BIM-Based Human Machine Interface (HMI) Framework for Energy Management

Abstract

1. Introduction

2. Related Works

3. BIM-Based HMI Framework Design

3.1. Overview

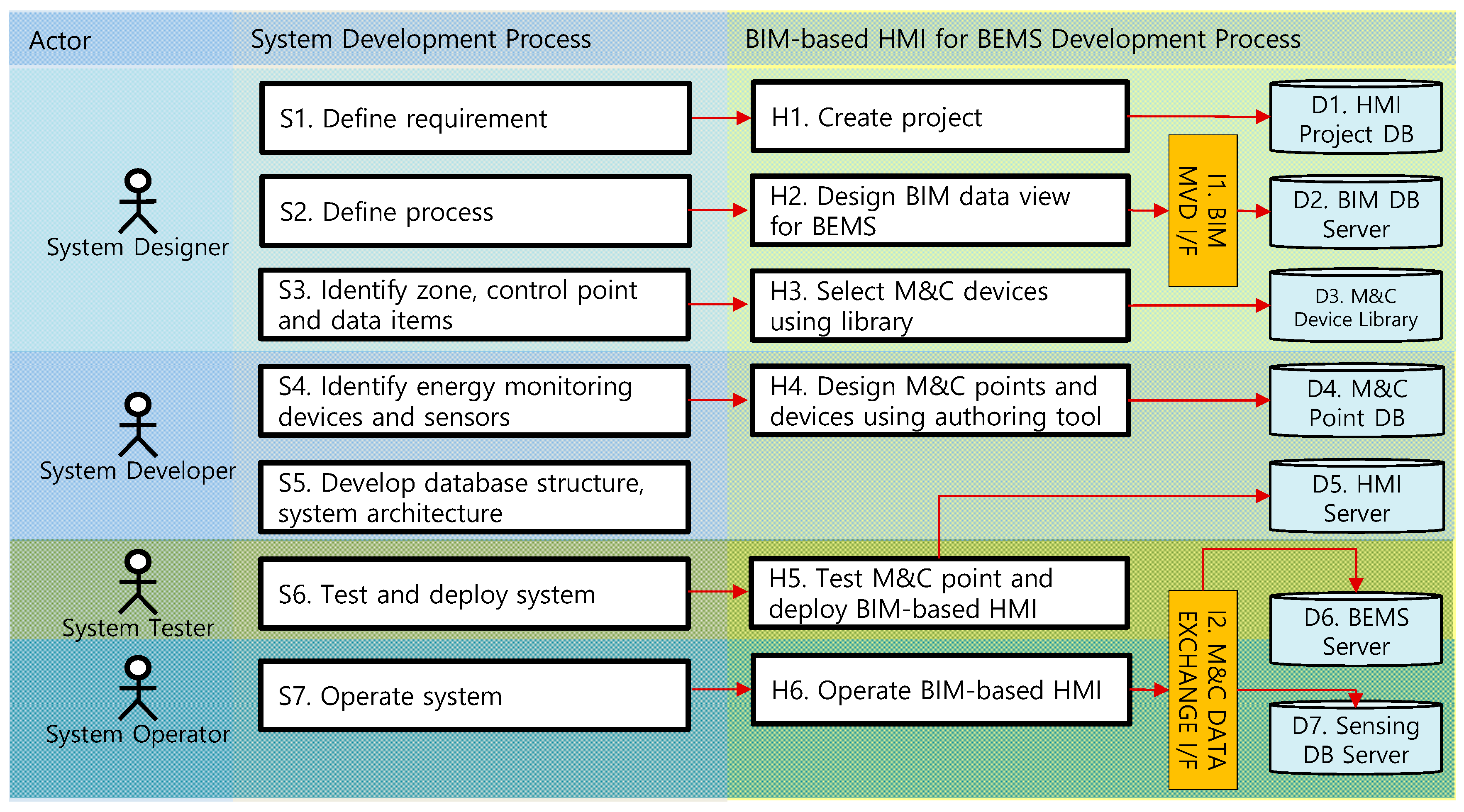

3.2. Process Analysis

- S1. Energy management system establishment requirements and stakeholder definition;

- S2. System utilization scenario and process definition;

- S3. Energy M&C point and data item definition;

- S4. Energy M&C device and sensor definition;

- S5. Energy management system architecture decision and development;

- S6. Energy management development, installation, and testing.

- R1. Classification of responsibility

- R2. Application-oriented customization and variability

- R3. Reusability

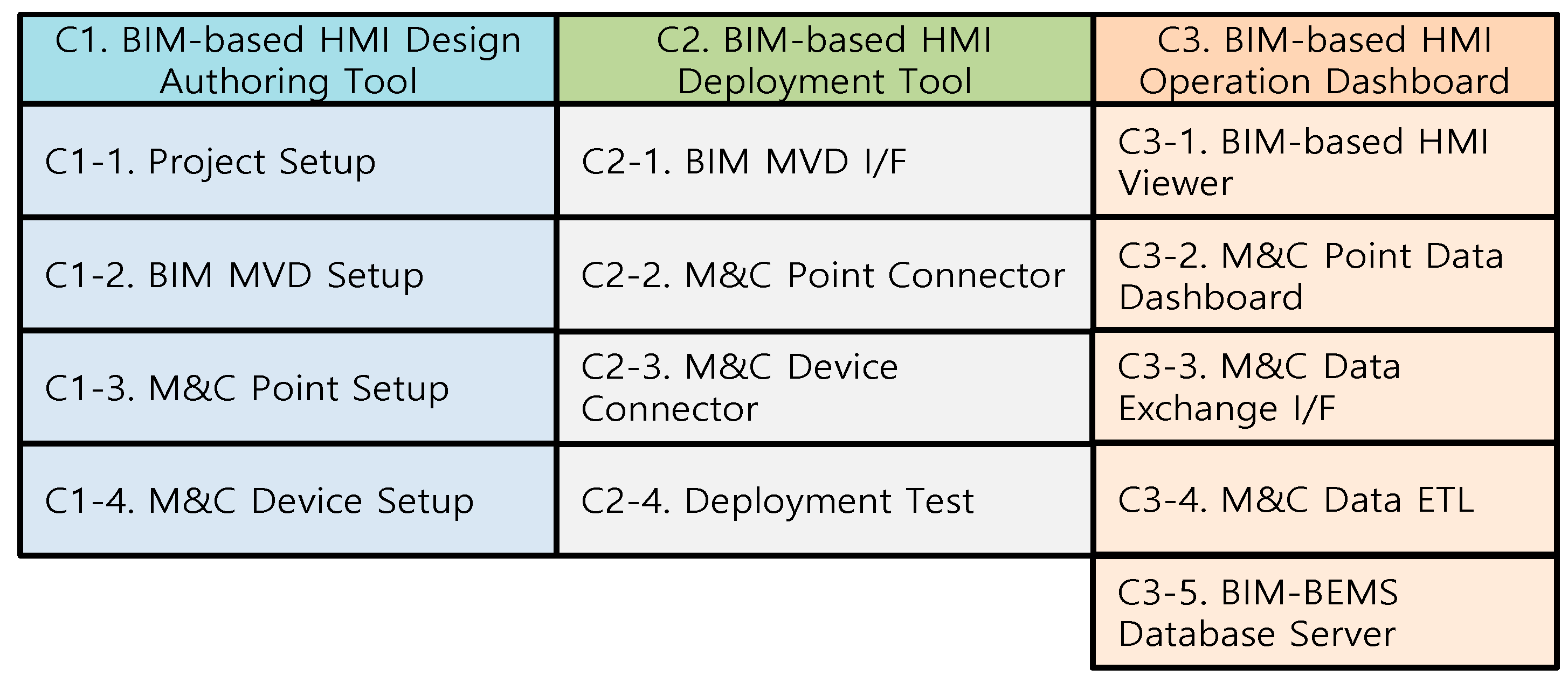

3.3. Framework Design

3.4. Considerations for BIM Database Development

3.5. Sensing Database Design

4. Case Study and Benefits Analysis

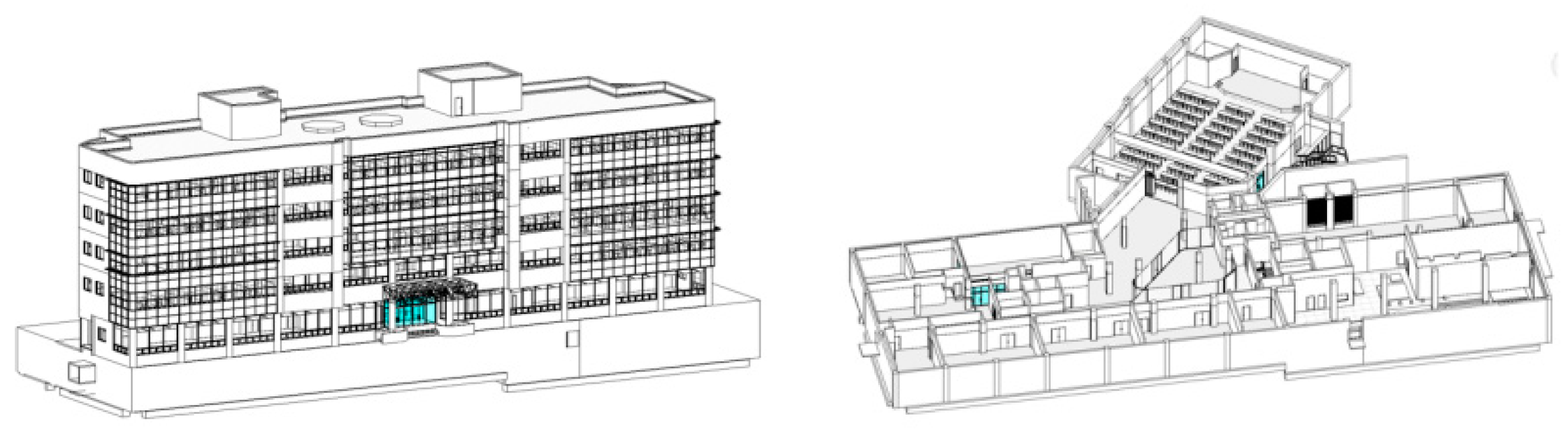

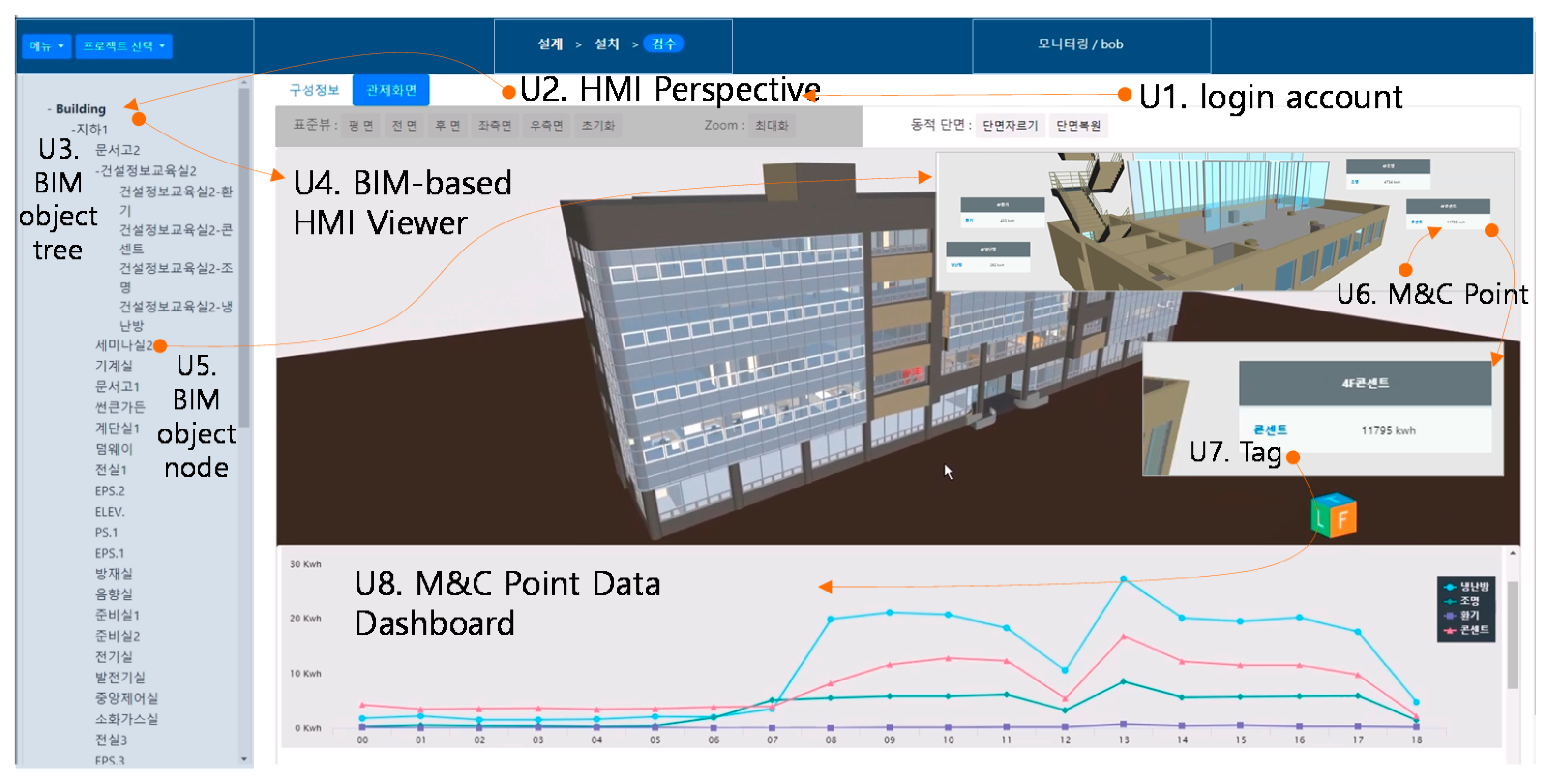

4.1. Case Study

- T1. Building K BIM data development.

- T2. Installation of systems and devices for acquiring energy management data in K buildings.

- T3. BIM-based HMI development and demonstration.

- Create a new BIM-based HMI project.

- Select and load the BIM and BIM MVD file.

- The modeled BIM data are filtered by MVD to reduce complexity, because the space and objects required for energy monitoring are part of it. Thereafter, the lightweight BIM data are stored in the BIM server.

- Select the M&C device from the Device Library.

- The M&C devices are already registered in the library. The sensor information that can be used for each device is predefined. In this step, only selection of the devices required for monitoring is performed.

- Create the M&C point.

- Allocate the M&C device’s sensor to the M&C point as a tag.

- The sensor of the created M&C device is assigned to the M&C point.

- Allocate the M&C point to the BIM space or element object.7. Deploy the BIM-based HMI project to the HMI server

- Since the information required for control is set, the created project is distributed to the HMI server.

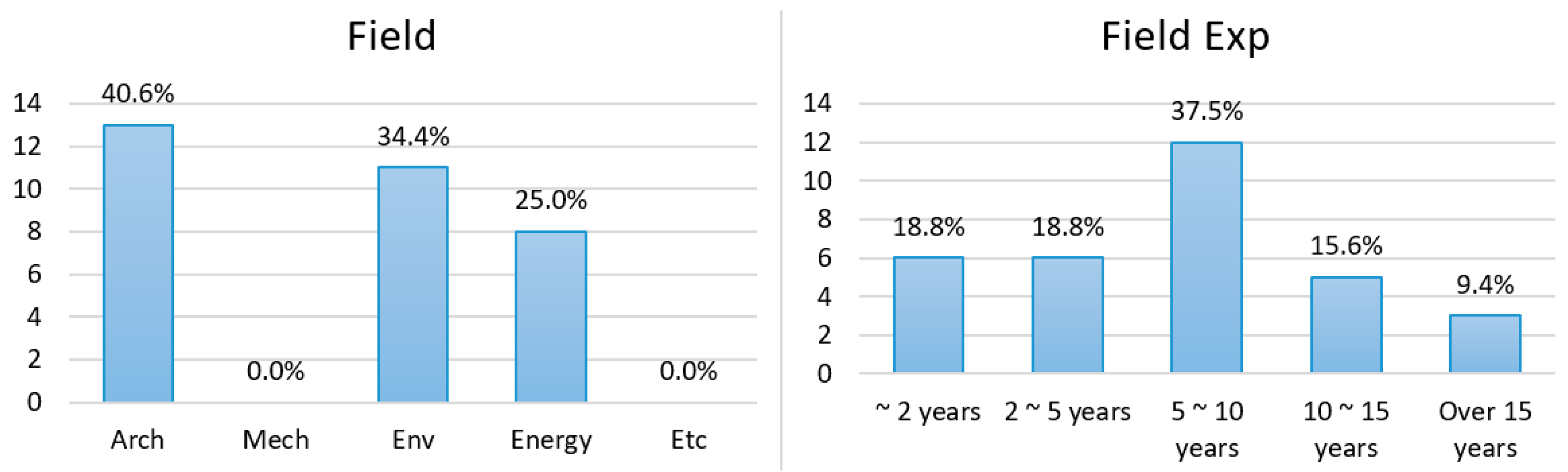

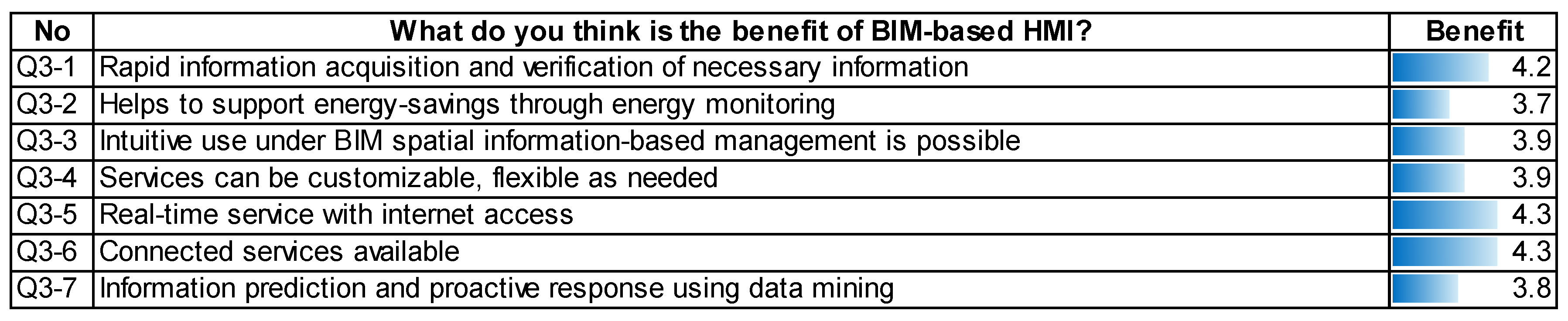

4.2. Analysis of the Interview Design and Benefits

- Prompt information verification—prompt acquisition and verification of necessary information.

- Helps save energy—savings through energy monitoring.

- Intuitive use of spatial information—management is possible in connection with spatial information such as BIM.

- Scalability—services can be flexibly customized or developed as needed.

- Real-time service—internet can be accessed anywhere and at any time.

- Connectivity—internet-based systems and connected services, e.g., sending a text message when an incident occurs.

- Proactive response—predicting and responding to future management information through data learning

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Xiong, Y. A BIM-Based Interoperability Platform in Support of Building Operation and Energy Management. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2020. [Google Scholar]

- Gao, X. A Framework for Developing Machining Learning Models for Facility Life Cycle Cost Analysis through BIM and IoT. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2019. [Google Scholar]

- Gao, X.; Pishdad-Bozorgi, P.; Shelden, D.R.; Tang, S. A scalable cyber-physical system data acquisition framework for the smart built environment. In Computing in Civil Engineering 2019: Smart Cities, Sustainability, and Resilience; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 259–266. [Google Scholar]

- Brady, L. An Investigation into the Management of Energy Performance for Building Services Systems: Design to Operation. Ph.D. Thesis, Liverpool John Moores University, Liverpool, UK, 2019. [Google Scholar]

- Terroso-Saenz, F.; González-Vidal, A.; Ramallo-González, A.P.; Skarmeta, A.F. An open IoT platform for the management and analysis of energy data. Future Gener. Comput. Syst. 2019, 92, 1066–1079. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. BIM-assisted building automation system information exchange using BACnet and IFC. Autom. Constr. 2020, 110, 103049. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P. BIM-enabled facilities operation and maintenance: A review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Alhashmi, S.A.; Al-Sumaiti, A.S.; Hassan, M.W.; Rasheed, M.B.; Rodriguez, S.R.R.; Kumar, R.; Heydarian-Forushani, E. Building energy management system: An overview of recent literature research. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, UAE, 26 March–10 April 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Zhang, Y.; Kang, K.; Lin, J.R.; Zhang, J.P.; Zhang, Y. Building an information modeling-based cyber-physical platform for building performance monitoring. Int. J. Distrib. Sens. Netw. 2020, 16, 1550147720908170. [Google Scholar] [CrossRef]

- Dagdougui, Y.; Ouammi, A.; Benchrifa, R. Energy management-based predictive controller for a smart building powered by renewable energy. Sustainability 2020, 12, 4264. [Google Scholar] [CrossRef]

- Edwards, R.E.; Lou, E.; Bataw, A.; Kamaruzzaman, S.N.; Johnson, C. Sustainability-led design: Feasibility of incorporating whole-life cycle energy assessment into BIM for refurbishment projects. J. Build. Eng. 2019, 24, 100697. [Google Scholar] [CrossRef]

- Xu, J.; Lu, W.; Anumba, C.J.; Niu, Y. From smart construction objects to cognitive facility Management. In Cyber-Physical Systems in the Built Environment; Springer: Cham, Switzerland, 2020; pp. 273–296. [Google Scholar]

- Jin, X.; Qi, F.; Wu, Q.; Mu, Y.; Jia, H.; Yu, X.; Li, Z. Integrated optimal scheduling and predictive control for energy management of an urban complex considering building thermal dynamics. Int. J. Electr. Power Energy Syst. 2020, 123, 106273. [Google Scholar] [CrossRef]

- Wang, W.; Hong, T.; Li, N.; Wang, R.Q.; Chen, J. Linking energy-cyber-physical systems with occupancy prediction and interpretation through WiFi probe-based ensemble classification. Appl. Energy 2019, 236, 55–69. [Google Scholar] [CrossRef]

- Maslesa, E.; Jensen, P.A. Managing environmental building performance through IT systems. Facilities 2019. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M.; Konstantinou, E. Moving from building information models to digital twins for operation and maintenance. In Proceedings of the Institution of Civil Engineers-Smart Infrastructure and Construction; ICE: Atlanta, GA, USA, 2020; pp. 1–11. [Google Scholar]

- Gong, X.; Michel, P.; Cantin, R. Multiple-criteria decision analysis of BIM influences in building energy management. In Building Simulation; Tsinghua University Press: Beijing, China, 2019; Volume 12, pp. 641–652. [Google Scholar]

- Lyons, L. Digitalisation: Opportunities for Heating and Cooling; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Manfren, M.; Aste, N.; Leonforte, F.; Del Pero, C.; Buzzetti, M.; Adhikari, R.S.; Zhixing, L. Parametric energy performance analysis and monitoring of buildings: HEART project platform case study. Sustain. Cities Soc. 2020, 61, 102296. [Google Scholar] [CrossRef]

- Reynolds, J. Real-Time and Semantic Energy Management across Buildings in a District Configuration. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2019. [Google Scholar]

- Mocerino, C. The new integrated management of efficient buildings: An intelligent method approach and AI. J. Civ. Eng. Archit. 2020, 14, 207–213. [Google Scholar] [CrossRef]

- Qi, X.; Liu, Y.; Zhang, Y.; Cao, S.; Zhu, W.; Tang, J. Research on BIM Model Identification System for Substation Project Management. J. Phys. Conf. Ser. 2020, 1486, 042026. [Google Scholar] [CrossRef]

- Wu, W.; Yang, X.; Fan, Q. GIS-BIM based virtual facility energy assessment (VFEA)—Framework development and use case of California State University, Fresno. In Computing in Civil and Building Engineering; ASCE: Reston, VA, USA, 2014; pp. 339–346. [Google Scholar]

- Pan, W.; Iturralde, K.; Bock, T.; Martinez, R.G.; Juez, O.M.; Finocchiaro, P. A Conceptual Design of an Integrated Façade System to Reduce Embodied Energy in Residential Buildings. Sustainability 2020, 12, 5730. [Google Scholar] [CrossRef]

- Cormier, A.; Robert, S.; Roger, P.; Stephan, L.; Wurtz, E. Towards a BIM-based service oriented platform: Application to building energy performance simulation. In Proceedings of the 12th Conference of International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011; Volume 1416. [Google Scholar]

- Khalid, M.U.; Bashir, M.K.; Newport, D. Development of a building information modelling (BIM)-based real-time data integration system using a building management system (BMS). In Building Information Modelling, Building Performance, Design and Smart Construction; Springer: Cham, Switzerland, 2017; pp. 93–104. [Google Scholar]

- Cuenca, J.; Larrinaga, F.; Eciolaza, L.; Curry, E. Towards cognitive cities in the energy domain. In Designing Cognitive Cities; Springer: Cham, Switzerland, 2019; pp. 155–183. [Google Scholar]

- Noran, O.; Bernus, P.; Caluianu, S. Situation-aware Building Information Models for Next Generation Building Management Systems. In Proceedings of the International Conference on Enterprise Information Systems, Prague, Czech Republic, 5–7 May 2020; pp. 75–82. [Google Scholar]

- Gray, F.M.; Dibowski, H.; Gall, J.; Braun, S. Occupant Feedback and Context Awareness: On the Application of Building Information Modeling and Semantic Technologies for Improved Complaint Management in Commercial Buildings. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 101–108. [Google Scholar] [CrossRef]

| Classification | References | Description |

|---|---|---|

| Data exchange | [1,22,28] | The studies in this category are concerned with data integration and interoperability between heterogeneous systems. The solutions for these studies use code classification, standard data model such as IFC, API (Application Program Interface) and BIM software add-in technology. |

| ICBM | [2,5,15,18,20,21,26,27,29] | The studies in this category apply the latest technologies to the field of energy management. They mainly use ICBM technology to explore effective energy management method or solution. |

| CPS | [3,7,8,9,12,14,16] | These studies propose and implement digital twin framework, concept for energy management. The studies in this category often describe techniques based on CPS. |

| Case studies | [4,11,17,23] | These studies are related to case studies and analysis related to energy management. |

| Simulation | [10,13,19,25] | The studies in this category focus on energy management and simulation for savings and usage prediction. |

| Others | [6,24] | Among the unclassified studies, studies on hardware technologies for energy saving are also included. These solutions are related to building walls and automation. They are not relevant to this study. |

| Component | Related Elements | Description |

|---|---|---|

| C1. BIM-based HMI Authoring Tool | H1, D1 | A writing tool that defines the screen, BIM space control area, M&C point, M&C device, dashboard, etc. in the BIM-based HMI development project |

| C1-1. Project Setup | H1, D1, D5 | Sets the basic information of the project to be energy-monitored Project = {ID, name, description, position, CRS, BIM_DB.source, BEMS.DB.source} ID = identification CRS = coordinate reference system (e.g., GCS, WGS84, and TM) BIM.DB.source = BIM server connection Uniform Resource Locator (URL) string and log-in information BEMS.DB.source = BEMS server connection URL string and log-in information |

| C1-2. BIM-BEMS MVD Setup | H2, D2, I1 | MVD is set up to define (by selectively filtering) the BIM data items required for energy management. BIM_MVD = {ID, name, description, data.filter *} data.filter = {BIM.object.type, element.member, condition, comparison.value, [data.view.format]} BIMobject.type = BIM object such as IfcDoor, IfcSpace etc element.member = {property | geometry} condition = {‘<’, ‘>’, ‘<=’, ‘>=’, ‘==’, ‘!=’} comparison.value = compared value dataview.format = defines the format for displaying the BIM data filtered by condition on the screen |

| C1-3. M&C Point Setup | H4, D4 | Sets the monitoring and control points on the BIM-based HMI screen M&C.pointset = {M&C_point *} M&C.point = {ID, name, description, tag *} tag = {ID, name, tag.BIM.object.GUID, position, device.ID, sensing.phase, format} tag.BIM.object.GUID = Global Unique Identification (GUID) of the BIM object whose data is to be monitored position = local coordinates within the BIM object for monitoring data If the value is NULL, the center coordinate of the space pointed to by the specified tag.BIM.object.GUID becomes the position. device.ID = ID of the device specified in the tag sensing.peroid = time interval for acquiring data from a device (in seconds) format = defines the format for displaying the sensor values obtained from the tagged device |

| C1-4. M&C Device Setup | H3, D3 | Device settings required for monitoring and control The device information is obtained from the pre-registered M&C device. M&C.devices = {M&C.device *} M&C.device = {ID, name, description, registered.device.ID, sensor.ID} registered.device.ID = specifies the ID registered in the M&C device library database sensor.ID = The device can contain several types of sensors. The sensor to be monitored must be designated. |

| C2. BIM-based HMI Deployment Tool | H5, D5 | Distributes the BIM-based HMI settings set by the component C1 to the actual operating HMI server |

| C2-1. BIM MVD I/F | H2, I1 | Using the BIM MVD setting value (C1-2), serves as an interface that filters data from the BIM server and converts them into the format required for display |

| C2-2. M&C Point Connector | H4, D4 | Connects the M&C point (C1-3) set in the BIM-based HMI Authoring Tool and the data source |

| C2-3. M&C Device Connector | H3, D2 | Connects with the set M&C device (C1-4) |

| C2-4. Deployment Test | H5, D5 | Before distribution to the HMI server, a test is performed to ensure that the data related to BIM and energy monitoring is displayed correctly. |

| C3. BIM-based HMI Operations Dashboard | H6, D6, D7 | Provides the BIM-based HMI operation functions |

| C3-1. BIM-based HMI Viewer | H6, D2, I1 | Provides a BIM viewer |

| C3-2. M&C Point Data Dashboard | H6, D4, D3, D7, I2 | Where the data connected to the M&C point are outputted |

| C3-3. M&C Data Exchange I/F | H6, D6, D7, I2 | Interface for obtaining data connected to the H&C point from the BIM, BEMS, and sensor data server |

| C3-4. M&C Data ETL (Extract, Transform, and Load) | H6, D6, D7, I2 | Converts the data obtained using component C3-3 and loads them into the sensing DB server |

| C3-5. BIM-BEMS Database Server | H2, H3, H4, H5, H6, I1, I2 | Provides the BIM and BEMS database servers required for control |

| No. | Requirement | Description |

|---|---|---|

| B1 | Separation of control space | Considering the energy monitoring control space, the BIM model is spaced and modeled. |

| B2 | Modeling only the elements necessary for control | Elements such as furniture, machinery, and electricity are modeled only when necessary. |

| B3 | Classification system definition and input | If the classification system for each BIM object element is well-defined, it is easy to set the GUID when connecting the control points. |

| B4 | Object GUID value present | Objects must have a uniquely distinguishable GUID value. |

| B5 | No overlap between objects | There should be no overlapping chips between objects. |

| B6 | Space alignment | Spaces defined in BIM must be in contact with each other without overlapping. |

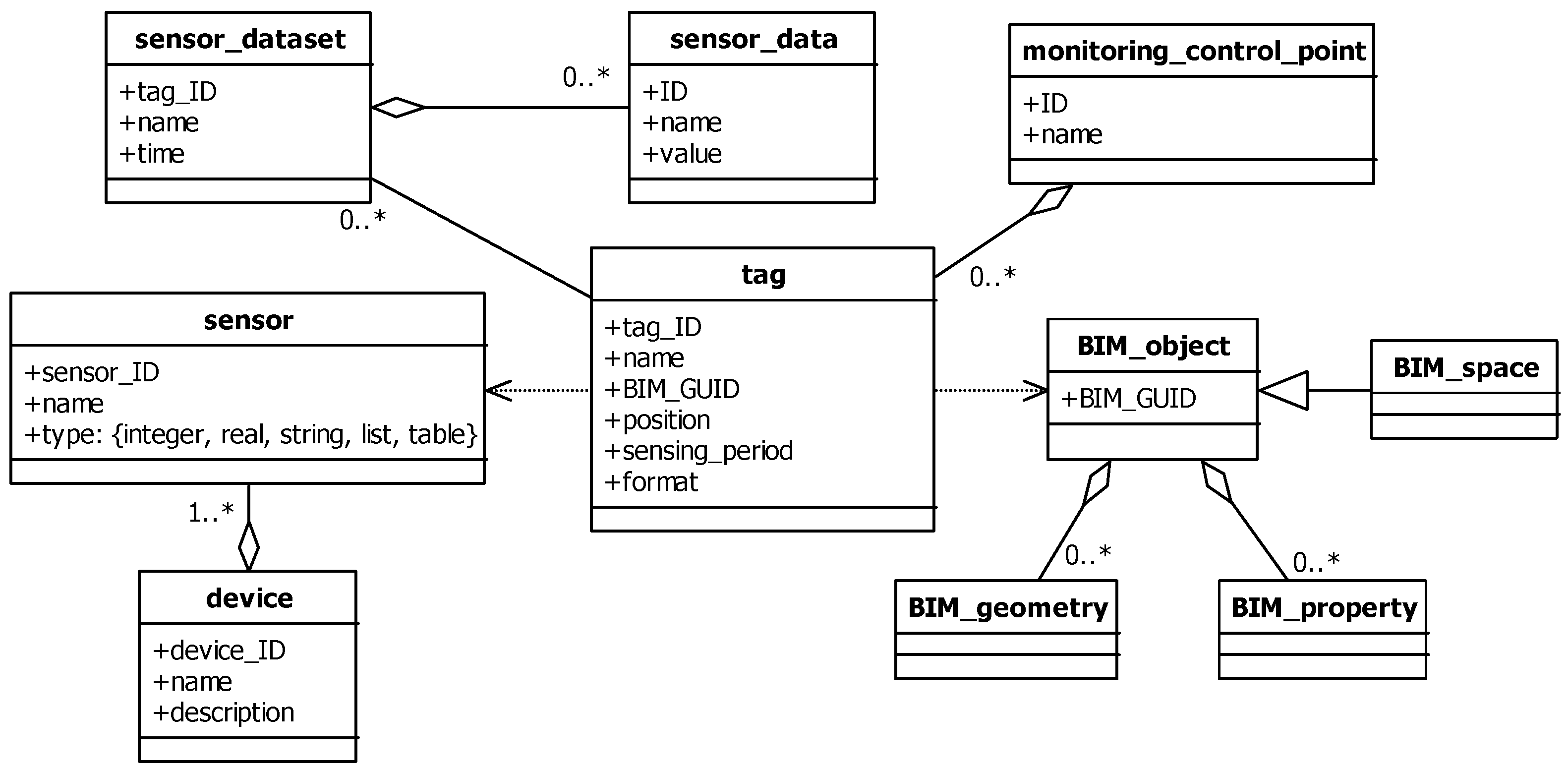

| Entity | Description |

|---|---|

| sensor_data | Saves the sensor data ID: sensor data identification name: sensor name value: the sensor value; saved according to the type specified in the sensor |

| sensor_dataset | Manages the data obtained from the sensor attached to the tag tag_ID: sensor tag ID time: time at which the sensor data were acquired |

| montoring_control_point | Manages tag information on the M&C points |

| tag | Manages tag data tag_ID: tag identification BIM_GUID: BIM object GUID position: position information associated with the BIM object sensing_peroid: defines the data sensing interval format: defines the format of the sensed data output |

| BIM_object | Defines the BIM object and manages its geometry and properties |

| BIM_geometry | Defines the BIM object geometry |

| BIM_property | Manages the BIM object properties |

| BIM_space | Manages the BIM spatial information and defines a spatial coordinate system that includes shapes |

| sensor | Manages the device sensor information sensor_ID: sensor identification type: sensor type; classified into integers, real numbers, strings, lists, and tables, depending on the data acquisition type |

| device | Manages the device and sensor information device_ID: device identification |

| Component | Development Tool |

|---|---|

| C1-1, C1-2, C2-2, C3-1 | javascript, node.js, java, python IfcOpenShell |

| C1-3, C1-4 | xbim toolkit, javascript |

| C2-1, C2-3 | java |

| C3-2 | bootstrap |

| C3-3 | RESTful API, MODBUS, MQTT, TCP/IP |

| C3-4 | Talend |

| C3-5 | BIMserver.org, MySQL |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, T. BIM-Based Human Machine Interface (HMI) Framework for Energy Management. Sustainability 2020, 12, 8861. https://doi.org/10.3390/su12218861

Kang T. BIM-Based Human Machine Interface (HMI) Framework for Energy Management. Sustainability. 2020; 12(21):8861. https://doi.org/10.3390/su12218861

Chicago/Turabian StyleKang, Taewook. 2020. "BIM-Based Human Machine Interface (HMI) Framework for Energy Management" Sustainability 12, no. 21: 8861. https://doi.org/10.3390/su12218861

APA StyleKang, T. (2020). BIM-Based Human Machine Interface (HMI) Framework for Energy Management. Sustainability, 12(21), 8861. https://doi.org/10.3390/su12218861