Abstract

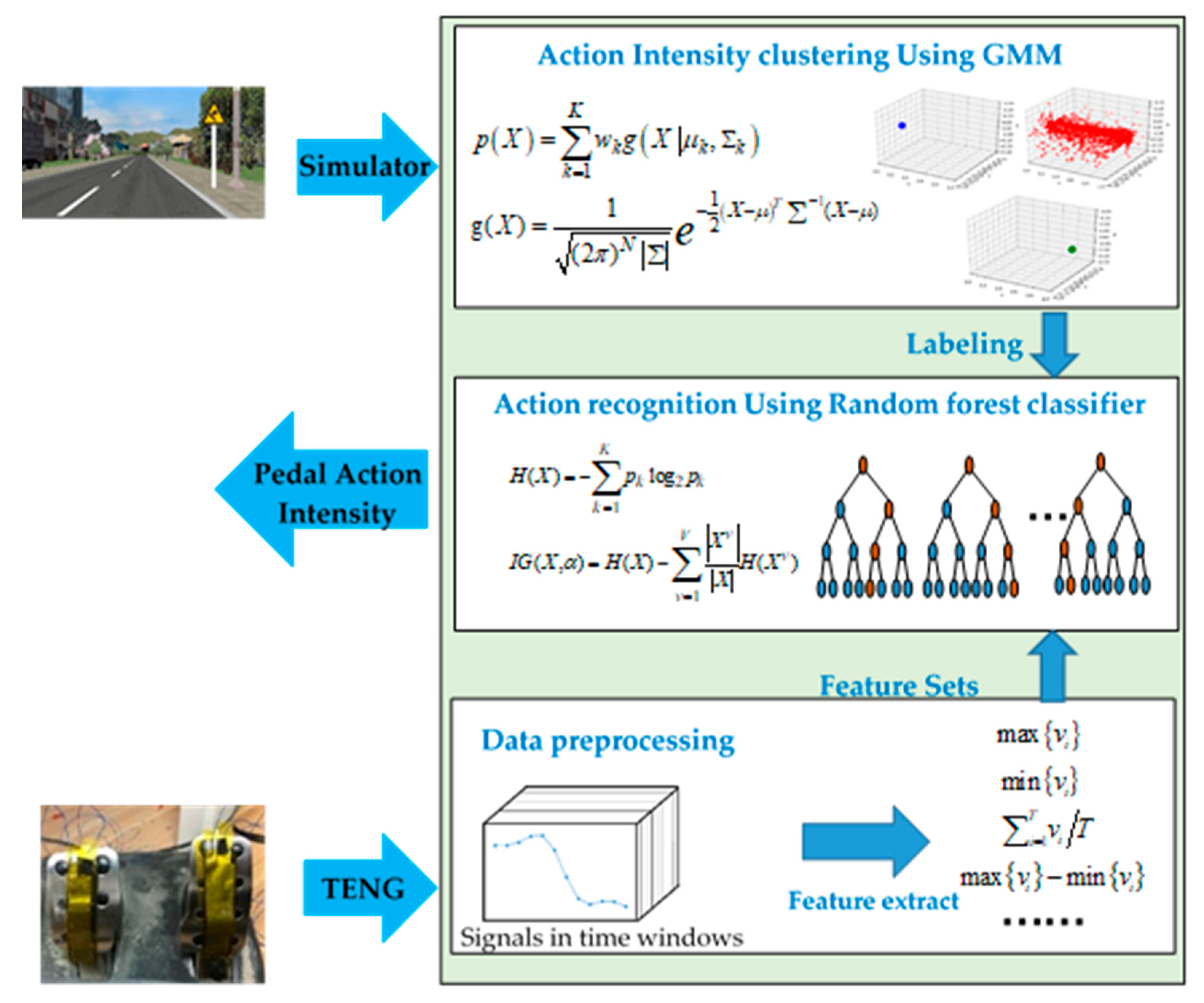

Driver’s driving actions on pedals can be regarded as an expression of driver’s acceleration/deceleration intention. Quickly and accurately detecting driving action intensity on pedals can have great contributions in preventing road traffic accidents and managing the energy consumption. In this paper, we report a pressure-sensitive and self-powered material named triboelectric nano-generators (TENGs). The generated voltage data of TENGs, which is associated with the pedal action, can be collected easily and stored sequentially. According to the characteristics of the voltage data, we have employed a hybrid machine learning method. After collecting signals from TENGs and driving simulator simultaneously, an unsupervised Gaussian mixture model is used to cluster the pedal events automatically using data from simulator. Then, multi-feature candidates of the voltage data from TENGs are extracted and ranked. A supervised random forest model that treats voltage data of TENGs as input data is trained and tested. Results show that data from TENGs can have a high accuracy of more than 90% using the random forest algorithm. The evaluating results demonstrate the accuracy of the proposed data-driven hybrid learning algorithm for recognition of driver’s pedal action intensity. Furthermore, technical and economic characteristics of TENGs and some common sensors are compared and discussed. This work may demonstrate the feasibility of using these data-driven methods on the detection of driver’s pedal action intensity.

1. Introduction

Road traffic accidents have resulted in the deaths of 1.35 million people every year around the world [1]. According to the National Highway Traffic Safety Administration, almost 80% road traffic accidents are related to driver’s improper driving actions. In the process of driver–vehicle interaction, manipulation actions on steering wheel, brake and gas pedals convey most of the command information from driver to vehicle [2]. Thus, improper manipulations may result in road traffic accidents [3,4]. Among all the kinds of driver’s actions on the vehicle, actions on brake and gas pedals are used by drivers to generate deceleration and acceleration of the vehicle. It acts as an important part of the serialized driving behavior [5]. Thus, a fast and accurate detection method for different action levels on pedals may contribute to the prevention of traffic accidents [6], which acts as a function in advanced driving assistance systems (ADAS) [7].

Intelligent vehicles have been raising increasing attention nowadays [8,9]. In order to meet the functional requirement of intelligent vehicles, more measurement data of drivers are needed. In terms of the data source, there are mainly three kinds of detection methods. Firstly, data from the Controller Area Network (CAN) is used. Zhou [10] employed a random forest algorithm to classify the brake intention into four levels: slight, medium, intensive and emergency braking. Lv [11] used a hybrid-learning method. The braking intensity is classified into three levels using Gaussian Mixture Model (GMM). Secondly, pictures captured by camera are used. Tran [12] proposed a new machine-vision based framework for driver foot tracking. A Hidden Markov Model (HMM) is used to infer the brake and acceleration pedal states. They classify the pedals’ states into seven classes and get a high accuracy of 94%. Ohn-Bar [13] equipped an in-vehicle video network to monitor the temporal activities from drivers. Brake events, overtake events and normal driving events can be detected separately. Physiological psychology signals from drivers are used in another method. Haufe [14] used electroencephalography (EEG) and electromyography to predict emergency braking. Detailed information of some representative research studies are listed in Table 1.

Table 1.

Summary of some representative research.

However, there are some drawbacks for these methods. For the method utilizing data from CAN bus, the processing time may be too long not to meet the real-time requirement [11]. Data from cameras can be influenced by the vibration, illumination and occlusion [12,13,15]. Data-collecting devices for physiological psychology signals are usually intrusive, which may influence the drivers’ intention to use them [14,16]. In order to better meet the requirement of real-time and robust, another detection approach for proper actions on pedals is needed.

The triboelectric nanogenerator (TENG), as a newly developed self-powering device, is gaining more and more attentions [18]. It can convert various kinds of mechanical energy into electrical signals by coupling between the contact-electrification effect and electrostatic induction effect. It has been widely used in energy harvesting [19,20,21,22,23,24,25,26,27], medical treatment [28,29], wearable devices [30,31,32], liquid detection [33], pressure detection [34,35], etc. The technical feasibility of using TENGs in vehicle is also researched. A detailed review of research on TENGs’ usage in vehicles is reviewed by Askari et al. [36]. However, there is hardly any research on its application in detecting the pedal action intensity of the vehicle [37].

In this study, we examine the possibility of using the voltage data of triboelectric nanogenerators (TENGs) in detecting the action intensity on the brake/gas pedal. In order to compare the response speeds of different sensors and evaluate the accuracy of detection using TENG, two driving simulator-based experiments were conducted. Reaction times of data from driving simulator, camera and TENG were compared.

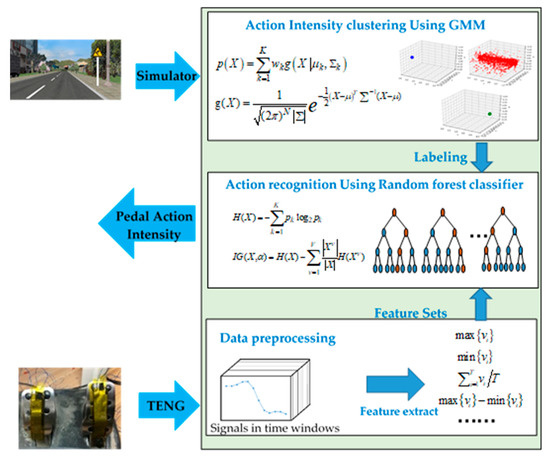

Owing to the electric-generation principle of triboelectric nano-generators (TENGs), the voltage data from triboelectric nano-generators (TENGs) is highly related with actions on pedal. However, it also has the characteristics of large scale and nonlinearity. A hybrid machine learning based algorithm was developed. An unsupervised algorithm was used to label the pedal action intensity according to data from driving simulator. The random forest algorithm was used in this classification task. Performances of models with different hypo-parameter sets were evaluated and compared.

2. Materials and Methods

Two driving simulator-based experiments were designed. In order to compare the potential detection speeds of different sensors, experiment 1 was conducted. Data from driving simulator, camera and TENGs were collected simultaneously. Response times for each sensor were defined and compared.

In experiment 2, participants were asked to accomplish a virtual driving task in a virtual high-way scenario. Data from a driving simulator and TENGs were collected. Using data from the driving simulator, a Gaussian Mixture Model (GMM) was employed to cluster them and label the voltage data collected from TENGs. Furthermore, a classification algorithm was developed to detect the intensity levels on brake/gas pedals based on the voltage signal in TENGs. Performances of the classification algorithms, which have different hypo-parameter sets, were compared.

2.1. Apparatus and Participants

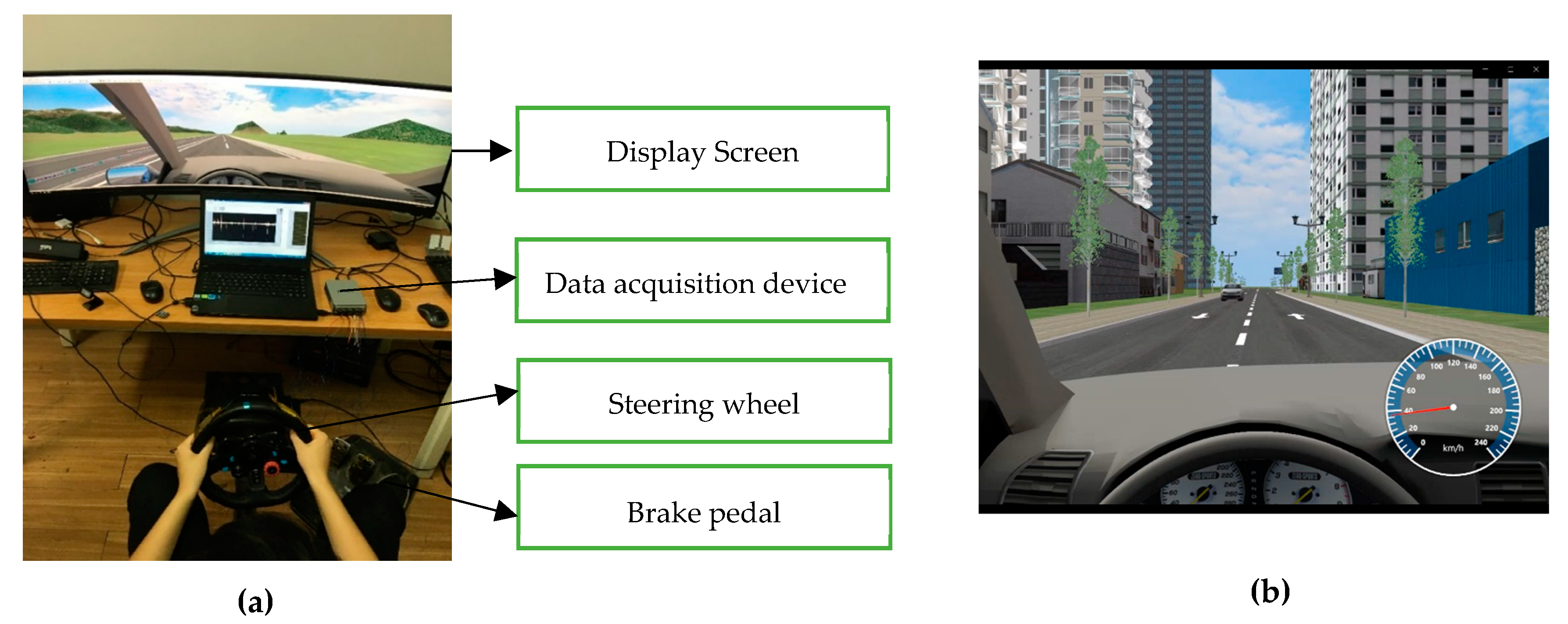

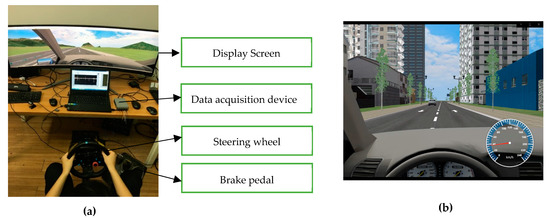

Apparatus and participants are described in this section. The experiment platform is shown in Figure 1. It is mainly composed of three parts: driving simulator, camera and triboelectric nano-generators (TENGs). We would introduce them, respectively, in the next paragraphs.

Figure 1.

(a) Driving simulator-based experiment platform, (b) driving scenario.

Driving simulator: A static driving simulator was used. The driving simulation software named UC-win/Road was used for designing and running driving scenarios. It can generate a triple visual field for virtual driving. During the simulated driving, pedals’ positions were obtained through the photoelectric sensor of the driving simulator and recorded by the driving simulator software together with the system time.

Camera: A Logitech C170 web camera was used. It recorded the pictures of the pedals during the experiment. It provided an alternative way to detect the actions on pedal. Using the OpenCV library, pictures were all attached with the coordinate system time.

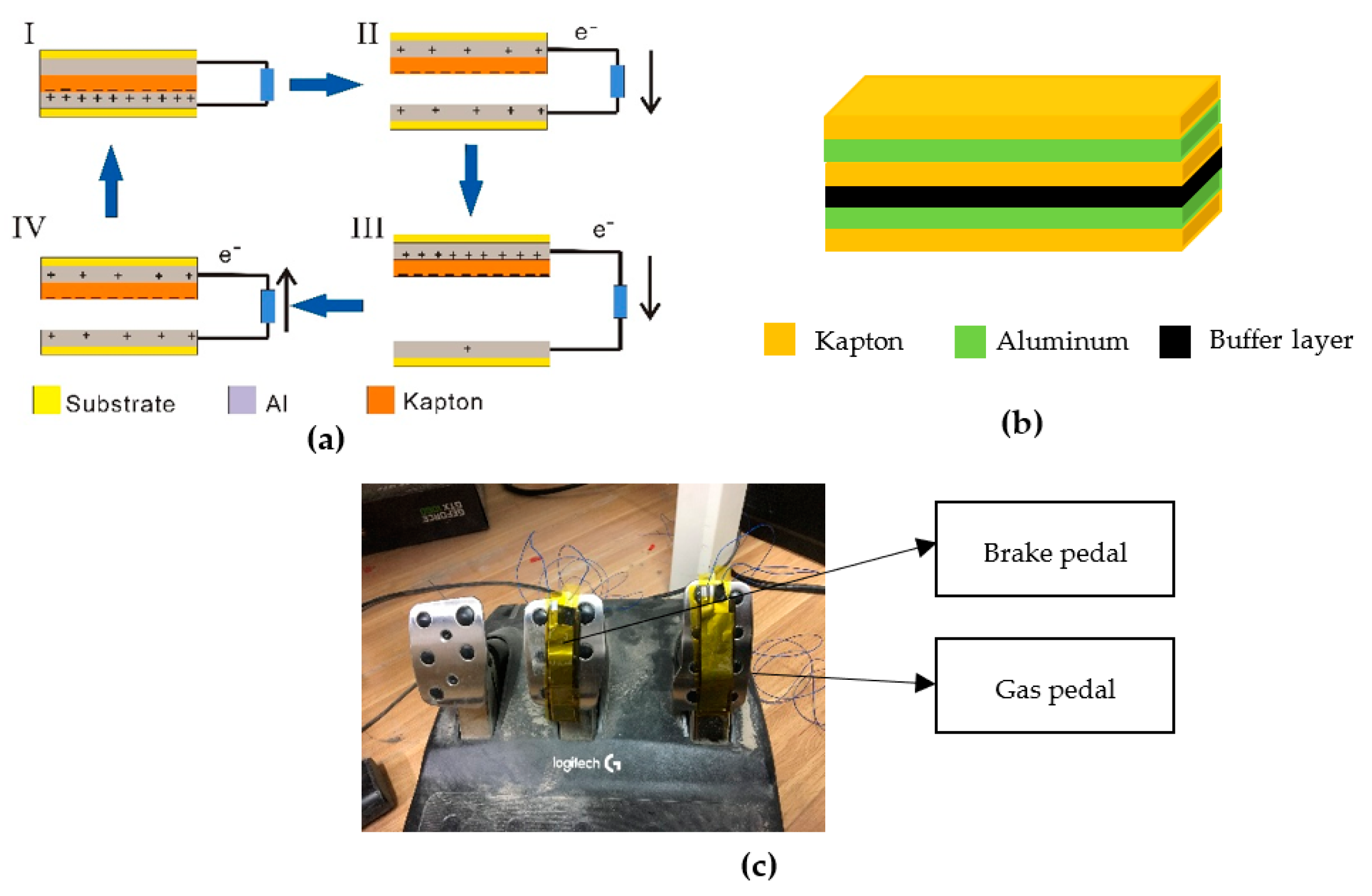

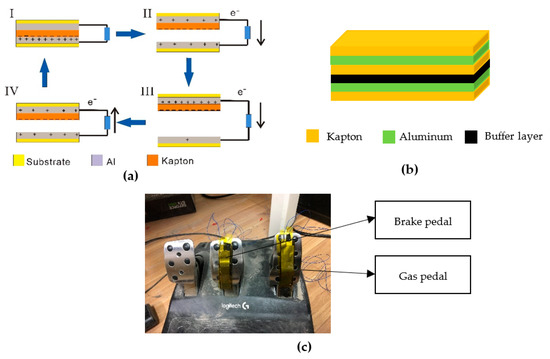

TENGs: In terms of structure, triboelectric nano-generators (TENGs) can be divided into four types: lateral sliding-mode-based TENG, vertical contact-separation-mode-based TENG, single-electrode-based TENG and freestanding triboelectric-layer-based nanogenerators. In this study, vertical contact-separation-mode-based triboelectric nano-generators (TENGs) were used. The structure of triboelectric nano-generators (TENGs) is shown in Figure 2. The voltage of triboelectric nano-generators (TENGs) was collected and converted into digital signals via a Keithley 6514 system electrometer. The working principle and characteristics of triboelectric nano-generators (TENGs) are described in the next paragraphs.

Figure 2.

(a) Schematic illustration of electrical signal’s generation from triboelectric nano-generator (TENG), (b) structure of sensors in this study, (c) photo showing the fixing position of TENGs on pedals.

As shown in Figure 2a, in the first stage I, the two friction layers are closely attached to each other, resulting in charge separation. As the two friction layers are closely contacted, the generated electric fields cancel each other, and the voltage at this time is zero. As the two friction layers are separated, a potential difference is established between the two electrodes. Due to the electrostatic induction effect, the driving electrons flow from the upper electrode to the lower electrode to achieve electrostatic balance, generating a positive voltage and current response (stage II). When the separation distance between the two friction layers continues to increase until the induced positive charge on the upper back electrode completely neutralizes the net negative charge on kapton, the voltage reaches its maximum at this time (stage III). At stage IV, kapton returned too close to aluminum again. At this time, in order to achieve electrostatic equilibrium again, electrons flowed from the lower electrode to the upper electrode, resulting in a voltage drop until the initial state was restored. This contact-separation mode of triboelectric nano-generators (TENGs) makes it have the ability to convert mechanical energy into electrical energy through the coupling of frictional electrification and electrostatic induction.

According to the requirement of our task, a customized TENG is needed. It should quickly generate voltage data when the driver has a pedal action, while it should quickly return to the original state when the pedal action ends. Kapton and Al are two materials with great different friction polarities in the friction sequence table. Al can be used as a friction layer and electrode at the same time and has a stronger ability to lose electrons than Cu in the positive friction polarity, while Kapton has a strong ability to obtain electrons in negative friction sequences. Choosing Kapton and Al as friction materials is an economical choice on the basis of meeting output requirements. As shown in Figure 2b, we improved the structure of TENG to adjust it in accomplishing pedal state detection. It is composed of kapton, aluminum and buffer layer. The top and bottom are encapsulated by kapton tape, the bottom kapton film of the upper layer is selected as a friction layer, and the middle aluminum is used as the back electrode of kapton. The aluminum strip on top of the lower layer acts as another friction layer and electrode. The upper and lower layers are separated by buffer layers on both sides to create a gap, so that the contact between the two friction layers can be separated when an external force is applied.

Participants: For experiment 1, 10 students (5 males; 5 females) were recruited. For experiment 2, 30 students (20 males; 10 females) were recruited. They ranged in age from 23 to 29. They were required to have a valid driver’s license and were all free from orthopedic or neurological disease.

2.2. Experiment Design

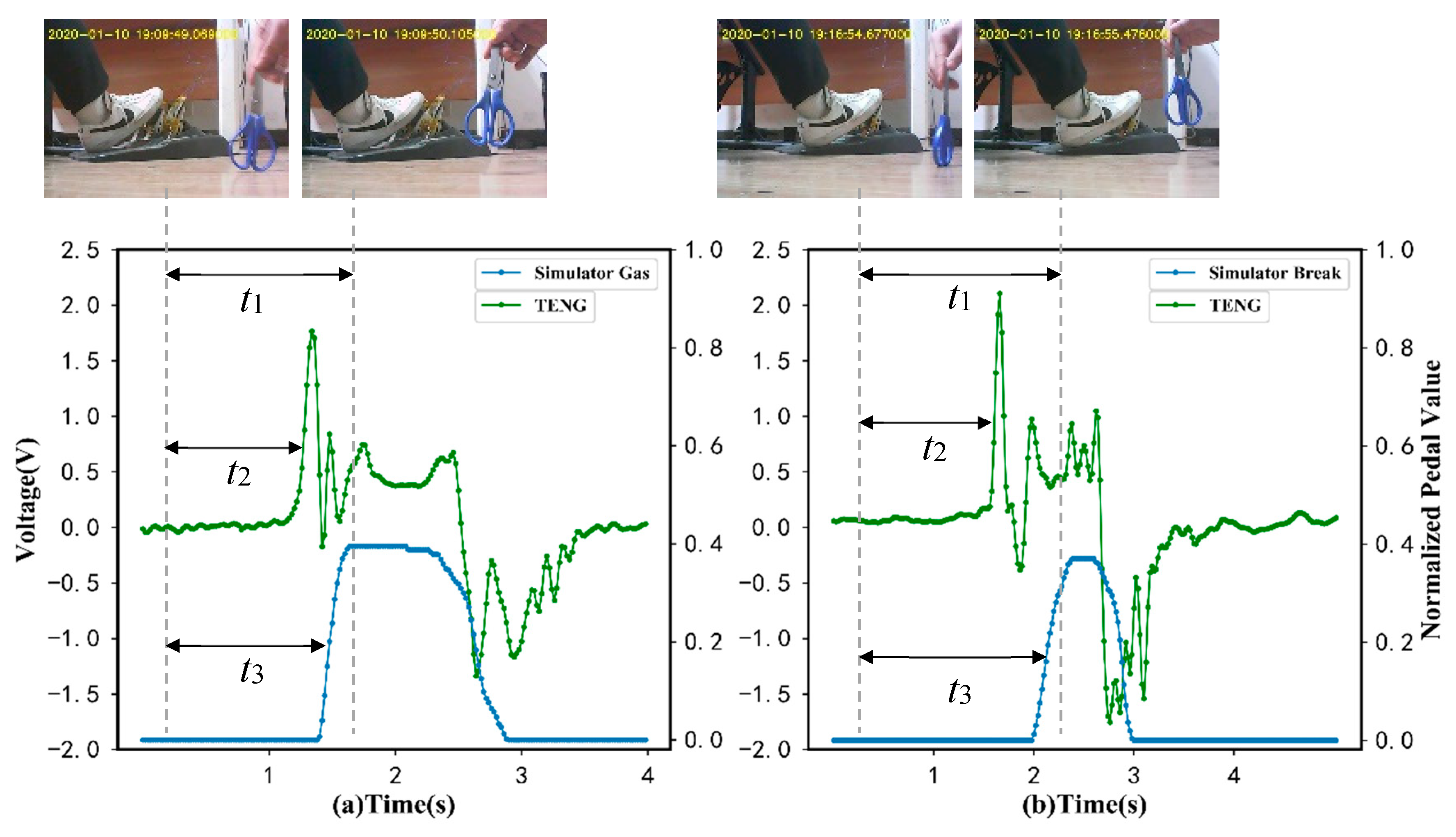

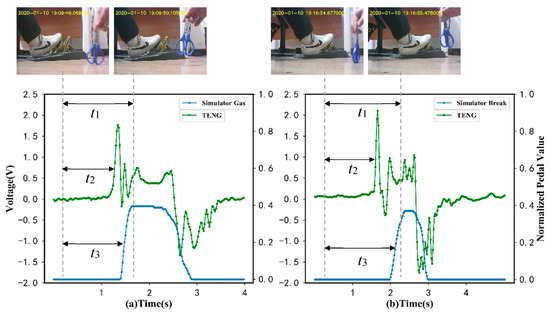

Experiment 1: As shown in Figure 3, pictures of the foot from camera, digital signals from TENG and simulator were collected synchronously. Participants were asked to make actions on the brake/gas pedal according to the command. In this study, we used a tapping action to generate the command. The tapping action was also recorded by the camera. The time interval between the command time and the time when the signal has a significant change was defined as the “reaction time” of a sensor. Detailed information is listed as follows:

Figure 3.

Schematic diagram of reaction time (a) gas pedal, (b) brake pedal.

TENG: We set the end time as the time when the voltage value is above 0.5 V.

Driving simulator: We set the end time as the time when the normalized value is above 0.1.

Camera: We set the end time as the time when we can obviously observe the displacement change in the picture.

Reaction time for the three kinds of data resource was extracted manually and compared statistically.

Experiment 2: In this experiment, participants were asked to perform simulated driving in a highway with a front vehicle. They were asked to follow the car in front but not to overtake it. The front vehicle was set to operate at a changing speed. Then frequent accelerating and deceleration can be generated and recorded. We collected data from the TENG and driving simulator synchronously. These data were used to train and test the detection algorithm. Data from the driving simulator was used as the ground truth of the action. It is clustered by an unsupervised algorithm. The clustering result was used as the labels of data from TENGs. A supervised machine learning algorithm was used as the detection algorithm to detect the action levels on pedals. Detailed information of the data and algorithm is shown in the next section.

2.3. Data and Algorithm

Data: For experiment 2, separate datasets were created for the two individual modalities driving simulator and TENG. They were all attached with the system timestamps from the same computer. In previous works, TENG application is suitable for dynamic- and oscillatory-type excitation. Considering the excitation of pedal force, the generated data from TENGs may be non-periodic, which is a new challenge of our work. In order to develop an algorithm that can automatically detect the action intensity levels on the brake/gas pedals, a machine-learning-based algorithm was developed. Data from the driving simulator were used as the ground truth. A GMM algorithm was used to cluster them. The result of clustering was used to label the data from TENGs. Classification algorithms can be trained and tested after labelling.

Labeling of actions using GMM: According to the data recorded from driving simulator, actions on brake/gas pedal were clustered using the Gaussian Mixture Model (GMM). The Gaussian Mixture Model (GMM) is a probability density function that is represented by the sum of weighted sub-Gaussian components. In this study, GMM was used to obtain the probability distribution of the gas/brake pedals. Three clusters were generated empirically for each pedal. Series of normalized brake/pedal values can be described as . Considering the first and second order differences, data from the driving simulator can be represented by the following equation:

where represents the normalized value of pedal, represents the difference of x between the adjacent moment, represents the difference of between the adjacent moment. For each 3-dimentional value at time t, the probability density can be represented by the following equation:

where K is the number of clusters in GMM, is the weight of each component’s Gaussian distribution. is the kth component’s probability. is the vector of mean values for each dimension. is the covariance matrix of each dimension.

Given the data , the purpose of training is to calculate for each component. The Expectation-Maximization (EM) algorithm was used, which contains two steps, i.e., the E-step and the M-step.

(1) E step: estimate the posterior probability of each component k in data point i:

(2) M step: update the parameters according to the following equations:

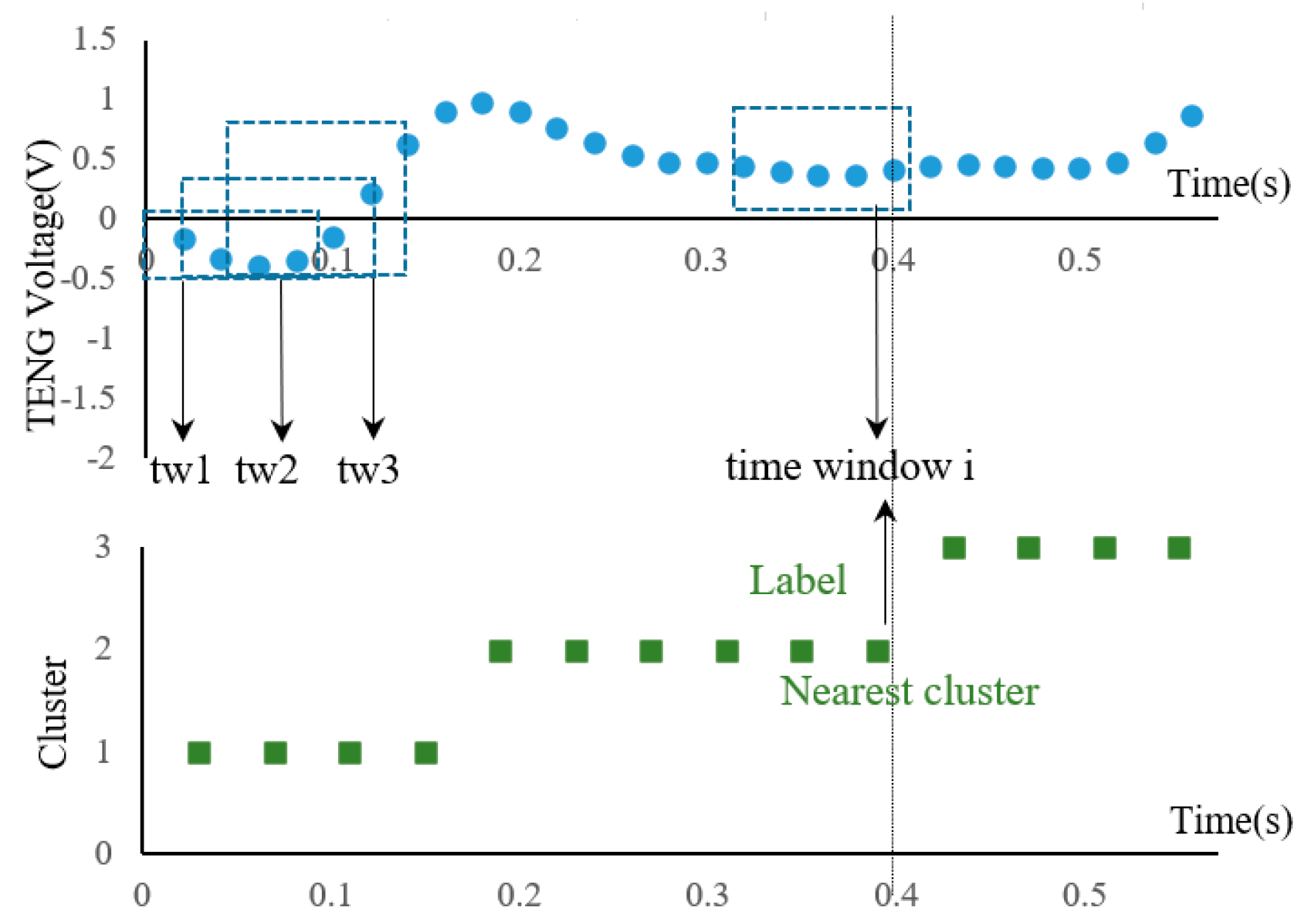

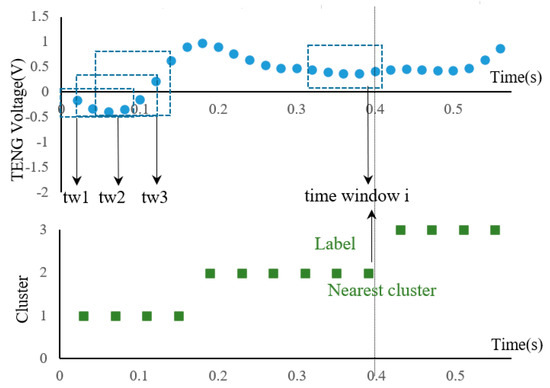

Feature selection: After the labeling stage, data from TENG were prepared for the classification. Firstly, we split the signal into time windows with the same width. For the stride of time windows, we set it to 1. Then the data from TENG were converted into time windows. Each time window was labelled by using the end point. The temporally nearest cluster result from the end point of time window was used as the label of each time window. The process of labelling is shown in Figure 4.

Figure 4.

Process of labeling from the clustering result.

Given a time window where represents the voltage from TENG at timepoint i. represents the width of the time window. After fast Fourier transform, we can obtain the amplitude and power vector , where represents the corresponding frequency. A feature vector would be generated. Features were extracted from the time window. Considering the common time domain and frequency domain features, we selected 42 feature candidates in this study. They are shown in Table A1 (Appendix A). Flowchart of experiment 2 is shown in Figure 5.

Figure 5.

Flowchart of experiment 2.

Model selection: After converting the time window into a feature vector, a classification algorithm was required to map the feature set into the label acquired from GMM. According to the research [38], the Random Forest (RF) algorithm achieved the best performance on 121 public datasets among 179 classification algorithms. Therefore, we used the Random Forest (RF) algorithm to infer the action level based on the TENG’s signals. Other common classification algorithms were also tested and compared.

The Random Forest algorithm is one kind of the ensemble learning methods. It is a classifier consisting of several decision trees. Its output is determined by the votes of these decision trees. A decision tree algorithm is a popular machine learning algorithm. It employed a tree structure to accomplish the classification task. It consists of one root node, multiple middle nodes and leaf nodes. The structure of the decision tree is constructed by optimizing the information entropy.

Several decision trees are employed in one Random Forest (RF) algorithm. Output of RF is the ensemble of outputs from these decision trees. Weights of each decision tree’s output are updated based on their performances.

3. Results

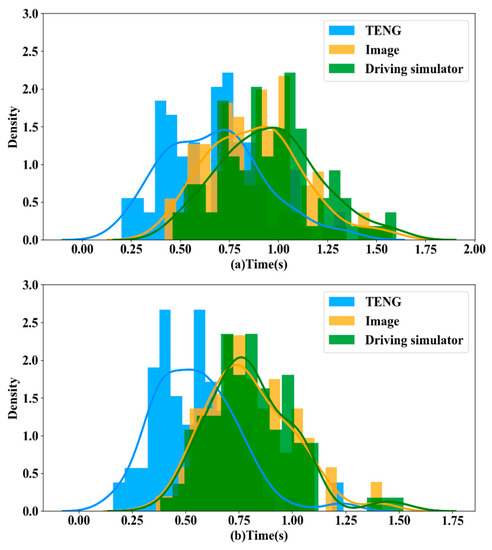

3.1. Reaction Time

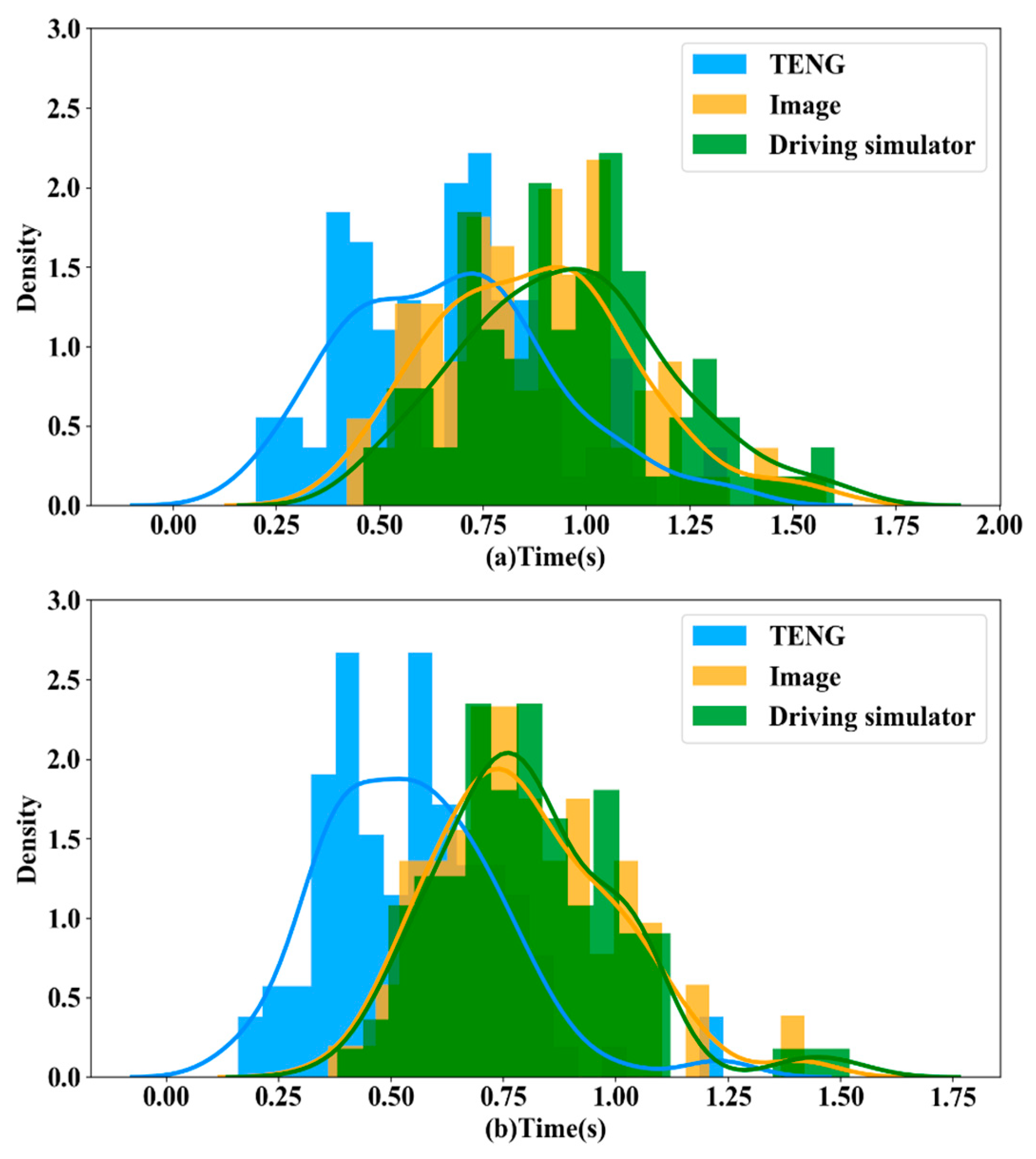

The sensitivity for responding to the driver’s stepping action can reach 100%, that is, the corresponding electrical signal can be measured for every stepping action. Reaction time for the three sensors was extracted manually. They were compared using paired t-test. Totally 80 (number of actions) × 3 (number of sensors) × 2 (number of pedals) = 480 reaction time was extracted. Distributions of each kind are shown in Figure 6. For the gas pedal, reaction times of TENG (mean = 0.670, SD = 0.250) were significantly shorter than the camera’s (mean = 0.880, SD = 0.243) and driving simulator’s (mean = 0.956, SD = 0.251). There is also a significant difference (p < 0.001) between the driving simulator’s and camera’s reaction time. Similar results were observed for the brake pedal. Reaction times of TENG (mean = 0.548, SD = 0.197) were significantly shorter than the camera’s (mean = 0.798 SD = 0.201) and driving simulator’s (mean = 0.806, SD = 0.202). No significant difference was observed between the driving simulator’s and camera’s reaction time on the brake pedal.

Figure 6.

Distributions of reaction time from different sensors. (a) Gas pedal, (b) brake pedal.

3.2. Performance of the Algorithm

Totally 5560 seconds’ driving data were recorded. For the data from driving simulator, we used GMM to cluster them into three clusters. Detailed information about them is shown in Table 2. TENG’s data were split into the training set and validation set. The training set takes up 70% of the data. All the TENG’s data were all labelled using the clustering result according to the time stamp.

Table 2.

Clustering results for brake/gas pedal.

(a) Training

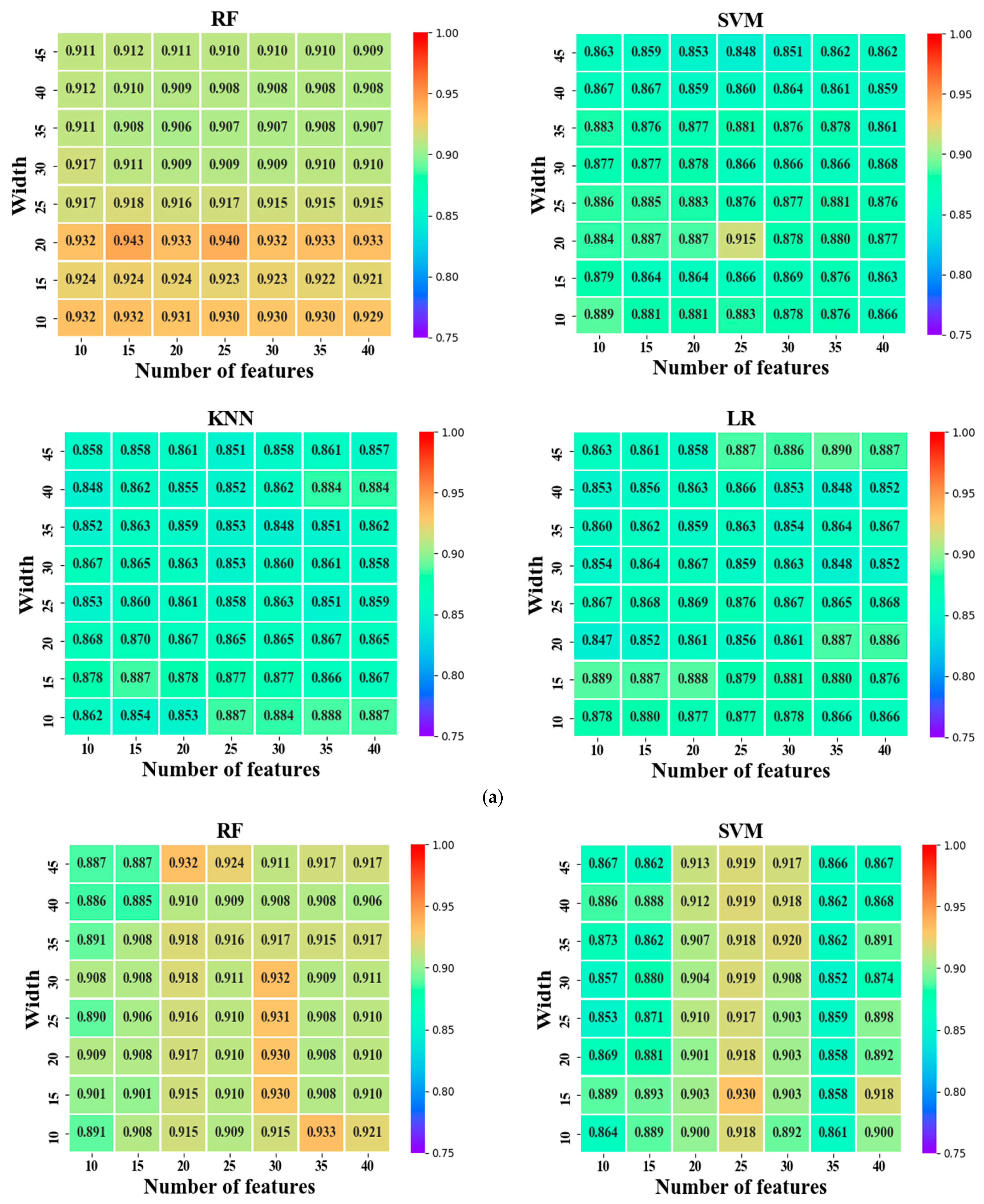

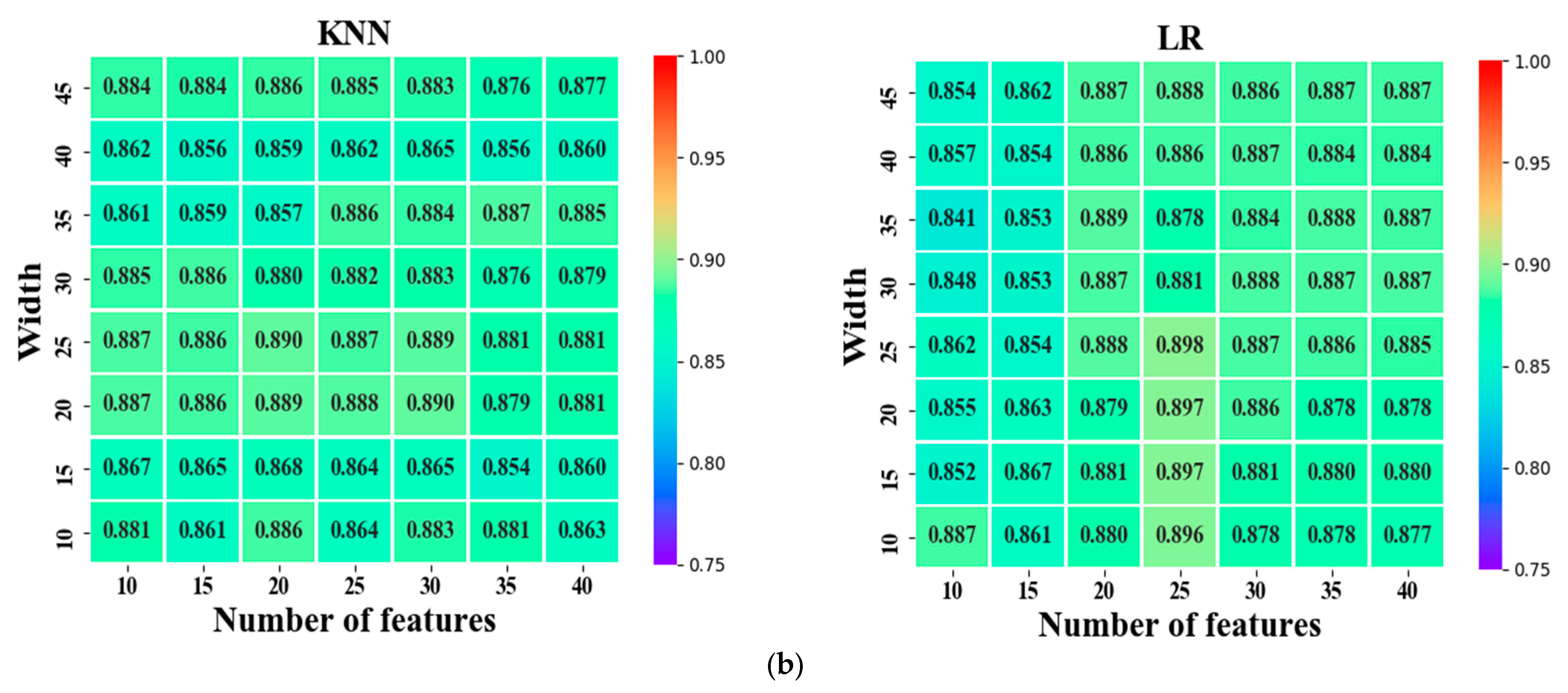

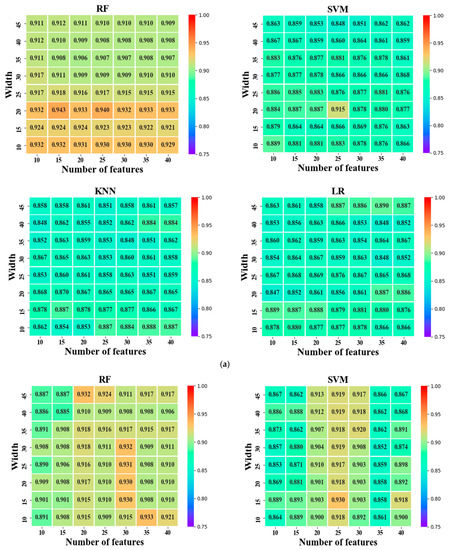

After labelling the TENG’s data, a random-forest-based classifier would be trained and tested. Voltage data of TENGs were split into training set and evaluating set. The training set takes up 70% of the data. To achieve the best performance of the algorithm, there are three hypo-parameters to be confirmed: width of time window, number of ranked features and the type of classifier. They are listed in Table 3.

Table 3.

Lists of hypo-parameters.

Width of time window: Width of the time windows should be confirmed when we split the data into time windows. Width of the time windows could have an effect on the accuracy and computation cost of the algorithm. In this study, the sampling interval was set to 0.02 s. We tested nine different widths of time window, namely, 5, 10, 15, 20, 25, 30, 35, 40, 45.

Number of ranked features: For one definite width of time window, we ranked the feature candidates according to the performance of the model using single feature candidate. Rankings of features were different with different widths of time window. After ranking the features, we could select the feature candidates according to the rankings. Number of ranked features could also influence the accuracy and computation cost of the algorithm, which should be confirmed. We tested eight different numbers of ranked features, namely, 5, 10, 15, 20, 25, 30, 35, 40.

Classifier: Besides the random forest algorithm, we also used three other common classification algorithms for comparison, namely support vector machine (SVM), logistic regression (LR) and K Nearest Neighbor (KNN).

In order to get the optimal combination of parameters, a ten-fold cross validation was conducted. We used micro F1 score as the evaluation criteria for each hypo-parameter group. It can be calculated by the following formula:

where P and R represent the precisions and recalls for the all classes, respectively.

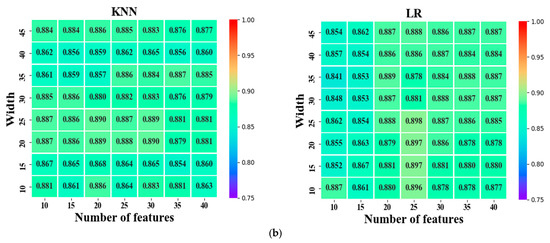

Relationship between micro F1 and hypo-parameters were illustrated in Figure 7.

Figure 7.

Performances of different classifiers: (a) gas pedal, (b) brake pedal.

From the figure, we can conclude that the F1 score changes with different hypo-parameter sets. For the Random Forest algorithm, it outperforms the other three algorithms in both detection tasks. It achieved the highest F1 score when it used 20 as the width of time window and 15 as the number of features for the gas pedal. Similarly, it achieved the highest F1 score when it used 10 as the width of time window and 35 as the number of features for the brake pedal. SVM ranks second in terms of performance. There is no significant difference between the performances of KNN and LR. Table 4 shows the hypo-parameter groups of each classifier when they achieve the highest F1 score.

Table 4.

Hypo-parameter sets of best performance for each classifier: (a) gas pedal, (b) brake pedal.

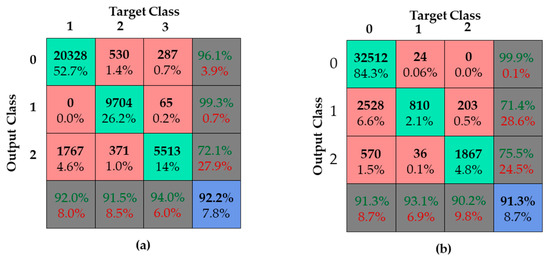

(b) Evaluating

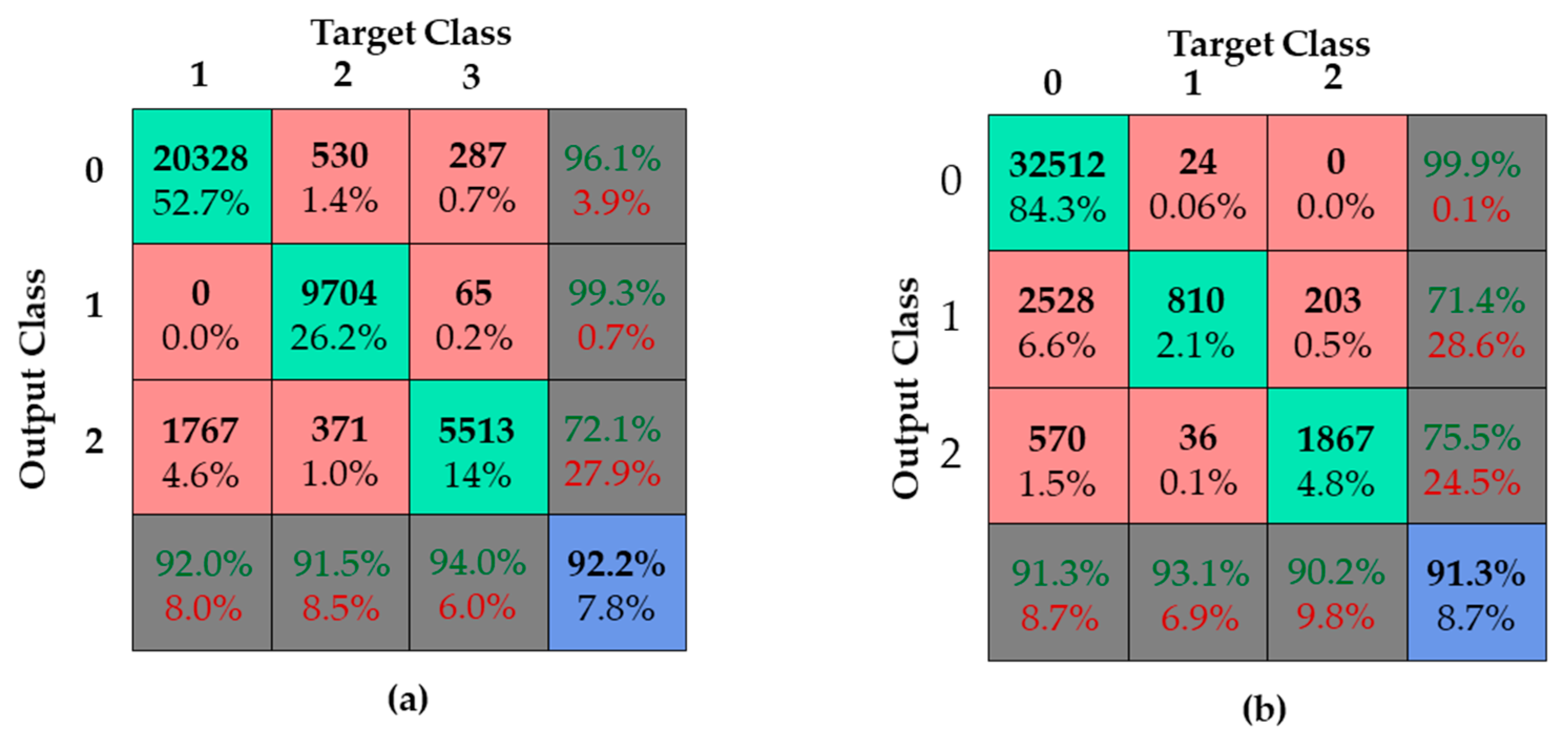

According to the performance (F1 score and training time) in the training set, we selected the Random Forest algorithm with the optimal hypo-parameter group to accomplish the evaluation task. We used the confusion matrix to assess the detail performance of the Random Forest algorithm. This is shown in Figure 8. For each cluster, more than 800 time windows of voltage data from TENGs were predicted and compared. According to the confusion matrixes, we can conclude that the prediction accuracies for every cluster for the two pedals were all more than 90%. For voltage data from gas pedal, cluster 3 achieves the best accuracy of 0.940. For voltage data from brake pedal, cluster 2 achieves the best accuracy of 0.931.

Figure 8.

Confusion matrixes for test sets: (a) gas pedal, (b) brake pedal.

4. Discussion and Conclusions

In this study, we examine the feasibility of using self-powered material triboelectric nano-generators (TENGs) to detect the pedal action’s intensity. Owing to the non-observability of the intensity level, an unsupervised algorithm was employed to automatically label the voltage data collected from triboelectric nano-generators. Data size can be large in unit time resulting from the mechanism of triboelectric nano-generators (TENGs). Thus, the data-driven classification algorithm would be explored and conducted. Owing to the characteristics of data collected from TENGs, a customized algorithm is needed. The excitation of pedal action is non-periodic and complex. We proposed a machine-learning-based algorithm. After ranking the feature candidates, features that were highly related with the labels were selected. From the training result, we can find that Random Forest outperforms the other three algorithms. This corresponds to the result of [38]. Evaluation results for detection in our study are above 90% on average. The evaluation result has proved the data from TENGs can be used as a data source for pedal action intensity detection. The result was comparable with other sensors, which will be compared in the next paragraphs.

In terms of application prospect, several attributes for sensors should be considered. Firstly, a shorter reaction time means a quicker response, which may help meet the real-time requirement. From our experiment 1, we compared the reaction time from driving simulator, camera and TENG. The result shows that the reaction time of TENG is significantly shorter than those of driving simulator and camera. It is consistent with the fact that spatial location-based sensors may have a longer reaction time than pressure-based sensors. The camera and simulator all need to detect the action when the pedal’s state is changed, while TENGs could generate data when there is a pressure force. This study examines the reaction speeds from different sensors and demonstrates the outstanding performance of TENGs.

Secondly, robustness is another key issue. From our experiment 2, we test the utility of TENGs in detecting different pedal action intensity. Results show that the TENG has accuracies of more than 90% in detecting the gas and brake pedals’ action intensity. For camera, Tran [12] used it in detecting driver foot gestures and achieved an accuracy of 94% on average. Lv [11] used data from CAN to detect the braking intensity levels. A maximal accuracy of 96.9% is achieved. Performances of TENG in our study were comparable with the results from other sensors accomplishing the similar tasks. Although recent research studies have reported that humidity can affect the performance of TENGs, environmental conditions in the vehicle are relatively stable compared with the environmental conditions outside. Furthermore, data mining technology can help deal with the complex and non-linear data.

Thirdly, the cost of the products is also an important indicator. Although the manufacturing cost of other sensors was constantly changing and gradually decreasing. The manufacturing cost of TENG was very low. It used the very common materials that can be seen everywhere in our daily lives. The cost of production was also very low, which is favorable for TENG’s application in many fields.

Finally, power supply during usage is another important indicator. Many kinds of sensors (camera, CAN) in vehicles need external power when collecting data. However, TENG, as a self-powered sensor, does not need external power. It can harvest the bioenergy from the driver and provide useful signals for the vehicle, which exhibits an obvious advantage [39]. The self-powered material can not only deal with the energy saving but also helps reduce the cost and consumption caused by power delivery. Moreover, its high portability provides us with a convenient way to use, recycle and develop, which may be another advantage. However, traffic accidents may be caused by various actions of drivers. Other than pedal actions, there are many driving behaviors that should be monitored for preventing accident. It is an important task in the future to simultaneously monitor several actions.

However, there are many factors that may influence the performance of the algorithm. The usage time is one of them. In fact, the TENG performance may change after several uses. To overcome this problem, we can establish a database of data collected from TENGs under different usage times. Then, we can train multiple classifiers suitable for different levels of usage time. Then, we can expand our algorithm using data from TENGs and the usage time as input. Alternatively, we can train a generalized classifier which can deal with all kinds of situations. In this study, we only investigate the TENGs’ performance in which they are used within 20 min. It would be our next work. In addition, driver’s pedal actions can be influenced by the driver’s characteristics. Thus, a complete database containing labelled data at different usage times collected from different kinds of drivers would be needed, which is our future work. Furthermore, steadier and more robust TENGs can be designed and manufactured in the future. It may help improve the performance of our algorithm.

Detecting the action intensity of pedals may have many contributions. Firstly, it can act as a data resource of some driving assistant systems that aim at preventing traffic accident [40,41]. Furthermore, estimating the action intensity of pedals may contribute to the estimation of fuel consumption [42]. Thus, our study may provide a new kind of sensor in detecting the improper pedal action intensity, which would help promote the traffic safety and energy conservation. TENGs have some advantages, such as low cost, self-powered, etc. Thus, TENGs have the potential of application in the next generation of advanced driver assistant system (ADAS) [43].

Author Contributions

Conceptualization, Q.C. and H.Z.; methodology, Q.C.; software, Q.C.; validation, X.J.; formal analysis, Q.C. and H.Z.; investigation, W.W.; resources, W.W. and C.S.; data curation, Q.C.; writing—original draft preparation, Q.C.; writing—review and editing, X.J.; visualization, Q.C.; supervision, W.W. and C.S.; project administration, W.W. and C.S.; funding acquisition, W.W., X.J. and C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by National Natural Science Foundation of China (No. 51805034, 51878045, 51672029 and 51372271), the National Key R&D Project from Ministry of Science and Technology, China (2019YBF1000320, 2016YFA0202702).

Acknowledgments

We would appreciate the technical support from CAS Center for Excellence in Nanoscience, Beijing Institute of Nanoenergy and Nanosystems.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Given a time window where vi represents the voltage from TENG at timepoint i. T represents the width of the time window. After fast Fourier transform, we can get the amplitude and power vector , where represents the corresponding frequency.

Table A1.

Feature candidates from time window.

Table A1.

Feature candidates from time window.

| Index | Name | Formula | Index | Name | Formula |

|---|---|---|---|---|---|

| 1 | Maximum value | 22 | Frequency of maximum amplitude | ||

| 2 | Minimum value | 23 | Minimum amplitude | ||

| 3 | Average value | 24 | Frequency of minimum amplitude | ||

| 4 | Peak value | 25 | Average amplitude | ||

| 5 | First quartile | 26 | Peak amplitude | ||

| 6 | Median value | 27 | Median amplitude | ||

| 7 | Third quartile | 28 | Maximum power | ||

| 8 | Variance | 29 | Minimum power | ||

| 9 | Standard deviation | 30 | Average power | ||

| 10 | Mean absolute value | 31 | Peak power | ||

| 11 | Mean square value | 32 | Median power | ||

| 12 | Root mean square value | 33 | Centroid frequency | ||

| 13 | Root amplitude | 34 | Mean-square frequency | ||

| 14 | Skewness | 35 | Root mean-square frequency | ||

| 15 | Kurtosis | 36 | Variance frequency | ||

| 16 | Crest factor | 37 | Root variance frequency | ||

| 17 | Waveform factor | 38 | Energy (0–2 Hz) | ||

| 18 | Pulse factor | 39 | Energy (2–4 Hz) | ||

| 19 | Margin factor | 40 | Energy (4–6 Hz) | ||

| 20 | Kurtosis factor | 41 | Energy (6–8 Hz) | ||

| 21 | Maximum amplitude | 42 | Energy (8–10 Hz) |

References

- World Health Organization. Global Status Report on Road Safety; World Health Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Elamrani Abou Elassad, Z.; Mousannif, H.; Al Moatassime, H. A real-time crash prediction fusion framework: An imbalance-aware strategy for collision avoidance systems. Transp. Res. Part C Emerg. Technol. 2020, 118, 102708. [Google Scholar] [CrossRef]

- Soares, S.; Monteiro, T.; Lobo, A.; Couto, A.; Cunha, L.; Ferreira, S. Analyzing driver drowsiness: From causes to effects. Sustainability 2020, 12, 1971. [Google Scholar] [CrossRef]

- Moretti, L.; Palazzi, F.; Cantisani, G. Operating times and users’ behavior at Urban road intersections. Sustainability 2020, 12, 4120. [Google Scholar] [CrossRef]

- Kamrani, M.; Srinivasan, A.R.; Chakraborty, S.; Khattak, A.J. Applying Markov decision process to understand driving decisions using basic safety messages data. Transp. Res. Part C Emerg. Technol. 2020, 115, 102642. [Google Scholar] [CrossRef]

- Dols, J.F.; Girbés-Juan, V.; Luna, Á.; Catalán, J. Data acquisition system for the characterization of biomechanical and ergonomic thresholds in driving vehicles. Sustainability 2020, 12, 7013. [Google Scholar] [CrossRef]

- Wu, Y.; Abdel-Aty, M.; Park, J.; Zhu, J. Effects of crash warning systems on rear-end crash avoidance behavior under fog conditions. Transp. Res. Part C Emerg. Technol. 2018, 95, 481–492. [Google Scholar] [CrossRef]

- Jensen, A.F.; Rasmussen, T.K.; Prato, C.G. A route choice model for capturing driver preferences when driving electric and conventional vehicles. Sustainability 2020, 12, 1149. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, T.; Gao, W.; Mei, D. Analysis on spatial pattern and driving factors of carbon emission in urban-rural fringe mixed-use communities: Cases study in East Asia. Sustainability 2020, 12, 3101. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, J.; He, L.; Ding, Y.; Cao, H.; Zhao, W. Control Oriented Prediction of Driver Brake Intention and Intensity Using a Composite Machine Learning Approach. Energies 2019, 12, 2483. [Google Scholar] [CrossRef]

- Lv, C.; Xing, Y.; Lu, C.; Liu, Y.; Guo, H.; Gao, H.; Cao, D. Hybrid-Learning-Based Classification and Quantitative Inference of Driver Braking Intensity of an Electrified Vehicle. IEEE Trans. Veh. Technol. 2018, 67, 5718–5729. [Google Scholar] [CrossRef]

- Tran, C.; Doshi, A.; Trivedi, M.M. Modeling and prediction of driver behavior by foot gesture analysis. Comput. Vis. Image Underst. 2012, 116, 435–445. [Google Scholar] [CrossRef]

- Ohn-Bar, E.; Tawari, A.; Martin, S.; Trivedi, M.M. On surveillance for safety critical events: In-vehicle video networks for predictive driver assistance systems. Comput. Vis. Image Underst. 2015, 134, 130–140. [Google Scholar] [CrossRef]

- Haufe, S.; Kim, J.W.; Kim, I.H.; Sonnleitner, A.; Schrauf, M.; Curio, G.; Blankertz, B. Electrophysiology-based detection of emergency braking intention in real-world driving. J. Neural Eng. 2014, 11, 056011. [Google Scholar] [CrossRef] [PubMed]

- Frank, S.; Kuijper, A. Robust driver foot tracking and foot gesture recognition using capacitive proximity sensing. J. Ambient Intell. Smart Environ. 2019, 11, 221–235. [Google Scholar] [CrossRef]

- Teng, T.; Bi, L.; Liu, Y. EEG-Based Detection of Driver Emergency Braking Intention for Brain-Controlled Vehicles. IEEE Trans. Intell. Transp. Syst. 2018, 19, 1766–1773. [Google Scholar] [CrossRef]

- Hernandez-Rojas, L.G.; Martinez, E.; Antelis, J.M. Detection of emergency braking intention using driver’s electroencephalographic signals. IEEE Lat. Am. Trans. 2019, 17, 111–118. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Zhou, J.; Zhou, J.; Song, J.; Song, J.; Liu, J.; Liu, J.; Xu, N.; Xu, N. Piezoelectric Field Effect Transistor and Nanoforce Sensor Based on a Single ZnO Nanowire. Nano Lett. 2006, 6, 2768–2772. [Google Scholar] [CrossRef]

- Li, S.; Zhang, D.; Meng, X.; Huang, Q.A.; Sun, C.; Wang, Z.L. A flexible lithium-ion battery with quasi-solid gel electrolyte for storing pulsed energy generated by triboelectric nanogenerator. Energy Storage Mater. 2018, 12, 17–22. [Google Scholar] [CrossRef]

- Hou, H.; Xu, Q.; Pang, Y.; Li, L.; Wang, J.; Zhang, C.; Sun, C. Efficient Storing Energy Harvested by Triboelectric Nanogenerators Using a Safe and Durable All-Solid-State Sodium-Ion Battery. Adv. Sci. 2017, 4, 1700072. [Google Scholar] [CrossRef]

- Song, W.; Gan, B.; Jiang, T.; Zhang, Y.; Yu, A.; Yuan, H.; Chen, N.; Sun, C.; Wang, Z.L. Nanopillar Arrayed Triboelectric Nanogenerator as a Self-Powered Sensitive Sensor for a Sleep Monitoring System. ACS Nano 2016, 10, 8097–8103. [Google Scholar] [CrossRef]

- Li, S.; Meng, X.; Yi, Q.; Alonso, J.A.; Fernández-Díaz, M.T.; Sun, C.; Wang, Z.L. Structural and electrochemical properties of LiMn0.6Fe0.4PO4 as a cathode material for flexible lithium-ion batteries and self-charging power pack. Nano Energy 2018, 52, 510–516. [Google Scholar] [CrossRef]

- Lin, Z.H.; Cheng, G.; Wu, W.; Pradel, K.C.; Wang, Z.L. Dual-mode triboelectric nanogenerator for harvesting water energy and as a self-powered ethanol nanosensor. ACS Nano 2014, 8, 6440–6448. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.W.; Cao, X.; Wang, N.; Ma, L.; Zhu, H.R.; Willander, M.; Jie, Y.; Wang, Z.L. An Ultrathin Flexible Single-Electrode Triboelectric-Nanogenerator for Mechanical Energy Harvesting and Instantaneous Force Sensing. Adv. Energy Mater. 2017, 7, 1601255. [Google Scholar] [CrossRef]

- Hou, T.C.; Yang, Y.; Zhang, H.; Chen, J.; Chen, L.J.; Lin Wang, Z. Triboelectric nanogenerator built inside shoe insole for harvesting walking energy. Nano Energy 2013, 2, 856–862. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, G.; Zhang, H.; Chen, J.; Zhong, X.; Lin, Z.H.; Su, Y.; Bai, P.; Wen, X.; Wang, Z.L. Triboelectric nanogenerator for harvesting wind energy and as self-powered wind vector sensor system. ACS Nano 2013, 7, 9461–9468. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Zhong, X.; Su, Y.; Zhou, Y.; Hu, C.; Wang, Z.L. Single-electrode-based rotating triboelectric nanogenerator for harvesting energy from tires. ACS Nano 2014, 8, 680–689. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, J.; Li, X.; Zhou, Z.; Meng, K.; Wei, W.; Yang, J.; Wang, Z.L. Triboelectric Nanogenerator Enabled Body Sensor Network for Self-Powered Human Heart-Rate Monitoring. ACS Nano 2017, 11, 8830–8837. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Hou, T.C.; Su, Y.; Hu, C.; Wang, Z.L. Triboelectric nanogenerator built inside clothes for self-powered glucose biosensors. Nano Energy 2013, 2, 1019–1024. [Google Scholar] [CrossRef]

- Pu, X.; Liu, M.; Chen, X.; Sun, J.; Du, C.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Ultrastretchable, transparent triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and tactile sensing. Sci. Adv. 2017, 3, e1700015. [Google Scholar] [CrossRef]

- He, X.; Zi, Y.; Guo, H.; Zheng, H.; Xi, Y.; Wu, C.; Wang, J.; Zhang, W.; Lu, C.; Wang, Z.L. A Highly Stretchable Fiber-Based Triboelectric Nanogenerator for Self-Powered Wearable Electronics. Adv. Funct. Mater. 2017, 27, 1604378. [Google Scholar] [CrossRef]

- Quan, T.; Wang, X.; Wang, Z.L.; Yang, Y. Hybridized Electromagnetic-Triboelectric Nanogenerator for a Self-Powered Electronic Watch. ACS Nano 2015, 9, 12301–12310. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Su, Y.; Chen, J.; Hu, C.; Wu, Z.; Liu, Y.; Ping Wong, C.; Bando, Y.; Wang, Z.L. Triboelectric nanogenerator as self-powered active sensors for detecting liquid/gaseous water/ethanol. Nano Energy 2013, 2, 693–701. [Google Scholar] [CrossRef]

- Parida, K.; Bhavanasi, V.; Kumar, V.; Bendi, R.; Lee, P.S. Self-powered pressure sensor for ultra-wide range pressure detection. Nano Res. 2017, 10, 3557–3570. [Google Scholar] [CrossRef]

- Lin, M.F.; Xiong, J.; Wang, J.; Parida, K.; Lee, P.S. Core-shell nanofiber mats for tactile pressure sensor and nanogenerator applications. Nano Energy 2018, 44, 248–255. [Google Scholar] [CrossRef]

- Askari, H.; Khajepour, A.; Khamesee, M.B.; Wang, Z.L. Embedded self-powered sensing systems for smart vehicles and intelligent transportation. Nano Energy 2019, 66, 104103. [Google Scholar] [CrossRef]

- Meng, X.; Cheng, Q.; Jiang, X.; Fang, Z.; Chen, X.; Li, S.; Li, C.; Sun, C.; Wang, W.; Wang, Z.L. Triboelectric nanogenerator as a highly sensitive self-powered sensor for driver behavior monitoring. Nano Energy 2018, 51, 721–727. [Google Scholar] [CrossRef]

- Fernández-Delgado, M.; Cernadas, E.; Barro, S.; Amorim, D. Do we need hundreds of classifiers to solve real world classification problems? J. Mach. Learn. Res. 2014, 15, 3133–3181. [Google Scholar] [CrossRef]

- Miao, C.; Liu, H.; Zhu, G.G.; Chen, H. Connectivity-based optimization of vehicle route and speed for improved fuel economy. Transp. Res. Part C Emerg. Technol. 2018, 91, 353–368. [Google Scholar] [CrossRef]

- Peiris, S.; Berecki-Gisolf, J.; Chen, B.; Fildes, B. Road trauma in regional and remote Australia and New Zealand in preparedness for ADAS technologies and autonomous vehicles. Sustainability 2020, 12, 4347. [Google Scholar] [CrossRef]

- Choi, J.; Lee, K.; Kim, H.; An, S.; Nam, D. Classification of inter-urban highway drivers’ resting behavior for advanced driver-assistance system technologies using vehicle trajectory data from car navigation systems. Sustainability 2020, 12, 5936. [Google Scholar] [CrossRef]

- Bifulco, G.N.; Galante, F.; Pariota, L.; Spena, M.R. A linear model for the estimation of fuel consumption and the impact evaluation of advanced driving assistance systems. Sustainability 2015, 7, 14326–14343. [Google Scholar] [CrossRef]

- Gonzalez, J.G.; Casado-Mansilla, D.; López-de-Ipiña, D. Analysis of driver’s reaction behavior using a persuasion-based IT artefact. Sustainability 2020, 12, 6857. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).