Modeling of Compressive Strength of Sustainable Self-Compacting Concrete Incorporating Treated Palm Oil Fuel Ash Using Artificial Neural Network

Abstract

1. Introduction

2. Materials and Methods

2.1. Constituent Materials

2.2. Mix Proportions of Concretes

2.3. Preparation and Testing of Concretes

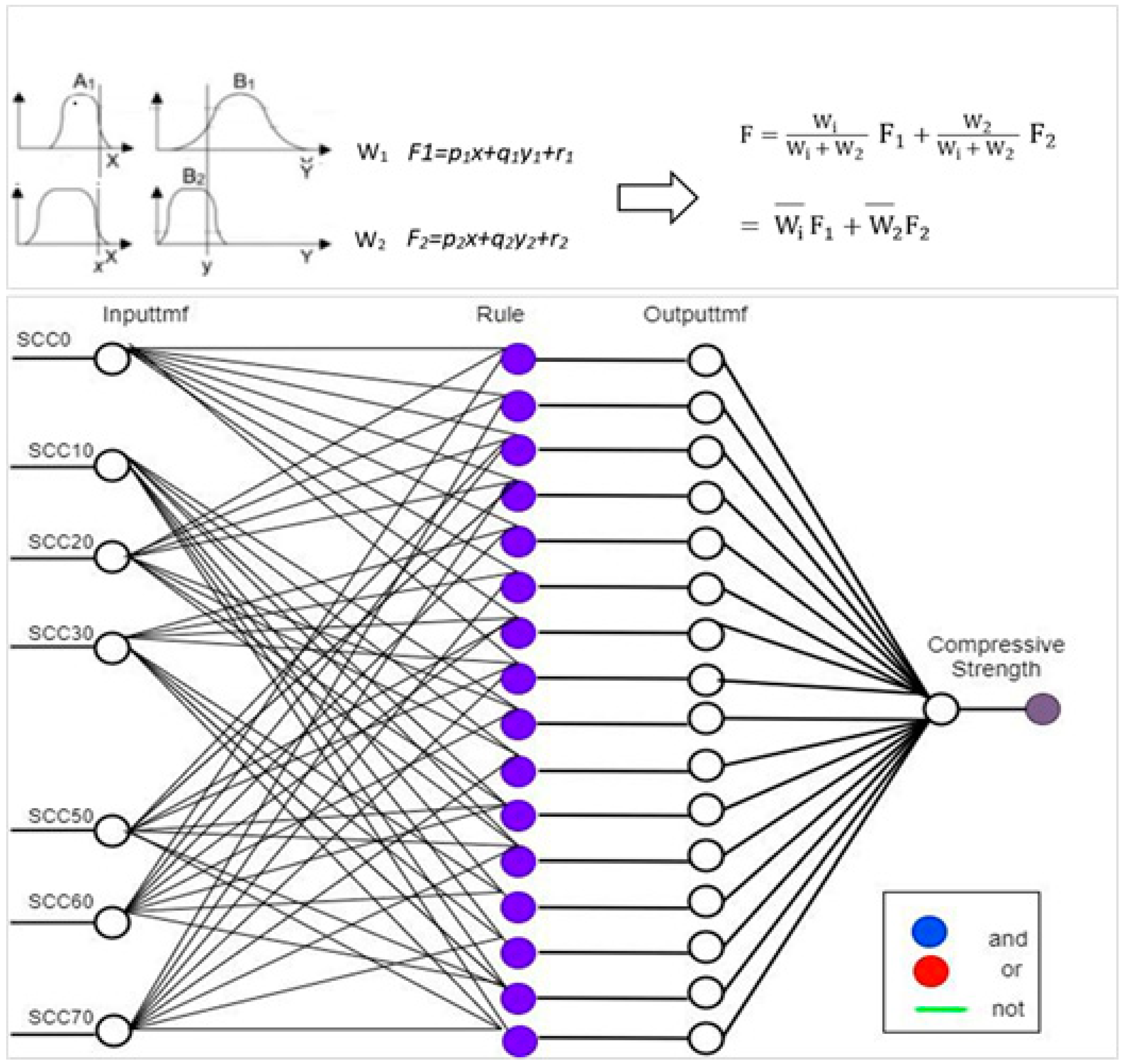

2.4. Adaptive Neuro-Fuzzy Inference System (ANFIS) Model

- and are membership functions;

- Ai represent the linguistic variable; and

- σi, bi, and ci are the parameters of the Bell function.

2.5. Performance Measurement

- Mean Square Error (MSE):

- Root Mean Square Error (RMSE):

- Mean Error:where:

- ○

- , and are the predicted and the experimental responses, respectively; and

- ○

- N is the total number of variables.

- % Regression Correlation Coefficient (R%):where:

- ○

- : Pearson’s correlation coefficient;

- ○

- : Input values of the first set of training data;

- ○

- : Input values of the second set of training data; and

- ○

- : Total of simple input data.

3. Results and Discussion

3.1. Compressive Strength of Concretes

3.2. Prediction of the Compressive Strength by the ANFIS Model

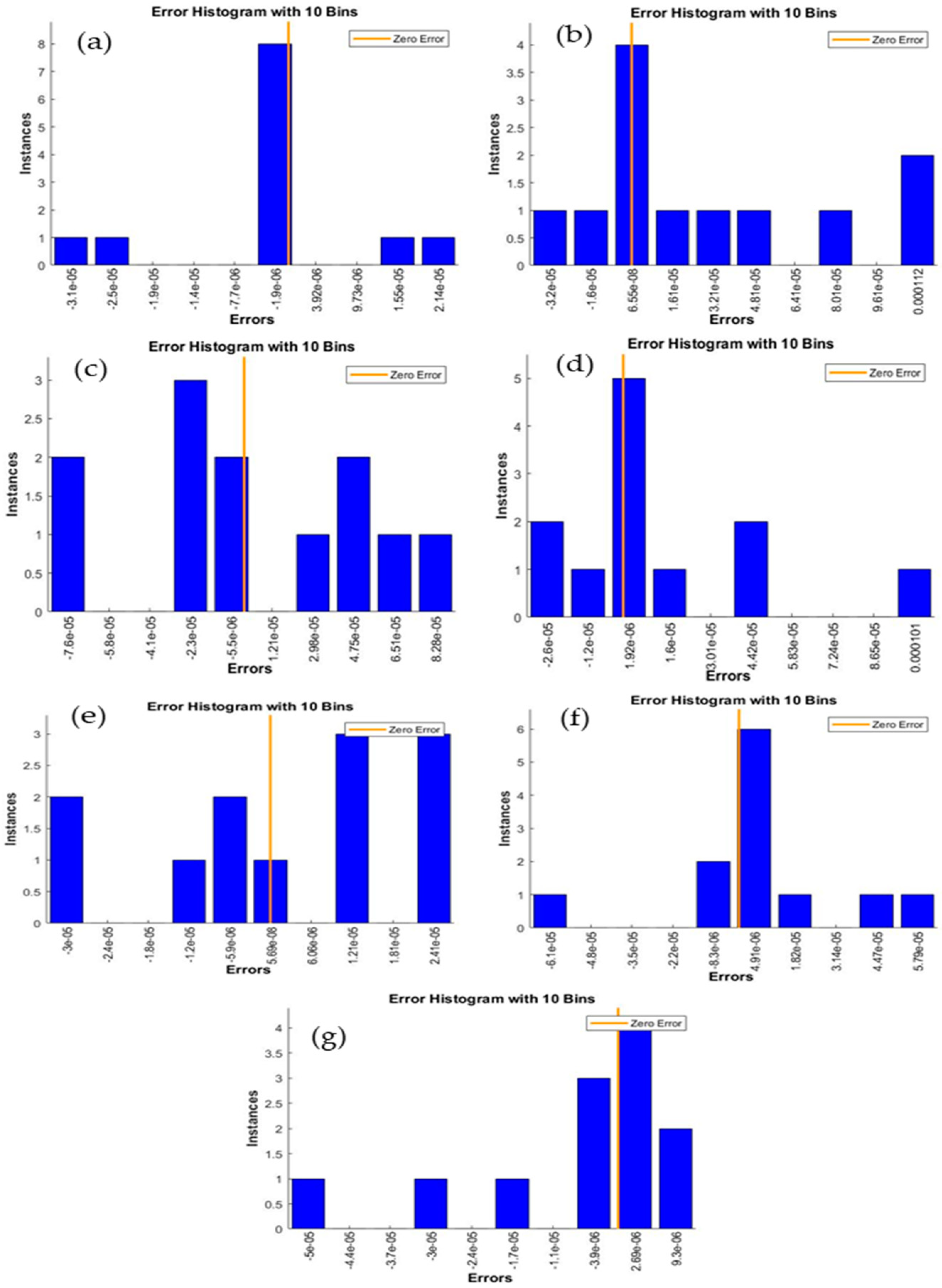

3.2.1. Training of the ANFIS Model

3.2.2. Testing of the ANFIS Model

4. Conclusions

- SCC containing low-volume T-POFA has exhibited comparable or higher compressive strengths in early-ages and later-ages when compared to SCC control.

- Compressive strengths of SCC incorporating high-volume T-POFA were lower than the reference SCC sample, however, with increased curing time, the compressive strengths were similar or higher than the SCC without T-POFA (control sample).

- The predicted results of the developed ANFIS model used to predict the compressive strengths of SCC were very close to the experimental values of SCC.

- Based on the predicted results of compressive strength, it is approved that the developed ANFIS model has successfully modeled the compressive strengths of SCC at different conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Ondova, M.; Stevulova, N.; Sicakova, A. Assessment of selected indicators of Portland cement containing fly ash in road concrete. Ad Alta. J. Interdiscip. Res. 2012, 2, 114–116. [Google Scholar]

- Lippiatt, B.; Ahmad, S. Measuring the life-cycle environmental and economic performance of concrete: The BEES approach. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; p. 213. [Google Scholar]

- Huda, N.; Bin Jumat, M.Z.; Islam, A.S. Flexural performance of reinforced oil palm shell & palm oil clinker concrete (PSCC) beam. Constr. Build. Mater. 2016, 127, 18–25. [Google Scholar] [CrossRef]

- Agensi Inovasi Malaysia. National Biomass Strategy 2020: New Wealth Creation for Malaysia’s Palm Oil Industry; Agensi Inovasi Malaysia: Cyberjaya, Malaysia, 2011; p. 32.

- Elinwa, A.U.; Mahmood, Y.A. Ash from timber waste as cement replacement material. Cem. Concr. Compos. 2002, 24, 219–222. [Google Scholar] [CrossRef]

- Safiuddin, M.; Salam, M.A.; Jumaat, M.Z. Correlations between Fresh Properties of Self-Consolidating Concrete Including Palm Oil Fuel Ash. Adv. Mater. Res. 2011, 409–416. [Google Scholar] [CrossRef]

- Safiuddin; West, J.; Soudki, K. Flowing ability of the mortars formulated from self-compacting concretes incorporating rice husk ash. Constr. Build. Mater. 2011, 25, 973–978. [Google Scholar] [CrossRef]

- Siddique, R. Properties of self-compacting concrete containing class F fly ash. Mater. Des. 2011, 32, 1501–1507. [Google Scholar] [CrossRef]

- Liu, M. Self-compacting concrete with different levels of pulverized fuel ash. Constr. Build. Mater. 2010, 24, 1245–1252. [Google Scholar] [CrossRef]

- Nasir, M.; Al-Kutti, W.A. Performance of Date Palm Ash as a Cementitious Material by Evaluating Strength, Durability, and Characterization. Buildings 2018, 9, 6. [Google Scholar] [CrossRef]

- Al-Kutti, W.A.; Islam, A.S.; Nasir, M. Potential use of date palm ash in cement-based materials. J. King Saud Univ. Eng. Sci. 2019, 31, 26–31. [Google Scholar] [CrossRef]

- Abdul, A.A.; Hussin, M. Durability of high-performance concrete containing palm oil fuel ash. In Proceedings of the 8th International Conference on Durability of Building Materials and Components, 8 dbmc, Vancouver, BC, Canada, 30 May–3 June 1999; pp. 465–474. [Google Scholar]

- Awal, A.; Shehu, I. Evaluation of heat of hydration of concrete containing high volume palm oil fuel ash. Fuel 2013, 105, 728–731. [Google Scholar] [CrossRef]

- Uysal, M.; Yilmaz, K. Effect of mineral admixtures on properties of self-compacting concrete. Cem. Concr. Compos. 2011, 33, 771–776. [Google Scholar] [CrossRef]

- Hossain, K.M.; Lachemi, M. Fresh, Mechanical, and Durability Characteristics of Self-Consolidating Concrete Incorporating Volcanic Ash. J. Mater. Civ. Eng. 2010, 22, 651–657. [Google Scholar] [CrossRef]

- Ozawa, K.; Maekawa, K.; Kunishima, H.; Okamura, H. Performance of concrete based on the durability design of concrete structures. In Proceedings of the 2nd 425 East-Asia-Pacific Conference on Structural Engineering and Construction, Chiang Mai, Thailand, 11–13 January 1989; pp. 445–456. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Lachemi, M. Self-compacting concrete incorporating high volumes of class F fly ash preliminary results. Cem. Concr. Res. 2001, 31, 413–420. [Google Scholar] [CrossRef]

- Uysal, M.; Sumer, M. Performance of self-compacting concrete containing different mineral admixtures. Constr. Build. Mater. 2011, 25, 4112–4120. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z.; Alengaram, U.J. The Effect of Palm Oil Fuel Ash as a Cementreplacement Material on Self-Compacting Concrete. Appl. Mech. Mater. 2014, 567, 529–534. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of Palm Oil Fuel Ash in High-Strength Concrete. J. Mater. Civ. Eng. 2004, 16, 623–628. [Google Scholar] [CrossRef]

- Johari, M.M.; Zeyad, A.; Bunnori, N.M.; Ariffin, K. Engineering and transport properties of high-strength green concrete containing high volume of ultrafine palm oil fuel ash. Constr. Build. Mater. 2012, 30, 281–288. [Google Scholar] [CrossRef]

- Tay, J. Ash from Oil-Palm Waste as a Concrete Material. J. Mater. Civ. Eng. 1990, 2, 94–105. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 2009, 23, 2641–2646. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A.; Ehsan, A.H. Influence of palm oil fuel ash on fresh and mechanical properties of self-compacting concrete. Sadhana 2015, 40, 1989–1999. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Sam, A.R.M.; Lim, N.H.A.S.; Samadi, M. Enhanced performance for aggressive environments of green concrete composites reinforced with waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2018, 185, 252–265. [Google Scholar] [CrossRef]

- Safiuddin; Salam, A.; Jumaat, M.Z. Utilization of palm oil fuel ash in concrete: A review / palmi aliejaus kuro pelenų naudojimas betone. apžvalga. J. Civ. Eng. Manag. 2011, 17, 234–247. [Google Scholar] [CrossRef]

- Karim, R.; Hossain, M.; Khan, M.N.N.; Zain, M.F.M.; Jamil, M.; Lai, F.C. On the Utilization of Pozzolanic Wastes as an Alternative Resource of Cement. Materials 2014, 7, 7809–7827. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Alengaram, U.J.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar. Mater. Des. 2014, 59, 532–539. [Google Scholar] [CrossRef]

- Kabir, S.M.A.; Alengaram, U.J.; Jumaat, M.Z.; Sharmin, A.; Islam, A. Influence of Molarity and Chemical Composition on the Development of Compressive Strength in POFA Based Geopolymer Mortar. Adv. Mater. Sci. Eng. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Johari, M.A.M.; Tayeh, B.A.; Yusuf, M.O. Pozzolanic reactivity of ultrafine palm oil fuel ash waste on strength and durability performances of high strength concrete. J. Clean. Prod. 2017, 144, 511–522. [Google Scholar] [CrossRef]

- Ramlochan, T.; Thomas, M.; Gruber, K.A. The effect of metakaolin on alkali–silica reaction in concrete. Cem. Concr. Res. 2000, 30, 339–344. [Google Scholar] [CrossRef]

- Helmuth, R. Fly ash in Cement and Concrete; Portland Cement Association: Illinois, IL, USA, 1987; Available online: http://worldcat.org/isbn/0893120855 (accessed on 15 September 2020).

- Eldagal, A.; Elmukhtar, O. Study on the Behaviour of High Strength Palm Oil Fuel Ash (POFA) Concrete. Master’s Thesis, Universiti Teknologi Malaysia, Skudai, Malaysia, 2008. [Google Scholar]

- Alanis, A.Y.; Arana, N.-D.; Lopez-Franco, C. Artificial Neural Networks for Engineering Applications; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar] [CrossRef]

- Yeh, I.-C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Kasperkiewicz, J.; Racz, J.; Dubrawski, A. HPC Strength Prediction Using Artificial Neural Network. J. Comput. Civ. Eng. 1995, 9, 279–284. [Google Scholar] [CrossRef]

- Lai, S.; Serra, M. Concrete strength prediction by means of neural network. Constr. Build. Mater. 1997, 11, 93–98. [Google Scholar] [CrossRef]

- Lee, S.-C. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Özta, S.A.; Pala, M.; Özbay, E.A.; Kanca, E.A.; Ça-glar, N.; Bhatti, M.A. Predicting the compressive strength and slump of high strength concrete using neural network. Constr. Build. Mater. 2006, 20, 769–775. [Google Scholar] [CrossRef]

- Hakim, S.J.; Noorzaei, J.; Jaafar, M.S.; Jameel, M.; Hassani, M.M. Application of artificial neural networks to predict compressive strength of high strength concrete. Int. J. Phys. Sci. 2011, 6, 975–981. [Google Scholar] [CrossRef]

- Dias, W.; Pooliyadda, S. Neural networks for predicting properties of concretes with admixtures. Constr. Build. Mater. 2001, 15, 371–379. [Google Scholar] [CrossRef]

- Paulson, A.J.; Prabhavathy, R.A.; Rekh, S.; Brindha, E. Application of neural network for prediction of compressive strength of silica fume concrete. Int. J. Civ. Eng. Technol. 2019, 10, 1859–1867. [Google Scholar] [CrossRef]

- Parichatprecha, R.; Nimityongskul, P. Analysis of durability of high performance concrete using artificial neural networks. Constr. Build. Mater. 2009, 23, 910–917. [Google Scholar] [CrossRef]

- Al-Swaidani, A.M.; Khwies, W.T. Applicability of Artificial Neural Networks to Predict Mechanical and Permeability Properties of Volcanic Scoria-Based Concrete. Adv. Civ. Eng. 2018, 2018, 1–16. [Google Scholar] [CrossRef]

- Bai, J.; Wild, S.; Ware, J.; Sabir, B. Using neural networks to predict workability of concrete incorporating metakaolin and fly ash. Adv. Eng. Softw. 2003, 34, 663–669. [Google Scholar] [CrossRef]

- Topçu, I.B.; Sarıdemir, M. Prediction of rubberized concrete properties using artificial neural network and fuzzy logic. Constr. Build. Mater. 2008, 22, 532–540. [Google Scholar] [CrossRef]

- Safiuddin; Raman, S.N.; Salam, A.; Jumaat, M.Z. Modeling of Compressive Strength for Self-Consolidating High-Strength Concrete Incorporating Palm Oil Fuel Ash. Materials 2016, 9, 396. [Google Scholar] [CrossRef]

- Garzón-Roca, J.; Marco, C.O.; Adam, J.M. Compressive strength of masonry made of clay bricks and cement mortar: Estimation based on Neural Networks and Fuzzy Logic. Eng. Struct. 2013, 48, 21–27. [Google Scholar] [CrossRef]

- Ayat, H.; Kellouche, Y.; Ghrici, M.; Boukhatem, B. Compressive strength prediction of limestone filler concrete using artificial neural networks. Adv. Comput. Des. 2018, 3, 289–302. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Piechówka-Mielnik, M.; Widziszowski, T.; Gardynik, A.; Mackiewicz, S. Hybrid ultrasonic-neural prediction of the compressive strength of environmentally friendly concrete screeds with high volume of waste quartz mineral dust. J. Clean. Prod. 2019, 212, 727–740. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Development of Self-Consolidating High Strength Concrete Incorporating Treated Palm Oil Fuel Ash. Materials 2015, 8, 2154–2173. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Utilization of high-volume treated palm oil fuel ash to produce sustainable self-compacting concrete. J. Clean. Prod. 2016, 137, 982–996. [Google Scholar] [CrossRef]

- EFNARC. Guidelines for Self-Compacting Concrete; Association House: London, UK, 2002; Volume 32, p. 34. [Google Scholar]

- Standard, B. Testing Hardened Concrete. Compressive Strength of Test Specimens, BS EN, 12390–12393; BSI: London, UK, 2006. [Google Scholar]

- Jang, J.-S.R. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Aldhyani, T.H.; Alrasheedi, M.; AlQarni, A.A.; Alzahrani, M.Y.; Bamhdi, A. Intelligent Hybrid Model to Enhance Time Series Models for Predicting Network Traffic. IEEE Access 2020, 8, 130431–130451. [Google Scholar] [CrossRef]

- Awal, A.A.; Abubakar, S.I. Properties of concrete containing high volume palm oil fuel ash: A short-term investigation. Malays. J. Civ. Eng. 2011, 23, 54–66. [Google Scholar] [CrossRef]

| Oxide Composition | OPC | T-POFA |

|---|---|---|

| SiO2 | 17.60 | 69.02 |

| Al2O3 | 4.02 | 3.9 |

| Fe2O3 | 4.47 | 4.33 |

| CaO | 67.43 | 5.01 |

| MgO | 1.33 | 5.18 |

| Na2O | 0.03 | 0.18 |

| K2O | 0.39 | 6.9 |

| SO3 | 4.18 | 0.41 |

| Others | 0.55 | 5.07 |

| SiO2 + Al2O3 + Fe2O3 | 26.09% | 77.25% |

| Loss on ignition (LOI) | 2.4 | 1.8 |

| Specific surface area, BET (m2/g) | 3.05 | 7.4 |

| Median particle size, d50 (µm) | 21 | 13 |

| Mix Code | Cement (kg/m3) | Water (kg/m3) | W/B Ratio | T-POFA | Fine Aggregate (F.A.) (kg/m3) | Coarse Aggregate (C.A.) (kg/m3) | Superplasticizer (%) | |

|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (wt%) | |||||||

| SCC0 | 480 | 168 | 0.35 | 0 | 0 | 925 | 760 | 1.3 |

| SCC10 | 432 | 168 | 0.35 | 48 | 10 | 923 | 760 | 1.3 |

| SCC20 | 384 | 168 | 0.35 | 96 | 20 | 948 | 770 | 1.3 |

| SCC30 | 336 | 168 | 0.35 | 144 | 30 | 944 | 770 | 1.3 |

| SCC50 | 240 | 168 | 0.35 | 240 | 50 | 925 | 758.2 | 1.3 |

| SCC60 | 192 | 168 | 0.35 | 288 | 60 | 925 | 758.2 | 1.3 |

| SCC70 | 144 | 168 | 0.35 | 336 | 70 | 925 | 758.2 | 1.3 |

| Sample No. | 1 Day (MPa) | 3 Days (MPa) | 7 Days (MPa) | 28 Days (MPa) | 56 Days (MPa) | 90 Days (MPa) |

|---|---|---|---|---|---|---|

| SCC0 | 39.0 | 51.2 | 57.5 | 67.1 | 70.5 | 72.0 |

| 40.5 | 50.8 | 58.5 | 68.1 | 71 | 74 | |

| 37.5 | 51.6 | 56.5 | 66.1 | 69 | 70 | |

| SCC10 | 38.2 | 56.0 | 63.2 | 69.0 | 77.0 | 80.6 |

| 40 | 55 | 64 | 71 | 76 | 81.2 | |

| 36.6 | 57 | 62.4 | 67 | 78 | 79.8 | |

| SCC20 | 36.0 | 54.6 | 61.8 | 73.0 | 86.0 | 88.0 |

| 37.5 | 55.2 | 62.8 | 74 | 87 | 87.5 | |

| 34.5 | 53.8 | 60.8 | 71 | 85 | 88.5 | |

| SCC30 | 33.5 | 47.0 | 63.2 | 71.7 | 84.5 | 86.2 |

| 34 | 49 | 64 | 70.7 | 85 | 87 | |

| 33 | 45 | 62.4 | 72.7 | 84 | 85.4 | |

| SCC50 | 28.0 | 40.0 | 52.0 | 69.0 | 75.2 | 78.4 |

| 29 | 42 | 53 | 67 | 76 | 79 | |

| 27 | 38 | 51 | 71 | 74.4 | 77.8 | |

| SCC60 | 17.0 | 29.0 | 50.0 | 68.0 | 74.7 | 76.6 |

| 18 | 31 | 52 | 68.5 | 75.7 | 77.6 | |

| 16 | 27 | 48 | 67.5 | 73.7 | 75.6 | |

| SCC70 | 14.0 | 26.0 | 47.0 | 65.5 | 72.9 | 74.5 |

| 14.5 | 27.5 | 49 | 66.5 | 73.9 | 75.5 | |

| 13.5 | 24.5 | 45 | 64.5 | 71.9 | 73.5 |

| Dataset | Training Dataset | |||

|---|---|---|---|---|

| MSE | RMSE | Mean Error | R (%) | |

| SCC0 | 4.4450 × 10−10 | 1.083 × 10−05 | 1.0581 × 10−06 | 100 |

| SCC10 | 1.5337 × 10−09 | 3.9162 × 10−05 | 3.16 × 10−06 | 100 |

| SCC20 | 3.0139 × 10−09 | 5.4899 × 10−05 | 5.115 × 10−06 | 100 |

| SCC30 | 1.5174 × 10−09 | 3.8954 × 10−05 | 1.2936 × 10−05 | 100 |

| SCC50 | 3.6809 × 10−10 | 1.9186 × 10−05 | 1.6667 × 10−06 | 100 |

| SCC60 | 9.557 × 10−10 | 3.0914 × 10−05 | 5.04 × 10−06 | 100 |

| SCC70 | 3.7251 × 10−10 | 1.9301 × 10−05 | 7.3697 × 10−06 | 100 |

| Dataset | Testing Dataset | |||

|---|---|---|---|---|

| MSE | RMSE | Mean Error | R (%) | |

| SCC0 | 0.4490 | 0.6701 | 0.0951 | 98.54 |

| SCC10 | 0.2439 | 0.4938 | 0.2658 | 88.85 |

| SCC20 | 0.1701 | 0.4124 | 0.3283 | 87.04 |

| SCC30 | 0.7396 | 0.8600 | 0.1443 | 94.04 |

| SCC50 | 0.7657 | 0.8751 | 0.0449 | 98.48 |

| SCC60 | 0.2035 | 0.4511 | 0.3896 | 98.72 |

| SCC70 | 0.8540 | 0.9241 | 0.9022 | 99.34 |

| Curing Time (Days) | Sample Code | Compressive Strength (MPa) | ||

|---|---|---|---|---|

| Experimental Values | Predicted Values | Mean Errors | ||

| Day 90 | SCC0 | 72 | 72.14 | 0.14 |

| SCC10 | 80 | 81.39 | 0.79 | |

| SCC20 | 88.0 | 88.02 | 0.022 | |

| SCC30 | 86.2 | 87.033 | 0.83 | |

| SCC50 | 78.4 | 78.02 | 0.37 | |

| SCC60 | 76.6 | 75.65 | 1.61 | |

| SCC70 | 74.5 | 75.56 | 1.06 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mughanam, T.; Aldhyani, T.H.H.; Alsubari, B.; Al-Yaari, M. Modeling of Compressive Strength of Sustainable Self-Compacting Concrete Incorporating Treated Palm Oil Fuel Ash Using Artificial Neural Network. Sustainability 2020, 12, 9322. https://doi.org/10.3390/su12229322

Al-Mughanam T, Aldhyani THH, Alsubari B, Al-Yaari M. Modeling of Compressive Strength of Sustainable Self-Compacting Concrete Incorporating Treated Palm Oil Fuel Ash Using Artificial Neural Network. Sustainability. 2020; 12(22):9322. https://doi.org/10.3390/su12229322

Chicago/Turabian StyleAl-Mughanam, Tawfiq, Theyazn H. H. Aldhyani, Belal Alsubari, and Mohammed Al-Yaari. 2020. "Modeling of Compressive Strength of Sustainable Self-Compacting Concrete Incorporating Treated Palm Oil Fuel Ash Using Artificial Neural Network" Sustainability 12, no. 22: 9322. https://doi.org/10.3390/su12229322

APA StyleAl-Mughanam, T., Aldhyani, T. H. H., Alsubari, B., & Al-Yaari, M. (2020). Modeling of Compressive Strength of Sustainable Self-Compacting Concrete Incorporating Treated Palm Oil Fuel Ash Using Artificial Neural Network. Sustainability, 12(22), 9322. https://doi.org/10.3390/su12229322