Spray Backstop: A Method to Reduce Orchard Spray Drift Potential without Limiting the Spray and Air Delivery

Abstract

1. Introduction

2. Materials and Methods

2.1. Aerial Monitoring

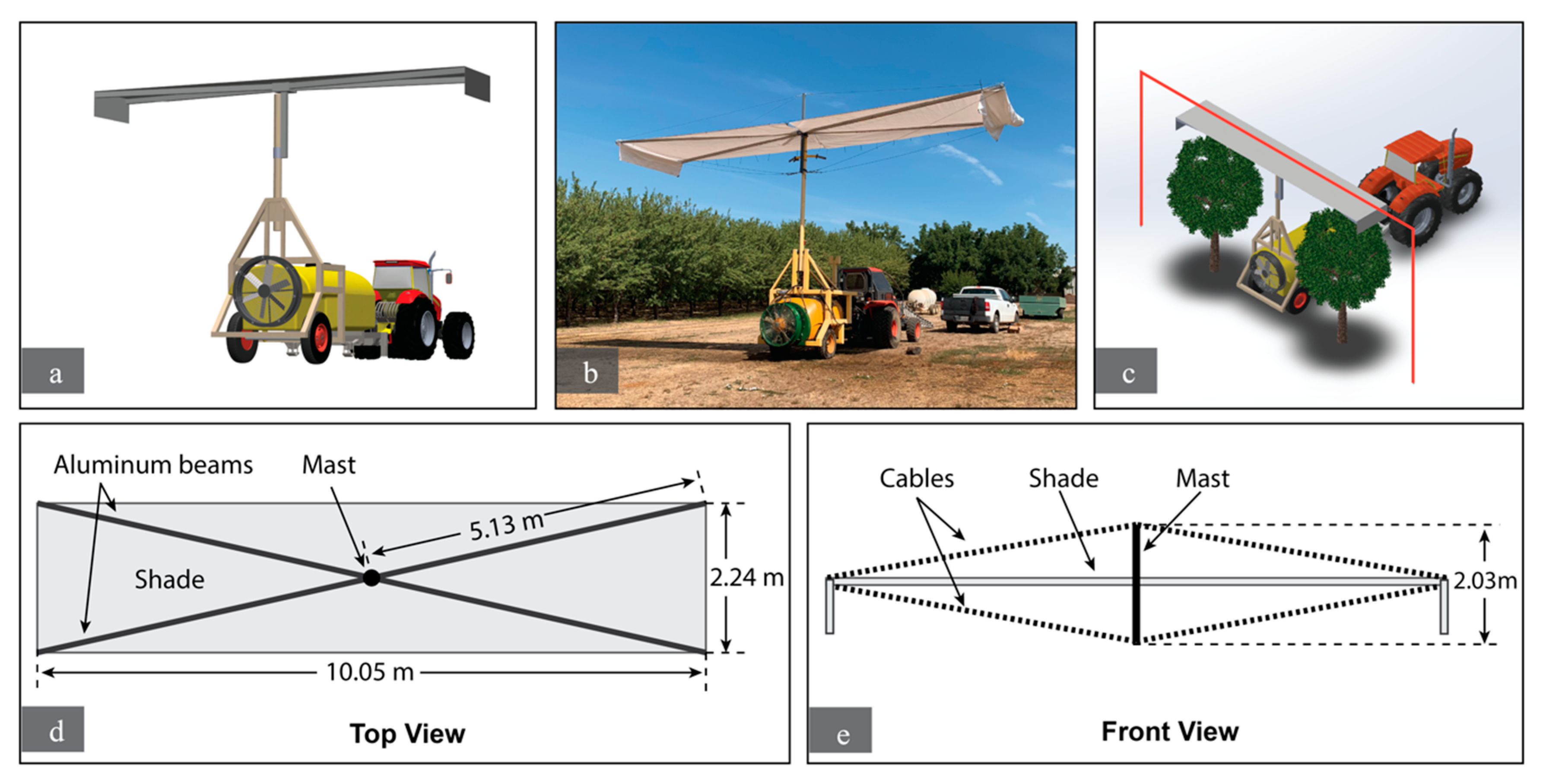

2.2. Design and Fabrication of the Spray Backstop

2.3. Test Conditions

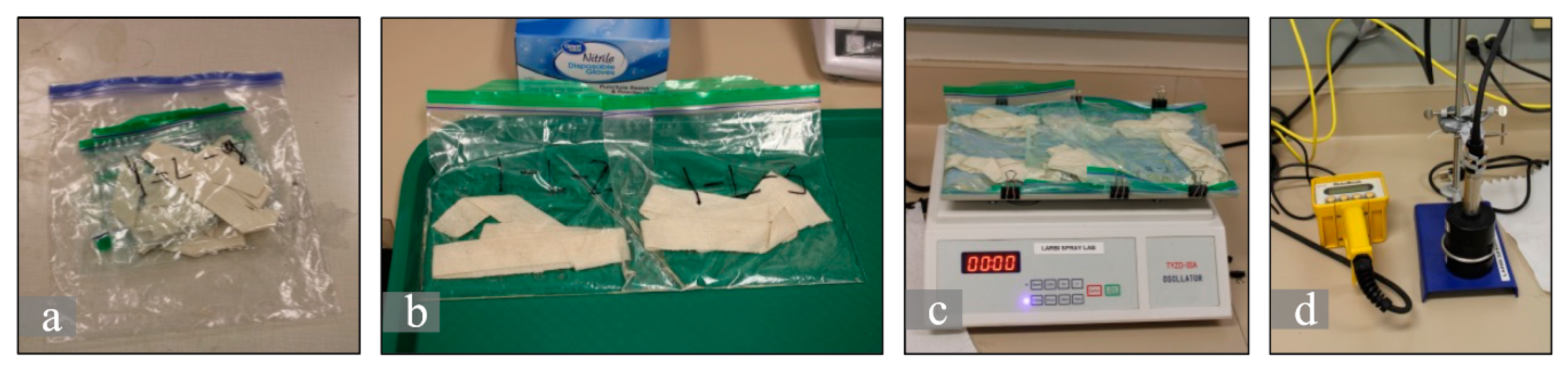

2.4. Sampling

2.5. Fluorometry and Analytics

2.6. Statistical Analysis of Dye Composition

3. Results and Discussion

3.1. Aerial Observation

3.2. Statistical Results

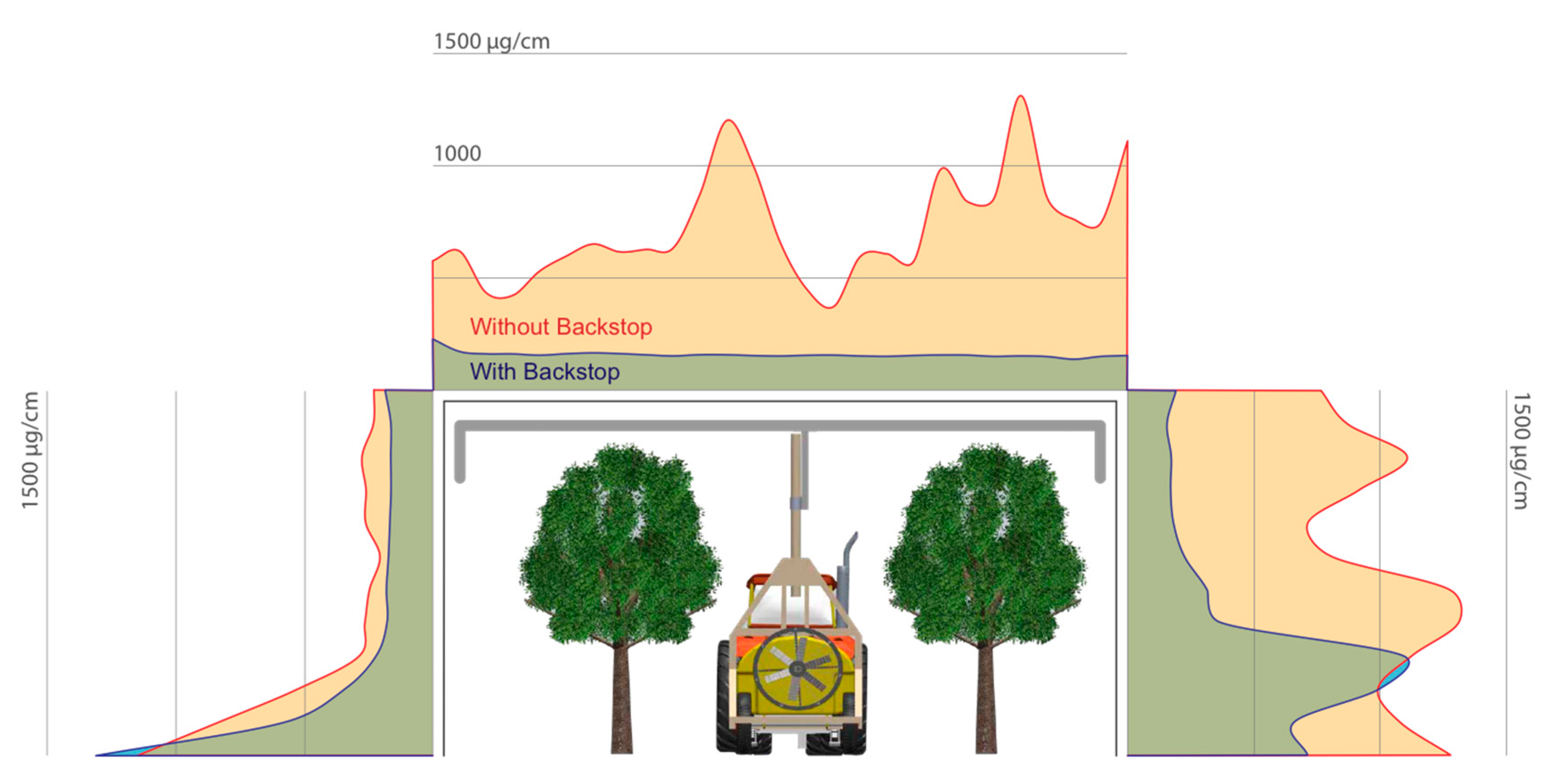

3.3. Drift Potential Pattern

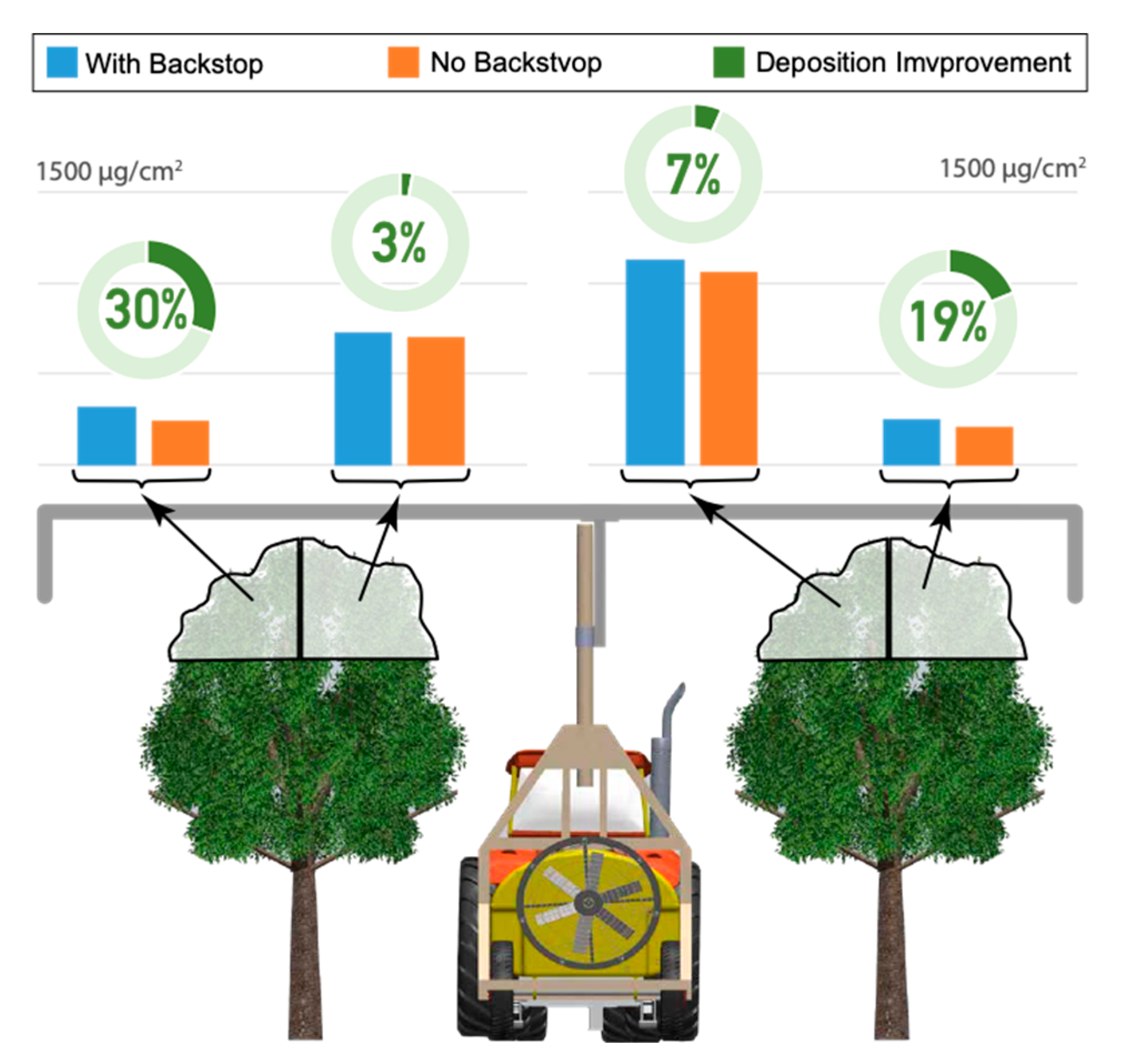

3.4. Treetop Deposition

3.5. Limitations and Potential Improvements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Left | Top | Right | |

|---|---|---|---|

| With Backstop | 318 | 159 | 437 |

| No Backstop | 397 | 721 | 1019 |

| Left Row | Right Row | |||||||

|---|---|---|---|---|---|---|---|---|

| Far Side | Near Side | Near Side | Far Side | |||||

| BS * | No BS | BS | No BS | BS | No BS | BS | No BS | |

| Top | 317 | 243 | 729 | 709 | 1134 | 1063 | 253 | 213 |

| Middle | 379 | 368 | 1031 | 1548 | 1158 | 1091 | 192 | 154 |

| Bottom | 215 | 420 | 871 | 1523 | 521 | 772 | 120 | 131 |

References

- CDFA. 2018 California Almond Acreage Report; California Department of Food and Agriculture: Sacramento, CA, USA, 2019. [Google Scholar]

- Fox, R.D.; Derksen, R.C.; Zhu, H.; Brazee, R.D.; Svensson, S.A. A history of air-blast sprayer development and future prospects. Trans. ASABE 2008, 51, 405–410. [Google Scholar] [CrossRef]

- Markle, J.C.; Niederholzer, F.J.A.; Zalom, F.G. Evaluation of spray application methods for navel orangeworm control in almonds. Pest Manag. Sci. 2016, 72, 2339–2346. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Giles, D.K.; Niederholzer, F.J.; Andaloro, J.T.; Lang, E.B.; Watson, L.J. Evaluation of an Unmanned Aerial Vehicle as a New Method of Pesticide Application for Almond Crop Protection. Pest Manag. Sci. 2020. [Google Scholar] [CrossRef] [PubMed]

- Siegel, J.P.; Strmiska, M.M.; Niederholzer, F.J.; Giles, D.K.; Walse, S.S. Evaluating insecticide coverage in almond and pistachio for control of navel orangeworm (Amyelois transitella) (Lepidoptera: Pyralidae). Pest Manag. Sci. 2019, 75, 1435–1442. [Google Scholar] [CrossRef] [PubMed]

- Fox, R.; Derksen, R.; Brazee, R. Drift from spraying orchards. In International Society of Citriculture Proceedings; US Department of Agriculture, Agricultural Research Service: Washington DC, USA, 2000. [Google Scholar]

- Matthews, G. Pesticide Application Methods; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Department of Pesticide Regulation (DPR). DPR 16-004 Pesticide Use Near Schoolsites Regulation; California Department of Pesticide Regulation, Ed.; California Department of Pesticide Regulation: Sacramento, CA, USA, 2016. [Google Scholar]

- Department of Pesticide Regulation (DPR). A Guide to Pesticide Regulation in California—Update, 2017 Regulation; California Department of Pesticide Regulation, Ed.; California Department of Pesticide Regulation: Sacramento, CA, USA, 2017. [Google Scholar]

- Benko, K. People need to know! Notification and the regulation of pesticide use near public schools in California. Environ. Plan. E Nat. Space 2020, 3, 164–185. [Google Scholar] [CrossRef]

- Cross, J.; Walklate, P.; Murray, R.; Richardson, G. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 2. Effects of spray quality. Crop Prot. 2001, 20, 333–343. [Google Scholar] [CrossRef]

- Cross, J.; Walklate, P.; Murray, R.; Richardson, G. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 3. Effects of air volumetric flow rate. Crop Prot. 2003, 22, 381–394. [Google Scholar] [CrossRef]

- Salyani, M.; Miller, D.R.; Farooq, M.; Sweeb, R.D. Effects of sprayer operating parameters on airborne drift from citrus air-carrier sprayers. Agric. Eng. Int. CIGR J. 2013, 15, 27–36. [Google Scholar]

- Lešnik, M.; Stajnko, D.; Vajs, S. Interactions between spray drift and sprayer travel speed in two different apple orchard training systems. Int. J. Environ. Sci. Technol. 2015, 12, 3017–3028. [Google Scholar] [CrossRef]

- Cross, J.; Walklate, P.; Murray, R.; Richardson, G. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 1. Effects of spray liquid flow rate. Crop Prot. 2001, 20, 13–30. [Google Scholar] [CrossRef]

- Salyani, M.; Sweeb, R.D.; Farooq, M. Comparison of string and ribbon samplers in orchard spray applications. Trans. ASABE 2006, 49, 1705–1710. [Google Scholar] [CrossRef]

- Salyani, M. Methodologies for assessment of spray deposition in orchard applications. In Proceedings of the 2000 ASAE Annual International Meeting, Milwaukee, WI, USA, 9–12 July 2000; pp. 1–11. [Google Scholar]

- Salyani, M.; Farooq, M.; Sweeb, R.D. Spray deposition and mass balance in citrus orchard applications. Trans. ASABE 2007, 50, 1963–1969. [Google Scholar] [CrossRef]

- Salyani, M.; Sweeb, R.D.; Farooq, M. Spray Capture Efficiencies of Ribbon and String Targets Used in Orchard Applications. In Proceedings of the 2006 ASAE Annual Meeting, Boston, MA, USA, 19–22 August 2006; p. 1. [Google Scholar]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Gallart, M. Use of a terrestrial LIDAR sensor for drift detection in vineyard spraying. Sensors 2013, 13, 516–534. [Google Scholar] [CrossRef] [PubMed]

- Dasso, A.S. Design, Construction and Evaluation of an Improved Orchard Sprayer for Nut Crops; University of California: Davis, CA, USA, 2012. [Google Scholar]

- Larbi, P.A.; Basulto, C. Fluorometer Setup, Calibration, and Pyranine Dye Comparison for Spray Deposit Analysis. Unpublished work.

| Source of Variation | Degrees of Freedom | Sum of Squares | Mean Squares | F-Statistic | p-Value | |

|---|---|---|---|---|---|---|

| Deposition on the top ribbon | backstop | 1 | 8.54 × 106 | 8.54 × 106 | 73.98 | 0.000 |

| error | 106 | 1.22 × 107 | 1.15 × 105 | - | - | |

| Deposition on the left ribbon | backstop | 1 | 7.54 × 104 | 7.54 × 104 | 0.52 | 0.475 |

| error | 46 | 6.69 × 106 | 1.46 × 105 | - | - | |

| Deposition on the right ribbon | backstop | 1 | 4.06 × 106 | 4.06 × 106 | 14.46 | 0.000 |

| error | 46 | 1.29 × 107 | 2.81 × 105 | - | - | |

| Deposition on the leaves | backstop | 1 | 7.21 × 104 | 7.21 × 104 | 0.34 | 0.56 |

| error | 22 | 4.61 × 106 | 2.09 × 105 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pourreza, A.; Moghimi, A.; Niederholzer, F.J.A.; Larbi, P.A.; Zuniga-Ramirez, G.; Cheung, K.H.; Khorsandi, F. Spray Backstop: A Method to Reduce Orchard Spray Drift Potential without Limiting the Spray and Air Delivery. Sustainability 2020, 12, 8862. https://doi.org/10.3390/su12218862

Pourreza A, Moghimi A, Niederholzer FJA, Larbi PA, Zuniga-Ramirez G, Cheung KH, Khorsandi F. Spray Backstop: A Method to Reduce Orchard Spray Drift Potential without Limiting the Spray and Air Delivery. Sustainability. 2020; 12(21):8862. https://doi.org/10.3390/su12218862

Chicago/Turabian StylePourreza, Alireza, Ali Moghimi, Franz J. A. Niederholzer, Peter A. Larbi, German Zuniga-Ramirez, Kyle H. Cheung, and Farzaneh Khorsandi. 2020. "Spray Backstop: A Method to Reduce Orchard Spray Drift Potential without Limiting the Spray and Air Delivery" Sustainability 12, no. 21: 8862. https://doi.org/10.3390/su12218862

APA StylePourreza, A., Moghimi, A., Niederholzer, F. J. A., Larbi, P. A., Zuniga-Ramirez, G., Cheung, K. H., & Khorsandi, F. (2020). Spray Backstop: A Method to Reduce Orchard Spray Drift Potential without Limiting the Spray and Air Delivery. Sustainability, 12(21), 8862. https://doi.org/10.3390/su12218862