Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique

Abstract

1. Introduction

2. Material and Methods

2.1. Material Collection and Preparation

2.2. Material Characterization

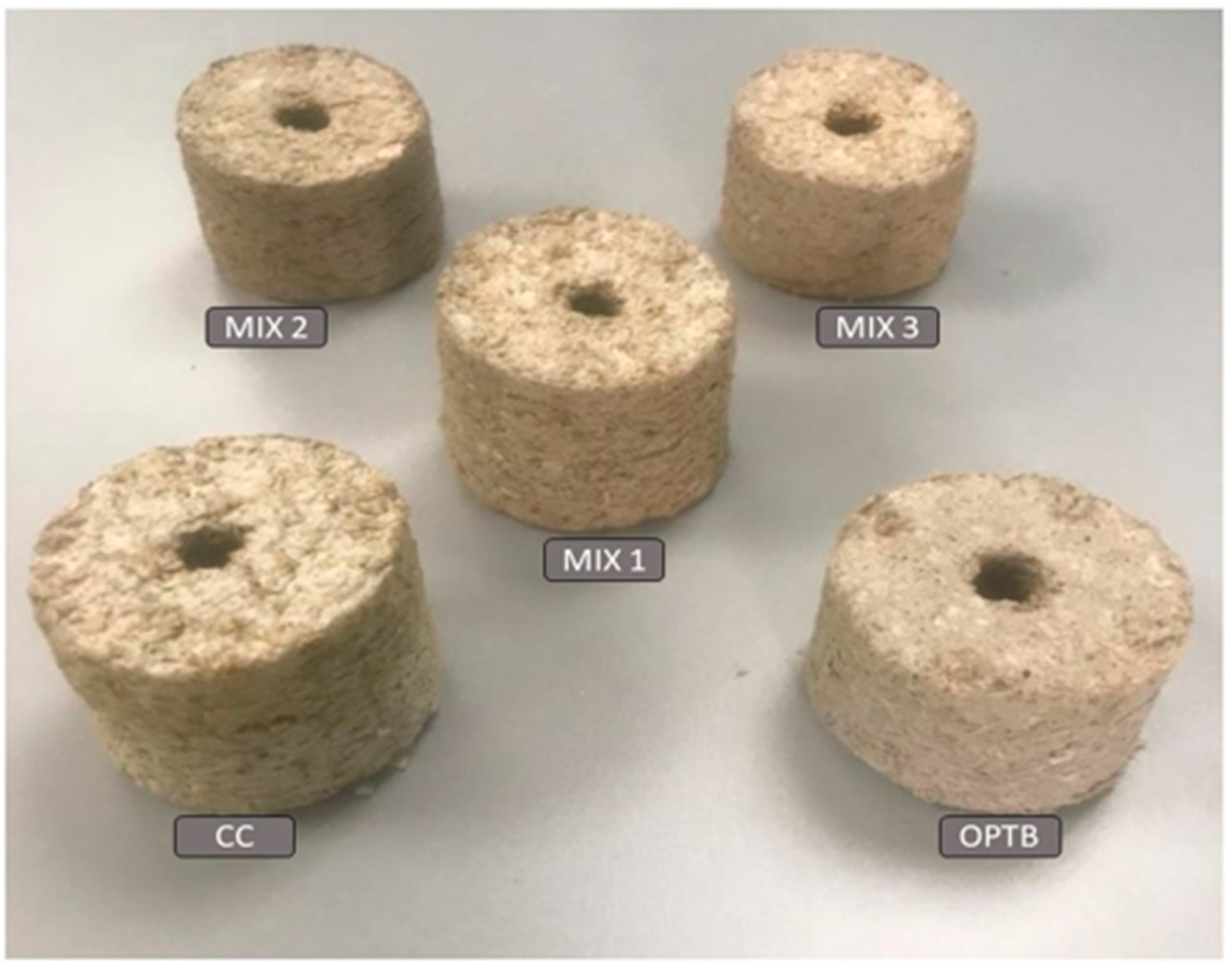

2.3. Briquette Production

2.4. Briquette Characterization

2.4.1. Moisture Content

2.4.2. Density

2.4.3. Water Resistance

2.4.4. Shatter Index

2.4.5. Compressive Strength

2.4.6. Calorific Value

2.5. Data Analysis

3. Results and Discussion

3.1. Proximate and Ultimate Analysis of Raw Materials

3.2. Briquette Characterization

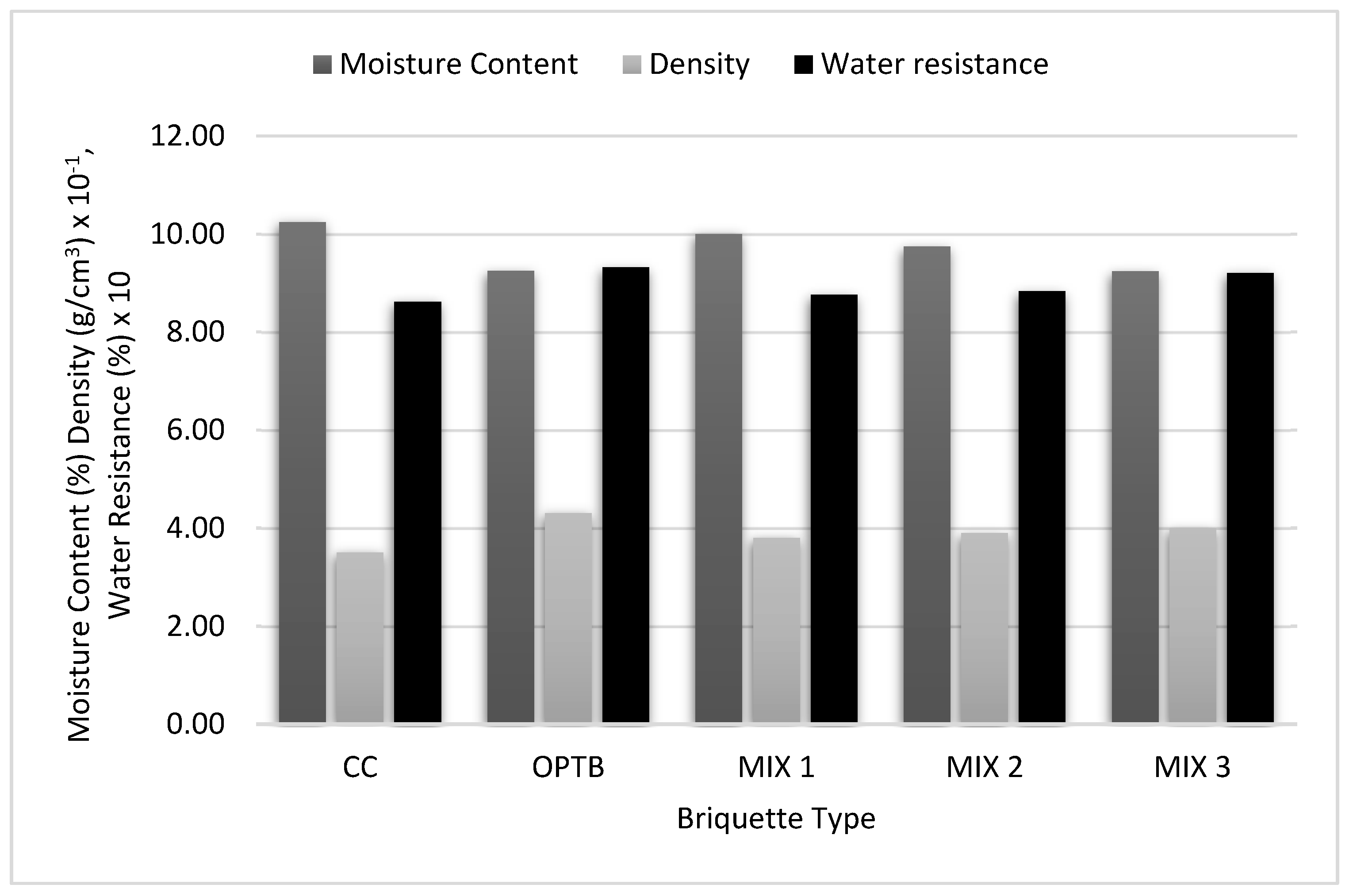

3.2.1. Moisture Content

3.2.2. Density

3.2.3. Water Resistance

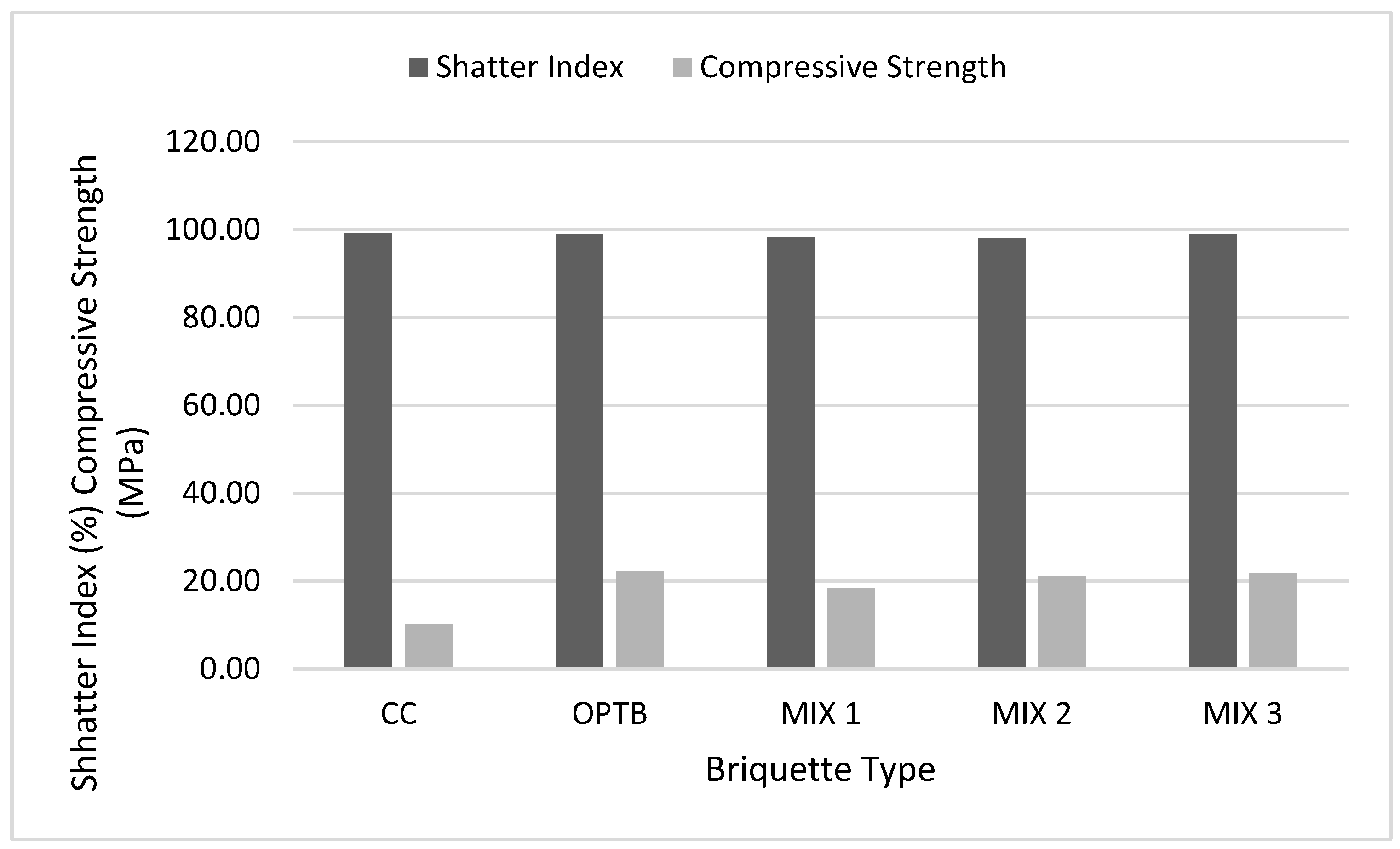

3.2.4. Shatter Index

3.2.5. Compressive Strength

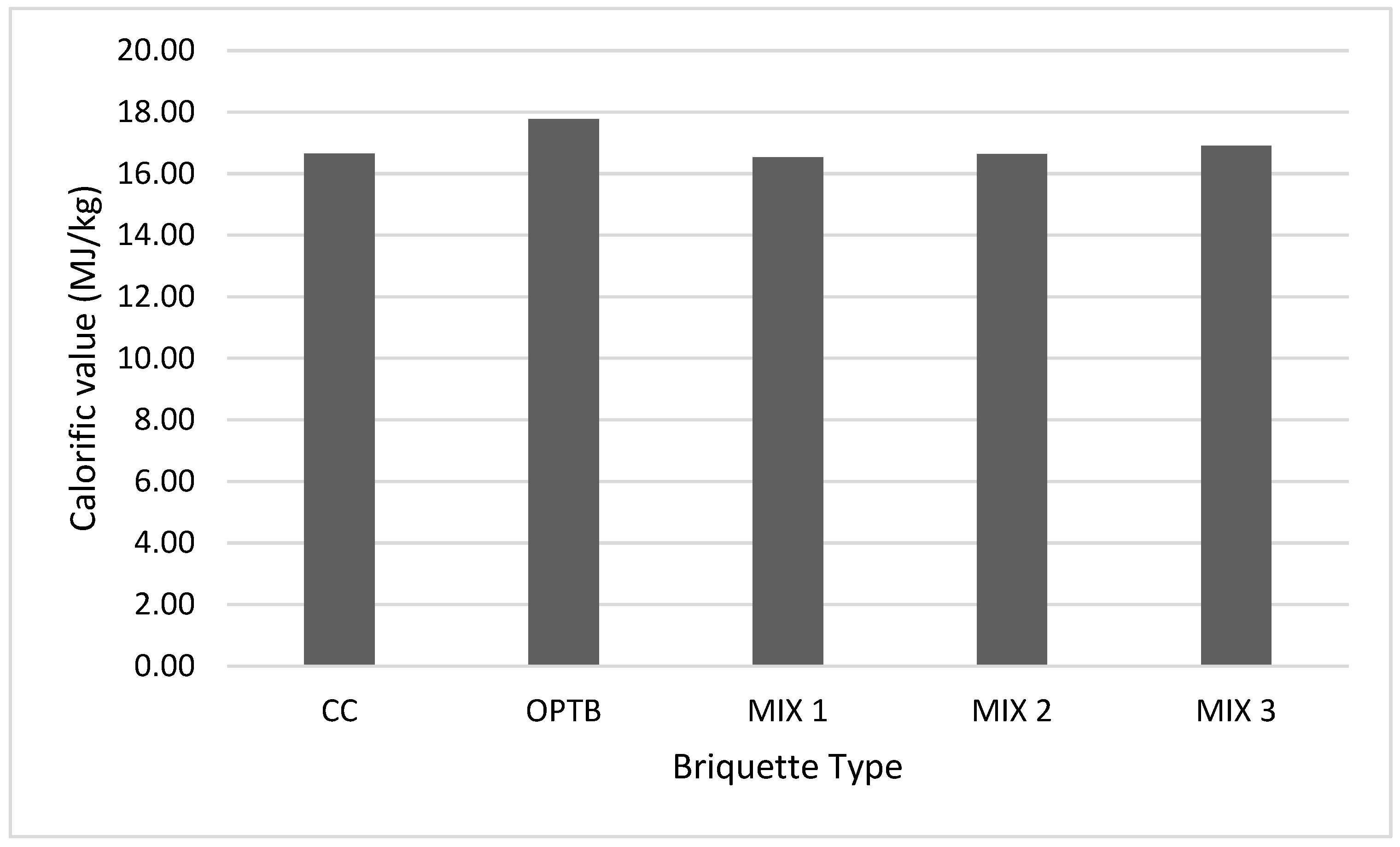

3.2.6. Calorific Value

3.3. Correlation between Density and Some Briquette Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Demirbas, A. the Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Trubetskaya, A.; Leahy, J.J.; Yazhenskikh, E.; Müller, M.; Layden, P.; Johnson, R.; Ståhl, K.; Monaghan, R.F.D. Characterization of woodstove briquettes from torrefied biomass and coal. Energy 2019, 171, 853–865. [Google Scholar] [CrossRef]

- Sawadogo, M.; Kpai, N.; Tankoano, I.; Tanoh, S.T.; Sidib, S. Cleaner production in Burkina Faso: Case study of fuel briquettes made from cashew industry waste. J. Clean. Prod. 2018, 195, 1047–1056. [Google Scholar] [CrossRef]

- Duca, D.; Riva, G.; Foppa Pedretti, E.; Toscano, G. Wood pellet quality with respect to en 14961-2 standard and certifications. Fuel 2014, 135, 9–14. [Google Scholar] [CrossRef]

- Ndindeng, S.A.; Mbassi, J.E.G.; Mbacham, W.F.; Manful, J.; Graham-Acquaah, S.; Moreira, J.; Dossou, J.; Futakuchi, K. Quality optimization in briquettes made from rice milling by-products. Energy Sustain. Dev. 2015, 29, 24–31. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Development of groundnut shells and bagasse briquettes as sustainable fuel sources for domestic cooking applications in Uganda. Renew. Energy 2017, 111, 532–542. [Google Scholar] [CrossRef]

- Zheng, S.; Liang, W.; Chu, H.; Zhou, H. Effects of radiation reabsorption of C1-C6 hydrocarbon flames at normal and elevated pressures. Fuel 2020, 266, 117061. [Google Scholar] [CrossRef]

- Felfli, F.F.; Mesa, P.J.M.; Rocha, J.D.; Filippetto, D.; Luengo, C.A.; Pippo, W.A. Biomass briquetting and its perspectives in Brazil. Biomass Bioenergy 2011, 35, 236–242. [Google Scholar] [CrossRef]

- Araújo, S.; Vilas Boas, M.A.; Neiva, D.M.; Carneiro, A.C.; Vital, B.; Breguez, M.; Pereira, H. Effect of a mild torrefaction for production of eucalypt wood briquettes under different compression pressures. Biomass Bioenergy 2016, 90, 181–186. [Google Scholar] [CrossRef]

- Sepúlveda, F.J.; Arranz, J.I.; Miranda, M.T.; Montero, I.; Rojas, C.V. Drying and pelletizing analysis of waste from cork granulated industry. Energies 2018, 11, 109. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Halim, H.B.A.; Ahmad, A.F.; Abbas, Z. Physical characterization of briquettes produced from paper pulp and Mesua ferrea mixtures. Biofuels 2019, 1–8. [Google Scholar] [CrossRef]

- Mendoza-Martinez, C.L.; Sermyagina, E.; Carneiro, O.A.D.C.; Vakkilainen, E.; Cardoso, M. Production and characterization of coffee-pine wood residue briquettes as an alternative fuel for local firing systems in Brazil. Biomass Bioenergy 2019, 123, 70–77. [Google Scholar] [CrossRef]

- Oladeji, J.T. Fuel Characterization of Briquettes Produced from Corncob and Rice Husk Resides. Pac. J. Sci. Technol. 2010, 11, 101–106. [Google Scholar]

- Sotannde, O.A.; Oluyege, A.O.; Abah, G.B. Physical and combustion properties of briquettes from sawdust of Azadirachta indica. J. For. Res. 2010, 21, 63–67. [Google Scholar] [CrossRef]

- Cooper, C.J.; Laing, C.A. A macro analysis of crop residue and animal wastes as a potential energy source in Africa. J. Energy S. Afr. 2007, 8, 10–19. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs. Fuel Process Technol. 2015, 133, 137–145. [Google Scholar] [CrossRef]

- Miranda, M.T.; Sepúlveda, F.J.; Arranz, J.I.; Montero, I.; Rojas, C.V. Analysis of pelletizing from corn cob waste. J. Environ. Manag. 2018, 228, 303–311. [Google Scholar] [CrossRef]

- Oladeji, J.T.; Enweremadu, C.C. The Effects of Some Processing Parameters on Physical and Densification Characteristics of Corncob Briquettes. Int. J. Energy Eng. 2012, 2, 22–27. [Google Scholar] [CrossRef]

- Zubairu, A.; Gana, S.A. Production and Characterization of Briquette Charcoal by Carbonization of Agro-Waste. Energy Power 2014, 4, 41–47. [Google Scholar]

- Adetogun, A.C.; Ogunjobi, K.M.; Are, D.B. Combustion properties of briquettes produced from maize cob of different particle sizes. J. Res. For. Wildl. Environ. 2014, 6, 28–38. [Google Scholar]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Effects of operating parameters on maize COB briquette quality. Biomass Bioenergy 2018, 112, 61–72. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Densification characteristics of corn cobs. Fuel Proc. Technol. 2010, 91, 559–565. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A.; Akowuah, J.O. Briquettes from maize cobs and Ceiba pentandra at room temperature and low compacting pressure without a binder. Int. J. Energy Environ. Eng. 2013, 4, 1–7. [Google Scholar] [CrossRef]

- Martinov, M.L.; Veselinov, B.V.; Bojić, S.J.; Djatkov, D.M. Investigation of maize cobs crushing—Preparation for use as a fuel. Therm. Sci. 2011, 15, 235–243. [Google Scholar] [CrossRef]

- Dungani, R.; Jawaid, M.; Khalil, H.A.; Jasni, J.; Aprilia, S.; Hakeem, K.R.; Hartati, S.; Islam, M.N. A review on quality enhancement of oil palm trunk waste by resin impregnation: Future materials. BioResources 2013, 8, 3136–3156. [Google Scholar] [CrossRef]

- Jalil, R.; Ibrahim, W.A.; Elham, P.; Sarif, M. Towards Zero Waste Production of Value Added Products from Waste Oil Palm Trunk (WOPT). In Proceedings of the 8th Biomass Asia Workshop, Hanoi, Vietnam, 29 November–1 December 2011; pp. 1–7. [Google Scholar]

- Rosli, F.; Mohd, C.; Ghazali, R.; Al, M.M.; Abdullah, B.; Hussin, K. A Review: Characteristics of Oil Palm Trunk (OPT) and Quality Improvement of Palm Trunk Plywood by Resin Impregnation Fauhan. BioResources 2016, 11, 5565–5580. [Google Scholar]

- Onoja, E.; Chandren, S.; Abdul Razak, F.I.; Mahat, N.A.; Wahab, R.A. Oil Palm (Elaeis guineensis) Biomass in Malaysia: The Present and Future Prospects. Waste Biomass Valorization 2019, 10, 2099–2117. [Google Scholar] [CrossRef]

- Ramamoorthy, N.K.; Tr, T.R.; Sahadevan, R. Production of bioethanol by an innovative biological pre-treatment of a novel mixture of surgical waste cotton and waste card board. Energy Sources Part A Recover Util. Environ. Eff. 2019, 1–12. [Google Scholar] [CrossRef]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 22, 962–979. [Google Scholar] [CrossRef]

- Karunanithy, C.; Wang, Y.; Muthukumarappan, K.; Pugalendhi, S. Physiochemical characterization of briquettes made from different feedstocks. Biotechnol. Res. Int. 2012, 2012, 41–48. [Google Scholar] [CrossRef]

- Abnisa, F.; Arami-Niya, A.; Wan Daud, W.M.A.; Sahu, J.N.; Noor, I.M. Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis. Energy Convers. Manag. 2013, 76, 1073–1082. [Google Scholar] [CrossRef]

- Loh, S.K. The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers. Manag. 2017, 141, 285–298. [Google Scholar] [CrossRef]

- Grover, P.D.; Mishra, S.K. Biomass Briquetting: Technology and Practices. Regional Wood Energy Development Programme In Asia; Field Document No 46; Food and Agriculture Organization: Rome, Italy, 1996. [Google Scholar]

- Husain, Z.; Zainac, Z.; Abdullah, Z. Briquetting of palm fibre and shell from the processing of palm nuts to palm oil. Biomass Bioenergy 2002, 22, 505–509. [Google Scholar] [CrossRef]

- Faizal, H.M.; Latiff, Z.A.; Wahid, M.A.; Darus, A.N. Physical and Combustion Characteristics of Biomass Residues from Palm Oil Mills; Mastorakis, N., Mladenov, V., Bojkovic, Z., Eds.; New Aspects of Fluid Mechanics, Heat Transfer and Environment; Wiley: New York, NY, USA, 2010; pp. 34–38. [Google Scholar]

- Nasrin, A.B.; Choo, Y.M.; Lim, W.S.; Joseph, L.; Michael, S.; Rohaya, M.H. Briquetting of Empty Fruit Bunch fibre and palm shell as a renewable energy fuel. J. Eng. Appl. Sci. 2011, 6, 446–451. [Google Scholar]

- Sing, C.Y.; Aris, S.S. A study of biomass fuel briquettes from oil palm mill residues. Asian J. Sci. Res. 2013, 6, 537–545. [Google Scholar] [CrossRef]

- Bazargan, A.; Rough, S.L.; McKay, G. Compaction of palm kernel shell biochars for application as solid fuel. Biomass Bioenergy 2014, 70, 489–497. [Google Scholar] [CrossRef]

- Hamid, M.F.; Idroas, M.Y.; Ishak, M.Z.; Zainal Alauddin, Z.A.; Miskam, M.A.; Abdullah, M.K. An Experimental Study of Briquetting Process of Torrefied Rubber Seed Kernel and Palm Oil Shell. Biomed. Res. Int. 2016, 2016, 1679734. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Effect of species, particle size and compacting pressure on relaxed density and compressive strength of fuel briquettes. Int. J. Energy Environ. Eng. 2013, 4, 30. [Google Scholar] [CrossRef]

- Yank, A.; Ngadi, M.; Kok, R. Physical properties of rice husk and bran briquettes under low pressure densification for rural applications. Biomass Bioenergy 2016, 84, 22–30. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Biosolids and microalgae as alternative binders for biomass fuel briquetting. Fuel 2017, 194, 339–347. [Google Scholar] [CrossRef]

- Romallosa, A.; Kraft, E. Feasibility of Biomass Briquette Production from Municipal Waste Streams by Integrating the Informal Sector in the Philippines. Resources 2017, 6, 12. [Google Scholar] [CrossRef]

- Harun, N.Y.; Parvez, A.M.; Afzal, M.T. Process and energy analysis of pelleting agricultural and woody biomass blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Katamani, P.; Afrifa, K.A. Fuel characteristics of binder free briquettes made at room temperature from blends of oil palm mesocarp fibre and Ceiba pentandra. Biomass Convers. Biorefinery 2019, 9, 541–551. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Relationship between Physico-Mechanical Properties, Compacting Pressure and Mixing Proportion of Briquettes Produced from Maize Cobs and Sawdust. J. Sustain. Bioenergy Syst. 2014, 4, 50–60. [Google Scholar] [CrossRef]

- Roy, R.; Kundu, K.; Kar, S.; Dahake, V.R.; Rajan, P. Production and evaluation of briquettes made from dry leaves, wheat straw, saw dust using paper pulp and cow dung as binder. Res. Front. 2015, 3, 51–58. [Google Scholar]

- ASTM D3175-18. Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM D3174-12. Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D3176-15. Standard Practice for Ultimate Analysis of Coal and Coke; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D2444-16. Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D2395-17. Standard Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Davies, R.M.; Davies, O.A. Physical and combustion characteristics of briquettes made from water hyacinth and phytoplankton scum as binder. J. Combust. 2013, 2013, 549894. [Google Scholar] [CrossRef]

- ASTM D440-86. Standard Test Method of Drop Shatter Test for Coal; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Antwi-Boasiako, C.; Acheampong, B.B. Strength properties and calorific values of sawdust-briquettes as wood-residue energy generation source from tropical hardwoods of different densities. Biomass Bioenergy 2016, 85, 144–152. [Google Scholar] [CrossRef]

- ASTM D2166-85. Standard Test Method of Compressive Strength of Wood; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM D5865-13. Standard Test Method for Gross Calorific Value of Coal and Coke; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Khabibi, J.; Irawan, B. Proximate analysis of lignocellulosic material as alternative bioenergy resources. J. Lignocellul Technol. 2016, 1, 38–43. [Google Scholar]

- Sette, C.R., Jr.; Hansted, A.L.S.; Novaes, E.; Lima, P.A.F.; Rodrigues, A.C.; de Souza Santos, D.R.; Yamaji, F.M. Energy enhancement of the eucalyptus bark by briquette production. Ind. Crops Prod. 2018, 122, 209–213. [Google Scholar] [CrossRef]

- DIN51731. Testing of Solid Fuels—Compressed Untreated Wood—Requirements and Testing; German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 1996. [Google Scholar]

- Liu, X.; Chen, M.; Wei, Y. Combustion behavior of corncob/bituminous coal and hardwood/bituminous coal. Renew. Energy 2015, 81, 355–365. [Google Scholar] [CrossRef]

- Arewa, M.E.; Daniel, I.C.; Kuye, A. Characterisation and comparison of rice husk briquettes with cassava peels and cassava starch as binders. Biofuels 2016, 7, 671–675. [Google Scholar] [CrossRef]

- Chin, O.C.; Siddiqui, K.M. Characteristics of some biomass briquettes prepared under modest die pressures. Biomass Bioenergy 2000, 18, 223–228. [Google Scholar] [CrossRef]

- Missagia, B.; Guerrero, C.; Narra, S.; Sun, Y.; Ay, P.; Krautz, H.J. Physicomechanical properties of rice husk pellets for energy generation. Energy Fuels 2011, 25, 5786–5790. [Google Scholar] [CrossRef]

- Tumuluru, S.J.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densifi cation systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Bioref. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Ahmad, K.K.Z.; Sazali, K.; Kamarolzaman, A.A. Characterization of fuel briquettes from banana tree waste. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 21744–21752. [Google Scholar]

- Miranda, T.; Montero, I.; Sepúlveda, F.; Arranz, J.; Rojas, C.; Nogales, S. A Review of Pellets from Different Sources. Materials 2015, 8, 1413–1427. [Google Scholar] [CrossRef]

- Onukak, I.; Mohammed-Dabo, I.; Ameh, A.; Okoduwa, S.; Fasanya, O. Production and Characterization of Biomass Briquettes from Tannery Solid Waste. Recycling 2017, 2, 17. [Google Scholar] [CrossRef]

- Moreno, A.I.; Font, R.; Conesa, J.A. Physical and chemical evaluation of furniture waste briquettes. Waste Manag. 2016, 49, 245–252. [Google Scholar] [CrossRef]

- Tumuluru, S.J.; Christopher, W.T.; Kenny, K.L.; Hess, J.R. A Review on Biomass Densification Technologies for Energy Application; Idaho National Laboratory: Falls, Idaho, 2010. [Google Scholar]

- Kers, J.; Kulu, P.; Aruniit, A.; Laurmaa, V.; Krizan, P.; Soos, L.; Kask, Ü. Determination of physical, mechanical and burning characteristics of polymeric waste material briquettes. Est. J. Eng. 2010, 16, 307–316. [Google Scholar] [CrossRef]

- Eriksson, S.; Prior, M. The Briquetting of Agricultural Wastes for Fuel, 11th ed.; FAO: Rome, Italy, 1990; 137p. [Google Scholar]

- Onchieku, J.M. Cost Benefit Analysis of Making Charcoal Briquettes Using Screw Press Machine Locally Designed and Fabricated. Int. Adv. Res. J. Sci. Eng. Technol. 2018, 5, 57–65. [Google Scholar]

- Olorunnisola, A. Production of Fuel Briquettes from Waste Paper and Coconut Husk Admixtures. CIGR Ejournal 2007, 9, 1–11. [Google Scholar]

- Rajaseenivasan, T.; Srinivasan, V.; Syed Mohamed Qadir, G.; Srithar, K. An investigation on the performance of sawdust briquette blending with neem powder. Alex. Eng. J. 2016, 55, 2833–2838. [Google Scholar] [CrossRef]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.; Varum, H. Characterization of corn cob as a possible raw building material. Constr. Build. Mater. 2012, 34, 28–33. [Google Scholar] [CrossRef]

- Sukiran, M.A.; Abnisa, F.; Wan Daud, W.M.A.; Abu Bakar, N.; Loh, S.K. A review of torrefaction of oil palm solid wastes for biofuel production. Energy Convers. Manag. 2017, 149, 101–120. [Google Scholar] [CrossRef]

- Yaman, S.; Şahan, M.; Haykiri-Açma, H.; Şeşen, K.; Küçükbayrak, S. Fuel briquettes from biomass-lignite blends. Fuel Process Technol. 2001, 72, 1–8. [Google Scholar] [CrossRef]

- Richards, S.R. Physical Testing of Fuel Briquettes. Fuel Process Technol. 1990, 25, 89–100. [Google Scholar] [CrossRef]

- Ajiboye, T.; Abdulkareem, S.; Anibijuwon, A.O.Y. Investigation of mechanical properties of briquette product of sawdust-charcoal as a potential domestic energy source. J. Appl. Sci. Environ. Manag. 2017, 20, 1179. [Google Scholar] [CrossRef]

- Borowski, G.; Stȩpniewski, W.; Wójcik-Oliveira, K. Effect of starch binder on charcoal briquette properties. Int. Agrophys. 2017, 31, 571–574. [Google Scholar] [CrossRef]

- Ujjinappa, S.; Sreepathi, L.K. Production and quality testing of fuel briquettes made from pongamia and tamarind shell. Sadhana 2018, 43, 1–7. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Malaťák, J.; Velebil, J. Evaluation of selected physical and mechanical properties of briquettes produced from cones of three coniferous tree species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- Deshannavar, U.B.; Hegde, P.G.; Dhalayat, Z.; Patil, V.; Gavas, S. Production and characterization of agro-based briquettes and estimation of calorific value by regression analysis: An energy application. Mater. Sci. Energy Technol. 2018, 1, 175–181. [Google Scholar] [CrossRef]

- Mandal, S.; Prasanna Kumar, G.V.; Bhattacharya, T.K.; Tanna, H.R.; Jena, P.C. Briquetting of Pine Needles (Pinus roxburgii) and Their Physical, Handling and Combustion Properties. Waste Biomass Valorization 2019, 10, 2415–2424. [Google Scholar] [CrossRef]

- Jamradloedluk, J.; Wiriyaumpaiwong, S. Production and Characterization of Rice Husk Based Charcoal Briquettes. KKU Eng. J. 2007, 34, 391–398. [Google Scholar]

- Wu, S.; Zhang, S.; Wang, C.; Mu, C.; Huang, X. High-strength charcoal briquette preparation from hydrothermal pretreated biomass wastes. Fuel Process Technol. 2018, 171, 293–300. [Google Scholar] [CrossRef]

- Borowski, G.; Hycnar, J.J. Utilization of fine coal waste as a fuel briquettes. Int. J. Coal Prep. Util. 2013, 33, 194–204. [Google Scholar] [CrossRef]

- Nwabue, F.I.; Unah, U.; Itumoh, E.J. Production and characterization of smokeless bio-coal briquettes incorporating plastic waste materials. Environ. Technol. Innov. 2017, 8, 233–245. [Google Scholar] [CrossRef]

- Romallosa, A.R.D. Quality Analyses of Biomass Briquettes Produced using a Jack-Driven Briquetting Machine. Int. J. Appl. Sci. Technol. 2017, 7, 8–16. [Google Scholar]

- Srivastava, N.S.L.; Narnaware, S.L.; Makwana, J.P.; Singh, S.N.; Vahora, S. Investigating the energy use of vegetable market waste by briquetting. Renew. Energy 2014, 68, 270–275. [Google Scholar] [CrossRef]

- Gill, N.; Dogra, R.; Dogra, B. Influence of Moisture Content, Particle Size, and Binder Ratio on Quality and Economics of Rice Straw Briquettes. Bioenergy Res. 2018, 11, 54–68. [Google Scholar] [CrossRef]

- Engineering Tool Box. Fuels—Higher and Lower Calorific Values. Available online: https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 30 October 2019).

- Rhén, C.; Gref, R.; Sjöström, M.; Wästerlund, I. Effects of raw material moisture content, densification pressure and temperature on some properties of Norway spruce pellets. Fuel Process Technol. 2005, 87, 11–16. [Google Scholar] [CrossRef]

- Taulbee, D.; Patil, D.P.; Honaker, R.Q.; Parekh, B.K. Briquetting of coal fines and sawdust part I: Binder and briquetting-parameters evaluations. Int. J. Coal Prep. Util. 2009, 29, 1–22. [Google Scholar] [CrossRef]

- Emerhi, E.A. Physical and combustion properties of briquettes produced from sawdust of three hardwood species and different organic binders. Adv. Appl. Sci. Res. 2011, 2, 236–246. [Google Scholar]

| S/No | Sample Name | Corncobs | OPTB |

|---|---|---|---|

| 1 | CC | 100 * | 0 |

| 2 | OPTB | 0 | 100 * |

| 3 | MIX 1 | 75 | 25 |

| 4 | MIX 2 | 50 | 50 |

| 5 | MIX 3 | 25 | 75 |

| Properties | This Study | Literature Data | ||||

|---|---|---|---|---|---|---|

| Corncobs | OPTB | Corncobs | OPT | |||

| [1] | [62] | [32] | [33] | |||

| Moisture content (% w.b.) | 9.27 | 9.27 | NA | 8.28 | 7.16 | NA |

| Volatile matter (% d.b.) | 74.39 | 78.92 | 87.40 | 71.16 | 82.60 | 86.70 |

| Ash content (% d.b.) | 2.42 | 8.01 | 1.10 | 2.70 | 5.27 | 3.35 |

| Fixed carbon (% d.b.) | 13.92 | 3.80 | 11.50 | 17.78 | 4.97 | NA |

| Carbon (% d.b.) | 42.70 | 42.12 | 49.00 | 49.00 | 42.72 | 51.41 |

| Hydrogen (% d.b.) | 6.49 | 6.48 | 5.40 | 5.40 | 5.61 | 11.82 |

| Oxygen (% d.b.) | 50.41 | 50.83 | 44.50 | 44.20 | 51.25 | 51.16 |

| Nitrogen (% d.b.) | 0.25 | 0.32 | 0.50 | 0.40 | 0.44 | 0.17 |

| Sulfur (% d.b.) | 0.15 | 0.25 | 0.20 | NA | NA | NA |

| Calorific value (MJ/kg d.b) | 16.13 | 16.71 | NA | 17.36 | NA | 17.47 |

| Moisture Content (% w.b.) | Density (g/cm3) | Water Resistance (%) | Shatter Index (%) | Compressive Strength (Mpa) | Calorific Value (MJ/kg d.b.) | |

|---|---|---|---|---|---|---|

| CC | 10.24 a | 0.35 a | 86.20 b | 99.20 a | 10.26 a | 16.65 a |

| OPTB | 9.25 a | 0.43 c | 93.20 a | 99.05 a | 22.33 c | 17.78 a |

| MIX 1 | 10.00 a | 0.38 b | 87.60 b | 98.28 a | 18.47 b | 16.54 a |

| MIX 2 | 9.75 a | 0.39 b | 88.30 b | 98.16 a | 21.09 c | 16.65 a |

| MIX 3 | 9.24 a | 0.40 b | 92.00 a | 99.08 a | 21.75 c | 16.91 a |

| Source of Variation | SS | Df | MS | p-Value | |

|---|---|---|---|---|---|

| Moisture content | Test samples | 3.20 | 4 | 0.80 | 0.54 a |

| Error/Residuals | 15.00 | 15 | 1.00 | ||

| Total | 18.20 | 19 | |||

| Density | Test samples | 0.01 | 4 | 0.003 | 0.000003 b |

| Error/Residuals | 0.002 | 15 | 0.0001 | ||

| Total | 0.01 | 19 | |||

| Water resistance | Test samples | 100.56 | 4 | 25.14 | 0.02 b |

| Error/Residuals | 89.31 | 15 | 5.95 | ||

| Total | 189.87 | 19 | |||

| Shatter index | Test samples | 3.88 | 4 | 0.97 | 0.52 a |

| Error/Residuals | 17.35 | 15 | 1.16 | ||

| Total | 21.234 | 19 | |||

| Compressive strength | Test samples | 397.92 | 4 | 99.48 | 0.0000002 b |

| Error/Residuals | 41.79 | 15 | 2.79 | ||

| Total | 439.70 | 19 | |||

| Calorific value | Test samples | 4.10 | 4 | 1.03 | 0.21 a |

| Error/Residuals | 9.36 | 15 | 0.62 | ||

| Total | 13.46 | 19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique. Sustainability 2020, 12, 2468. https://doi.org/10.3390/su12062468

Kpalo SY, Zainuddin MF, Manaf LA, Roslan AM. Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique. Sustainability. 2020; 12(6):2468. https://doi.org/10.3390/su12062468

Chicago/Turabian StyleKpalo, Sunday Yusuf, Mohamad Faiz Zainuddin, Latifah Abd Manaf, and Ahmad Muhaimin Roslan. 2020. "Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique" Sustainability 12, no. 6: 2468. https://doi.org/10.3390/su12062468

APA StyleKpalo, S. Y., Zainuddin, M. F., Manaf, L. A., & Roslan, A. M. (2020). Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique. Sustainability, 12(6), 2468. https://doi.org/10.3390/su12062468