Optimizing the Environmental and Economic Sustainability of Remote Community Infrastructure

Abstract

1. Introduction

2. Methodology

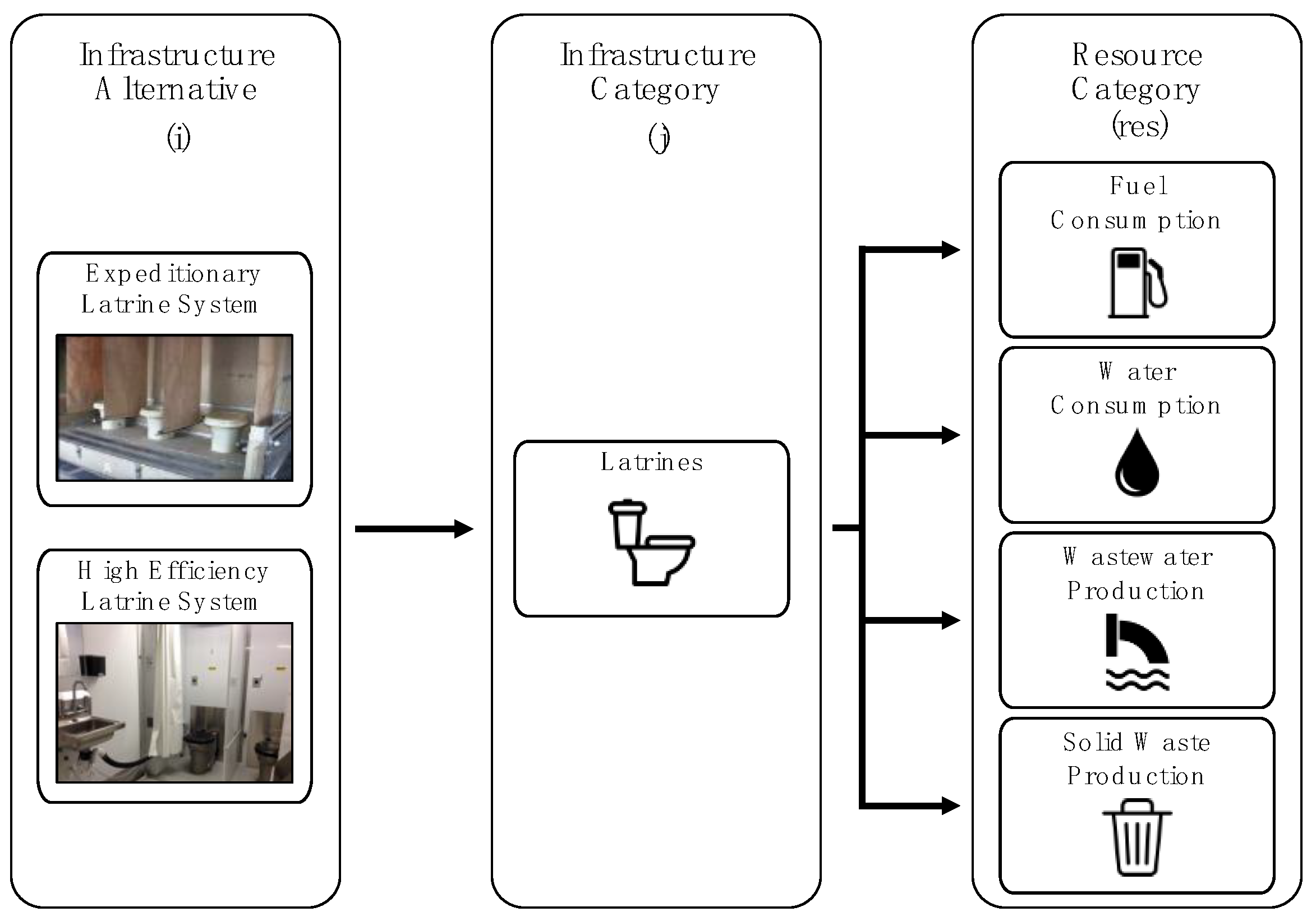

2.1. Decision Variables

2.2. Metric Identification

2.2.1. Environmental Impact Metric

- EI = environmental impact of infrastructure portfolio (tons CO2e);

- IEI = initial environmental impact of infrastructure alternative (tons CO2e);

- DEI = daily environmental impact of infrastructure alternative (tons CO2e/day);

- t = time (days);

- i = infrastructure alternative;

- j = infrastructure category;

- J = total infrastructure categories; and

- p = portfolio of alternatives: one alternative per infrastructure category.

- r = emissions rate of transportation mode (tons CO2e/ton cargo/km) [28];

- mode = mode of transportation (air, land, or sea);

- w = weight of infrastructure alternative (tons); and

- d = transportation distance (km).

- v = volume of resources (kg/day or L/day);

- res = resources, 1: fuel, 2: potable water, 3: wastewater, and 4: solid-waste;

- r = emissions rate of resource (tons CO2e/kg or tons CO2e/L) [29];

- c = carrying capacity of vehicle (kg or L); and

- f = efficiency of vehicle transporting resources (km/L).

2.2.2. Cost Metric

- C = life-cycle cost of infrastructure portfolio ($);

- IC = initial cost of alternative ($); and

- DC = daily cost of alternative ($/day).

- PC = cost to procure alternative or initiate service ($); and

- OC = operating cost of transportation mode ($/km).

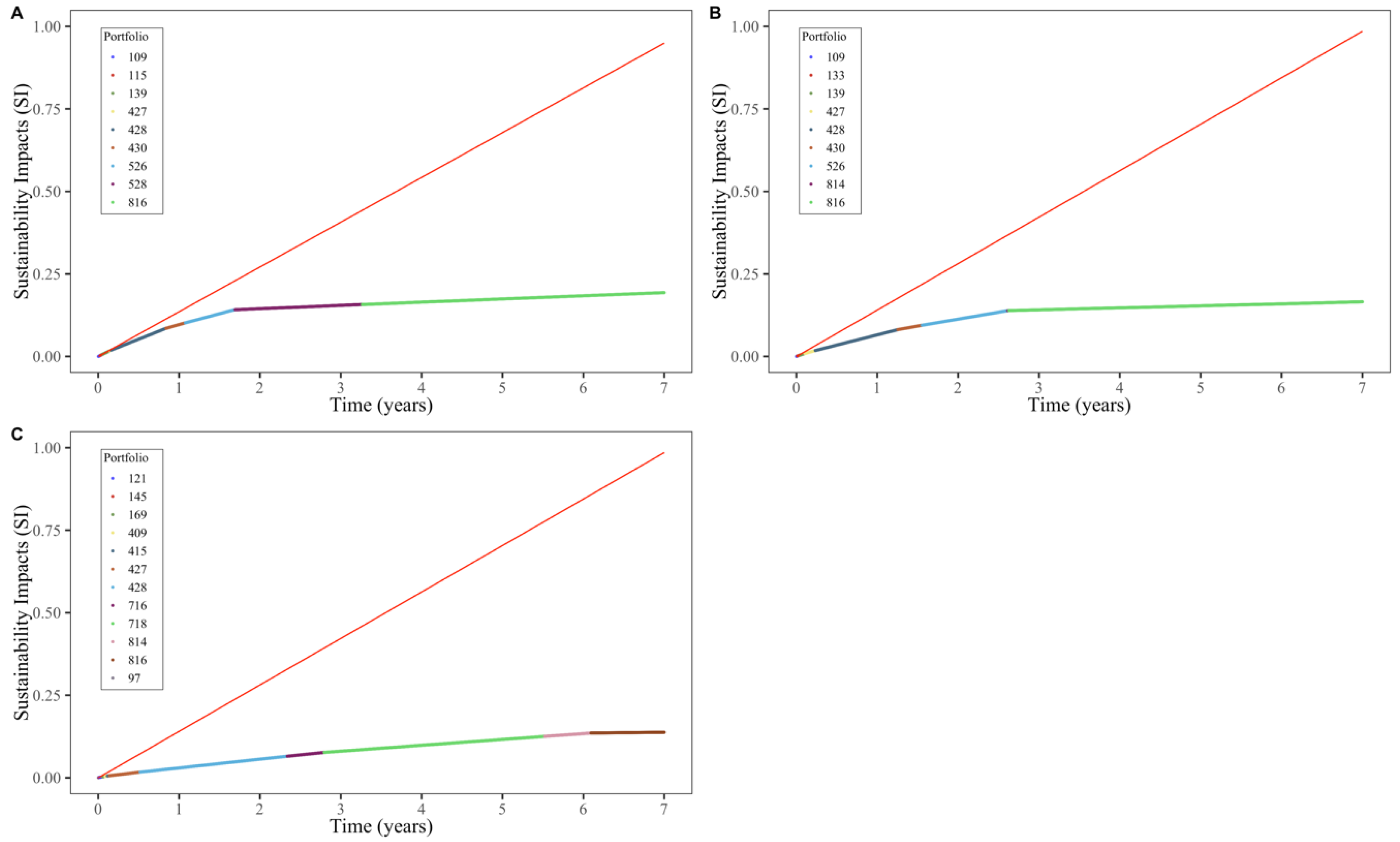

2.3. Objective Function

- EInorm = normalized environmental impact of an infrastructure portfolio; and

- Cnorm = normalized cost of an infrastructure portfolio.

- wtEI = importance weight of environmental impact;

- wtC = importance weight of cost; and

- SI = negative sustainability impacts of an infrastructure portfolio.

3. Model Input Data

4. Case Study

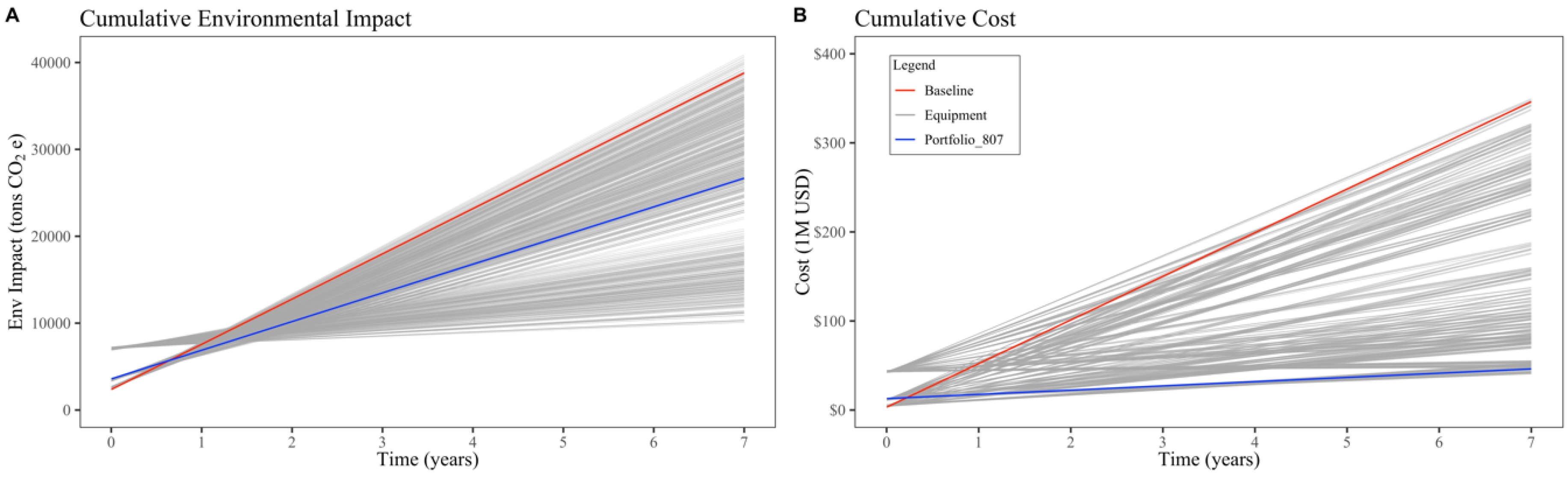

4.1. Baseline

4.2. Equipment Alternatives

4.3. Procedural Alternatives

4.4. Optimal Alternatives

5. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arriaga, M.; Canizares, C.A.; Kazerani, M. Northern Lights: Access to Electricity in Canada’s Northern and Remote Communities. IEEE Power Energy Mag. 2014, 12, 50–59. [Google Scholar] [CrossRef]

- Cave, G.; Goodwin, W.; Harrison, M.; Sadiq, A.; Tryfonas, T. Design of a sustainable forward operating base. In Proceedings of the 2011 6th International Conference on System of Systems Engineering; IEEE: Albuquerque, NM, USA, 2011; pp. 251–257. [Google Scholar]

- Arriaga, M.; Canizares, C.A.; Kazerani, M. Renewable Energy Alternatives for Remote Communities in Northern Ontario, Canada. IEEE Trans. Sustain. Energy 2013, 4, 661–670. [Google Scholar] [CrossRef]

- Anderson, H.G.; Stumpf, A.L.; Rodriguez, G.; Hunter, S.L.; Kinnevan, K. Sustainability Criteria for Contingency Bases; Construction Engineering Research Laboratory; ERDC: Champaign, IL, USA, 2014; p. 96.

- Akinyele, D.O.; Rayudu, R.K. Strategy for developing energy systems for remote communities: Insights to best practices and sustainability. Sustain. Energy Technol. Assess. 2016, 16, 106–127. [Google Scholar] [CrossRef]

- Noblis. Sustainable Forward Operating Bases; Strategic Environmental Research and Development Program (SERDP); Defense Technical Information Center: Fort Belvoir, VA, USA, 2010.

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Pachauri, R.K., Meyer, L.A., Eds.; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2014; ISBN 978-92-9169-143-2. [Google Scholar]

- Putnam, N.H.; Kinnevan, K.J.; Webber, M.E.; Seepersad, C.C. Trucks off the Road: A Method for Assessing Economical Reductions of Logistical Requirements at Contingency Base Camps. Eng. Manag. J. 2016, 28, 86–98. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- WNA. Comparison of Lifecycle Greenhouse Gas Emissions of Various Electricity Generation Sources; World Nuclear Association: London, UK, 2011; p. 12. [Google Scholar]

- Xing, S.; Xu, Z.; Jun, G. Inventory analysis of LCA on steel- and concrete-construction office buildings. Energy Build. 2008, 40, 1188–1193. [Google Scholar] [CrossRef]

- Racoviceanu, A.I.; Karney, B.W.; Kennedy, C.A.; Colombo, A.F. Life-Cycle Energy Use and Greenhouse Gas Emissions Inventory for Water Treatment Systems. J. Infrastruct. Syst. 2007, 13, 261–270. [Google Scholar] [CrossRef]

- Vince, F.; Aoustin, E.; Bréant, P.; Marechal, F. LCA tool for the environmental evaluation of potable water production. Desalination 2008, 220, 37–56. [Google Scholar] [CrossRef]

- El-Fadel, M.; Massoud, M. Methane emissions from wastewater management. Environ. Pollut. 2001, 114, 177–185. [Google Scholar] [CrossRef]

- Toprak, H. Temperature and organic loading dependency of methane and carbon dioxide emission rates of a full-scale anaerobic waste stabilization pond. Water Res. 1995, 29, 1111–1119. [Google Scholar] [CrossRef]

- Batool, S.A.; Chuadhry, M.N. The impact of municipal solid waste treatment methods on greenhouse gas emissions in Lahore, Pakistan. Waste Manag. 2009, 29, 63–69. [Google Scholar] [CrossRef] [PubMed]

- Borglin, S.; Shore, J.; Worden, H.; Jain, R. An overview of the sustainability of solid waste management at military installations. Int. J. Environ. Technol. Manag. 2010, 13, 51. [Google Scholar] [CrossRef]

- Zhao, W.; van der Voet, E.; Zhang, Y.; Huppes, G. Life cycle assessment of municipal solid waste management with regard to greenhouse gas emissions: Case study of Tianjin, China. Sci. Total Environ. 2009, 407, 1517–1526. [Google Scholar] [CrossRef] [PubMed]

- Karatas, A.; El-Rayes, K. Optimal Trade-Offs between Housing Cost and Environmental Performance. J. Archit. Eng. 2016, 22, 04015018. [Google Scholar] [CrossRef]

- Ozcan-Deniz, G.; Yimin, Z.; Ceron, V. Time, Cost, and Environmental Impact Analysis on Construction Operation Optimization Using Genetic Algorithms. J. Manag. Eng. 2012, 28, 265–272. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.N. Performance indicators for sustainability assessment of buildings. In Proceedings of the International Construction Specialty Conference of the Canadian Society for Civil Engineering (ICSC), Vancouver, BC, Canada, 7–10 June 2015. [Google Scholar]

- Coello, C.A. Twenty Years of Evolutionary Multi-Objective Optimization: A Historical View of the Field. Evol. Comput. Group. 2005, 20.

- El-Anwar, O.; El-Rayes, K.; Elnashai, A.S. Maximizing the Sustainability of Integrated Housing Recovery Efforts. J. Constr. Eng. Manag. 2010, 136, 794–802. [Google Scholar] [CrossRef]

- Poreddy, B.R.; Daniels, B. Mathematical Model of Sub-System Interactions for Forward Operating Bases. In Proceedings of the 2012 Industrial and Systems Engineering Research Conference, Hilton Bonnet Creek, Orlando, FL, USA, 19–23 May 2012. [Google Scholar]

- Filer, J.; Schuldt, S. Quantifying the Environmental and Economic Performance of Remote Communities. Eur. J. Sustain. Dev. 2019, 8, 176–184. [Google Scholar] [CrossRef]

- Houghton, J.T.; Jenkins, G.J.; Ephraums, J.J. Climate Change: the IPCC (Intergovernmental Panel on Climate Change) Scientific Assessment; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Reilly, J.; Babiker, M.; Mayer, M. Comparing Greenhouse Gases; MIT Joint Program on the Science and Policy of Global Change: Cambridge, MA, USA, 2001; p. 23. [Google Scholar]

- Chao, C.-C. Assessment of carbon emission costs for air cargo transportation. Transp. Res. Part D Transp. Environ. 2014, 33, 186–195. [Google Scholar] [CrossRef]

- US EPA. Greenhouse Gases Equivalencies Calculator—Calculations and References. Available online: https://www.epa.gov/energy/greenhouse-gases-equivalencies-calculator-calculations-and-references (accessed on 15 June 2019).

- Gildea, G.S.; Carpenter, P.D.; Campbell, B.J.; Quigley, J.; Diaz, J.; Langley, J.; Putnam, N.; Hargreaves, B.; Donahue, K.; Lindo, W.; et al. SLB-STO-D Analysis Report: Modeling and Simulation Analysis of Fuel, Water, and Waste Reductions in Base Camps: 50, 300, and 1000 Persons; US Army Natick Solider RD&E Center: Natick, MA, USA, 2017; p. 368.

- Gildea, G.S.; Carpenter, P.D.; Campbell, B.J.; Quigley, J.; Langley, J.; Putnam, N.; Rinckel, D.; Hargreaves, B.; Lindo, W.; Harris, W.F.; et al. SLB-STO-D: 50, 300, 1000-Person Base Camp, Analysis of FY12 Operationally Relevant Technical Baseline; US Army Natick Solider RD&E Center: Natick, MA, USA, 2017; p. 98.

- Gildea, G.S.; Carpenter, P.D.; Campbell, B.J.; Harris, W.F.; McCluskey, M.A.; Miletti, J.A. SLB-STO-D: Selected Technology Assessment; US Army Natick Solider RD&E Center: Natick, MA, USA, 2018; p. 226.

- R Core Team. R: A Language and Environment for Statistical Computing; R Core Team: Vienna, Austria, 2019. [Google Scholar]

- Wickham, H. ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2016; ISBN 978-3-319-24277-4. [Google Scholar]

- Oshkosh Heavy Tactical Vehicles. Available online: https://oshkoshdefense.com/heavy-tactical-vehicles/ (accessed on 4 January 2020).

- Cherubini, F.; Bargigli, S.; Ulgiati, S. Life cycle assessment (LCA) of waste management strategies: Landfilling, sorting plant and incineration. Energy 2009, 34, 2116–2123. [Google Scholar] [CrossRef]

- Ritsick, C. C-17 Facts: Everything You Need To Know. Available online: https://militarymachine.com/c-17-facts/ (accessed on 20 June 2019).

- Harris, W.F., III; Gildea, G.S.; Carpenter, P.D.; Campbell, B.J.; Benasutti, P.B.; Turner, A.J.; Krutsch, M.C.; Miletti, J.A. SLB-STO-D: Demonstration #2—300-Person Camp Demonstration; US Army Natick Solider RD&E Center: Natick, MA, USA, 2017; p. 221.

- Thomsen, N.; Wagner, T.; Hoisington, A.; Schuldt, S. A sustainable prototype for renewable energy: Optimized prime-power generator solar array replacement. Int. J. Energy Prod. Manag. 2019, 4, 28–39. [Google Scholar] [CrossRef]

| Input Category | Inputs |

|---|---|

| Community Features | (1) required personnel (persons) (2) environment (e.g., desert, temperate, or tropical) (3) duration (days) (4) equipment delivery method (ground, air, or sea) (5) equipment delivery distance (km) (6) distance to local services (km) (7) transportation method efficiencies (km/L) (8) transportation method capacities (kg or L) |

| Planning Factors | (1) power consumption (kW/person/day) (2) potable water consumption (L/person/day) (3) solid waste production (kg/person/day) (4) wastewater production (L/person/day) |

| Infrastructure Alternative Characteristics | (1) fuel consumption (L/day) (2) water consumption (L/day) (3) wastewater production (L/day) (4) solid waste production (kg/day) (5) procurement cost (USD) (6) operating costs (USD) (7) shipping weight (kg) (8) emissions factor (ton CO2/unit) |

| Resource | Variable | Value | Units | Reference |

|---|---|---|---|---|

| Fuel | Cost (SCfuel) | 4 | $/L | [6] |

| Emissions Rate (rfuel) | 2.6 × 10−3 | metric tons CO2/L | [29] | |

| Delivery Distance (dfuel) | 65 | km | ||

| Vehicle Efficiency (ffuel) | 0.8 | km/L | [34] | |

| Vehicle Capacity (cfuel) | 18,925 | L | [35] | |

| Water | Cost (SCwater) | 2.6 | $/L | [6] |

| Delivery Distance (dwater) | 40 | km | ||

| Vehicle Efficiency (fwater) | 0.7 | km/L | [35] | |

| Vehicle Capacity (cwater) | 17,033 | L | [35] | |

| Wastewater | Cost (SCww) | 0.5 | $/L | |

| Emissions Rate (rww) | 2.3 × 10−5 | metric tons CO2/L | ||

| Delivery Distance (dww) | 80 | km | ||

| Vehicle Efficiency (fww) | 0.7 | km/L | [35] | |

| Vehicle Capacity (cww) | 15,140 | L | [35] | |

| Solid Waste | Cost (SCsw) | 8.8 | $/kg | |

| Emissions Rate—landfill (rsw) | 1.3 × 10−3 | metric tons CO2/kg | [36] | |

| Emissions Rate—burn pit (rsw) | 9.9 × 10−4 | metric tons CO2/kg | ||

| Emissions Rate—incinerator (rsw) | 6.4 × 10−4 | metric tons CO2/kg | [36] | |

| Delivery Distance (dsw) | 72 | km | ||

| Vehicle Efficiency (fsw) | 0.7 | km/L | [35] | |

| Vehicle Capacity (csw) | 16.5 | tons | [35] | |

| Equipment Alternatives | Cost (OCair) | 29 | $/km | [37] |

| Emissions Rate (rair) | 4.1 × 10−4 | metric tons CO2/km | [28] | |

| Delivery Distance (dair) | 5172 | km | ||

| Aircraft Capacity (cair) | 86 | tons | [37] |

| Resource Category | Volume | Unit |

|---|---|---|

| Fuel Demand | 3944 | L/day |

| Power Demand | 5108 | kWh/day |

| Potable Water Demand | 33,017 | L/day |

| Wastewater Demand | 32,282 | L/day |

| Solid Waste Demand | 1302 | kg/day |

| Infra. Cat. | Infrastructure Alternative | vfuel | vwater | vww | vsw | wt | PC | |

|---|---|---|---|---|---|---|---|---|

| (L) | (L) | (L) | (kg) | (kg) | (USD/unit) | |||

| Equipment Alternatives | Baseline site | 3944 | 33,017 | 32,282 | 1302 | 506,835 | 1,191,215 | |

| Facility Insulation | (Baseline Alt.)—Single ply tent liner | 3129 | 23,000 | |||||

| Insulated tent liner & photovoltaic array shade | 3478 | 33,017 | 32,282 | 1302 | 17,647 | 487,830 | ||

| Power Production | (Baseline Alt.)—60 kW tactical generator | 41,929 | 650,000 | |||||

| Hybrid generator and battery system | 2740 | 33,017 | 32,282 | 1302 | 241,061 | 7,200,000 | ||

| Photovoltaic array and battery system | 397 | 33,017 | 32,282 | 1302 | 1,015,840 | 35,600,000 | ||

| Food Preparation | (Baseline Alt.)—Expeditionary kitchen system | 6349 | 150,000 | |||||

| Fuel-fired expeditionary kitchen system | 3823 | 33,304 | 32,570 | 1302 | 6984 | 170,000 | ||

| Refrigeration | (Baseline Alt.)—Multi-temperature refrig. system | 18,225 | 120,000 | |||||

| High efficiency refrigeration system with solar array | 3914 | 33,017 | 32,282 | 1302 | 17,493 | 136,150 | ||

| Water Production | (Baseline Alt.)—Bottled water imported to site | 0 | 0 | |||||

| Reverse osmosis water purification system | 4148 | -4349 | 32,282 | 1302 | 3628 | 284,500 | ||

| Latrines | (Baseline Alt.)—Expeditionary latrine system | 11,646 | 200,000 | |||||

| High efficiency latrine system | 4383 | 25,401 | 23,020 | 1305 | 13,393 | 240,000 | ||

| Solid Waste Mgmt | (Baseline Alt.)—Waste exported from site to landfill | 0 | 0 | |||||

| Open-air burn pit | 4020 | 33,017 | 32,282 | 160 | 0 | 5000 | ||

| Incinerator | 4008 | 33,017 | 32,282 | 226 | 38,774 | 750,000 | ||

| Wastewater Mgmt | (Baseline Alt.)—Waste exported from site | 0 | 0 | |||||

| Activated sludge bioreactor | 3952 | 33,017 | 3452 | 1302 | 12,898 | 400,000 | ||

| Activated sludge bioreactor and reverse osmosis water purification system | 3963 | 15,806 | 1768 | 1302 | 22,571 | 1,150,000 | ||

| Procedural Alternatives | Billeting | (Baseline Alt.)—14 personnel per tent | 425,292 | 45,885 | ||||

| Billeting consolidation, 18 personnel per tent | 3732 | 33,017 | 32,282 | 1302 | 402,436 | 35,910 | ||

| Power Production | (Baseline Alt.)—60 kW tactical generator | 38,704 | 600,000 | |||||

| Generator reallocation according to avg. loading | 3168 | 33,017 | 32,282 | 1302 | 27,415 | 425,000 | ||

| 60 kW tactical generator grid | 2324 | 33,017 | 32,282 | 1302 | 40,316 | 625,000 | ||

| Laundry Services | (Baseline Alt.)—Unlimited laundry allowance | 261 | 2250 | |||||

| 1/2 baseline laundry allowance | 3921 | 31,597 | 32,282 | 1302 | 156 | 1350 | ||

| Hygiene Services | (Baseline Alt.)—10-min daily showers | 4 | 80 | |||||

| 7-min weekly showers | 3876 | 17,998 | 17,260 | 1302 | 4 | 80 | ||

| Latrines | (Baseline Alt.)—Unlimited toilet flushes | 11,646 | 200,000 | |||||

| Reduced toilet flushes | 3936 | 27,634 | 26,900 | 1302 | 11,646 | 200,000 |

| Infrastructure Category | Baseline | Portfolio #807 |

|---|---|---|

| Fac. Insulation | Single ply tent liner | Single ply tent liner |

| Power Pro. | 60 kW tactical generator | Hybrid generator and battery system |

| Food Prep. | Expeditionary kitchen system | Expeditionary kitchen system |

| Refrigeration | Multi-temperature refrigeration system | High efficiency refrigeration system with solar array |

| Water Pro. | Bottled water imported to site | Reverse osmosis water purification system |

| Latrines | Expeditionary latrine system | Expeditionary latrine system |

| Solid Waste Mgmt. | Waste exported from site to landfill | Incinerator |

| Wastewater Mgmt. | Waste exported from site | Activated sludge bioreactor and reverse osmosis water purification system |

| Initial EI (CO2e) | 2356 | 3581 |

| Daily EI (CO2e) | 14 | 9 |

| Initial C (USD) | 3,100,000 | 12,900,000 |

| Daily C (USD) | 134,000 | 13,000 |

| Infrastructure Category | Portfolio #816 | Portfolio #97 |

|---|---|---|

| Fac. Insulation | Insulated tent liner and photovoltaic array shade | Single ply tent liner |

| Power Pro. | Photovoltaic array and battery system | 60 kW tactical generator |

| Food Prep. | Fuel-fired expeditionary kitchen system | Expeditionary kitchen system |

| Refrigeration | High efficiency refrigeration system with solar array | Multi-temperature refrigeration system |

| Water Pro. | Reverse osmosis water purification system | Bottled water imported to site |

| Latrines | Expeditionary latrine system | Expeditionary latrine system |

| Solid Waste Mgmt. | Incinerator | Open-air burn pit |

| Wastewater Mgmt. | Activated sludge bioreactor and reverse osmosis water purification system | Waste exported from site |

| Initial EI (CO2e) | 7253 | 2356 |

| Daily EI (CO2e) | 1 | 14 |

| Initial C (USD) | 44,730,000 | 3,100,000 |

| Daily C (USD) | 1500 | 123,000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filer, J.E.; Delorit, J.D.; Hoisington, A.J.; Schuldt, S.J. Optimizing the Environmental and Economic Sustainability of Remote Community Infrastructure. Sustainability 2020, 12, 2208. https://doi.org/10.3390/su12062208

Filer JE, Delorit JD, Hoisington AJ, Schuldt SJ. Optimizing the Environmental and Economic Sustainability of Remote Community Infrastructure. Sustainability. 2020; 12(6):2208. https://doi.org/10.3390/su12062208

Chicago/Turabian StyleFiler, Jamie E., Justin D. Delorit, Andrew J. Hoisington, and Steven J. Schuldt. 2020. "Optimizing the Environmental and Economic Sustainability of Remote Community Infrastructure" Sustainability 12, no. 6: 2208. https://doi.org/10.3390/su12062208

APA StyleFiler, J. E., Delorit, J. D., Hoisington, A. J., & Schuldt, S. J. (2020). Optimizing the Environmental and Economic Sustainability of Remote Community Infrastructure. Sustainability, 12(6), 2208. https://doi.org/10.3390/su12062208