Nowadays, the level of competition in the global marketplace requires that manufacturing companies efficiently adopt a sustainable workplace. However, there is a variety of production-related problems, such as late deliveries, line stoppages, bottlenecks, unbalanced production lines, hours of production, overtime, inefficient material handling equipment, risky body postures for employees, and high production costs, among others.

1.1. Problems for Sustainable Workplaces

In the case of late deliveries, Peng and Lu [

1] report an analysis regarding the impact of delivery performance on customer transactions, which affects the customers’ transaction amounts and the price units. On the other hand, Fazlollahtabar [

2] reports a case study applied to an assembly line in which late deliveries of products were the source of poor performance in the manufacturing system, and he proposed a parallel line of autonomous assembly of guided vehicles. Late deliveries reflect a low-quality logistics infrastructure, which represents a barrier for sustainability [

3].

In the case of unbalanced production lines and bottlenecks, different authors have confirmed that they decrease the manufacturing systems’ productivity and diminish the capacity in the production system [

4,

5] because bottlenecks can cause line stoppages [

6,

7], which in turn adversely affect performance. For example, Ren et al. [

4] and Zupan and Herakovic [

8] present case studies in which unbalanced bottlenecks and production lines cause a low level of productivity in an assembly area, which was solved by balancing the production lines and redesigning their distribution. In addition, Gu et al. [

6] claim that maintenance problems cause bottlenecks in complex manufacturing systems, which result in the loss of production. In other words, unbalanced production lines create organizational problems, decrease the supply chain performance, and increase production costs. Therefore, the appropriate balance in a production line is a traditional production strategy that helps reduce bottlenecks in manufacturing systems.

Furthermore, regarding production line stoppages, these are responsible for production losses [

9] and for production cost increases [

10,

11], especially when they occur unexpectedly; consequently, they affect subsequent manufacturing operations [

12]. According to Hossen et al. [

13], losses due to inactivity and equipment downtime and failures represent 89.3% of total losses due to downtime in a production system. Nevertheless, Peng and Zhou [

10] mention that mixed-model assembly lines are currently widely adopted in the automotive industry to achieve an ongoing customization, since it is not allowed to have a material shortage because it is extremely expensive to afford due to the stoppages from the resulting production lines.

Similarly, Sonmez et al. [

9] state that production line stoppages due to broken machinery cause production loss in manufacturing systems, and Zhao et al. [

14] present a preventive maintenance (PM) modeling based on delay times for manufacturing systems in a steel industry. Specifically, line stoppages are a consequence of raw material shortage. Finally, Peng and Zhou [

11] investigate a problem of programming multiple servers in an automotive assembly line, where the supply of parts just in time (JIT) is a critical and costly problem.

Regarding overtime, Hansson et al. [

15] report a study to determine if the batch preparation process affects work efficiency when it is compared with only preparing one batch, and found that the kitting process is associated with overtime as a result of the material batching and feeding process. In addition, they conducted two experiments and discovered that the preparation of a single batch took longer than the batch preparation, which represented a higher production cost. Similarly, several studies argue that overtime is a specific aspect of certain tasks or departments associated with manufacturing systems. For example, Wang et al. [

16] indicate that poor process planning make operators work longer, which translates into higher production costs.

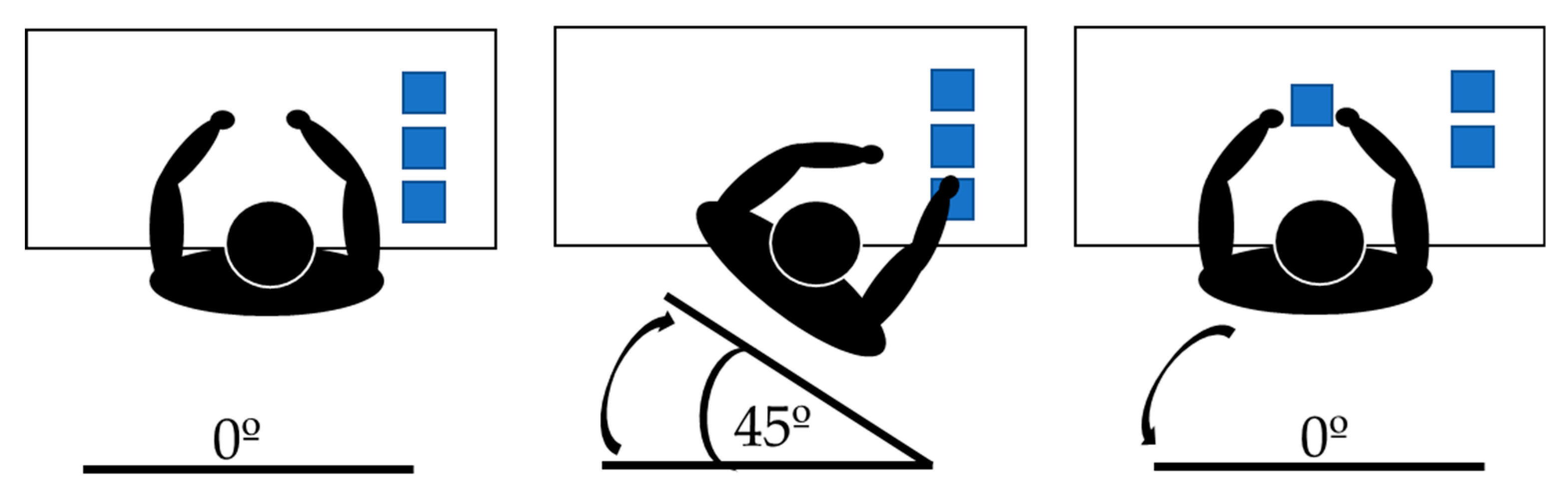

Moreover, El-Namrouty and Abushaaban [

17] mention that the material handling process and inefficient body movements or postures do not add value to a product, generate a long production cycle time, or make inefficient the implementation of human resources. Regarding body movements and postures, they imply an inadequate implementation of ergonomics in the production system, since operators will perform hazardous tasks, such as stretching, bending, or lifting, when it is not required. For example, Kamat et al. [

18] and Gómez-Galán et al. [

19] mention that uncomfortable body postures, as well as repetitive movements, represent a risk factor for employees, since they can cause musculoskeletal disorders and negatively affect employees’ health and performance, altering their well-being. In the same way, Yeow et al. [

20] showed that repetitive movements may cause fatigue and loss of concentration while performing a task, which increases the probability of making mistakes, negatively affecting their performance. These problems may be generated by a poor design of workstations, which generates uncomfortable postures, causes musculoskeletal disorders, and consequently, affects work performance and well-being [

21], as well as causing high production costs [

17].

In conclusion, all of these problems cause high costs, a lack of competitive advantage, and a weak market position, which, along with the times of work shifts, lack of human resource performance, and well-being, represent a barrier for sustainable workplaces [

3,

22].

1.2. Sustainability Strategies

According to the literature, there are eight sustainability strategies. These strategies are classified into two perspectives: Strategies adopted by project organizations, and strategies adopted by project hosts [

23]. One of these strategies is setting strategic and tactical sustainability goals. This strategy is focused explicitly on sustainability issues when developing project strategies, paying special attention to instances where sustainability issues align with other aspects [

24]. Another strategy is influencing the sustainability of project practices, which consists in supporting the incorporation of sustainability into project practices and technical systems through, e.g., construction tools, prefabrication, and waste management systems [

25].

Table 1 summarizes the eight sustainability strategies provided by the literature.

As can be observed in

Table 1, none of these strategies are focused on achieving sustainable workplaces by integrating standardized work and anthropometry. That is why this research proposes an integrative approach of standardized work and anthropometry as a strategy to achieve sustainable workplaces and well-being for operators.

In order to solve the previous issues, multiple strategies are implemented in manufacturing systems. For example, in the supplier selection process, companies are focused on attributes related to delivery time and performance [

1], since they avoid having technical stoppages due to a lack of raw material [

1]. For example, a business-to-business (B2B) study indicates that those that have an appropriate delivery performance can have higher prices on their products, as well as gaining more customers due to their price flexibility [

32]. Another example of a competitiveness strategy is the Fulfillment by Amazon (FBA) service, which provides a greater flexibility in their sales practices and manages the full compliance of a product from external suppliers after it has been purchased. In addition, a recent survey reported that 73% of FBA users have obtained increases in unit sales over 20% [

33]. On the contrary, the low performance of deliveries causes a decrease in sales and even sale losses.

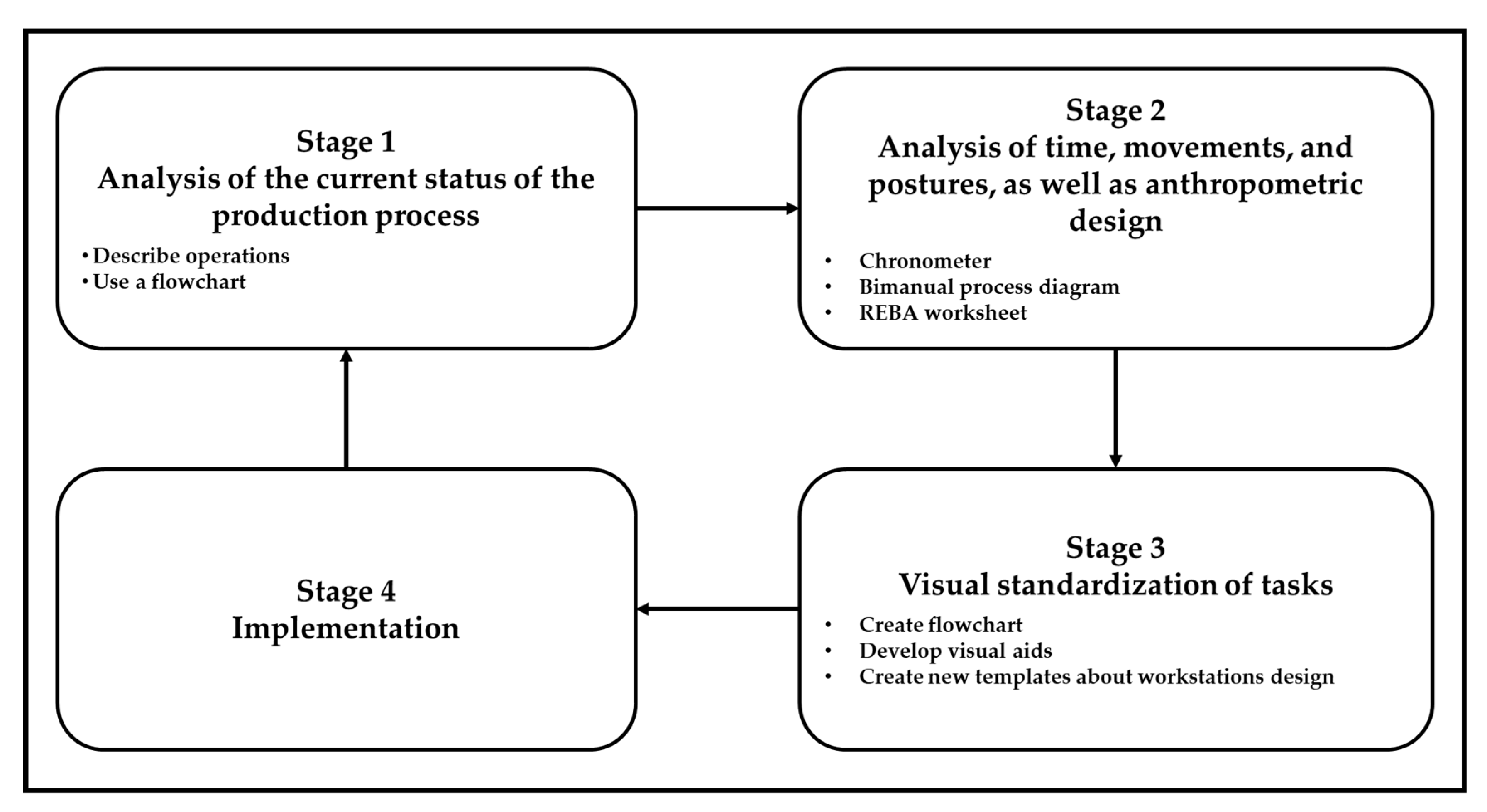

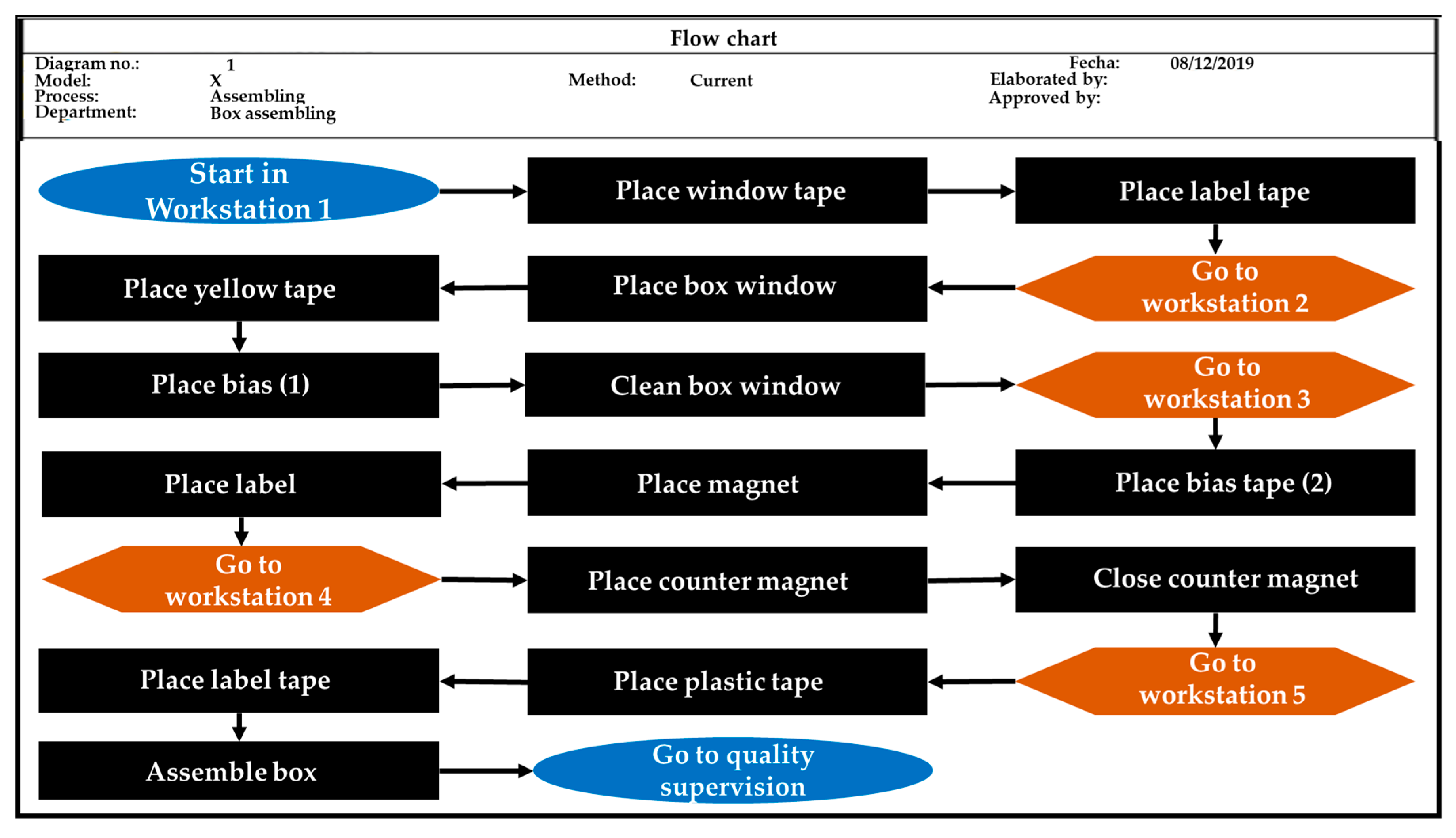

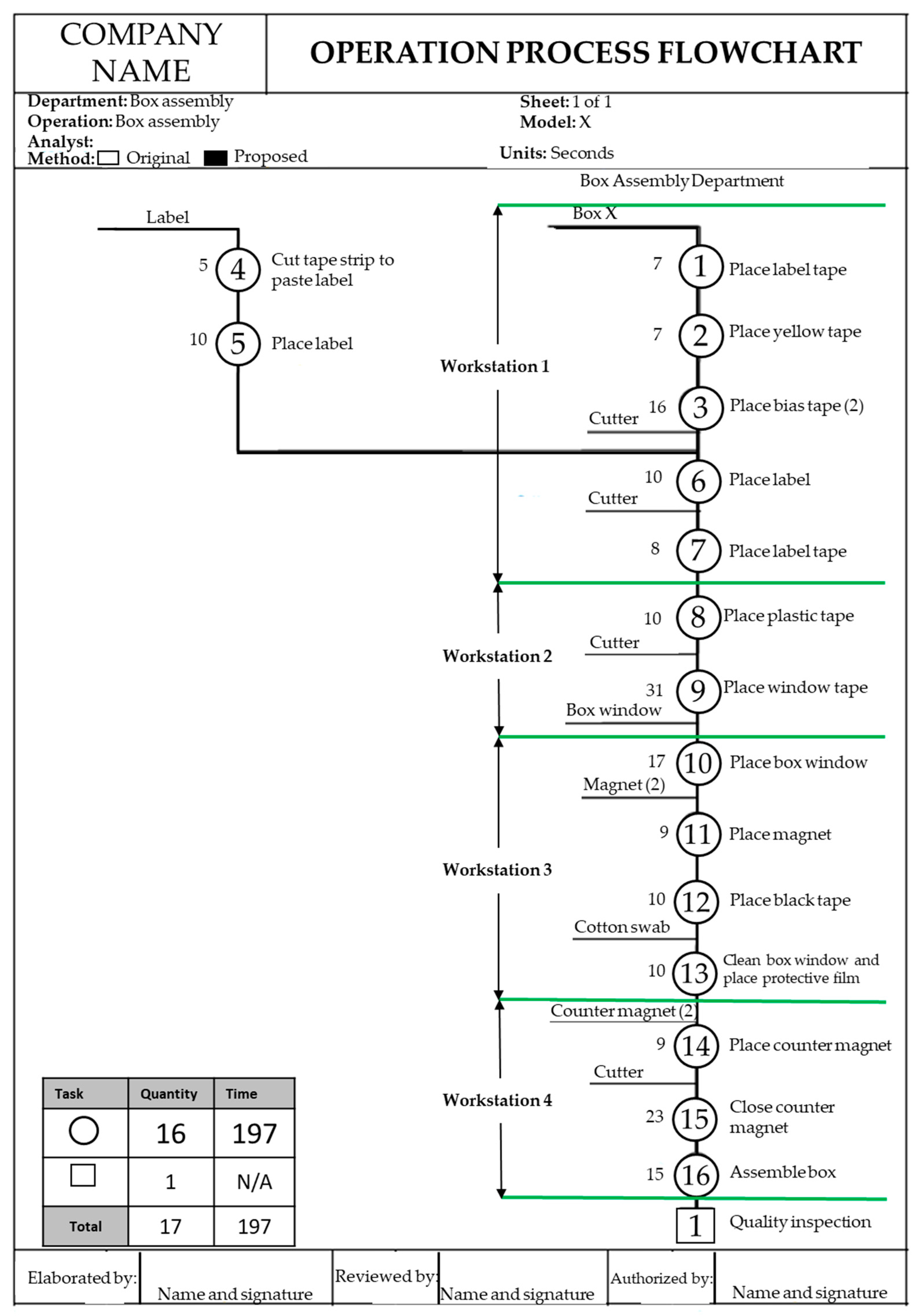

In addition, standardized work (SW) is a fundamental tool for solving manufacturing problems because it offers almost immediate results for the organizational performance, since it increases productivity and reduces delivery times [

34]. Similarly, SW is a set of specific instructions that are required for assembling a product in the most efficient way, since it allows definition of the best methods and sequenced tasks needed for each production process and employee; consequently, it helps to reduce waste [

34,

35,

36] and increase the well-being and performance of the human factor. In addition, SW is probably the most reliable method for performing any manufacturing task, since it is one of the safest and most efficient tools for meeting timely, orderly, and quality deliveries [

37].

Likewise, SW defines how each operator must perform each task or job in the production system; as a result, random tasks that reduce life cycle times are avoided [

34,

38]; in fact, SW uses takt-time to meet the customer demand [

39]. Specifically, the main objective of SW involves eliminating Mura [

40]; this is a general term for unevenness or irregularity in physical materials or in human condition, which is a key concept for performance improvement systems, since it is one of the three forms of waste that can be found in manufacturing systems (Muda, Mura, and Muri) [

41]. Hence, SW does not mean that a work routine will be changed; instead, it implies that “it is the best method to know how to perform a task better” [

38,

42]. In addition, SW consists of three elements [

34]: Uptime, work sequence, and standard inventory.

SW applications in productive systems are found in the work of Nallusamy [

43], who applied line balancing and SW in the Computer Numerical Control (CNC) industry to reduce activities that did not add value to a product by 17%, while its production increased by five units per day with two employees, and up to seven units by day with a single employee. Similarly, Nallusamy and Saravanan [

44] implemented these two tools in a manufacturing company to reduce cycle time and increase productivity. In addition, Mor et al. [

34] implemented SW, obtaining a 31.6 s reduction in cycle times and 6.5% increase in production. Finally, Ordieres-Mere and Villalba-Diez [

45] implemented SW in the inter-communication processes in the automotive industry to increase the optimization of the total performance by 4%.

In summary, SW helps to increase the competitiveness of companies because it is not only focused on controlling production processes, but it also minimizes costs and maximizes efficiency [

46]. Specifically, in small and medium enterprises (SMEs), SW represents a tool that compensates for the lack of advanced manufacturing technology (AMT) in production processes; however, SW is often poorly implemented or misunderstood [

34].

Lee et al. [

47] define anthropometry as a measurement of the human body, which is necessary for the design of workstations, and multiple cases are reported; for example, Colim et al. [

48] studied a furniture assembly workstation where most employees were continually exposed to risk factors for musculoskeletal disorders; they redesigned workstations by considering anthropometric data from employees and, as a result, body posture was improved and the risk of suffering skeletal muscle disorders was eliminated. Likewise, Kibria and Rafiquzzaman [

49] indicate that working for long periods in a sitting position in front of a computer causes several types of pain, discomfort, and health problems in university teachers; therefore, workstation designs with an anthropometric approach were proposed. Finally, Lee and Cha [

50] report that console operators in nuclear power plants face human–computer interaction problems due to inappropriate console design; consequently, they redesigned the consoles by considering anthropometry. In conclusion, based on the previous examples, the correct use of anthropometry in workstation redesign improves the well-being, health, comfort, and safety of operators [

51].

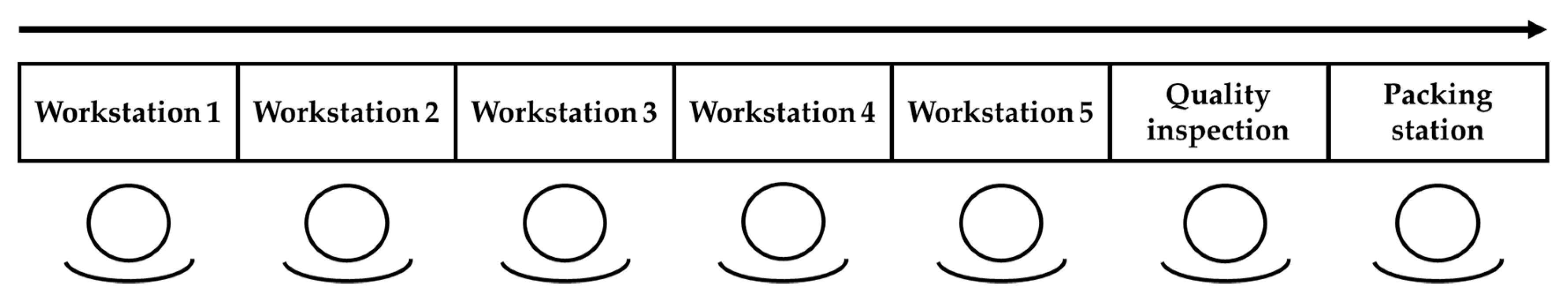

Workstation design influences the postures and movements that operators perform during task execution [

52]. The most basic movements are named Therbligs, which were introduced by Frank B. Gilbreth, who, in his early work in the study of movement, developed certain subdivisions or events that he considered common to all kinds of manual work. The term refers to 17 elemental subdivisions or basic movements. According to Palit and Setiawan [

53], Therbligs can be effective or ineffective. On the one hand, effective Therbligs directly advance work progress and can often be shortened, but generally cannot be removed entirely. On the other hand, ineffective Therbligs do not advance the progress of the job and should be removed if possible. Some of the 17 Therbligs, along with their symbols, are Reach (RE), Move (M), Grasp (G), Assemble (A), and Disassemble (DA), to mention few. A complete view of the 17 Therbligs (effective or ineffective), their definitions, and their symbols can be seen in Palit and Setiawan [

53] and Freivalds and Niebel [

54]. According to Jia et al. [

55], the Therblig is one of the basic concepts in the study of movement, and is defined as a basic energy demand unit. The basic idea of the study of movement is to divide the worker’s operation into simple motion elements, which are Therbligs [

55].

Concerning the relationship between anthropometry and sustainability, the literature mentions that a poor workplace design is a major risk factor responsible for the uncomfortable conditions that operators on assembly lines are exposed to, especially when operators are working multiple hours a day, decreasing their well-being [

56]. As mentioned above, this poor design generates uncomfortable postures, causing musculoskeletal disorders. The anthropometric design of the workstations facilitates the sustainable development of the workplace and, therefore, of the operators [

56].

Different authors, such as Kim et al. [

57] and Nadadur and Parkinson [

58], mention that anthropometry is essential to improve the sustainability and physical suitability of a workplace design. In addition, these authors suggest that anthropometry positively impacts sustainability by reducing the consumption of raw materials, increasing the useful life of products (including workstations), and considering the variability among the user population. Therefore, anthropometric design allows improvement of global sustainability by efficiently using available resources, prolonging the time of use of products, and increasing their versatility by satisfying different user populations.

The uniqueness of this research is that it proposes and integrates an approach by combining SW and the anthropometric design of workstations in the production processes in order to improve sustainability in manufacturing companies and well-being in operators. The integrated approach is illustrated in a real case study as a response to an industrial problem.