Evaluating the Relationship between Fruit and Vegetable Growers Use of Plastic Biodegradable Mulches, and Environmental Stewardship and Labor Savings: The Case of Tennessee Fruit and Vegetable Farmers

Abstract

1. Introduction

2. Materials and Methods

2.1. Data

2.2. Empirical Model and Estimation Procedures

2.3. Model Specifications

2.4. Diagnostic Tests

3. Results

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Emmert, E.M. Black polyethylene for mulching vegetables. Proc. Am. Soc. Hortic. Sci. 1957, 69, 464–469. [Google Scholar]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Fessenden, M. Most Plastic Trash Comes from Farms. Smithsonina.com. 2015. Available online: https://www.smithsonianmag.com/smart-news/most-plastic-trash-comes-farms-heres-what-were-trying-do-about-it-180954873/ (accessed on 20 July 2019).

- Levitan, L.; Barros, A. Recycling Agricultural Plastics in New York State. Environmental Risk Analysis Program; Cornell University: Ithaca, NY, USA, 2003; Available online: http://cwmi.css.cornell.edu/recyclingagplastics.pdf (accessed on 30 July 2019).

- Sintim, H.Y.; Bandopadhyay, S.; English, M.E.; Bary, A.I.; DeBruyn, J.M.; Schaeffer, S.M.; Miles, C.A.; Reganold, J.P.; Flury, M. Impacts of biodegradable plastic mulches on soil health. Agric. Ecosyst. Environ. 2019, 273, 36–49. [Google Scholar] [CrossRef]

- Touchaleaume, F.; Martin-Closas, L.; Angellier-Coussy, H.; Chevillard, A.; Cesar, G.; Gontard, N.; Gastaldi, E. Performance and environmental impact of biodegradable polymers as agricultural mulching films. Chemosphere 2016, 144, 433–439. [Google Scholar] [CrossRef]

- Liu, E.K.; He, W.Q.; Yan, C.R. ‘White revolution’ to ‘white pollution’—Agricultural plastic film mulch in China. Environ. Res. Lett. 2014, 9, 091001. [Google Scholar] [CrossRef]

- Cowan, J.S.; Miles, C.A.; Andrews, P.K.; Inglis, D.A. Biodegradable mulch performed comparably to polyethylene in high tunnel tomato (Solanum lycopersicum L.) production. J. Sci. Food Agric. 2014, 94, 1854–1864. [Google Scholar] [CrossRef]

- Ghimire, S.; Wszelaki, A.L.; Moore, J.C.; Inglis, D.A.; Miles, C.A. Use of biodegradable mulches in pie pumpkin production in two diverse climates. HortScience 2018, 53, 288–294. [Google Scholar] [CrossRef]

- Waterer, D. Evaluation of biodegradable mulches for production of warm-season vegetable crops. Can. J. Plant. Sci. 2010, 90, 737–743. [Google Scholar] [CrossRef]

- Goldberger, J.; Jones, R.; Miles, C.; Wallace, R.; Inglis, D. Barriers and bridges to the adoption of biodegradable plastic mulches for U.S. specialty crop production. Renew. Agric. Food Syst. 2013, 30, 143–153. [Google Scholar] [CrossRef]

- Velandia, M.; Wszelaki, A.; Galinato, S. Economic evaluation of biodegradable plastic in Tennessee pumpkin production. Agronomy 2019, 10, 51. [Google Scholar] [CrossRef]

- Goldberger, J.; DeVetter, L.W.; Dentzman, K.E. Polyethylene and biodegradable plastic mulches for strawberry production in the United States: Experiences and opinions of growers in three regions. HortTechnology 2019, 29, 619–628. [Google Scholar] [CrossRef]

- Scaringelli, M.A.; Giannoccaro, G.; Prosperi, M.; Lopolito, A. Adoption of biodegradable mulching films in agriculture: Is there a negative prejudice towards materials derived from organic wastes? Ital. J. Agron. 2016, 11, 619–628. [Google Scholar] [CrossRef]

- Velandia, M.; Smith, A.; Wszelaki, A.; Galinato, S.; Marsh, T. The Economics of Adopting Biodegradable Plastic Mulch Films; W650; University of Tennessee: Knoxville, TN, USA, 2018; Available online: https://bit.ly/2OfzOPe (accessed on 20 October 2019).

- World Medical Association. WMA Declaration of Helsinki—Ethical Principles for Medical Research Involving human subjects. Available online: https://bit.ly/3bCByie (accessed on 15 February 2020).

- Pick Tennessee Products. Pick Tennessee Products Application. Available online: https://bit.ly/2TduPCS (accessed on 24 February 2020).

- Tennessee Ag Enhancement Program (TAEP). TAEP Investment Project, 2019 Application B. Available online: https://bit.ly/2T7yt1f (accessed on 24 February 2020).

- Dillman, D.A.; Smyth, J.D.; Christian, L.M. Internet, Mail, and Mixed-Mode Surveys. The Tailored Design Method; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- McCabe, S.E.; Diez, A.; Boyd, C.J.; Nelson, T.F.; Weitzman, E.R. Comparing web and mail responses in a mixed mode survey in college alcohol use research. Addict. Behav. 2006, 31, 1619–1627. [Google Scholar] [CrossRef] [PubMed][Green Version]

- U.S. Department of Agriculture (USDA), National Agricultural Statistics Service (NASS). 2017 Census of Agriculture. Census Data Query Tool (CDQT). Available online: https://www.nass.usda.gov/Publications/AgCensus/2017/Online_Resources/Census_Data_Query_Tool/index.php (accessed on 19 August 2019).

- Schonbeck, M. Mulching for Weed Management in Organic Vegetable Production. eOrganic 4870, eXtension. Available online: https://tinyurl.com/y4qxsl7j (accessed on 26 August 2019).

- Feldman, R.S.; Holmes, C.E.; Blomgren, T.A. Use of fabric and compost mulches for vegetable production in a low tillage permanent bed system: Effects on crop yield and labor. Am. J. Altern. Agric. 2000, 15, 146–153. [Google Scholar] [CrossRef]

- Gibbens, S. ‘Alarming’ Level of Microplastics Found in a Major U.S. River. Environment, Planet or Plastic, National Geographi. Available online: https://on.natgeo.com/2SXmUL0 (accessed on 25 February 2020).

- National Geographic. Planet or Plastic. Available online: https://on.natgeo.com/390CqLM (accessed on 25 February 2020).

- StataCorp. Base Reference Manual; Statacorp LP: College Station, TX, USA, 2013. [Google Scholar]

- Chouinard, H.H.; Wandschneider, P.R.; Paterson, T. Inferences from sparse data: An integrated, meta-utility approach to conservation research. Ecol. Econ. 2016, 122, 71–78. [Google Scholar] [CrossRef]

- Koundouri, P.; Nauges, C.; Tzouvelekas, V. Technology adoption under production uncertainty: Theory and application to irrigation technology. Am. J. Agric. Econ. 2006, 88, 658–670. [Google Scholar] [CrossRef]

- D’Souza, G.; Cyphers, D.; Phipps, T. Factors affecting the adoption of sustainable agricultural practices. Agric. Resour. Econ. Rev. 1993, 22, 159–165. [Google Scholar] [CrossRef]

- Liu, T.; Bruins, R.J.F.; Heberling, M.T. Factors influencing farmers’ adoption of best management practices: A review and synthesis. Sustainability 2018, 10, 432. [Google Scholar] [CrossRef]

- Fernandez-Cornejo, J.; Beach, E.D.; Huang, W. The adoption of IPM techniques by vegetable growers in Florida, Michigan, and Texas. J. Agric. Appl. Econ. 1994, 26, 158–172. [Google Scholar] [CrossRef][Green Version]

- Mulimbi, W.; Nalley, L.; Dixon, B.; Snell, H.; Huang, Q. Factors influencing adoption of conservation agriculture in the Democratic Republic of the Congo. J. Agric. Appl. Econ. 2019, 51, 622–645. [Google Scholar] [CrossRef]

- Feder, G.; Umali, D.L. The adoption of agricultural innovations: A review. Technol. Forecast. Soc. Chang. 1993, 43, 215–239. [Google Scholar] [CrossRef]

- Hayes, D.; Wadsworth, L.; Sintim, H.; Flury, M.; English, M.; Schaeffer, S.; Saxton, A. Effect of diverse weathering conditions on the physiochemical properties of biodegradable plastic mulches. Polym. Test. 2017, 62, 454–467. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Ecoregion Download Files by State—Region 4. Available online: https://www.epa.gov/eco-research/ecoregion-download-files-state-region-4 (accessed on 27 August 2019).

- Greene, W.H. Econometric Analysis, 7th ed.; Pearson: New York, NY, USA, 2012. [Google Scholar]

- Akaike, H. Information theory as an extension of the maximum likelihood principle. In Second International Symposium on Information Theory; Petrov, B.N., Csaki, F., Eds.; Akademiai Kiado: Budapest, Hungary, 1973; pp. 267–281. [Google Scholar]

- Belsley, D.A.; Kuh, E.; Welsch, R.E. Regression Diagnostics: Identifying Influential Data and Sources of Collinearity; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- U.S. Department of Labor, Employment and Training Administration. Adverse Effect Wage Rates—Year 2019. Available online: https://bit.ly/2Q1xDmg (accessed on 1 August 2019).

- Ghimire, S.; Hayes, D.; Cowan, J.; Inglis, D.; DeVetter, L.; Miles, C. Biodegradable Plastic mulch and Suitability for Sustainable and Organic Agriculture; FS103E; Washington State University Extension: Mount Vernon, VA, USA, 2018; Available online: https://bit.ly/2SG8M8P (accessed on 19 February 2020).

| Variable Description | n | Mean | Std Dev | Min | Max |

|---|---|---|---|---|---|

| Mulch Use | |||||

| PE_USE = 1 if farmer has used PE mulch; zero otherwise | 184 | 0.5978 | 0 | 1 | |

| BDM_USE = 1 if farmer has used BDM; zero otherwise | 181 | 0.1547 | 0 | 1 | |

| EXP_PE—Years using PE mulch; zero otherwise | 108 | 9.7407 | 9.8866 | 1 | 50 |

| EXP_BDM—Number of years using BDM | 31 | 1.4194 | 1.2048 | 0 | 6 |

| Labor_hours (h/ha)—Labor hours associated with removal and disposal of PE mulch in hours per hectare that would be eliminated if using BDM | 101 | 42.6134 | 39.1441 | 0 | 198 |

| Farmer and Farm Business Characteristics | |||||

| Age—Age in years | 178 | 56.8539 | 14.5986 | 1 | 60 |

| BSdegree or higher = 1 if farmer has a bachelor’s degree or higher; zero otherwise | 185 | 0.5946 | 0 | 1 | |

| Farm Size_F&V—Hectares in fruit and vegetable production | 156 | 4.3019 | 13.6608 | 0.0243 | 157 |

| Environmental Stewardship | |||||

| Environmental Stewardship—simple average of the scores associated with the statements below | 177 | 3.1497 | 0.9937 | 1 | 5 |

| “I only buy products in packages that can be recycled” | 177 | 2.8249 | 1.1169 | 1 | 5 |

| “I try to convince my family or friends not to buy environmentally harmful products” | 177 | 3.4746 | 1.2204 | 1 | 5 |

| Risk Attitude | |||||

| Risk Attitude—simple average of the scores associated with the statements below | 179 | 2.6257 | 0.9770 | 1 | 5 |

| “I like taking financial risks with my farm business” | 178 | 2.3258 | 1.1377 | 1 | 5 |

| “I accept more risk in my farm than other farmers” | 179 | 2.9218 | 1.0885 | 1 | 5 |

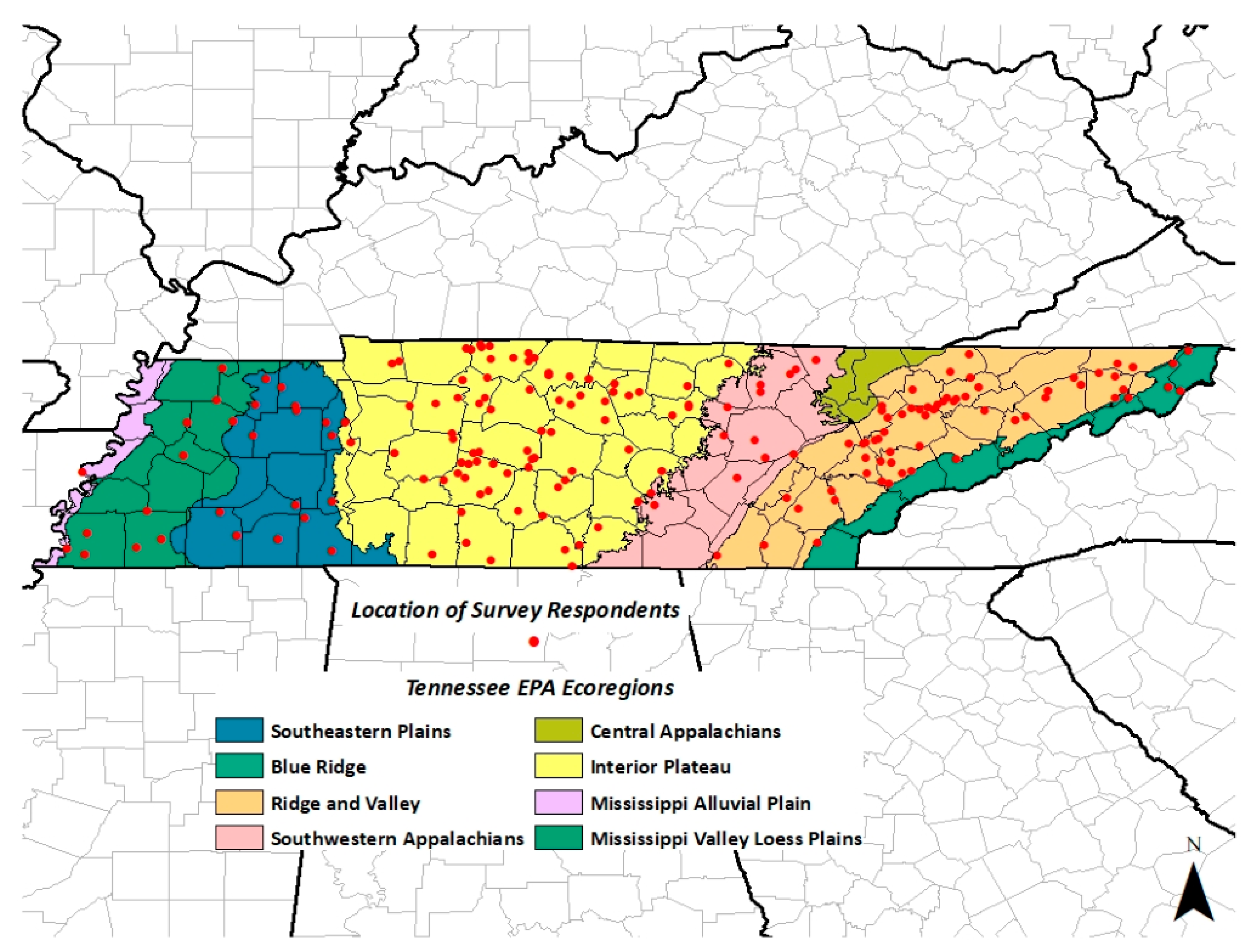

| Ecoregion—1 if the primary farm is located in the Blue Ridge region; 2 if it is located in the Ridge and Valley region; 3 if it is located in the Southwestern Appalachians region; 4 if it is located in the Interior Plateau region; 5 if it is located in the Southeastern Plains region; and 6 if it is located in the Mississippi Valley Loess Plains region | |||||

| Blue Ridge | 183 | 0.0328 | 0 | 1 | |

| Ridge and Valley | 183 | 0.3060 | 0 | 1 | |

| Southwestern Appalachians | 183 | 0.0765 | 0 | 1 | |

| Interior Plateau | 183 | 0.4317 | 0 | 1 | |

| Southeastern Plains | 183 | 0.0929 | 0 | 1 | |

| Mississippi Valley Loess Plains | 183 | 0.0601 | 0 | 1 | |

| Dependent Variable = 1 If Farmer Has Used BDM | |||||

|---|---|---|---|---|---|

| Model Specification | |||||

| (1) Full sample | (2) Full sample Ecoregions | (3) PE users | (4) PE users Ecoregions | (5) PE users, controlling for labor cost and PE experience | |

| Age | 0.0005 | 0.0004 | 0.0009 | 0.0009 | 0.0001 |

| (0.0021) | (0.0021) | (0.0033) | (0.0033) | (0.0040) | |

| BSdegree or above | −0.0493 | −0.0502 | −0.1117 | −0.1103 | −0.1584 |

| (0.0636) | (0.0634) | (0.1063) | (0.1068) | (0.1231) | |

| Farm size F&V | 0.0157 *** | 0.0155 *** | 0.0212 *** | 0.0207 *** | 0.0204 *** |

| (0.0048) | (0.0049) | (0.0070) | (0.0072) | (0.0074) | |

| Environmental Stewardship | 0.0263 (0.0341) | 0.0234 (0.0338) | 0.0871 * (0.0531) | 0.0840 * (0.0524) | 0.1094 * (0.0597) |

| Risk attitude | 0.0117 | 0.0089 | 0.0090 | 0.0065 | 0.0021 |

| (0.0305) | (0.0310) | (0.0540) | (0.0553) | (0.0645) | |

| Ecoregion | −0.0184 | −0.0362 | |||

| (0.0211) | (0.0369) | ||||

| Labor hours(h/ha)/10 | 0.0406 *** (0.0143) | ||||

| Experience PE | 0.0109 | ||||

| (0.0070) | |||||

| Observations | 146 | 146 | 89 | 89 | 80 |

| Wald statistic χ2(k) | 13.51 ** | 14.45 ** | 12.31 ** | 13.06 ** | 25.88 *** |

| Log-pseudolikelihood | −57.4529 | −57.1791 | −43.6553 | −43.2549 | −35.4992 |

| AIC | 126.9058 | 128.3583 | 99.3106 | 100.5098 | 86.9984 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velandia, M.; Rejesus, R.; Clark, C.; DeLong, K.L.; Wszelaki, A.; Schexnayder, S.; Jensen, K. Evaluating the Relationship between Fruit and Vegetable Growers Use of Plastic Biodegradable Mulches, and Environmental Stewardship and Labor Savings: The Case of Tennessee Fruit and Vegetable Farmers. Sustainability 2020, 12, 2075. https://doi.org/10.3390/su12052075

Velandia M, Rejesus R, Clark C, DeLong KL, Wszelaki A, Schexnayder S, Jensen K. Evaluating the Relationship between Fruit and Vegetable Growers Use of Plastic Biodegradable Mulches, and Environmental Stewardship and Labor Savings: The Case of Tennessee Fruit and Vegetable Farmers. Sustainability. 2020; 12(5):2075. https://doi.org/10.3390/su12052075

Chicago/Turabian StyleVelandia, Margarita, Roderick Rejesus, Christopher Clark, Karen L. DeLong, Annette Wszelaki, Susan Schexnayder, and Kimberly Jensen. 2020. "Evaluating the Relationship between Fruit and Vegetable Growers Use of Plastic Biodegradable Mulches, and Environmental Stewardship and Labor Savings: The Case of Tennessee Fruit and Vegetable Farmers" Sustainability 12, no. 5: 2075. https://doi.org/10.3390/su12052075

APA StyleVelandia, M., Rejesus, R., Clark, C., DeLong, K. L., Wszelaki, A., Schexnayder, S., & Jensen, K. (2020). Evaluating the Relationship between Fruit and Vegetable Growers Use of Plastic Biodegradable Mulches, and Environmental Stewardship and Labor Savings: The Case of Tennessee Fruit and Vegetable Farmers. Sustainability, 12(5), 2075. https://doi.org/10.3390/su12052075