Open-Mindedness Culture, Knowledge-Sharing, Financial Performance, and Industry 4.0 in SMEs

Abstract

:1. Introduction

2. Literature Review

2.1. Open-Mindedness Culture and Industry 4.0

2.2. The Open-Mindedness Culture, Knowledge-Sharing, and Industry 4.0

2.3. Firm Performance and Industry 4.0

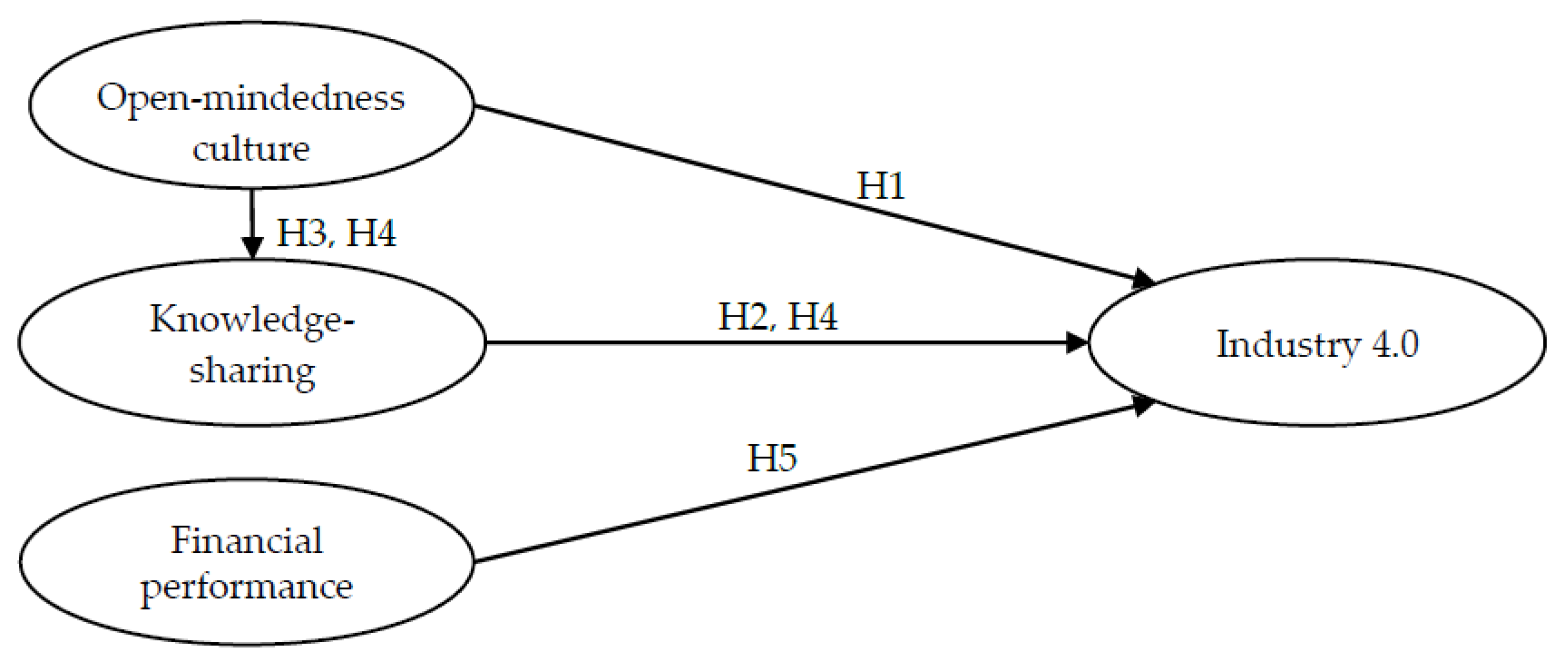

2.4. The Hypothesized Model

3. Materials and Methods

3.1. Sample and Data Collection

3.2. Measures

3.3. Data Analysis

4. Results

4.1. Measurement Model

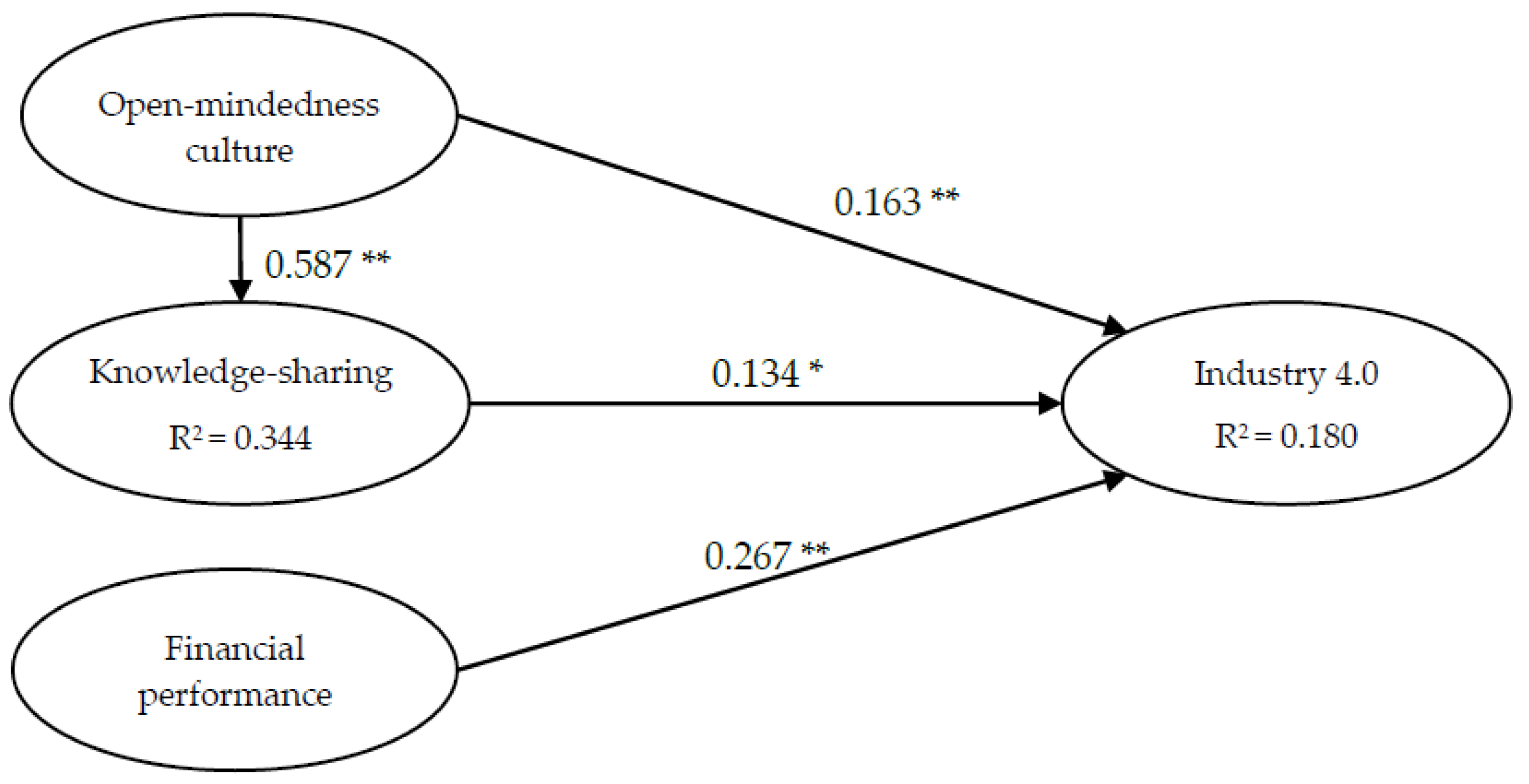

4.2. Structural Model

5. Discussion and Conclusions

5.1. Summary of the Main Research Results

- There is a positive relationship between the open-mindedness culture and willingness to implement Industry 4.0 in SMEs;

- A positive relationship exists between knowledge-sharing and willingness to implement Industry 4.0 in SMEs;

- The antecedent of knowledge-sharing is open-mindedness culture;

- Knowledge-sharing mediates the positive effect of open-mindedness culture on willingness to implement Industry 4.0 in SMEs;

- Financial performance has a positive impact on willingness to implement Industry 4.0 in SMEs.

5.2. Theoretical Contributions

5.3. Practical Contributions

5.4. Limitation and Further Studies

Author Contributions

Funding

Conflicts of Interest

References

- Li, D.; Fast-Berglund, Å.; Paulin, D. Current and future Industry 4.0 capabilities for information and knowledge sharing: Case of two Swedish SMEs. Int. J. Adv. Manuf. Technol. 2019, 105, 3951–3963. [Google Scholar] [CrossRef] [Green Version]

- Kagermann, H. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; Forschungsunion: Berlin, Germany, 2013. [Google Scholar]

- Khan, A.; Turowski, K. A Preliminary Study on Industry 4.0. J. Ind. Intell. Inf. 2016. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Müller, J.M. Business model innovation in small- and medium-sized enterprises: Strategies for industry 4.0 providers and users. J. Manuf. Technol. Manag. 2019, 30, 1127–1142. [Google Scholar] [CrossRef]

- Miśkiewicz, R.; Wolniak, R. Practical Application of the Industry 4.0 Concept in a Steel Company. Sustainability 2020, 12, 5776. [Google Scholar] [CrossRef]

- Veile, J.W.; Kiel, D.; Müller, J.M.; Voigt, K.-I. Lessons learned from Industry 4.0 implementation in the German manufacturing industry. J. Manuf. Technol. Manag. 2019. Ahead of Print. [Google Scholar] [CrossRef] [Green Version]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Sommer, L. Industrial revolution—Industry 4.0: Are German manufacturing SMEs the first victims of this revolution? J. Ind. Eng. Manag. 2015, 8, 1512–1532. [Google Scholar] [CrossRef] [Green Version]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- Somohano-Rodríguez, F.M.; Madrid-Guijarro, A.; López-Fernández, J.M. Does Industry 4.0 really matter for SME innovation? J. Small Bus. Manag. 2020, 1–28. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. The role of absorptive capacity and innovation strategy in the design of industry 4.0 business Models-A comparison between SMEs and large enterprises. Eur. Manag. J. 2020. [Google Scholar] [CrossRef]

- Ates, A.; Garengo, P.; Cocca, P.; Bititci, U. The development of SME managerial practice for effective performance management. J. Small Bus. Enterp. Dev. 2013, 20, 28–54. [Google Scholar] [CrossRef]

- Krajňáková, E.; Navikaitė, A.; Navickas, V. Paradigm shift of small and medium-sized enterprises competitive advantage to management of customer satisfaction. Inž. Ekon. 2015, 327–332. [Google Scholar] [CrossRef] [Green Version]

- Michna, A. The mediating role of firm innovativeness in the relationship between knowledge sharing and customer satisfaction in SMEs. Eng. Econ. 2018, 29, 93–103. [Google Scholar] [CrossRef]

- Michna, A.; Kmieciak, R.; Czerwińska-Lubszczyk, A. Dimensions of Intercompany Cooperation in the Construction Industry and their Relations to Performance of SMEs. Eng. Econ. 2020, 31, 221–232. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.; Oke, A. Construction 4.0: The Future of the Construction Industry in South Africa. Int. J. Civ. Environ. Eng. 2018, 12, 150–156. [Google Scholar]

- Büschgens, T.; Bausch, A.; Balkin, D.B. Organizational Culture and Innovation: A Meta-Analytic Review: Organizational Culture and Innovation. J. Prod. Innov. Manag. 2013, 30, 763–781. [Google Scholar] [CrossRef]

- Carmona, L.J.D.M.; Gomes, G.; Costa, D.d.L.C. Elements of organizational culture that encourage innovation development. Rev. Adm. FACES J. 2020, 19. [Google Scholar] [CrossRef]

- Naranjo-Valencia, J.C.; Jiménez-Jiménez, D.; Sanz-Valle, R. Studying the links between organizational culture, innovation, and performance in Spanish companies. Rev. Latinoam. Psicol. 2016, 48, 30–41. [Google Scholar] [CrossRef] [Green Version]

- Le, P.B.; Lei, H. Determinants of innovation capability: The roles of transformational leadership, knowledge sharing and perceived organizational support. J. Knowl. Manag. 2019, 23, 527–547. [Google Scholar] [CrossRef]

- Yao, J.; Crupi, A.; Di Minin, A.; Zhang, X. Knowledge sharing and technological innovation capabilities of Chinese software SMEs. J. Knowl. Manag. 2020, 24, 607–634. [Google Scholar] [CrossRef]

- Bigliardi, B. The effect of innovation on financial performance: A research study involving SMEs. Innovation 2013, 15, 245–255. [Google Scholar] [CrossRef]

- Nguyen, D.; Nguyen, H.; Nguyen, K.S. Ownership feature and firm performance via corporate innovation performance: Does it really matter for Vietnamese SMEs? J. Asian Bus. Econ. Stud. 2018, 25, 239–250. [Google Scholar] [CrossRef] [Green Version]

- Miron, E.; Erez, M.; Naveh, E. Do personal characteristics and cultural values that promote innovation, quality, and efficiency compete or complement each other? J. Organ. Behav. 2004, 25, 175–199. [Google Scholar] [CrossRef]

- Martins, E.C.; Terblanche, F. Building organisational culture that stimulates creativity and innovation. Eur. J. Innov. Manag. 2003, 6, 64–74. [Google Scholar] [CrossRef]

- Alofan, F.; Chen, S.; Tan, H. National cultural distance, organizational culture, and adaptation of management innovations in foreign subsidiaries: A fuzzy set analysis of TQM implementation in Saudi Arabia. J. Bus. Res. 2020, 109, 184–199. [Google Scholar] [CrossRef]

- Wu, L.-F.; Huang, I.-C.; Huang, W.-C.; Du, P.-L. Aligning organizational culture and operations strategy to improve innovation outcomes: An integrated perspective in organizational management. J. Organ. Chang. Manag. 2019, 32, 224–250. [Google Scholar] [CrossRef]

- Hernández-Mogollon, R.; Cepeda-Carrión, G.; Cegarra-Navarro, J.G.; Leal-Millán, A. The role of cultural barriers in the relationship between open-mindedness and organizational innovation. J. Organ. Chang. Manag. 2010, 23, 360–376. [Google Scholar] [CrossRef]

- Baker, W.E.; Sinkula, J.M. The Synergistic Effect of Market Orientation and Learning Orientation on Organizational Performance. J. Acad. Mark. Sci. 1999, 27, 411–427. [Google Scholar] [CrossRef]

- Cegarra-Navarro, J.-G.; Sánchez-Polo, M.T. Influence of the open-mindedness culture on organizational memory: An empirical investigation of Spanish SMEs. Int. J. Hum. Resour. Manag. 2011, 22, 1–18. [Google Scholar] [CrossRef]

- Kmieciak, R. Improving SME performance through organizational memory: The role of open-mindedness culture. J. Organ. Chang. Manag. 2019, 32, 473–491. [Google Scholar] [CrossRef]

- Reijseger, G.; Peeters, M.C.W.; Taris, T.W.; Schaufeli, W.B. From Motivation to Activation: Why Engaged Workers are Better Performers. J. Bus. Psychol. 2017, 32, 117–130. [Google Scholar] [CrossRef]

- Samaranayake, S.U.; Takemura, T. Employee Readiness for Organizational Change: A Case Study in an Export Oriented Manufacturing Firm in Sri Lanka. Eurasian J. Bus. Econ. 2017, 10, 1–16. [Google Scholar] [CrossRef]

- Mirzaee, S.; Ghaffari, A. Investigating the impact of information systems on knowledge sharing. J. Knowl. Manag. 2018, 22, 501–520. [Google Scholar] [CrossRef]

- Yang, J.-T. Individual attitudes to learning and sharing individual and organisational knowledge in the hospitality industry. Serv. Ind. J. 2009, 29, 1723–1743. [Google Scholar] [CrossRef]

- Mehdikhani, R.; Valmohammadi, C. Strategic collaboration and sustainable supply chain management: The mediating role of internal and external knowledge sharing. J. Enterp. Inf. Manag. 2019, 32, 778–806. [Google Scholar] [CrossRef]

- Van den Hooff, B.; De Ridder, J.A. Knowledge sharing in context: The influence of organizational commitment, communication climate and CMC use on knowledge sharing. J. Knowl. Manag. 2004, 8, 117–130. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Wang, N.; Liang, H. Knowledge sharing, intellectual capital and firm performance. Manag. Decis. 2014, 52, 230–258. [Google Scholar] [CrossRef] [Green Version]

- Yang, J. The impact of knowledge sharing on organizational learning and effectiveness. J. Knowl. Manag. 2007, 11, 83–90. [Google Scholar] [CrossRef]

- Dong, Y.; Bartol, K.M.; Zhang, Z.-X.; Li, C. Enhancing employee creativity via individual skill development and team knowledge sharing: Influences of dual-focused transformational leadership: Influences of Dual-Focused TFL on Creativity. J. Organ. Behav. 2017, 38, 439–458. [Google Scholar] [CrossRef]

- Zeb, A.; Abdullah, N.H.; Hussain, A.; Safi, A. Authentic leadership, knowledge sharing, and employees’ creativity. Manag. Res. Rev. 2019, 43, 669–690. [Google Scholar] [CrossRef]

- Arsawan, I.W.E.; Kariati, N.M.; Prayustika, P.A.; Wirga, I.W. Elucidating Knowledge Sharing on Innovative Work Behavior: Multiperspective Analysis. ICORE 2019, 5, 670–686. [Google Scholar]

- Hülsheger, U.R.; Anderson, N.; Salgado, J.F. Team-level predictors of innovation at work: A comprehensive meta-analysis spanning three decades of research. J. Appl. Psychol. 2009, 94, 1128–1145. [Google Scholar] [CrossRef]

- Liu, Y.; Phillips, J.S. Examining the antecedents of knowledge sharing in facilitating team innovativeness from a multilevel perspective. Int. J. Inf. Manag. 2011, 31, 44–52. [Google Scholar] [CrossRef]

- Lin, H. Knowledge sharing and firm innovation capability: An empirical study. Int. J. Manpow. 2007, 28, 315–332. [Google Scholar] [CrossRef] [Green Version]

- Radaelli, G.; Lettieri, E.; Mura, M.; Spiller, N. Knowledge Sharing and Innovative Work Behaviour in Healthcare: A Micro-Level Investigation of Direct and Indirect Effects. Creat. Innov. Manag. 2014, 23, 400–414. [Google Scholar] [CrossRef]

- Slavin, R.E. Research on cooperative learning and achievement: What we know, what we need to know. Contemp. Educ. Psychol. 1996, 21, 43–69. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.B.; Kim, K.; Ullah, S.M.E.; Kang, S.-W. How transformational leadership facilitates innovative behavior of Korean workers: Examining mediating and moderating processes. Pers. Rev. 2016, 45, 459–479. [Google Scholar] [CrossRef]

- AlShamsi, O.M.; Ajmal, M.M. Knowledge sharing in technology-intensive manufacturing organizations: Analytic hierarchy process approach. Bus. Process Manag. J. 2019, 25, 802–824. [Google Scholar] [CrossRef]

- Yang, Z.; Nguyen, V.T.; Le, P.B. Knowledge sharing serves as a mediator between collaborative culture and innovation capability: An empirical research. J. Bus. Ind. Mark. 2018, 33, 958–969. [Google Scholar] [CrossRef]

- Alavi, M.; Kayworth, T.R.; Leidner, D.E. An Empirical Examination of the Influence of Organizational Culture on Knowledge Management Practices. J. Manag. Inf. Syst. 2005, 22, 191–224. [Google Scholar] [CrossRef]

- Kumar Jha, J.; Varkkey, B. Are you a cistern or a channel? Exploring factors triggering knowledge-hiding behavior at the workplace: Evidence from the Indian R&D professionals. J. Knowl. Manag. 2018, 22, 824–849. [Google Scholar] [CrossRef]

- Mueller, J. A specific knowledge culture: Cultural antecedents for knowledge sharing between project teams. Eur. Manag. J. 2014, 32, 190–202. [Google Scholar] [CrossRef]

- Liao, L.-F. A learning organization perspective on knowledge-sharing behavior and firm innovation. Hum. Syst. Manag. 2006, 25, 227–236. [Google Scholar]

- Wah, C.Y.; Menkhoff, T.; Loh, B.; Evers, H.-D. Social Capital and Knowledge Sharing in Knowledge-Based Organizations: An Empirical Study. Int. J. Knowl. Manag. 2007, 3, 29–48. [Google Scholar] [CrossRef]

- Lin, F.; Evans, R.D.; Kharel, R.; Williams, R.A. Competitor Intelligence and Product Innovation: The Role of Open-Mindedness and Interfunctional Coordination. IEEE Trans. Eng. Manag. 2019, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Le, P.B.; Lei, H.; Le, T.T.; Gong, J.; Ha, A.T. Developing a collaborative culture for radical and incremental innovation: The mediating roles of tacit and explicit knowledge sharing. Chin. Manag. Stud. 2020. Ahead of Print. [Google Scholar] [CrossRef]

- Kablan, A. Dark Factories from an Industry 4.0 Perspective: Its Effects on Cost Accounting and Managerial Accounting. In Digital Business Strategies in Blockchain Ecosystems; Hacioglu, U., Ed.; Contributions to Management Science; Springer: Cham, Switzerland, 2020; pp. 503–518. ISBN 978-3-030-29738-1. [Google Scholar]

- Thames, L.; Schaefer, D. Software-defined Cloud Manufacturing for Industry 4.0. Procedia CIRP 2016, 52, 12–17. [Google Scholar] [CrossRef] [Green Version]

- Klieštik, T.; Nica, E.; Musa, H.; Poliak, M.; Mihai, E.A. Networked, Smart, and Responsive Devices in Industry 4.0 Manufacturing Systems. Econ. Manag. Financ. Mark. 2020, 15, 23–29. [Google Scholar] [CrossRef]

- Lee, R.; Lee, J.-H.; Garrett, T.C. Synergy effects of innovation on firm performance. J. Bus. Res. 2019, 99, 507–515. [Google Scholar] [CrossRef]

- Xie, X.; Huo, J.; Zou, H. Green process innovation, green product innovation, and corporate financial performance: A content analysis method. J. Bus. Res. 2019, 101, 697–706. [Google Scholar] [CrossRef]

- Bettiol, M.; Capestro, M.; Maria, E.D.; Furlan, A. Impacts of industry 4.0 investments on firm performance: Evidence from Italy; Working Papers 0233; Dipartimento di Scienze Economiche “Marco Fanno”: Padova, Italy, 2019. [Google Scholar]

- Haseeb, M.; Hussain, H.I.; Ślusarczyk, B.; Jermsittiparsert, K. Industry 4.0: A Solution towards Technology Challenges of Sustainable Business Performance. Soc. Sci. 2019, 8, 154. [Google Scholar] [CrossRef] [Green Version]

- Rukundo, J.B. Firm performance and innovation in the developing countries: Evidence from firm-level survey. Corp. Ownersh. Control 2017, 15, 235–245. [Google Scholar] [CrossRef] [Green Version]

- Abbas, J.; Zhang, Q.; Hussain, I.; Akram, S.; Afaq, A.; Shad, M.A. Sustainable Innovation in Small Medium Enterprises: The Impact of Knowledge Management on Organizational Innovation through a Mediation Analysis by Using SEM Approach. Sustainability 2020, 12, 2407. [Google Scholar] [CrossRef] [Green Version]

- Mariani, M.; Borghi, M. Industry 4.0: A bibliometric review of its managerial intellectual structure and potential evolution in the service industries. Technol. Forecast. Soc. Chang. 2019, 149, 119752. [Google Scholar] [CrossRef]

- Kmieciak, R.; Michna, A.; Meczynska, A. Innovativeness, empowerment and IT capability: Evidence from SMEs. Ind. Manag. Data Syst. 2012, 112, 707–728. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Podsakoff, N.P. Sources of Method Bias in Social Science Research and Recommendations on How to Control It. Annu. Rev. Psychol. 2012, 63, 539–569. [Google Scholar] [CrossRef] [Green Version]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Saini, R. Linking Knowledge Management and Innovation in SMEs: A Structural Equation Modeling Approach. IUP J. Knowl. Manag. 2015, 13, 45–64. [Google Scholar]

- Darroch, J. Developing a measure of knowledge management behaviors and practices. J. Knowl. Manag. 2003, 7, 41–54. [Google Scholar] [CrossRef]

- Wang, C.L.; Hult, G.T.M.; Ketchen, D.J.; Ahmed, P.K. Knowledge management orientation, market orientation, and firm performance: An integration and empirical examination. J. Strateg. Mark. 2009, 17, 99–122. [Google Scholar] [CrossRef]

- Lonial, S.C.; Carter, R.E. The Impact of Organizational Orientations on Medium and Small Firm Performance: A Resource-Based Perspective. J. Small Bus. Manag. 2015, 53, 94–113. [Google Scholar] [CrossRef]

- Nawanir, G. The Effect of Lean Manufacturing on Operations Performance and Business Performance in Manufacturing Companies In Indonesia. Ph.D. Thesis, Universiti Utara, Kuala Lumpur, Malaysia, 2016. [Google Scholar]

- Ringle, C.M.; Wende, S.; Becker, J.-M. SmartPLS 3; SmartPLS GmbH: Boenningstedt, Germany, 2015. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Benitez, J.; Henseler, J.; Castillo, A.; Schuberth, F. How to perform and report an impactful analysis using partial least squares: Guidelines for confirmatory and explanatory IS research. Inf. Manag. 2020, 57, 103168. [Google Scholar] [CrossRef]

- Ringle, C.M.; Sarstedt, M.; Mitchell, R.; Gudergan, S.P. Partial least squares structural equation modeling in HRM research. Int. J. Hum. Resour. Manag. 2020, 31, 1617–1643. [Google Scholar] [CrossRef]

- Rönkkö, M.; McIntosh, C.N.; Antonakis, J.; Edwards, J.R. Partial least squares path modeling: Time for some serious second thoughts. J. Oper. Manag. 2016, 47–48, 9–27. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, G. PLS Path Modeling with R; Trowchez Editions: Berkeley, CA, USA, 2013. [Google Scholar]

- Schermelleh-Engel, K.; Moosbrugger, H.; Müller, H. Evaluating the Fit of Structural Equation Models: Tests of Significance and Descriptive Goodness-of-Fit Measures. Methods Psychol. Res. 2003, 8, 23–74. [Google Scholar]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef]

- Carrión, G.C.; Nitzl, C.; Roldán, J.L. Mediation Analyses in Partial Least Squares Structural Equation Modeling: Guidelines and Empirical Examples. In Partial Least Squares Path Modeling: Basic Concepts, Methodological Issues and Applications; Latan, H., Noonan, R., Eds.; Springer: Cham, Switzerland, 2017; pp. 173–195. ISBN 978-3-319-64069-3. [Google Scholar]

- Nitzl, C.; Roldan, J.L.; Cepeda, G. Mediation analysis in partial least squares path modeling: Helping researchers discuss more sophisticated models. Ind. Manag. Data Syst. 2016, 116, 1849–1864. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Cegarra-Navarro, J.G.; Wensley, A.K.P. Congenital learning in the Spanish telecommunication industry. J. Bus. Ventur. 2009, 24, 533–543. [Google Scholar] [CrossRef]

- Jansen, J.J.P.; Van Den Bosch, F.A.J.; Volberda, H.W. Exploratory Innovation, Exploitative Innovation, and Performance: Effects of Organizational Antecedents and Environmental Moderators. Manag. Sci. 2006, 52, 1661–1674. [Google Scholar] [CrossRef] [Green Version]

| Item | Question |

|---|---|

| Open-mindedness culture (OMC) | |

| OMC1 | In our company, managers encourage employees to “think outside of the box”. |

| OMC2 | Original ideas are highly valued in this organization. |

| OMC3 | We are not afraid to reflect critically on the shared assumptions we have about the way we do business. * |

| OMC4 | Managers in this business unit do not want their “view of the world” to be questioned. (R) * |

| OMC5 | Problems, failures, and experiences are discussed openly to avoid making similar mistakes in the future. |

| Knowledge-sharing (KS) | |

| KS1 | We have special resources (people, infrastructure) to share knowledge and flow of information so that all employees have access to knowledge and information to the extent relevant to their tasks and goals. |

| KS2 | Our leaders share with employees updated information on competitors, industry trends, and organizational goals. |

| KS3 | Our remuneration system is conducive to teamwork and knowledge-sharing. |

| Financial performance (FP) | |

| FP1 | In our company, the return on investment is positive. |

| FP2 | The profitability of our company is higher than the profitability of competitors. |

| FP3 | The revenue growth in our company is higher than that of competitors. |

| Industry 4.0 (I) | |

| I1 | In the next 3-5 years, our company plans a significant increase in digitization and computerization. |

| I2 | In the next 3-5 years, our company plans to increase the degree of automation. |

| I3 | Our company plans to increase investment expenditure related to Industry 4.0 over the next five years. |

| I4 | Our company is involved in the development and implementation of Industry 4.0 solutions (digitization, computerization, cloud computing, Internet of Things, etc.) much more than competitors. |

| Construct | Mean | SD | Cα | rho_A | CR | AVE | Item | Loading | Kurtosis | Skewness |

|---|---|---|---|---|---|---|---|---|---|---|

| OMC | 3.98 | 0.85 | 0.73 | 0.73 | 0.85 | 0.65 | OMC1 | 0.748 | −0.716 | −0.654 |

| OMC2 | 0.836 | 1.470 | −1.167 | |||||||

| OMC5 | 0.834 | 1.482 | −1.266 | |||||||

| KS | 3.41 | 0.99 | 0.75 | 0.78 | 0.85 | 0.66 | KS1 | 0.718 | −1.253 | −0.138 |

| KS2 | 0.869 | −0.043 | −0.828 | |||||||

| KS3 | 0.844 | −0.385 | −0.452 | |||||||

| FP | 3.26 | 0.71 | 0.72 | 0.73 | 0.84 | 0.65 | FP1 | 0.709 | 0.515 | −0.961 |

| FP2 | 0.833 | 1.405 | 0.078 | |||||||

| FP3 | 0.860 | 1.386 | −0.027 | |||||||

| I | 2.96 | 0.99 | 0.79 | 0.80 | 0.86 | 0.61 | I1 | 0.801 | −0.893 | −0.398 |

| I2 | 0.753 | −1.242 | −0.070 | |||||||

| I3 | 0.823 | −0.859 | −0.280 | |||||||

| I4 | 0.742 | −0.789 | 0.213 |

| Construct | 1. | 2. | 3. | 4. | |

|---|---|---|---|---|---|

| 1. | Open-mindedness culture | 0.807 | 0.767 | 0.356 | 0.401 |

| 2. | Knowledge sharing | 0.587 * | 0.813 | 0.384 | 0.380 |

| 3. | Financial performance | 0.255 * | 0.288 * | 0.803 | 0.439 |

| 4. | Industry 4.0 | 0.310 * | 0.307 * | 0.347 * | 0.781 |

| Hypothesis | Suggested Effect | Path Coefficient | t-Value | p-Value | 95% BCa CI | Support |

|---|---|---|---|---|---|---|

| H1: Open-mindedness culture → Industry 4.0 | + | 0.163 | 3.527 | 0.000 | (0.069; 0.251)Sig. | Yes |

| H2: Knowledge-sharing → Industry 4.0 | + | 0.134 | 2.633 | 0.008 | (0.034; 0.236)Sig. | Yes |

| H3: Open-mindedness culture → Knowledge-sharing | + | 0.587 | 17.550 | 0.000 | (0.513; 0.646)Sig. | Yes |

| H5: Financial performance → Industry 4.0 | + | 0.267 | 6.293 | 0.000 | (0.175; 0.342)Sig. | Yes |

| Hypothesis | Direct Effect | 95% BCa CI | Indirect Effect | 95% BCa CI | Total Effect | 95% BCa CI |

|---|---|---|---|---|---|---|

| H4: Open-mindedness culture → Knowledge-sharing → Industry 4.0 | 0.163 | (0.069;0.253) Sig. | 0.079 | (0.020;0.142) Sig. | 0.242 | (0.165;0.315) Sig. |

| Relationship | Path Coefficient | Micro vs. Small | Micro vs. Medium | Small vs. Medium | |||||

|---|---|---|---|---|---|---|---|---|---|

| Micro | Small | Medium | P.c.diff. | p-value | P.c.diff. | p-value | P.c.diff. | p-Value | |

| FP → I | 0.256 * | 0.233 * | 0.238 * | 0.023 | 0.833 | 0.018 | 0.892 | −0.004 | 0.976 |

| KS → I | 0.028 | 0.209 * | 0.247 | −0.181 | 0.091 | −0.218 | 0.207 | −0.037 | 0.828 |

| OMC → I | 0.288 * | 0.080 | 0.159 | 0.208 | 0.032 | 0.129 | 0.435 | −0.079 | 0.656 |

| OMC → KS | 0.562 * | 0.609 * | 0.660 * | −0.047 | 0.498 | −0.097 | 0.325 | −0.051 | 0.628 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michna, A.; Kmieciak, R. Open-Mindedness Culture, Knowledge-Sharing, Financial Performance, and Industry 4.0 in SMEs. Sustainability 2020, 12, 9041. https://doi.org/10.3390/su12219041

Michna A, Kmieciak R. Open-Mindedness Culture, Knowledge-Sharing, Financial Performance, and Industry 4.0 in SMEs. Sustainability. 2020; 12(21):9041. https://doi.org/10.3390/su12219041

Chicago/Turabian StyleMichna, Anna, and Roman Kmieciak. 2020. "Open-Mindedness Culture, Knowledge-Sharing, Financial Performance, and Industry 4.0 in SMEs" Sustainability 12, no. 21: 9041. https://doi.org/10.3390/su12219041

APA StyleMichna, A., & Kmieciak, R. (2020). Open-Mindedness Culture, Knowledge-Sharing, Financial Performance, and Industry 4.0 in SMEs. Sustainability, 12(21), 9041. https://doi.org/10.3390/su12219041