Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products

Abstract

1. Introduction

Software and Data Availability

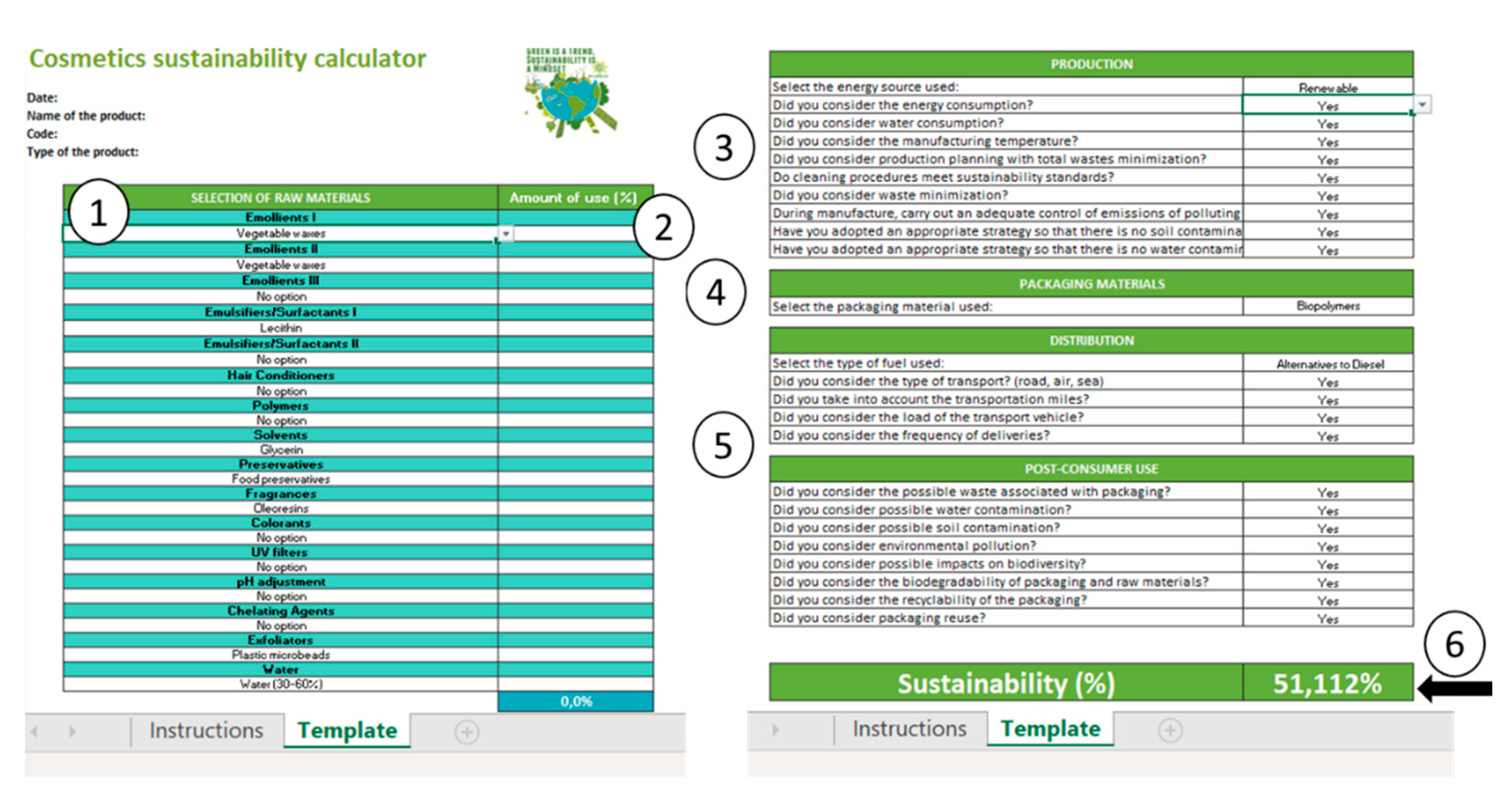

- Select the raw materials to be used in the formulation, among the groups presented*.

- Enter the percentage of each raw material selected.

- Regarding the production, start by selecting the source of energy used and then answer the subsequent questions carefully (selecting yes or no).

- Concerning the packaging materials, select the material chosen.

- In relation to distribution and post-consumer use answer the subsequent questions carefully (selecting yes or no).

- Upon completion, check the % of sustainability of the product.

- In the end, do not forget to reflect about the consumer use phase.

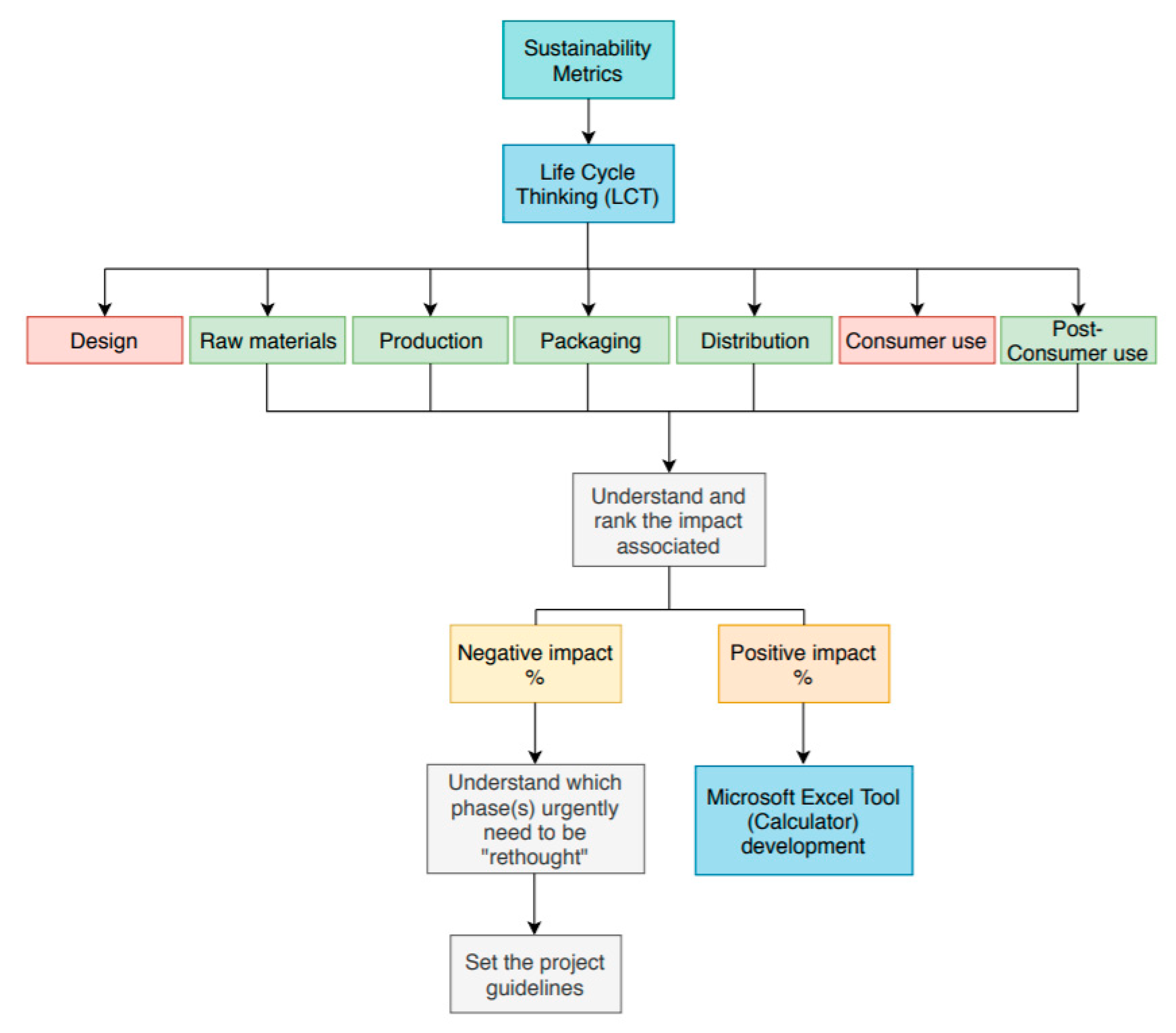

2. Materials and Methods

2.1. Design of Survey

2.2. Data Analysis and Interpretation

2.3. MS Excel Add-in/Workbook—Sustainability Calculator

- Treatment of the data obtained with the survey (exposited on a Microsoft Excel sheet apart);

- Creation of a Microsoft Excel sheet that corresponds to the auxiliary calculations (i.e., application of the Equations (1)–(3) presented below);

- Creation of the template creation; only this Microsoft Excel sheet will be visible to the user, the remaining sheets (1 and 2) will be hidden and protected from user alterations with a password.

- α = Impact of the corresponding phase (%)

- Production phase impact % = 19.6%

- Packaging phase impact % = 20.0%

- Distribution phase impact % = 17.6%

- Post-Consumer use phase impact % = 20.1%

- Data

- Data validation

- Validation criteria: List

- Source: select from the data list

2.4. Proof of Concept

3. Results

3.1. Product Life Cycle

3.1.1. Raw Materials Selection

3.1.2. Production, Packaging, Distribution and Post-Consumer Use

3.2. Sustainability Calculator—Proof of Concept

4. Discussion

4.1. Product Life Cycle

4.1.1. Raw Materials Selection

4.1.2. Production, Packaging, Distribution and Post-Consumer Use

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Bruntland, G.H. Report of the World Commission on Environment and Development: Our Common Future; Oxford University Press: Oslo, Norway, 1987. [Google Scholar]

- Carriço, C.; Ribeiro, H.; Marto, J. Converting cork by-products to ecofriendly cork bioactive ingredients: Novel pharmaceutical and Cosmetics sustainability calculatorapplications. Ind. Crop. Prod. 2018, 125, 72–84. [Google Scholar] [CrossRef]

- Fernandes, A.R.; Eberlin, S.; Foglio, M.A.; Souto, E.B.; Mazzola, P.G.; Marto, J.; Cefali, L.C.; da Silva Gonçalves, F.C.; Ribeiro, H.M.; Ataide, J.A. In vitro SPF and Photostability Assays of Emulsion Containing Nanoparticles with Vegetable Extracts Rich in Flavonoids. AAPS PharmSciTech 2018, 20, 9. [Google Scholar]

- Marto, J.; Neves, Â.; Gonçalves, L.M.; Pinto, P.; Almeida, C.; Simões, S. Rice Water: A Traditional Ingredient with Anti-Aging Efficacy. Cosmetics 2018, 5, 26. [Google Scholar] [CrossRef]

- Marto, J.M.; Gouveia, L.F.; Gonçalves, L.M.D.; Ribeiro, H.M.; Almeida, A.J. Design of minocycline-containing starch nanocapsules for topical delivery. J. Microencapsul. 2018, 35, 1–13. [Google Scholar] [CrossRef]

- Marto, J.; Pinto, P.; Fitas, M.; Gonçalves, L.; Almeida, A.; Ribeiro, H. Safety assessment of starch-based personal care products: Nanocapsules and pickering emulsions. Toxicol. Appl. Pharmacol. 2018, 342, 14–21. [Google Scholar] [CrossRef]

- Ribeiro, H.M.; Allegro, M.; Marto, J.; Pedras, B.; Oliveira, N.G.; Paiva, A.; Barreiros, S.; Gonçalves, L.M.D.; Simões, P.M.C. Converting Spent Coffee Grounds into Bioactive Extracts with Potential Skin Antiaging and Lightening Effects. ACS Sustain. Chem. Eng. 2018, 6, 6289–6295. [Google Scholar] [CrossRef]

- Bom, S.; Jorge, J.; Ribeiro, H.; Marto, J. A step forward on sustainability in the cosmetics industry: A review. J. Clean. Prod. 2019, 225, 270–290. [Google Scholar] [CrossRef]

- Saurat, M.; Ritthoff, M.; Luz, S. Overview of Existing Sustainability Assessment Methods and Tools, and of Relevant Standards; European Union: Brussels, Belgium, 2015. [Google Scholar]

- Pihkola, H.; Pajula, T.; Federley, M.; Myllyoja, J. Sustainability Assessment in the Process Industry—Future Actions and Development Needs; VTT Technical Research Centre of Finland: Brussels, Belgium, 2017. [Google Scholar]

- Srinivasan, R.S.; Braham, W.W.; Campbell, D.E.; Curcija, D.C.; Rinker, M.E. Sustainability Assesstment Frameworks, Evaluation Tools and Metrics for Buildings and its Environment—A Review. In Proceedings of the International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011; pp. 350–357. [Google Scholar]

- Sahota, A. Sustainability: How the Cosmetics Industry Is Greening up, 1st ed.; Sahota, A., Ed.; John Wiley & Sons, Ltd.: London, UK, 2013; ISBN 9781118676516. [Google Scholar]

- Georgalas, A. Are Silicones Safe and Sustainable? What Are the Alternatives? Cosmet. &Toilet.: Northbrook, IL, USA, 2014; p. 129. [Google Scholar]

- Lambert, J. Silicone Safety and the Cosmetic Industry; Cosmet. &Toilet.: Northbrook, IL, USA, 2013. [Google Scholar]

- Loh, X.J. Polymers for Personal Care Products and Cosmetics; Royal Society of Chemistry: Cambridge, UK, 2016; ISBN 978-1-78262-295-6. [Google Scholar]

- Lochhead, R.Y. The Role of Polymers in Cosmetics: Recent Trends. In Cosmetic Nanotechnology—Polymers and Colloids in Cosmetics; Morgan, S., Havelka, K., Lochhead, R., Eds.; ACS Publications: Washington, DC, USA, 2007; pp. 3–56. ISBN 0-8412-3996-7. [Google Scholar]

- Murthy, N.; Wilson, S.; Sy, J. Biodegradation of Polymers. Polym. Sci. A Compr. Ref. 2012, 9, 547–560. [Google Scholar]

- Welton, T. Solvents and sustainable chemistry. Proc. R. Soc. A Math. Phys. Eng. Sci. 2015, 471, 20150502. [Google Scholar] [CrossRef]

- Clarke, C.J.; Tu, W.-C.; Levers, O.; Bröhl, A.; Hallett, J.P. Green and Sustainable Solvents in Chemical Processes. Chem. Rev. 2018, 118, 747–800. [Google Scholar] [CrossRef]

- Byrne, F.P.; Jin, S.; Paggiola, G.; Petchey, T.H.M.; Clark, J.H.; Farmer, T.J.; Hunt, A.J.; McElroy, C.R.; Sherwood, J. Tools and techniques for solvent selection: Green solvent selection guides. Sustain. Chem. Process. 2016, 4, 1034. [Google Scholar] [CrossRef]

- Sansom, C. Solvents and sustainability. Chem. World 2018. Available online: https://www.chemistryworld.com/features/solvents-and-sustainability/3008751.article#/ (accessed on 13 February 2020).

- Kulke, T. Fragrances and Sustainability. Perfum. Flavorist 2015, 40, 16–23. [Google Scholar]

- Panten, J.; Surburg, H.; Panten, J.; Surburg, H. Flavors and Fragrances, 1. General Aspects. Ullmann’s Encycl. Ind. Chem. 2015, 1–9. [Google Scholar]

- Bridges, B. Fragrance: Emerging health and environmental concerns. Flavour Fragr. J. 2002, 17, 361–371. [Google Scholar] [CrossRef]

- Berger, R.G. Flavours and Fragrances: Chemistry, Bioprocessing and Sustainability, 1st ed.; Berger, R.G., Gunter, R., Eds.; Springer: Berlin, Germany, 2007; ISBN 9783540493396. [Google Scholar]

- O’Lenick, A.J.; Matson, E. Comparatively Speaking: Natural vs. Synthetic Fragrance; Cosmet. &Toilet.: Northbrook, IL, USA, 2011. [Google Scholar]

- Georgalas, A. Formulating with Natural Colors; Cosmet. &Toilet.: Northbrook, IL, USA, 2014; Volume 129, p. 68. [Google Scholar]

- Kate, A.T.; Schipper, I.; Kiezebrink, V.; Remmers, M. Beauty and a Beast—Child Labour in India for Sparkling Cars and Cosm.; SOMO: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Janjua, N.; Kongshoj, B.; Andersson, A.-M.; Wulf, H. Sunscreens in human plasma and urine after repeated whole-body topical application. J. Eur. Acad. Dermatol. Venereol 2008, 22, 456–461. [Google Scholar] [CrossRef]

- Sánchez-Quiles, D.; Tovar-Sánchez, A. Are sunscreens a new environmental risk associated with coastal tourism? Environ. Int. 2015, 83, 158–170. [Google Scholar] [CrossRef]

- Radice, M.; Manfredini, S.; Ziosi, P.; Dissette, V.; Buso, P.; Fallacara, A.; Vertuani, S. Herbal extracts, lichens and biomolecules as natural photo-protection alternatives to synthetic UV filters. A systematic review. Fitoterapia 2016, 114, 144–162. [Google Scholar] [CrossRef]

- Lourith, N.; Kanlayavattanakul, M.; Chingunpitak, J. Development of sunscreen products containing passion fruit seed extract. Braz. J. Pharm. Sci. 2017, 53, 53. [Google Scholar] [CrossRef][Green Version]

- Hunt, A. (Ed.) Element Recovery and Sustainability; Green Chemistry Series; Royal Society of Chemistry: Cambridge, UK, 2013; ISBN 978-1-84973-616-9. [Google Scholar]

- Nörtemann, B. Biodegradation of Chelating Agents: EDTA, DTPA, PDTA, NTA, and EDDS. In ACS Symposium Series; Am. Chem. Soc. (ACS): Washington, DC, USA, 2005; Volume 910, pp. 150–170. [Google Scholar]

- Smith, M. Factsheet on Microplastics—NATRUE Position; Nature: Belgium, Brussels, 2017. [Google Scholar]

- Rochman, C.M.; Kross, S.M.; Armstrong, J.B.; Bogan, M.T.; Darling, E.S.; Green, S.J.; Smyth, A.R.; Veríssimo, D. Scientific Evidence Supports a Ban on Microbeads. Environ. Sci. Technol. 2015, 49, 10759–10761. [Google Scholar] [CrossRef]

- Rosney, D. Why Microbeads in Shower Gels are Bad for Marine Life; BBC Newsbeat: London, UK, 2016. [Google Scholar]

- Obrien, J.C.; Torrente-Murciano, L.; Mattia, D.; Scott, J.L. Continuous Production of Cellulose Microbeads via Membrane Emulsification. ACS Sustain. Chem. Eng. 2017, 5, 5931–5939. [Google Scholar] [CrossRef]

- Scudo, A.; Liebmann, B.; Corden, C.; Tyrer, D.; Kreissig, J.; Warwick, O. Intentionally Added Microplastics in Products; Amec Foster Wheeler Environ. & Infrastruct.: London, UK, 2017. [Google Scholar]

| Raw Materials Selected | Qualitative and Quantitative Composition (%) | |

|---|---|---|

| F1 | F2 | |

| Emollients I | Mineral derivatives (20%) | Vegetable waxes (10%) |

| Emollients II | Silicone oils (10%) | Vegetable oils (20%) |

| Emulsifiers/Surfactants | Silicone and PEG emulsifiers (5%) | Lecithin (5%) |

| Hair Conditioners | - | - |

| Polymers | - | - |

| Solvents | Glycerin (3%) | Glycerin (3%) |

| Preservatives | Parabens (1%) | Essential oils (1%) |

| Fragrances | Synthetic fragrance (0.2%) | Oleoresin (0.2%) |

| Pigments | - | - |

| UV filters | - | - |

| pH adjustment | - | - |

| Chelating agents | - | - |

| Exfoliators | - | - |

| Water | 60.8% | 60.8% |

| Parameters | F1 | F2 | |

|---|---|---|---|

| Selection of Raw Materials | Synthetic origin | Vegetable origin | |

| Production | Energy source | Non-renewable | Renewable |

| Remaining parameters | Not taken into account the minimization of possible impacts | Taken into account the minimization of possible impacts | |

| Packaging materials | Plastic/Polymeric materials | Biopolymers or plant-based plastics | |

| Distribution | Fuel type | Diesel | Alternatives to diesel |

| Remaining parameters | Not taken into account the minimization of possible impacts | Taken into account the minimization of possible impacts | |

| Post-consumer use | Not taken into account the minimization of possible impacts | Taken into account the minimization of possible impacts | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bom, S.; Ribeiro, H.M.; Marto, J. Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products. Sustainability 2020, 12, 1437. https://doi.org/10.3390/su12041437

Bom S, Ribeiro HM, Marto J. Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products. Sustainability. 2020; 12(4):1437. https://doi.org/10.3390/su12041437

Chicago/Turabian StyleBom, Sara, Helena Margarida Ribeiro, and Joana Marto. 2020. "Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products" Sustainability 12, no. 4: 1437. https://doi.org/10.3390/su12041437

APA StyleBom, S., Ribeiro, H. M., & Marto, J. (2020). Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products. Sustainability, 12(4), 1437. https://doi.org/10.3390/su12041437