Abstract

Defining the circular economy (CE) as a material and energy model coincides with the definition given by multiple authors in which Industrial Symbiosis (IS) has been deemed as a foundational strategy to support the implementation of the CE. The consumption of secondary materials is essential to achieve a successful transformation from a linear economy to a CE focused on IS practices. In this scenario, small and medium enterprises (SMEs) play a major role as stakeholders in developing CE systems as it is not possible to create this model with each company working in isolation. However, there is a lack of empirical studies on the role played by relevant local stakeholders such as individual firms interacting in the development of a local CE system. This study aimed to study the challenges that SMEs face in developing a CE system. A case study is selected as a research strategy using a mixed-method approach: a sequential quantitative (questionnaire) and qualitative (semi-structured interviews) data collection techniques were employed for this research. It was observed that an absence of inter-organisational collaboration and a misunderstanding of the roles played by SMEs may impede the implementation of a local CE system level.

1. Introduction

The Circular Economy (CE) concept can be summarised as a paradigm shift aimed at preventing the depletion of resources by closing energy and materials loops throughout its different implementation levels: micro (enterprises and consumers), meso (economic agents integrated into the symbiosis) and macro (city, regions and governments) [1].

The practical applications of implementing this paradigm shift at different levels are rooted in different schools of thought that, taken together, shape the idea of closed loops [2]. Several authors have listed the most renowned schools of thought that refine the foundational umbrella of the CE, such as cradle to cradle, industrial ecology, biomimicry, performance economy and regenerative design [3,4,5,6,7,8,9].

In particular, industrial symbiosis (IS) as a sub-research field of industrial ecology has been described as a crucial approach to a successful CE implementation due to its capacity to provide tools and mechanisms in order to spur companies’ growth while dealing with natural resource depletion [10,11,12,13]. Thus, a successful transition to a CE model driven by IS would contribute to finally closing the loop by decreasing dependence on raw materials and minimising waste from the industrial system [14,15].

However, a lack of interdisciplinary collaboration in a CE and a lack of coherence regarding how it can be implemented has been an obstacle. Some other obstacles are related to unspecified roles, lack of government coordination and low levels of participation that hinder a successful transformation. A broad collaboration of stakeholders is necessary for a CE implementation strategy that relies on the consumption of secondary products [16]. Consequently, the implementation of a local CE system requires that the interests of various partners within the value chain be aligned to achieve a circular solution [17]. Hofmann and Jaeger-Erben [18] suggest that research should be focused on the different facets of inter-organizational relationships amongst firm units to advance a collaborative value creation network. The focus on developing local CE systems becomes relevant because this local scale could easily be mobilised for collaborative action [19]. However, it seems that there is a lack of empirical studies on the role of local stakeholders such as individual firms working in collaborative groups in the development of a local CE system [20,21].

Consequently, this study aimed to analyse the challenges that SMEs as a key player face in developing a local CE system that might hinder its implementation. The study was done in northern Spain wherein approximately 300 SMEs are located near to each other in an industrial park (IP) in order to provide greater knowledge with the aim to study a potential transformation into a local CE system. This paper is structured as follows: Section 2 details the conceptualisation behind the term CE. Section 3 describes the methodology used for this study. Section 4 discusses the results obtained from the methodology described in Section 3 and Section 5 outlines the conclusions that can be drawn from this study.

2. Theoretical Background

Although the CE and its principles are easy to understand, fully implementing them has been difficult due to their complexity [15]. Promoting a CE involves different stakeholders working in networks of relations which has also been recognized in the literature on IS [19]. Therefore, this study uses the analytical framework for the transformation from a linear economy to a CE through an IS proposed by [22] wherein IS initiatives are utilised to implement a circular system. IS has been identified as one of the practical routes for embedding CE in manufacturing activities to accelerating the transition from wasteful to closed-loop systems [23,24].

In that sense, IS enforces an approach that takes inspiration from how industrial systems mimic natural ecosystems, and it can simulate the distribution of materials, energy and information flows [25]. The proximity between companies is regarded as a critical component, as it facilitates the sharing of supplies and a reduction in transportation costs [26,27]. This may lead to better resource efficiency and a reduction in waste generation and greenhouse gas emissions. The most widely known definition is given by [28], who described IS as a system that gathers distinct industries in a joint approach to gain a competitive advantage by linking the physical exchanges of resources in a context where cooperation and synergistic opportunities offered by geographic proximity are significant.

Taking the particular features of IS, authors such as [15] have pointed out that a common characteristic of IS is the diversity of sectors involved and the multiple opportunities that could be created across value chains in diverse industrial sectors to implement a CE. Likewise, some IS efforts have been implemented on scales that differ from the typical IP or global supply chain, that is, at the facility level. This level is characterised by its small facility size, the close proximity of businesses, limits on the volume and range of available resource flows and easy-entry for small enterprises and start-up businesses, with most cases in the USA and Germany [29].

According to [30], since its origin, most IS research was predominantly theoretical (48%), however, there have been reported case studies whose content describes the research of IS in regions around the globe equivalent to 31% of the existing literature. In that regard, Asia represents the largest number of case studies reported on IS with a 49.0% share of the total, followed by Europe with a 37.5% share of case studies and North America with 9.1%.

China is undoubtedly the country with the most case studies of IS reported in the literature accounting for 34% of all publications. The countries of North and North-West Europe absorb the majority of published studies in Europe, corresponding to 72% of the total of European studies. Leading the case studies are the United Kingdom, followed by Sweden, Denmark and the Netherlands [31].

To observe the different case studies worldwide, Table 1 highlights the cases highlights the cases organised by region, and these are arranged based on the number of cases studied. The case studies in Table 1 were also depicted according to their economic activities as described by [30]. Many of the IS initiatives in Table 1 pursue efficiency in resource consumption. Although ecological interest might arise as the fundamental reason for developing IS, in most cases self-interest is a primary reason organisations collaborate in IS networks [32].

Table 1.

IS case studies.

In some cases, such as Sweden, Germany, Finland, Japan and Italy, the main preconditions that allowed the creation of symbiotic exchanges were that some waste-to-resource exchanges were already implemented in the region and companies had previous capabilities in collaborative projects. And thus companies had already the required mind set, know-how and skills as well as a high level of awareness of environmental issues and legislative pressure [33].

In regions such as Portugal, Italy, Japan and Korea, other factors played a key role in their realisation, namely the local and national governments. Other stakeholders were also supportive during the creation of the IS networks; for instance, they provided funds and promoted conditions that helped the further development of the network and collaboration among companies (e.g., creating recycling norms for different types of waste in Korea). In some other IS cases, such as in China, the main precondition for IS implementation was the fact that the government had the tools to strongly influence companies’ decision-making process, as well as the authority to shape the business environment [34].

Approximately 35 IS case studies in Europe have been reported in the literature, corresponding to reports in several countries such as Italy, Sweden, Germany, Denmark, The Netherlands, Finland, United Kingdom and Portugal [33,40]. IS is well-rooted in different countries, yet, the development of IS has proven to be discordant in Europe, as a result of implementing policies at a country level that are in line with a more CE which has enabled the spread of IS initiatives in certain countries [31].

European countries, such as Spain, while not having many reported cases of IS in the literature, have tried to promote programs for the adoption of IS [82]. Table 2 compiles the characteristics of various cases of potential IS analysed in Spain. According to the table, it is clear that IS applications and analysis studies are not abundant in Spain, however, it is arguable to observe that there are still many untapped opportunities for developing new IS [83]. However, despite all the efforts made to implement IS initiatives at a global scale or at least tap its potential, IS is still a niche strategy that faces multiple challenges (e.g., regulatory, legislative barriers and financial hurdles, organisational issues) [84].

Table 2.

Cases of potential industrial symbioses in Spain.

Overall, the development of CE in China and Europe, which together accounts for the most case studies, has relied on different pathways. China’s CE development is based on its large supply chain capabilities through several regional industrial agglomerations which are targeted for CE development and policies [87,88]. Whereas countries in Europe seek to create secondary materials that compete with and reduce the dependence on primary materials without considerations of scale [89,90,91]. Unlike China, the CE implementation through the creation of a European secondary materials market as part of its CE action plan [92] poses a risk for the European Union as SMEs represent 99% of its total businesses [93]. SMEs are characterized for their heterogeneity in the market which could hinder a transition to a CE system [94]. Nonetheless, SMEs involved in a CE are significantly essential to sustain higher values for the resources that cycle through the industrial system [95].

Hence, SMEs have a key role in implementing the CE, yet, the sharing of restricted technical and financial resources through networks might need to be overcome [84,96]. As SMEs only handle small amounts of resources, it is only feasible to achieve economies of scale and scope by means of IS initiatives that otherwise cannot be appropriately captured at the level of the individual firm if separately organized [16,22].

This could be one of the biggest obstacles to implement the CE system in Europe or wherever SMEs represent the majority of industrial operations as it relies on the consumption of secondary products and that absence of engagement with these stakeholders in the implementation stage could result in a lack of support [16]. Thus, IS, in order to be widely implemented as one of the core strategies that manage resources and waste in a local CE system [97,98], will need to be based on collaboration between actors such as businesses, the community, policymakers and institutions [11]. Therefore, the cooperation within SMEs and other actors to achieve a local CE system will only be possible at the group level. Consequently, more insights are needed to tackle the potential challenges of SMEs in developing CE systems, as they tend to have a local scope with singular features [15].

3. Methodology

The aim of this paper was to analyse the challenges that SMEs as a key player face in developing a local CE system, especially in nearby industrial areas such as an IP to understand the circularity of materials. Currently, there are more than 400 IPs registered in Spain [15,33]. In order to explore what capabilities companies possess that enable them to participate in a potential local CE system, a case study is selected as a research strategy using a mixed-method approach: a sequential quantitative (questionnaire) and qualitative (semi-structured interviews) as data collection techniques, which might lead to more general theoretical insight [99].

Thus, this study was carried out with SMEs located in the Basque Country region, Spain. The companies are located within an IP which comprises 306 companies from different sectors with an average of 3 to 5 employees and 300 m2 of usable space, with a small number of companies (13) having more than 10 employees. The companies are characterised by their heterogeneity, but due to the number of businesses located near each other, they can take advantage of this sort of industrial association through resource sharing [84].

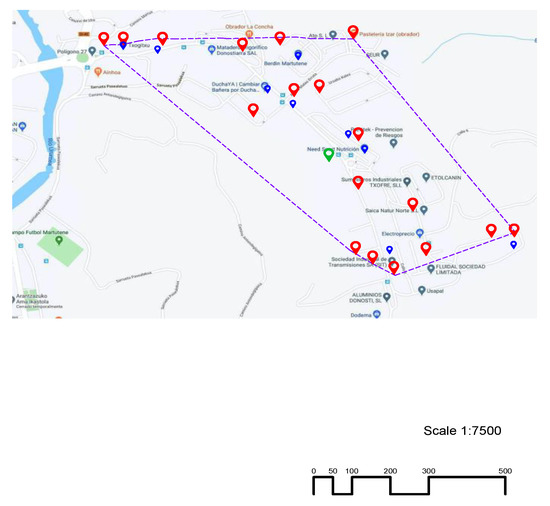

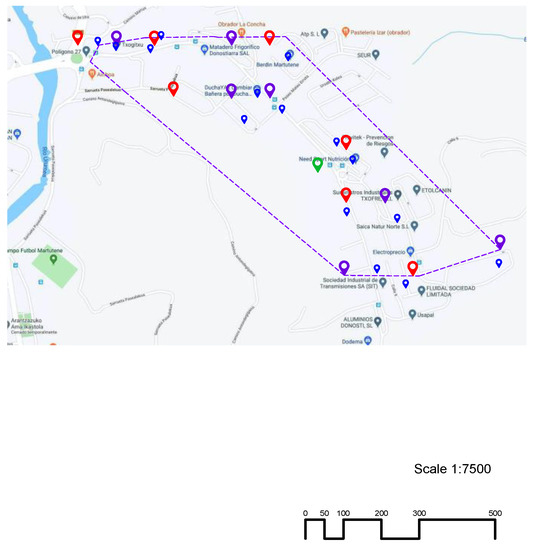

Two steps have been taken to carry out this research: (1) A software to detect potential residue-resource matches between companies to verify that there are real possibilities for collaboration. This step has been carried out with the iNex software that allows the creation of potential networks and (2) Semi-structured interviews to identify the limiting factors that make it difficult to carry out a local CE system. Firstly, the iNex software (a web-based platform) was used to generate potential matches centred on waste-to-resource in 148 companies. These potential matches give us an idea of what kind of resources could generate symbiosis between companies. The higher number of companies chosen at this stage compared with the interview phase (17) is due to the iNex software’s requirement for more data in order to identify waste to be used as a resource, thus, a waste-to-resource network could be created. The iNex software is also able to determine the potential of waste as a feedstock within an entire area, which it does by running a cartographic analysis of a defined area.

This iNex software in particular performs its task following the European nomenclature adapted to recyclers (resource code). It works by indicating a city, a department, a region and the search radius. Then it registers the sectors of activity defined by the European nomenclature glossary (NACE). Afterwards, from the previous result, specific characteristics can be set to search for the desired material. The NACE nomenclature glossary corresponds to the statistical classification of economic activities in the European Union, and the software uses both and the resource code so that, it is able to list the different resources and waste of each of the companies. Finally, potential matches are defined, providing waste and key people to contact so a collaboration may sprout.

In order to provide the software with the data needed, companies were asked to provide information about the industrial activity, the number of employees, work schedule and specific questions about their production processes such as type and input/output quantity of materials/residue. The results provided by the software served to create networks in which the resource is selected, and the potential waste replaces it.

Secondly, a semi-structured interview was chosen as a qualitative research method for this study due to its nature of gathering and analysing data in relation to the research topic [100]. This methodology allowed us to collect in-depth information about the real possibilities of developing a CE system. Thus, face-to-face, semi-structured interviews were conducted at 17 companies from different sectors to gain insights into the performance of the SMEs. Although more companies had agreed to be interviewed, after 17 interviews a point of saturation had been reached whereby categories were considered sufficiently dense and data collection no longer generated new leads [100]. This type of interview is suitable, as this is an exploratory study [101]. The aim of this type of interview is to gain information about the experiences of individuals in companies which are focused and detailed, thereby revealing interviewees’ views, feelings, intentions and actions, as well as the context and organisation of their activities, in order to understand the reality within companies [102,103].

To guarantee the reliability of the information in this study, the interviews were conducted at each company by two researchers; they were audio-recorded and later transcribed. The interview transcripts were reviewed and independently coded. Then, the codes were arranged and organised before the final responses related to a firm’s characteristics were obtained. Codification resulted in a list of core categories related to potential collaboration in IS and the links among them. The codes developed were further transformed into data that were analysed through a standard procedure. The interview data were analysed using the software ATLAS/ti, which is commonly used in qualitative research to understand the connections between several responses.

4. Results and Discussion

Through the study done with the SMEs, it was possible to observe whether potential by-product synergies could be obtained, as can be seen later in this article. Some of the industry sectors are food, automobile, carpentry, construction, glassware, plumbing, training, home and decoration, printing, information technology, engineering, electrical installations, machining, furniture, fashion and accessories, computer security, industrial services, telecommunications and transport.

4.1. First Step: Potential Material Synergies

Using software to foster recirculation of materials has been discussed in other studies, where tools to match the supply and demand of wastes have strengthened relationships among companies over time [104,105]. Similar studies have adopted a related strategy that includes models of an online sharing platform that facilitates waste-to-resources matching [67,106]. Thus, theoretical resource networks were obtained through the iNex software in order to identify whether there are potential synergies among the SMEs.

This study focused on the resources of SMEs, targeting the most common resources and the largest amount of waste generated by 148 companies. The companies, which generated waste suitable to be considered in a synergy, were called donors, and the companies with the potential to receive waste as a resource were named recipients. In this study, networks were created to determine the waste that was considered most relevant for potential circular resource use.

The waste network accounting for the largest number of companies is “waste packaging”, within which there are two types: “packaging” (23 recipients and 67 donors) and “absorbents, filtration materials, cleaning cloths and protective clothing” (67 donors). The “municipal and related waste from businesses, industries and institutions, including selectively collected fractions” were also present in many companies (47 donors and 26 recipients), accounting for 33 donors and 26 recipients, the most common ones found in the study.

More than 10 companies generated 33 of the 99 waste networks created, and only 5 of the 33 waste networks can be used as resources for other companies. For instance, “paper and cardboard” or “paper and cardboard packaging” waste can be used as “fibre paste obtained from recycled paper or cardboard”. The “tyres out of use” obtained from vehicles can replace “embankments”, and it has been suggested that the “wooden pallet (good conditions and damaged)” can have different uses, such as fuel, tables, cabinets and pallets.

According to these theoretical networks, most of them seem unlikely to carry out a waste-to-resource exchange due to a clear necessity to transform some materials prior to their new use (e.g., paper cardboard into fibre paste) and a lack of knowledge about what kind of wastes can be transformed into resources which usually happens in manufacturing companies [107]. However, an increasing pressure over primary resource consumption and the need to reduce waste generation open up opportunities for the creation of new roles in resource management [30]. In the following section, we describe the theoretical networks of waste-to-resource exchanges that will help to form a local CE system.

4.1.1. Waste Network

Based on the waste that could be used as resources by the greatest number of companies within the IP (Figure 1), four networks were created (Table 3). The category of resources related to the largest number of companies is “Mineral Products” (32 donors and 24 recipients) and “Heat” (17 donors and 17 recipients), in its different temperature and state variants, was the most requested resource of this category. The second category with the largest number of related companies is “plastics, rubber and its manufactures” (48 related companies, 46 donors and 2 recipients).

Figure 1.

Example of waste network.

Table 3.

Waste networks.

Among polymers, the one with the largest number of donors is linear polyethylene (41 companies). Of the 82 resources, more than nine companies required nine and five of them might be obtained from waste generated within the IP. The high-temperature heat in liquid or gaseous form that companies need could be obtained from waste from other companies that comes in different forms, such as combustion of mixed non-dangerous wood, as suggested by the software, or through organic kitchen waste.

4.1.2. Resource Networks

After the most common resources in the IP were identified, the potential networks were created (Figure 2). Five resource networks were made in order to obtain these resources in a simulated IS (Table 4). Observing the list of wastes from the 148 companies studied, five networks were created with the objective of promoting the correct management of the most common waste (some of them dangerous) in the IP.

Figure 2.

Example of resource network.

Table 4.

Resource networks.

These networks were created due to their potential creation of synergies in an IS. Some of the resource networks were made up of companies that could either make joint resource acquisitions or form a general network that could oversee a joint waste management consortium [108]. The characteristics of resource networks created in iNex are in (Table 4).

Fifty percent of the companies put in the software generated “Containers that contain waste or are contaminated by dangerous substances” and most of these generate residues of “Absorbents, filtration materials, cleaning cloths and protective clothing”. In the waste network, 33 companies located in the IP appear in “Batteries and accumulators.” In this category are the “Lead accumulators”, “Alkaline batteries without mercury” and “Electrolytes of batteries and accumulators collected separately”, all of which must be handled in an appropriate manner.

Within the “Gases in pressure vessels and discarded chemical products” category, there was a series of residues that were dangerous and others that were not. However, all of them are closely related, and it was considered appropriate to create a network with the companies involved in order to manage them properly in case a potential synergy might not be feasible at the time under the current legislation (Table 5). Lastly, due to the high presence of the automotive sector in the industrial zone, a network was created to collect “Used oil and liquid fuel”.

Table 5.

Characteristics of resource networks generated by iNex.

These sort of exchanges in practice will have limited information on resources that have left the boundaries of their organizations, but still are likely to remain in the circularity system as a whole, as indicated by research on IS. This uncertainty is a problem to procure secondary materials as imperfect information limits the value for local CE systems [109]. However, this value creation might be of use to waste management companies seeking out new approaches to transition to new circular business models [110]. These organizations are increasingly interested in creating inter-organisational resource networks to build long term partnerships and take advantage of available knowledge resources such as regional material flows [110]. This task cannot be undertaken by SMEs on their own as it could generate a burden rather than a strategic advantage.

4.2. Second Step: Semi-Structured Interviews

As previously shown, the iNex waste-to-resource software proved that waste-to-resource networks could be created within the area under analysis (IP), providing potential synergies whereby waste and by-products could theoretically be recaptured in other product supply chains Although these sorts of exchanges, including methods and economic and environmental benefits, are very present in the literature, other aspects such as organisational planning are frequently neglected [98,111]. Thus, a potential circular resource use might be enriched by paying attention to how material flows are shaped by and interrelate with non-material flows, namely, different forms of social embeddedness, in order to promote change [112].

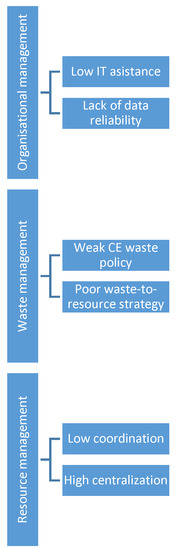

Therefore, a deeper understanding of the ongoing issues within the SMEs that can help facilitate the creation of local circular systems was achieved in this study. This was possible by associating the lack of waste-to-resource exchanges due to technical capacities with the unwillingness to carry out these exchanges. This association was helped by using the ATLAS/ti software, as shown in Figure 3, based on the interviews with the 17 companies located in the IP. As observed, Figure 3 reveals some constraints and challenges that were associated with common topics as a result of the responses provided by the interviewees. In this manner, it was possible to cluster responses to get the overall perspective of companies with regard to a certain issue.

Figure 3.

Clustered responses of the interviewees.

Three groups of answers were clustered according to the responses. The first group “organisational management” refers to the problems related to establishing synergistic relations based on the social dynamics of different actors, which were described as problems with the current administration of the IP with regard to technological assistance and information oversight. According to [111], these organisational management factors could potentially damage formal agreements and therefore, restraining the organisation of new relations in the process of a local circular system. Addressing these issues would certainly help to strengthen organisational management factors towards implementing the CE for secondary materials [22].

The second clustered group “waste management” recognizes the lack of leadership of waste management companies in leading SMEs towards a model where waste is seen as a resource. In comparison, some authors claim that waste management companies should lead the way forward by expanding their role towards new business models around IS as they shift to a more integrated sustainable service in order to create value for their customers [110]. A shift to new business models from waste management companies focusing on the quality of the recovered material instead of the amount of waste processed will be key for the CE [113]. In this second cluster, the absence of clear policies or frameworks to encourage if not enforce the integration of CE principles to harness opportunities in creating synergies among companies was also acknowledged. Although [15] highlight the key role companies played in the creation of a local circular system, they also discuss the role of the institution in creating a level-playing field for industries. Authors such as [114], suggest that this challenge for both businesses and policymakers must be dealt with organisational designs that facilitate the adoption of this strategy as they work with different stakeholders.

The third group of responses clustered as “resource management” points out a low synchronisation in developing guidelines or procedures for managing resources as well as a high centralisation in logistics, which makes it difficult to support the initiation process for resource partnerships in a potential local circular system [108]. In that regard, finding partners to create value will largely depend on the ability of companies to operate under a model of high coordination and low centralization to overcome this challenge [115].

It should be noted that although they were not asked about the problems of the IP, 43% of the interviewees commented that there is a problem with the traffic jams. Some of them also reported that waste management in general could be improved. Now, the companies interviewed are not pursuing any type of collaborative activity with other companies in the IP, but some of them expressed their interest in undertaking activities together, such as goods distribution or joint purchases. Table 6 shows the responses by type of joint action. It was observed that 57% of the companies interviewed distribute their products to local customers, which means that the delivery of products could be done jointly to some degree.

Table 6.

Main interviewees’ responses.

As Table 6 indicates, 21% of companies would be willing to share transport. The majority of the companies reported that they do not want to share transport due to distrust and fear of competition. Thus, working on cooperation from the perspective of behavioural aspects such as trust and reciprocity might encourage companies to advise each other, which is a key aspect in the adoption of a CE model [116]. Moreover, considering that one of the problems of this IP is traffic jams, this could be an opportunity to establish collaboration on delivery. Doing so will create bonding and the confidence to start new circular business models based on knowledge exchange or new business cooperation around a product or waste [85] as proven by [93] wherein SMEs were able to find potential users for their by-products.

Although one of the difficulties in cycling resources, as explained above, is the lack of confidence in the relationship between companies in the IP [98], the high number of companies in the park (306) and their proximity are factors that might facilitate the adoption of a CE system [117]. This would also reduce transportation costs and it might achieve greater collective benefits [27]. Nevertheless, companies’ reluctance as to whether they should engage in a transition is generally grounded in concerns about dependency on partners perceived as unreliable or that the outputs might be of low quality [118,119]. Software like that utilised in this study (iNex software) might improve this condition by providing transparency and traceability of a waste-to-resource approach using IT tools [107].

In that sense, [85] proposed information and communication technology tools to be accepted and used by companies to further their development. By demonstrating that such tools have ‘‘social effectiveness’’, it may stimulate mutual relationships and information exchange, which could strengthen the communicative link among the members of companies. Beyond the perceptions of partners and whether they are willing to engage in synergies as was observed during the interviews, the idea of CE still largely confined to the domain of material flows (Mathews and Tan, 2011).

For example, the key elements that were highlighted throughout the interview process are being addressed to a limited extent in research and industrial applications [120]. Thus, a broader approach to engaging in the transformation to a CE system that goes beyond a merely material exchange would be needed as none of the companies involved in this study have stressed the value that could be generated at this level.

Authors such as [18] have advocated for deeper exploration on circular business models from an organisational transition management approach as little work has been done from this perspective, especially with companies arguing that cost-benefit analyses or risk management are motives for not embarking on such initiatives, as shown in this study. Furthermore, participating in inter-organizational relationships between firm units would allow companies to allocate resources for the CE in order to coordinate and encourage cooperation [18,98]. This high need for coordination coupled with a decentralized control of waste to resource exchanges might help in creating value in symbiotic relations to connect all types of organisations to trade wastes and by-products between each other to accelerate the transition towards CE [107,115]. It might appear that a new approach with managerial implications that adopt new organisational designs could help to tackle these challenges [114]. Therefore, one of the key factors to implementing a CE must be to equally incorporate all the stakeholders, that includes inter-firm cooperation and the expansion of resource sharing [16], which would eventually lead to fewer units of new materials being sourced due to resources flowing back and forth among resource users such as SMEs [21].

5. Conclusions

This study showed that improving the existing resource management practice requires different parts of a system such as stakeholders and technological processes to be integrated into developing a local CE system. The contribution of this study in the form of a case study highlights the difficulties of setting a local CE system with several SMEs involved. Thus, this research explored the features of SMEs to gain a deeper knowledge of potential roles that might support the transition to a CE. To that end, the opportunities for promoting the CE through the adoption of IS as an operational and systematic tool were explored by using the iNex and Atlas/ti software packages to identify such synergies. Software like the one used in this study might help to contribute to inter-organizational resource management. Although the iNex software provided clear evidence for creating a potential inter-organizational resource management practice and therefore, helping to develop a local CE system, the results delivered by the interviews showed that multiple perspectives should be considered. The results of the face-to-face, semi-structured interviews suggest that focusing on individual actors might contribute to the transition to a CE model.

In particular, some of the companies expressed interest in improving some aspects, such as sharing the infrastructure and, in some cases, carrying out joint activities that could contribute to adding value and competitiveness. Thus, it would be necessary to build and encourage a sense of community among the companies since the success of a CE with this focus will be achieved through collaborative relationships.

In this regard, different stakeholders should also take measures to develop a local CE system. A deeper exploration should be carried out to assess how different parties can help to develop this system. One option that was explored in this research is the promotion of secondary markets. However, other aspects that incentivise the search to close the loop must be explored from a broader perspective. Thus, further research should be targeted to exploring how an inter-organisational perspective could foster collaboration in order to develop a CE with the inclusion of a plurality of perspectives that encompasses all stakeholders involved. Surmounting these barriers will create bonding and trust, in order to transition to a CE model.

Finally, the outcomes highlighted in this study illustrate an evident risk in transferring the principles of the CE to real practice in industries through an IS approach. The key findings in this study may help to advance research on inter-organisational coordination which could contribute to the transition to a CE model. Further research must be focused on the particular role of individual stakeholders in this transitioning process to develop local CE systems.

Author Contributions

Conceptualization, C.J. and M.O.; methodology, C.J.; formal analysis, J.R.-M.; investigation, M.O.; data curation, J.R.-M.; writing—original draft preparation, J.R.-M.; writing—review and editing, M.J.Á. Alvarez; supervision, C.J., M.O. and M.J.Á. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation towards the Circular Economy. Ellen MacArthur Found. 2013, 1, 1–96. [CrossRef]

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York City, NY, USA, 2010; ISBN 0865475873. [Google Scholar]

- Graedel, T.E.; Allenby, B.R. Industrial Ecology and Sustainable Engineering; Prentice Hall: Upper Saddle River, NJ, USA, 2010; ISBN 0136008062. [Google Scholar]

- Janine, B. Biomimicry: Innovation Inspired by Nature; Harper Collins: New York, NY, USA, 2002. [Google Scholar]

- Stahel, W. The Performance Economy; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 0230274900. [Google Scholar]

- Lyle, J.T. Regenerative Design for Sustainable Development; John Wiley & Sons: Hoboken, NJ, USA, 1996; ISBN 0471178438. [Google Scholar]

- Martín Gómez, A.M.; Aguayo González, F.; Marcos Bárcena, M. Smart eco-industrial parks: A circular economy implementation based on industrial metabolism. Resour. Conserv. Recycl. 2018, 135, 58–69. [Google Scholar] [CrossRef]

- Saavedra, Y.M.B.; Iritani, D.R.; Pavan, A.L.R.; Ometto, A.R. Theoretical contribution of industrial ecology to circular economy. J. Clean. Prod. 2018, 170, 1514–1522. [Google Scholar] [CrossRef]

- Daddi, T.; Nucci, B.; Iraldo, F. Using Life Cycle Assessment (LCA) to measure the environmental benefits of industrial symbiosis in an industrial cluster of SMEs. J. Clean. Prod. 2017, 147, 157–164. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Millar, N.; McLaughlin, E.; Börger, T. The Circular Economy: Swings and Roundabouts? Ecol. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef]

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—On the implementation of the Circular Economy Action Plan; European Commission: Brussels, Belgium, 2019.

- Hofmann, F.; Jaeger-Erben, M. Organizational transition management of circular business model innovations. Bus. Strategy Environ. 2020, 29, 2770–2788. [Google Scholar] [CrossRef]

- Ghinoi, S.; Silvestri, F.; Steiner, B. The role of local stakeholders in disseminating knowledge for supporting the circular economy: A network analysis approach. Ecol. Econ. 2020, 169, 106446. [Google Scholar] [CrossRef]

- Domenech, T.; Bahn-Walkowiak, B. Transition Towards a Resource Efficient Circular Economy in Europe: Policy Lessons From the EU and the Member States. Ecol. Econ. 2019, 155, 7–19. [Google Scholar] [CrossRef]

- Figge, F.; Thorpe, A.S.; Good, J. Us before me: A group level approach to the circular economy. Ecol. Econ. 2020, 179, 106838. [Google Scholar] [CrossRef]

- De Abreu, M.C.S.; Ceglia, D. On the implementation of a circular economy: The role of institutional capacity-building through industrial symbiosis. Resour. Conserv. Recycl. 2018, 138, 99–109. [Google Scholar] [CrossRef]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Mallawaarachchi, H.; Sandanayake, Y.; Karunasena, G.; Liu, C. Unveiling the conceptual development of industrial symbiosis: Bibliometric analysis. J. Clean. Prod. 2020, 258, 120618. [Google Scholar] [CrossRef]

- Chertow, M.; Ehrenfeld, J. Organizing Self-Organizing Systems: Toward a Theory of Industrial Symbiosis. J. Ind. Ecol. 2012, 16, 13–27. [Google Scholar] [CrossRef]

- Schiller, F.; Penn, A.; Druckman, A.; Basson, L.; Royston, K. Exploring space, exploiting opportunities: The case for analyzing space in industrial ecology. J. Ind. Ecol. 2014, 18, 792–798. [Google Scholar] [CrossRef]

- Chertow, M.R. “Uncovering” Industrial Symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Mulrow, J.S.; Derrible, S.; Ashton, W.S.; Chopra, S.S. Industrial Symbiosis at the Facility Scale. J. Ind. Ecol. 2017, 21, 559–571. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A comprehensive review of industrial symbiosis. J. Clean. Prod. 2019, 247, 119113. [Google Scholar] [CrossRef]

- Bassi, F.; Dias, J.G. The use of circular economy practices in SMEs across the EU. Resour. Conserv. Recycl. 2019, 146, 523–533. [Google Scholar] [CrossRef]

- Lombardi, D.R.; Laybourn, P. Redefining industrial symbiosis: Crossing academic–practitioner boundaries. J. Ind. Ecol. 2012, 16, 28–37. [Google Scholar] [CrossRef]

- Library of Industrial Symbiosis Case Studies and Linked Exchanges. Available online: https://www.repository.cam.ac.uk/handle/1810/267849 (accessed on 12 October 2020).

- Shi, H.; Chertow, M.; Song, Y. Developing country experience with eco-industrial parks: A case study of the Tianjin Economic-Technological Development Area in China. J. Clean. Prod. 2010, 18, 191–199. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects. J. Ind. Ecol. 2006, 10, 239–255. [Google Scholar] [CrossRef]

- Chopra, S.S.; Khanna, V. Understanding resilience in industrial symbiosis networks: Insights from network analysis. J. Environ. Manag. 2014, 141, 86–94. [Google Scholar] [CrossRef]

- Domenech, T.; Davies, M. Structure and morphology of industrial symbiosis networks: The case of Kalundborg. Procedia Soc. Behav. Sci. 2011, 10, 79–89. [Google Scholar] [CrossRef]

- Branson, R. Re-constructing Kalundborg: The reality of bilateral symbiosis and other insights. J. Clean. Prod. 2016, 112, 4344–4352. [Google Scholar] [CrossRef]

- Mirata, M.; Emtairah, T. Industrial symbiosis networks and the contribution to environmental innovation: The case of the Landskrona industrial symbiosis programme. J. Clean. Prod. 2005, 13, 993–1002. [Google Scholar] [CrossRef]

- Baas, L.; Boons, F. The introduction and dissemination of the industrial symbiosis projects in the Rotterdam Harbour and Industry Complex. Int. J. Environ. Technol. Manag. 2007, 7, 551–577. [Google Scholar] [CrossRef]

- Cerceau, J.; Mat, N.; Junqua, G.; Lin, L.; Laforest, V.; Gonzalez, C. Implementing industrial ecology in port cities: International overview of case studies and cross-case analysis. J. Clean. Prod. 2014, 74, 1–16. [Google Scholar] [CrossRef]

- Baas, L. Planning and uncovering industrial symbiosis: Comparing the Rotterdam and Östergötland regions. Bus. Strategy Environ. 2011, 20, 428–440. [Google Scholar] [CrossRef]

- Baas, L.W.; Korevaar, G. Eco-Industrial Parks in the Netherlands: The Rotterdam Harbor and Industry Complex. In Sustainable Development in the Process Industries; Wiley: Hoboken, NJ, USA, 2010; pp. 59–79. [Google Scholar]

- Experiences of Industrial Symbiosis in Italy Proceedings of Conferences Promoted by ENEA at Ecomondo in 2012, 2013 and 2014. Available online: https://www.enea.it/it/seguici/pubblicazioni/pdf-volumi/ExperiencesofIndustrialSymbiosisinItaly_Proceedings.pdf (accessed on 12 October 2020).

- Pakarinen, S.; Mattila, T.; Melanen, M.; Nissinen, A.; Sokka, L. Sustainability and industrial symbiosis—The evolution of a Finnish forest industry complex. Resour. Conserv. Recycl. 2010, 54, 1393–1404. [Google Scholar] [CrossRef]

- Mattila, T.J.; Pakarinen, S.; Sokka, L. Quantifying the Total Environmental Impacts of an Industrial Symbiosis—A Comparison of Process-, Hybrid and Input−Output Life Cycle Assessment. Environ. Sci. Technol. 2010, 44, 4309–4314. [Google Scholar] [CrossRef] [PubMed]

- Sokka, L.; Pakarinen, S.; Melanen, M. Industrial symbiosis contributing to more sustainable energy use—An example from the forest industry in Kymenlaakso, Finland. J. Clean. Prod. 2011, 19, 285–293. [Google Scholar] [CrossRef]

- Simboli, A.; Taddeo, R.; Morgante, A. Analysing the development of Industrial Symbiosis in a motorcycle local industrial network: The role of contextual factors. J. Clean. Prod. 2014, 66, 372–383. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A.; Erkman, S. The Development of Industrial Symbiosis in Existing Contexts. Experiences from Three Italian Clusters. Ecol. Econ. 2017, 139, 55–67. [Google Scholar] [CrossRef]

- Costa, I.; Ferrão, P. A case study of industrial symbiosis development using a middle-out approach. J. Clean. Prod. 2010, 18, 984–992. [Google Scholar] [CrossRef]

- Velenturf, A.P.M. Promoting industrial symbiosis: Empirical observations of low-carbon innovations in the Humber region, UK. J. Clean. Prod. 2016, 128, 116–130. [Google Scholar] [CrossRef]

- Mirata, M. Experiences from early stages of a national industrial symbiosis programme in the UK: Determinants and coordination challenges. J. Clean. Prod. 2004, 12, 967–983. [Google Scholar] [CrossRef]

- van Berkel, R.; Fujita, T.; Hashimoto, S.; Fujii, M. Quantitative assessment of urban and industrial symbiosis in Kawasaki, Japan. Environ. Sci. Technol. 2009, 43, 1271–1281. [Google Scholar] [CrossRef]

- Dong, H.; Ohnishi, S.; Fujita, T.; Geng, Y.; Fujii, M.; Dong, L. Achieving carbon emission reduction through industrial & urban symbiosis: A case of Kawasaki. Energy 2014, 64, 277–286. [Google Scholar] [CrossRef]

- Ohnishi, S.; Dong, H.; Geng, Y.; Fujii, M.; Fujita, T. A comprehensive evaluation on industrial & urban symbiosis by combining MFA, carbon footprint and emergy methods—Case of Kawasaki, Japan. Ecol. Indic. 2017, 73, 513–524. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Progress toward a circular economy in China: The drivers (and inhibitors) of eco-industrial initiative. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, H.; Chen, B.; Yang, N. Social network analysis and network connectedness analysis for industrial symbiotic systems: Model development and case study. Front. Earth Sci. 2013, 7, 169–181. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, H.; Yuan, X.; Zuo, J.; Zhang, J.; Gao, Z.; Hong, J. Investigating vulnerability of ecological industrial symbiosis network based on automatic control theory. Environ. Sci. Pollut. Res. 2018, 25, 27321–27333. [Google Scholar] [CrossRef]

- Shi, L.; Chertow, M. Organizational boundary change in industrial symbiosis: Revisiting the Guitang Group in China. Sustainability 2017, 9, 1085. [Google Scholar] [CrossRef]

- Zhang, X.; Chai, L. Structural features and evolutionary mechanisms of industrial symbiosis networks: Comparable analyses of two different cases. J. Clean. Prod. 2019, 213, 528–539. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, H.; Fath, B.D. Ecological network analysis of an industrial symbiosis system: A case study of the Shandong Lubei eco-industrial park. Ecol. Modell. 2015, 306, 174–184. [Google Scholar] [CrossRef]

- Guo, L.; Hu, X. Green technological trajectories in eco-industrial parks and the selected environment. J. Knowl. Based Innov. China 2011, 3, 54–68. [Google Scholar] [CrossRef]

- Yu, C.; Dijkema, G.P.J.; de Jong, M. What Makes Eco-Transformation of Industrial Parks Take Off in China? J. Ind. Ecol. 2015, 19, 441–456. [Google Scholar] [CrossRef]

- Yu, F.; Han, F.; Cui, Z. Assessment of life cycle environmental benefits of an industrial symbiosis cluster in China. Environ. Sci. Pollut. Res. 2015, 22, 5511–5518. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.; Li, X.; Shi, L.; Qian, Y. Quantifying CO2 emission reduction from industrial symbiosis in integrated steel mills in China. J. Clean. Prod. 2015, 103, 801–810. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, W. Industrial symbiosis management strategy based on flow analysis of industrial solid waste exchange in TEDA, Tianjin—A case study of industrial symbiosis phenomenon in China. In 2011 International Conference on Materials for Renewable Energy & Environment; IEEE: Piscataway, NJ, USA, 2011; Volume 1, pp. 345–349. [Google Scholar]

- Park, J.M. A review of the National Eco-Industrial Park Development Program in Korea: Progress and achievements in the first phase, 2005–2010. J. Clean. Prod. 2015, 30, 1e12. [Google Scholar] [CrossRef]

- Park, J.Y.; Park, H. Securing a competitive advantage through Industrial Symbiosis Development. J. Ind. Ecol. 2014, 18, 677–683. [Google Scholar] [CrossRef]

- Park, H.-S.; Behera, S.K. Methodological aspects of applying eco-efficiency indicators to industrial symbiosis networks. J. Clean. Prod. 2014, 64, 478–485. [Google Scholar] [CrossRef]

- Kim, H.; Ohnishi, S.; Fujii, M.; Fujita, T.; Park, H. Evaluation and allocation of greenhouse gas reductions in industrial symbiosis. J. Ind. Ecol. 2018, 22, 275–287. [Google Scholar] [CrossRef]

- Behera, S.K.; Kim, J.-H.; Lee, S.-Y.; Suh, S.; Park, H.-S. Evolution of ‘designed’ industrial symbiosis networks in the Ulsan Eco-industrial Park: ‘research and development into business’ as the enabling framework. J. Clean. Prod. 2012, 29–30, 103–112. [Google Scholar] [CrossRef]

- Chertow, M.R.; Ashton, W.S.; Espinosa, J.C. Industrial Symbiosis in Puerto Rico: Environmentally Related Agglomeration Economies. Reg. Stud. 2008, 42, 1299–1312. [Google Scholar] [CrossRef]

- Ashton, W.S. The structure, function, and evolution of a regional industrial ecosystem. J. Ind. Ecol. 2009, 13, 228–246. [Google Scholar] [CrossRef]

- Ashton, W.S. Managing performance expectations of industrial symbiosis. Bus. Strategy Environ. 2011, 20, 297–309. [Google Scholar] [CrossRef]

- Ashton, W. Understanding the organization of industrial ecosystems: A social network approach. J. Ind. Ecol. 2008, 12, 34–51. [Google Scholar] [CrossRef]

- Ashton, W.S.; Bain, A.C. Assessing the “short mental distance” in eco-industrial networks. J. Ind. Ecol. 2012, 16, 70–82. [Google Scholar] [CrossRef]

- Bain, A.; Shenoy, M.; Ashton, W.; Chertow, M. Industrial symbiosis and waste recovery in an Indian industrial area. Resour. Conserv. Recycl. 2010, 54, 1278–1287. [Google Scholar] [CrossRef]

- Bain, A.; Ashton, W.; Shenoy, M. Resource reuse and recycling in an Indian industrial network: Efficiency and flexibility considerations. In 2009 Second International Conference on Infrastructure Systems and Services: Developing 21st Century Infrastructure Networks (INFRA); IEEE: Piscataway, NJ, USA, 2009; pp. 1–7. [Google Scholar]

- Van Beers, D.; Bossilkov, A.; Corder, G.; Van Berkel, R. Industrial symbiosis in the Australian minerals industry: The cases of Kwinana and Gladstone. J. Ind. Ecol. 2007, 11, 55–72. [Google Scholar] [CrossRef]

- MacLachlan, I. Kwinana Industrial Area: Agglomeration economies and industrial symbiosis on Western Australia’s Cockburn Sound. Aust. Geogr. 2013, 44, 383–400. [Google Scholar] [CrossRef]

- Harris, S. Industrial symbiosis in the Kwinana industrial area (Western Australia). Meas. Control 2007, 40, 239–244. [Google Scholar] [CrossRef]

- de Ferreira, I.A.; de Fraga, M.C.; Godina, R.; Barreiros, M.S.; Carvalho, H. A proposed index of the implementation and maturity of circular economy practices-the case of the pulp and paper industries of Portugal and Spain. Sustainability 2019, 11, 1722. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Pimentel, C.; Matias, J.C.O. The Potential of Industrial Symbiosis: Case Analysis and Main Drivers and Barriers to Its Implementation. Sustainability 2019, 11, 7095. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Álvarez, R.; Ruiz-Puente, C. Development of the Tool SymbioSyS to Support the Transition towards a Circular Economy Based on Industrial Symbiosis Strategies. Waste Biomass Valori. 2017, 8, 1521–1530. [Google Scholar] [CrossRef]

- Puente, M.C.R.; Arozamena, E.R.; Evans, S. Industrial symbiosis opportunities for small and medium sized enterprises: Preliminary study in the Besaya region (Cantabria, Northern Spain). J. Clean. Prod. 2015, 87, 357–374. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H.; Hu, M.C. Moving to a Circular Economy in China: Transforming Industrial Parks into Eco-industrial Parks. Calif. Manag. Rev. 2018, 60, 157–181. [Google Scholar] [CrossRef]

- Liu, Z.; Adams, M.; Cote, R.P.; Geng, Y.; Li, Y. Comparative study on the pathways of industrial parks towards sustainable development between China and Canada. Resour. Conserv. Recycl. 2018, 128, 417–425. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular Economy Rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- McDowall, W.; Geng, Y.; Huang, B.; Barteková, E.; Bleischwitz, R.; Türkeli, S.; Kemp, R.; Doménech, T. Circular Economy Policies in China and Europe. J. Ind. Ecol. 2017, 21, 651–661. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2015.

- Llorente-González, L.J.; Vence, X. Decoupling or “decaffing”? The underlying conceptualization of circular economy in the European union monitoring framework. Sustainability 2019, 11, 4898. [Google Scholar] [CrossRef]

- Patricio, J.; Axelsson, L.; Blomé, S.; Rosado, L. Enabling industrial symbiosis collaborations between SMEs from a regional perspective. J. Clean. Prod. 2018, 202, 1120–1130. [Google Scholar] [CrossRef]

- Ormazabal, M.; Puga-Leal, R. An exploratory study of UK companies’ taxonomy based on environmental drivers. J. Clean. Prod. 2016, 133, 479–486. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and Its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Santos, J.; Baumgartner, R.J.; Ormazabal, M. Key strategies, resources, and capabilities for implementing circular economy in industrial small and medium enterprises. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 1473–1484. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A. Implementing eco-industrial parks in existing clusters. Findings from a historical Italian chemical site. J. Clean. Prod. 2012, 33, 22–29. [Google Scholar] [CrossRef]

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ. Environ. 2015, 28, 32–53. [Google Scholar] [CrossRef]

- Ketokivi, M.; Choi, T. Renaissance of case research as a scientific method. J. Oper. Manag. 2014, 32, 232–240. [Google Scholar] [CrossRef]

- Charmaz, K.; Liska, L. Grounded theory. Qual. Res. Heal. Sci. Methodol. Methods Process. 2013, 9780203777, 30–55. [Google Scholar] [CrossRef]

- Bierly, P.E., III; Daly, P.S. Alternative knowledge strategies, competitive environment, and organizational performance in small manufacturing firms. Entrep. Theory Pract. 2007, 31, 493–516. [Google Scholar] [CrossRef]

- Charmaz, K. Constructing Grounded Theory: A Practical Guide through Qualitative Analysis; SAGE: Newbury Park, CA, 2006; ISBN 144620040X. [Google Scholar]

- DiCicco-Bloom, B.; Crabree, B.F. The qualitative research interview. Qual. Res. Account. Manag. 2006, 40, 314–321. [Google Scholar] [CrossRef]

- Albino, V.; Fraccascia, L.; Giannoccaro, I. Exploring the role of contracts to support the emergence of self-organized industrial symbiosis networks: An agent-based simulation study. J. Clean. Prod. 2016, 112, 4353–4366. [Google Scholar] [CrossRef]

- Yazan, D.M.; Romano, V.A.; Albino, V. The design of industrial symbiosis: An input–output approach. J. Clean. Prod. 2016, 129, 537–547. [Google Scholar] [CrossRef]

- Fraccascia, L.; Yazan, D.M. The role of online information-sharing platforms on the performance of industrial symbiosis networks. Resour. Conserv. Recycl. 2018, 136, 473–485. [Google Scholar] [CrossRef]

- Kerdlap, P.; Low, J.S.C.; Ramakrishna, S. Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour. Conserv. Recycl. 2019, 151, 104438. [Google Scholar] [CrossRef]

- Velenturf, A.P.M. Initiating resource partnerships for industrial symbiosis. Reg. Stud. Reg. Sci. 2017, 4, 117–124. [Google Scholar] [CrossRef]

- Figge, F.; Thorpe, A.S. The symbiotic rebound effect in the circular economy. Ecol. Econ. 2019, 163, 61–69. [Google Scholar] [CrossRef]

- Aid, G.; Eklund, M.; Anderberg, S.; Baas, L. Expanding roles for the Swedish waste management sector in inter-organizational resource management. Resour. Conserv. Recycl. 2017, 124, 85–97. [Google Scholar] [CrossRef]

- Mortensen, L.; Kørnøv, L. Critical factors for industrial symbiosis emergence process. J. Clean. Prod. 2019, 212, 56–69. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Esposito, M.; Tse, T.; Soufani, K. Introducing a Circular Economy: New Thinking with New Managerial and Policy Implications. Calif. Manag. Rev. 2018, 60, 5–19. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Business models for industrial symbiosis: A taxonomy focused on the form of governance. Resour. Conserv. Recycl. 2019, 146, 114–126. [Google Scholar] [CrossRef]

- Doménech, T.; Davies, M. The role of embeddedness in industrial symbiosis networks: Phases in the evolution of industrial symbiosis networks. Bus. Strategy Environ. 2011, 20, 281–296. [Google Scholar] [CrossRef]

- Boons, F.; Chertow, M.; Park, J.; Spekkink, W.; Shi, H. Industrial Symbiosis Dynamics and the Problem of Equivalence: Proposal for a Comparative Framework. J. Ind. Ecol. 2017, 21, 938–952. [Google Scholar] [CrossRef]

- Miller, V.V.; Mukherji, A. Music: A metaphor for industrial ecology. Prog. Ind. Ecol. an Int. J. 2010, 7, 239–256. [Google Scholar] [CrossRef]

- Levänen, J.O.; Hukkinen, J.I. A methodology for facilitating the feedback between mental models and institutional change in industrial ecosystem governance: A waste management case-study from northern Finland. Ecol. Econ. 2013, 87, 15–23. [Google Scholar] [CrossRef]

- Holgado, M.; Benedetti, M.; Evans, S.; Baptista, A.J.; Lourenço, E.J. Industrial Symbiosis Implementation by Leveraging on Process Efficiency Methodologies. Procedia CIRP 2018, 69, 872–877. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).