Implications of Green Logistics Management on Sustainable Business and Supply Chain Performance: Evidence from a Survey in the Greek Agri-Food Sector

Abstract

1. Introduction

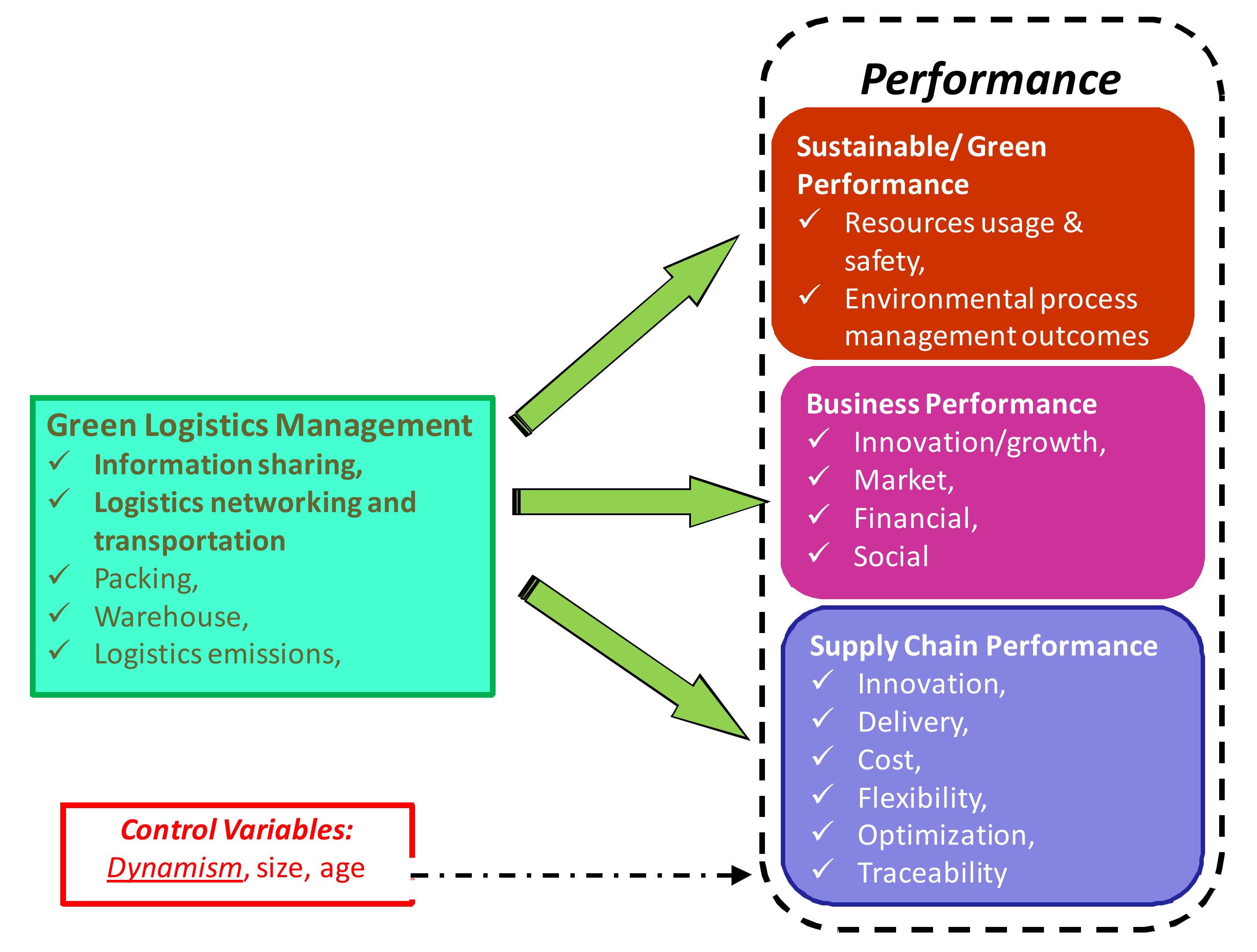

2. Green Logistics/Supply Chain Management Impact to Sustainable Performance

3. Conceptual Framework

4. Research Method

4.1. Sample

4.2. Measurement

5. Statistical Analysis and Results

5.1. Principal Component Analysis

5.2. Multiple Regression Analyses Results

6. Discussion

6.1. Effects of GLM on Business Performance

6.2. Effects of GLM on Green Performance

6.3. Effects of GLM on Supply Chain Performance

6.4. Effects of Control Variables on Performance

7. Conclusions

- (a)

- In particular, logistics networking and transportation as well as information sharing seem to dominate as they are strongly related to three out of four business performance dimensions. Moreover, green packaging is significantly associated with financial and social performance.

- (b)

- Likewise, logistics networking and transportation prevails as it is the only one which is strongly related to both green performance dimensions (resources usage and safety, environmental process management outcomes).

- (c)

- Following a similar pattern, only logistics networking and information sharing are strongly linked to supply chain performance aspects.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Part of Article’s Title | Number of Articles | Number of Articles also Including “Performance” in Their Title |

|---|---|---|

| Green supply chain | 3480 | 593 |

| Green logistics | 1150 | 57 |

| Sustainable supply chain | 2380 | 246 |

| Sustainable logistics | 801 | 24 |

| Total | 7811 | 920 |

| Including also “management” | ||

| Green supply chain management | 1610 | 320 |

| Green logistics management | 86 | 15 |

| Sustainable supply chain management | 1010 | 120 |

| Sustainable logistics management | 74 | 3 |

| Total | 2780 | 458 |

| Year | Authors | Green Logistics (Supply Chain) Management Items (Drivers) | GP | BP | FP | OP | SCP | SP |

|---|---|---|---|---|---|---|---|---|

| 2011 | [69] | Information sharing, Packing, Warehouse, Transportation, Loading/unloading, Logistics networking, Logistics emissions | X | |||||

| 2010 | [135] | Hazardous materials, environmental accidents, technology | X | |||||

| 2011 | [136] | Green supply chain management capabilities, Strategic level of purchasing department, Environment commitment, Green supplier assessment, Collaboration with suppliers | X | X | X | |||

| 2011 | [137] | Eco-design, green purchasing, Green manufacturing capacity, green marketing and consumption, recycling products, processing ability, information, technology | X | |||||

| 2012 | [138] | Green supply Distribution strategies and transportation execution Warehousing and green building Reverse logistics Cooperation with customers’ Investment recovery Eco-design and packaging Internal management | X | X | X | |||

| 2017 | [139] | Intra-organizational environment management, Product eco-design, Green supplier integration, Green customer cooperation, Reverse logistics | X | X | X | X | ||

| 2015 | [140] | Green Procurement, Green Manufacturing, Green Distribution, Green Logistics | X | X | X | |||

| 2019 | [141] | Cost, Time, Quality, Flexibility, Innovation, Resource, Information | X | X | ||||

| 2019 | [142] | Green purchasing, Green Logistics, Green Human Resource Management | X | |||||

| 2018 | [143] | Purchasing, Manufacturing, Warehousing, Distribution, Reverse Logistics, Remanufacturing–Recycling, Green Transportation | X | X | X | |||

| 2014 | [144] | Internal GSCM, GSCM with customers, GSCM with suppliers | X | X | ||||

| 2018 | [145] | Operational attributes, information sharing, collaboration, environmental awareness and attitudes | X | |||||

| 2016 | [146] | Green Design, Green Purchasing, Green Transformation, Green Logistics and Reverse Logistics | X | |||||

| 2019 | [93] | Green purchasing, Green manufacturing, Green distribution, Green packaging, Green marketing, Environmental education, Internal environmental management and investment recovery | X | X | X | |||

| 2018 | [147] | Internal practices, External practices, Investment recovery and eco-design | X | X | X | |||

| 2017 | [148] | Transportation and Warehousing activities | X | X | X | X | ||

| 2018 | [149] | Procurement, Energy | X | |||||

| 2015 | [150] | Environmental criteria for supplier evaluations, environmental management system certification, auditing, environmental information sharing, educational and technical assistance, environmental collaboration | X | X | X | X | ||

| 2018 | [151] | Green purchasing (in bound greening), green manufacturing (focal company), green distribution (out bound greening) and environmentally oriented reverse logistics | X | X | ||||

| 2014 | [152] | Green purchasing and inbound logistics, green manufacturing, green materials management, green distribution/marketing and reverse logistics | X | |||||

| 2018 | [153] | Environmental collaboration, Internal environmental management, Green purchasing, Green production, Cooperation with customers, Eco-design, green logistics, recycling | X | X | ||||

| 2018 | [154] | Internal Environmental Management, Cooperation with customers, Investment Recovery, Eco-design, Supplier selection, Environmental collaboration, Supplier evaluation | X | X | X | |||

| 2012 | [155] | Green Purchase, Customer Cooperation, Investment Recovery | X | X | ||||

| 2018 | [156] | Internal green practices focus on the company-wide green activities concerning mainly the eco-design of internal processes. External green practices focus primarily on green collaboration with suppliers | X | |||||

| 2015 | [157] | Upstream firms (green purchasing, collaboration with suppliers and green design), focal firms (green-related programs), and downstream firms (collaboration with customers, green packaging, green product portfolio and reverse logistics) | X | X | X | X |

References

- Lichtfouse, E.; Navarrete, M.; Debaeke, P.; Souchère, V.; Alberola, C.; Ménassieum, J. Agronomy for Sustainable Agriculture: A Review. In Sustainable Agriculture; Lichtfouse, E., Navarrete, M., Debaeke, P., Véronique, S., Alberola, C., Eds.; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Naseer, M.A.R.; Ashfaq, M.; Hassan, S.; Abbas, A.; Razzaq, A.; Mehdi, M.; Ariyawardana, A.; Anwar, M. Critical Issues at the Upstream Level. In Sustainable Supply Chain Management of Agri-Food Industries: Evidence from Pakistan’s Citrus Industry. Sustainability 2019, 11, 1326. [Google Scholar] [CrossRef]

- Kumar, C.G.; Murugaiyan, P.; Madanmohan, G. Agri-Food Supply Chain Management: Literature Review. Intell. Inf. Manag. 2017, 9, 68–96. [Google Scholar]

- Manikas, I.; Malindretos, G.; Moschouris, S. A community based Agro-food Hub model for sustainable farming. Sustainability 2019, 11, 1017. [Google Scholar]

- Jemai, J.; Chung, B.D.; Sarkar, B. Environmental effect for a complex green supply chain management to control waste: A sustainable approach. J. Clean. Prod. 2020, 277, 122919. [Google Scholar] [CrossRef]

- Kaloxylos, A.A.; Wolfert, J.; Verwaart, T.; Terol, C.M.; Brewster, C.; Robbemond, R.; Sundmakere, H. The Use of Future Internet Technologies in the Agriculture and Food Sectors: Integrating the Supply Chain. Procedia Technol. 2013, 8, 51–60. [Google Scholar] [CrossRef]

- Gennari, P.; Navarro, D.K. The Challenge of Measuring Agricultural Sustainability in All its Dimensions. J. Sustain. Res. 2019, 1, e190013. [Google Scholar]

- Bhattacharya, M.; Paramati, S.R.; Ozturk, I.; Bhattacharya, S. The effect of renewable energy consumption on economic growth: Evidence from top 38 countries. Appl. Energy 2016, 162, 733–741. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Qianli, D. Impact of green supply chain management practices on firms’ performance: An empirical study from the perspective of Pakistan. Environ. Sci. Pollut. Res. 2017, 13, 173–201. [Google Scholar] [CrossRef]

- Tan, B.Q.; Wang, F.; Liu, J.; Kang, K.; Costa, F. A Blockchain-Based Framework for Green Logistics in Supply Chains. Sustainability 2020, 12, 4656. [Google Scholar] [CrossRef]

- Sarkis, J. Strategic Decision Framework for Green Supply Chain Management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Srivastava, S. Green supply-chain management: A state-of the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Tang, S.H.; Zulkifli, N.; Ariffin, M.K.A. An Integrated Framework of Green Supply Chain Management Implementation. Int. J. Innov. Manag. Technol. 2013, 4, 86–89. [Google Scholar]

- Green, J.; Kenneth, W.; Pamela, J.; Zelbst, J.M.; Vikram, S.B. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Machado, V.C. The influence of green practices on supply chain performance: A case study Approach. Transp. Res. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Polychroniou, P.; Trivellas, P. The impact of strong and balanced organizational cultures on firm performance: Assessing moderated effects. Int. J. Qual. Serv. Sci. 2018, 10, 16–35. [Google Scholar] [CrossRef]

- Sarkar, B.; Guchhai, R.; Sarkar, M.; Cárdenas-Barróna, L.E. How does an industry manage the optimum cash flow within a smart production system with the carbon footprint and carbon emission under logistics framework? Int. J. Prod. Econ. 2019, 213, 243–257. [Google Scholar] [CrossRef]

- Lu, M.; Xie, R.; Chen, P.; Zou, Y.; Tang, J. Green Transportation and Logistics Performance: An Improved Composite. Sustainability 2019, 11, 2976. [Google Scholar] [CrossRef]

- Günther, H.; Kannegiesser, M.; Autenrie, N. The role of electric vehicles for supply chain sustainability in the automotive industry. J. Clean. Prod. 2015, 90, 220–233. [Google Scholar] [CrossRef]

- Bonsu, N. Towards a circular and low-carbon economy: Insights from the transitioning to electric vehicles and net zero economy. J. Clean. Prod. 2020, 256, 120659. [Google Scholar] [CrossRef]

- McKinnon, Α. Freight Transport Deceleration: Its Possible Contribution to the Decarbonisation of Logistics. Transp. Rev. 2016, 36, 418–436. [Google Scholar] [CrossRef]

- Raut, R.D.; Narkhede, B.E.; Gardas, B.B.; Raut, V. Multi-criteria decision making approach: A sustainable warehouse location selection problem. Int. J. Manag. Concepts Philos. 2017, 10, 260–281. [Google Scholar] [CrossRef]

- Bogataj, M.; Grubbström, R.W.; Bogataj, L. Efficient location of industrial activity cells in a global supply chain. Int. J. Prod. Econ. 2011, 133, 243–250. [Google Scholar] [CrossRef]

- Sarkar, B.; Majumder, A. A study on three different dimensional facility location problems. Econ. Model. 2013, 30, 879–887. [Google Scholar] [CrossRef]

- Nishitani, K. Demand for ISO 14001 adoption in the global supply chain: An empirical analysis focusing on environmentally conscious markets. Resour. Energy Econ. 2010, 32, 395–407. [Google Scholar] [CrossRef]

- Shahabadkar, P.; Hebbal, S.S.; Prashant, S. Deployment of Interpretive Structural Modeling Methodology in Supply Chain Management—An Overview. Int. J. Ind. Eng. Prod. Res. 2012, 23, 195–205. [Google Scholar]

- Welker, G.A.; Van der Vaart, T.; Van Donk, P.D. The Influence of Business Conditions on Supply Chain Information-Sharing Mechanisms: A Study among Supply Chain links of SMEs. Int. J. Prod. Econ. 2007, 113, 706–720. [Google Scholar] [CrossRef]

- Khurana, M.K.; Mishra, P.K.; Singh, A.R. Barriers to Information Sharing in Supply Chain of Manufacturing Industries. Int. J. Manuf. Syst. 2011, 1, 9–29. [Google Scholar] [CrossRef]

- Malindretos, G.; Aidonis, D.; Folinas, D.; Triantafillou, D. Holistic Value Chain and Sustainability. Potential role of co-operatives 2013. In Proceedings of the ICA Global Research Conference, Cooperatives during crisis and Post-Crisis Period—COOPCY, Nicosia, Cyprus, 12–15 June 2013. [Google Scholar]

- Zhu, Q.; Krikke, H.; Caniëls, M.C.J. Supply chain integration: Value creation through managing inter-organizational learning. Int. J. Oper. Prod. Manag. 2018, 38, 211–229. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, S.T.; Choi, D. Green supply chain management and organizational performance. Ind. Manag. Data Syst. 2012, 112, 1148–1180. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and interorganizational resources: A literature review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar]

- Seuring, S. Supply chain management for sustainable products—Insights from research applying mixed methodologies. Bus. Strategy Environ. 2011, 20, 471–484. [Google Scholar] [CrossRef]

- Ward, P.T.; Duray, R. Manufacturing strategy in context: Environment, competitive strategy and manufacturing strategy. J. Oper. Manag. 2000, 18, 123–138. [Google Scholar] [CrossRef]

- Kristal, M.M.; Huang, X.; Roth, A.V. The effect of an ambidextrous supply chain strategy on combinative competitive capabilities and business performance. J. Oper. Manag. 2010, 28, 415–429. [Google Scholar] [CrossRef]

- Dess, G.G.; Robinson, R.B. Measuring organizational performance in the absence of objective measures: The case of the privately-held firm and conglomerate business unit. Strateg. Manag. J. 1984, 5, 265–273. [Google Scholar] [CrossRef]

- Vickery, S.K.; Droge, C.; Markland, R.E. Dimensions of manufacturing strength in the furniture industry. J. Oper. Manag. 1997, 15, 317–330. [Google Scholar] [CrossRef]

- Ward, P.T.; McCreery, J.K.; Ritzman, L.; Sharma, D. Competitive priorities in operations management. Decis. Sci. 1998, 29, 1035–1046. [Google Scholar] [CrossRef]

- Roth, A.V.; Schroeder, R.G.; Huang, X.; Kristal, M.M. Handbook of Multi-Item Scales for Research in Operations Management; Sage Publications: Thousand Oaks, CA, USA, 2008. [Google Scholar]

- Reklitis, P.; Trivellas, P. Performance Implications of Aligning Generic Strategies with the Business Environment. Int. J. Manag. Decis. Mak. 2002, 3, 319–336. [Google Scholar] [CrossRef]

- Zhen, L.; Routray, J.K. Operational indicators for measuring agricultural sustainability in developing countries. Environ. Manag. 2003, 32, 34–46. [Google Scholar] [CrossRef]

- Lewis, P.; Thomas, H. The linkage between strategy, strategic groups, and performance in the UK retail grocery industry. Strateg. Manag. J. 1990, 11, 385–397. [Google Scholar] [CrossRef]

- Frazier, G.; Howell, R. Business definition and performance. J. Mark. 1983, 47, 59–67. [Google Scholar] [CrossRef]

- Boeker, W. Organizational strategy: An ecological perspective. Acad. Manag. J. 1991, 34, 613–635. [Google Scholar]

- Dess, G.; Davis, P. Porter’s (1980) generic strategies as determinants of strategic group membership and organizational performance. Acad. Manag. J. 1984, 27, 467–488. [Google Scholar]

- Aramyan, L.H.; Lansink, A.G.J.M.O.; Van Kooten, O. Performance measurement in agri-food supply chains: A case study. Supply Chain Manag. 2007, 12, 304–315. [Google Scholar] [CrossRef]

- Gold, S.; Kunz, N.; Reiner, G. Sustainable Global Agrifood Supply Chains: Exploring the Barriers. J. Ind. Ecol. 2016, 21, 249–260. [Google Scholar] [CrossRef]

- Bourlakis, M.; Maglaras, G.; Aktas, E.; Gallear, D.; Fotopoulos, C. Firm size and sustainable performance in food supply chains: Insights from Greek SMEs. Int. J. Prod. Econ. 2014, 152, 112–130. [Google Scholar] [CrossRef]

- Fynes, B.; de Burca, S.; Marshall, D. Environmental uncertainty, supply chain relationship quality and performance. J. Purch. Supply Manag. 2004, 10, 179–190. [Google Scholar] [CrossRef]

- Choi, T.Y.; Eboch, K. The TQM paradox: Relations among TQM practices, plant performance, and customer satisfaction. J. Oper. Manag. 1998, 17, 59–75. [Google Scholar] [CrossRef]

- Fynes, B.; Voss, C. A path analytic model of quality practices, quality performance and business performance. Prod. Oper. Manag. 2001, 10, 494–513. [Google Scholar] [CrossRef]

- Dixon, J.R. Measuring manufacturing flexibility: An empirical investigation. Eur. J. Oper. Res. 1992, 60, 131–143. [Google Scholar] [CrossRef]

- Shao, J.; Moser, R.; Henke, M. Multidimensional supply performance framework: A conceptual development and empirical analysis. Int. J. Prod. Econ. 2012, 138, 26–34. [Google Scholar] [CrossRef]

- Calik, E.; Bardudeen, F. A measurement scale to evaluate sustainable innovation performance in manufacturing organizations. Procedia CIRP 2016, 40, 449–454. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Yang, C.S.; Lu, C.S.; Haider, J.J.; Marlow, P.B. The effect of green supply chain management on green performance and firm competitiveness in the context of container shipping in Taiwan. Transp. Res. 2013, 55, 55–73. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Tsolakis, N.K.; Keramydas, C.A.; Toka, A.K.; Aidonis, D.A.; Iakovou, E.T. Agrifood supply chain management: A comprehensive hierarchical decision-making framework and a critical taxonomy. Biosyst. Eng. 2004, 120, 47–64. [Google Scholar] [CrossRef]

- Dania, W.A.P.; Xing, K.; Amer, Y. Collaboration behavioural factors for sustainable agri-food supply chains: A systematic review. J. Clean. Prod. 2018, 186, 851–864. [Google Scholar] [CrossRef]

- Das, D. Development and validation of a scale for measuring Sustainable Supply Chain Management practices and performance. J. Clean. Prod. 2017, 164, 1344–1362. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. When strategies matter: Adoption of sustainable supply chain management practices in an emerging economy’s context. Resour. Conserv. Recycl. 2018, 138, 194–206. [Google Scholar] [CrossRef]

- Mardani, A.; Streimikiene, D.; Zavadskas, E.K.; Cavallaro, F.; Nilashi, M.; Jusoh, A.; Zare, H. Application of Structural Equation Modeling (SEM) to Solve Environmental Sustainability Problems: A Comprehensive Review and Meta-Analysis. Sustainability 2017, 9, 1814. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and challenges in sustainable supply chain: An operations research perspective. Eur. J. Oper. Res. 2017, 268, 399–431. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Sarkis, J.; Wang, X. Assessing green supply chain practices in the Ghanaian mining industry: A framework and evaluation. Int. J. Prod. Econ. 2016, 181, 325–341. [Google Scholar] [CrossRef]

- Tundys, B.; Wisniewski, T. The Selected Method and Tools for Performance Measurement in the Green Supply Chain—Survey Analysis in Poland. Sustainability 2018, 10, 549. [Google Scholar] [CrossRef]

- Sharma, V.; Chandna, P.; Bhardwaj, A. Green supply chain management related performance indicators in agro industry: A review. J. Clean. Prod. 2016, 141, 1195–1208. [Google Scholar] [CrossRef]

- Luo, J.; Ji, C.; Qiu, C.; Jia, F. Agri-Food Supply Chain Management: Bibliometric and Content Analyses. Sustainability 2018, 10, 1573. [Google Scholar] [CrossRef]

- Choi, Y.; Zhang, N. Does proactive green logistics management improve business performance? A case of Chinese logistics enterprises. Afr. J. Bus. Manag. 2011, 5, 7564–7574. [Google Scholar]

- Choi, Y. Green management of logistics enterprises and its sustainable performance in Korea. Afr. J. Bus. Manag. 2012, 6, 1475–1482. [Google Scholar]

- Kaiser, H.F.; Rice, J. Little Jiffy, Mark IV. Educ. Psychol. Meas. 1974, 34, 111–117. [Google Scholar] [CrossRef]

- Chin, W.W. The partial least squares approach to structural equation modeling. In Modern Methods for Business Research; Marcoulides, G.A., Ed.; Lawrence Erlbaum Assoc. Inc.: Mahwah, NJ, USA, 1998; pp. 295–336. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Nunnally, J.C.; Bernstein, I.H. Psychometric Theory, 3rd ed.; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Bagozzi, R.P.; Yi, Y.; Phillips, L.W. Assessing construct validity in organizational research. Adm. Sci. Q. 1991, 36, 421–458. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P. Being “Green and Competitive”: The Impact of Environmental Actions and Collaborations on Firm Performance. Bus. Strategy Environ. 2013, 24, 142–185. [Google Scholar] [CrossRef]

- Sila, I. Investigating changes in TQM’s effects on corporate social performance and financial performance over time. J. Total Qual. Manag. Bus. Excell. 2020, 31, 210–229. [Google Scholar] [CrossRef]

- Mariano, E.B.; Gobbo, J.A., Jr.; de Castro, C.F.; do Nascimento, R.D.A. CO2 emissions and logistics performance: A composite index proposal. J. Clean. Prod. 2017, 163, 166–178. [Google Scholar] [CrossRef]

- Önder, M. Contribution of Plays and Toys to Children’s Value Education. Asian J. Educ. Train. 2018, 4, 146–149. [Google Scholar] [CrossRef]

- Melander, L.; Pazirandeh, A. Collaboration beyond the supply network for green innovation: Insight from 11 cases. Supply Chain Manag. 2019, 24, 509–523. [Google Scholar] [CrossRef]

- Yunhui, Z.; Ningshuo, Z.; Taiwen, F.; Chuanli, Z.; Jianming, Z. The green spillover effect of green customer integration: Does internal integration matter? Corp. Soc. Responsib. Environ. Manag. 2020, 27, 325–338. [Google Scholar]

- Jermsittiparsert, K.; Sriyakul, T.; Sangperm, N. The Influence of Customer and Technology Supply Chain Integration on Social Sustainable Performance with Moderating Role of Organizational Structure. Int. J. Supply Chain Manag. 2019, 8, 71–82. [Google Scholar]

- Moggi, S.; Bonomi, S.; Ricciardi, F. Against Food Waste: CSR for the Social and Environmental Impact through a Network-Based Organizational Model. Sustainability 2018, 10, 3515. [Google Scholar] [CrossRef]

- Heide, J.B.; Miner, A.S. The shadow of the future: Effects of anticipated interaction and frequency of contact on buyer-seller cooperation. Acad. Manag. J. 1992, 35, 265–291. [Google Scholar] [CrossRef]

- Tae-Sik, R.; Young-Moo, K.; Xiu, J. A Study on the Influence of Reasonable Mobile Task Instruction and Mobile Information Sharing on Employee Job Satisfaction: The Moderating Effect of Self-Efficacy. J. Inst. Internet Broadcast. Commun. 2019, 19, 37–49. [Google Scholar]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N. Sustainable business model and supply chain conceptions—Towards an integrated perspective. In Implementing Triple Bottom Line Sustainability into Global Supply Chains; Bals, L., Tate, W., Eds.; Greenleaf: Sheffield, UK, 2016; pp. 337–363. [Google Scholar]

- Reklitis, P.; Trivellas, P.; Mantzaris, I.; Mantzari, E.; Reklitis, D. Employee Perceptions of Corporate Social Responsibility Activities and Work-Related Attitudes: The Case of a Greek Management Services Organization. In Sustainability and Social Responsibility: Regulation and Reporting, 1st ed.; Gal, G., Akisik, O., Wooldridge, W., Eds.; Springer: Singapore, 2018; pp. 225–240. [Google Scholar] [CrossRef]

- Reklitis, P.; Fotiadis, A.; Trivellas, P. Emotional Exhaustion and Perceived Corporate Social Responsibility: A Case Study of a Port Logistics Organization. Springer Proceedings in Business and Economics; Sakas, D., Nasiopoulos, D., Eds.; Springer: Cham, Switzerland, 2019; pp. 17–24. [Google Scholar] [CrossRef]

- Reklitis, P.; Fotiadis, A.; Trivellas, P. Perceived Corporate Social Responsibility and Job Satisfaction in a Port Logistics Organization. Springer Proceedings in Business and Economics; Sakas, D., Nasiopoulos, D., Eds.; Springer: Cham, Switzerland, 2019; pp. 9–16. [Google Scholar] [CrossRef]

- Huang, Y.-S.; Hung, J.-S.; Ho, J.-W. A study on information sharing for supply chains with multiple suppliers. Comput. Ind. Eng. 2017, 104, 114–123. [Google Scholar] [CrossRef]

- Guan, Z.; Zhang, X.; Zhou, M.; Dan, Y. Demand information sharing in competing supply chains with manufacturer-provided service. Int. J. Prod. Econ. 2020, 220, 107450. [Google Scholar] [CrossRef]

- Çankaya, S.Y.; Sezen, B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- García-Arca, J.; Garrido, A.; Prado-Prado, J.C. “Sustainable Packaging Logistics”. The link between Sustainability and Competitiveness in Supply Chains. Sustainability 2017, 9, 1098. [Google Scholar] [CrossRef]

- Rundh, B. The role of packaging within marketing and value creation. Br. Food J. 2016, 118, 2491–2511. [Google Scholar] [CrossRef]

- Vernuccio, M.; Cozzolino, A.; Michelin, I.L. An exploratory study of marketing, logistics, and ethics in packaging innovation. Eur. J. Innov. Manag. 2010, 13, 333–354. [Google Scholar] [CrossRef]

- Nordin, N.; Selke, S. Social aspect of sustainable packaging. Packag. Technol. Sci. 2010, 23, 317–326. [Google Scholar] [CrossRef]

- Ni, W.; Sun, H. The effect of sustainable supply chain management on business performance: Implications for integrating the entire supply chain in the Chinese manufacturing sector. J. Clean. Prod. 2019, 232, 1176–1186. [Google Scholar] [CrossRef]

- Recanati, F.; Marveggio, D.; Dotelli, G. From beans to bar: A life cycle assessment towards sustainable chocolate supply chain. Sci. Total Environ. 2018, 613, 1013–1023. [Google Scholar] [CrossRef]

- Rebolledo-Leiva, R.; Angulo-Meza, L.; Iriarte, A.; Gonzalez-Araya, M.C. Joint carbon footprint assessment and data envelopment analysis for the reduction of greenhouse gas emissions in agriculture production. Sci. Total Environ. 2017, 593, 36–46. [Google Scholar] [CrossRef] [PubMed]

- Miranda-Ackerman, M.A.; Azzaro-Pantel, C.; Aguilar-Lasserre, A.A. A green supply chain network design framework for the processed food industry: Application to the orange juice agrofood cluster. Comput. Ind. Eng. 2017, 109, 369–389. [Google Scholar] [CrossRef]

- Sherafati, M.; Bashiri, M.; Tavakkoli-Moghaddam, R.; Pishvaee, M.S. Supply chain network design considering sustainable development paradigm: A case study in cable industry. J. Clean. Prod. 2019, 234, 366–380. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, Z.; Wang, H.; Yi, Y.; Zhang, Y. Optimization of monitoring network system for Eco safety on Internet of Things platform and environmental food supply chain. Comput. Commun. 2020, 151, 320–330. [Google Scholar] [CrossRef]

- Nordmark, I.; Ljungberg, D.; Gebresenbet, G.; Bosona, T.; Jüriado, R. Integrated Logistics Network for the Supply Chain of Locally Produced Food, Part II: Assessment of E-Trade, Economic Benefit and Environmental Impact. J. Serv. Sci. Manag. 2012, 5. [Google Scholar] [CrossRef]

- Geiger, C. ICT in Green Freight Logistics. In Green Transportation Logistics: The Quest for Win-Win Solutions; Psaraftis, H.N., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 205–241. [Google Scholar]

- Al-Odeh, M.; Smallhood, J. Sustainable Supply Chain Management: Literature Review, Trends, and Framework. Int. J. Comput. Eng. Manag. 2012, 15, 85–90. [Google Scholar]

- Vance, L.; Heckl, I.; Bertok, B.; Cabezas, H.; Friedler, F. Designing sustainable energy supply chains by the P-graph method for minimal cost, environmental burden, energy resources input. J. Clean. Prod. 2015, 94, 144–154. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Baron, R.A.; Tang, J. The role of entrepreneurs in firm-level innovation: Joint effects of positive affect, creativity, and environmental dynamism. J. Bus. Ventur. 2011, 26, 49–60. [Google Scholar] [CrossRef]

- Kim, M.; Chai, S. The impact of supplier innovativeness, information sharing and strategic sourcing on improving supply chain agility: Global supply chain perspective. Int. J. Prod. Econ. 2017, 187, 42–52. [Google Scholar] [CrossRef]

- Marinagi, C.; Trivellas, P.; Reklitis, P. Information Quality and Supply Chain Performance: The Mediating Role of Information Sharing. Procedia Soc. Behav. Sci. 2015, 175, 473–479. [Google Scholar] [CrossRef]

- Raweewana, Μ.; Ferrell, W.G., Jr. Information sharing in supply chain collaboration. Comput. Ind. Eng. 2018, 126, 269–281. [Google Scholar] [CrossRef]

- Liu, H.; Ke, W.; Wei, K.K.; Hua, Z. Effects of supply chain integration and market orientation on firm performance: Evidence from China. Int. J. Oper. Prod. Manag. 2013, 33, 322–346. [Google Scholar] [CrossRef]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Bagchi, P.K.; Skjøtt-Larsen, T. Supply chain integration: A European survey. Int. J. Logist. Manag. 2005, 16, 275–294. [Google Scholar] [CrossRef]

- Fabbe-Costes, N.; Jahre, M. Supply chain integration improves performance: The Emperor’s new suit? Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 835–855. [Google Scholar] [CrossRef]

- Karippacheril, T.G.; Rios, L.D.; Srivastava, L. Global Markets, Global Challenges: Improving Food Safety and Traceability While Empowering Smallholders through ICT. In Agriculture (Updated Edition): Connecting Smallholders to Knowledge, Networks, and Institutions; World Bank Group: Washington, DC, USA, 2017. [Google Scholar] [CrossRef]

- Stajniak, M.J.; Koliński, A. The Impact of Transport Processes Standardization on Supply Chain Efficiency. Sci. J. Logist. 2016, 12, 37–46. [Google Scholar]

- Prashar, D.; Jha, N.; Jha, S.; Lee, Y.; Joshi, G.P. Blockchain-Based Traceability and Visibility for Agricultural Products: A Decentralized Way of Ensuring Food Safety in India. Sustainability 2020, 12, 3497. [Google Scholar] [CrossRef]

- Lahkani, M.J.; Wang, S.; Urbański, M.; Egorova, M. Sustainable B2B E-Commerce and Blockchain-Based Supply Chain Finance. Sustainability 2020, 12, 3968. [Google Scholar] [CrossRef]

- Mukherjee, S.; Carter, C.; Koh, S.C.L. Blockchain Disruption in Transport; Working paper; Catapult Transport Systems and The University of Sheffield: Milton Keynes, UK, 2018. [Google Scholar] [CrossRef]

- Pournader, M.; Shi, Y.; Seuring, S.; Koh, S.C.L. Blockchain applications in supply chains, transport and logistics: A systematic review of the literature. Int. J. Prod. Res. Spec. Issue Blockchain Transp. Logist. 2020, 58, 2063–2081. [Google Scholar] [CrossRef]

- Koh, S.C.L.; Dolgui, A.; Sarkis, J. Blockchain in transport and logistics—Paradigms and transitions. Int. J. Prod. Res. Spec. Issue Blockchain Transp. Logist. 2020, 58, 2054–2062. [Google Scholar] [CrossRef]

- Cingoz, A.; Akdogan, A.A. Strategic flexibility, environmental dynamism, and innovation performance: An empirical study. Procedia Soc. Behav. Sci. 2013, 99, 582–589. [Google Scholar] [CrossRef]

- Malindretos, G.; Tsiboukas, K.; Argyropoulou-Konstantaki, S. Sustainable wine supply chain and entrepreneurship. The exploitation of by-products in a waste management process. Int. J. Bus. Sci. Appl. Manag. 2016, 11, 34–46. [Google Scholar]

- Hill, W.L.C.; Jones, G.R. Strategic Management: An Integrated Approach, 8th ed.; Houghton Mifflin Company: Boston, MA, USA, 2008. [Google Scholar]

- Wu, W.Y.; Nguyen, P.T. The Antecedents of Dynamiv Service Innovation Capabilities: The Moderating Roles of Market Dynamism and Market Orientation. Int. J. Innov. Manag. 2019, 1950066. [Google Scholar] [CrossRef]

- Talib, M.S.A.; Sawari, S.S.M.; Hamid, A.B.; Chin, T.A. Emerging Halal food market: An Institutional Theory of Halal certificate implementation. Manag. Res. Rev. 2016, 39, 987–997. [Google Scholar] [CrossRef]

- Guzi, M.; Pedraza, P.P. A web survey analysis of subjective well-being. Int. J. Manpow. 2015, 36, 48–67. [Google Scholar] [CrossRef]

- Dickerson, A.; Green, F. Fears and realisations of employment insecurity. Labour Econ. 2012, 19, 198–210. [Google Scholar] [CrossRef]

- Chiffoleau, Y.; Dourian, T. Sustainable Food Supply Chains: Is Shortening the Answer? A Literature Review for a Research and Innovation Agenda. Sustainability 2020, 12, 9831. [Google Scholar] [CrossRef]

- Pérez-Mesa, J.C.; Piedra-Muñoz, L.; García-Barranco, M.C.; Giagnocavo, C. Response of Fresh Food Suppliers to Sustainable Supply Chain Management of Large European Retailers. Sustainability 2019, 11, 3885. [Google Scholar] [CrossRef]

- Kamblea, S.S.; Gunasekaranb, A.; Gawankarc, S.A. Achieving sustainable performance in a data-driven agriculture supply chain: A review for research and applications. Int. J. Prod. Econ. 2020, 219, 179–194. [Google Scholar] [CrossRef]

- Tian, X.; Sarkis, J. Expanding green supply chain performance measurement through emergy accounting and analysis. Int. J. Prod. Econ. 2020, 225, 107576. [Google Scholar] [CrossRef]

- Wu, G.C.; Cheng, Y.H.; Huang, S.Y. The study of knowledge transfer and green management performance in green supply chain management. Afr. J. Bus. Manag. 2010, 4, 44–48. [Google Scholar]

- Large, R.O.; Thomsen, C.G. Drivers of Green Supply Chain Management Performance: Evidence from Germany. J. Purch. Supply Manag. 2011, 17, 176–184. [Google Scholar] [CrossRef]

- Li, Y. Research on the Performance Measurement of Green Supply Chain Management in China. J. Sustain. Dev. 2011, 4, 101. [Google Scholar] [CrossRef]

- Perotti, S.; Zorzini, M.; Enrico, B.; Guido, C.; Micheli, J.L. Green supply chain practices and company performance: The case of 3PLs in Italy. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 640–672. [Google Scholar] [CrossRef]

- Geng, R.; Mansouri, S.A.; Aktas, E. The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies. Int. J. Prod. Econ. 2017, 183, 245–258. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z. Green Supply Chain Management. Environmental Collaboration and Sustainability Performance. Proc. CIRP 2015, 26, 695–699. [Google Scholar] [CrossRef]

- Tundys, B.; Fernando, Y. Sustainable Supply Chain Management-Key Performance Indicators (KPIs) as an element for measuring of processes. Transp. Econ. Transp. Serv. Mark. 2019, 83, 31–50. [Google Scholar]

- Jermsittiparsert, K.; Siriattakul, P.; Wattanapongphasuk, S. Determining the Environmental Performance of Indonesian SMEs influence by Green Supply Chain Practices with Moderating Role of Green HR Practices. Int. J. Supply Chain Manag. 2019, 8, 59–70. [Google Scholar]

- Yu, Z.; Golpîra, H.; Khan, S.A.R. The relationship between Green Supply Chain Performance, Energy Demand, Economic Growth and Environmental Sustainability: An Empirical Evidence from Developed Countries. LogForum 2018, 14, 479–494. [Google Scholar] [CrossRef]

- Yu, W.; Feng, M.; Wiengarten, F. Integrated green supply chain management and operational performance. Supply Chain Manag. 2014, 19, 683–696. [Google Scholar] [CrossRef]

- Ibrahim, I.; Jamil, N.A.; Halin, I.A. Green Enterprise Resource Planning and Green Logistics Performance. The SIJ Transactions on Industrial. Financ. Bus. Manag. 2018, 6, 1–6. [Google Scholar]

- Uygun, O.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Mumtaz, U.; Ali, Y.; Petrillo, A. A linear regression approach to evaluate the green supply chain management impact on industrial organizational performance. Sci. Total Environ. 2018, 624, 162–169. [Google Scholar] [CrossRef]

- Makmor, M.F.M.; Saad, M. Leadership and Management Commitment towards Logistics Performance Improvement in Malaysia with the Adoption of Green Logistics as the Moderating variable. Int. J. Acad. Res. Bus. Soc. Sci. 2017, 7, 2222–6990. [Google Scholar] [CrossRef]

- Chrisostom, A.O.; Monari, F. Influence Green Logistics Management on Performance of registered Automotive Firms in Kenya. Int. J. Acad. Res. Bus. Soc. Sci. 2018, 8, 351–365. [Google Scholar] [CrossRef]

- Lee, S.-Y. The effects of green supply chain management on the supplier’s performance through social capital accumulation. Supply Chain Manag. 2015, 20, 42–55. [Google Scholar] [CrossRef]

- Achuora, J. Effect of Green Supply Chain Management Practices on the performance of manufacturing firms in Kenya. Glob. Sci. J. 2018, 6, 669–862. [Google Scholar]

- Muma, B.O.; Nyaoga, R.B.; Matwere, R.B.; Nyambega, E. Green supply chain management and environmental performance among tea processing firms in Kericho County-Kenya. Int. J. Econ. Financ. Manag. Sci. 2014, 2, 270–276. [Google Scholar] [CrossRef]

- Aslam, H.; Rashid, K.; Wahla, A.R.; Tahira, U. Drivers of Green Supply Chain Management Practices and their Impact on Firm Performance: A Developing Country Perspective. J. Quant. Methods 2018, 2, 87–111. [Google Scholar] [CrossRef]

- Foo, P.-Y.; Lee, V.H.; Tan, G.W.-H.; Ooi, K.-B. A gateway to realising sustainability performance via green supply chain management practices: A PLS–ANN approach. Expert Syst. Appl. 2018, 107, 1–14. [Google Scholar] [CrossRef]

- Chan, R.Y.K.; He, H.; Chan, H.K.; Wang, W.Y.C. Environmental orientation and corporate performance: The mediation mechanism of green supply chain management and moderating effect of competitive intensity. Ind. Mark. Manag. 2012, 41, 621–630. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.; Zhang, S.; Zhao, X. Effects of customer and cost drivers on green supply chain management practices and environmental performance. J. Clean. Prod. 2018, 189, 673–682. [Google Scholar] [CrossRef]

- Kuei, C.H.; Madu, C.N.; Chow, W.S.; Chen, Y. Determinants and associated performance improvement of green supply chain management in China. J. Clean. Prod. 2015, 95, 163–173. [Google Scholar] [CrossRef]

| Green Logistics Management Items (Drivers) | Items Group |

|---|---|

| 1. Green packing materials | Packing |

| 2. Packing material amount | |

| 3. Information sharing with manufacturing firms and retailers | Information sharing |

| 4. Efficient and accurate ordering system | |

| 5. Reduction of warehouse fee | Warehouse |

| 6. Location selection of warehouse | |

| 7. Greenhouse gas (GHG) | Logistics emissions |

| 8. Adoption of green technologies to save resources | |

| 9. Pollution emissions in logistics activities | |

| 10. Standardization of transport | Logistics networking and Transport |

| 11. Optimization of vehicles’ routing | |

| 12. Greener vehicles—transport modes | |

| 13. Loading and unloading safety | |

| 14. Unit load to improve efficiency | |

| 15. Logistics networking | |

| 16. Information technology design and use at the logistics network |

| Business Performance KPIs | ΚPIs Group | Indicative Literature |

|---|---|---|

| 1. Sales volume | Market performance | Dess and Robinson [36] Vickery et al. [37] Ward et al. [38] Roth et al. [39] Reklitis and Trivellas [40] Polychroniou and Trivellas [16] Zhen and Routray [41] Lewis and Thomas [42] Frazier and Howell [43] Boeker [44] Dess and Davis [45] Green et al. [14] Aramyan et al. [46] Gold et al. [47] Bourlakis et al. [48] |

| 2. Sales growth | ||

| 3. Market share | ||

| 4. Market share growth | ||

| 5. Firm’s reputation | ||

| 6. Profit margin | Financial performance | |

| 7. Return on Equity (ROE) | ||

| 8. Return on Investment (ROI) | ||

| 9. Net Profits | ||

| 10. New product development | Innovation/ growth performance | |

| 11. New market entrance | ||

| 12. Innovativeness and Quality | ||

| 13. Employee satisfaction | Social performance | |

| 14. Corporate Social Responsibility |

| Supply Chain Performance KPIs | ΚPIs Group | Indicative Literature |

|---|---|---|

| 1. Innovation development with suppliers | Supply Chain Innovation | Fynes et al. [49] Choi and Eboch [50] Fynes and Voss [51] Dixon [52] Shao et al. [53] Aramyan et al. [46] Gold et al. [47] Bourlakis et al. [48] |

| 2. Innovation identification within the supply base | ||

| 3. Speed of delivery relative to competitors | Delivery | |

| 4. Percentage of orders delivered on-time. | ||

| 5. Unit cost of product relative to competitors. | Cost | |

| 6. Unit cost of product over life cycle | ||

| 7. Volume flexibility | Flexibility | |

| 8. Variety (product line) flexibility | ||

| 9. Inventory optimization | Optimization | |

| 10. Cash management optimization | ||

| 11. Tracking/feedback systems’ efficiency | Traceability |

| Green Performance KPIs | ΚPIs Group | Indicative Literature |

|---|---|---|

| 1. Energy consumption | Resources usage and safety | Calik and Bardudeen [54] Zhu et al. [55] Green et al. [14] Aramyan et al. [46] Gold et al. [47] Bourlakis et al. [48] |

| 2. Water consumption | ||

| 3. Restrain usage of dangerous/hazardous materials | ||

| 4. Environmental accidents | ||

| 5. Carbon dioxide emissions | ||

| 6. Novelty in environmental issues relative to competitors | Environmental process management performance | |

| 7. Waste management | ||

| 8. Environmental performance in transportation process (e.g., lower fuel consumption) |

| Items (KMO = 0.891) | GLM1 2 | GLM2 | GLM3 | GLM4 | GLM5 |

|---|---|---|---|---|---|

| 1. Green packing materials | 0.669 | ||||

| 2. Packing material amount | 0.847 | ||||

| 3. Information sharing with manufacturing firms and retailers | 0.821 | ||||

| 4. Efficient and accurate ordering system | 0.829 | ||||

| 5. Reduction of warehouse fee | 0.820 | ||||

| 6. Location selection of warehouse | 0.789 | ||||

| 7. Greenhouse gas (GHG) | 0.715 | ||||

| 8. Adoption of green technologies to save resources | 0.773 | ||||

| 9. Pollution emissions in logistics activities | 0.678 | ||||

| 10. Standardization of transport | 0.689 | ||||

| 11. Optimization of vehicles’ routing | 0.840 | ||||

| 12. Greener vehicles—transport modes | 0.680 | ||||

| 13. Loading and unloading efficiently | 0.741 | ||||

| 14. Unit load to improve efficiency | 0.653 | ||||

| 15. Logistics networking | 0.810 | ||||

| 16. Information technology design and use at the logistics network | 0.715 | ||||

| Eigenvalues | 4.202 | 2.573 | 2.006 | 1.966 | 1.711 |

| Variance explained (%) | 26.26 | 16.08 | 12.54 | 12.29 | 10.69 |

| Cumulative variance explained (%) | 26.26 | 42.35 | 54.88 | 67.17 | 77.86 |

| Cronbach’s alpha | 0.904 | 0.841 | 0.751 | 0.820 | 0.704 |

| Composite Reliability (CR) | 0.891 | 0.766 | 0.786 | 0.810 | 0.735 |

| Average Variance Extracted (AVE) | 0.541 | 0.523 | 0.647 | 0.681 | 0.582 |

| Items (KMO = 0.822) | BP1 2 | BP2 | BP3 | BP4 |

|---|---|---|---|---|

| 1. Sales volume | 0.877 | |||

| 2. Sales growth | 0.730 | |||

| 3. Market share | 0.781 | |||

| 4. Market share growth | 0.859 | |||

| 5. Firm’s reputation | 0.661 | |||

| 6. Profit margin | 0.771 | |||

| 7. ROE | 0.814 | |||

| 8. ROI | 0.697 | |||

| 9. Net Profits | 0.901 | |||

| 10. New product development | 0.792 | |||

| 11. New market entrance | 0.814 | |||

| 12. Innovativeness and Quality | 0.869 | |||

| 13. Employee satisfaction | 0.880 | |||

| 14. Corporate Social Responsibility | 0.842 | |||

| Eigenvalues | 3.543 | 2.976 | 2.474 | 1.779 |

| Variance explained (%) | 25.31 | 21.26 | 17.67 | 12.71 |

| Cumulative variance explained (%) | 25.31 | 46.57 | 64.24 | 76.94 |

| Cronbach’s alpha | 0.893 | 0.862 | 0.852 | 0.741 |

| Composite Reliability (CR) | 0.889 | 0.875 | 0.865 | 0.852 |

| Average Variance Extracted (AVE) | 0.617 | 0.639 | 0.682 | 0.742 |

| Items (KMO = 0.793) | SC1 2 | SC2 | SC3 | SC4 | SC5 | SC6 |

|---|---|---|---|---|---|---|

| 1. Innovation development with suppliers | 0.889 | |||||

| 2. Innovation identification within the supply base | 0.895 | |||||

| 3. Speed of delivery relative to competitors | 0.885 | |||||

| 4. Percentage of orders delivered on-time. | 0.882 | |||||

| 5. Unit cost of product relative to competitors. | 0.895 | |||||

| 6. Unit cost of product over life cycle | 0.734 | |||||

| 7. Volume flexibility | 0.694 | |||||

| 8. Variety (product line) flexibility | 0.883 | |||||

| 9. Inventory optimization | 0.758 | |||||

| 10. Cash management optimization | 0.850 | |||||

| 11. Tracking/feedback systems’ efficiency | 0.928 | |||||

| Eigenvalues | 2.066 | 1.860 | 1.745 | 1.678 | 1.290 | 1.093 |

| Variance explained (%) | 18.78 | 16.91 | 15.87 | 15.26 | 11.72 | 9.94 |

| Cumulative variance explained (%) | 18.78 | 35.69 | 51.56 | 66.81 | 78.54 | 88.48 |

| Cronbach’s alpha | 0.910 | 0.846 | 0.782 | 0.800 | 0.740 | - |

| Composite Reliability (CR) | 0.886 | 0.877 | 0.801 | 0.771 | 0.786 | - |

| Average Variance Extracted (AVE) | 0.796 | 0.780 | 0.670 | 0.631 | 0.649 | - |

| Items (KMO = 0.740) | GP1 2 | GP2 |

|---|---|---|

| 1. Energy consumption | 0.843 | |

| 2. Water consumption | 0.773 | |

| 3. Restrain usage of dangerous/hazardous materials | 0.607 | |

| 4. Environmental accidents | 0.824 | |

| 5. Carbon dioxide emissions | 0.827 | |

| 6. Novelty in environmental issues relative to competitors | 0.937 | |

| 7. Waste management | 0.608 | |

| 8. Improving environmental performance in transportation (e.g., lower fuel consumption) | 0.876 | |

| Eigenvalues | 3.260 | 2.286 |

| Variance explained (%) | 40.75 | 28.58 |

| Cumulative variance explained (%) | 40.75 | 69.33 |

| Cronbach’s alpha | 0.847 | 0.784 |

| Composite Reliability (CR) | 0.884 | 0.856 |

| Average Variance Extracted (AVE) | 0.608 | 0.672 |

| Items (KMO = 0.847) | DYN |

|---|---|

| 1. The rate of innovation of new products and services | 0.794 |

| 2. The rate of change of tastes and preferences of customers | 0.841 |

| 3. The rate of change of distribution channels | 0.824 |

| 4. The rate of change of suppliers | 0.730 |

| Eigenvalues | 2.549 |

| Variance explained (%) | 63.74 |

| Cronbach’s alpha | 0.802 |

| Composite Reliability (CR) | 0.875 |

| Average Variance Extracted (AVE) | 0.637 |

| Variable 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. GL_IS | 0.825 | ||||||||||||||||

| 2. GL_pck | 0.486 ** | 0.763 | |||||||||||||||

| 3. GL_Net | 0.426 ** | 0.301 ** | 0.735 | ||||||||||||||

| 4. GL_emi | 0.470 ** | 0.479 ** | 0.615 ** | 0.723 | |||||||||||||

| 5. GL_war | 0.376 ** | 0.342 ** | 0.569 ** | 0.580 ** | 0.805 | ||||||||||||

| 6. E_dyn | 0.365 ** | 0.295 ** | 0.225 * | 0.274 ** | 0.205 * | 0.798 | |||||||||||

| 7. BP_inn | 0.301 ** | 0.253 ** | 0.410 ** | 0.402 ** | 0.371 ** | 0.339 ** | 0.826 | ||||||||||

| 8. BP_mrk | 0.306 ** | 0.148 | 0.325 ** | 0.307 ** | 0.402 ** | 0.134 | 0.480 ** | 0.786 | |||||||||

| 9. BP_fina | 0.330 ** | 0.155 | 0.309 ** | 0.151 | 0.148 | 0.175 | 0.482 ** | 0.541 ** | 0.799 | ||||||||

| 10. BP_soci | 0.480 ** | 0.295 ** | 0.406 ** | 0.420 ** | 0.404 ** | 0.062 | 0.266 ** | 0.339 ** | 0.210 * | 0.861 | |||||||

| 11. GP_rus | 0.047 | 0.018 | 0.215 * | 0.008 | 0.098 | 0.244 ** | 0.244 ** | 0.209 * | 0.382 ** | −0.088 | 0.780 | ||||||

| 12. GP_ems | 0.222 * | 0.246 ** | 0.507 ** | 0.471 ** | 0.274 ** | 0.262 ** | 0.451 ** | 0.213 * | 0.414 ** | 0.173 | 0.521 ** | 0.820 | |||||

| 13. SC_inn | 0.407 ** | 0.274 ** | 0.395 ** | 0.322 ** | 0.123 | 0.233 * | 0.603 ** | 0.209 * | 0.413 ** | 0.360 ** | 0.103 | 0.275 ** | 0.892 | ||||

| 14. SC_deli | 0.481 ** | 0.290 ** | 0.460 ** | 0.476 ** | 0.417 ** | 0.320 ** | 0.429 ** | 0.338 ** | 0.270 ** | 0.381 ** | 0.177 | 0.461 ** | 0.335 ** | 0.884 | |||

| 15. SC_cost | 0.417 ** | 0.210 * | 0.339 ** | 0.173 | 0.198 * | 0.333 ** | 0.264 ** | 0.211 * | 0.392 ** | 0.088 | 0.288 ** | 0.456 ** | 0.334 ** | 0.407 ** | 0.818 | ||

| 16. SC_flex | 0.421 ** | 0.241 ** | 0.255 ** | 0.189 * | 0.214 * | 0.225 * | 0.374 ** | 0.298 ** | 0.435 ** | 0.231 * | 0.203 * | 0.365 ** | 0.408 ** | 0.387 ** | 0.590 ** | 0.794 | |

| 17. SC_opti | 0.474 ** | 0.238 ** | 0.444 ** | 0.298 ** | 0.220 * | 0.202 * | 0.512 ** | 0.269 ** | 0.442 ** | 0.377 ** | 0.136 | 0.296 ** | 0.671 ** | 0.479 ** | 0.463 ** | 0.516 ** | 0.805 |

| 18. SC_trac 2 | 0.248 ** | 0.172 | 0.410 ** | 0.292 ** | 0.343 ** | 0.215 * | 0.310 ** | 0.396 ** | 0.159 | 0.342 ** | 0.112 | 0.299 ** | 0.296 ** | 0.353 ** | 0.312 ** | 0.397 ** | 0.469 ** |

| Mean | 5.24 | 5.19 | 5.22 | 5.41 | 5.63 | 5.19 | 5.32 | 5.32 | 4.68 | 5.77 | 3.73 | 4.74 | 4.86 | 5.83 | 5.06 | 5.13 | 5.50 |

| STD | 1.029 | 1.189 | 1.080 | 1.227 | 1.157 | 1.018 | 1.291 | 1.077 | 1.106 | 1.114 | 1.433 | 1.317 | 1.287 | 0.957 | 1.054 | 1.042 | 0.874 |

| Dependent Variables | ||||||

|---|---|---|---|---|---|---|

| Independent Variables | BP1 2 | BP2 | BP3 | BP4 | GP1 | GP2 |

| Control variables | ||||||

| Firm’s age | 0.086 | 0.044 | −0.038 | 0.097 | 0.138 | 0.041 |

| Firm’s size | 0.421 ** | 0.134 | 0.172 | 0.134 | −0.008 | −0.014 |

| Environmental Dynamism | −0.076 | 0.024 | 0.204 * | −0.195 * | 0.209 | 0.164 |

| Green Supply Chain Management | ||||||

| Information sharing | 0.225 * | 0.239 * | 0.112 | 0.343 *** | −0.103 | −0.134 |

| Logistics emissions | −0.051 | −0.231 | 0.039 | −0.033 | −0.250 | 0.207 |

| Warehouse | 0.111 | −0.050 | 0.133 | 0.058 | 0.058 | −0.117 |

| Packing | 0.174 | 0.236 * | 0.021 | 0.278 * | 0.073 | 0.118 |

| Logistics networking and transportation | 0.065 | 0.301 * | 0.298 ** | 0.207 * | 0.324 * | 0.423 *** |

| Adjusted-R2 | 0.387 *** | 0.244 ** | 0.347 *** | 0.418 *** | 0.224 ** | 0.318 *** |

| Dependent Variables | ||||||

|---|---|---|---|---|---|---|

| Independent Variables | SC1 2 | SC2 | SC3 | SC4 | SC5 | SC6 |

| Control variables | ||||||

| Firm’s age | −0.134 | −0.135 | −0.079 | 0.068 | −0.118 | −0.090 |

| Size | 0.088 | 0.117 | −0.123 | 0.026 | 0.025 | 0.312 * |

| Environmental Dynamism | 0.042 | 0.139 | 0.236 * | 0.068 | 0.022 | 0.079 |

| Green Supply Chain Management | ||||||

| Information sharing | 0.281 * | 0.256 * | 0.301 ** | 0.343 ** | 0.337 ** | 0.018 |

| Logistics emissions | 0.076 | 0.171 | −0.135 | −0.156 | −0.049 | −0.091 |

| Warehouse | −0.219 | 0.124 | 0.065 | 0.024 | −0.048 | 0.057 |

| Packing | 0.054 | −0.081 | −0.010 | 0.191 | 0.014 | 0.116 |

| Logistics networking and transportation | 0.318 * | 0.124 | 0.261 * | 0.108 | 0.342 ** | 0.298 * |

| Adjusted-R2 | 0.285 *** | 0.357 *** | 0.326 *** | 0.233 ** | 0.308 *** | 0.259 *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trivellas, P.; Malindretos, G.; Reklitis, P. Implications of Green Logistics Management on Sustainable Business and Supply Chain Performance: Evidence from a Survey in the Greek Agri-Food Sector. Sustainability 2020, 12, 10515. https://doi.org/10.3390/su122410515

Trivellas P, Malindretos G, Reklitis P. Implications of Green Logistics Management on Sustainable Business and Supply Chain Performance: Evidence from a Survey in the Greek Agri-Food Sector. Sustainability. 2020; 12(24):10515. https://doi.org/10.3390/su122410515

Chicago/Turabian StyleTrivellas, Panagiotis, Georgios Malindretos, and Panagiotis Reklitis. 2020. "Implications of Green Logistics Management on Sustainable Business and Supply Chain Performance: Evidence from a Survey in the Greek Agri-Food Sector" Sustainability 12, no. 24: 10515. https://doi.org/10.3390/su122410515

APA StyleTrivellas, P., Malindretos, G., & Reklitis, P. (2020). Implications of Green Logistics Management on Sustainable Business and Supply Chain Performance: Evidence from a Survey in the Greek Agri-Food Sector. Sustainability, 12(24), 10515. https://doi.org/10.3390/su122410515