Sustainable Solutions for Wearable Technologies: Mapping the Product Development Life Cycle

Abstract

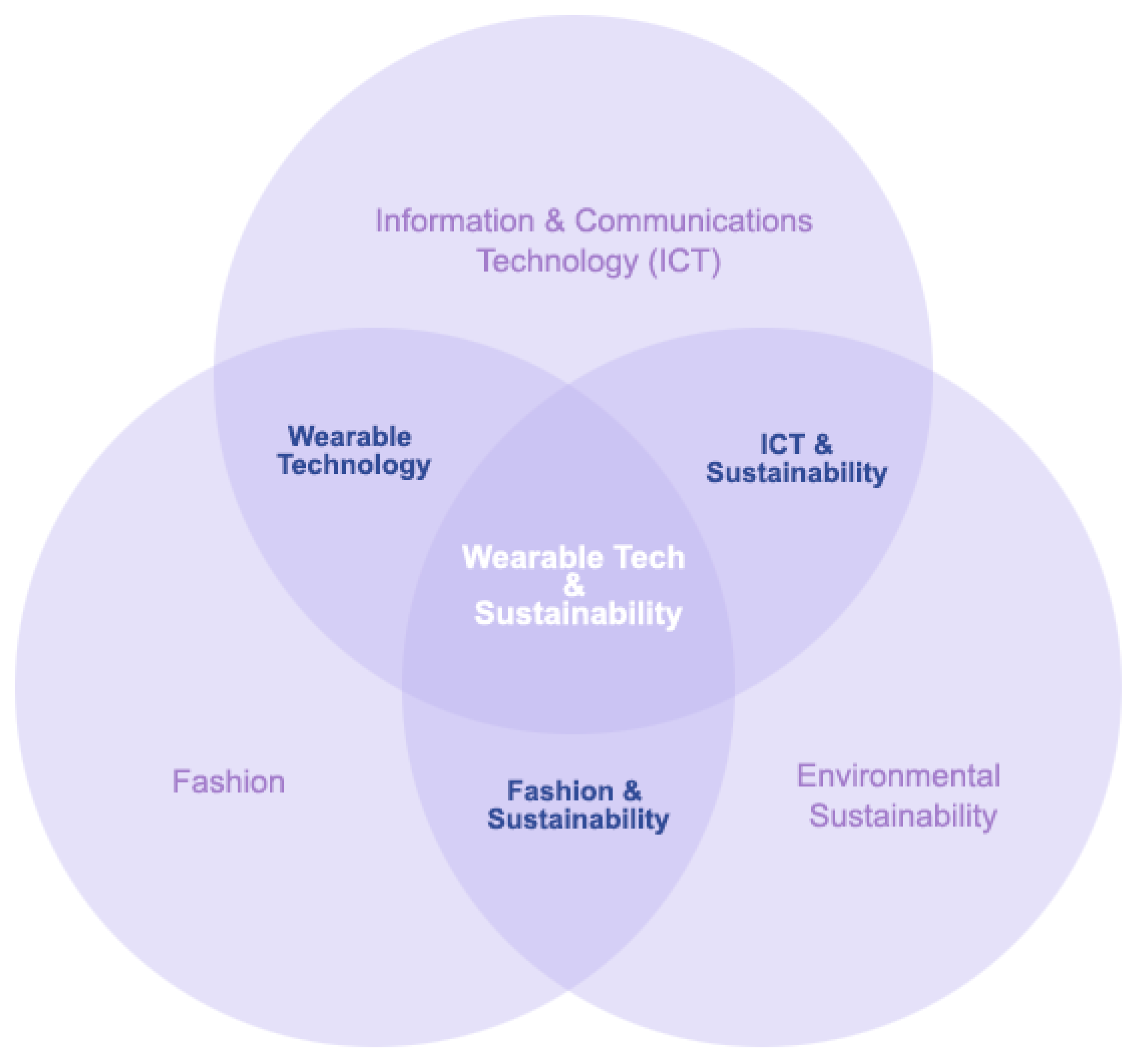

1. Introduction

Environmental Sustainability and the Role of Designers

2. Materials and Methods

3. Results

3.1. Fashion Design and Sustainability

3.1.1. Extracting Materials

3.1.2. Manufacturing

3.1.3. Distribution

3.1.4. Use and Consumption

3.1.5. Disposal: Recycling, Mending and Repair Activism

3.2. ICT and Sustainability

3.2.1. Material Extraction

3.2.2. Manufacturing

3.2.3. Distribution

3.2.4. Use and Energy Consumption

3.2.5. Disposal

3.3. Wearable Technologies and Sustainability

3.3.1. Selection of Materials

3.3.2. Manufacturing

3.3.3. Distribution

3.3.4. Use and Consumption

3.3.5. Disposal

4. Discussion: Implications for Design and Development of Wearable Technologies and Sustainability

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Köhler, A.R. Anticipatory Eco-design Strategies for Smart Textiles: Perspectives on Environmental Risk Prevention in the Development of an Emerging Technology. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, September 2013. [Google Scholar]

- Smelik, A.M.; Toussaint, L.; van Dongen, P. Solar fashion: An embodied approach to wearable technology. Int. J. Fash. Stud. 2016, 3, 287–303. [Google Scholar] [CrossRef]

- Tamminen, S.; Holmgren, E. The Anthropology of Wearables: The Self, The Social, and the Autobiographical. In Proceedings of the Ethnographic Praxis in Industry Conference Proceedings (EPIC), Minneapolis, MN, USA, 29 August–1 September 2016; pp. 154–174. [Google Scholar]

- Lupton, D. Digital Sociology, 1st ed.; Routledge: London, UK, 2014; ISBN 9781315776880. [Google Scholar]

- Statista. Wearables. Available online: https://www.statista.com/outlook/319/100/wearables/worldwide (accessed on 7 July 2020).

- Worldwide Wearables Market Braces for Short-Term Impact before Recovery in 2020, According to IDC. Available online: https://www.businesswire.com/news/home/20200316005755/en/Worldwide-Wearables-Market-Braces-Short-Term-Impact-Recovery (accessed on 21 September 2020).

- Lee, J.; Kim, D.; Ryoo, H.Y.; Shin, B.S. Sustainable wearables: Wearable technology for enhancing the quality of human life. Sustainability 2016, 8, 466. [Google Scholar] [CrossRef]

- Spil, T.A.M.; Kijl, B.; Romijnders, V. The Adoption and Diffusion of Wearables. In ICT Unbounded, Social Impact of Bright ICT Adoption. International Conference on Transfer and Diffusion of IT, TDIT (IFIP WG 8.6), Accra, Ghana, 21–22 June 2019; Dwivedi, Y., Ayaburi, E., Boateng, R., Effah, J., Eds.; Springer: Cham, Switzerland, 2019; pp. 31–47. [Google Scholar]

- Dunne, L.E.; Profita, H.; Zeagler, C.; Clawson, J.; Gilliland, S.; Do, E.Y.; Budd, J. The Social Comfort of Wearable Technology and Gestural Interaction. In Proceedings of the 36th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC’14), Chicago, IL, USA, 26–30 August 2014; pp. 4159–4162. [Google Scholar]

- Juhlin, O.; Zhang, Y.; Wang, J.; Andersson, A. Fashionable Services for Wearables: Inventing and Investigating a New Design Path for Smart Watches. In Proceedings of the 9th Nordic Conference on Human-computer Interaction (NordiCHI’16), Gothenburg, Sweden, 23–27 October 2016; pp. 1–10. [Google Scholar]

- Pan, Y.; Blevis, E. Fashion Thinking. In Proceedings of the 2014 Conference on Designing Interactive Systems (DIS’14), Vancouver, BC, Canada, 21–25 June 2014; pp. 1005–1014. [Google Scholar]

- Seymour, S. Fashionable Technology: The Intersection of Design, Fashion, Science, and Technology, 1st ed.; Springer: Vienna, Austria, 2008; ISBN 978-3-211-74498-7. [Google Scholar]

- von Radziewsky, L.; Krüger, A.; Löchtefeld, M. Scarfy: Augmenting Human Fashion Behaviour with Self-actuated Clothes. In Proceedings of the Ninth International Conference on Tangible, Embedded, and Embodied Interaction (TEI’15), Stanford, CA, USA, 15–19 January 2015; pp. 313–316. [Google Scholar]

- Perovich, L.; Mothersill, P.; Farah, J. Awakened Apparel. In Proceedings of the 8th International Conference on Tangible, Embedded and Embodied Interaction (TEI’14), Munich, Germany, 16–19 February 2014; pp. 77–80. [Google Scholar]

- Bigger, E.; Fraguada, L. Programmable Plaid: The Search for Seamless Integration in Fashion and Technology. In Proceedings of the 2016 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp’16), Heidelberg, Germany, 12–16 September 2016; pp. 464–469. [Google Scholar]

- Roinesalo, P.; Lappalainen, T.; Colley, A.; Häkkilä, J. Breaking of the Dawn Jacket: Light in the Arctic Winter. In Proceedings of the 2017 ACM International Symposium on Wearable Computers (ISWC’17), Maui, HI, USA, 11–15 September 2017; pp. 232–237. [Google Scholar]

- Pakanen, M.; Lappalainen, T.; Roinesalo, P.; Häkkilä, J. Exploring Smart Handbag Concepts through Co-design. In Proceedings of the 15th International Conference on Mobile and Ubiquitous Multimedia (MUM’16), Rovaniemi, Finland, 12–15 December 2016; pp. 37–48. [Google Scholar]

- Colley, A.; Pakanen, M.; Koskinen, S.; Mikkonen, K.; Häkkilä, J. Smart Handbag as a Wearable Public Display–Exploring Concepts and User Perceptions. In Proceedings of the 7th Augmented Human International Conference (AH’16), Geneva, Switzerland, 25–27 February 2016; pp. 1–8. [Google Scholar]

- Rantala, I.; Colley, A.; Häkkilä, J. Smart Jewelry: Augmenting Traditional Wearable Self-expression Displays. In Proceedings of the 7th ACM International Symposium on Pervasive Displays (PerDis’18), Munich, Germany, 6–8 June 2018; pp. 1–8. [Google Scholar]

- Prahl, A. Design for Circularity: Material Innovation for Wearable Technology. In Proceedings of the Circular Transitions: A Mistra Future Fashion Conference on Textile Design and the Circular Economy, London, UK, 23–24 November 2016; Goldsworthy, K., Earley, R., Eds.; pp. 285–302. [Google Scholar]

- Passary, S. Tommy Hilfiger, Diesel, And Hugo Boss Reveal Android Wear 2.0 Smartwatches. Available online: https://www.techtimes.com/articles/203173/20170327/tommy-hilfiger-diesel-and-hugo-boss-reveal-android-wear-2-0-smartwatches.htm (accessed on 14 July 2020).

- van der Velden, N.M.; Kuusk, K.; Köhler, A.R. Life cycle assessment and eco-design of smart textiles: The importance of material selection demonstrated through e-textile product redesign. Mater. Des. 2015, 84, 313–324. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Frequently Asked Questions. Available online: https://www.unenvironment.org/explore-topics/sustainable-development-goals/why-do-sustainable-development-goals-matter/frequently (accessed on 12 July 2019).

- Elkington, J.; Trisoglio, A. Developing realistic scenarios for the environment: Lessons from Brent Spar. Long Range Plan. 1996, 29, 762–769. [Google Scholar] [CrossRef]

- Alhaddi, H. Triple bottom line and sustainability: A literature review. Bus. Manag. Stud. 2015, 1, 6–10. [Google Scholar] [CrossRef]

- Perry, A.; Malinin, L.; Sanders, E.; Li, Y.; Leigh, K. Explore consumer needs and design purposes of smart clothing from designers’ perspectives. Int. J. Fash. Des. Technol. Educ. 2017, 10, 372–380. [Google Scholar] [CrossRef]

- Page, T. Barriers to the adoption of wearable technology. I-Manag. J. Inf. Technol. 2015, 4, 1–13. [Google Scholar] [CrossRef]

- Lazar, A.; Koehler, C.; Tanenbaum, J.; Nguyen, D. Why We Use and Abandon Smart Devices. In Proceedings of the 2015 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp’15), Osaka, Japan, 7–11 September 2015; pp. 635–646. [Google Scholar]

- O’Mahony, M.; Gwilt, A. Where Does Wearable Technology Fit in the Circular Economy. In Circular Transitions, A Mistra Future Fashion Conference on Textile Design and the Circular Economy; Goldsworthy, K., Earley, R., Eds.; University of the Arts London: London, UK, 23–24 November 2016; pp. 303–315. [Google Scholar]

- Köhler, A.R. Material scarcity: A reason for responsibility in technology development and product design. Sci. Eng. Ethics 2013, 19, 1165–1179. [Google Scholar] [CrossRef]

- Spangenberg, J.H.; Fuad-Luke, A.; Blincoe, K. Design for Sustainability (DfS): The interface of sustainable production and consumption. J. Clean. Prod. 2010, 18, 1485–1493. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2010; ISBN 0-86547-587-3. [Google Scholar]

- Stahel, W.R. The circular economy. Nat. News 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Rozas, L.W.; Klein, W.C. The value and purpose of the traditional qualitative literature review. J. Evid. Based Soc. Work 2010, 7, 387–399. [Google Scholar] [CrossRef]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef]

- Bryman, A. Social Research Methods, 4th ed.; Oxford University Press: New York, NY, USA, 2012; ISBN 978-0-19-958805-3. [Google Scholar]

- United Nations Environment Programme, (UNEP). Putting the Breaks on Fast Fashion. Available online: https://www.unenvironment.org/news-and-stories/story/putting-brakes-fast-fashion (accessed on 3 May 2019).

- Global Fashion Agenda. A Call to Action for A Circular Fashion System. Available online: https://globalfashionagenda.com/wp-content/uploads/2017/04/GFA17_Call-to-action_Poluc-brief_FINAL_9May.pdf (accessed on 3 May 2019).

- Lawless, E.; Medvedev, K. Assessment of sustainable design practices in the fashion industry: Experiences of eight small sustainable design companies in the Northeastern and Southeastern United States. Int. J. Fash. Des. Technol. Educ. 2016, 9, 41–50. [Google Scholar] [CrossRef]

- Aakko, M.; Koskennurmi-Sivonen, R. Designing sustainable fashion: Possibilities and challenges. Res. J. Text. Appar. 2013, 17, 13–22. [Google Scholar] [CrossRef]

- Alyssa Couture. The Recycled Polyester Trend and Raised Questions About Sustainability. Available online: https://consciousmagazine.co/recycled-polyester-trend-and-raised-questions-about-its-sustainability/ (accessed on 2 February 2020).

- Šajn, N. Environmental Impact of the Textile and Clothing Industry. European Parliament Research Service. Available online: http://www.europarl.europa.eu/RegData/etudes/BRIE/2019/633143/EPRS_BRI(2019)633143_EN.pdf (accessed on 29 September 2019).

- Fletcher, K. Slow fashion: An invitation for systems change. Fash. Pract. 2010, 2, 259–265. [Google Scholar] [CrossRef]

- Niinimäki, K.; Hassi, L. Emerging design strategies in sustainable production and consumption of textiles and clothing. J. Clean. Prod. 2011, 19, 1876–1883. [Google Scholar] [CrossRef]

- CFDA. Materials Index. Available online: https://cfda.com/resources/materials (accessed on 29 September 2019).

- About BCI—Better Cotton Initiative. Available online: https://bettercotton.org/about-bci/ (accessed on 21 November 2019).

- Global Organic Textile Standard. Available online: https://www.global-standard.org/the-standard/general-description.html (accessed on 10 December 2019).

- Global Fashion Agenda Toolboxes. Available online: https://globalfashionagenda.com/commitment/#toolboxes (accessed on 3 July 2020).

- Rissanen, T.; McQuillan, H. Zero Waste Fashion Design; Bloomsbury Publishing: London, UK, 2016; ISBN 1472581989. [Google Scholar]

- EU Ecolabel: Clothing and Textiles/Textile Products. Available online: http://ec.europa.eu/ecat/category/en/14/textile-products (accessed on 17 December 2019).

- Shen, B. Sustainable fashion supply chain: Lessons from H&M. Sustainability 2014, 6, 6236–6249. [Google Scholar] [CrossRef]

- Di Benedetto, A.C. Corporate social responsibility as emerging business model in fashion marketing. J. Glob. Fash. Mark. 2017, 8, 251–265. [Google Scholar] [CrossRef]

- Niinimäki, K.; Koskinen, I. I love this dress, it makes me feel beautiful! Empathic knowledge in sustainable design. Des. J. 2011, 14, 165–186. [Google Scholar] [CrossRef]

- Valle-Noronha, J. On the Agency of Clothes: Surprise as a Tool towards Stronger Engagements. In Proceedings of the 3rd Biennial Research Through Design Conference (RTD2017), Edinburgh, UK, 22–24 March 2017; pp. 519–534. [Google Scholar]

- Fletcher, K.; Klepp, I.G. Opening Up the Wardrobe: A Methods Book; Novus Press: Oslo, Norway, 2017; ISBN 978-82-7099-893-7. [Google Scholar]

- Valle-Noronha, J.; Niinimäki, K.; Kujala, S. Notes on wearer–worn attachments: Learning to wear. Cloth. Cult. 2018, 5, 225–246. [Google Scholar] [CrossRef]

- Jung, S.; Jin, B. A theoretical investigation of slow fashion: Sustainable future of the apparel industry. Int. J. Consum. Stud. 2014, 38, 510–519. [Google Scholar] [CrossRef]

- Gwilt, A. What prevents people repairing clothes? An investigation into community-based approaches to sustainable product service systems for clothing repair. Mak. Futures J. 2014, 3. Available online: http://shura.shu.ac.uk/8125/1/Gwilt__Alison.pdf (accessed on 24 July 2020).

- Durrani, M. “People gather for stranger things, so why not this?” Learning sustainable sensibilities through communal garment-mending practices. Sustainability 2018, 10, 2218. [Google Scholar] [CrossRef]

- Middleton, J. Mending. In Routledge Handbook of Sustainability and Fashion; Fletcher, K., Tham, M., Eds.; Routledge: London, UK, 2014; pp. 280–292. [Google Scholar]

- Graziano, V.; Trogal, K. The politics of collective repair: Examining object-relations in a postwork society. Cult. Stud. 2017, 31, 634–658. [Google Scholar] [CrossRef]

- Nurmi, A. “Clothes as a service” will disrupt the fashion system. In Sustainable Fashion in a Circular Economy; Niinimäki, K., Ed.; Aalto University: Helsinki, Finland, 2018; pp. 236–240. ISBN 978-952-60-0089-3. [Google Scholar]

- Belkhir, L.; Elmeligi, A. Assessing ICT global emissions footprint: Trends to 2040 & recommendations. J. Clean. Prod. 2018, 177, 448–463. [Google Scholar] [CrossRef]

- Wäger, P.A.; Hischier, R.; Widmer, R. The material basis of ICT. In ICT Innovations for Sustainability; Advances in Intelligent Systems and Computing 310; Hilty, L., Aebischer, B., Eds.; Springer: Cham, Switzerland, 2015; pp. 209–221. ISBN 978-3-319-09227-0. [Google Scholar]

- Hilty, L.M.; Lohmann, W. The five most neglected issues in “Green IT”. Cepis Upgrad. Eur. J. Inform. Prof. 2011, 12, 11–15. [Google Scholar]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Reck, B.K. On the materials basis of modern society. Proc. Natl. Acad. Sci. USA 2015, 112, 6295–6300. [Google Scholar] [CrossRef] [PubMed]

- Mueller, S.R.; Wäger, P.A.; Widmer, R.; Williams, I.D. A geological reconnaissance of electrical and electronic waste as a source for rare earth metals. Waste Manag. 2015, 45, 226–234. [Google Scholar] [CrossRef]

- Izatt, R.M.; Izatt, S.R.; Bruening, R.L.; Izatt, N.E.; Moyer, B.A. Challenges to achievement of metal sustainability in our high-tech society. Chem. Soc. Rev. 2014, 43, 2451–2475. [Google Scholar] [CrossRef]

- Telenko, C.; Seepersad, C.C.; Webber, M.E. A Compilation of Design for Environment Principles and Guidelines. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC/CIE2008), Brooklyn, NY, USA, 3–6 August 2008; pp. 289–301. [Google Scholar]

- Gross, R.A.; Kalra, B. Biodegradable polymers for the environment. Science 2002, 297, 803–807. [Google Scholar] [CrossRef]

- Frenzel, M.; Tolosana-Delgado, R.; Gutzmer, J. Assessing the supply potential of high-tech metals—A general method. Resour. Policy 2015, 46, 45–58. [Google Scholar] [CrossRef]

- Ali, S.H.; Giurco, D.; Arndt, N.; Nickless, E.; Brown, G.; Demetriades, A.; Durrheim, R.; Enriquez, M.A.; Kinnaird, J.; Littleboy, A.; et al. Mineral supply for sustainable development requires resource governance. Nature 2017, 543, 367–372. [Google Scholar] [CrossRef] [PubMed]

- Blengini, G.A.; Nuss, P.; Dewulf, J.; Nita, V.; Peirò, L.T.; Vidal-Legaz, B.; Latunussa, C.; Mancini, L.; Blagoeva, D.; Pennington, D.; et al. EU methodology for critical raw materials assessment: Policy needs and proposed solutions for incremental improvements. Resour. Policy 2017, 53, 12–19. [Google Scholar] [CrossRef]

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the 2017 List of Critical Raw Materials for the EU. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52017DC0490&from=EN (accessed on 4 December 2019).

- Quariguasi Frota Neto, J.; Walther, G.; Bloemhof, J.; van Nunen, J.A.E.E.; Spengler, T. From closed-loop to sustainable supply chains: The WEEE case. Int. J. Prod. Res. 2010, 48, 4463–4481. [Google Scholar] [CrossRef]

- Quariguasi Frota Neto, J.; Bloemhof, J. An analysis of the eco-efficiency of remanufactured personal computers and mobile phones. Prod. Oper. Manag. 2012, 21, 101–114. [Google Scholar] [CrossRef]

- Hunt, C.P.; Wickham, M.; Pittson, R.; Lewison, J. Reusable, Unzippable, Sustainable Electronics (ReUse) Interconnect System for the Circular Economy. Report for NPL, MAT 75. 2 February 2018. Available online: http://eprintspublications.npl.co.uk/6645/ (accessed on 24 July 2020).

- Kasser, U.; Pöll, M.; Graffe, K. Ökologische Bewertung mit Hilfe der Grauen Energie; Bundesamt für Umwelt, Wald und Landschaft (BUWAL): Bern, Switzerland, 1999. [Google Scholar]

- Hischier, R.; Coroama, V.C.; Schien, D.; Achachlouei, M.A. Grey energy and environmental impacts of ICT hardware. In ICT Innovations for Sustainability; Advances in Intelligent Systems and Computing 310; Hilty, L., Aebischer, B., Eds.; Springer: Cham, Switzerland, 2015; pp. 171–189. ISBN 978-3-319-09227-0. [Google Scholar]

- Köhler, A.; Erdmann, L. Expected environmental impacts of pervasive computing. Hum. Ecol. Risk Assess. Int. J. 2004, 10, 831–852. [Google Scholar] [CrossRef]

- Plepys, A. The grey side of ICT. Environ. Impact Assess. Rev. 2002, 22, 509–523. [Google Scholar] [CrossRef]

- EU Directive 2002/95/EC of the European Parliament and of the Council of 27 January 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment. Off. J. Eur. Union 2003, 13, 19–23.

- US EPA. Sustainable Materials Management (SMM) Electronics Challenge. Available online: https://www.epa.gov/smm-electronics/sustainable-materials-management-smm-electronics-challenge (accessed on 27 September 2019).

- Patrignani, N.; Whitehouse, D. Slow Tech and ICT: A Responsible, Sustainable and Ethical Approach; Springer: Cham, Switzerland, 2017; ISBN 978-3-319-68943-2. [Google Scholar]

- Greenpeace. Guide to Greener Electronics. Available online: https://www.greenpeace.org/usa/reports/greener-electronics-2017/ (accessed on 18 July 2019).

- Roy, R. Sustainable product-service systems. Futures 2000, 32, 289–299. [Google Scholar] [CrossRef]

- Doualle, B.; Medini, K.; Boucher, X.; Brissaud, D.; Laforest, V. Design of sustainable product-service systems (PSS): Towards an incremental stepwise assessment method. Procedia CIRP 2016, 48, 152–157. [Google Scholar] [CrossRef]

- EnergyStar. The Simple Choice for Energy Efficiency. Available online: https://www.energystar.gov/ (accessed on 8 December 2019).

- Green Electronics Council. EPEAT for Manufacturers. Available online: https://greenelectronicscouncil.org/epeat/manufacturers/ (accessed on 4 December 2019).

- Newman, J. 6 Things You’d Never Guess About Google’s Energy Use. Available online: http://techland.time.com/2011/09/09/6-things-youd-never-guess-about-googles-energy-use/ (accessed on 19 November 2019).

- Preist, C.; Schien, D.; Shabajee, P. Evaluating Sustainable Interaction Design of Digital Services. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems (CHI 2019), Glasgow, UK, 4–9 May 2019; pp. 1–12. [Google Scholar]

- Lomas, Natasha. Can Fairphone 3 Scale Ethical Consumer Electronics? Available online: https://techcrunch.com/2019/08/27/can-fairphone-3-scale-ethical-consumer-electronics/ (accessed on 11 October 2020).

- The Repair Association. Available online: https://repair.org (accessed on 21 November 2019).

- Böni, H.; Schluep, M.; Widmer, R. Recycling of ICT equipment in industrialized and developing countries. ICT Innov. Sustain. 2015, 223–241. [Google Scholar] [CrossRef]

- Williams, E. Environmental effects of information and communications technologies. Nature 2011, 479, 354–358. [Google Scholar] [CrossRef] [PubMed]

- Kahhat, R.; Williams, E. Materials flow analysis of e-waste: Domestic flows and exports of used computers from the United States. Resour. Conserv. Recycl. 2012, 67, 67–74. [Google Scholar] [CrossRef]

- Oswald, I.; Reller, A. E-waste: A story of trashing, trading, and valuable resources. Gaia-Ecol. Perspect. Sci. Soc. 2011, 20, 41–47. [Google Scholar] [CrossRef]

- Chi, X.; Streicher-Porte, M.; Wang, M.Y.L.; Reuter, M.A. Informal electronic waste recycling: A sector review with special focus on China. Waste Manag. 2011, 31, 731–742. [Google Scholar] [CrossRef]

- Williams, E.; Kahhat, R.; Allenby, B.; Kavazanjian, E.; Kim, J.; Xu, M. Environmental, social, and economic implications of global reuse and recycling of personal computers. Environ. Sci. Technol. 2008, 42, 6446–6454. [Google Scholar] [CrossRef]

- Boothroyd, G.; Alting, L. Design for assembly and disassembly. CIRP Ann. Manuf. Technol. 1992, 41, 625–636. [Google Scholar] [CrossRef]

- Platcheck, E.R.; Schaeffer, L.; Kindlein, W.; Cãndido, L.H.A. Methodology of ecodesign for the development of more sustainable electro-electronic equipments. J. Clean. Prod. 2008, 16, 75–86. [Google Scholar] [CrossRef]

- National Physical Laboratory. Recyclable Electronics: Just Add Hot Water. Available online: https://phys.org/news/2012-06-recyclable-circuit-boards.html (accessed on 27 September 2019).

- Ossevoort, S.H.W. Improving the sustainability of smart textiles. In Multidisciplinary Know-How for Smart-Textiles Developers; Kirstein, T., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 399–419. [Google Scholar]

- Fleischmann, K.; Hielscher, S.; Merritt, T. Making things in Fab Labs: A case study on sustainability and co-creation. Digit. Creat. 2016, 27, 113–131. [Google Scholar] [CrossRef]

- Yao, L.; Ou, J.; Cheng, C.; Steiner, H.; Wang, W.; Wang, G.; Ishii, H. bioLogic: Natto Cells as Nanoactuators for Shape Changing Interfaces. In Proceedings of the 33rd Annual ACM Conference on Human Factors in Computing Systems (CHI’15), Seoul, Korea, 18–23 April 2015; pp. 1–10. [Google Scholar]

- Flores, R. Scientists Create Biodegradable, Paper-based Biobatteries. Available online: https://www.binghamton.edu/news/story/1227/scientists-create-biodegradable-paper-based-biobatteries (accessed on 16 August 2019).

- Bourzac, K. Biodegradable Batteries to Power Smart Medical Devices. Available online: https://www.technologyreview.com/s/522581/biodegradable-batteries-to-power-smart-medical-devices/ (accessed on 26 July 2016).

- Goncu-Berk, G. Smart Textiles and Clothing: An Opportunity or A Threat for Sustainability? In Proceedings of the Textile Intersections 2019, Loughborough, UK, 12–14 September 2019. [Google Scholar] [CrossRef]

- Tseng, M.; Chiu, S.F.; Tan, R.R.; Siriban-Manalang, A.B. Sustainable consumption and production for Asia: Sustainability through green design and practice. J. Clean. Prod. 2013, 40, 1–5. [Google Scholar] [CrossRef]

- Timmins, M. Environmental and waste issues concerning the production of smart clothes and wearable technology. In Smart Clothes and Wearable Technology; McCann, J., Bryson, D., Eds.; Woodhead Publishing: Cambridge, UK, 2009; pp. 319–331. [Google Scholar]

- Prahl, A. Designing Wearable Sensors for Preventative Health: An Exploration of Material, Form and Function. Ph.D. Thesis, University of the Arts London, London, UK, September 2015. [Google Scholar]

- Buechley, L.; Eisenberg, M. The LilyPad Arduino: Toward wearable engineering for everyone. Pervasive Comput. 2008, 7, 12–15. [Google Scholar] [CrossRef]

- Adafruit. Getting Started with FLORA. Available online: https://learn.adafruit.com/getting-started-with-flora/flora-projects (accessed on 21 November 2019).

- Flex-Ability. An E-textile Interface Kit for Persons with Limited Mobility. Available online: http://flex-ability.org/ (accessed on 7 December 2019).

- Chen, D.; Heyer, S.; Ibbotson, S.; Salonitis, K.; Steingrímsson, J.G.; Thiede, S. Direct digital manufacturing: Definition, evolution, and sustainability implications. J. Clean. Prod. 2015, 107, 615–625. [Google Scholar] [CrossRef]

- Raasch, C.; Herstatt, C.; Balka, K. On the open design of tangible goods. RD Manag. 2009, 39, 382–393. [Google Scholar] [CrossRef]

- Bonvoisin, J. Implications of Open Source Design for Sustainability. In Proceedings of the 3d International Conference on Sustainable Design and Manufacturing (SDM’16), Chania, Greece, 4–6 April 2016; pp. 45–59. [Google Scholar]

- Li, L.; Cheung, T.W. Sustainable development of smart textiles: A review of ‘self-functioning’ abilities which makes textiles alive. J. Text. Eng. Fash. Technol. 2018, 4, 151–156. [Google Scholar] [CrossRef]

- Brutten, M. Nano-Tex introduces Fortify DP: An Innovation in Wrinkle-Free Technology. Report for Nano-Tex Company. 29 September 2011. Available online: https://www.textileweb.com/doc/nano-tex-introduces-fortify-dp-an-innovation-0001 (accessed on 13 October 2020).

- Roinesalo, P.; Virtanen, L.; Lappalainen, T.; Kylmänen, A.; Häkkilä, J. Solar Shirt: Design of an Environmental Awareness Wearable. In Proceedings of the 2016 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp’16), Heidelberg, Germany, September 2016; pp. 495–499. [Google Scholar]

- Thielen, M.; Sigrist, L.; Magno, M.; Hierold, C.; Benini, L. Human body heat for powering wearable devices: From thermal energy to application. Energy Convers. Manag. 2017, 131, 44–54. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Yi, F.; Zi, Y.; Lin, J.; Wang, X.; Xu, Y.; Wang, Z.L. Sustainably powering wearable electronics solely by biomechanical energy. Nat. Commun. 2016, 7, 12744. [Google Scholar] [CrossRef] [PubMed]

- Kuusk, K. Crafting Sustainable Smart Textile Services. Ph.D. Thesis, Technische Universiteit, Eindhoven, The Netherlands, February 2016. [Google Scholar]

- Juhlin, O.; Zhang, Y. Unpacking Social Interaction that Make Us Adore: On the Aesthetics of Mobile Phones as Fashion Items. In Proceedings of the 13th International Conference on Human Computer Interaction with Mobile Devices and Services (MobileHCI’11), Stockholm, Sweden, 30 August–2 September 2011; pp. 241–250. [Google Scholar]

- Fernández-Caramés, T.; Fraga-Lamas, P. Towards the Internet of smart clothing: A review on IoT wearables and garments for creating intelligent connected e-textiles. Electronics 2018, 7, 405. [Google Scholar] [CrossRef]

- Fortmann, J.; Root, E.; Boll, S.; Heuten, W. Tangible Apps Bracelet: Designing Modular Wrist-worn Digital Jewelry for Multiple Purposes. In Proceedings of the 2016 ACM Conference on Designing Interactive Systems (DIS’16), Brisbane, Australia, 4–8 June 2016; pp. 841–852. [Google Scholar]

- Hilty, L.M.; Wäger, P.; Lehmann, M.; Hischier, R.; Ruddy, T.F.; Binswanger, M. The Future Impact of ICT on Environmental Sustainability. Fourth Interim Report. Refinement and Quantification. Institute for Prospective Technological Studies, Sevilla 2004. Available online: https://ec.europa.eu/digital-single-market/en/news/future-impact-icts-environmental-sustainability (accessed on 24 July 2020).

- Galloway, A.; Brucker-Cohen, J.; Gaye, L.; Goodman, E.; Hill, D. Design for Hackability. In Proceedings of the 5th Conference on Designing Interactive Systems (DIS’04), Cambridge, MA, USA, 1–4 August 2004; pp. 363–366. [Google Scholar]

- Pateman, M.; Harrison, D.; Marshall, P.; Cecchinato, M.E. The Role of Aesthetics and Design: Wearables In Situ. In Proceedings of the Extended Abstracts of the 2018 CHI Conference on Human Factors in Computing Systems (CHI’18), Montreal, QC, Canada, 21–26 April 2018; pp. 1–6. [Google Scholar]

- Koo, H.; Dunne, L.; Bye, E. Design functions in transformable garments for sustainability. Int. J. Fash. Des. Technol. Educ. 2013, 7, 10–20. [Google Scholar] [CrossRef]

- Harrison, C.; Lim, B.; Shick, A.; Hudson, S. Where to Locate Wearable Displays? Reaction Time Performance of Visual Alerts from Tip to Toe. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems (CHI’09), Boston, MA, USA, 4–9 April 2009; pp. 941–944. [Google Scholar]

- Köhler, A.R.; Hilty, L.M.; Bakker, C. Prospective impacts of electronic textiles on recycling and disposal. J. Ind. Ecol. 2011, 15, 496–511. [Google Scholar] [CrossRef]

- Ogunseitan, O.A.; Schoenung, J.M.; Saphores, J.D.M.; Shapiro, A.A. The electronics revolution: From e-wonderland to e-wasteland. Science 2009, 326, 670–671. [Google Scholar] [CrossRef]

- Bovea, M.D.; Ibáñez-Forés, V.; Pérez-Belis, V.; Quemades-Beltrán, P. Potential reuse of small household waste electrical and electronic equipment: Methodology and case study. Waste Manag. 2016, 53, 204–217. [Google Scholar] [CrossRef] [PubMed]

- Höök, K.; Löwgren, J. Strong concepts: Intermediate-level knowledge in interaction design research. Acm Trans. Comput. Hum. Interact. 2012, 19, 1–18. [Google Scholar] [CrossRef]

- Sas, C.; Whittaker, S.; Dow, S.; Forlizzi, J.; Zimmerman, J. Generating Implications for Design through Design Research. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems (CHI’14), Toronto, ON, Canada, 26 April 2014; pp. 1971–1980. [Google Scholar]

- Dourish, P. Implications for Design. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems (CHI 2006), Montréal, QC, Canada, 22–27 April 2006; pp. 541–550. [Google Scholar]

- SparkFun Sustainability Effort. Available online: https://www.sparkfun.com/news/794 (accessed on 27 September 2019).

- Digi-Key Environmental—Conservation, Education & Waste Reduction. Available online: https://www.digikey.com/en/resources/environmental/initiative (accessed on 27 September 2019).

- Fly Dragon Initiative Material Change Report. Available online: https://www.thedragonflyinitiative.com/material-change-report (accessed on 27 September 2019).

- US EPA. Identifying Greener Electronics. Overviews and Factsheets. Available online: https://www.epa.gov/greenerproducts/identifying-greener-electronics (accessed on 27 September 2019).

- Protolabs. Injection Moulding, Rapid Prototyping, 3D Printing, CNC. Available online: https://www.protolabs.co.uk/ (accessed on 17 December 2019).

- Bar-Cohen, A.; Iyengar, M. Design and optimization of air-cooled heat sinks for sustainable development. Ieee Trans. Compon. Packag. Technol. 2002, 25, 584–591. [Google Scholar] [CrossRef]

- Studio HILO. What We Do. Available online: https://www.studiohilo.com/what-we-offer (accessed on 21 November 2019).

- United Nations Environment Programme (UNEP). Metal Stocks in Society: Scientific Synthesis. Metal Stocks in Society: Scientific. 2011. Available online: http://wedocs.unep.org/handle/20.500.11822/8438 (accessed on 24 July 2020).

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 91301. [Google Scholar] [CrossRef]

- Fullerton, D.; Wolverton, A. Two generalizations of a deposit-refund system. Am. Econ. Rev. 2000, 90, 238–242. [Google Scholar] [CrossRef]

- Consumer Reports. What You Need to Know about Electronics Trade-in Programs. Available online: https://www.consumerreports.org/cro/news/2013/09/electronics-trade-in-programs/index.htm (accessed on 7 September 2019).

- Kuusk, K.; Niinimäki, K.M.; Wensveen, S.A.G.; Tomico Plasencia, O. Smart Textile Products and Services in Sustainability Context. In Proceedings of the Ambience14&10i3m, Scientific Conference for Smart and Functional Textiles, Well-Being, Thermal Comfort in Clothing, Design, Thermal Manikins and Modelling, Tampere, Finland, 7–9 September 2014; Available online: https://www.researchgate.net/profile/Kristi_Kuusk/publication/299377389_Smart_Textile_Products_and_Services_in_Sustainability_Context/links/56f2b0e308aea5a8982ff961/Smart-Textile-Products-and-Services-in-Sustainability-Context.pdf (accessed on 24 July 2020).

- Pan, Y.; Roedl, D.; Blevis, E.; Thomas, J. Fashion thinking: Fashion practices and sustainable interaction design. Int. J. Des. 2015, 9, 53–66. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Lifecycle categories | Fashion Design | ICT | Wearable Technologies | |

| Materials |

|

|

| |

| Manufacturing |

|

|

| |

| Distribution |

|

|

| |

| Use |

|

| ||

| Disposal |

|

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gurova, O.; Merritt, T.R.; Papachristos, E.; Vaajakari, J. Sustainable Solutions for Wearable Technologies: Mapping the Product Development Life Cycle. Sustainability 2020, 12, 8444. https://doi.org/10.3390/su12208444

Gurova O, Merritt TR, Papachristos E, Vaajakari J. Sustainable Solutions for Wearable Technologies: Mapping the Product Development Life Cycle. Sustainability. 2020; 12(20):8444. https://doi.org/10.3390/su12208444

Chicago/Turabian StyleGurova, Olga, Timothy Robert Merritt, Eleftherios Papachristos, and Jenna Vaajakari. 2020. "Sustainable Solutions for Wearable Technologies: Mapping the Product Development Life Cycle" Sustainability 12, no. 20: 8444. https://doi.org/10.3390/su12208444

APA StyleGurova, O., Merritt, T. R., Papachristos, E., & Vaajakari, J. (2020). Sustainable Solutions for Wearable Technologies: Mapping the Product Development Life Cycle. Sustainability, 12(20), 8444. https://doi.org/10.3390/su12208444