Transferability of Process Parameters in Laser Powder Bed Fusion Processes for an Energy and Cost Efficient Manufacturing

Abstract

1. Introduction

2. Materials and Methods

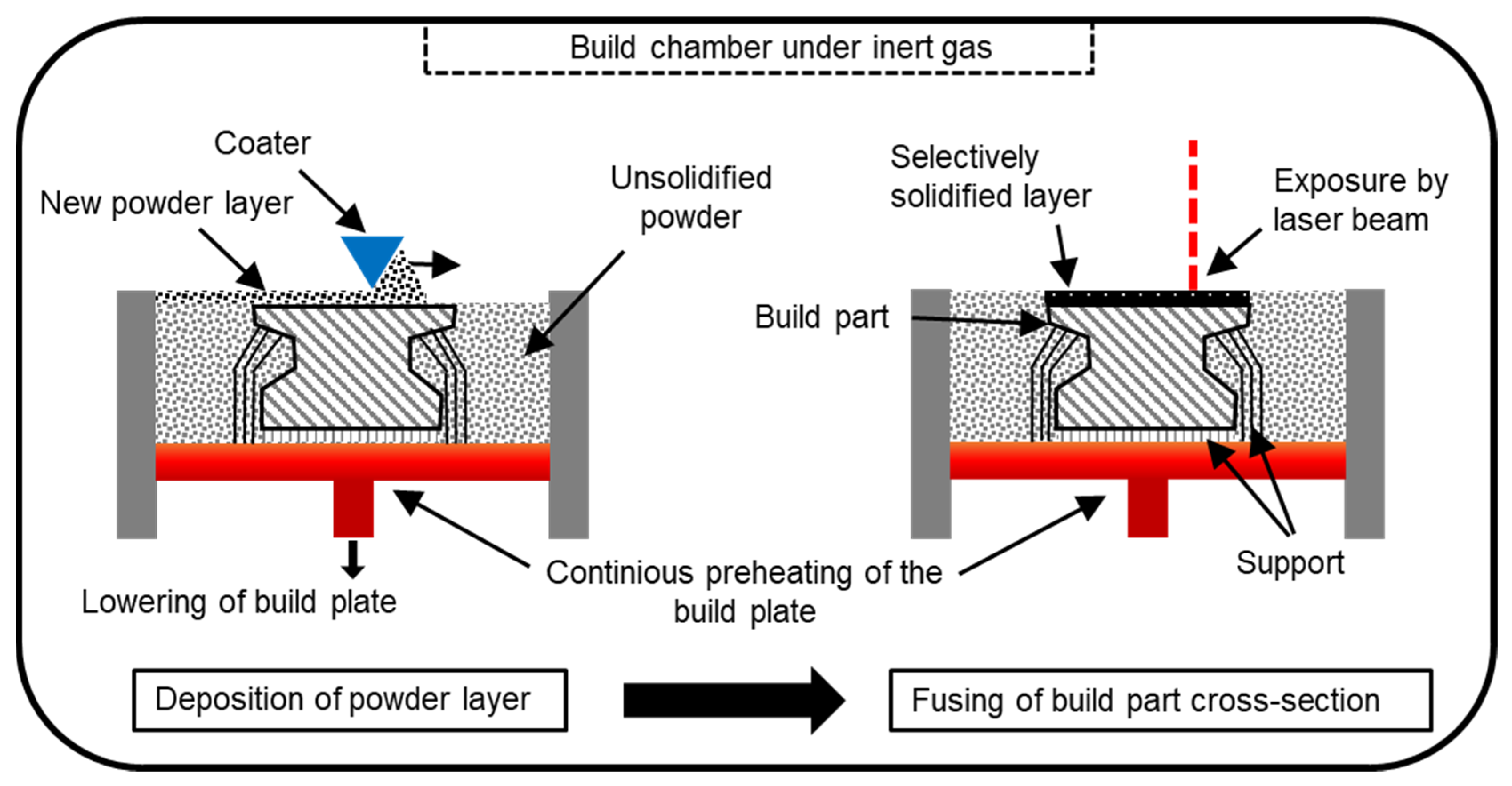

2.1. Processing

2.2. Powder Material

2.3. Mechanical and Microstructural Properties

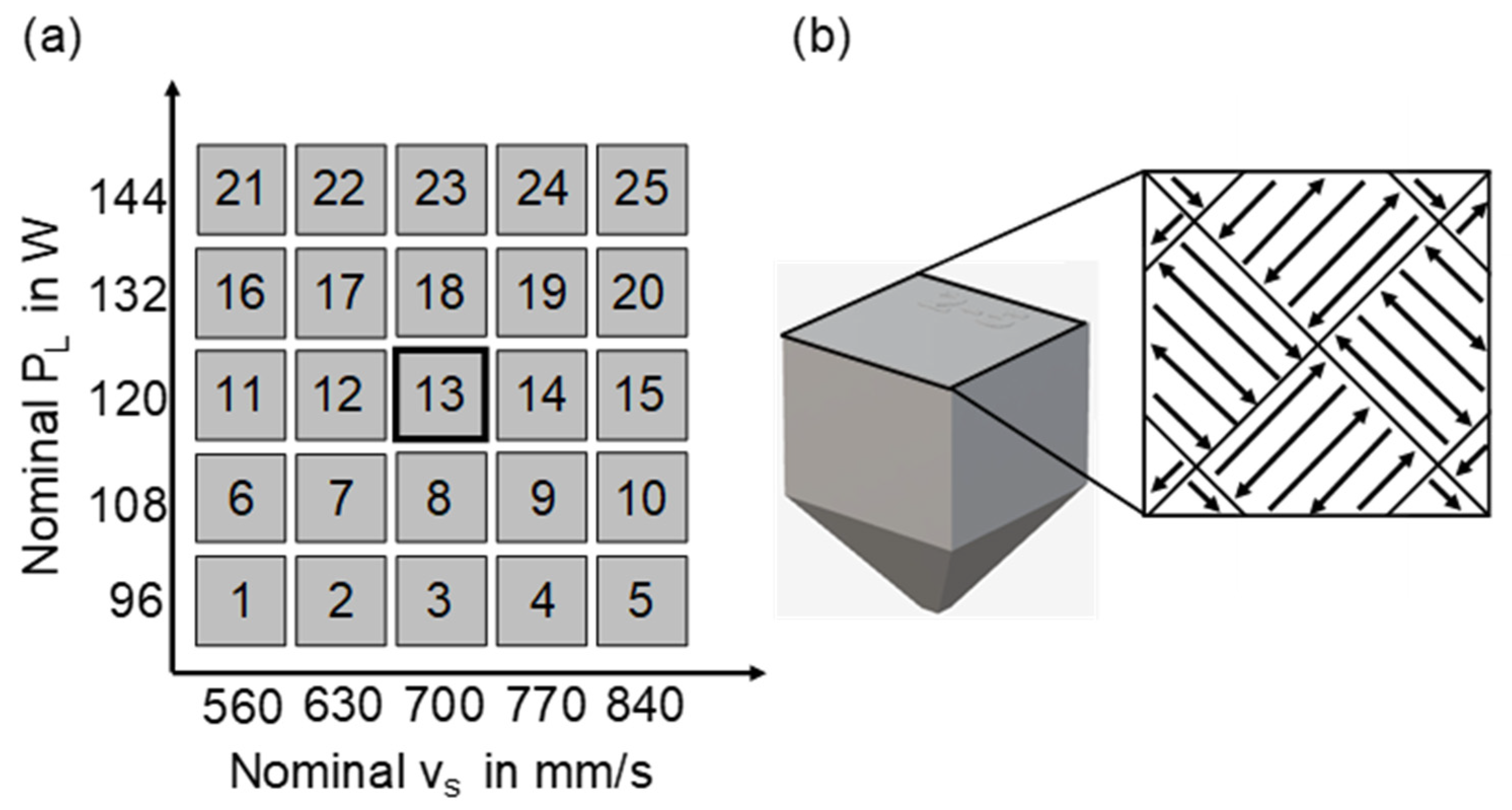

2.4. Process Parameters for Test Samples

3. Results

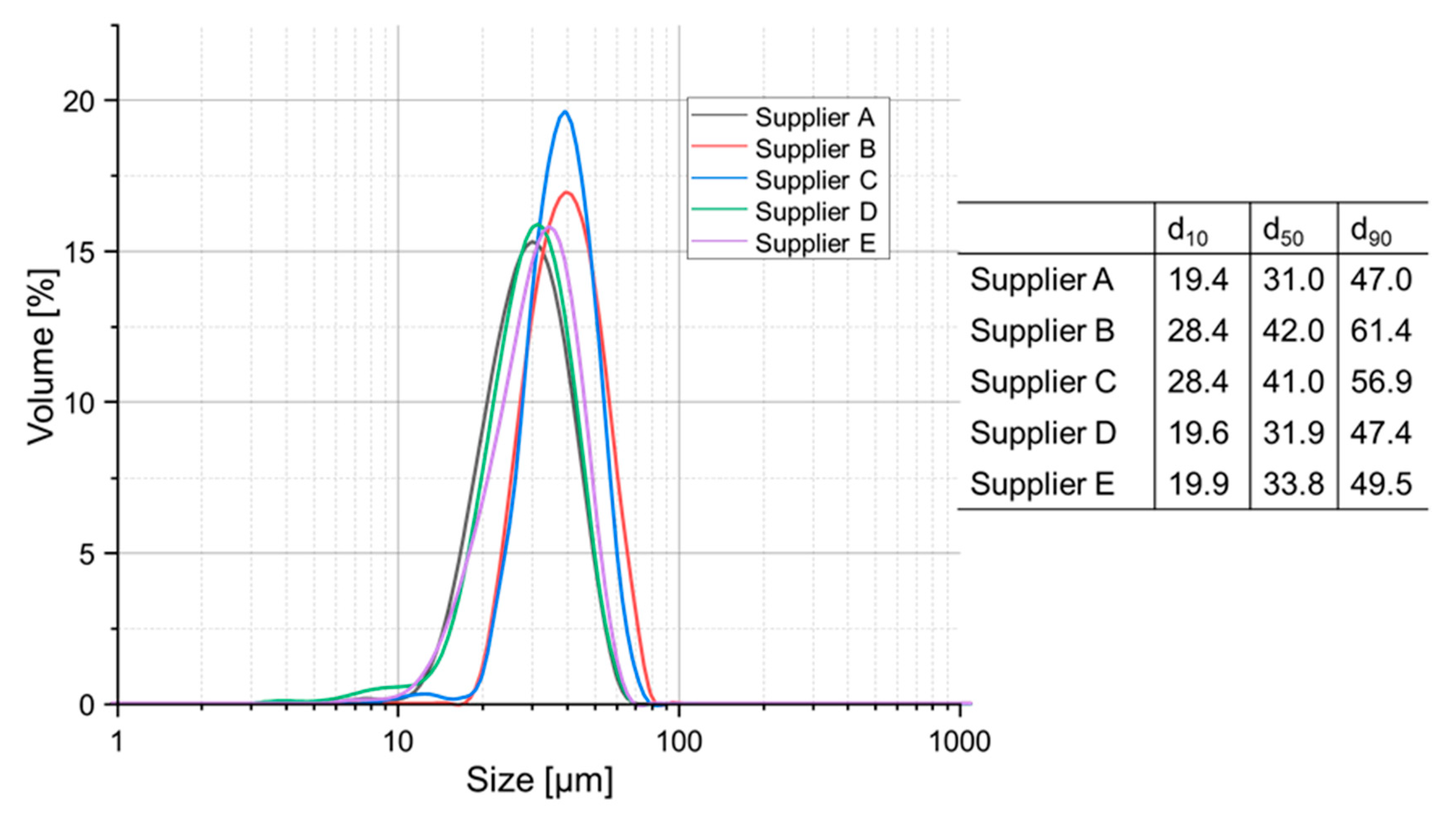

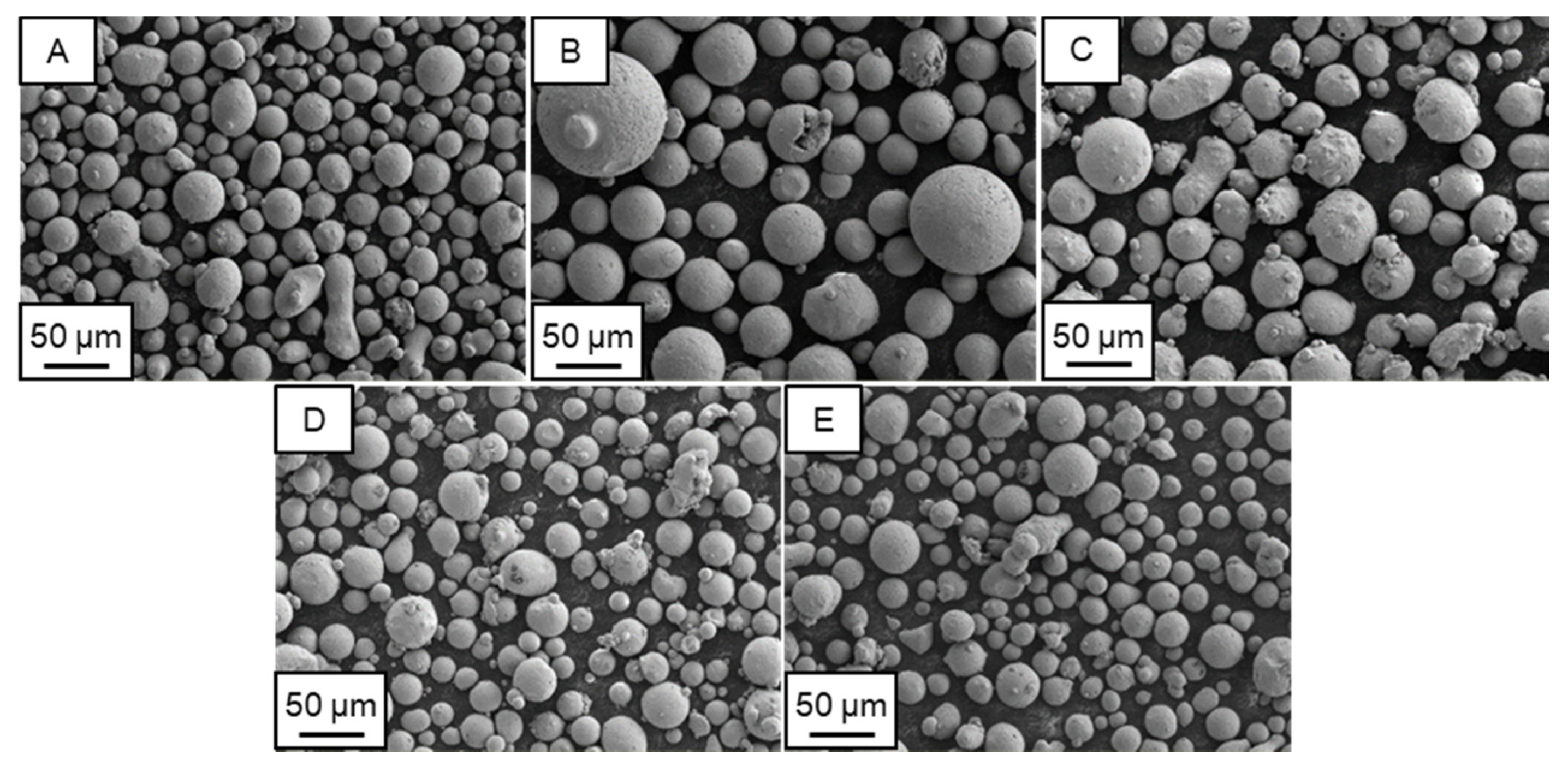

3.1. Particle Size Distribution and Particle Morphology

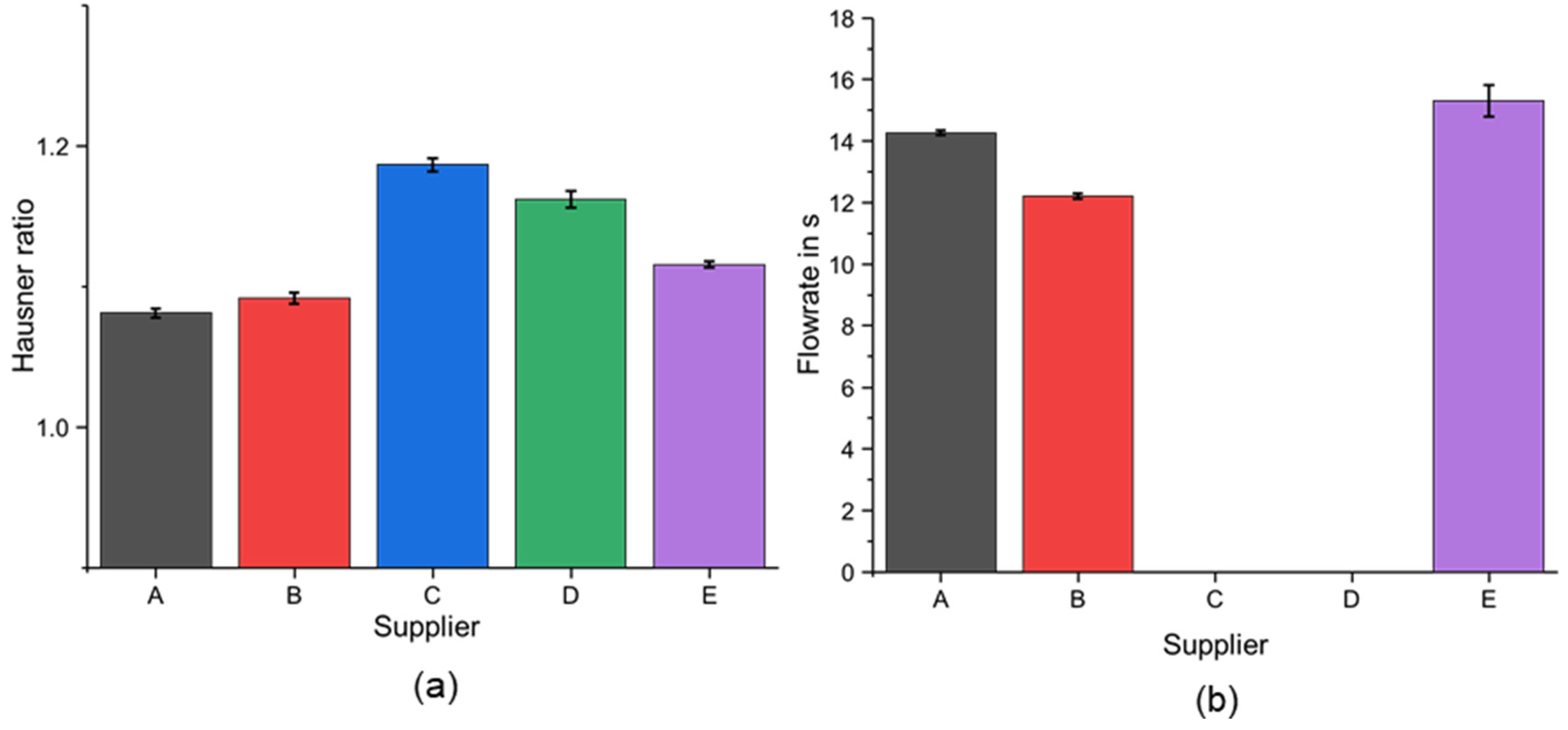

3.2. Flowability

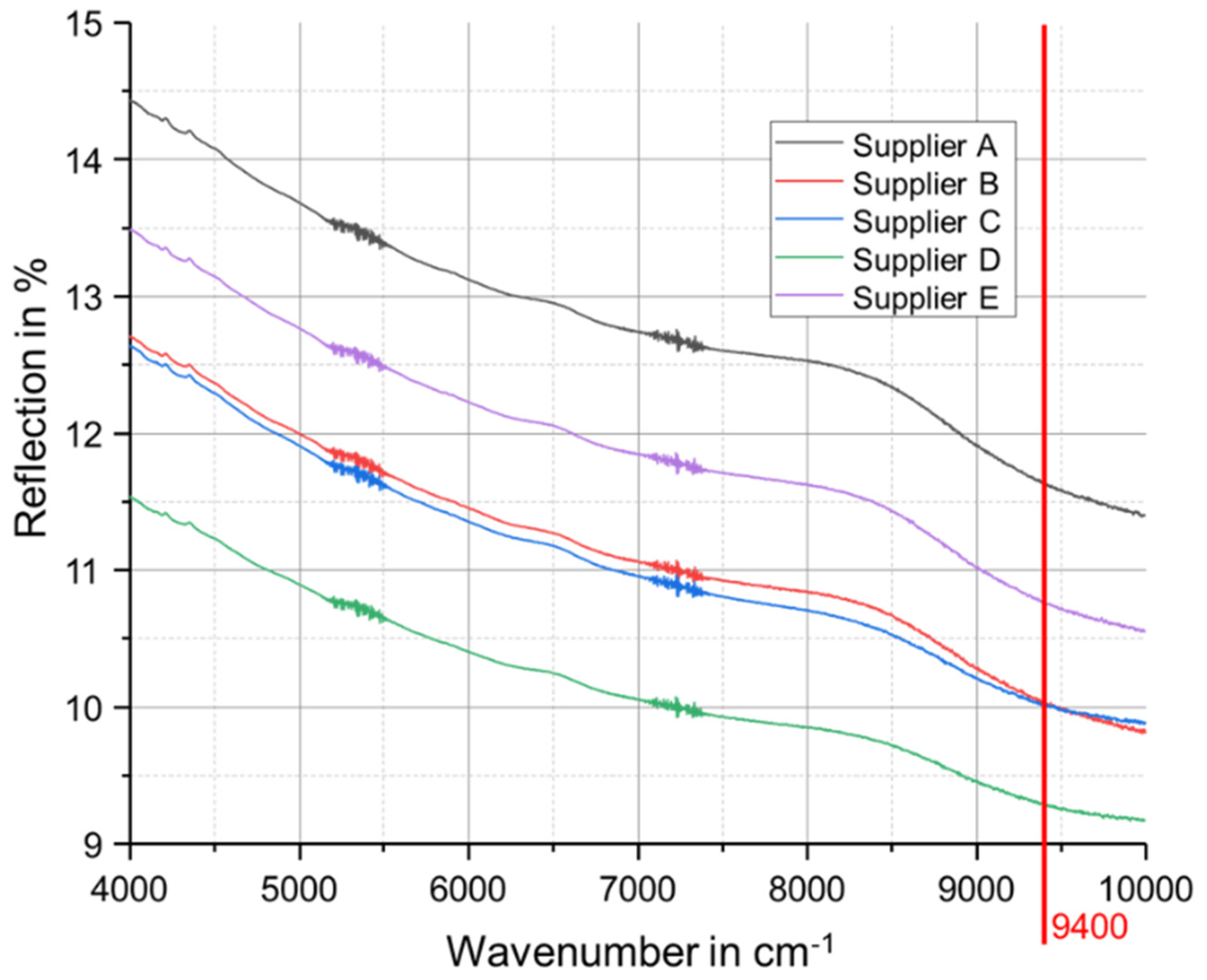

3.3. Absorptivity

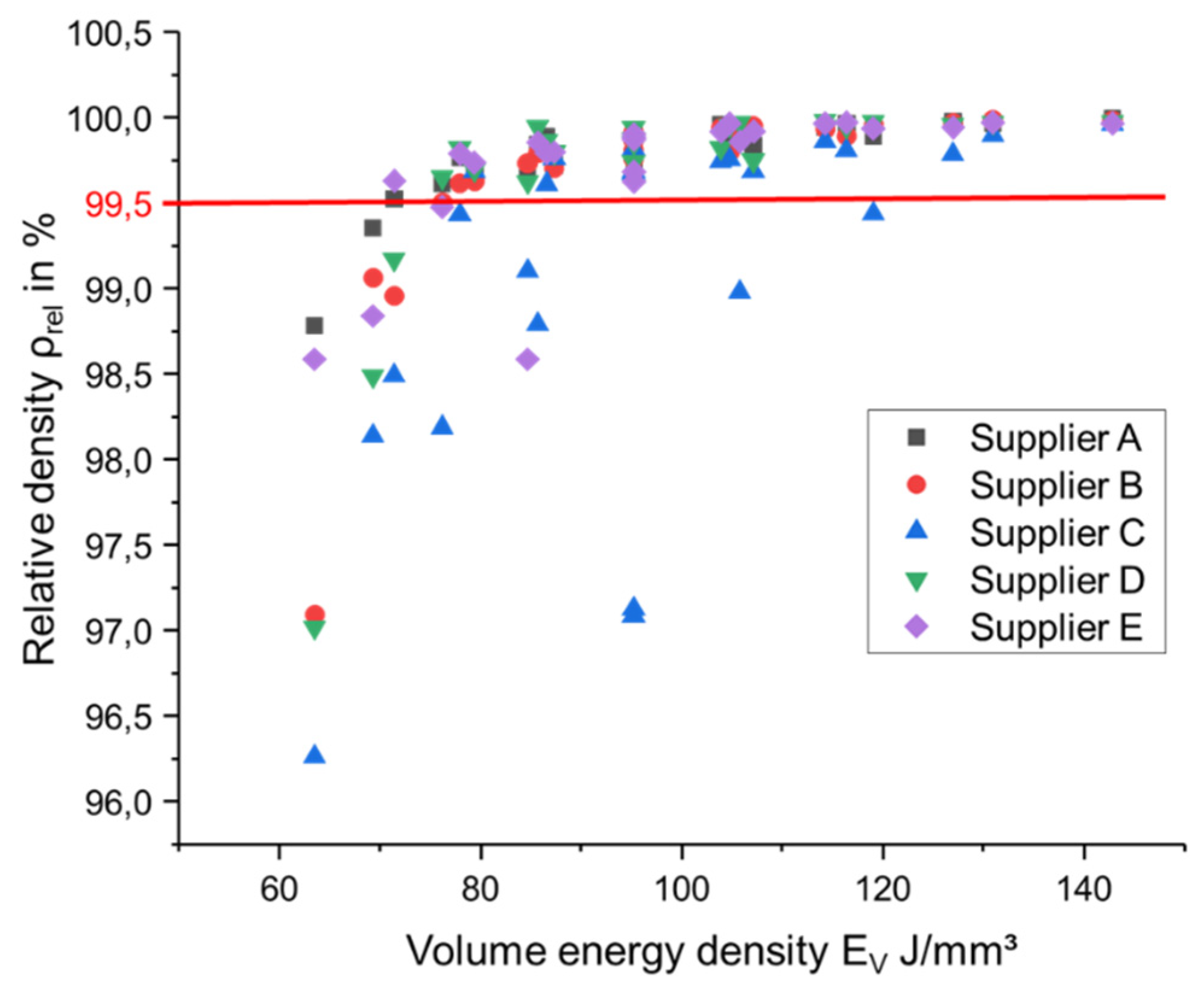

3.4. Relative Density

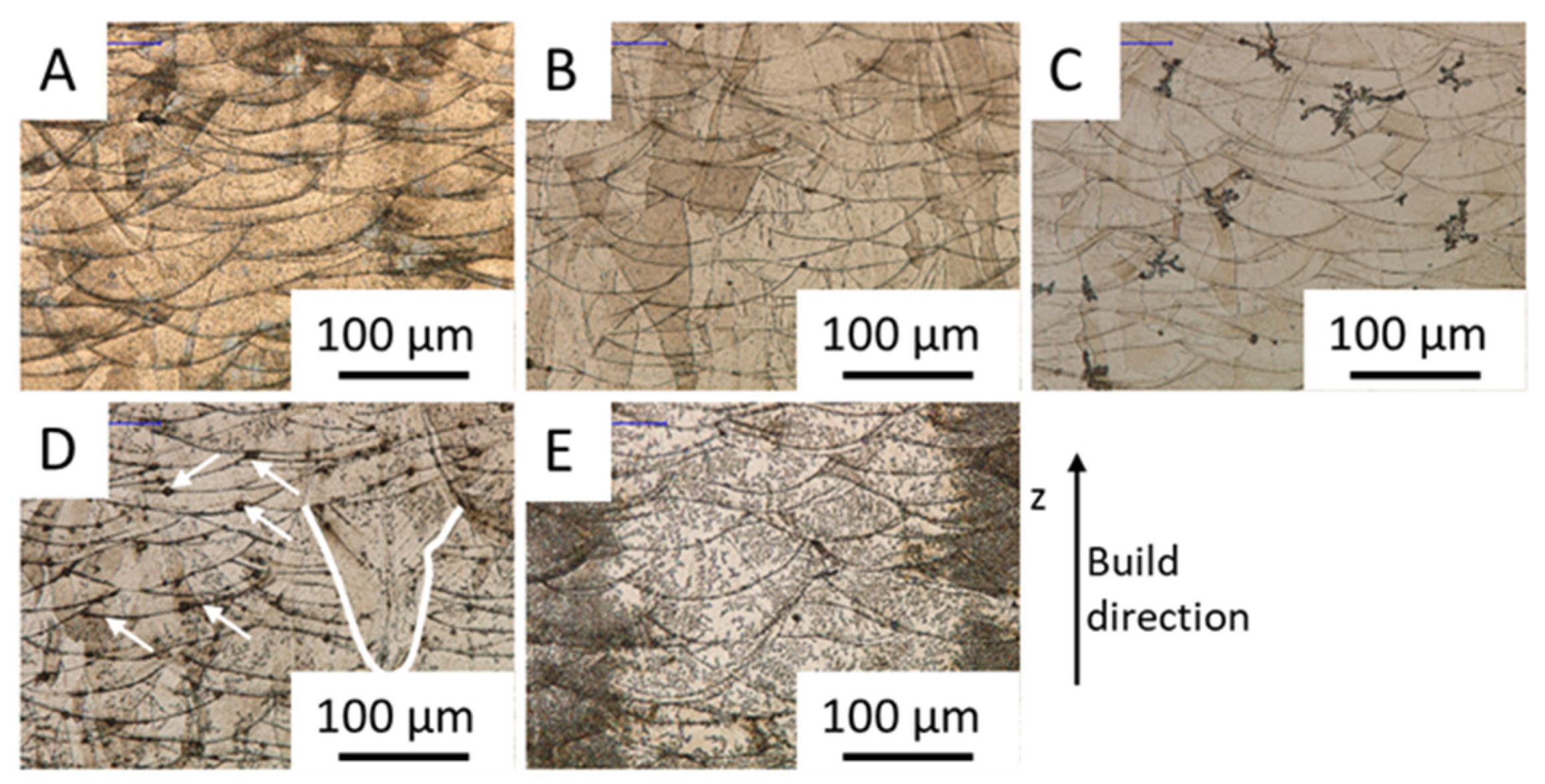

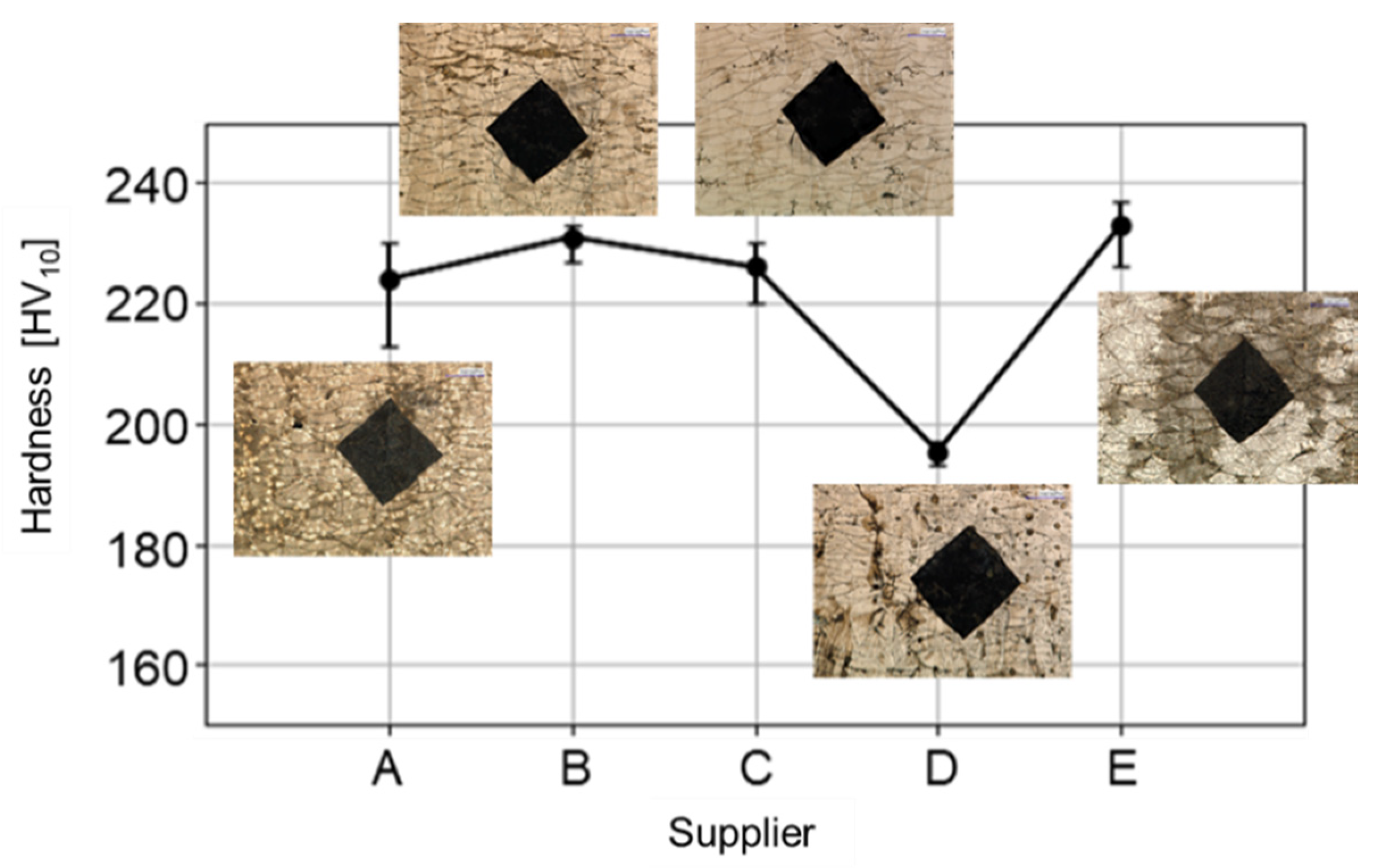

3.5. Microstructure and Hardness Testing

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gebhardt, A. Additive Fertigungsverfahren. In Additive Manufacturing Und 3D-Drucken Für Prototyping-Tooling-Produktion, 5th ed.; Hanser: München, Germany, 2016. [Google Scholar]

- Deutsches Institut für Normung e. V. Additive Manufacturing-General Principles-Terminology; Beuth Verlag GmbH: Berlin, Germany, 2018. [Google Scholar]

- Wohlers, T.T. 3D Printing and Additive Manufacturing State of the Industry; Wohlers Report; WOHLERS Associates: Fort Collins, CO, USA, 2018. [Google Scholar]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 41101. [Google Scholar] [CrossRef]

- Kellens, K.; Yasa, E.; Renaldi, W.; Dewulf, W.; Kruth, J.P.; Duflou, J.R. Energy and Resource Efficiency of SLS/SLM Processes. In Proceedings of the 23rd Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 1–16. [Google Scholar]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf. 2018, 26, 834–845. [Google Scholar] [CrossRef]

- Zhang, B.; Dembinski, L.; Coddet, C. The study of the laser parameters and environment variables effect on mechanical properties of high compact parts elaborated by selective laser melting 316L powder. Mater. Sci. Eng. A 2013, 584, 21–31. [Google Scholar] [CrossRef]

- Sehrt, J.T. Möglichkeiten Und Grenzen Bei Der Generativen Herstellung Metallischer Bauteile Durch Das Strahlschmelzverfahren; Duisburg-Essen University: Duisburg, Germany, 2010. [Google Scholar]

- Yang, Y.; Gu, D.; Dai, D.; Ma, C. Laser energy absorption behavior of powder particles using ray tracing method during selective laser melting additive manufacturing of aluminum alloy. Mater. Des. 2018, 143, 12–19. [Google Scholar] [CrossRef]

- Gu, D.; Yang, Y.; Xi, L.; Yang, J.; Xia, M. Laser absorption behavior of randomly packed powder-bed during selective laser melting of SiC and TiB2 reinforced Al matrix composites. Opt. Laser Technol. 2019, 119, 105600. [Google Scholar] [CrossRef]

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2016, 1, 9–20. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure e. V. VDI 3405 Blatt 2.3. Additive Fertigungsverfahren-Strahlschmelzen Metallischer Bauteile Charakterisierung von Pulverwerkstoffen; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2019. [Google Scholar]

- Zou, R.P.; Yu, A.B. Evaluation of the packing characteristics of mono-sized non-spherical particles. Powder Technol. 1995, 71–79. [Google Scholar] [CrossRef]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Addit. Manuf. 2020, 31, 100929. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Di, W.; Song, C.; Yang, Y.; Bai, Y. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater. Des. 2016, 100, 291–299. [Google Scholar]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. On the characterization of stainless steel 316L parts produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2018, 95, 1953–1974. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Deng, S.; Liao, H.; Coddet, C. Microstructure and tensile properties of iron parts fabricated by selective laser melting. Opt. Laser Technol. 2014, 56, 451–460. [Google Scholar] [CrossRef]

- Yusuf, S.; Chen, Y.; Boardman, R.; Yang, S.; Gao, N. Investigation on Porosity and Microhardness of 316L Stainless Steel Fabricated by Selective Laser Melting. Metals 2017, 7, 64. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Du, M.; Xie, Z. 316L Stainless Steel with Gradient Porosity Fabricated by Selective Laser Melting. J. Mater. Eng. Perform. 2010, 19, 666–671. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wang, Z.; Wang, L.; Liu, J.; Jiang, W. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl. Surf. Sci. 2010, 256, 4350–4356. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, ISEM 2010, Shanghai, China, 19–23 April 2010. [Google Scholar]

- Chen, W.; Yin, G.; Feng, Z.; Liao, X. Effect of Powder Feedstock on Microstructure and Mechanical Properties of the 316L Stainless Steel Fabricated by Selective Laser Melting. Metals 2018, 8, 729. [Google Scholar] [CrossRef]

- Spierings, A.B.; Levy, G. Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades. In Proceedings of the Solid Freeform Fabrication Proceedings, Austin, TX, USA, 3–5 August 2009. [Google Scholar]

- Cooke, A.; Slotwinski, J. Properties of Metal Powders for Additive Manufacturing: A Review of the State of the Art of Metal Powder Property Testing; National Institute of Standards and Technology IR: Washington, DC, USA, 2012; pp. 1–18. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e. V. Nichtrostende Stähle—Teil 1: Verzeichnis Der Nichtrostenden Stähle; Beuth Verlag GmbH: Berlin, Germany, 2014. [Google Scholar]

- Deutsches Institut für Normung e. V. Metallpulver—Ermittlung der Fülldichte; Beuth Verlag GmbH: Berlin, Germany, 2018. [Google Scholar]

- Deutsches Institut für Normung e. V. Metallpulver—Bestimmung der Durchflussrate mit Hilfe Eines Kalibrierten Trichters (Hall flowmeter) (ISO 4490:2018); Beuth Verlag GmbH: Berlin, Germany, 2018. [Google Scholar]

- Meiners, W. Direktes Selektives Laser Sintern Einkomponentiger Metallischer Werkstoffe; Aachen, Technology Hochsch. Diss.: Aachen, Germany, 1999. [Google Scholar]

- Hitzler, L.; Hirsch, J.; Heine, B.; Merkel, M.; Hall, W.; Öchsner, A. On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel. Materials 2017, 10, 1136. [Google Scholar] [CrossRef] [PubMed]

- Schulze, D. Pulver und Schüttgüter. Fließeigenschaften und Handhabung, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

| Element | Fe | Cr | Ni | Si | Mo | Mn | P | S | C |

|---|---|---|---|---|---|---|---|---|---|

| Content in wt.% | bal. | 16.5–18.5 | 10.0–13.0 | max. 1.0 | 2.0–2.5 | max. 2.0 | max. 0.045 | max. 0.015 | max. 0.03 |

| Supplier | A | B | C | D | E |

|---|---|---|---|---|---|

| Pricing | 2.42 | 1 | 1.03 | 1.77 | 1.32 |

| Supplier | A | B | C | D | E |

|---|---|---|---|---|---|

| Sphericity | 0.91 | 0.94 | 0.87 | 0.89 | 0.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pannitz, O.; Sehrt, J.T. Transferability of Process Parameters in Laser Powder Bed Fusion Processes for an Energy and Cost Efficient Manufacturing. Sustainability 2020, 12, 1565. https://doi.org/10.3390/su12041565

Pannitz O, Sehrt JT. Transferability of Process Parameters in Laser Powder Bed Fusion Processes for an Energy and Cost Efficient Manufacturing. Sustainability. 2020; 12(4):1565. https://doi.org/10.3390/su12041565

Chicago/Turabian StylePannitz, Oliver, and Jan T. Sehrt. 2020. "Transferability of Process Parameters in Laser Powder Bed Fusion Processes for an Energy and Cost Efficient Manufacturing" Sustainability 12, no. 4: 1565. https://doi.org/10.3390/su12041565

APA StylePannitz, O., & Sehrt, J. T. (2020). Transferability of Process Parameters in Laser Powder Bed Fusion Processes for an Energy and Cost Efficient Manufacturing. Sustainability, 12(4), 1565. https://doi.org/10.3390/su12041565