Properties of Wood Particleboards Containing Giant Reed (Arundo donax L.) Particles

Abstract

1. Introduction

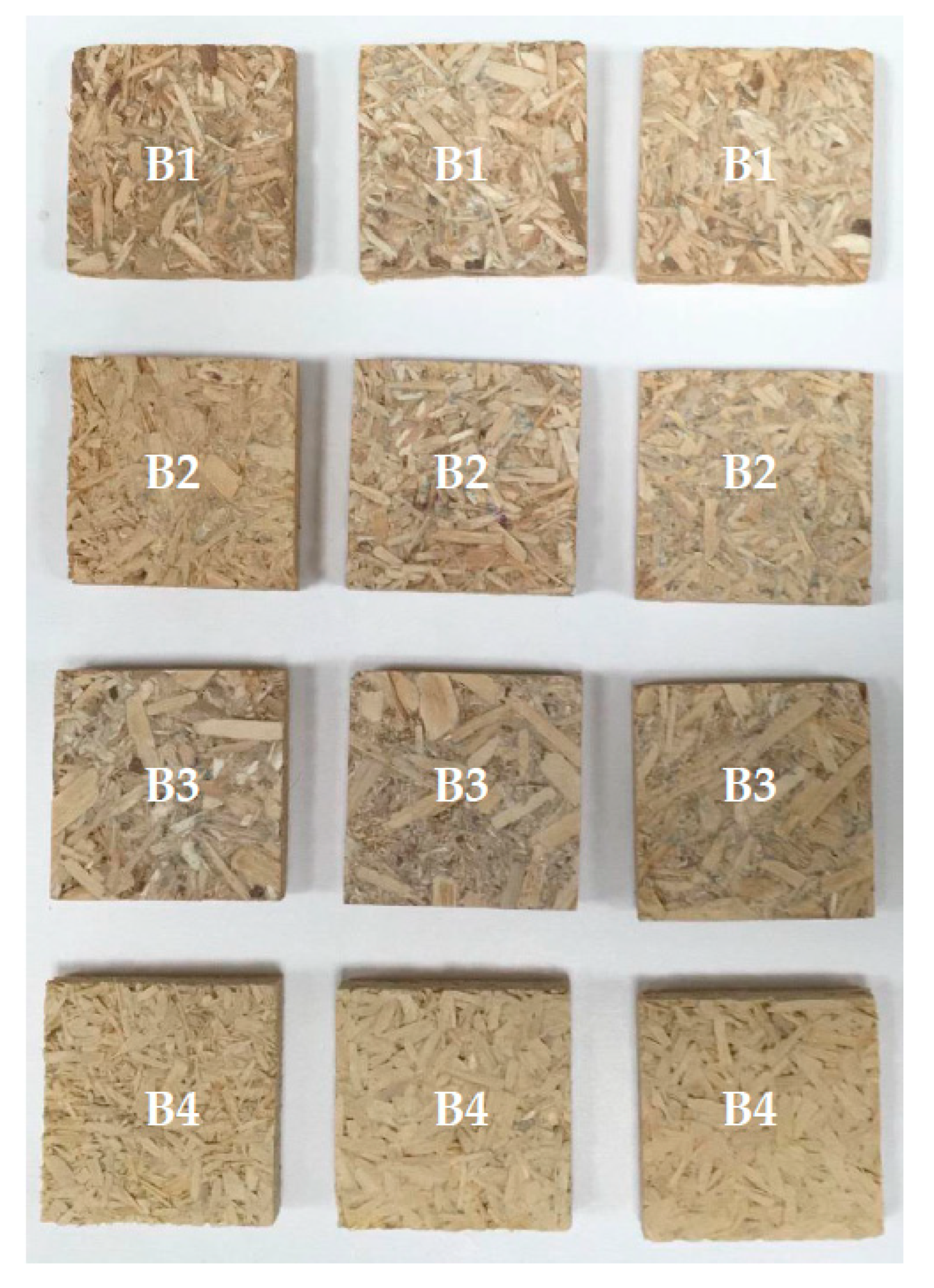

2. Materials and Methods

3. Results and Discussion

3.1. Physical Properties

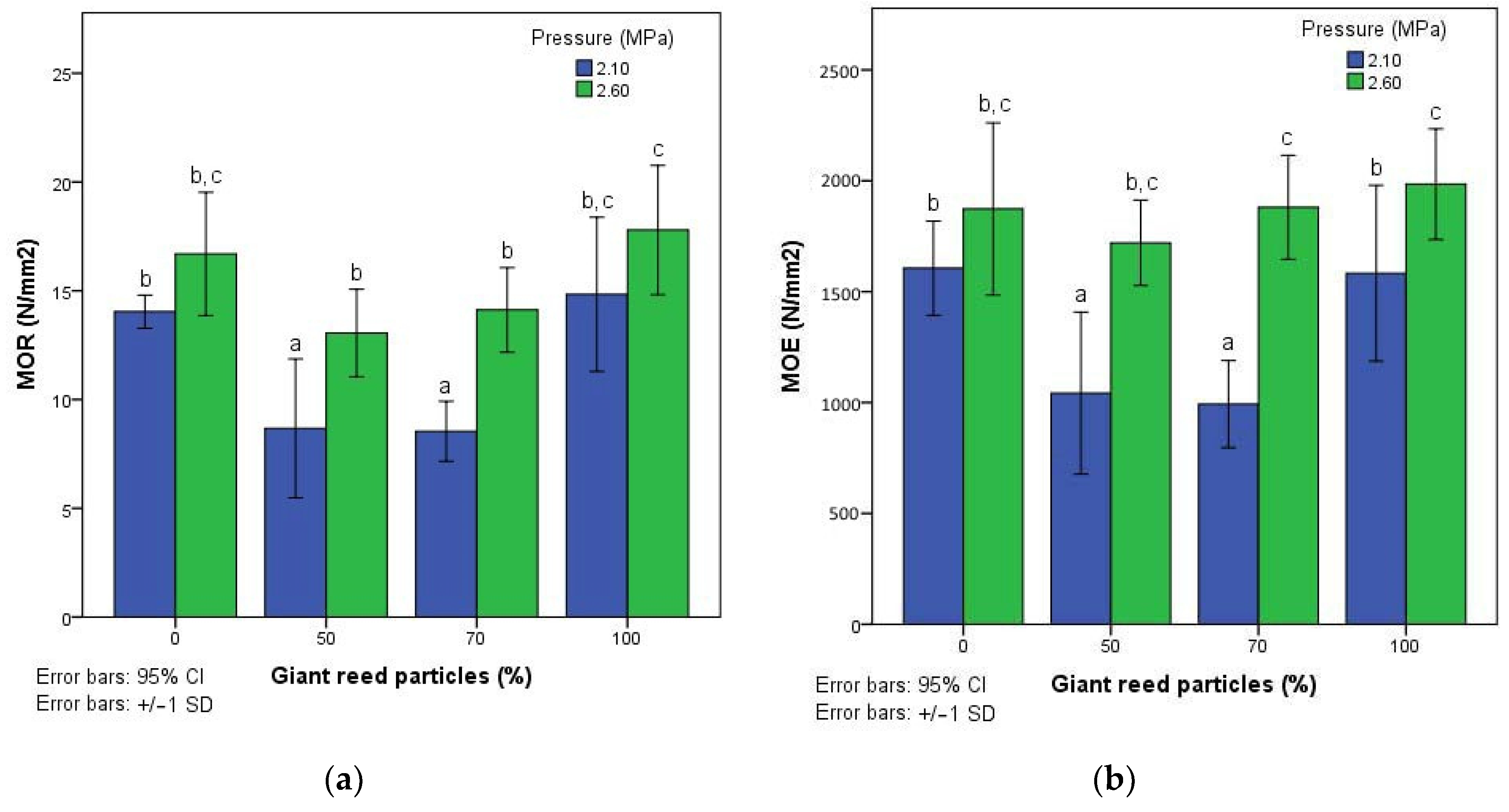

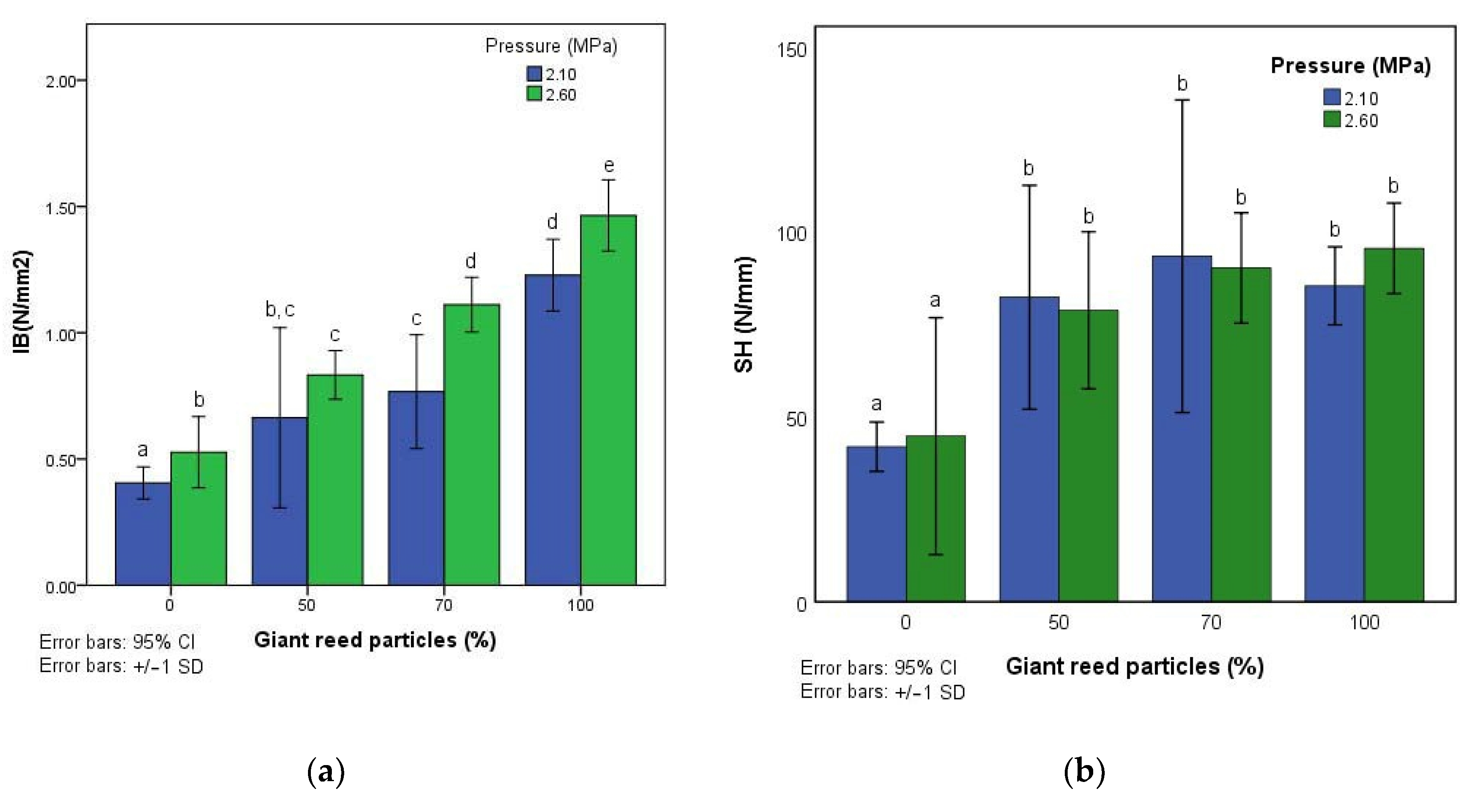

3.2. Mechanical Properties

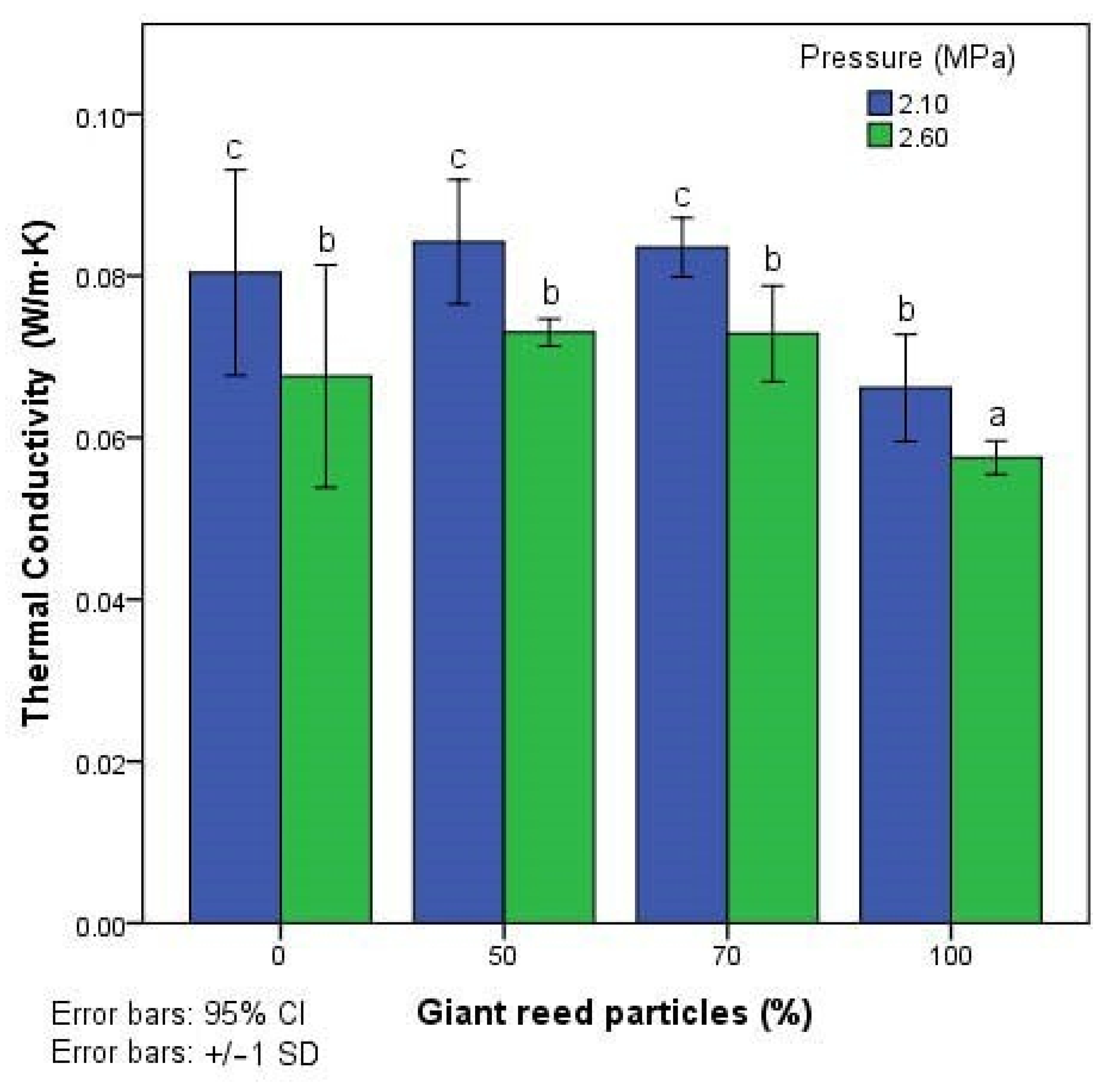

3.3. Thermal Conductivity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAO. El Estado de los Bosques en el Mundo; Organización de las Naciones Unidas para la Alimentación y la Agricultura: Rome, Italy, 2014. [Google Scholar]

- Mantau, U.; Saal, U.; Prins, K.; Steierer, F.; Lindner, M.; Verkerk, H.; Eggers, J.; Leek, N.; Oldenburguer, J.; Asikainen, A.; et al. Real Potential for Changes in Growth and Use of EU Forests; EUwood: Hamburg, Germany, 2010. [Google Scholar]

- Bektas, I.; Güler, C.; Kalaycioğlu, H.; Mengeloglu, F.; Nacar, M. The Manufacture of Particleboards using Sunflower Stalks (helianthus annuus L.) And Poplar Wood (populus alba L.). J. Compos. Mater. 2005, 39, 467–473. [Google Scholar] [CrossRef]

- Guler, C.; Bektas, I.; Kalaycioglu, H. The experimental particleboard manufacture from sunflower stalks (Helianthus annuus L.) and Calabrian pine (Pinus brutia Ten.). Forest Prod. J. 2005, 56, 56–60. [Google Scholar]

- Guler, C.; Copur, Y.; Tascioglu, C. The manufacture of particleboards using mixture of peanut hull (Arachis hypoqaea L.) and European Black pine (Pinus nigra Arnold) wood chips. Bioresour. Technol. 2008, 99, 2893–2897. [Google Scholar] [CrossRef] [PubMed]

- Guler, C.; Büyüksarı, Ü. Effect of production parameters on the physical and mechanical properties of particleboards made from peanut (Arachis hypogaea L.) hull. BioResources 2011, 6, 5027–5036. [Google Scholar]

- Pirayesh, H.; Khazaeian, A.; Tabarsa, T. The potential for using walnut (Juglans regia L.) shell as a raw material for wood-based particleboard manufacturing. Compos. Part B Eng. 2012, 43, 3276–3280. [Google Scholar] [CrossRef]

- Pirayesh, H.; Khanjanzadeh, H.; Salari, A. Effect of using walnut/almond shells on the physical, mechanical properties and formaldehyde emission of particleboard. Compos. Part B Eng. 2013, 45, 858–863. [Google Scholar] [CrossRef]

- Çöpür, Y.; Güler, C.; Akgül, M.; Taşçıoğlu, C. Some chemical properties of hazelnut husk and its suitability for particleboard production. Build. Environ. 2007, 42, 2568–2572. [Google Scholar] [CrossRef]

- Barbu, M.C.; Sepperer, T.; Tudor, E.M.; Petutschnigg, A. Walnut and Hazelnut Shells: Untapped Industrial Resources and Their Suitability in Lignocellulosic Composites. Appl. Sci. 2020, 10, 6340. [Google Scholar] [CrossRef]

- Scatolino, M.V.; de Oliveira Costa, A.; Júnior, J.B.G.; de Paula Protásio, T.; Mendes, R.F.; Mendes, L.M. Eucalyptus wood and coffee parchment for particleboard production: Physical and mechanical properties. Cienc. Agrotech. 2017, 41, 139–146. [Google Scholar] [CrossRef]

- De Araújo Veloso, M.C.R.; Pires, M.R.; Villela, L.S.; Scatolino, M.V.; de Paula Protásio, T.; Mendes, L.M.; Júnior, J.B.G. Potential destination of Brazilian cocoa agro-industrial wastes for production of materials with high added value. Waste Manag. 2020, 118, 36–44. [Google Scholar] [CrossRef]

- Yang, H.-S.; Kim, D.-J.; Kim, H.-J. Rice straw–wood particle composite for sound absorbing wooden construction materials. Bioresour. Technol. 2003, 86, 117–121. [Google Scholar] [CrossRef]

- Pirayesh, H.; Moradpour, P.; Sepahvand, S. Particleboard from wood particles and sycamore leaves: Physico-mechanical properties. Eng. Agric. Eviron. Food 2015, 8, 38–43. [Google Scholar] [CrossRef]

- Silva, D.W.; Scatolino, M.V.; do Prado, N.R.T.; Mendes, R.F.; Mendes, L.M. Addition of different proportions of castor husk and pine wood in particleboards. Waste Biomass Valoris. 2018, 9, 139–145. [Google Scholar] [CrossRef]

- Jimenez, J.J.P.; Acda, M.N.; Razal, R.A.; Abasolo, W.P.; Hernandez, H.P.; Elepaño, A.R. Effect of tobacco stalk additive particle size on the bond strength and formaldehyde emission of urea formaldehyde bonded plywood. Philipp. J. Sci. 2020, 149, 351–360. [Google Scholar]

- Kowaluk, G.; Szymanowski, K.; Kozlowski, P.; Kukula, W.; Sala, C.; Robles, E.; Czarniak, P. Functional assessment of particleboards made of apple and plum orchard pruning. Waste Biomass Valoris. 2020, 11, 2877–2886. [Google Scholar] [CrossRef]

- Nemli, G.; Demirel, S.; Gümüşkaya, E.; Aslan, M.; Acar, C. Feasibility of incorporating waste grass clippings (Lolium perenne L.) in particleboard composites. Waste Manag. 2009, 29, 1129–1131. [Google Scholar] [CrossRef]

- García-Ortuño, T.; Andréu-Rodríguez, J.; Ferrández-García, M.T.; Ferrández-Villena, M.; Ferrández-García, C.E. Evaluation of the physical and mechanical properties of particleboard made from giant reed (Arundo donax L.). BioResources 2011, 6, 477–486. [Google Scholar]

- Ferrández-García, C.E.; Andreu-Rodríguez, J.; Ferrández-García, M.T.; Ferrández-Villena, M.; García-Ortuño, T. Panels made from giant reed bonded with non-modified starches. BioResources 2012, 7, 5904–5916. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Experimental Evaluation of a New Giant Reed (Arundo donax L.). Composite Using Citric Acid as a Natural Binder. Agronomy 2019, 9, 882. [Google Scholar]

- European Committee for Standardization. EN 309. Particleboards. Definitions and Classification; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- European Committee for Standardization. EN 323. Wood-Based Panels. Determination of Density; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- European Committee for Standardization. EN 317. Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- European Committee for Standardization. EN 319. Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of de Board; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- European Committee for Standardization. EN 310. Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- European Committee for Standardization. EN 320. Particleboards and Fibreboards—Determination of Resistance to Axial Withdrawal of Screw; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- European Committee for Standardization. EN 312. Particleboards. Specifications; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization. EN 12667. Thermal Performance of Building Materials and Products: Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods: Products of High and Medium Thermal Resistance; European Committee for Standardization: Brussels, Belgium, 2001. [Google Scholar]

- Obataya, E.; Norimoto, M. Acoustic properties of a reed (Arundo donax L.) used for the vibrating plate of a clarinet. J. Acoust. Soc. Am. 1999, 106, 1106–1110. [Google Scholar] [CrossRef]

- Khedari, J.; Charoenvai, S.; Hirunlabh, J. New insulating particleboards from durian peel and coconut coir. Build. Environ. 2003, 38, 435–441. [Google Scholar] [CrossRef]

| Sieve (mm) | Pine Wood Particles (%) | Giant Reed Particles (%) |

|---|---|---|

| 4 | 36.4 | 24.9 |

| 2 | 26.3 | 30.1 |

| 1 | 27.1 | 20.4 |

| 0.5 | 5.3 | 14.4 |

| 0.25 | 2.0 | 6.5 |

| 0.125 | 2.2 | 2.1 |

| 0.063 | 0.4 | 1.5 |

| <0.063 | 0.3 | 0.1 |

| Type of Board | Proportion of Pine Wood Particles (%) | Proportion of Giant Reed Particles (%) | Pressure (MPa) | Time (min) | Temperature (°C) | Number of Boards |

|---|---|---|---|---|---|---|

| A1 | 100 | 0 | 2.1 | 4 | 120 | 4 |

| A2 | 50 | 50 | ||||

| A3 | 30 | 70 | ||||

| A4 | 0 | 100 | ||||

| B1 | 100 | 0 | 2.6 | |||

| B2 | 50 | 50 | ||||

| B3 | 30 | 70 | ||||

| B4 | 0 | 100 |

| Type of Board | Density (kg/m3) | TS 2 h (%) | TS 24 h (%) | WA 2 h (%) | WA 24 h (%) |

|---|---|---|---|---|---|

| A1 | 842.91 (5.93) | 26.04 (0.57) | 27.70 (0.95) | 53.52 (4.80) | 52.08 (0.81) |

| A2 | 695.27 (22.39) | 13.51 (0.52) | 15.95 (0.55) | 57.55 (5.46) | 63.59 (8.83) |

| A3 | 632.72 (23.54) | 12.20 (0.41) | 14.23 (0.23) | 56.49 (1.52) | 61.69 (3.75) |

| A4 | 631.41 (26.19) | 12.36 (0.82) | 34.46 (4.69) | 14.88 (0.78) | 46.34 (7.80) |

| B1 | 850.20 (44.54) | 22.83 (2.07) | 24.61 (2.56) | 52.86 (5.23) | 57.69 (5.17) |

| B2 | 743.26 (21.29) | 16.44 (1.60) | 18.03 (1.87) | 54.54 (3.37) | 61.28 (3.08) |

| B3 | 741.73 (37.47) | 15.64 (1.29) | 18.30 (1.98) | 45.90 (6.67) | 54.65 (7.84) |

| B4 | 738.16 (30.02) | 12.12 (3.45) | 23.29 (5.31) | 16.25 (2.59) | 41.35 (5.63) |

| Factor | Properties | Sum of Squares | d.f. | Half Quadratic | F | Sig. |

|---|---|---|---|---|---|---|

| % of reed added | Density (kg/m3) | 65,724.901 | 3 | 21,908.300 | 6.252 | 0.002 |

| TS 24 h (%) | 1260.236 | 3 | 420.079 | 17.876 | 0.000 | |

| WA 24 h (%) | 2054.597 | 3 | 684.866 | 16.689 | 0.000 | |

| MOR (N/mm2) | 162.434 | 3 | 54.145 | 5.832 | 0.002 | |

| MOE (N/mm2) | 533,881.466 | 3 | 177,960.489 | 1.187 | 0.329 | |

| IB (N/mm2) | 3.451 | 3 | 1.150 | 40.724 | 0.000 | |

| SH (N/mm) | 9422.803 | 3 | 3140.934 | 12.105 | 0.000 | |

| Thermal C. (W/m·K) | 0.002 | 3 | 0.001 | 12.108 | 0.000 | |

| Pressure applied | Density (kg/m3) | 34,161.109 | 1 | 34,161.109 | 8.196 | 0.007 |

| TS 24 h (%) | 98.413 | 1 | 98.413 | 1.835 | 0.184 | |

| WA 24 h (%) | 20.619 | 1 | 20.619 | 0.220 | 0.642 | |

| MOR (N/mm2) | 93.261 | 1 | 93.261 | 8.755 | 0.005 | |

| MOE (N/mm2) | 2,517,539.649 | 1 | 2,517,539.649 | 28.529 | 0.000 | |

| IB (N/mm2) | 0.344 | 1 | 0.344 | 3.108 | 0.086 | |

| SH (N/mm) | 105.462 | 1 | 105.462 | 0.212 | 0.648 | |

| Thermal C. (W/m·K) | 0.001 | 1 | 0.001 | 8.074 | 0.007 |

| Type of Board | MOR (N/mm2) | MOE (N/mm2) | IB (N/mm2) | TS 24 h (%) |

|---|---|---|---|---|

| B2 | 13.1 | 1.734 | 0.83 | 18.03 |

| B3 | 14.1 | 1.880 | 1.11 | 18.30 |

| Grade P1 | 10.5 | - | 0.28 | - |

| Grade P2 | 11.0 | 1.800 | 0.40 | - |

| Grade P3 | 15.0 | 2.050 | 0.45 | 17.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrandez-Villena, M.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, C.E.; Garcia, M.T.F. Properties of Wood Particleboards Containing Giant Reed (Arundo donax L.) Particles. Sustainability 2020, 12, 10469. https://doi.org/10.3390/su122410469

Ferrandez-Villena M, Ferrandez-Garcia A, Garcia-Ortuño T, Ferrandez-Garcia CE, Garcia MTF. Properties of Wood Particleboards Containing Giant Reed (Arundo donax L.) Particles. Sustainability. 2020; 12(24):10469. https://doi.org/10.3390/su122410469

Chicago/Turabian StyleFerrandez-Villena, Manuel, Antonio Ferrandez-Garcia, Teresa Garcia-Ortuño, Clara Eugenia Ferrandez-Garcia, and Maria Teresa Ferrandez Garcia. 2020. "Properties of Wood Particleboards Containing Giant Reed (Arundo donax L.) Particles" Sustainability 12, no. 24: 10469. https://doi.org/10.3390/su122410469

APA StyleFerrandez-Villena, M., Ferrandez-Garcia, A., Garcia-Ortuño, T., Ferrandez-Garcia, C. E., & Garcia, M. T. F. (2020). Properties of Wood Particleboards Containing Giant Reed (Arundo donax L.) Particles. Sustainability, 12(24), 10469. https://doi.org/10.3390/su122410469