differences | 0.121 | 0.094 | 0.135 | 0.087 | 0.096 | 0.105 |

| Kolmogorov–Smirnov | 0.872 | 0.944 | 0.817 | 1.016 | 1.039 | 0.936 |

| Asymp. Sig.(2-tailed) | 0.535 | 0.438 | 0.324 | 0.420 | 0.238 | 0.341 |

| NHS | NGMC | MLE | AIC | NHS | NGMC | MLE | AIC | NHS | NGMC | MLE | AIC |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 1 | 388 | −168 | 3 | 3 | 325 | −63 | 2 | 2 | 397 | −185 |

| 2 | 2 | 306 | −49 | 2 | 1 | 359 | −102 | 3 | 3 | 364 | −124 |

| 3 | 3 | 385 | −153 | 2 | 2 | 312 | −58 | 2 | 1 | 372 | −135 |

| 2 | 1 | 328 | −68 | 3 | 3 | 355 | −94 | 3 | 2 | 393 | −174 |

| 3 | 2 | 341 | −73 | 3 | 1 | 369 | −127 | 3 | 3 | 377 | −146 |

| ARMA | ES | ANN | HMM | DG-HMM | |

|---|---|---|---|---|---|

| MAE | 18.34 | 19.60 | 20.47 | 16.83 | 14.35 |

| R2 | 0.875 | 0.892 | 0.899 | 0.906 | 0.913 |

| Ȓ2 | 0.861 | 0.890 | 0.874 | 0.898 | 0.911 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Yuan, G.; Cai, J.; Wei, S. Forecasting of Disassembly Waste Generation under Uncertainties Using Digital Twinning-Based Hidden Markov Model. Sustainability 2021, 13, 5391. https://doi.org/10.3390/su13105391

Yang Y, Yuan G, Cai J, Wei S. Forecasting of Disassembly Waste Generation under Uncertainties Using Digital Twinning-Based Hidden Markov Model. Sustainability. 2021; 13(10):5391. https://doi.org/10.3390/su13105391

Chicago/Turabian StyleYang, Yinsheng, Gang Yuan, Jiaxiang Cai, and Silin Wei. 2021. "Forecasting of Disassembly Waste Generation under Uncertainties Using Digital Twinning-Based Hidden Markov Model" Sustainability 13, no. 10: 5391. https://doi.org/10.3390/su13105391

APA StyleYang, Y., Yuan, G., Cai, J., & Wei, S. (2021). Forecasting of Disassembly Waste Generation under Uncertainties Using Digital Twinning-Based Hidden Markov Model. Sustainability, 13(10), 5391. https://doi.org/10.3390/su13105391