Main Dimensions in the Building of the Circular Supply Chain: A Literature Review

Abstract

1. Introduction

- What is the definition of circular supply chain? What other terms are used as synonyms and what differential aspects can be established?

- What theories of strategic management could be applied to the analysis of the circular supply chain that would make it easier to frame the practices to be carried out?

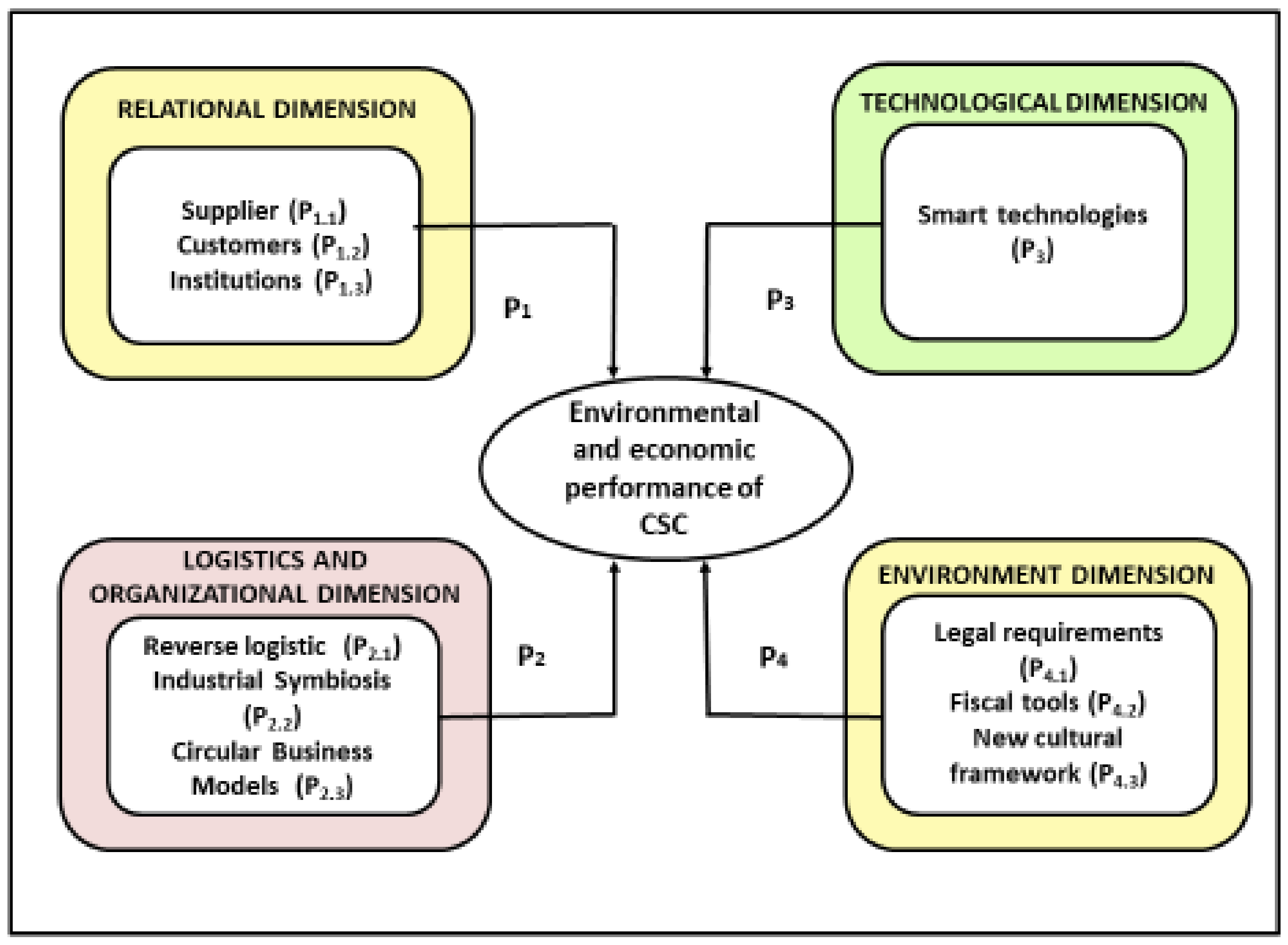

- What are the dimensions that allow the design of circular supply chains? What kind of challenges do they pose?

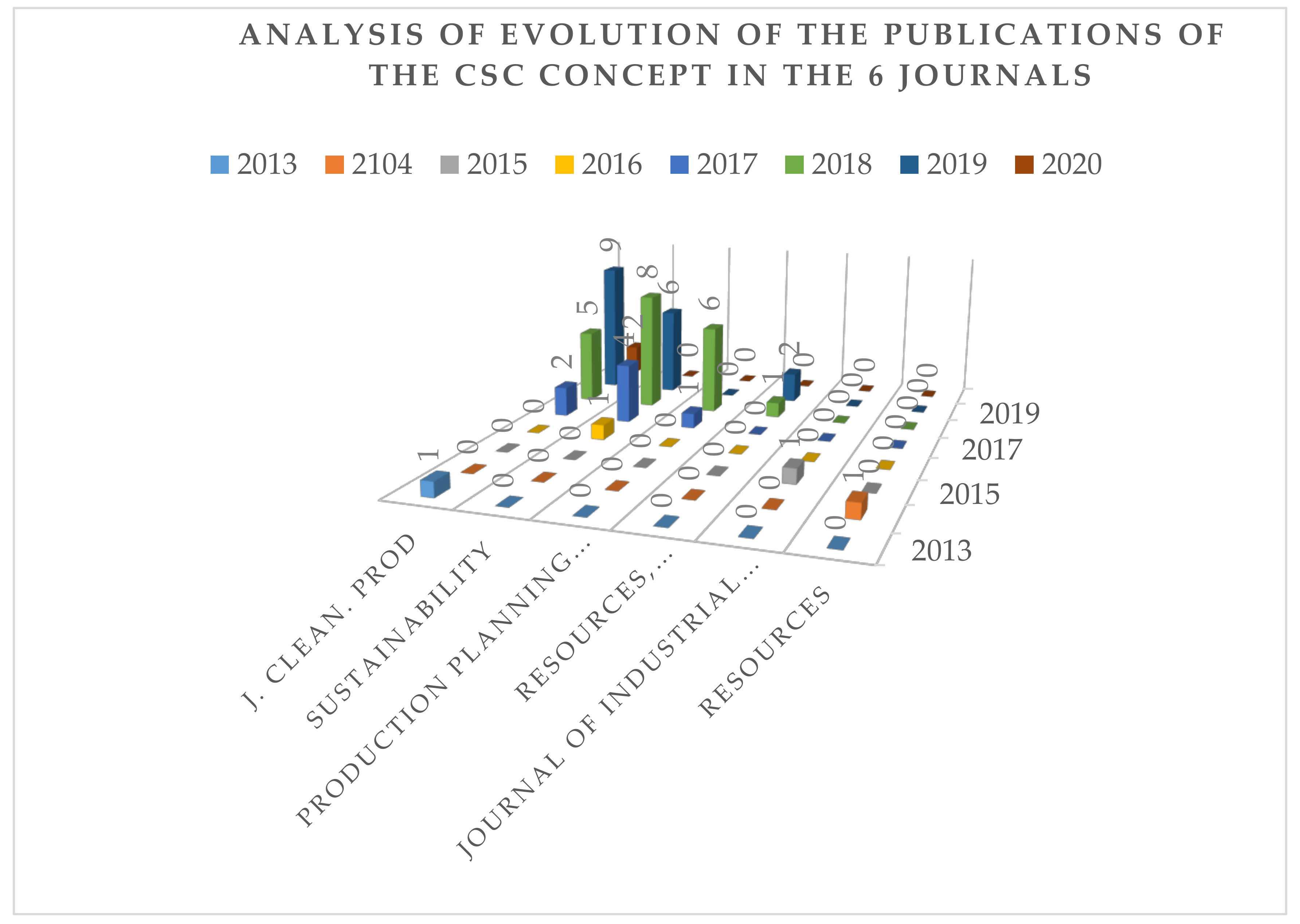

2. Materials and Methods

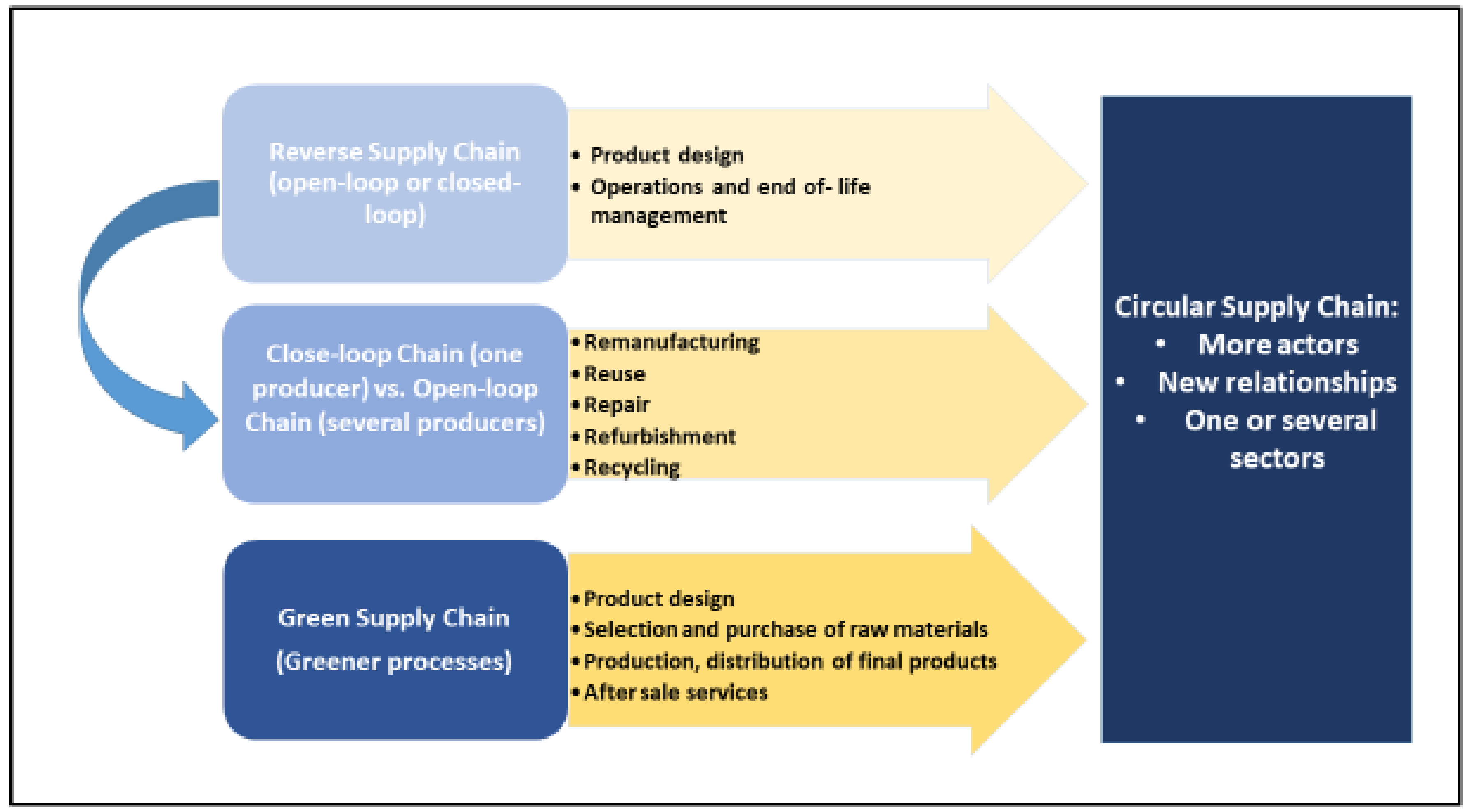

3. The Conceptualization of Circular Supply Chain

3.1. Reverse Supply Chain

3.2. Closed-loop Chain vs. Open-loop Chain

3.3. Green Supply Chain:

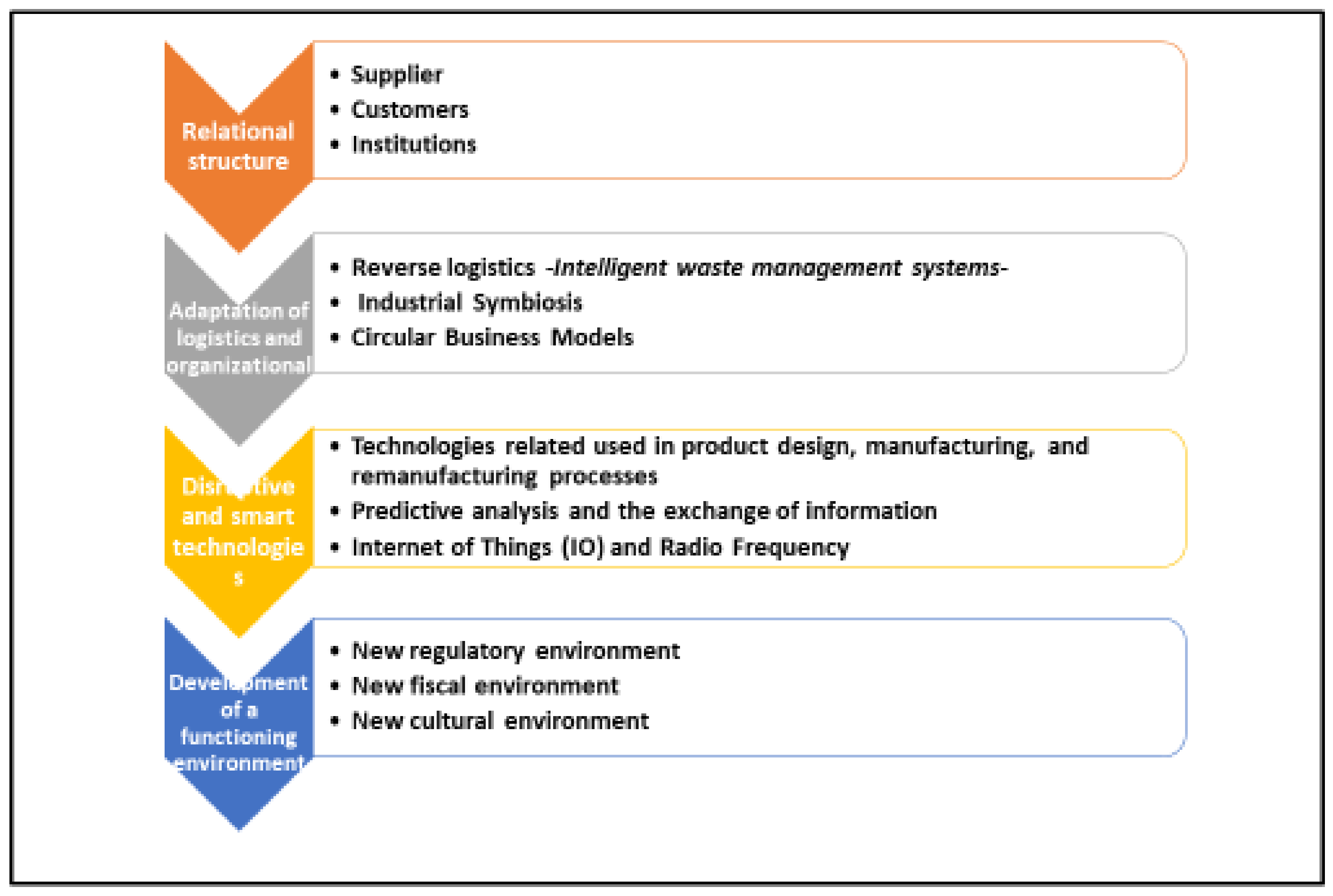

4. Building the Circular Supply Chain: Dimensional Design

4.1. Circular Supply Chain Management (CSCM)

4.2. Theoretical Perspectives in Strategic Management Literature

4.3. Relational Structure

4.3.1. Suppliers

4.3.2. Customers

4.3.3. Institutions

4.4. Adaptation of Logistics and Organizational Management

4.5. The Use of Disruptive and Smart Technologies

4.6. Development of a Functioning Environment: New Regulatory, Fiscal, and Cultural Environment

5. Discussion and Conclusions

5.1. Theoretical Contribution

5.2. Practical Contribution

5.3. Limitations and Directions of Future Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Theophilus, O.; Dulebenets, M.A.; Pasha, J.; Abioye, O.F.; Kavoosi, M. Truck Scheduling at Cross-Docking Terminals: A Follow-Up State-Of-The-Art Review. Sustainability 2019, 11, 5245. [Google Scholar] [CrossRef]

- Masoumi, S.M.; Kazemi, N.; Abdul-Rashid, S.H. Sustainable Supply Chain Management in the Automotive Industry: A Process-Oriented Review. Sustainability 2019, 11, 3945. [Google Scholar] [CrossRef]

- Dulebenets, M.A. A Diploid Evolutionary Algorithm for Sustainable Truck Scheduling at a Cross-Docking Facility. Sustainability 2018, 10, 1333. [Google Scholar] [CrossRef]

- Dong, C.; Li, Q.; Shen, B.; Tong, X. Sustainability in Supply Chains with Behavioral Concerns. Sustainability 2019, 11, 4051. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Rosa, P. Recycling of end-of-life vehicles: Assessing trends and performances in Europe. Technol. Forecast. Soc. Chang. 2020, 152, 119887. [Google Scholar] [CrossRef]

- Guo, F.; Liu, Q.; Liu, D.; Guo, Z. On Production and Green Transportation Coordination in a Sustainable Global Supply Chain. Sustainability 2017, 9, 2071. [Google Scholar] [CrossRef]

- Zhu, L.; Ren, X.; Lee, C.; Zhang, Y. Coordination Contracts in a Dual-Channel Supply Chain with a Risk-Averse Retailer. Sustainability 2017, 9, 2148. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 36, 82–1299. [Google Scholar] [CrossRef]

- Beu, D.; Ciugudeanu, C.; Buzdugan, M. Circular Economy Aspects Regarding LED Lighting Retrofit—From Case Studies to Vision. Sustainability 2018, 10, 3674. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Siyambalapitiya, J.; Zhang, X.; Liu, X. Is Governmentality the Missing Link for Greening the Economic Growth? Sustainability 2018, 10, 4204. [Google Scholar] [CrossRef]

- Veleva, V.; Bodkin, G. Corporate-entrepreneur collaborations to advance a circular economy. J. Clean. Prod. 2018, 188, 20–37. [Google Scholar] [CrossRef]

- Mont, O. Innovative approaches to optimising design and use of durable consumer goods. Int. J. Prod. Dev. 2008, 6, 227–250. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Núñez-Cacho, P.; Molina-Moreno, V.; Corpas-Iglesias, F.A.; Cortés-García, F.J. Family Businesses Transitioning to a Circular Economy Model: The Case of “Mercadona”. Sustainability 2018, 10, 538. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef]

- Mangla, S.; Luthra, S.; Mishra, N.; Singh, A.; Rana, N.; Dora, M.; Dwivedi, Y. Barriers to effective circular supply chain management in a developing country context. Prod. Plan. Control 2018, 29, 551–569. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pau, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Mehr, J.; Jedelhauser, M.; Binder, C.R. Transition of the Swiss Phosphorus System towards a Circular Economy—Part 1: Current State and Historical Developments. Sustainability 2018, 10, 1479. [Google Scholar] [CrossRef]

- Sinclair, M.; Sheldrick, L.; Moreno, M.; Dewberry, E. Consumer Intervention Mapping—A Tool for Designing Future Product Strategies within Circular Product Service Systems. Sustainability 2018, 10, 2088. [Google Scholar] [CrossRef]

- Chu, S.H.; Yang, H.; Lee, M.; Park, S. The Impact of Institutional Pressures on Green Supply Chain Management and Firm Performance: Top Management Roles and Social Capital. Sustainability 2017, 9, 764. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O. Integrating construction supply chains within a circular economy: An ANFIS-based waste analytics system (A-WAS). J. Clean. Prod. 2019, 229, 863–873. [Google Scholar] [CrossRef]

- Guide, V.D.R.; Harrison, T.P.; Van Wassenhove, L.N. The Challenge of Closed-Loop Supply Chains. Interfaces 2003, 33, 3–6. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply chain configurations in the Circular Economy: A systematic literature review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.S.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Homrich, A.S.; Galvao, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Terzi, S. Towards Circular Business Models: A systematic literature review on classification frameworks and archetypes. J. Clean. Prod. 2019, 236, 117696. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Lahti, T.; Wincent, J.; Parida, V. A Definition and Theoretical Review of the Circular Economy, Value Creation, and Sustainable Business Models: Where Are We Now and Where Should Research Move in the Future? Sustainability 2018, 10, 2799. [Google Scholar] [CrossRef]

- Reichertz, J. Abduction: The logic of discovery of grounded theory. Forum Qual. Soz. 2009, 11, 1–16. [Google Scholar]

- Kitchenham, B. Procedures for Performing Systematic Reviews, TR/SE-0401; Keele University: Keele, UK, 2004. [Google Scholar]

- Kalmykova, Y.; Sadagopanb, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Ferreira Gregorio, V.; Pié, L.; Terceño, A. A Systematic Literature Review of Bio, Green and Circular Economy Trends in Publications in the Field of Economics and Business Management. Sustainability 2018, 10, 4232. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Pearce, D.; Turner, R.K. Economics of Natural Resources and the Environment; Johns Hopkins University Press: Baltimore, MD, USA, 1990. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Avdiushchenko, A. Toward a Circular Economy Regional Monitoring Framework for European Regions: Conceptual Approach. Sustainability 2018, 10, 4398. [Google Scholar] [CrossRef]

- Van Buren, N.; Demmers, M.; van der Heijden, R.; Witlox, F. Towards a Circular Economy: The Role of Dutch Logistics Industries and Governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

- De Angelis, R.; Howard, M.; Miemczyk, J. Supply Chain Management and the Circular Economy: Towards the Circular Supply Chain. Prod. Plan. Control 2017, 29, 425–437. [Google Scholar] [CrossRef]

- Liu, L.; Liang, Y.; Song, Q.; Li, J. A review of waste prevention through 3R under the concept of circular economy in China. J. Mater. Cycles Waste 2017, 7, 1–10. [Google Scholar] [CrossRef]

- de Mattos, C.A.; de Albuquerque, T.L.M. Enabling Factors and Strategies for the Transition Toward a Circular Economy (CE). Sustainability 2018, 10, 4628. [Google Scholar] [CrossRef]

- Fonseca, L.; Domingues, J.; Pereira, M.; Martins, F.; Zimon, D.; Fonseca, L.M.; Domingues, J.P.; Pereira, M.T.; Martins, F.F.; Zimon, D. Assessment of Circular Economy within Portuguese Organizations. Sustainability 2018, 10, 2521. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the business models for circular economy—Towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Sánchez-Molina, J.; Peña-García, A. Proposal to Foster Sustainability through Circular Economy-Based Engineering: A Profitable Chain from Waste Management to Tunnel Lighting. Sustainability 2017, 9, 2229. [Google Scholar] [CrossRef]

- Oncioiu, I.; Căpuşneanu, S.; Türkeș, M.C.; Topor, D.I.; Oprea Constantin, D.-M.; Marin-Pantelescu, A.; Hint, M.S. The Sustainability of Romanian SMEs and Their Involvement in the Circular Economy. Sustainability 2018, 10, 2761. [Google Scholar] [CrossRef]

- Zambon, I.; Colantoni, A.; Cecchini, M.; Mosconi, E.M. Rethinking Sustainability within the Viticulture Realities Integrating Economy, Landscape and Energy. Sustainability 2018, 10, 320. [Google Scholar] [CrossRef]

- Nußholz, J.L.K.; Rasmussen, F.N.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Muñoz-Torres, M.J.; Fernández-Izquierdo, M.Á.; Rivera-Lirio, J.M.; Ferrero-Ferrero, I.; Escrig-Olmedo, E.; Gisbert-Navarro, J.V.; Marullo, M.C. An Assessment Tool to Integrate Sustainability Principles into the Global Supply Chain. Sustainability 2018, 10, 535. [Google Scholar] [CrossRef]

- Masi, D.; Kumar, V.; Garza-Reyes, J.A.; Godsell, J. Towards a more circular economy: Exploring the awareness, practices, and barriers from a focal firm perspective. Prod. Plan. Control 2018, 29, 539–550. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Daú, G.; Scavarda, A.; Scavarda, L.F.; Portugal, V.J.T. The Healthcare Sustainable Supply Chain 4.0: The Circular Economy Transition Conceptual Framework with the Corporate Social Responsibility Mirror. Sustainability 2019, 11, 3259. [Google Scholar] [CrossRef]

- French, M.L.; LaForge, R.L. Closed-loop supply chains in process industries: An empirical study of producer re-use issues. J. Oper. Manag. 2006, 24, 271–286. [Google Scholar] [CrossRef]

- Taghikhah, F.; Voinov, A.; Shukla, N. Extending the supply chain to address sustainability. J. Clean. Prod. 2019, 229, 652–666. [Google Scholar] [CrossRef]

- Hussain, M.; Malik, M. Organizational enablers for circular economy in the context of sustainable supply chain management. J. Clean. Prod. 2020, 256, 120375. [Google Scholar] [CrossRef]

- Su, B.W.; Heshmati, A.; Geng, Y.; Yu, X.M. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Coenen, J.; van der Heijden, R.; van Riel, A.C.R. Making a Transition toward more Mature Closed-Loop Supply Chain Management under Deep Uncertainty and Dynamic Complexity: A Methodology. Sustainability 2019, 11, 2318. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; pp. 671–689. [Google Scholar]

- Geissdoerfer, M.; Morioka, S.M.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Weetman, C. A Circular Economy Handbook for Business and Supply Chains: Repair, Remake, Redesign, Rethink; Kogan Page: London, UK, 2017. [Google Scholar]

- Govindan, K.; Mina, H.; Esmaeili, A.; Gholami-Zanjani, S.M. An Integrated Hybrid Approach for Circular supplier selection and Closed loop Supply Chain Network Design under Uncertainty. J. Clean. Prod. 2020, 242, 118317. [Google Scholar] [CrossRef]

- Wernerfelt, B. A resource-based view of the firm. Strateg. Manag. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Grant, R.M. The Resource-Based Theory of competitive advantage: Implications for strategy formulation. Calif. Manag. Rev. 1991, 34, 114–135. [Google Scholar] [CrossRef]

- Mousavi, S.; Bossink, B.; van Vliet, M. Dynamic capabilities and organizational routines for managing innovation towards sustainability. J. Clean. Prod. 2018, 203, 224–239. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Teece, D.J. Dynamic Capabilities: Routines versus Entrepreneurial Action. J. Manag. Stud. 2012, 49, 1395–1401. [Google Scholar] [CrossRef]

- Portillo-Tarragona, P.; Scarpellini, S.; Moneva, J.M.; Valero-Gil, J.; Aranda-Usón, A. Classification and Measurement of the Firms’ Resources and Capabilities Applied to Eco-Innovation Projects from a Resource-Based View Perspective. Sustainability 2018, 10, 3161. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Mäkinen, S.J. Creating value in the circular economy: A structured multiple-case analysis of business models. J. Clean. Prod. 2018, 201, 988–1000. [Google Scholar] [CrossRef]

- Laurenti, R.; Singh, J.; Frostell, B.; Sinha, R.; Binder, C.R. The Socio-Economic Embeddedness of the Circular Economy: An Integrative Framework. Sustainability 2018, 10, 2129. [Google Scholar] [CrossRef]

- Sumter, D.; Bakker, C.; Balkenende, R. The Role of Product Design in Creating Circular Business Models: A Case Study on the Lease and Refurbishment of Baby Strollers. Sustainability 2018, 10, 2415. [Google Scholar] [CrossRef]

- Matos, S.; Silvestre, B. Managing stakeholder relations when developing sustainable business models: The case of the Brazilian energy sector. J. Clean. Prod. 2013, 45, 61–73. [Google Scholar] [CrossRef]

- Laubscher, M.; Marinelli, T. Integration of circular economy in business. In Proceedings of the Conference; Going Green-Care Innovation 2014, Vienna, Austria, 17–20 November 2014. [Google Scholar]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2018, 23, 36–61. [Google Scholar] [CrossRef]

- Gulati, R.; Nitin, N.; Zaheer, A. Strategic Networks. Strateg. Manag. J. 2000, 21, 203–215. [Google Scholar] [CrossRef]

- Freeman, L.C. Centrality in Social Networks Conceptual Clarification. Soc. Netw. 1979, 1, 215–239. [Google Scholar] [CrossRef]

- Kogut, B. The network as knowledge: Generative rules and the emergence of structure. Strateg. Manag. J. 2000, 21, 405–425. [Google Scholar] [CrossRef]

- Brown, P.; Bocken, N.; Balkenende, R. Why Do Companies Pursue Collaborative Circular Oriented Innovation? Sustainability 2019, 11, 635. [Google Scholar] [CrossRef]

- Meherishi, L.; Narayana, S.A.; Ranjani, K.S. Sustainable packaging for supply chain management in the circular economy: A review. J. Clean. Prod. 2019, 237, 117582. [Google Scholar] [CrossRef]

- Albuquerque, T.L.M.; Mattos, C.A.; Scur, G.; Kissimoto, K. Life cycle costing and externalities to analyze circular economy strategy: Comparison between aluminum packaging and tinplate. J. Clean. Prod. 2019, 234, 477–486. [Google Scholar] [CrossRef]

- Zhang, A.; Venkatesh, V.G.; Liu, Y.; Wan, M.; Qu, T.; Huisingh, D. Barriers to smart waste management for a circular economy in China. J. Clean. Prod. 2019, 240, 118198. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Salim, H.; Stewart, R.A.; Sahin, O.; Dudley, M. Drivers, barriers and enablers to end-of-life management of solarphotovoltaic and battery energy storage systems: A systematic literature review. J. Clean. Prod. 2019, 211, 537–554. [Google Scholar] [CrossRef]

- Zeng, H.; Chen, X.; Xiao, X.; Zhou, Z. Institutional pressures, sustainable supply chain management, and circular economy capability: Empirical evidence from Chinese eco-industrial park firms. J. Clean. Prod. 2017, 155, 54–65. [Google Scholar] [CrossRef]

- Prosman, E.J.; Sacchi, R. New environmental supplier selection criteria for circular supply chains: Lessons from a consequential LCA study on waste recovery. J. Clean. Prod. 2018, 172, 2782–2792. [Google Scholar] [CrossRef]

- Borrello, M.; Caracciolo, F.; Lombardi, A.; Pascucci, S.; Cembalo, L. Consumers’ Perspective on Circular Economy Strategy for Reducing Food Waste. Sustainability 2017, 9, 141. [Google Scholar] [CrossRef]

- Zhu, X.; Yu, L.; Li, W. Warranty Period Decision and Coordination in Closed-Loop Supply Chains Considering Remanufacturing and Consumer Behavior. Sustainability 2019, 11, 4237. [Google Scholar] [CrossRef]

- de Oliveira, C.T.; Luna, M.M.M.; Campos, L.M.S. Understanding the Brazilian expanded polystyrene supply chain and its reverse logistics towards circular economy. J. Clean. Prod. 2019, 235, 562–573. [Google Scholar] [CrossRef]

- Singhal, D.; Tripathya, S.; Jena, S.K. Remanufacturing for the circular economy: Study and evaluation of critical factors. Resour. Conserv. Recycl. 2020, 156, 104681. [Google Scholar] [CrossRef]

- Duan, C.; Xiu, G.; Yao, F. Multi-Period E-Closed-Loop Supply Chain Network Considering Consumers’ Preference for Products and AI-Push. Sustainability 2019, 11, 4571. [Google Scholar] [CrossRef]

- Niu, S.H.; Zhuo, H.; Xue, K. DfRem-Driven Closed-Loop Supply Chain Decision-Making: A Systematic Framework for Modeling Research. Sustainability 2019, 11, 3299. [Google Scholar] [CrossRef]

- Guarnieria, P.; Cerqueira-Streita, J.A.; Batista, L.C. Reverse logistics and the sectoral agreement of packaging industry in Braziltowards a transition to circular economy. Resour. Conserv. Recycl. 2020, 152, 104541. [Google Scholar] [CrossRef]

- Subramoniam, R.; Huisingh, D.; Babu, R. Remanufacturing for the automotive aftermarket-strategic factors: Literature review and future research needs. J. Clean. Prod. 2009, 17, 1163–1174. [Google Scholar] [CrossRef]

- Emmanuel-Ebikake, O.; Sassanelli, C.; Terzi, S. PSS design through Design for Supply Chain: State of the art review. In Proceedings of the 28th CIRP Design Conference, Nantes, France, 23–25 May 2018. [Google Scholar]

- Oghazi, P.; Mostaghel, R. Circular Business Model Challenges and Lessons Learned—An Industrial Perspective. Sustainability 2018, 10, 739. [Google Scholar] [CrossRef]

- Maaß, O.; Grundmannm, P.H. Governing Transactions and Interdependences between inked Value Chains in a Circular Economy: The Case ofWastewater Reuse in Braunschweig (Germany). Sustainability 2018, 10, 1125. [Google Scholar] [CrossRef]

- Mishra, J.L.; Hopkinson, P.G.; Tidridge, G. Value creation from circular economy-led closed loop supply chains: A case study of fast-moving consumer goods. Prod. Plan. Control 2018, 29, 509–521. [Google Scholar] [CrossRef]

- Yang, M.; Smart, P.; Kumar, M.; Jolly, M.; Evans, S. Product-service systems business models for circular supply chains. Prod. Plan. Control 2018, 29, 498–508. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rossi, M.; Pezzotta, G.; Pacheco, D.J.P.; Terzi, S. Defining lean product service systems features and research trends through a systematic literature review. Int. J. Prod. Lifecycle Manag. 2019, 12, 37–61. [Google Scholar] [CrossRef]

- Ali, S.H. Social and Environmental Impact of the Rare Earth Industries. Resources 2014, 3, 123–134. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Tortorella, G.L. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2018, 30, 607–627. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Luo, Z.; Wamba, S.F.; Roubaud, D. Can Big Data and Predictive Analytics Improve Social and Environmental Sustainability? Technol. Forecast. Soc. Chang. 2017, 144, 534–545. [Google Scholar] [CrossRef]

- Liang, S.; Feng, Y.; Xu, M. Structure of the Global Virtual Carbon Network: Revealing Important Sectors and Communities for Emission Reduction. J. Ind. Ecol. 2015, 19, 307–320. [Google Scholar] [CrossRef]

- Vlajic, J.V.; Mijailovic, R.; Bogdanova, M. Creating loops with value recovery: Empirical study of fresh food supply chains. Prod. Plan. Control 2018, 29, 522–538. [Google Scholar] [CrossRef]

- Strauch, S.M.; Wenzel, L.C.; Bischoff, A.; Dellwig, O.; Klein, J.; Schüch, A.; Wasenitz, B.; Palm, H.W. Commercial African Catfish (Clarias gariepinus) Recirculating Aquaculture Systems: Assessment of Element and Energy Pathways with Special Focus on the Phosphorus Cycle. Sustainability 2018, 10, 1805. [Google Scholar] [CrossRef]

- Withers, P.J.A.; Doody, D.G.; Sylvester-Bradle, R. Achieving Sustainable Phosphorus Use in Food Systems through Circularisation. Sustainability 2018, 10, 1804. [Google Scholar] [CrossRef]

- Braun, A.; Kleine-Moellhoff, P.; Reichenberger, V.; Seiter, S.T. Case Study Analysing Potentials to Improve Material Efficiency in Manufacturing Supply Chains, Considering Circular Economy Aspects. Sustainability 2018, 10, 880. [Google Scholar] [CrossRef]

- Bocken, N.; Short, S.; Rana, P.; Evans, S. A literature and practice review to develop Sustainable Business Model Archetypes. J. Clean. Prod. 2014, 65, 42–45. [Google Scholar] [CrossRef]

- D’Adamo, I.; Falcone, P.M.; Ferella, F. A Socio-Economic Analysis of Biomethane in the Transport Sector: The Case of Italy. Waste Manag. 2019, 95, 102–115. [Google Scholar] [CrossRef]

| Journal | Number of Documents | Ranking/Impact SCOPUS 2018 | Category |

|---|---|---|---|

| Journal of Cleaner Production | 19 | Q1/1,62 (SJR) | Engineering industrial and manufacturing engineering; environmental science; industrial and manufacturing engineering; renewable energy, sustainability and the environment |

| Sustainability (Switzerland) | 19 | Q2/0,55 (SJR) | Geography, planning and development; management, monitoring, policy and law |

| Production Planning and Control | 7 | Q1/1,43 (SJR) | Business, management and accounting strategy and management; computer science; computer science applications; decision sciences management science and operations research; engineering industrial and manufacturing engineering |

| Resources, Conservation and Recycling | 3 | Q1/1,54 (SJR) | Waste management and disposal |

| Journal of Industrial Ecology | 1 | Q1/1,49 (SJR) | Environmental science; social sciences |

| Resources | 1 | Q2/0,65 (SJR) | Environmental science; management, monitoring, policy and law nature and landscape conservation |

| Authors | Denomination | Definition | Configurations (C) or indicators (I) tools | Enablers (E) or Inhibitors (I) |

|---|---|---|---|---|

| Chu et al. (2017) [23] | Green supply chain | A set of practices that combines environmental issues with supply chain (SC) management in order to guarantee environmental compliance and promote the environmental capability. | Environmental performance, environmental management systems, environmental audits, demand for greener products, useful information, technical assistance, and joint development of products (I). | Institutional pressures—government, customer, and competitor pressures (I). |

| De Angelis et al. (2017) [41] | Circular supply chain | The embodiment of circular economy (CE) principles within supply chain management. | Shift from product ownership; structural flexibility and start-ups in regional/local loops; open and closed material loops in technical and biological cycles; closer collaboration; and public and private procurement in the service industry (C). | N.A. |

| Masi et al. (2017) [26] | Circular supply chain | A critical unit of action for the implementation of the CE because of the necessity for joint effort beyond organizational boundaries to involve external coordination with upstream partners. | Eco-industrial parks, environmental or green SCs, and closed-loop SCs (C). | Financial, technological, societal, informational, and institutional (E). |

| Geissdoerfer et al. (2018) [60] | Circular supply chain | The supply chain that allows to close, narrow, slow down, intensify, and dematerialize resource loops. | Value proposition in terms of economic, environmental, and social value the firm aim at delivering; creation and delivery system with focus on the role of the business in closing the loop of the product life cycle; and value captured by the various stakeholders. | Economic, environmental, and social goals; proactive stakeholders management; and long-term perspective (E). |

| Kazancoglu et al. (2018) [8] | Green supply chain | It provides the resource optimization and it is seen as a solution to solve environmental problems and consumption patterns within the whole supply chain. | Environmental performance; economic/ financial performance; operational performance; logistics performance; organizational performance; and marketing performance (I). | N.A. |

| Leising et al. (2018) [83] | Circular supply chain collaboration | It enables connecting a network of actors in their supply chain by managing data transparency, material flows and exchanges, responsibilities, predictability, and sharing benefits. | Actor learning; networks dynamics; business model; and visions (C). | N.A. |

| Mangla et al. (2018) [19] | Circular supply chains | Application of reuse, recycling, and remanufacturing to circular model of flow of products, by-products, and waste. | N.A. | Driving barriers; linkage barriers; autonomous barriers; and dependent barriers (I). |

| Mishra et al. (2018) [98] | Closed-loop supply chain (CLSC) | The design, control, and operation of a system to maximize value creation over the entire life cycle of a product. | Circular design; business model design; forward and reverse supply chain. | Strategic leadership for CE enabled CLSC program, systems, and training program; chemical hazards; and legislation circularity scorecard (E). |

| Prosman and Sacchi (2018) [86] | Circular supply chains | A leap towards a more environmentally friendly economy that includes forward supply chains and reverse activities. | Supplier selection criteria—induced transport; affected waste handling activity; and usability of discarded products. | N.A. |

| Vlajic et al. (2018) [105] | Circular supply chains | Concept that considers value recovery in the context of circular flows, as well as those elements that might affect their creation. | Product residual value; quantities available for recovery; value from recovery; and markets for recovered (I) products. | N.A. |

| Yang et al. (2018) [99] | Circular supply chains/closed-loop supply chain | The design, control, and operation of a system to maximize value creation over the entire life cycle of a product with dynamic recovery of value from different types and volumes of returns over time. | Product-service systems business models—power of the inner circle; power of circling long; power of cascaded; and power of pure circles (C). | N.A. |

| Coenen et al. (2019) [58] | Closed-loop supply chain | It serves the circular economy because developments such as climate change and resource scarcity have become serious issues in global politics. | Six maturity stages—based on the well-known capability maturity framework and the concept of double-loop learning. | N.A. |

| Daú et al. (2019) [53] | Supply chain 4.0 | It, by bringing the disruptive technologies together in their supply chains, brings together, in addition to Industry 4.0 technologies, sustainable practices. | Time, infrastructure, cost, and institutional (C). | Smart technologies (E). |

| de Oliveira et al. (2019) [89] | Circular supply chain | It is based on sustainable supply chain narratives, including reverse logistics, sustainable supply chain management (SSCM), and closed-loop supply chains (CLSC). | Reverse logistics, sustainable supply chain management (C), and closed-loop supply chains (C). | Logistics and economic challenges, technology and innovation, consumer knowledge and legislation (E). |

| Duan et al. (2019) [91] | E-channel closed-loop supply chain network (E-CLSCN) | Closed-loop process of resources-production-consumption-collection-remanufacturing under the e-channel to emphasize the simultaneous improvement of social and environmental benefits to realize the sustainable development of economy and society, while achieving economic benefits. | Multi-period CLSCN (C). | Social and government participation (E), uncertain factors (I), and consumers’ behavior (E). |

| Farooque et al. (2019) [27] | Circular supply chain | The integration of circular thinking into the supply chain and its surrounding industrial and natural ecosystems. | Focused on product-level circularity or focused on value-based assessment of resource efficiency and CE related performance of supply chain actors (I). | Geographic and industrial contexts (E). |

| Meherishi et al. (2019) [80] | Sustainable packaging in supply chain management (SPSCM). | Use of packaging layers and associated waste along the supply chain. | Circular economy design; new business models; reverse cycles. | Government policies; collaboration between players; incentives to players in the supply chain to adopt circular. economy practices (E). |

| Niu et al. (2019) [92] | Design for remanufacture (DfRem)-driven closed-loop supply chain | It affects both the manufacturing process of the initial product and the recycling and remanufacturing processes of subsequent waste products. | Design for remanufacture (DfRem)-driven two-stage; and multi-period modeling processes (C). | Industry 4.0 (E). |

| Taghikhah et al. (2019) [55] | Extended sustainable supply chain (ESSC) | The ESSC framework assumes that other managerial techniques should also be employed, with a focus on the social dimension, on education, motivation, nudging, and persuasion as part of development towards sustainability. | Green consumers behavior—environmental behavior factors; and strategies for behavior change (C). | N.A. |

| Zhang et al. (2019) [82] | Circular supply chain | A transition to CE requires a paradigm shift to an innovative and more sustainable supply chain ecosystem. | Smart waste management, and smart enabling technologies. | The lack of regulatory pressures; the lack of environmental education and culture of environmental protection; and the lack of market pressures and demands (I). |

| Zhu et al. (2019) [88] | Closed-loop supply chain | It enables waste products to be professionally restored to the same quality and performance as new products and is considered to be the most valuable product recycling method. | Decentralized or centralized decision system (C). | Warranty services (E). |

| Govindan et al. (2020) [62] | Circular closed-loop supply chain | Incorporating circular economy (CE) into their supply chain network to extend the sustainability frontier by reducing the need for virgin materials, which contributes to the circulation of resources. | Supplier selection; and supply chain network design. | Decision-making methods (E). |

| Hussain and Malik (2020) [56] | Circular supply chain | The future high performing state given the CE’s established links with strong sustainability. | N.A. | Collaboration within supply chain network; and supply chain configuration (E). |

| Singhal, et al. (2020) [90] | Circular supply chain (CSC) | CSC helps organizations in making efficient use of resources and results in increased value to the society. | Design for remanufacturing; management prescience; collection strategy; and purchase intention (C). | N.A. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Sánchez, R.; Settembre-Blundo, D.; Ferrari, A.M.; García-Muiña, F.E. Main Dimensions in the Building of the Circular Supply Chain: A Literature Review. Sustainability 2020, 12, 2459. https://doi.org/10.3390/su12062459

González-Sánchez R, Settembre-Blundo D, Ferrari AM, García-Muiña FE. Main Dimensions in the Building of the Circular Supply Chain: A Literature Review. Sustainability. 2020; 12(6):2459. https://doi.org/10.3390/su12062459

Chicago/Turabian StyleGonzález-Sánchez, Rocío, Davide Settembre-Blundo, Anna Maria Ferrari, and Fernando E. García-Muiña. 2020. "Main Dimensions in the Building of the Circular Supply Chain: A Literature Review" Sustainability 12, no. 6: 2459. https://doi.org/10.3390/su12062459

APA StyleGonzález-Sánchez, R., Settembre-Blundo, D., Ferrari, A. M., & García-Muiña, F. E. (2020). Main Dimensions in the Building of the Circular Supply Chain: A Literature Review. Sustainability, 12(6), 2459. https://doi.org/10.3390/su12062459