Abstract

This work investigates Industry 4.0 technologies by developing a new key performance indicator that can determine the energy consumption of machine tools for a more sustainable supply chain. To achieve this, we integrated the machine tool indicator into a cyber–physical system for easy and real-time capturing of data. We also developed software that can turn these data into relevant information (using Python): Using this software, we were able to view machine tool activities and energy consumption in real time, which allowed us to determine the activities with greater energy burdens. As such, we were able to improve the application of Industry 4.0 in machine tools by allowing informed real-time decisions that can reduce energy consumption. In this research, a new Key Performance Indicator (KPI) was been developed and calculated in real time. This KPI can be monitored, can measure the sustainability of machining processes in a green supply chain (GSC) using Nakajima’s six big losses from the perspective of energy consumption, and is able to detect what the biggest energy loss is. This research was implemented in a cyber–physical system typical of Industry 4.0 to demonstrate its applicability in real processes. Other productivity KPIs were implemented in order to compare efficiency and sustainability, highlighting the importance of paying attention to both terms at the same time, given that the improvement of one does not imply the improvement of the other, as our results show.

1. Introduction

Circular economy (CE) is an economic movement that seeks the reduction of the environmental impact caused by manufacturing operations and promotes the cyclic and responsible use of resources [1]. CE plays an important role in the quest for sustainable development objectives related to sustainability and the environment. Kirchherr et al. (2017) described the CE concept of material reduction, reuse, recycling, and recovery through the complete supply chain (SC) as a business model that substitutes the “end-of-life” concept, as it promotes sustainable development [2]. As a result of industry strategies to create a competitive advantage through CE, the green supply chain (GSC) concept was developed—for example, to reduce energy consumption or to lower resource use throughout the SC [3].

Otherwise, traditional industry is being transformed into a new industry known as Industry 4.0. New technologies arising from Industry 4.0 offer numerous advantages for the new SC model through the real-time data obtained from the production systems [4]. Industry 4.0 is capable of aligning CE objectives through the development of the industry digitalization [5], enabling companies to move towards sustainable development.

When we add CE considerations to the SC concept, we obtain an environmentally focused SC, which has economic and operational benefits. Obtaining a good Key Performance Indicator (KPI) formula is crucial for the performance evaluation and correct operation of a GSC [6]. However, GSC indicators and related concepts, such as drivers and consequences of GSC implementation, have not been studied in depth [7]. Moreover, numerous indicators are being used without standardization [8]; thus, the best KPI cannot be determined, and water and energy consumption in particular are not enough developed [9].

The objective of this study is to develop a new KPI capable of measuring the impact of energy consumption on the six big losses, which could become a standardized KPI for GSC. Although it could be extrapolated to other SC processes, it can usually be used in machine tools. This KPI is implemented for a cyber–physical system, presenting the importance of digitalization and Industry 4.0 in the development of GSCs. With this new KPI, it will be possible for decision-makers to rate the sustainability of a product at the strategic level. The new KPI can also identify improvements that can be made in a machine tool at the production level, thereby reducing its energy consumption and effectively reducing production cost.

This manuscript begins with a literature review of the key research concepts and their correlation. It goes ahead to describe the origin of our KPI, its development, and its implementation in a cyber–physical system. On that note, a case of study has been carried out to show this KPI’s development and implementation. The results were discussed and compared with other KPIs. The paper ends with conclusions and proposals for future studies.

2. Literature Review

2.1. Industry 4.0 and the Importance of Cyber–Physical Systems.

Industry 4.0 refers to a new industrial age in which information and production systems are integrated [10]. Industry 4.0 is associated with the fourth industrial revolution, was born in Hannover in 2011, and has expanded throughout Europe owing to the desires of companies to improve their production systems [11].

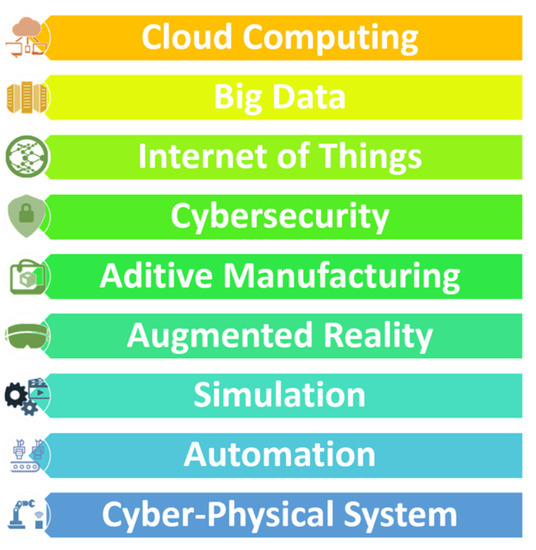

Industry 4.0 comprises nine key technologies responsible for its development (Figure 1). Cyber–physical systems (CPSs) are indispensable to Industry 4.0 owing to their contributions to improving the efficiency, operation transparency, and control capacity of production processes [11].

Figure 1.

Industry 4.0 technologies.

CPSs are based on the integration of physical and virtual processes of networked machines to obtain real-time information, which enhances the decision-making for production processes and maintenance. Furthermore, thanks to the Internet of Things (IoT) technology, the real-time information obtained from CPSs can be stored and is transmissible to other devices that monitor decision execution status [4].

2.2. Circular Economy and Enterprises

Lately, enterprises have been concerned about the social and environmental impacts of their operations. There is a common goal to devise and implement initiatives that reduce energy consumption, popularly referred to as reducing the carbon footprint (Nascimento et al., 2019). Enterprises are pursuing sustainable manufacturing as well as the integration of manufacturing processes and operations for the related economic benefits. The 2030 United Nations General Assembly Agenda has 17 proposed objectives for sustainable development, some of which are enterprise-level agendas [12], e.g., process loss reduction, improved time efficiency, and waiting time reduction. To evaluate the supply chain (SC) performance, it is vital to develop some metrics and Key Performance Indicators (KPIs) [13]. CE is an umbrella concept; thus, it is difficult to conceptualize in a single definition [1]. However, some authors have worked on a consensus proposal, giving rise to the following definition: ‘An economic system that represents a change of paradigm in the way that human society is interrelated with nature and aims to prevent the depletion of resources, close energy and material loops, and facilitate sustainable development through its implementation at the micro (enterprises and consumers), meso (economic agents integrated in symbiosis), and macro (cities, regions, and governments) levels. Attaining this circular model requires cyclical and regenerative environmental innovations in the way society legislates, produces, and consumes’ [14]. CE encompasses many concepts. For this study, we selected two key concepts of the CE model, i.e., energy consumption and carbon footprint. The inadequate means for measuring the carbon footprint through the SC are a serious problem for enterprises [15]. The carbon footprint is defined as the total amount of greenhouse gas emissions produced by an organization or product in CO2 equivalent units [16].

The Ellen MacArthur Foundation [17] proposed the ReSOLVE framework with six courses of action to guide enterprises on CE implementation, which are described as follows:

- Regenerate: Shift to renewable energy and materials.

- Share: Design products with enhanced durability to prolong life through maintenance.

- Optimize: Use a technology-centered strategy with potential benefits, such as increased performance, from technological improvements.

- Loop: Keep components and materials in closed loops.

- Virtualize: Replacement of tangible with virtual systems.

- Exchange: Substitution of old and non-renewable goods with new and renewable goods.

Lopes de Sousa Jabbour et al. (2018) referred to the ReSOLVE framework as the basis for the implementation of CE processes utilizing Industry 4.0 technologies [18]. Referring to the optimization concept of the ReSOLVE framework, we also demonstrate how technology benefits CE implementation.

2.3. Green Supply Chain and Industry 4.0 Applications

Industry 4.0 has rapidly developed information and communication technologies (ICTs), such as CPSs, IoT, and cloud computing, which have been proposed to facilitate the implementation of a sustainable production [19].

Regarding sustainable production, the GSC appeared following the CE concept as a strategy to develop a competitive advantage through it [3]. GSC procurement and manufacturing activities encompass recycling, reducing energy consumption, life cycle analysis, energy efficiency, and machine tool life cycle costs, according to green standards [20]. Some standards related to machine tool environmental evaluations, such as the ISO 14955-1:2017, are also associated with these concepts [21]. The development of these standards led to machine monitoring for data relating to energy efficiency [22].

Some examples of the influence of Industry 4.0 in sustainability can be found in the literature. S. Luthra et al. (2018) proposed a business model for Industry 4.0 [23] that can be useful for environmental control and protection in a GSC, for example, by reducing process time or increasing time flexibility [24]. S. Smetana et al. (2020) used data-integrated assessment systems to provide transparency and integrate nutritional and environmental properties in a food supply chain [25]. R. Sharma et al. (2020) asserted that digital technologies are a fundamental component for sustainable decision-making in manufacturing due to their capability of optimizing the resource usage, thus reducing the harmful impact on the environment [26]. G. Beier et al. (2020) considered efficiency as one of the most important sustainable topics, and ensured that Industry 4.0 contributes to resource and energy efficiency as well as to the improvement of resource productivity and efficiency [5]. These examples enlighten us to the potential that Industry 4.0 has to create sustainable industrial value [27].

2.4. Relationship between the Lean Methodology and Green Supply Chain

One of the goals of lean theory is to use fewer resources to obtain the same results. This goal is environmentally beneficial and requires the reduction of material use. Material use reduction has an environmental impact and quality improvement benefits owing to rework reduction and less wastage, which, in turn, lead to cost reduction and less environmental pollution. The lean methodology and GSC concept lead to material reductions and wastage elimination. Tăucean et al. (2019) states that the lean theory covers part of the sustainable development objectives like environmental protection, waste reduction, and greenhouse gas reduction. The fundamental pillars of the lean theory are waste reduction and emission reduction, which are also proposed in the CE model [12]

Muda, Mura, and Muri, known as the three MUs, are big enemies of lean production efficiency. Muda covers seven types of wastes: defects, overproduction, waiting, transportation, inventory, motion, and overprocessing, while Muri refers to any action related with tangible or intangible stress conditions, and Mura identifies irregular machine or person use [28].

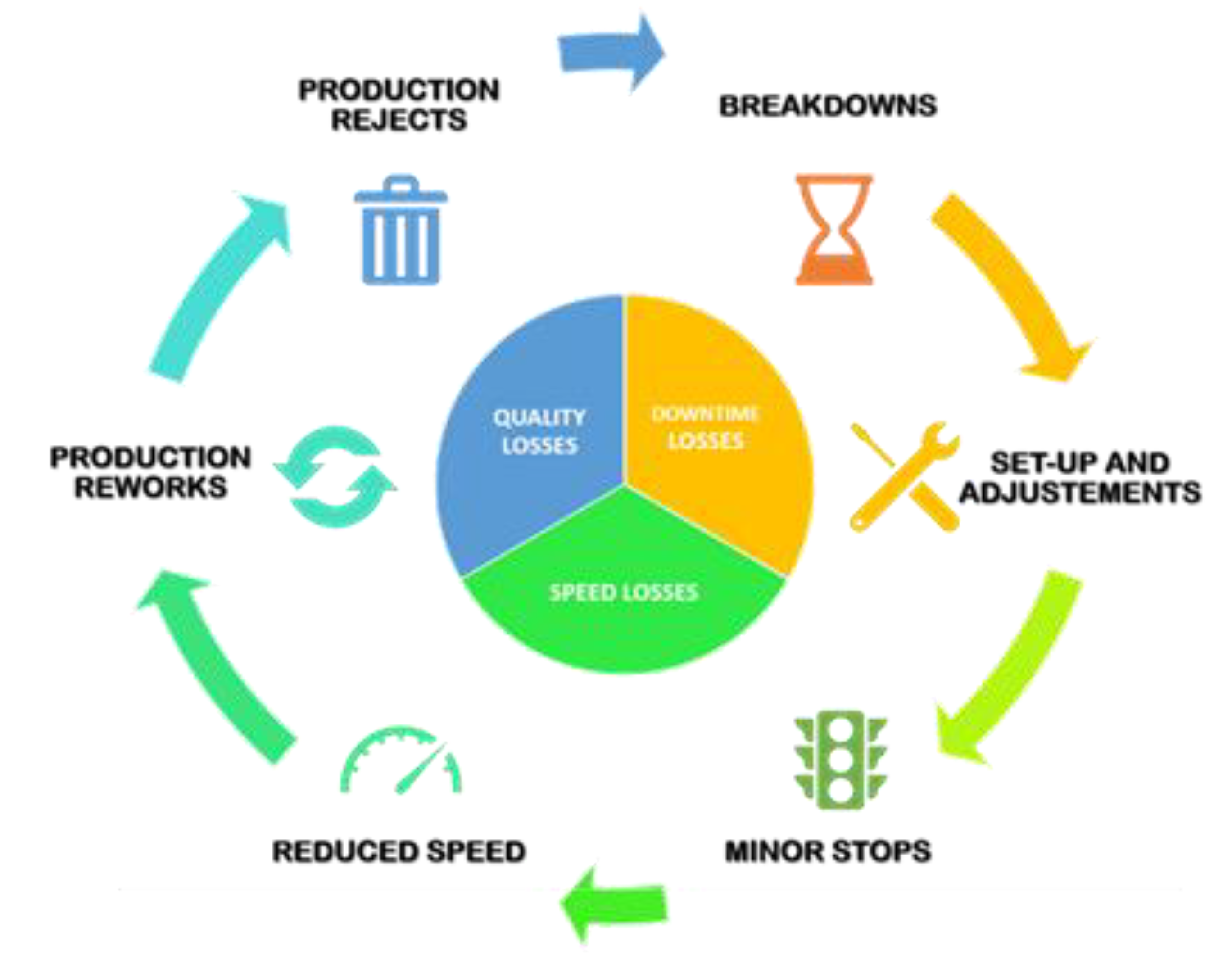

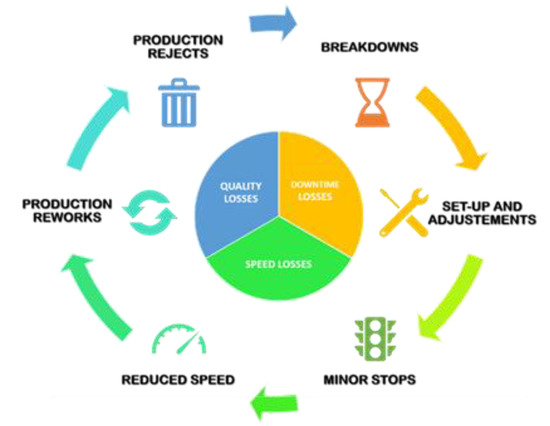

In regard to wastes, this article, oriented toward machines, has chosen the concept of the six big losses developed by Nakajima as the lean tool to establish this KPI. Losses are defined as activities that consume resources without value addition [29]. Nakajima categorizes these losses into three big blocks, i.e., time, speed, and quality loss, described as follows (as can be seen in Figure 2) [30].

Figure 2.

Six big losses.

- Breakdowns: time losses.

- Set-up and adjustments.

- Minor stops during production.

- Reduced speed.

- Reworks: products with minor defects that can be reworked.

- Rejects: products with defects.

These losses were used by Nakajima to develop a new KPI named overall equipment effectiveness (OEE), a productivity measure of individual equipment in a manufacturing environment by multiplying three indicators: availability, performance, and quality [29]. Despite the importance of the effective productivity measures of the OEE, many researchers have identified weaknesses of this KPI—for example, its inadequate capacity to measure other equipment in a production line, its inadequate consideration of indicators and customer satisfaction, and its inadequate means to measure environmental impacts or resource consumption efficiency [31]. It also has a major shortcoming in the way it is calculated, i.e., with the same weight of the three components of OEE, giving no significance to economic features of production [32].

2.5. Key Performance Indicators for a Green Supply Chain

Despite many studies that conclude that adding lean methodologies to Industry 4.0 is a powerful tool for transforming traditional SCs into sustainable SCs, the ideas and techniques require high levels of organization and are hard to apply at a production level. The challenge is no longer for enterprises to be competing with each other, but rather to compete between SCs while they keep up with the changes occurring in the industrial world [13].

The objective of a GSC must be to eliminate or reduce negative environmental impacts and waste resources [33], such as energy waste, which is considered in this article. In particular, owing to the high environmental impact and energy consumption of SC machines, it is useful to identify ecological and technical weaknesses throughout the SC [34]. The competitive advantage of a GSC energy consumption indicator like the one developed herein cannot be emphasized enough.

There are different KPIs used in finance, operations, and resource performance (e.g., water, energy, non-renewable resources, and waste). The KPIs rely on industry type, production methodology, and business strategy [6]. Olugu et al. (2011) made an automotive industry indicator derived from items like supplier sustainability, greening cost, total cost for environmentally sustainable operations, recycled material level on a product, and energy-consumption-associated costs [35]. Zhao et al. (2017) proposed a total greenhouse gas emission calculation through a complete SC [36]. Domingo and Aguado (2015) and Durán et al. (2018) added a sustainability dimension to the OEE by multiplying it by a sustainability factor [37,38]. C. Sassanelli et al. (2019) showed a Circular economy Performance Indicator (CPI) that is able to measure the minimum energy required for the process of making a product [39]. As can be observed, there is a wide range of indicators, which means that there is a lack of standardization [8] that our KPI could reduce because of its standard use in machine tools.

The use of indicators is an important element to determine an organization’s efficiency. However, nowadays, the air pollution is the most assessed criterion for sustainability, and others, such as water and energy consumption, must be included in future research [13].

3. Materials and Methods

Green practices are implemented along the GSC in order to optimize waste and energy consumption [40]. A great example is Apple; the company is working hard to reduce energy consumption, i.e., developing smarter power management software [41].

Our KPI development is aligned with these green practices because of its capability to show the energy waste on a machine tool. This section describes the definition and implementation of this new KPI in a cyber–physical system.

To define the indicator, the first step is to investigate the impact of the six big losses on the energy consumption of a machine tool. Wudhikarn et al. (2010) developed a similar methodology to define a cost KPI (Overall Equipment Cost Loss—OECL) based on the six big losses. Despite the similarities in both methodologies, the objectives are completely different. The main objective of our study is to reduce CO2 emissions by detecting energy losses during the machine tool production processes, while Wudhikarn et al. (2010) focused on addressing the weaknesses of the OEE [32]. In addition, that research shows losses in monetary units [42]; therefore, that KPI presents a financial dimension, which is not directly related to GSC, whereas our KPI has a sustainable dimension that allows it to be directly related to GSC.

Moreover, the OEE has been applied as a measurement tool of productivity; it is considered an emerging topic that can be adapted to other domains for measuring the effectiveness of material, economic, and human resources [43]. There are a great number of authors who have tried to add a sustainable component to the OEE by modifying its original calculation. Domingo and Aguado (2015) added a fourth sustainability parameter to the OEE [37], resulting in the OEEE (Overall Environmental Equipment Effectiveness), and Durán et al. (2018) defined an OEE only at the production system level with a sustainable component [38]. On the contrary, we contemplated different aspects in an integrated way to provide an analysis of sustainability without modifying the original calculation of OEE; thus, our KPI, defined as Energy Consumption Losses (ECL) is not an extension of OEE, but a new KPI with the same origin that OEE has—the six big losses.

The second step is the integration of Industry 4.0 technologies, which are applied to a machine tool, into a cyber–physical system, allowing us to obtain real-time data on factors such as energy consumption for calculations of a machine tool KPI.

3.1. Application of the Six Big Losses to Energy Consumption in a Machine Tool

Referring to the six losses identified by Nakajima [30], the six energy losses are detailed below:

- (1)

- Breakdown and adjustment losses caused by material and personnel: all energy consumption associated with turning the machine on and off, maintenance actions, and adjustments.

- (2)

- Waiting time losses: energy consumption associated with set-up and adjustments, as well as the duration when the machine is consuming power, but is not available for production, e.g., consumption during tool changes or while changing a piece.

- (3)

- Reduced speed losses: energy consumption associated with the times when the machine works at a rate lower than its possible speed.

- (4)

- Minor stoppage losses: extra energy consumption by flow obstruction, process jams, incorrect feed, checks, or stops leading to additional flow time. In this case, they are associated with stops of less than five minutes, but this value can vary for each company.

- (5)

- Rework losses: energy consumption of rework activity after the process.

- (6)

- Reject losses: energy consumption associated with products that are rejected, in other words, the consumption of making a piece that is discarded.

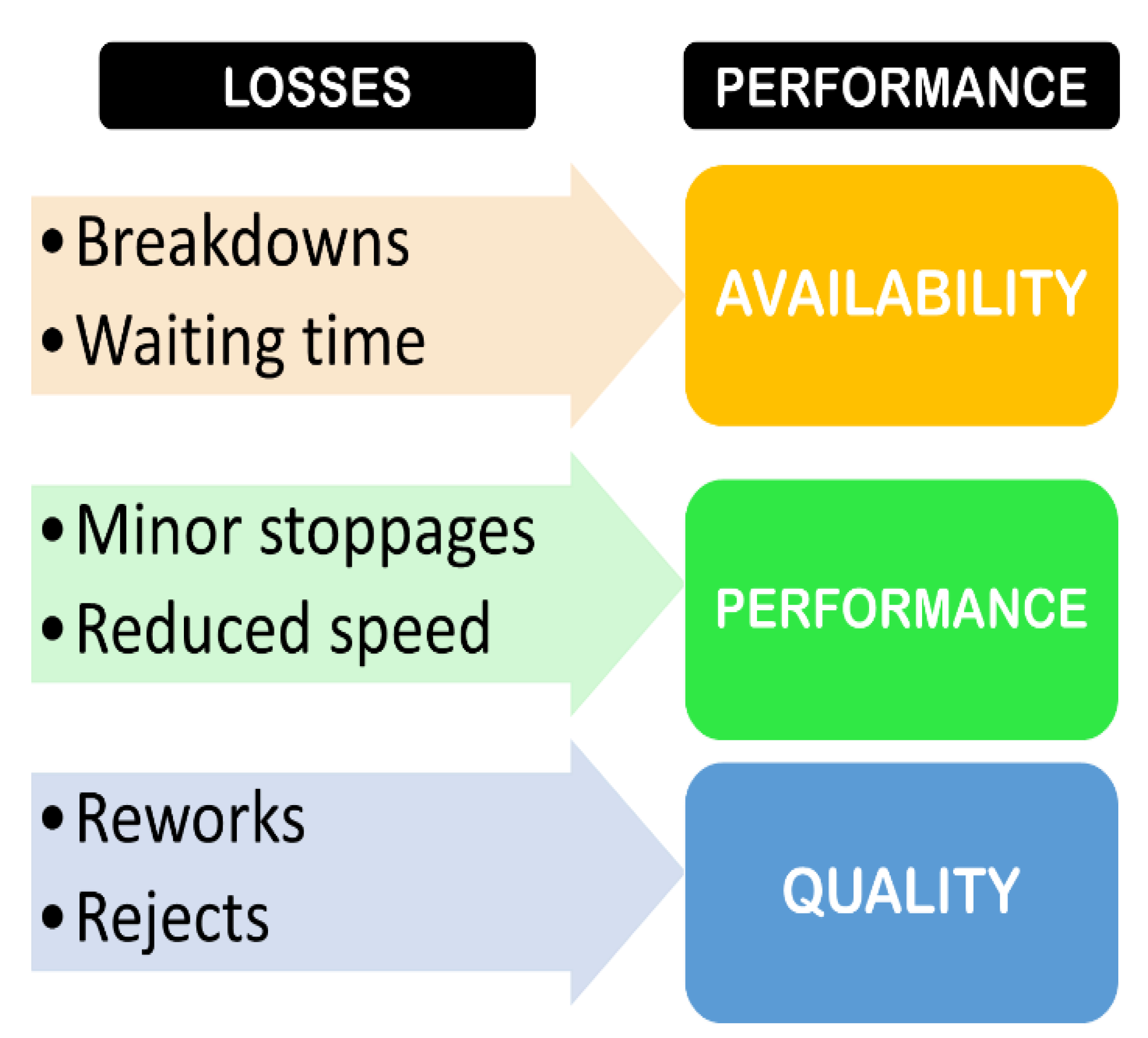

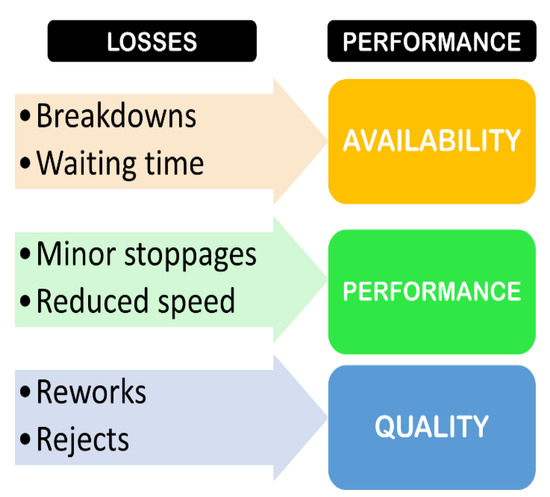

Continuing the description of the losses established by Nakajima, we can associate these six big losses with three performance dimensions, i.e., availability, performance, and quality (Figure 3). These dimensions are the basis for OEE calculations [44]. In the case of energy consumption, these three dimensions are the energy consumption associated with problems of availability, performance, and quality that occur in a machine tool.

Figure 3.

The relation between six big losses and their performance.

3.2. Green KPI Definition: Energy Consumption Losses (ECL)

Referring to the six big losses of the energy consumption of a machine tool that were defined in the previous section, we developed a new KPI. Energy consumption losses (ECL) are defined as the losses associated with the six big losses during a specific period, e.g., a working day. ECL is expressed as the sum of three components:

where ECA, ECP, and ECQ are the energy consumption associated with availability, performance, and quality, respectively. Therefore, ECA can be expressed as:

where BEC and WTEC are the energy consumption associated with breakdowns and waiting time, respectively. They are calculated as follows:

where n is the number of breakdowns, EC on/off is the energy consumption to turn the machine on and off during a breakdown, EC repairsn is the energy used during repairs, and EC adjustmentsn is the energy used during adjustments.

Here, variable n is the number of waiting periods occurring during a set period, and EC waiting timen is the energy consumption during that waiting period.

The ECP is expressed as:

where MSEC and RSEC are the energy consumption of minor stoppage and reduced speeds, respectively. They are calculated as follows:

MSEC is the energy consumption associated with minor stoppages, where n is the number of stoppages occurring during a set period.

RSEC is the energy consumption occurring from working at a lower speed than the established speed.

The ECQ consumption related to quality is expressed as:

where:

RwEC = EC one piece manufactured × No. reworks

RjEC = EC one piece manufactured × No. rejects

RwEC is the rework energy consumption by pieces or parts that must be reworked owing to the presence of a defect, and RjEC is the reject energy consumption associated with pieces that must be discarded.

ECL can thus be defined in energy units; however, we chose to define it as a carbon footprint, since the emissions of ECL throughout the SC are increasingly being contemplated so that they can be compared and even added to other GSC carbon footprint calculations [15]. This KPI shows the emitted carbon footprint, which can be reduced by applying measures that decrease the amount of waste generated. For this reason, the final equation is defined as follows, where GHG Emission c energy is the coefficient of greenhouse gas emissions caused by the energy generation:

ECL [(kg CO2 eq] = ECL [kWh] × GHG Emission c energy[kg CO2 eq/kWh]

3.3. Cyber–Physical System Implementation

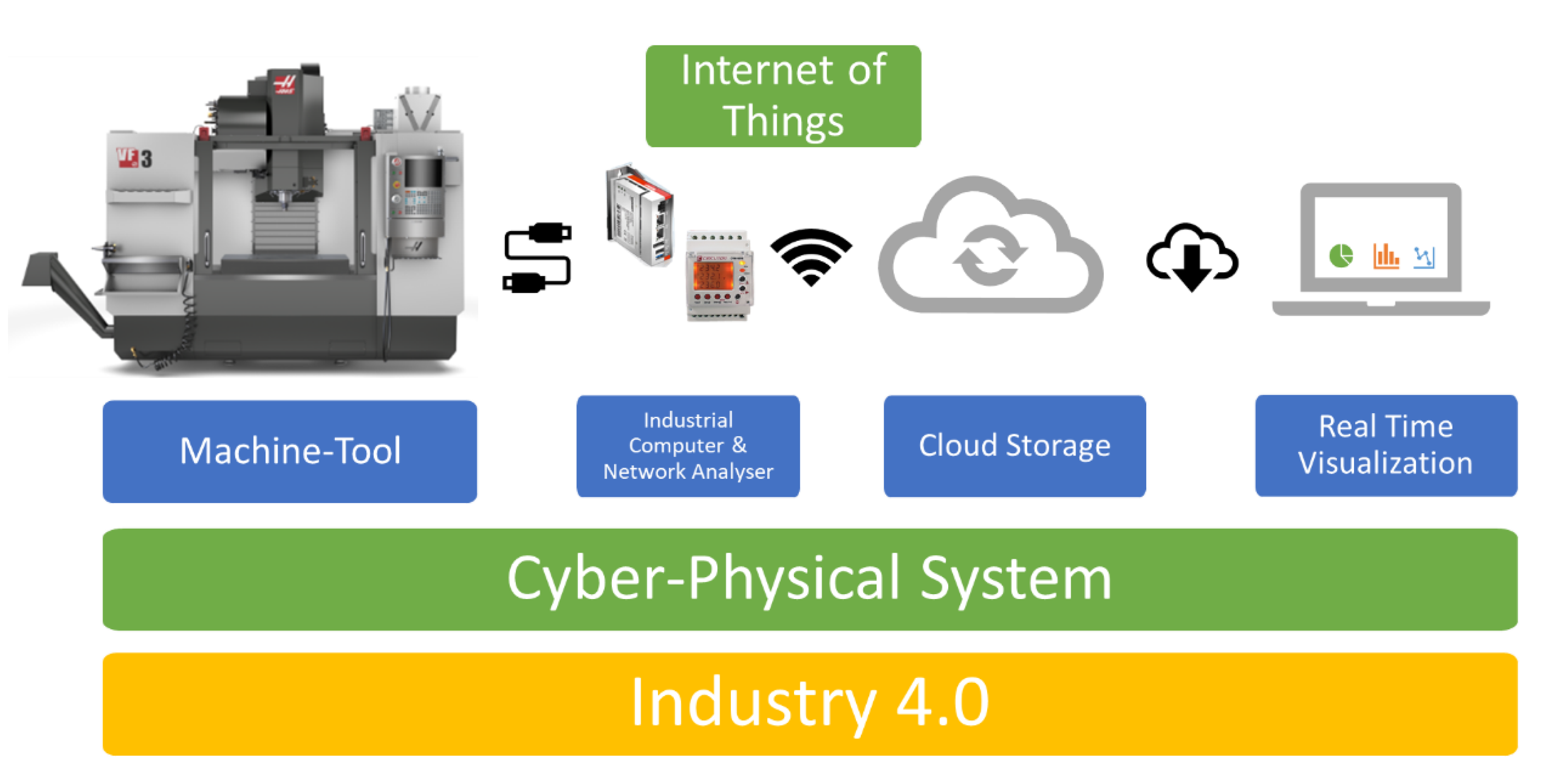

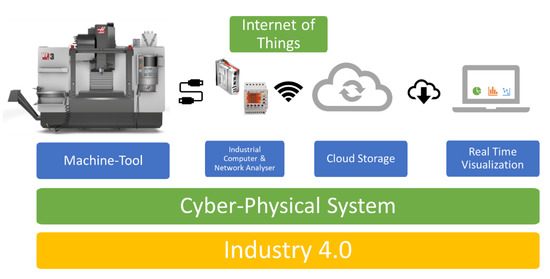

Another objective of this study is to realize a new KPI that can link the lean theory with CE for a GSC. The proposed KPI must also demonstrate the contribution of Industry 4.0 to the development of the GSC. In the past, it was difficult to collect precisely the data related to energy consumption; however, the Industry 4.0 technologies (CPS, IoT, and cloud computing) enhance this process [45]. For this reason, the machine needs to be integrated into a cyber–physical system for ECL calculations in a machine tool so that energy consumption data can be obtained through IoT technology in real time and then treated and used for ECL calculations by Python, a programming language that allows the development of software quickly and easily [46].

CPS consists of two components, i.e., a complex physical system and a cyber core capable of monitoring, coordinating, and controlling the physical system. The integration of the two components is crucial [47]. This type of system shows the user the operating status of the physical system in real time.

CPS is considered as part of the development of smart manufacturing, playing a major role in linking the real and virtual world [48]. CPS has been implemented successfully in other manufacturing processes. Monitoring energy is one of the most relevant examples of CPS use. S. Ma et al. (2019) used a CPS to monitor, integrate, simulate, evaluate, and adjust the state of energy consumption in a production process [45]. EnyFlow is an energy monitoring solution for gaining energy transparency. This solution collects energy demand data each second from machine sensors, stores it in a central database, and shows the results on an application [49]. Apart from energy consumption, there are other uses, such as monitoring a 3D thermal emission, trying to become a more energy-efficient system [49], or implementing a CPS in an Auto-Guided Vehicle (AGV) to improve the material flow in a production line [50].

For this study, the physical system consists of a machine tool (HAAS VF-3), which is a five-axis vertical milling machine; three of the axes (X, Y, Z) and the other two (A and C) were added by incorporating a Trunnion 160 double-cradle table. A system of monitoring machinery was added to this physical system. These were then connected to an industrial computer (Beckhoff) capable of capturing data in real time and storing it in the cloud, turning the machine tool into a CPS (see Figure 4).

Figure 4.

Implementation of a cyber–physical system.

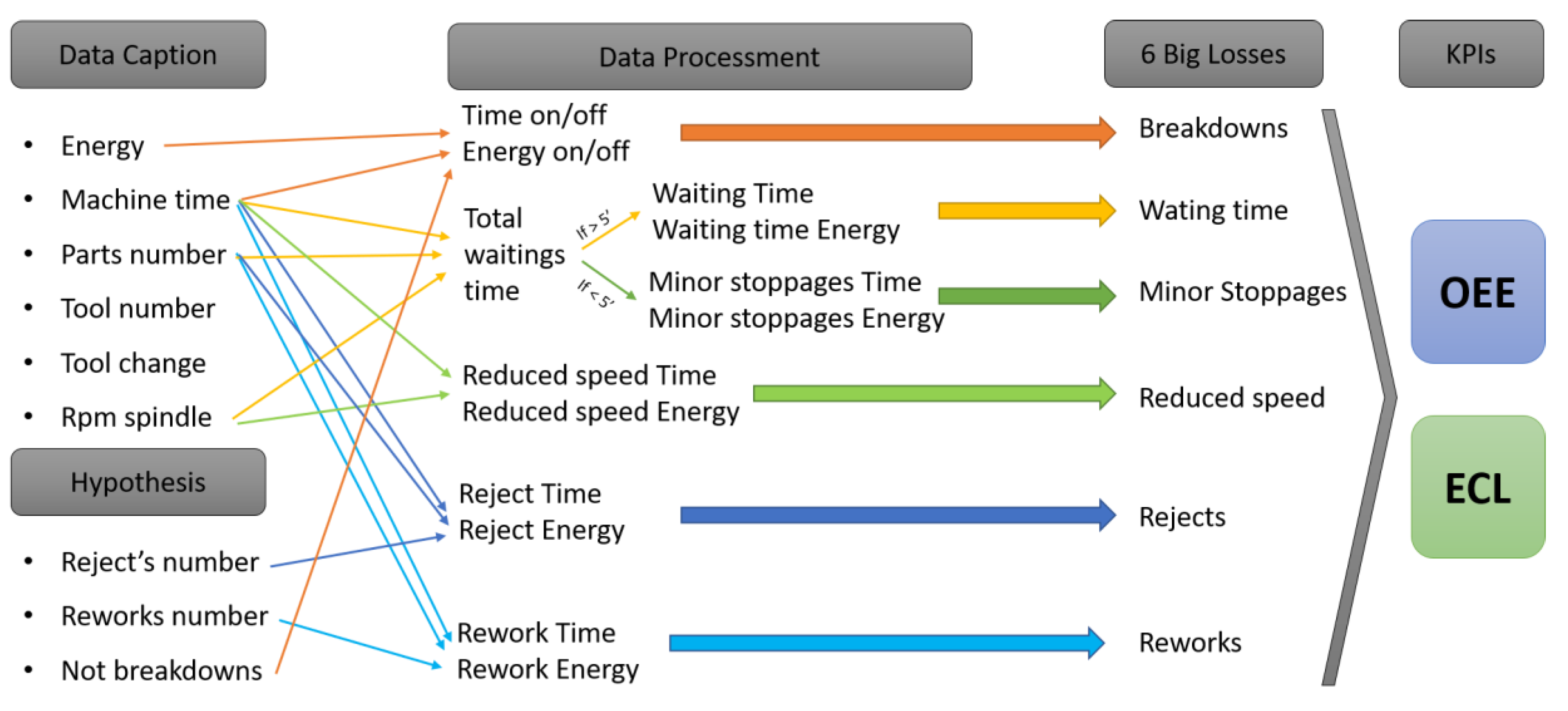

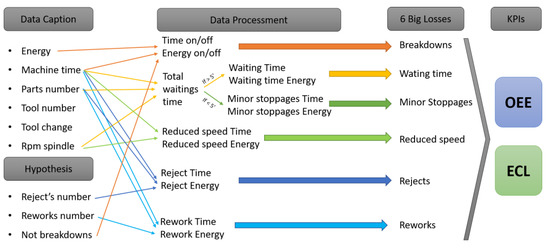

3.4. Calculating the Green KPI in a Cyber–Physical System

Once the machine tool was integrated into the physical and computational system, we analyzed, checked, and selected the most appropriate variables for calculation of the green KPI in real time. We developed software capable of transforming the data obtained by the CPS into indicators and other information relevant to the user using Python. The software can calculate the ECL and OEE by applying the equations in Section 3.2 to the consumption and time data obtained from the CPS. As can be seen in Figure 5, our CPS is able to capture variables, such as machine time, energy consumption, number of pieces produced (number of parts), what tool is being used (tool number) and when it is changed (tool change), and the spindle rotation (rpm of the spindle). However, other parameters must be given as hypotheses. In this case, the number of reworks, rejects, and the maintenance time and breakdowns are hypothesized, and the difference between stoppage and minor stoppage was established as five minutes. Once the data are acquired, the combination of energy or time data with other variables allows us to know the time and energy associated with every big loss and, therefore, to calculate the OEE (time variables) and the ECL (energy variables).

Figure 5.

Flow chart of the Key Performance Indicator (KPI) calculation.

Performing these calculations on a conventional machine would be complex, since it would be almost impossible to distinguish the energy consumption and durations associated with each of the six big losses. This is simpler with the cyber–physical system because it is possible to know what type of activity is occurring in real time. Data such as time, spindle rotation, manufactured parts, tool number, and energy consumption allow the determination of the process that the system is carrying out, how long it takes, how much energy the machine consumes, if the machine is working properly or not, and if the machine is working at reduced speed.

4. Results and Discussions

In this section, a test is performed, and the results obtained from the test are presented and analyzed; first, the results of the ECL indicator are shown, and then a comparison is made between the ECL and the OEE.

4.1. Test Description

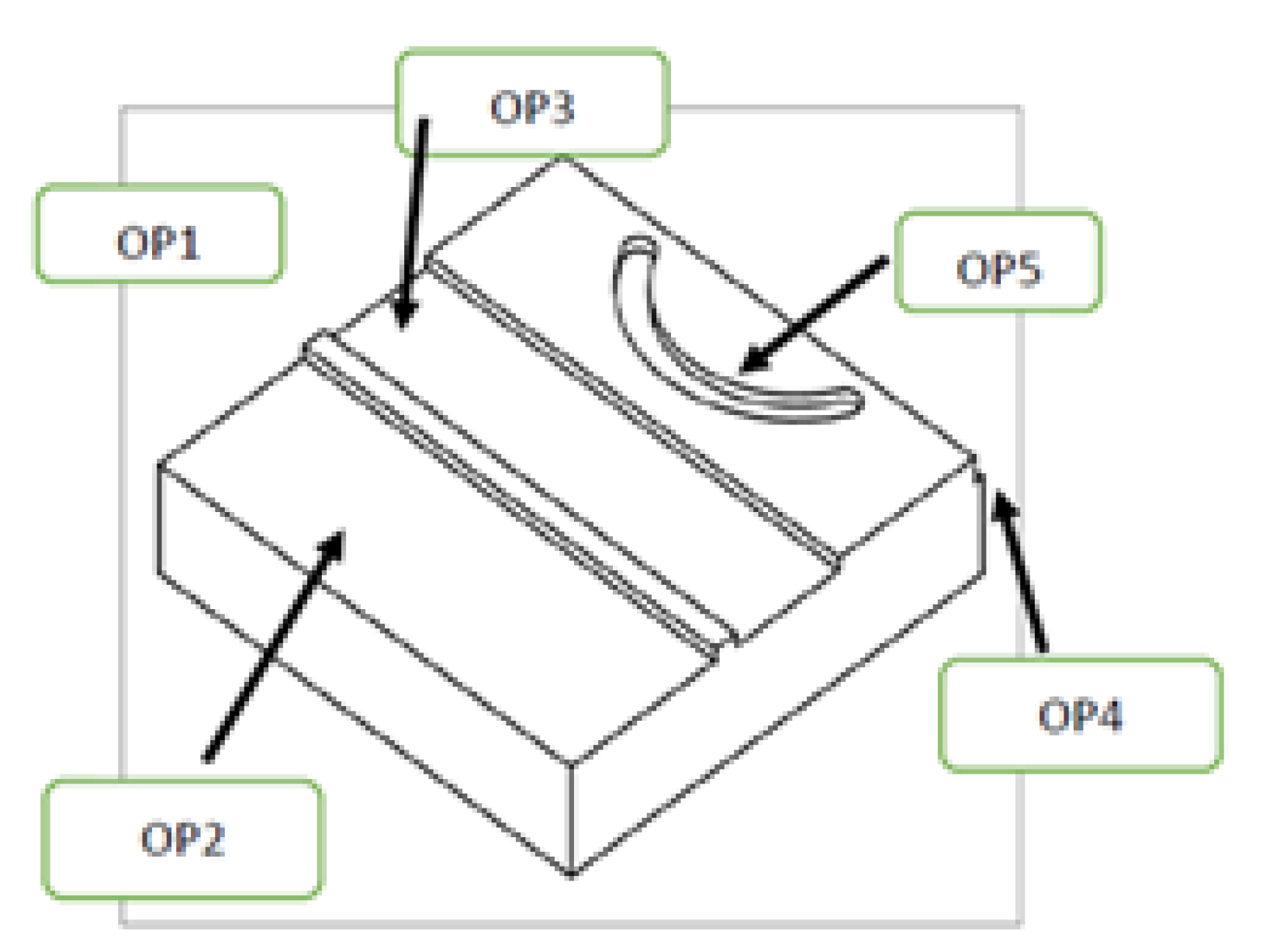

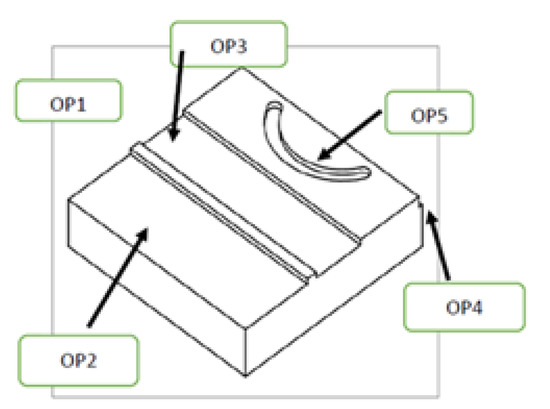

For this study, the piece shown in Figure 6 was designed and machined from aluminum blocks of 100 × 100 × 20 mm, on which the following operations (OP), each one made with a different tool, were performed:

Figure 6.

Machined part design during testing.

- OP1: face milling on the top side with an octagonal plate of Ø80 of five plates.

- OP2: face milling at 90 degrees with a plate of Ø63 with five plates.

- OP3: slot milling with two plates with a cutter of Ø25.

- OP4: shoulder milling with cutter of Ø14 of three cuts and a cut to the center; in other words, the tool has an edge toward the center and low cutting.

- OP5: circular slot milling with a fast steel cutter of Ø10 HSS (High Speed Steel) with three cuts and a center cut.

In order to carry out our test, five pieces of the same item are manufactured at three different tool feed rates, i.e., 100% (case 1), 75% (case 2), and 50% (case 3) of the feed rate recommended by the manufacturer according to the material and the quality.

Each case required a different duration: case 1: 23 min, case 2: 26 min, and case 3: 33 min. For the three cases, it was assumed that there were no breakdowns during the machining of the five pieces and that for each case, one piece is rejected and another needs to be reworked.

The real-time data from the three cases are collected and processed by the cyber–physical system with two programs developed in Python. The first one was programmed to obtain the ECL and the second one to calculate the OEE. We needed the OEE calculation to make comparisons and to analyze the relationship between the two KPIs. In addition, the ECL indicator aimed to address the limitations of the OEE, as described in Section 2.4.

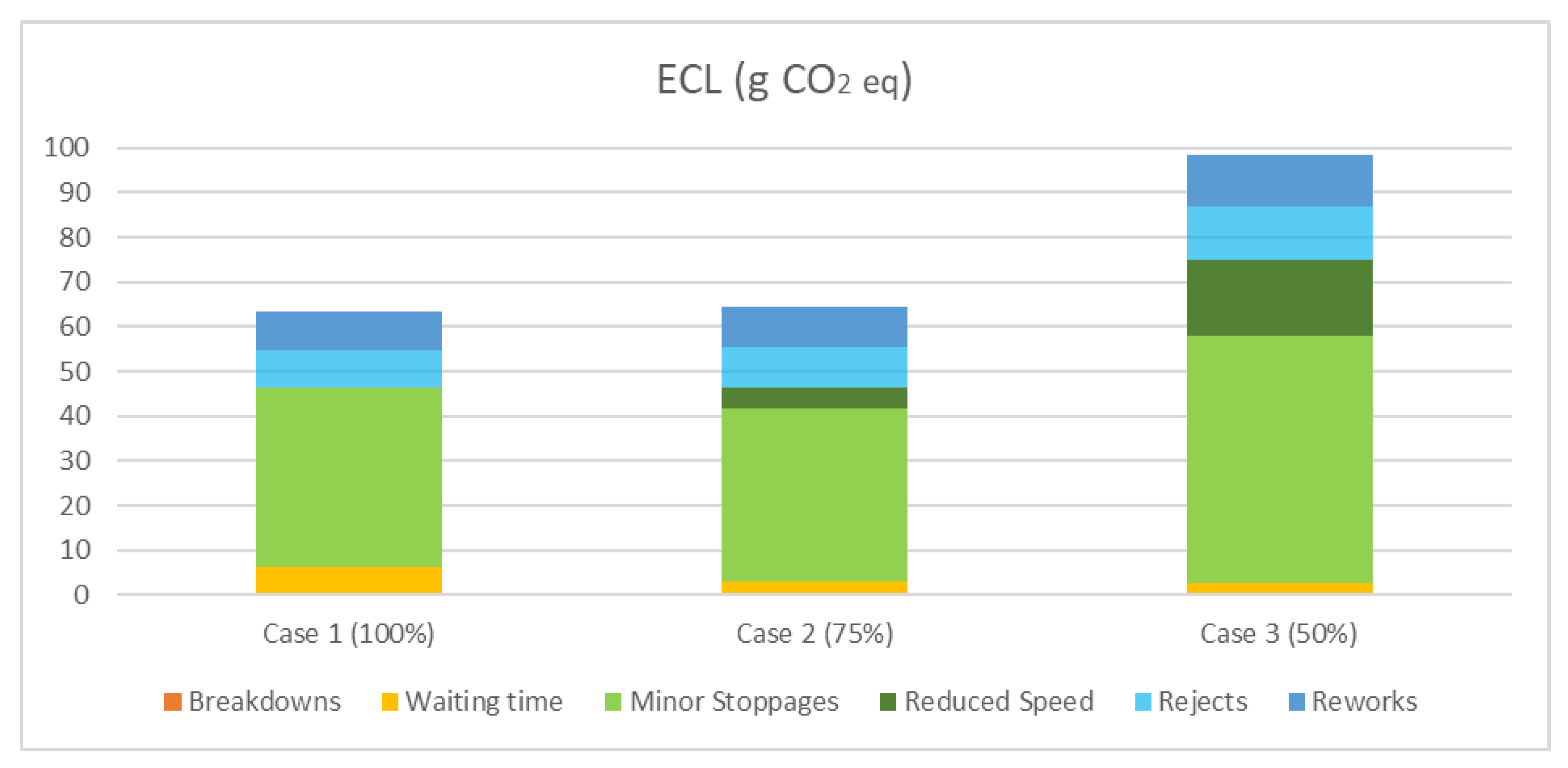

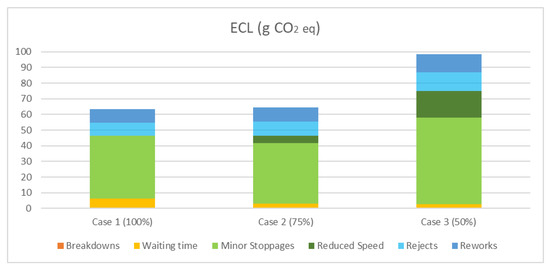

4.2. Energy Consumption Loss Results

Implementing the formulas described in Section 3.2 and with the support of the programs developed in Python, results were obtained on availability, performance, and quality components (Table 1). A graphical visualization of the comparison of each case and the six big losses is shown in Figure 7.

Table 1.

Test results.

Figure 7.

Stacked bar chart for the three tests.

This new KPI allows us to observe that in case 1, CO2 emissions were reduced by 2% and 36% in comparison to machining in cases 2 and 3.

In the three cases, it can be observed that the highest energy consumption is caused by minor stoppage losses. In cases 1 and 2, whose ECL is similar, there are two reasons for the differences, i.e., case 1 is at the maximum speed, and therefore, there are no losses related to the reduced speed, and the energy consumption associated with quality losses is lower. In case 3, the increase in energy consumption is associated with losses related to reduced speed and minor stoppages.

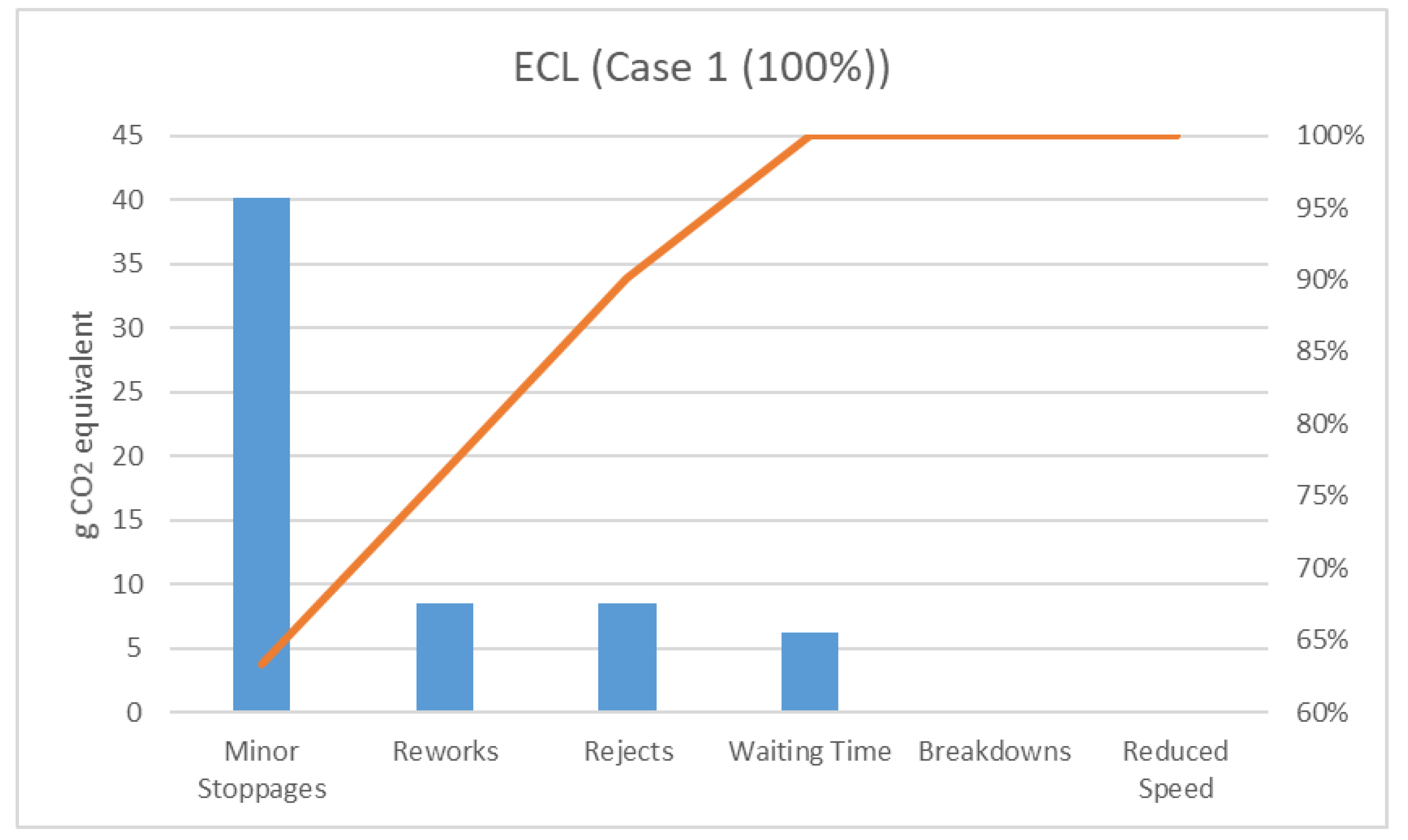

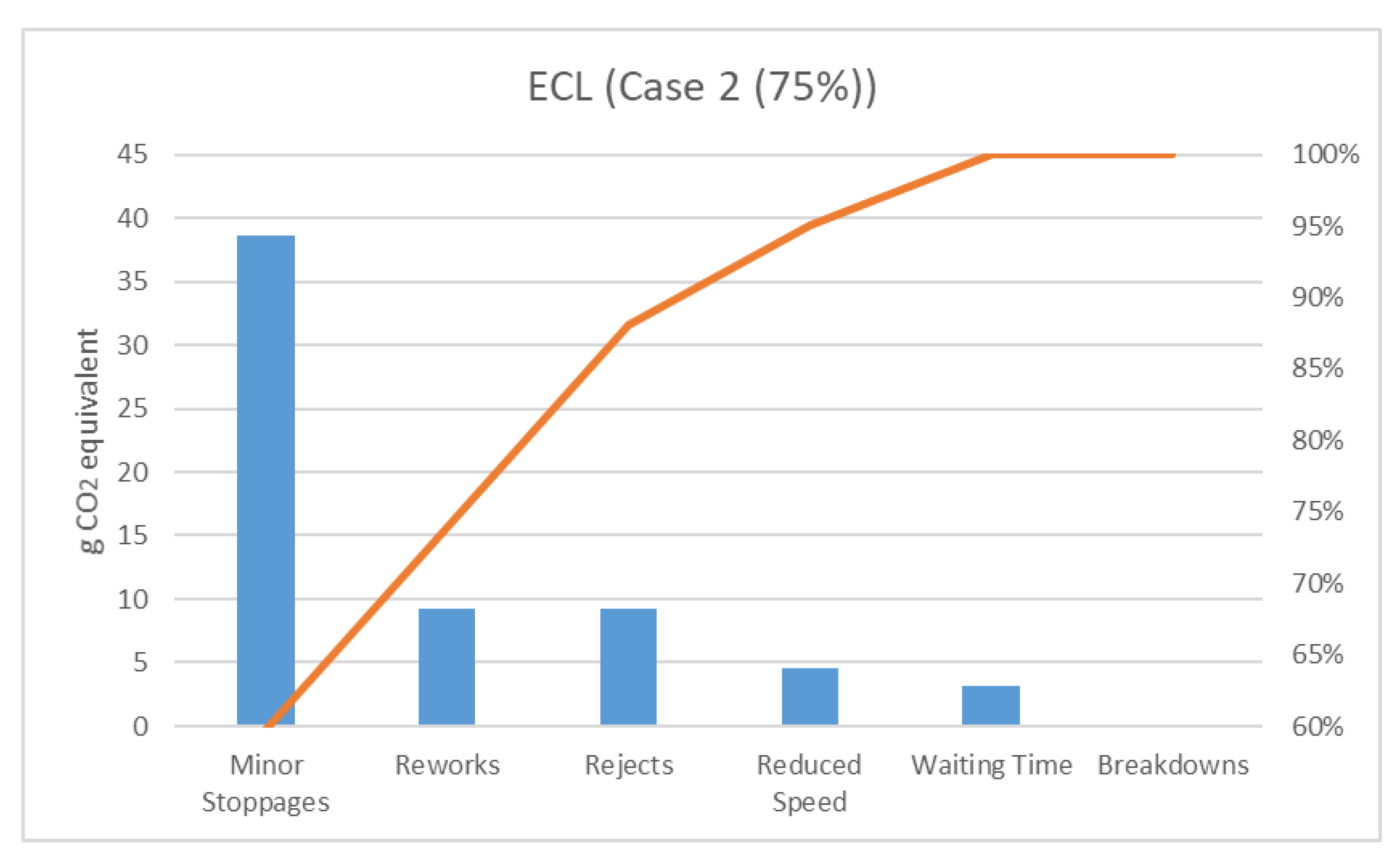

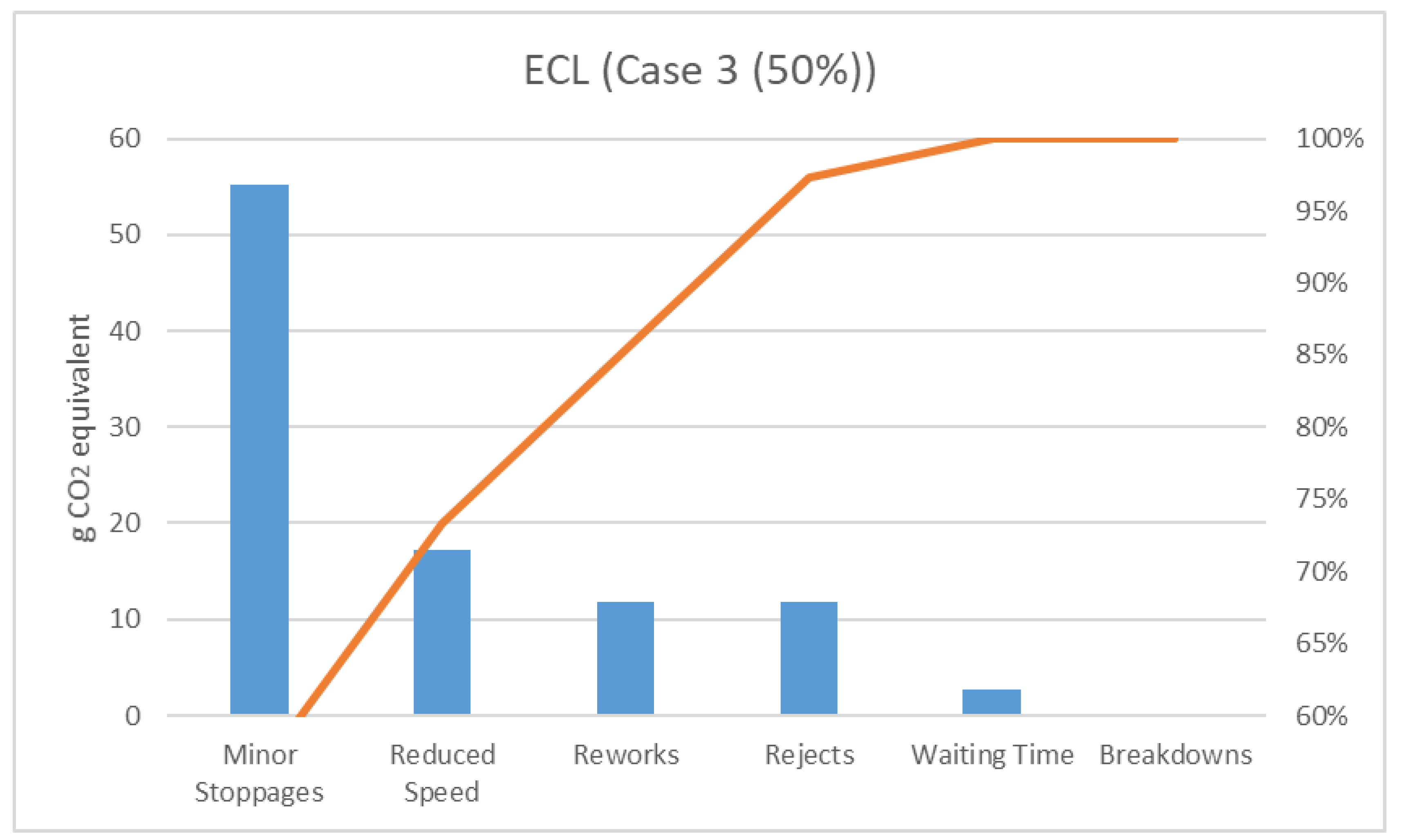

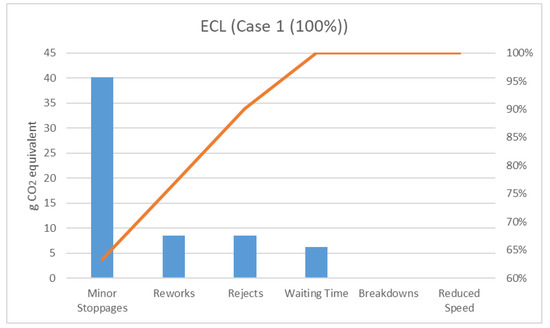

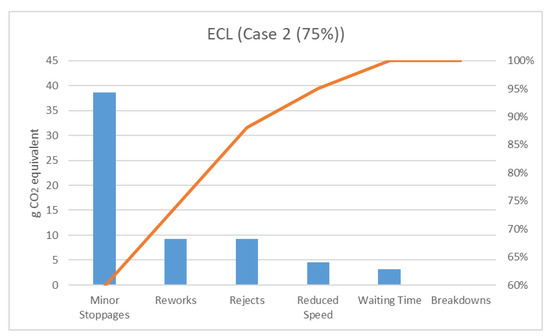

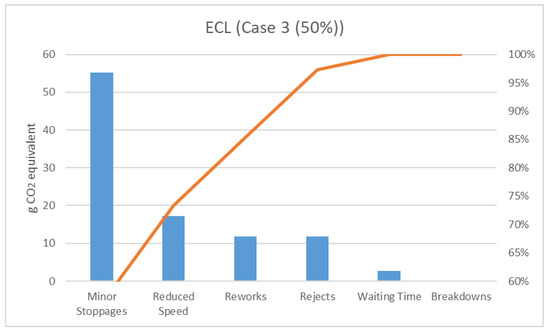

The Python program was developed to show a Pareto diagram for each case, as shown in Figure 8, Figure 9 and Figure 10, allowing the identification of 20% of the causes that lead to 80% of the effects, thus improving the ECL analysis.

Figure 8.

Energy consumption loss (ECL) Pareto diagram for case 1.

Figure 9.

ECL Pareto diagram for case 2.

Figure 10.

ECL Pareto diagram for case 3.

From the Pareto diagrams, losses that consume the highest energy can be identified. They should be the ones to be corrected first. In the three tests, the minor stoppage losses consumed the highest energy. The next problems to be solved in cases 1 and 2 are reworks and rejections, since the production of a defective part is approximately 10% of the ECL, i.e., 10% of CO2 emissions into the atmosphere are attributed to the energy used to manufacture a defective part. In contrast, in case 3, the second big loss was due to reduced speed, and was almost 20% of the ECL. As the Pareto diagram shows, in the three cases, minimizing the first two losses would save 80% of the energy losses of the machine tool.

The analysis of these results shows that the use of the green KPI highlights areas of improvement to the company from a sustainable point of view, since it identifies the most important losses. This indicator and its future application to other process involved in SC would be key in the development of a GSC [6], especially given that machine tools consume 35% of the global electricity and produce 20% of CO2 emissions [22].

Furthermore, the continuous CPS monitoring and, therefore, the continuous calculation of the ECL allow a comparison between the ECL values calculated over several days, which could be considered as a predictive maintenance tool. If the ECL abruptly increases, it could be a signal that something is going wrong with the machine and it should be reviewed.

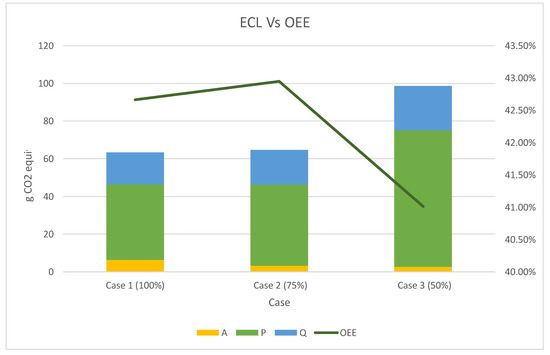

4.3. Comparison between the ECL and OEE

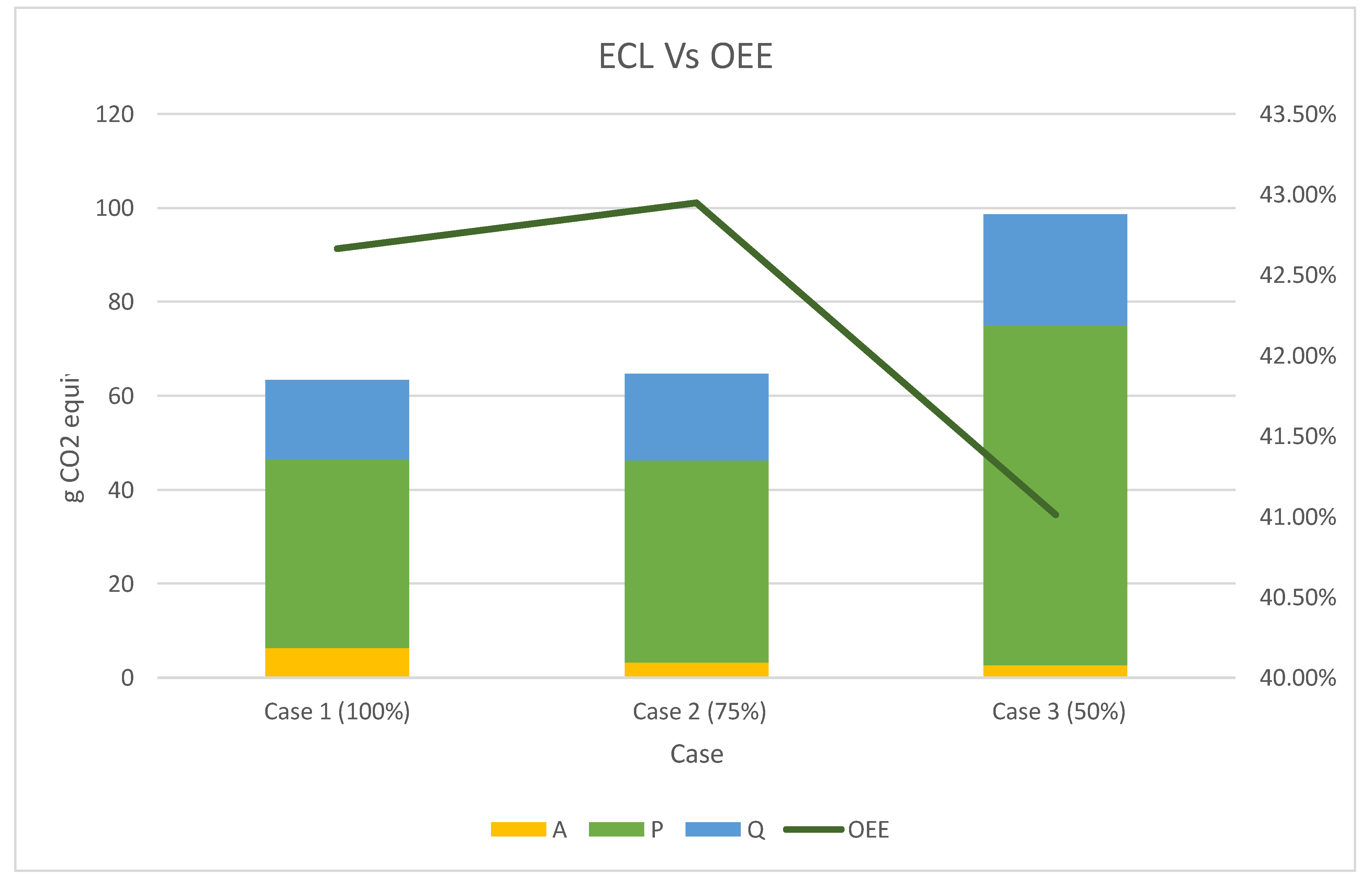

As the origin of both indicators is the six big losses, the data collected from the machine tool can be processed as time losses for the calculation of the OEE (see Table 2) at the same time that they are processed as energy losses for the ECL (see Figure 5).

Table 2.

Overall equipment effectiveness (OEE) results for the three cases.

Figure 11 presents a comparison between the OEE (%) and ECL. It can be observed that case 2 shows the highest percentage of OEE; however, it does not correspond to the lowest ECL. In contrast, case 1 shows the lowest ECL and a lower percentage of OEE. With these results, it can be concluded that having a larger OEE does not conditionally signify the most sustainable productive method.

Figure 11.

ECL (in g of CO2 equivalent and separated into losses due to availability (A), performance (P), and quality (Q)) vs. OEE.

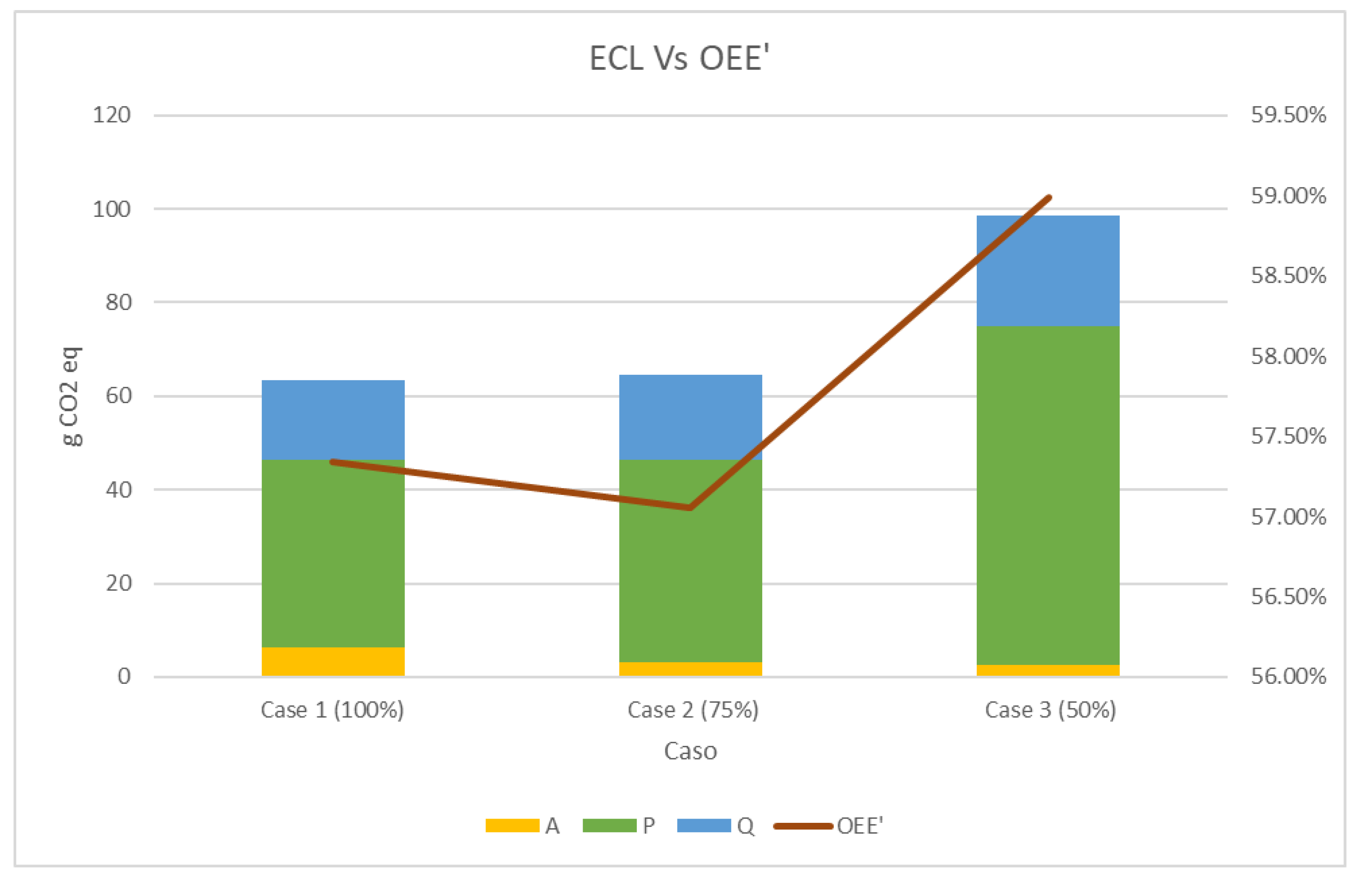

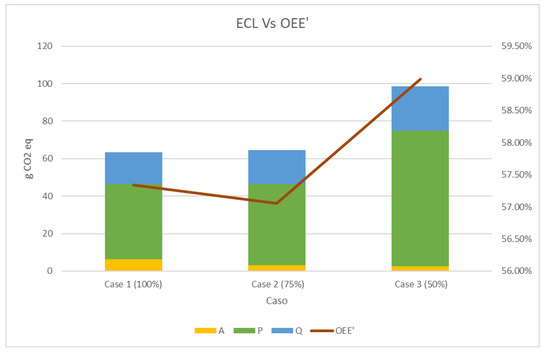

To highlight this comparison, a new indicator was used, which is called OEE’. OEE’ is the opposite of OEE; it shows the machine’s unproductivity and is calculated as follows in Equation (12):

This calculation allows the comparison between two loss expressions, OEE’ and ECL (see Figure 12) and sustains the idea seen in Figure 11. It is not necessary that the lower the time losses are, the lower the energy losses have to be.

Figure 12.

Comparison between ECL and the opposite of OEE (OEE’).

A company only seeking to improve its OEE may be wasting the opportunity to consider sustainability within the analysis; the ECL indicator we have developed is aligned with the effectiveness of equipment by integrating the sustainability of a machine tool, making possible the comparison between effectiveness (OEE or OEE’) and sustainability (ECL). This comparison allows us to find the stability between an efficient production process and a sustainable one.

This KPI, as a derivation of the six big losses, provides environmental value by identifying energy consumption losses and CO2 emissions in a CPS. This adaptation closes the gap between the energy consumption indicator [51] and CO2 emission caused by the energy losses described before.

5. Conclusions

The objective of this study was to develop a new KPI to be calculated in real time that is capable of indicating the sustainability of a machining process in a GSC using Nakajima’s six big losses from the perspective of energy consumption in a cyber–physical system typical of Industry 4.0.

In this study, we posit that Industry 4.0 technologies help profoundly in machine tool analysis. Adequate real-time data collection allowed us to eliminate complex calculus with real-time responses to unforeseen failures. As can be seen in our test, once the equations are developed and implemented, thanks to the digitalization, the calculation in real time is immediate. Furthermore, the system allows the display of several types of visual information through different graphics, such as a Pareto diagram, which can inform us at a glance about the most important losses; in our case, this makes us able to generate improvement actions.

The ECL results obtained from the test and its comparison with the OEE bring out the importance of paying attention to both terms (effectiveness and sustainability) at the same time; thus, an improvement of one does not imply improvement of the other.

We consider this new KPI, which is related to CE and GSC, a key aspect for continuous GSC improvement and an advantage for enterprises because the ECL is capable of determining the carbon footprint, and improvements in the ECL contribute to environmental improvements and company savings related to energy consumption and carbon footprint. However, the progressive monitoring of the ECL is not the sole objective, but predictive maintenance of machines was also considered. A higher value of ECL means an increase in energy consumption; therefore, it can be interpreted as a machine tool problem that should be checked.

This research has some limitations that should be addressed in future research. ECL has only been calculated as a machine tool KPI, so future research should consider the integration of the ECL indicator horizontally—towards other processes in the GSC—and vertically—towards other logistics operations. Furthermore, the KPI was calculated for a single machine tool; we are implementing a CPS in another machine tool in order to create a machine park and expand the KPI calculation. The knowledge acquired during this research as to sensor functioning, variable identification and adjustment, and KPI implementation in a CPS helps us to extrapolate it to other SC processes and systems and allows us an easier and quicker development of this machine park.

In conclusion, the outcome of this study shows the importance of covering different dimensions in SC by providing a real-time view that shows what is happening and that is not skewed by one-way targeting. In addition, this study highlights the important role that Industry 4.0 technologies can play in greening the SC by using monitorization to develop and implement new KPIs.

Author Contributions

Conceptualization, methodology, and investigation, P.M. and M.P.L.; software, P.M.; validation, M.P.L.; resources, L.d.C.N.C.; writing—original draft preparation, P.M.; writing—review and editing, M.P.L. and L.d.C.N.C.; supervision, M.P.L. and J.R.; project administration, J.R. and J.C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to acknowledge the participation of TECNALIA RESEARCH & INNOVATIONS through their the implementation of the cyber–physical system and for their expertise in electronics and communication, as well as the Precision Mechanic Service of the Universidad de Zaragoza and their contributions during the essays.

Conflicts of Interest

The authors declare no conflict of interest.

Glossary

This part shows the equation’s glossary:

| BEC | Energy consumption associated with breakdowns. |

| ECA | Energy consumption associated with unavailability. |

| EC adjustments | Energy used during adjustment. |

| EC on/off | Energy consumption to turn the machine on and off during a breakdown. |

| ECP | Energy consumption associated with performance. Bench marking |

| ECQ | Energy consumption associated with quality. |

| EC repairs | Energy used during repair. |

| EC waiting time | Energy consumption during the waiting period. |

| MSEC | Energy consumption of minor stoppage. |

| RjEC | Energy consumption associated with pieces that must be discarded. |

| RSEC | Energy consumption associated with reduced speed. |

| RwEC | Energy consumption by pieces or parts that must be reworked due to the presence of a defect. |

| WTEC | Energy consumption associated by waiting time. |

References

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; De Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.D.S.; Jabbour, C.J.C.; Foropon, C.; Filho, M.G. When titans meet – Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reißig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes – A literature review. J. Clean. Prod. 2020, 259, 120856. [Google Scholar] [CrossRef]

- Micheli, G.J.; Cagno, E.; Mustillo, G.; Trianni, A. Green supply chain management drivers, practices and performance: A comprehensive study on the moderators. J. Clean. Prod. 2020, 259, 121024. [Google Scholar] [CrossRef]

- García-Granero, E.M.; Piedra-Muñoz, L.; Galdeano-Gómez, E. Eco-innovation measurement: A review of firm performance indicators. J. Clean. Prod. 2018, 191, 304–317. [Google Scholar] [CrossRef]

- Banasik, A.; Bloemhof-Ruwaard, J.M.; Kanellopoulos, A.; Claassen, G.D.H.; Van Der Vorst, J.G.A.J. Multi-criteria decision making approaches for green supply chains: A review. Flex. Serv. Manuf. J. 2016, 30, 366–396. [Google Scholar] [CrossRef]

- Moreno-Camacho, C.A.; Montoya-Torres, J.R.; Jaegler, A.; Gondran, N. Sustainability metrics for real case applications of the supply chain network design problem: A systematic literature review. J. Clean. Prod. 2019, 231, 600–618. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Taucean, I.M.; Tămășilă, M.; Ivascu, L.; Miclea, Ș.; Negrut, M.L. Integrating Sustainability and Lean: SLIM Method and Enterprise Game Proposed. Sustainability 2019, 11, 2103. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Determining and applying sustainable supplier key performance indicators. Supply Chain Manag. Int. J. 2014, 19, 275–291. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Sundarakani, B.; De Souza, R.; Goh, M.; Wagner, S.M.; Manikandan, S. Modeling carbon footprints across the supply chain. Int. J. Prod. Econ. 2010, 128, 43–50. [Google Scholar] [CrossRef]

- Wang, L.; Hui, M. Research on joint emission reduction in supply chain based on carbon footprint of the product. J. Clean. Prod. 2020, 263, 121086. [Google Scholar] [CrossRef]

- Ellen Macarthur Foundation. Delivering the Circular Economy a Toolkit for Policymakers; Ellen Macarthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Jabbour, A.B.L.D.S.; Jabbour, C.J.C.; Filho, M.G.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, C.-H.; Zheng, P.; Zhong, R.Y. An integrated framework for active discovery and optimal allocation of smart manufacturing services. J. Clean. Prod. 2020, 273, 123144. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299. [Google Scholar] [CrossRef]

- Putz, M.; Koriath, H.; Kuznetsov, A. Resource consumption classes of machine tools. MM Sci. J. 2019, 2019, 3301–3309. [Google Scholar] [CrossRef]

- Zeng, D.; Cao, H.; Jafar, S.; Tan, Y.; Su, S. A Life Cycle Ecological Sensitivity Analysis Method for Eco-Design Decision Making of Machine Tool. Procedia CIRP 2018, 69, 698–703. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process. Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153. [Google Scholar] [CrossRef]

- Smetana, S.M.; Aganovic, K.; Heinz, V. Food Supply Chains as Cyber-Physical Systems: A Path for More Sustainable Personalized Nutrition. Food Eng. Rev. 2020, 1–12. [Google Scholar] [CrossRef]

- Sharma, R.; Jabbour, C.J.C.; Jabbour, A.B.L.D.S. Sustainable manufacturing and industry 4.0: What we know and what we don’t. J. Enterp. Inf. Manag. 2020. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Romero, D.; Gaiardelli, P.; Thürer, M.; Powell, D.; Wuest, T. Cyber-Physical Waste Identification and Elimination Strategies in the Digital Lean Manufacturing World. In Information Technology in Educational Management; Springer Science and Business Media LLC, Springer: Berlin/Heidelberg, Germany, 2019; Volume 566, pp. 37–45. [Google Scholar]

- Muchiri, P.; Pintelon, L. Performance measurement using overall equipment effectiveness (OEE): Literature review and practical application discussion. Int. J. Prod. Res. 2008, 46, 3517–3535. [Google Scholar] [CrossRef]

- Jonsson, P.; Lesshammar, M. Evaluation and improvement of manufacturing performance measurement systems - the role of OEE. Int. J. Oper. Prod. Manag. 1999, 19, 55–78. [Google Scholar] [CrossRef]

- García-Arca, J.; Prado-Prado, J.C.; Fernández-González, A.J. Integrating KPIs for improving efficiency in road transport. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 931–951. [Google Scholar] [CrossRef]

- Wudhikarn, R.; Smithikul, C.; Manopiniwes, W. Developing Overall Equipment Cost Loss Indicator. Adv. Intell. Soft Comput. 2010, 66, 557–567. [Google Scholar]

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Götze, U.; Koriath, H.-J.; Kolesnikov, A.; Lindner, R.; Paetzold, J. Integrated methodology for the evaluation of the energy- and cost-effectiveness of machine tools. CIRP J. Manuf. Sci. Technol. 2012, 5, 151–163. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y.; Shaharoun, A.M. Development of key performance measures for the automobile green supply chain. Resour. Conserv. Recycl. 2011, 55, 567–579. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, Y.; Zhang, N.; Huang, T. An optimization model for green supply chain management by using a big data analytic approach. J. Clean. Prod. 2017, 142, 1085–1097. [Google Scholar] [CrossRef]

- Domingo, R.; Aguado, S. Overall Environmental Equipment Effectiveness as a Metric of a Lean and Green Manufacturing System. Sustainability 2015, 7, 9031–9047. [Google Scholar] [CrossRef]

- Durán, O.; Capaldo, A.; Acevedo, P.A.D. Sustainable Overall Throughputability Effectiveness (S.O.T.E.) as a Metric for Production Systems. Sustainability 2018, 10, 362. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Pourhejazy, P.; Kwon, O.K. A Practical Review of Green Supply Chain Management: Disciplines and Best Practices. J. Int. Logist. Trade 2016, 14, 156–164. [Google Scholar] [CrossRef]

- Wudhikarn, R. Improving overall equipment cost loss adding cost of quality. Int. J. Prod. Res. 2011, 50, 3434–3449. [Google Scholar] [CrossRef]

- Ng, C.; Enrique, M.; Korner, H. Overall Equipment Effectiveness: Systematic Literature Review and Overview of Different Approaches. Appl. Sci. 2020, 10, 6469. [Google Scholar] [CrossRef]

- Ljungberg, Õ. Measurement of overall equipment effectiveness as a basis for TPM activities. Int. J. Oper. Prod. Manag. 1998, 18, 495–507. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Lv, J.; Yang, H.; Wu, J. Energy-cyber-physical system enabled management for energy-intensive manufacturing industries. J. Clean. Prod. 2019, 226, 892–903. [Google Scholar] [CrossRef]

- Wagner, M.; Llort, G.; Mercadal, E.; Gimenez, J.; Labarta, J. Performance Analysis of Parallel Python Applications. Procedia Comput. Sci. 2017, 108, 2171–2179. [Google Scholar] [CrossRef]

- Antsaklis, P.J.; Goodwine, B.; Gupta, V.; McCourt, M.J.; Wang, Y.; Wu, P.; Xia, M.; Yu, H.; Zhu, F. Control of cyberphysical systems using passivity and dissipativity based methods. Eur. J. Control. 2013, 19, 379–388. [Google Scholar] [CrossRef]

- Herrmann, C.; Schmidt, C.; Kurle, D.; Blume, S.; Thiede, S. Sustainability in manufacturing and factories of the future. Int. J. Precis. Eng. Manuf. Technol. 2014, 1, 283–292. [Google Scholar] [CrossRef]

- Thiede, S. Environmental Sustainability of Cyber Physical Production Systems. Procedia CIRP 2018, 69, 644–649. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Z.; Lv, J. CPS-Based Smart Control Model for Shopfloor Material Handling. IEEE Trans. Ind. Inform. 2017, 14, 1764–1775. [Google Scholar] [CrossRef]

- Barletta, I.; Andersson, J.; Johansson, B.; May, G.; Taisch, M. Assessing a proposal for an energy-based Overall Equipment Effectiveness indicator through Discrete Event Simulation. In Proceedings of the Winter Simulation Conference 2014, Savannah, GA, USA, 7–10 December 2014; pp. 1096–1107. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).