Assessing the Theoretical Prospects of Bioethanol Production as a Biofuel from Agricultural Residues in Bangladesh: A Review

Abstract

1. Introduction

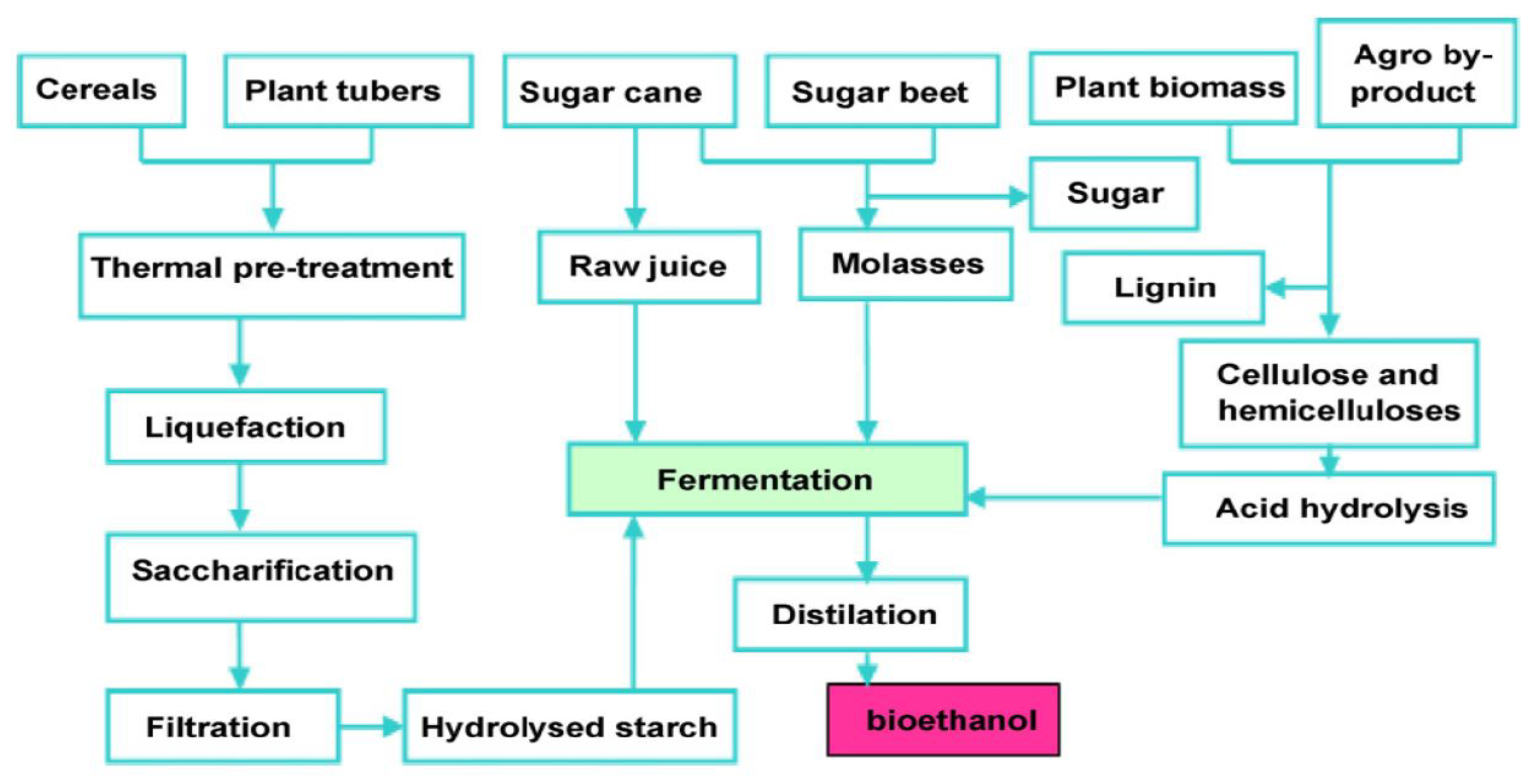

2. Transformation of Agro-Waste into Bioethanol

2.1. Current Alternative Process Strategies for Bioethanol Production

2.2. Consolidate Bioprocessing by Fungi Species: A Viable Solution

3. The Scenario of Bioenergy Potential and Production in Bangladesh

4. Methods and Data Source

4.1. Field Residue and Process Residue

4.2. Utilization of Crop Residue

4.3. Total Residue Available and Bioethanol Conversion Rate

5. Results and Discussions

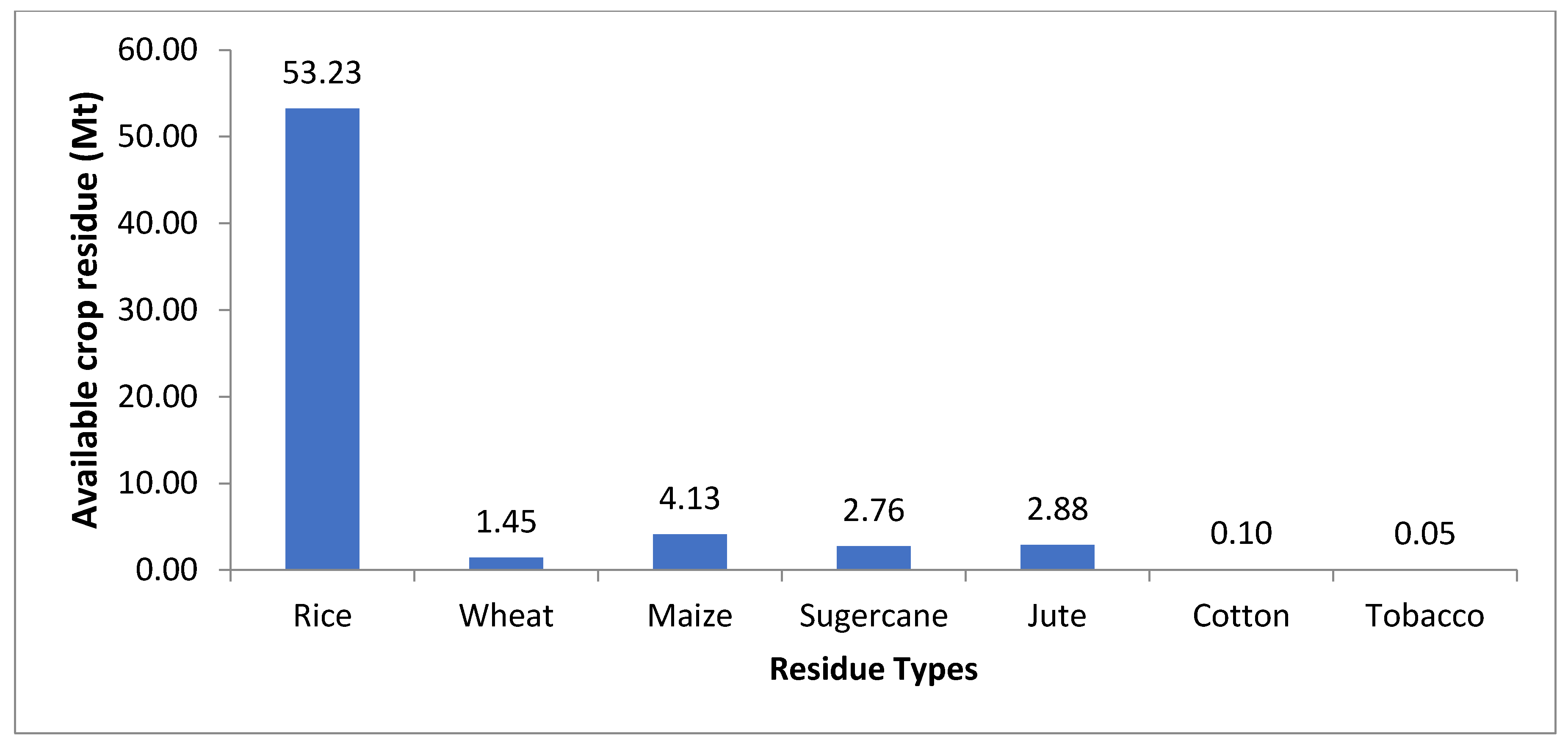

5.1. Accessible Crop Residues

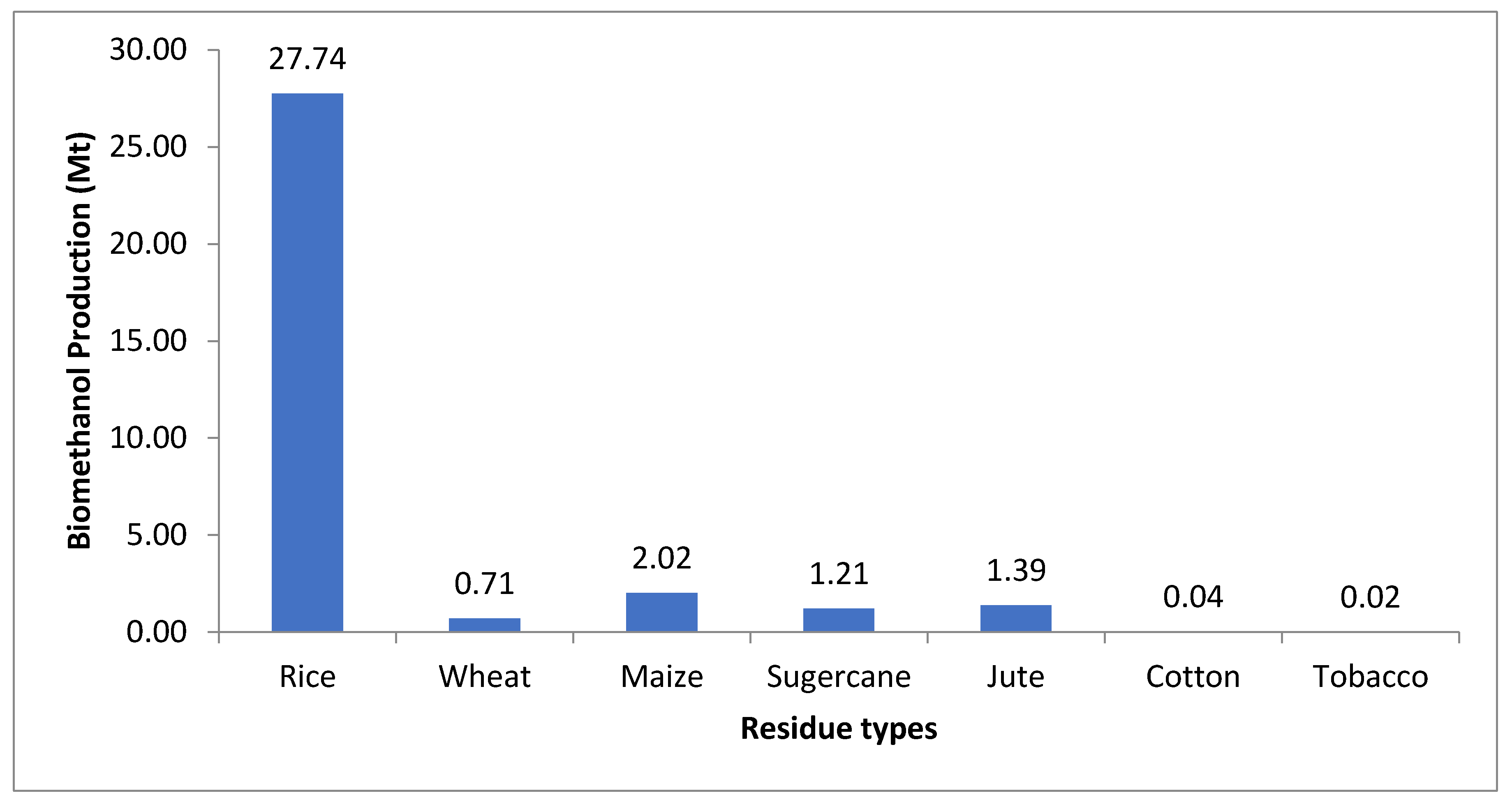

5.2. Bioethanol Production

6. Significance of Biofuel Energy

6.1. Impact on Various Sectors in Bangladesh

6.2. Future Studies

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| CI | Compression Ignition |

| FRI | Field Residue Index |

| PRI | Processing Residue Index |

| SI | Spark Ignition |

| E5 | 5% Ethanol mixed with 95% gasoline |

| HHV | Higher heating value |

| Mt | Mega tonnes |

| MSW | Municipal solid waste |

| ARP | Ammonia recycling percolation |

| AFE | Ammonia fiber explosion |

| EH | Enzymatic hydrolysis |

| SSF | Simultaneous saccharification and fermentation |

| SSCF | Simultaneous saccharification and co-fermentation |

| CBP | Consolidated bioprocessing |

| SHCF | Separate hydrolysis and co-fermentation |

| FB | Fermentation of biomass |

| BY | Bioethanol yield |

References

- Jamil, F.; Aslam, M.; Al-Muhtaseb, A.H.; Bokhari, A.; Rafiq, S.; Khan, Z.; Inayat, A.; Ahmed, A.; Hossain, S.; Khurrum, M.S.; et al. Greener and sustainable production of bioethylene from bioethanol: Current status, opportunities and perspectives. Rev. Chem. Eng. 2020, 1, 36. [Google Scholar]

- Ahmed, A.; Abu Bakar, M.S.; Azad, A.K.; Sukri, R.S.; Mahlia, T.M.I. Potential thermochemical conversion of bioenergy from Acacia species in Brunei Darussalam: A review. Renew. Sustain. Energy Rev. 2017, 82, 3060–3076. [Google Scholar] [CrossRef]

- Chowdhury, T.; Chowdhury, H.; Ahmed, A.; Park, Y.K.; Chowdhury, P.; Hossain, N.; Sait, S.M. Energy, exergy, and sustainability analyses of the agricultural sector in Bangladesh. Sustainability 2020, 12, 4447. [Google Scholar] [CrossRef]

- Moogi, S.; Nakka, L.; Potharaju, S.S.P.; Ahmed, A.; Farooq, A.; Jung, S.C.; Rhee, G.H.; Park, Y.K. Copper promoted Co/MgO: A stable and efficient catalyst for glycerol steam reforming. Int. J. Hydrog. Energy 2020. [Google Scholar] [CrossRef]

- Abu Bakar, M.S.; Ahmed, A.; Jeffery, D.M.; Hidayat, S.; Sukri, R.S.; Mahlia, T.M.I.; Jamil, F.; Khurrum, M.S.; Inayat, A.; Moogi, S.; et al. Pyrolysis of solid waste residues from Lemon Myrtle essential oils extraction for bio-oil production. Bioresour. Technol. 2020, 1–5. [Google Scholar] [CrossRef]

- Liu, S.; Abrahamson, L.P.; Scott, G.M. Biorefinery: Ensuring biomass as a sustainable renewable source of chemicals, materials, and energy. Biomass Bioenergy 2012, 39, 1–4. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Imtenan, S.; Shahir, S.A.; Mobarak, H.M. Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: A review. Energy Convers. Manag. 2014, 80, 202–228. [Google Scholar] [CrossRef]

- Moogi, S.; Jae, J.; Kannapu, H.P.R.; Ahmed, A.; Park, E.D.; Park, Y. Enhancement of aromatics from catalytic pyrolysis of yellow poplar: Role of hydrogen and methane decomposition. Bioresour. Technol. 2020, 123835. [Google Scholar] [CrossRef]

- Behera, S.S.; Ray, R.C. Forest Bioresources for Bioethanol and Biodiesel production with Emphasis on Mohua (Madhuca latifolia L.) Flowers and Seeds. In Bioethanol Production from Food Crops; Elsevier: Amsterdam, The Netherlands, 2019; pp. 233–247. ISBN 9780128137666. [Google Scholar]

- Swain, M.R.; Mohanty, S.K. Bioethanol Production from Corn and Wheat: Food, Fuel, and Future. In Bioethanol Production from Food Crops; Elsevier: Amsterdam, The Netherlands, 2019; pp. 45–59. ISBN 9780128137666. [Google Scholar]

- Solange, M.; José, T. Lignocellulose as Raw Material in Fermentation Processes. In Current Research, Technology and Education Topics in Applied Microbiology and Microbial Biotechnology; Méndez-Vilas, A., Ed.; Formatex Research Center: Badajoz, Spain, 2010; pp. 897–907. [Google Scholar]

- Biomass Energy Foundation. Proximate/Ultimate Analysis. Available online: http://drtlud.com/BEF/proximat.htm (accessed on 3 April 2020).

- Grover, S.; Kathuria, R.S.; Kaur, M. Energy values and technologies for non woody biomass: As a clean source of energy. IOSR J. Electr. Electron. Eng. 2012, 1, 10–14. [Google Scholar] [CrossRef]

- Khuong, L.S.; Zulkifli, N.W.M.; Masjuki, H.H.; Mohamad, E.N.; Arslan, A.; Mosarof, M.H.; Azham, A. A review on the effect of bioethanol dilution on the properties and performance of automotive lubricants in gasoline engines. RSC Adv. 2016, 6, 66847–66869. [Google Scholar] [CrossRef]

- Mosaddek Hossen, M.; Sazedur Rahman, A.H.M.; Kabir, A.S.; Faruque Hasan, M.M.; Ahmed, S. Systematic assessment of the availability and utilization potential of biomass in Bangladesh. Renew. Sustain. Energy Rev. 2017, 67, 94–105. [Google Scholar] [CrossRef]

- Uddin, M.N.; Taweekun, J.; Techato, K.; Rahman, M.A.; Mofijur, M.; Rasul, M.G. Sustainable Biomass as an Alternative Energy Source: Bangladesh Perspective. Energy Procedia 2019, 160, 648–654. [Google Scholar] [CrossRef]

- Salam, M.A.; Ahmed, K.; Akter, N.; Hossain, T.; Abdullah, B. A review of hydrogen production via biomass gasification and its prospect in Bangladesh. Int. J. Hydrog. Energy 2018, 43, 14944–14973. [Google Scholar] [CrossRef]

- Household Different Biomass Resources Consumption throughout Bangladesh. 2018. Available online: https://www.statista.com/statistics/281606/ethanol-production-in-selected-countries (accessed on 17 March 2020).

- Hossain, S.F.; Bint-E-Naser, M.S.; Khan, A. Case Study: A Review on Prospects and Constraints of Bioethanol Production in Bangladesh. In Biofuels: Advances & Perspectives; Kaushik, G., Chaturvedi, S., Chel, A., Eds.; Studium Press LLC: New Delhi, India, 2017; pp. 69–86. ISBN 978-93-85046-22-3. [Google Scholar]

- Parisutham, V.; Kim, T.H.; Lee, S.K. Feasibilities of consolidated bioprocessing microbes: From pretreatment to biofuel production. Bioresour. Technol. 2014, 161, 431–440. [Google Scholar] [CrossRef] [PubMed]

- Gil, N.; Ferreira, S.; Amaral, M.E.; Domingues, F.C.; Duarte, A.P. The influence of dilute acid pretreatment conditions on the enzymatic saccharification of Erica spp. for bioethanol production. Ind. Crops Prod. 2010, 32, 29–35. [Google Scholar] [CrossRef]

- Axelsson, L.; Franzén, M.; Ostwald, M.; Berndes, G.; Lakshmi, G.; Ravindranath, N.H. Perspective: Jatropha cultivation in southern India: Assessing farmers’ experiences. Biofuels Bioprod. Biorefin. 2012, 6, 246–256. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Niño, L.; Martínez-Patiño, C.; Álvarez, C.; Castro, E.; Negro, M.J. Biorefinery based on olive biomass. State of the art and future trends. Bioresour. Technol. 2014, 159, 421–432. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.F.; Ramli, N.; Kamal Bahrin, E.; Abd-Aziz, S. Cellulosic biobutanol by Clostridia: Challenges and improvements. Renew. Sustain. Energy Rev. 2017, 79, 1241–1254. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Boyce, A.N.; Faruq, G. Fuel ethanol production from lignocellulosic biomass: An overview on feedstocks and technological approaches. Renew. Sustain. Energy Rev. 2016, 66, 751–774. [Google Scholar] [CrossRef]

- Cardona, C.A.; Quintero, J.A.; Paz, I.C. Production of bioethanol from sugarcane bagasse: Status and perspectives. Bioresour. Technol. 2010, 101, 4754–4766. [Google Scholar] [CrossRef]

- Isroi; Millati, R.; Syamsiah, S.; Niklasson, C.; Cahyanto, M.N.; Lundquist, K.; Taherzadeh, M.J. Biological pretreatment of lignocelluloses with white-rot fungi and its applications: A review. BioResources 2011, 6, 5224–5259. [Google Scholar] [CrossRef]

- Najafi, G.; Ghobadian, B.; Tavakoli, T.; Yusaf, T. Potential of bioethanol production from agricultural wastes in Iran. Renew. Sustain. Energy Rev. 2009, 13, 1418–1427. [Google Scholar] [CrossRef]

- Carrillo-Nieves, D.; Rostro Alanís, M.J.; de la Cruz Quiroz, R.; Ruiz, H.A.; Iqbal, H.M.N.; Parra-Saldívar, R. Current status and future trends of bioethanol production from agro-industrial wastes in Mexico. Renew. Sustain. Energy Rev. 2019, 102, 63–74. [Google Scholar] [CrossRef]

- Paulova, L.; Patakova, P.; Branska, B.; Rychtera, M.; Melzoch, K. Lignocellulosic ethanol: Technology design and its impact on process efficiency. Biotechnol. Adv. 2015, 33, 1091–1107. [Google Scholar] [CrossRef]

- Kaida, R.; Kaku, T.; Baba, K.; Oyadomari, M.; Watanabe, T.; Hartati, S.; Sudarmonowati, E.; Hayashi, T. Enzymatic saccharification and ethanol production of Acacia mangium and Paraserianthes falcataria wood, and Elaeis guineensis trunk. J. Wood Sci. 2009, 55, 381–386. [Google Scholar] [CrossRef]

- Bilal, M.; Nawaz, M.Z.; Iqbal, H.M.N.; Hou, J.; Mahboob, S.; Al-Ghanim, K.A.; Hairong, C. Engineering ligninolytic consortium for bioconversion of lignocelluloses to ethanol and chemicals. Protein Pept. Lett. 2018, 25. [Google Scholar] [CrossRef] [PubMed]

- Barkalow, D.G.; Whistler, R.L. Cellulose, AccessScience. 2008. Available online: http://www.accessscience.com (accessed on 30 March 2020).

- Mesa, L.; González, E.; Romero, I.; Ruiz, E.; Cara, C.; Castro, E. Comparison of process configurations for ethanol production from two-step pretreated sugarcane bagasse. Chem. Eng. J. 2011, 175, 185–191. [Google Scholar] [CrossRef]

- Olofsson, K.; Bertilsson, M.; Lidén, G. A short review on SSF - An interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol. Biofuels 2008, 1, 1–14. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Rizzo, A.M.; Prussi, M.; Tedeschi, S.; Zimbardi, F.; Braccio, G.; Viola, E.; Pardelli, P.T. 2nd generation lignocellulosic bioethanol: Is torrefaction a possible approach to biomass pretreatment? Biomass Convers. Biorefin. 2011, 1, 9–15. [Google Scholar] [CrossRef]

- Rastogi, M.; Shrivastava, S. Recent advances in second generation bioethanol production: An insight to pretreatment, saccharification and fermentation processes. Renew. Sustain. Energy Rev. 2017, 80, 330–340. [Google Scholar] [CrossRef]

- Kim, T.H.; Taylor, F.; Hicks, K.B. Bioethanol production from barley hull using SAA (soaking in aqueous ammonia) pretreatment. Bioresour. Technol. 2008, 99, 5694–5702. [Google Scholar] [CrossRef] [PubMed]

- Morales-Rodriguez, R.; Gernaey, K.V.; Meyer, A.S.; Sin, G. A Mathematical model for simultaneous saccharification and co-fermentation (SSCF) of C6 and C5 sugars. Chin. J. Chem. Eng. 2011, 19, 185–191. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Acid-based hydrolysis processes for ethanol from lignocellulosic materials: A review. Bioresources 2007, 125, 127–134. [Google Scholar] [CrossRef]

- Amore, A.; Faraco, V. Potential of fungi as category i Consolidated BioProcessing organisms for cellulosic ethanol production. Renew. Sustain. Energy Rev. 2012, 16, 3286–3301. [Google Scholar] [CrossRef]

- Amoah, J.; Ishizue, N.; Ishizaki, M.; Yasuda, M.; Takahashi, K.; Ninomiya, K.; Yamada, R.; Kondo, A.; Ogino, C. Development and evaluation of consolidated bioprocessing yeast for ethanol production from ionic liquid-pretreated bagasse. Bioresour. Technol. 2017, 245, 1413–1420. [Google Scholar] [CrossRef]

- Brethauer, S.; Studer, M.H. Consolidated bioprocessing of lignocellulose by a microbial consortium. Energy Environ. Sci. 2014, 7, 1446–1453. [Google Scholar] [CrossRef]

- Okamoto, K.; Uchii, A.; Kanawaku, R.; Yanase, H. Bioconversion of xylose, hexoses and biomass to ethanol by a new isolate of the white rot basidiomycete Trametes versicolor. Springerplus 2014, 3, 1–9. [Google Scholar] [CrossRef]

- Mattila, H.; Kuuskeri, J.; Lundell, T. Single-step, single-organism bioethanol production and bioconversion of lignocellulose waste materials by phlebioid fungal species. Bioresour. Technol. 2017, 225, 254–261. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of United Nations. Available online: http://faostat.fao.org/site/339/default (accessed on 5 March 2020).

- Chovau, S.; Degrauwe, D.; Van Der Bruggen, B. Critical analysis of techno-economic estimates for the production cost of lignocellulosic bio-ethanol. Renew. Sustain. Energy Rev. 2013, 26, 307–321. [Google Scholar] [CrossRef]

- Kaneko, S.; Mizuno, R.; Maehara, T.; Ichinose, H. Consolidated Bioprocessing Ethanol Production by Using a Mushroom. In Bioethanol; Intech: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Uçkun Kiran, E.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Bioconversion of food waste to energy: A review. Fuel 2014, 134, 389–399. [Google Scholar] [CrossRef]

- Lee, D.Y.; Ebie, Y.; Xu, K.Q.; Li, Y.Y.; Inamori, Y. Continuous H2 and CH4 production from high-solid food waste in the two-stage thermophilic fermentation process with the recirculation of digester sludge. Bioresour. Technol. 2010, 101, S42–S47. [Google Scholar] [CrossRef] [PubMed]

- Renewables 2015 Global Status Report. Available online: http://www.ren21.net/wp-content/uploads/2015/07/REN12-GSR2015_Onlinebook_low1.pdf (accessed on 5 May 2020).

- Rofiqul Islam, M.; Rabiul Islam, M.; Rafiqul Alam Beg, M. Renewable energy resources and technologies practice in Bangladesh. Renew. Sustain. Energy Rev. 2008, 12, 299–343. [Google Scholar] [CrossRef]

- Baky, M.A.H.; Hassan Khan, M.N.; Kader, M.F.; Chowdhury, H.A. Production of Biogas by Anaerobic Digestion of Food Waste and Process Simulation. In Proceedings of the ASME 2014 8th International Conference on Energy Sustainability collocated with the ASME 2014 12th International Conference on Fuel Cell Science, Engineering and Technology, Boston, MA, USA, 30 June 2014. [Google Scholar]

- Islam, A.; Chan, E.S.; Taufiq-Yap, Y.H.; Mondal, M.A.H.; Moniruzzaman, M.; Mridha, M. Energy security in Bangladesh perspective—An assessment and implication. Renew. Sustain. Energy Rev. 2014, 32, 154–171. [Google Scholar] [CrossRef]

- Halder, P.K.; Paul, N.; Beg, M.R.A. Prospect of Pongamia pinnata (Karanja) in Bangladesh: A Sustainable Source of Liquid Fuel. J. Renew. Energy 2014, 2014, 1–12. [Google Scholar] [CrossRef]

- Nabi, M.N.; Hoque, S.M.N.; Akhter, M.S. Karanja (Pongamia Pinnata) biodiesel production in Bangladesh, characterization of karanja biodiesel and its effect on diesel emissions. Fuel Process. Technol. 2009, 90, 1080–1086. [Google Scholar] [CrossRef]

- Ahiduzzaman, M.; Islam, A.K.M.S. Greenhouse gas emission and renewable energy sources for sustainable development in Bangladesh. Renew. Sustain. Energy Rev. 2011, 15, 4659–4666. [Google Scholar] [CrossRef]

- Ahiduzzaman, M. Sustainability of biomass energy development technology (densification) in Bangladesh. Int. J. Bio. Res. 2006, 1, 40–46. [Google Scholar]

- Huda, A.S.N.; Mekhilef, S.; Ahsan, A. Biomass energy in Bangladesh: Current status and prospects. Renew. Sustain. Energy Rev. 2014, 30, 504–517. [Google Scholar] [CrossRef]

- Halder, P.K.; Paul, N.; Beg, M.R.A. Assessment of biomass energy resources and related technologies practice in Bangladesh. Renew. Sustain. Energy Rev. 2014, 39, 444–460. [Google Scholar] [CrossRef]

- Mamun, M.R.A.; Kabir, M.S.; Alam, M.M.; Islam, M.M. Utilization pattern of biomass for rural energy supply in Bangladesh. Int. J. Sustain. Crop Prod. 2009, 4, 62–71. [Google Scholar]

- Wang, Y.J.; Bi, Y.Y.; Gao, C.Y. The Assessment and Utilization of Straw Resources in China. Agric. Sci. China 2010, 9, 1807–1815. [Google Scholar] [CrossRef]

- Fang, Y.R.; Wu, Y.; Xie, G.H. Crop residue utilizations and potential for bioethanol production in China. Renew. Sustain. Energy Rev. 2019, 113. [Google Scholar] [CrossRef]

- Ren, J.; Yu, P.; Xu, X. Straw utilization in China-status and recommendations. Sustainability 2019, 11, 1762. [Google Scholar] [CrossRef]

- Zhichen, L.; Xuantong, Z. Energy utilization potential of wheat straw in an ecological balance-a case study of henan province in China. Resources 2019, 8, 41. [Google Scholar] [CrossRef]

- He, K.; Zhang, J.; Zeng, Y.; Zhang, L. Households’ willingness to accept compensation for agricultural waste recycling: Taking biogas production from livestock manure waste in Hubei, P.R. China as an example. J. Clean. Prod. 2016, 131, 410–420. [Google Scholar] [CrossRef]

- Garivait, S.; Chaiyo, U.; Patumsawad, S.; Deakhuntod, J. Physical and chemical properties of thai biomass fuels from agricultural residues. In Proceedings of the 2nd Joint International Conference on Sustainable Energy and Environment, Bangkok, Thailand, 21–23 November 2006; pp. 1–23. [Google Scholar]

- Szymanska-Chargot, M.; Chylinska, M.; Gdula, K.; Koziol, A.; Zdunek, A. Isolation and characterization of cellulose from different fruit and vegetable pomaces. Polymers 2017, 9, 495. [Google Scholar] [CrossRef]

- Jiang, D.; Zhuang, D.; Fu, J.; Huang, Y.; Wen, K. Bioenergy potential from crop residues in China: Availability and distribution. Renew. Sustain. Energy Rev. 2012, 16, 1377–1382. [Google Scholar] [CrossRef]

- Seglah, P.A.; Wang, Y.; Wang, H.; Bi, Y. Estimation and efficient utilization of straw resources in Ghana. Sustainability 2019, 11, 4172. [Google Scholar] [CrossRef]

- Teixeira Franco, R.; Buffière, P.; Bayard, R. Ensiling for biogas production: Critical parameters. A review. Biomass Bioenergy 2016, 94, 94–104. [Google Scholar] [CrossRef]

- Algieri, A.; Andiloro, S.; Tamburino, V.; Zema, D.A. The potential of agricultural residues for energy production in Calabria (Southern Italy). Renew. Sustain. Energy Rev. 2019, 104, 1–14. [Google Scholar] [CrossRef]

- Mehralian, M.; Chegini, Z.G.; Khashij, M. Activated carbon prepared from pistachio waste for dye adsorption: Experimental and CCD-based design. Pigment Resin Technol. 2019, 49, 136–144. [Google Scholar] [CrossRef]

- Taghizadeh-Alisaraei, A.; Assar, H.A.; Ghobadian, B.; Motevali, A. Potential of biofuel production from pistachio waste in Iran. Renew. Sustain. Energy Rev. 2017, 72, 510–522. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenergy 2004, 26, 361–375. [Google Scholar] [CrossRef]

- Bangladesh Bureau of Statisctics (BBS). Yearbook of Agricultural Statistics of Bangladesh; BBS: Dhaka, Bangladesh, 2020.

- Carbon Emissions from Burning Biomass Energy. Available online: http://www.pfpi.net/wp-content/uploads/2011/04/PFPI-biomass-carbon-accounting-overview_April.pdf (accessed on 4 October 2020).

- Chowdhury, H.; Chowdhury, T.; Chowdhury, P.; Islam, M.; Saidur, R.; Sait, S.M. Integrating sustainability analysis with sectoral exergy analysis: A case study of rural residential sector of Bangladesh. Energy Build. 2019, 202, 109397. [Google Scholar] [CrossRef]

- Banu, L.B. Technologies for efficient use of wood fuel: Improved chulli, compressed husk, briquetting and other technologies. In National Training Course on Wood Fuel in Bangladesh—Production and Marketing; FAO: Bogra, Bangladesh, 1996. [Google Scholar]

- Ahmed, A.; Abu Bakar, M.S.; Hamdani, R.; Park, Y.K.; Lam, S.S.; Sukri, R.S.; Hussain, M.; Majeed, K.; Phusunti, N.; Jamil, F.; et al. Valorization of underutilized waste biomass from invasive species to produce biochar for energy and other value-added applications. Environ. Res. 2020, 186, 109596. [Google Scholar] [CrossRef]

- Reza, S.; Ahmed, A.; Caesarendra, W.; Bakar, M.S.A.; Shams, S.; Saidur, R.; Aslfattahi, N.; Azad, A.K. Acacia Holosericea: An Invasive Species for Bio-char, Bio-oil, and Biogas Production. Bioengineering 2019, 6, 33. [Google Scholar] [CrossRef]

- Radenahmad, N.; Morni, N.A.; Ahmed, A.; Abu Bakar, M.; Zaini, J.; Azad, A. Characterization of rice husk as a potential renewable energy source. In Proceedings of the 7th Brunei InternationalL Conference on Engineering and Technology (BICET 2018), Bandar Seri Begawan, Brunei, 12–14 November 2018; pp. 1–4. [Google Scholar]

- Abdullah, A.; Ahmed, A.; Akhter, P.; Razzaq, A.; Zafar, M.; Hussain, M.; Shahzad, N.; Majeed, K.; Khurrum, S.; Saifullah, M.; et al. Bioenergy potential and thermochemical characterization of lignocellulosic biomass residues available in Pakistan. Korean Inst. Chem. Eng. 2020, 37, 1–8. [Google Scholar] [CrossRef]

- Chowdhury, T.; Chowdhury, H.; Hossain, N.; Ahmed, A.; Hossen, M.S.; Chowdhury, P.; Thirugnanasambandam, M.; Saidur, R. Latest Advancements on Livestock Waste Management and Biogas Production: Bangladesh’s perspective. J. Clean. Prod. 2020, 272. [Google Scholar] [CrossRef]

- Ahmed, A.U. Bangladesh Climate Change Impacts and Vulnerability: A Synthesis; Climate Change Cell, Department of Environment, CDMP, Government of the People’s Republic of Bangladesh: Dhaka, Bangladesh, 2006. [Google Scholar]

- Sarker, M.A.R.; Alam, K.; Gow, J. Exploring the Relationship between Climate Change and Rice Yield in Bangladesh: An Analysis of Time Series Data. Agric. Syst. 2012, 112, 11–16. [Google Scholar] [CrossRef]

| Fuel Property | E5 | Bioethanol |

|---|---|---|

| Density at 15 °C | 834.3 kg/m3 | 790.0 kg/m3 |

| Kinematic viscosity at 40 °C | 2.53 mm2/s | 1.130 mm2/s |

| Cetane number | - | 5.8 |

| Octane number | - | 110 |

| Flashpoint | 24 °C | 13 °C |

| Calorific value | 43.6318 MJ/kg | 25.22, 26.70 MJ/kg |

| Water content | 100 mg kg−1 | 2024 mg kg−1 |

| Biomass Resources | Wholly Use | Boiler | ||

|---|---|---|---|---|

| Cuisine | Streaming Rice | Others | ||

| Sawdust (kg) | 8 | 8 | 0.02 | 0.02 |

| Firewood (kg) | 1106 | 1065 | 29 | 93 |

| Tree leaves (kg) | 502 | 471 | 30 | 0.9 |

| Crop residue (kg) | 708 | 539 | 164 | 2.7 |

| Dung stick (kg) | 524 | 504 | 16 | 4.2 |

| Pretreatment | Advantages | Disadvantages | |

|---|---|---|---|

| Chemical | Acids | High amount of glucose supply | Financial cost associated with acids and recovery |

| Combination of bases as well as oxidizing agents | Ambient temperatures | Generation of degradation products | |

| Solvents which are organic in nature | Responsible for not only lignin but also hemicellulose hydrolysis | Expensive | |

| Ozonolysis | High delignification efficiency | Draining as well as recycling of solvents | |

| Low generation of degradation products | Large amounts of ozone needed. | ||

| High glucose yield | |||

| Ionic liquids | Low formation of toxic inhibitors | Costly solvents | |

| Low generation of degradation products | Draining as well as recycling of solvents are necessary | ||

| Physical | Irradiation or microwave | Faster heat transfer | Poor radiation penetration in products |

| Shorter reaction times | |||

| Milling | Cellulose crystallinity is decreased | Greater intake of energy | |

| Mechanical comminution | Cellulose crystallinity is decreased | Greater consumption of energy | |

| Causes reduction in the degree of polymerization | |||

| Extrusion | Low formation of toxic inhibitors | Temperature regulation difficulties associated with temperature control, cooling capacity is not flexible | |

| Generation of degradation products is lower | Limited residence time | ||

| Biological | Low energy consumption | Low rate of hydrolysis | |

| Capital cost is less | |||

| Chemicals are not required at all | |||

| Mild environmental conditions | |||

| Physicochemical | Liquid hot water | Not catalyst requirement | Not developed at commercial scale |

| Low-cost reactor construction | |||

| Steam explosion | Causes lignin transformation and hemicelluloses solubilization | Generation of toxic compounds | |

| Cost-effective | |||

| CO2 explosion | Increases accessible surface area | Very high-pressure requirements | |

| Cost-effective | |||

| Ammonia fiber explosion | Enhance the surface areas which can be accessed | A high amount of NH3 is needed, so cost increases | |

| Inhibitors formation is lower | |||

| Soaking aqueous ammonia | Performed at a lower temperature | Higher cost | |

| Low formation of inhibitors |

| Process Alternatives | Advantages | Disadvantage |

|---|---|---|

| SHF |

|

|

| CBP |

|

|

| SHCF |

|

|

| PSSF |

|

|

| SSF |

|

|

| SSCF |

|

|

| Microorganism | Lignocellulosic Biomass | Ethanol Concentration or Yield | Comments |

|---|---|---|---|

| Neurospora-crassa (mesophilic fungus) | Sorghum bagasse | 81.5% | Solid-state cultivation is utilized for enzyme generation |

| Phlebia radiata 0043 | Core board | 5.9 g/L (10.4% ethanol yield) | bioethanol and organic acids, oxalate and fumarate, are produced |

| Fusarium oxysporum | Cellulose 123 | 0.044 g/L/h and a yield of 0.35 g/g cellulose | Grows on cellulose when aerobic conditions are ensured |

| Paecilomyces variotii | Wheat bran | 1.2 g/L of ethanol. | Unusually powerful pentose metabolic pathway. |

| Peniophora cinerea | Glucose, mannose, fructose, galactose, sucrose, maltose and also cellobiose | 0.41, 0.45, 0.44, 0.19, 0.41, 0.44 and 0.45 g per g hexose respectively | In PASC (amorphous cellulose), P. cinerea was cultured and after 18 days it reached a maximum ethanol yield of 3 g/L |

| Trametes suaveolens | Glucose, mannose, fructose, galactose, sucrose, maltose and cellobiose | 0.39, 0.3, 0.13, 0.2, 0.37, 0.35 and 0.31 g ethanol/g hexose | Under both aerobic and semiaerobic conditions, 20 g/L of carbon source should be used |

| Trametes versicolor | Wheat bran and rice straw | 5.0 and 4.8 g/L, accordingly. 92% and 91% of the theoretical yield. | Favorable conversion to ethanol is shown by Strain KT9427 |

| Mucor indicus | Lignocellulosic hydrolysates | 0.42–0.48 g/g substrate | It is evident from the filamentous morphology of M. indicts that highest yield of ethanol can be achieved |

| Trichoderma reesei A10 | Microcrystalline cellulose | 0.4 g/L of ethanol | Extracted from cow dung. Under anaerobic conditions shows no growth. |

| Source of Biomass | Biomass Generation (Million Tons) | Energy in PJ | Electricity Generation (TWh) |

|---|---|---|---|

| Agricultural residues | 94.10 | 582.68 | 161.80 |

| Forest residues | 17.44 | 210.74 | 58.53 |

| Livestock residues | 88.89 | 456.65 | 126.81 |

| Municipal solid waste | 13.38 | 95.55 | 26.57 |

| Total | 213.81 | 1345.62 | 373.71 |

| Crops | Crop Production in Year (ton) (2012–2013) | Crops Residue | Total Residue | |

|---|---|---|---|---|

| Field Residue (FR) | Process Residue (PR) | |||

| Rice | 344.30 × 105 | 1.757 | 0.20 | FR + PR |

| Wheat | 10.36 × 105 | 1.70 | 0.30 | FR + PR |

| Maize | 20.42 × 105 | 2.00 | 0.30 | FR + PR |

| Sugarcane | 73.00 × 105 | 0.30 | 0.33 | FR + PR |

| Jute | 16.57 × 105 | 2.00 | NA | FR |

| Cotton | 0.28 × 105 | 3.52 | 0.47 | FR + PR |

| Tobacco | 0.79 × 105 | 0.69 | NA | FR |

| Primary Source | Residue | Utilization |

|---|---|---|

| Rice | Rice straw | (i) Animal feed, (ii) animal bedding, (iii) housing materials, and (iv) fuel |

| Rice | Rice husk | (i) Poultry bedding, (ii) cattle feed, and (iii) fuel |

| Wheat | Wheat straw | (i) Fuel and (ii) housing material |

| Jute | Jute stalk | (i) Fuel and (ii) housing material |

| Groundnut | Groundnut straw | (i) Fuel and (ii) animal feed |

| Vegetable | Vegetable plants | (i) Fuel and (ii) animal feed |

| Pulse | Pulse straw | (i) Fuel and (ii) animal feed |

| Sugarcane | Sugarcane leafs | (i) Fuel and (ii) animal feed |

| Sugarcane bagasse | (i) Fuel | |

| Maize | Maize leafs | (i) Fuel and (ii) animal feed maize husk |

| Maize straw | (i) Fuel | |

| Forest | Leaves, twigs, and branches | (i) Fuel and (ii) fencing |

| Wood | (i) Furniture and (ii) fuel | |

| Wood residue | (i) fuel |

| Residue | Collectable Coefficient | Conversion Rate (g kg−1) |

|---|---|---|

| Rice | 0.79 | 521.09 |

| Wheat | 0.70 | 487.75 |

| Maize | 0.88 | 487.89 |

| Bean | 0.54 | 363.51 |

| Tubers | 0.76 | 561.20 |

| Cotton | 0.88 | 442.65 |

| Peanut | 0.83 | 342.54 |

| Tobacco | 0.93 | 401.59 |

| Sugarcane | 0.70 | 439.62 |

| Canola (Rapeseed) | 0.65 | 460.20 |

| Rape and Mustard | 0.84 | 492.19 |

| Other oil crops | 0.85 | 492.19 |

| Jute | 0.87 | 481.14 |

| Other fibers | 0.86 | 481.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miskat, M.I.; Ahmed, A.; Chowdhury, H.; Chowdhury, T.; Chowdhury, P.; Sait, S.M.; Park, Y.-K. Assessing the Theoretical Prospects of Bioethanol Production as a Biofuel from Agricultural Residues in Bangladesh: A Review. Sustainability 2020, 12, 8583. https://doi.org/10.3390/su12208583

Miskat MI, Ahmed A, Chowdhury H, Chowdhury T, Chowdhury P, Sait SM, Park Y-K. Assessing the Theoretical Prospects of Bioethanol Production as a Biofuel from Agricultural Residues in Bangladesh: A Review. Sustainability. 2020; 12(20):8583. https://doi.org/10.3390/su12208583

Chicago/Turabian StyleMiskat, Monirul Islam, Ashfaq Ahmed, Hemal Chowdhury, Tamal Chowdhury, Piyal Chowdhury, Sadiq M. Sait, and Young-Kwon Park. 2020. "Assessing the Theoretical Prospects of Bioethanol Production as a Biofuel from Agricultural Residues in Bangladesh: A Review" Sustainability 12, no. 20: 8583. https://doi.org/10.3390/su12208583

APA StyleMiskat, M. I., Ahmed, A., Chowdhury, H., Chowdhury, T., Chowdhury, P., Sait, S. M., & Park, Y.-K. (2020). Assessing the Theoretical Prospects of Bioethanol Production as a Biofuel from Agricultural Residues in Bangladesh: A Review. Sustainability, 12(20), 8583. https://doi.org/10.3390/su12208583