A Critical Review of Academic Approaches, Methods and Tools to Assess Circular Economy at the Micro Level

Abstract

:1. Introduction

2. Overview of the Research Context

3. Materials and Methods

3.1. Clarification of Core Concepts

3.2. Systematic Literature Review

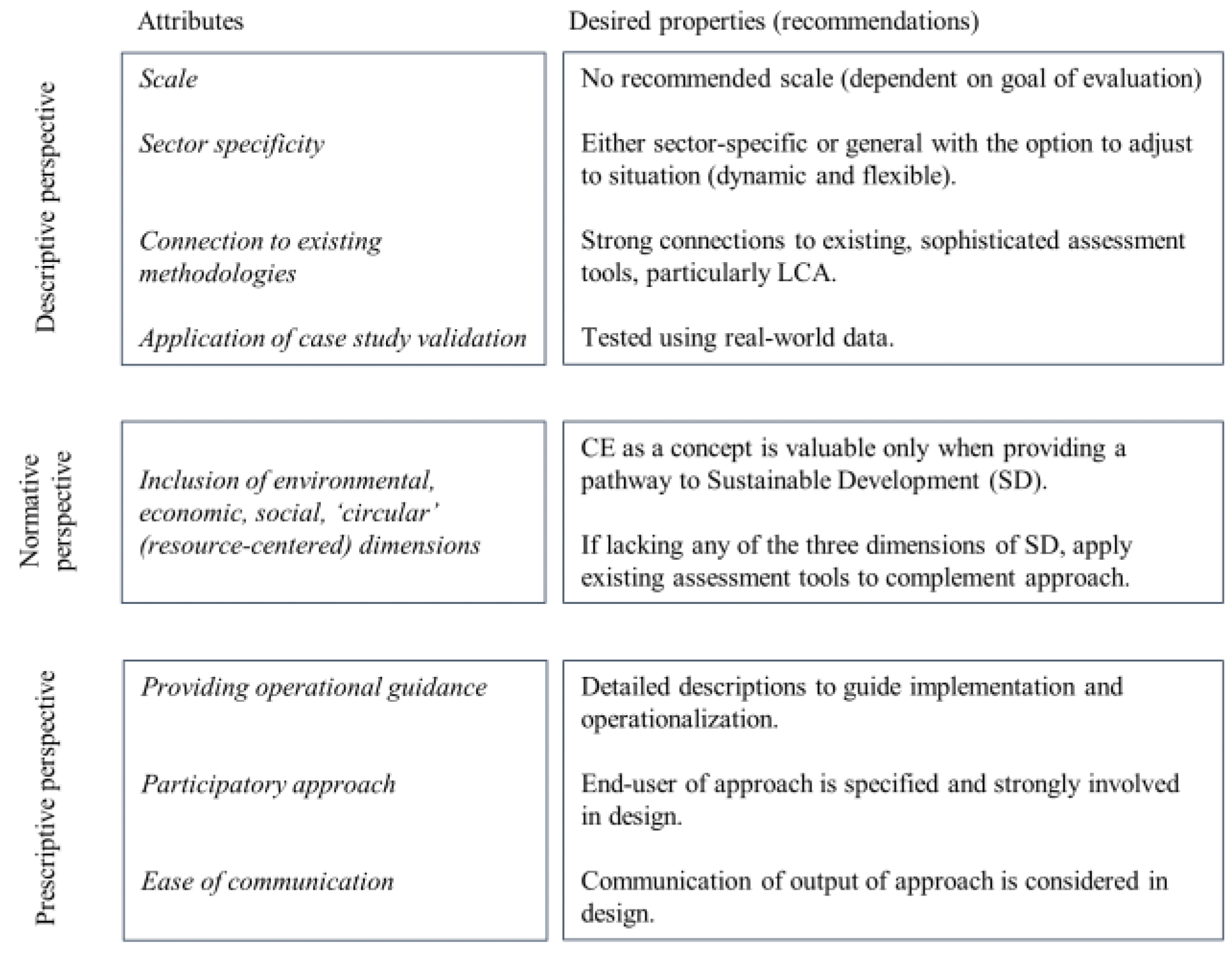

3.3. The Critical Review Framework

- (i)

- General perspective—the first perspective contains the general characteristics of the inventoried approaches.

- (ii)

- Descriptive perspective: Methodological connections—according to Reference [40], descriptive analysis engages with what has happened in the past to better understand current phenomena. The question becomes: ‘How has research constructed previous approaches to assess CE?’ This leads to evaluating the following methodological traits:

- Scale of assessment—the micro scale of evaluation still contains a variety of sub-scales, and no scientific consensus on its definition exists. The entire range of categories of different micro level scales of assessment has been included in the review.

- Sector specificity—since product- and firm heterogeneity appear not to have been addressed in detail in literature, sector specificity has been included as an element of interest in the descriptive dimension of the critical review framework. The type of sector was analyzed as well.

- Connection to existing methodologies (LCA/MFA/input-output analyses)—it will be valuable to explore how decades of knowledge on sustainability quantification, resulting in the development of widely used tools, are exhibited in newly introduced concepts such as CE. Therefore, the connections between CE assessment and LCA, S-LCA, LCC, MFA, and input–output analysis have been included. These methods were later completed by frequently occurring underlying methods that were used in combination with other methods (i.e., MCI).

- Case study and validation—to test the practical application of their proposed approaches, authors use case studies as a source for input data. The inventoried publications were screened for the application of a validation approach using case study data.

- (iii)

- Normative perspective: SD as the end goal of CE—reference [40] describe a normative model as “(…) an abstract system that attempts to capture how ideal people behave” (p. 17). In stakeholder theory, the concept of a ‘normative core’ has been described as explicitly moral, and an effort to answer questions such as: ‘What is the purpose of the firm?’ [41]. In the context of CE assessment, this results in the question: ‘What should the ideal outcome of applying CE be for the concept to be valuable?’ The concept of CE is here interpreted to be valuable only when providing a pathway to SD (see Section 2). Hereby, this study intends to address (valid) criticisms of CE that state that resource-efficiency measures do not lead to sustainable outcomes per se (see e.g., [21]). The present research refers to the model of sustainable development cited in [8], proposing SD indicators in the environmental, economic, and social domain. When other dimensions are included, it is checked whether these belong to any of these categories or are more suited to the separate ‘circular’ dimension, which could be seen as a box containing any resource-efficiency related dimensions.

- (iv)

- Prescriptive perspective: Participatory design and questions of implementation—lastly, reference [40] introduces the prescriptive decision-making model. This model addresses the question: “What should an individual do to make better choices? What modes of thought, decision aids, conceptual schemes are useful—useful not for idealized, mythical, de-psychologized automate—but for real people?” (p. 17). A very practical perspective that incorporates human—and organizational—limitations emerges. Three implementation-oriented prescriptive attributes are considered: The presence of providing operational guidance is assessed through using the search terms ‘implementation’, ‘practitioner’, ‘operational’, and ‘application’. The application of a participatory approach was assessed in three steps: (1) By reviewing whether the intended end-user of the approach is mentioned, (2) if so, what the characteristics of these end-users are, and (3) whether end-users were involved in the design of the proposed approach. The authors’ consideration of ease of communication is evaluated through searching for ‘simplicity’ and ‘communication’, ‘user friendly’, ‘intuitive’, and ‘visualization’.

4. Results

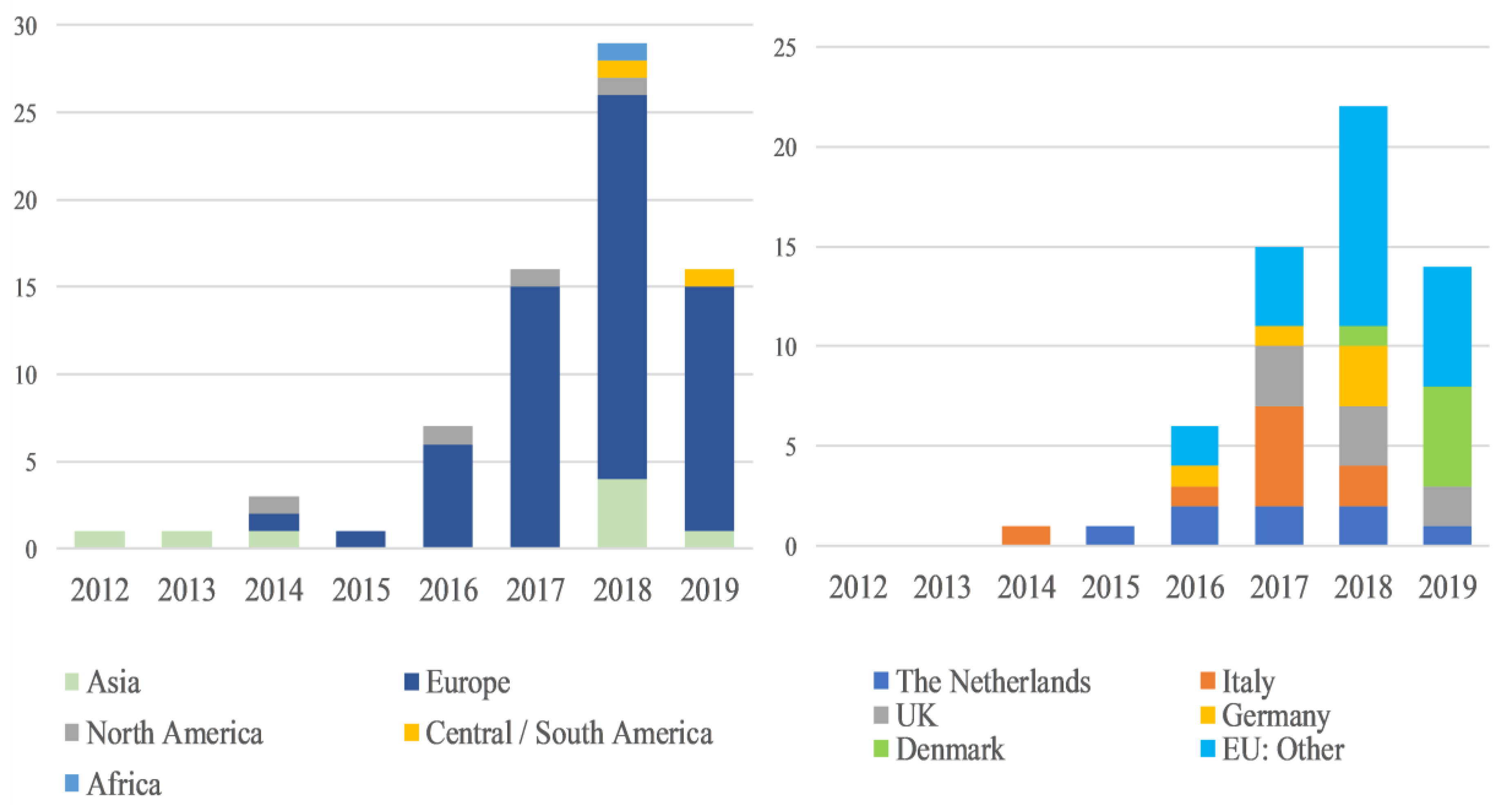

4.1. General Attributes

4.2. Descriptive Perspective: Methodological Attributes

4.3. Normative Perspective: SD as the End Goal of CE

4.4. Prescriptive Perspective: Participatory Construction and Questions of Implementation

5. Critical Reflection and Suggested Key Desired Properties

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Reference | Name Approach | Scale | Sector Specific | Connection to Methods | Case Study | Number of SD Dimensions/CE Dimension Included | Provides Operational Guidance | Intended End-User | Ease of Communication | Participatory |

|---|---|---|---|---|---|---|---|---|---|---|

| [101] | N/A | Various | No | No | No | 0/Yes | No | N/A | No | No |

| [71] | PR-MCDT | Product | No | No | Yes | 3/Yes | Yes | Managers | No | Yes |

| [102] | CPA (and CPI) | Product | No | No | Yes | 0/Yes | No | N/A | No | No |

| [89] | REAPro | Product | No | Yes, LCA | Yes | 1/Yes | Yes | Various | No | No |

| [72] | SCI | Company | No | Yes, MCI | No | 3/Yes | Yes | Managers | Yes | No |

| [94] | e-BEP | Business model | No | Yes, LCA | Yes | 1/No | Yes | Other | Yes | Yes |

| [73] | N/A | Business model | No | No | Yes | 3/Yes | Yes | Various | Yes | Yes |

| [43] | N/A | Product | Yes | Yes, ISO 22628, UNIFE (MRF/ERF) | Yes | 0/Yes | No | Various | No | No |

| [52] | N/A | Other | No | Yes, LCA, LCC, S-LCA | Yes | 3/Yes | No | Designers | No | No |

| [65] | N/A | Supply chain | No | No | Yes | 0/Yes | No | (Specific) companies | No | No |

| [74] | N/A | Company | No | Yes, LCA | Yes | 3/Yes | No | Managers | No | Yes |

| [98] | CEIP | Product | No | No | Yes | 0/Yes | No | (Specific) companies | Yes | Yes |

| [103] | N/A | Business model | No | No | No | 0/Yes | No | N/A | No | Yes |

| [53] | CI | Plant/installation | Yes | Yes, LCA, MFA, multi-objective optimization | Yes | 0/Yes | No | Policy makers | No | Yes |

| [84] | N/A | Product | Yes | Yes, LCA | No | 1/Yes | No | N/A | No | No |

| [104] | CEV | Other | No | Yes, MCI and the Korse model | Yes | 0/Yes | No | N/A | No | No |

| [75] | N/A | Business model | No | No | No | 3/Yes | No | N/A | No | No |

| [96] | CEI/KRI | Product | Yes | No | Yes | 1/Yes | No | Policy makers | No | No |

| [97] | VRE | Other | No | No | Yes | 1/No | No | Policy makers | Yes | No |

| [92] | Various | Various scales | No | Yes, LCA | No | 1/No | No | N/A | No | No |

| [83] | Environmental-economic assessment | Other | No | Yes, LCA | Yes | 2/No | No | N/A | No | No |

| [68] | RSI | Company | Yes | Yes, LCA | No | 3/Yes | No | N/A | Yes | No |

| [81] | N/A | Product | No | No | Yes | 2/Yes | No | Designers | No | No |

| [105] | N/A | Company | No | No | Yes | 0/Yes | No | Various | No | No |

| [100] | Repairability Indicator | Product | Yes | No | Yes | 0/Yes | No | Other | No | Yes |

| [106] | CEV | Other | No | No | Yes | 0/Yes | No | N/A | No | No |

| [107] | N/A | Product | No | No | No | 0/Yes | No | Various | No | No |

| [108] | Longevity indicator | Product | No | Yes, MFA | Yes | 0/Yes | No | Managers | No | No |

| [54] | N/A | Other | Yes | Yes, LCA, LCC | Yes | 2/No | No | Designers | No | No |

| [55] | LCA, SLCA, LCC and CBM | Business model | No | Yes, LCA, LCC, S-LCA | Yes | 3/No | Yes | Managers | Yes | No |

| [76] | CMT | Company | No | No | Yes | 3/Yes | Yes | N/A | No | No |

| [45] | Hybrid LCA | Supply chain | No | Yes, LCA, EIO | Yes | 1/Yes | No | Policy makers | No | No |

| [47] | N/A | Product | Yes | Yes, ‘Streamlined’ LCA | Yes | 1/Yes | No | N/A | No | No |

| [44] | N/A | Supply chain | Yes and No | Yes, Fuzzy Cognitive Mapping | Yes | 3/Yes | No | Policy makers | No | No |

| [48] | N/A | Material | Yes | Yes, CED | No | 1/Yes | Yes | Designers | No | No |

| [109] | N/A | Company | No | No | No | 0/Yes | Yes | Companies | No | No |

| [56] | RBR | Material | Yes | Yes, LCA, RBR, RCBR | Yes | 1/No | No | N/A | No | No |

| [69] | N/A | Business model | Yes | Yes, LCA | Yes | 3/Yes | No | Companies | No | No |

| [70] | N/A | Product | Yes | No | Yes | 3/Yes | No | Other | No | No |

| [77] | N/A | Supply chain | No | Yes, LCA | No | 3/Yes | Yes | Various | No | No |

| [57] | N/A | Plant/installation | Yes | Yes, LCA, MFA | Yes | 0/Yes | No | Various | No | No |

| [110] | N/A | Business model | No | No | Yes | 0/Yes | No | Other | No | No |

| [58] | N/A | Other | No | Yes, LCA, MFA, CTA, I/O analysis, LCC, CBA | Yes | 3/Yes | No | Other | No | No |

| [78] | N/A | Company | No | No | No | 3/Yes | No | Decision makers | No | No |

| [66] | N/A | Business model | No | No | Yes | 3/Yes | No | Companies | No | No |

| [62] | PWF | Product | No | Yes, LCA | Yes | 0/Yes | No | Other | Yes | No |

| [82] | N/A | Product | No | No | Yes | 2/Yes | No | Designers | Yes | Yes |

| [85] | CE Evaluation Index System | Company | Yes | Yes, QUALIFLEX & VIKOR | Yes | 1/Yes | No | Decision makers | No | No |

| [93] | EnvPack | Packaging | Yes | Yes, LCA | Yes | 1/No | No | Various | No | No |

| [13] | Product-level circularity | Product | No | No | Yes | 1/No | No | N/A | No | No |

| [95] | EVPT (Environmental Value Propositions Table) + step-by-step evaluation. | Business model | No | Yes, LCA | Yes | 1/No | Yes | Companies | No | No |

| [51] | N/A | Business model | No | No | Yes | 0/Yes | No | Various | No | No |

| [111] | N/A | Product | No | Yes, LFI by EMF | Yes | 0/Yes | Yes | Various | No | Yes |

| [15] | MRS, MCI, LCA, MDCDA | Packaging | Yes | Yes¸ LCA, MRS and MCI | Yes | 1/Yes | No | N/A | No | No |

| [80] | N/A | Supply chain | Yes | Yes, Fuzzy set theory | Yes | 2/Yes | No | Decision makers | Yes | Yes |

| [112] | Reuse potential | Material | No | No | Yes | 0/Yes | No | Various | Yes | No |

| [86] | N/A | Packaging | Yes | Yes, LCA | No | 1/Yes | No | Designers | No | No |

| [59] | Dashboard of quantitative system indicators | Company | No | Yes, LCA, MFA, LCC, S-LCA | No | 3/Yes | Yes | N/A | No | No |

| [113] | N/A | Company | No | No | No | 0/No | Yes | (Specific) companies | Yes | Yes |

| [46] | LCA and MFCA | Company | No | Yes, LCA, MFCA | Yes | 2/No | Yes | Various | Yes | Yes |

| [67] | N/A | Company | No | No | Yes | 3/Yes | No | Companies | Yes | Yes |

| [99] | Hybrid top-down and bottom-up framework | Product | No | No | Yes | 0/No | Yes | Other | Yes | Yes |

| [90] | EVR & CTF | Business model | No | Yes, LCA | Yes | 1/Yes | No | N/A | No | No |

| [87] | N/A | Packaging | Yes | Yes, LCA | Yes | 1/Yes | No | Various | No | Yes |

| [42] | E-factor, PMI, RME, LCA | Product | Yes | Yes, LCA, E-factor | Yes | 1/Yes | No | N/A | No | No |

| [88] | N/A | Supply chain | No | Yes, Fuzzy set theory | Yes | 1/Yes | Yes | Decision makers | No | No |

| [64] | QC | Material | No | No | Yes | 0/Yes | No | Various | No | No |

| [50] | RDI | Product | No | Yes, MSI, TRL | Yes | 1/Yes | No | Various | No | Yes |

| [114] | RI | Product | No | No | Yes | 0/Yes | No | Various | Yes | No |

| [60] | N/A | Plant/installation | Yes | Yes, LCA, NPV, IRR, questionnaire on stakeholder perception | Yes | 3/No | No | Policy makers | No | Yes |

| [63] | eDIM | Product | No | No | Yes | 0/Yes | Yes | Policy makers | Yes | No |

| [79] | ‘Expanded Zero Waste’ | Various scales | No | Yes, LCA | No | 3/Yes | No | N/A | No | No |

| [61] | Building Circularity Indicator | Other | Yes | Yes, LCA, EPD | Yes | 2/Yes | No | N/A | No | Yes |

| [91] | N/A | Other | No | Yes, LCA | Yes | 1/No | No | (Specific) Companies | No | Yes |

References

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm. J. Clean. Prod. 2017. [Google Scholar] [CrossRef] [Green Version]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation (EMF). Circular Economy—Towards the Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Cullen, J.M. Circular Economy: Theoretical Benchmark or Perpetual Motion Machine? J. Ind. Eco. 2017, 21, 483–486. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Azapagic, A.; Perdan, S. Indicators of sustainable development for industry: A general framework. Process Saf. Environ. Prot. 2000, 78, 243–261. [Google Scholar] [CrossRef]

- Malovics, G.; Nagypal Csigene, N.; Kraus, S. The role of corporate social responsibility in strong sustainability. J. Behav. and Exp. Econ. 2008, 37, 907–918. [Google Scholar] [CrossRef]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- EEA. Circular economy in Europe. Developing the knowledge base. Eur. Environ. Agency 2016. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef] [Green Version]

- Linder, M.; Sarasini, S.; van Loon, P. A Metric for Quantifying Product-Level Circularity. J. Ind. Eco. 2017, 21, 545–558. [Google Scholar] [CrossRef] [Green Version]

- Tecchio, P.; McAlister, C.; Mathieux, F.; Ardente, F. In search of standards to support circularity in product policies: A systematic approach. J. Clean. Prod. 2017, 168, 1533–1546. [Google Scholar] [CrossRef] [PubMed]

- Niero, M.; Kalbar, P.P. Coupling material circularity indicators and life cycle based indicators: A proposal to advance the assessment of circular economy strategies at the product level. Resour. Conserv. Recycl. 2019, 140, 305–312. [Google Scholar] [CrossRef]

- Cristoni, N.; Tonelli, M. Perceptions of Firms Participating in a Circular Economy. Eur. J. Sust. Dev. 2018, 7, 105–118. [Google Scholar] [CrossRef] [Green Version]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sust. En. Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Bruel, A.; Kronenberg, J.; Troussier, N.; Guillaume, B. Linking Industrial Ecology and Ecological Economics: A Theoretical and Empirical Foundation for the Circular Economy. J. Ind. Ecol. 2018, 23, 12–21. [Google Scholar] [CrossRef] [Green Version]

- Millar, N.; McLaughlin, E.; Börger, T. The Circular Economy: Swings and Roundabouts? Eco. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef] [Green Version]

- Corona, B.; Shen, L.; Reike, D.; Carreón, J.R.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy—moving away from the three dimensions of sustainability. J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; De Pauw, I.; Bakker, C.; Van Der Grinten, B.; Bocken, N.M.P.; De Pauw, I.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 1015, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Zielińska, A. Comparative Analysis of Circular Economy Implementation in Poland and other European Union Countries. J. Int. Studies 2019, 12, 337–347. [Google Scholar] [CrossRef] [Green Version]

- Hirsch, P.M.; Levin, D.Z. Umbrella Advocates Versus Validity Police: A Life-Cycle Model. Org. Sci. 1999, 10, 199–212. [Google Scholar] [CrossRef]

- Parchomenko, A.; Nelen, D.; Gillabel, J.; Rechberger, H. Measuring the circular economy—A Multiple Correspondence Analysis of 63 metrics. J. Clean. Prod. 2019, 210, 200–216. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Keeble, J.J.; Berkeley, S. Using indicators to measure sustainability. J. Business Ethics 2003, 44, 149–158. [Google Scholar] [CrossRef]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Clean. Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- Dopfer, K.; Foster, J.; Potts, J. Micro-meso-macro. J. Evol. Econ. 2004, 14, 263–279. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving ‘leapfrog development’. Int. J. Sust. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef] [Green Version]

- British Standardisation Institute. Framework for Implementing the Principles of the Circular Economy in Organizations (BSI No. 8001:2017); 2017; Available online: https://www.bsigroup.com/en-GB/standards/benefits-of-using-standards/becoming-more-sustainable-with-standards/BS8001-Circular-Economy/ (accessed on 10 April 2020).

- AFNOR. Circular Economy Project Management System—Requirements and Guidelines (XP X30-901). 2018. Available online: https://www.boutique.afnor.org (accessed on 20 February 2020).

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recyc. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Wohlin, C. Guidelines for Snowballing in Systematic Literature Studies and a Replication in Software Engineering. Ease ‘14 Proc. 18th Int. Conf. Environ. Assess. Softw. Eng. 2014, 38, 1–10. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation and Granta Design. Circularity Indicators: An Approach to Measuring Circularity—product overview. Ellen Macarthur Found. 2015, 1–10. [Google Scholar] [CrossRef]

- Bell, S.; Morse, S. Breaking through the glass ceiling: Who really cares about sustainability indicators? Local Environ. 2001, 6, 291–309. [Google Scholar] [CrossRef]

- Parmar, B.L.; Freeman, R.E.; Harrison, J.S.; Wicks, A.C.; Parmar, B.; de Colle, S. Stakeholder theory: The state of the art. Stakehold. Theory State Art 2010, 4, 1–343. [Google Scholar] [CrossRef]

- Sheldon, R.A. Metrics of Green Chemistry and Sustainability: Past, Present, and Future. ACS Sust. Chem. Eng. 2018, 6, 32–48. [Google Scholar] [CrossRef] [Green Version]

- Berzi, L.; Delogu, M.; Pierini, M.; Romoli, F. Evaluation of the end-of-life performance of a hybrid scooter with the application of recyclability and recoverability assessment methods. Resour. Conserv. Recyc. 2016, 108, 140–155. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Tornese, F.; Thorn, B.; LCarrano, A.; Pazour, J. A Measurement Tool for Circular Economy Practices: A Case Study in Pallet Supply Chains. 15th IMHRC Proceedings—Progress in Material Handling Research. 2018. Available online: https://digitalcommons.georgiasouthern.edu/pmhr_2018 (accessed on 4 December 2019).

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Rieckhof, R.; Guenther, E. Integrating life cycle assessment and material flow cost accounting to account for resource productivity and economic-environmental performance. Int. J. LCA 2018, 23, 1491–1506. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Mossa, G.; Mummolo, G.; Tornese, F.; Verriello, R. Circular economy strategies for electric and electronic equipment: A fuzzy cognitive map. Environ. Eng. Mgmt. J. 2017, 16, 1807–1818. [Google Scholar]

- Hildebrandt, J.; Bezama, A.; Thrän, D. Cascade use indicators for selected biopolymers: Are we aiming for the right solutions in the design for recycling of bio-based polymers? Waste Mgmt. Res. 2017, 35, 367–378. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Road Vehicles—Recyclability and Recoverability—Calculation Method; (ISO No. 22628:2002); 2018; Available online: https://www.iso.org/standard/35061.html (accessed on 2 February 2020).

- Sultan, A.A.M.; Lou, E.; Mativenga, P.T. What should be recycled: An integrated model for product recycling desirability. J. Clean. Prod. 2017, 154, 51–60. [Google Scholar] [CrossRef]

- Matschewsky, J. Unintended circularity? Assessing a product-service system for its potential contribution to a circular economy. Sustainability 2019, 11, 2725. [Google Scholar] [CrossRef] [Green Version]

- Bradley, R.; Jawahir, I.S.; Badurdeen, F.; Rouch, K. A Framework for Material Selection in Multi-Generational Components: Sustainable Value Creation for a Circular Economy. Procedia Cirp 2016, 48, 370–375. [Google Scholar] [CrossRef] [Green Version]

- Cobo, S.; Dominguez-Ramos, A.; Irabien, A. Trade-Offs between Nutrient Circularity and Environmental Impacts in the Management of Organic Waste. Environ. Sci. Technol. 2018, 52, 10923–10933. [Google Scholar] [CrossRef] [Green Version]

- Fregonara, E.; Giordano, R.; Ferrando, D.G.; Pattono, S. Economic-Environmental Indicators to Support Investment Decisions: A Focus on the Buildings’ End-of-Life Stage. Buildings 2017, 7, 65. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Muiña, F.; González-Sánchez, R.; Ferrari, A.; Settembre-Blundo, D. The Paradigms of Industry 4.0 and Circular Economy as Enabling Drivers for the Competitiveness of Businesses and Territories: The Case of an Italian Ceramic Tiles Manufacturing Company. Soc. Sci. 2018, 7, 255. [Google Scholar] [CrossRef] [Green Version]

- Huysveld, S.; Hubo, S.; Ragaert, K.; Dewulf, J. Advancing circular economy benefit indicators and application on open-loop recycling of mixed and contaminated plastic waste fractions. J. Clean. Prod. 2019, 211, 1–13. [Google Scholar] [CrossRef]

- Kiselev, A.V.; Magaril, E.R.; Rada, E.C. Energy and Sustainability Assessment of Municipal Wastewater Treatment Under Circular Economy Paradigm. Energy Sust. VIII 2019, 1, 109–120. [Google Scholar] [CrossRef] [Green Version]

- Koch, R.; Kuindersma, P.; van Harmelen, T.; Keijzer, E.; Kootstra, L.; Verstraeten-Jochemsen, J. IMPACT: A Tool for R&D Management of Circular Economy Innovations. Procedia Cirp 2018, 69, 769–774. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resours Conserv. Recyc. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Styles, D.; Prade, T.; Gunnarsson, I.; Thelin, G.; D’Hertefeldt, T.; Rodhe, L. Closing nutrient loops through decentralized anaerobic digestion of organic residues in agricultural regions: A multi-dimensional sustainability assessment. Resour. Conserv. Recyc. 2018, 136, 110–117. [Google Scholar] [CrossRef] [Green Version]

- Verberne, J.J.H. Building Circularity Indicators—An Approach for Measuring Circularity of a Building. 2016. Available online: https://pure.tue.nl/ws/files/46934924/846733-1.pdf (accessed on 23 November 2019).

- Laurenti, R.; Martin, M.; Stenmarck, Å. Developing Adequate Communication of Waste Footprints of Products for a Circular Economy—A Stakeholder Consultation. Resources 2018, 7, 78. [Google Scholar] [CrossRef] [Green Version]

- Vanegas, P.; Peeters, J.R.; Cattrysse, D.; Tecchio, P.; Ardente, F.; Mathieux, F.; Duflou, J.R. Ease of disassembly of products to support circular economy strategies. Resour. Conserv. Recyc. 2018, 135, 323–334. [Google Scholar] [CrossRef] [PubMed]

- Steinmann, Z.J.N.; Huijbregts, M.A.J.; Reijnders, L. How to define the quality of materials in a circular economy. Resour. Conserv. Recyc. 2019, 141, 362–363. [Google Scholar] [CrossRef]

- Braun, A.T.; Kleine-Moellhoff, P.; Reichenberger, V.; Seiter, S. Case study analysing potentials to improve material efficiency in manufacturing supply chains, considering circular economy aspects. Sustainability 2018, 10, 880. [Google Scholar] [CrossRef] [Green Version]

- Kristensen, H.S.; Remmen, A. A framework for sustainable value propositions in product-service systems. J. Clean. Prod. 2019, 223, 25–35. [Google Scholar] [CrossRef]

- Rossi, M.; Germani, M.; Zamagni, A. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. J. Clean. Prod. 2016, 129, 361–373. [Google Scholar] [CrossRef]

- Fatimah, Y.A.; Aman, M. Remanufacturing sustainability indicators: An Indonesian small and medium enterprise case study. IOP Conf. Ser. Mat. Sci. Eng. 2018, 403. [Google Scholar] [CrossRef]

- Jensen, J.P.; Prendeville, S.M.; Bocken NM, P.; Peck, D. Creating Sustainable Value through Remanufacturing: Three Industry Cases. J. Clean. Prod. 2019, 218, 304–314. [Google Scholar] [CrossRef] [Green Version]

- Jiménez-Rivero, A.; García-Navarro, J. Indicators to Measure the Management Performance of End-of-Life Gypsum: From Deconstruction to Production of Recycled Gypsum. Waste Biomass Valor. 2016, 7, 913–927. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Circular economy assessment tool for end of life product recovery strategies. J. Remanufact. 2019, 9, 169–185. [Google Scholar] [CrossRef] [Green Version]

- Azevedo, S.; Godina, R.; Matias, J. Proposal of a Sustainable Circular Index for Manufacturing Companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef] [Green Version]

- Bertoni, M. Multi-criteria decision making for sustainability and value assessment in early PSS design. Sustainability 2019, 11, 1952. [Google Scholar] [CrossRef] [Green Version]

- Bressanelli, G.; Perona, M.; Saccani, N. Assessing the impacts of Circular Economy: A framework and an application to the washing machine industry. Int. J. Mgmt. Decis. Mak. 2018, 18, 1. [Google Scholar] [CrossRef]

- De Pádua Pieroni, M.; Pigosso, D.C.A.; McAloone, T.C. Sustainable Qualifying Criteria for Designing Circular Business Models. Procedia Cirp 2018, 69, 799–804. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Salomé Valls, A.; Peter Nadeem, S.; Anosike, A.; Kumar, V. A circularity measurement toolkit for manufacturing SMEs. Int. J. Prod. Res. 2018, 7543. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299. [Google Scholar] [CrossRef]

- Kravchenko, M.; McAloone, T.C.; Pigosso, D.C.A. Implications of developing a tool for sustainability screening of circular economy initiatives. Procedia Cirp 2019, 80, 625–630. [Google Scholar] [CrossRef]

- Veleva, V.; Bodkin, G.; Todorova, S. The need for better measurement and employee engagement to advance a circular economy: Lessons from Biogen’s “zero waste” journey. J. Clean. Prod. 2017, 154, 517–529. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y. An expert fuzzy rule-based system for closed-loop supply chain performance assessment in the automotive industry. Expert Syst. Appl. 2012, 39, 375–384. [Google Scholar] [CrossRef]

- Favi, C.; Germani, M.; Luzi, A.; Mandolini, M.; Marconi, M. A design for EoL approach and metrics to favour closed-loop scenarios for products. Int. J. Sust. Eng. 2017, 10, 136–146. [Google Scholar] [CrossRef]

- Lee, H.M.; Lu, W.F.; Song, B. A framework for assessing product End-Of-Life performance: Reviewing the state of the art and proposing an innovative approach using an End-of-Life Index. J. Clean. Prod. 2014, 66, 355–371. [Google Scholar] [CrossRef]

- Fan, W.; Zhang, P.; Xu, Z.; Wei, H.; Lu, N.; Wang, X.; Weng, B.; Chen, Z.; Wu, F.; Dong, X. Life cycle environmental impact assessment of circular agriculture: A case study in Fuqing, China. Sustainability 2018, 10, 1810. [Google Scholar] [CrossRef] [Green Version]

- Cordella, M.; Sanfelix, J.; Alfieri, F. Development of an Approach for Assessing the Reparability and Upgradability of Energy-related Products. Procedia Cirp 2018, 69, 888–892. [Google Scholar] [CrossRef]

- Liang, W.; Zhao, G.; Hong, C. Performance assessment of circular economy for phosphorus chemical firms based on VIKOR-QUALIFLEX method. J. Clean. Prod. 2018, 196, 1365–1378. [Google Scholar] [CrossRef] [Green Version]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the environmental sustainability of food packaging: An extended life cycle assessment including packaging-related food losses and waste and circularity assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef] [Green Version]

- Schmidt Rivera, X.C.; Leadley, C.; Potter, L.; Azapagic, A. Aiding the design of innovative and sustainable food packaging: Integrating techno-environmental and circular economy criteria. Energy Procedia 2019, 161, 190–197. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier’s performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Ardente, F.; Mathieux, F. Identification and assessment of product’s measures to improve resource efficiency: The case-study of an Energy using Product. J. Clean. Prod. 2014, 83, 126–141. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Walker, S.; Coleman, N.; Hodgson, P.; Collins, N.; Brimacombe, L. Evaluating the environmental dimension of material efficiency strategies relating to the circular economy. Sustainability 2018, 10, 666. [Google Scholar] [CrossRef] [Green Version]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Ligthart, T.N.; Thoden van Velzen, E.U.; Brouwer, M. EnvPack an LCA-based tool for environmental assessment of packaging chains. Part 1: Scope, methods and inventory of tool. Int. J. LCA 2018, 24, 900–914. [Google Scholar] [CrossRef]

- Barletta, I.; Despeisse, M.; Johansson, B. The Proposal of an Environmental Break-Even Point as Assessment Method of Product-Service Systems for Circular Economy. Procedia Cirp 2018, 72, 720–725. [Google Scholar] [CrossRef]

- Manninen, K.; Koskela, S.; Antikainen, R.; Bocken, N.; Dahlbo, H.; Aminoff, A. Do circular economy business models capture intended environmental value propositions. J. Clean. Prod. 2018, 171, 413–422. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, F.; Rem, P.C. A Robust Indicator for Promoting Circular Economy through Recycling. J. Environ. Prot. 2015, 6, 1095–1104. [Google Scholar] [CrossRef] [Green Version]

- Di Maio, F.; Rem, P.C.; Baldé, K.; Polder, M. Measuring resource efficiency and circular economy: A market value approach. Resour. Conserv. Recyc. 2017, 122, 163–171. [Google Scholar] [CrossRef]

- Cayzer, S.; Griffiths, P.; Beghetto, V. Design of indicators for measuring product performance in the circular economy. Int. J. Sust. Eng. 2017, 10, 289–298. [Google Scholar] [CrossRef] [Green Version]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to Assess Product Performance in the Circular Economy? Proposed Requirements for the Design of a Circularity Measurement Framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef] [Green Version]

- Flipsen, B.; Bakker, C.; Van Bohemen, G. Developing a reparability indicator for electronic products. 2016 Electronics Goes Green 2016+ EGG 2016 2017, 1–9. [Google Scholar] [CrossRef]

- Akrivos, V.; Haines-Gadd, M.; Mativenga, P.; Charnley, F. Improved metrics for assessment of immortal materials and products. Procedia CIRP 2019, 80, 596–601. [Google Scholar] [CrossRef]

- Angioletti, C.M.; Despeisse, M.; Roca, R. Product Circularity Assessment Methodology. IFIP Adv. Inf. Com. Technol. 2017. [Google Scholar] [CrossRef] [Green Version]

- Ceptureanu, S.I.; Ceptureanu, E.G.; Murswieck, R.G.D. Perceptions of circular business models in SMEs. Amfiteatru Econ. 2018, 20, 310–324. [Google Scholar] [CrossRef]

- Czikkely, M.; Olah, J.; Lakner, Z.; Fogarassy, C.; Popp, J. Waste water treatment with adsorptions by mushroom compost The circular economic valuation concept for material cycles. Int. J. Eng. Bus. Mgmt. 2018, 10, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Figge, F.; Stevenson Thorpe, A.; Givry, P.; Canning, L.; Franklin-Johnson, E. Longevity and Circularity as Indicators of Eco-Efficient Resource Use in the Circular Economy. Eco. Econ. 2018, 150, 297–306. [Google Scholar] [CrossRef]

- Fogarassy, C.; Horvath, B.; Kovacs, A.; Szoke, L.; Takacs-Gyorgy, K. A circular evaluation tool for sustainable event management—An olympic case study. Acta Polytech. Hung. 2017, 14, 161–177. [Google Scholar] [CrossRef]

- Franco, M.A. A system dynamics approach to product design and business model strategies for the circular economy. J. Clean. Prod. 2019, 241, 118327. [Google Scholar] [CrossRef]

- Franklin-Johnson, E.; Figge, F.; Canning, L. Resource duration as a managerial indicator for Circular Economy performance. J. Clean. Prod. 2016, 133, 589–598. [Google Scholar] [CrossRef]

- Howard, M.; Hopkinson, P.; Miemczyk, J. The regenerative supply chain: A framework for developing circular economy indicators. Int. J. Prod. Res. 2018, 0, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Kjaer, L.L.; Pigosso DC, A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption. J. Ind. Eco. 2019, 23, 22–35. [Google Scholar] [CrossRef] [Green Version]

- Mesa, J.; Esparragoza, I.; Maury, H. Developing a set of sustainability indicators for product families based on the circular economy model. J. Clean. Prod. 2018, 196, 1429–1442. [Google Scholar] [CrossRef]

- Park, J.Y.; Chertow, M.R. Establishing and testing the “reuse potential” indicator for managing wastes as resources. J. Environ. Mgmt. 2014, 137, 45–53. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Ormazabal, M.; Jaca, C.; Viles, E. Key elements in assessing circular economy implementation in small and medium-sized enterprises. Bus. Strat. Environ. 2018, 27, 1525–1534. [Google Scholar] [CrossRef]

- Van Schaik, A.; Reuter, M.A. Recycling Indices Visualizing the Performance of the Circular Economy. World Metall. Erzmetall 2016, 69, 4. [Google Scholar]

- Clement, S.; Tepper, P.; Acker, H.; Seebach, D.; Adell, A. Driving energy efficient innovation through procurement: A practical guide for public authorities. Smart SPP 2011. Available online: https://smart-spp.eu/ (accessed on 23 May 2020).

- Johnson, M.P.; Schaltegger, S. Two Decades of Sustainability Management Tools for SMEs: How Far Have We Come. J. Small Bus. Mgmt. 2016, 54, 481–505. [Google Scholar] [CrossRef]

| References | Number of Inventoried Approaches | Summary and Differences/Common Aspects with the Review here Proposed |

|---|---|---|

| [23] | 72 | Zooms in on ‘validity’, ‘reliability’, and ‘utility’ of metrics, and connection to existing methodologies (Life Cycle Assessment (LCA)/Material Flow Analysis (MFA), no focus on micro level. |

| [24] | 30 | Focus on micro level, zooming in on ‘CE categories’ and connection to Sustainable Development (SD) dimensions. Less attention for implementation perspective. Also includes grey literature. |

| [29] | 20 | Introduces classification framework for CE indicators, both on macro- as well as micro level. Addresses different CE strategies captured by indicators. |

| [28] | 63 | Applies Multiple Correspondence Analysis (MCA) to assess metrics. No distinction between different levels of assessment. |

| [12] | 55 | Proposes intricate taxonomy of indicators, applying 10 differentiation categories. |

| [30] | 45 | Collects and reviews CE performance assessment methods. Primary focus on methodological foundation. No specification of level of assessment. |

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Academic literature | Grey literature approaches |

| Micro level approaches | Meso or macro level approaches |

| Newly proposed CE assessment approaches (i.e., not based on conventional methodologies) | Conventional LCA, Life Cycle Costing (LCC), Social Life Cycle Assessment (S-LCA) studies, eco-design or eco-innovation studies |

| Approaches that combine or expand existing methodologies or indicators to propose new CE assessment approaches | Conventional eco-design, eco-innovation, and general sustainability assessment-oriented studies |

| Applications of existing CE indicators such as Material Circularity Indicator (MCI) |

| Perspective | Goal | Attribute | Analyzed Characteristic |

|---|---|---|---|

| (i) General | To describe published approaches’ general characteristics | Age | Year of publication |

| Peer-reviewed | Yes/No | ||

| Source | Name of journal, book, or other sources | ||

| Country | Country of home university of author | ||

| Name and abbreviation | Name and abbreviation of the approach | ||

| (ii) Descriptive | To assess methodologies underlying the inventoried approaches | Scale of assessment | Determine scale of application within ‘micro level’, establish categories of scale of application |

| Sector specificity | Determine whether the approaches are designed to be applied in a specific sector, and, if so, document which sector | ||

| Connection to existing methodologies | Determine methodological connections by applying search terms ‘LCA’, ‘MFA’, ‘input output’, ‘MCI’. Complement after in-depth review of approaches | ||

| Application of case study validation | Screen publications for occurrence of application of proposed approaches in case study setting | ||

| (iii) Normative | To obtain a better understanding of connections to the three dimensions of SD | Inclusion of the three SD dimensions | Determine whether and how the environmental, economic, and social dimensions of SD are considered |

| Inclusion of ‘CE’ dimensions | Determine whether and how ‘CE’ (resource-related) dimensions are considered | ||

| (iv)Prescriptive | To evaluate the presence of implementation considerations and inclusion of end-user needs | Providing operational guidance | Does the publication mention ‘implementation’, ‘practitioner’, ‘operational’, or ‘application’? |

| Participatory approach | Is the end-user mentioned? | ||

| If so, who is the intended end-user? | |||

| Are the end-user or other stakeholders involved in the design of the evaluation approach? | |||

| Ease of communication | Does the publication mention ‘simplicity’ or ‘communication’? |

| Scale | Approaches (N.) | General (N.) | Detailed (N.) |

|---|---|---|---|

| Product | 22 | Product (16) | Chemicals (1), energy-related product (1), gypsum product (1), automotive vehicle (1), product family (1), end-of-life product (1) |

| Company | 12 | Company (9) | Small and Medium-sized Enterprise (SME) (2), Circular Economy initiative (1) |

| Business model | 11 | Business model (6) | Product-Service System (5) |

| Other | 9 | - | Building (2), component (1), technology (1), sector/industry (1), farm (1), event (1), strategy (1), innovation (1) |

| Supply chain | 6 | Supply chain (6) | - |

| Material | 4 | Material (2) | Biobased polymers (1), waste (1) |

| Packaging | 4 | Product packaging (3) | Packaging chain (1) |

| Plant/installation | 3 | - | Treatment plant (1), installation (1), Wastewater Treatment (WWT) plant (1) |

| Various scales | 3 | - | Materials and products (1), products, services, or processes (1), company or strategy (1) |

| Total | 74 | 42 | 32 |

| Connection with… | Number of Approaches |

|---|---|

| LCA | 32 |

| LCA | 18 |

| LCA + other methods | 14 |

| MFA | 5 |

| Fuzzy set theory | 3 |

| MCI | 3 |

| Other methods | 15 |

| No connection to other methods | 31 |

| Reference | Method |

|---|---|

| [52] | LCA, LCC, S-LCA |

| [53] | LCA, MFA, multi-objective optimization |

| [54] | LCA, LCC |

| [55] | LCA, LCC, S-LCA |

| [45] | LCA, Environmental Input-Output (EIO) |

| [56] | LCA, Recyclability Benefit Rate (RBR), Recycled Content Benefit Rate (RCBR) |

| [57] | LCA, MFA |

| [58] | LCA, MFA, Constructive Technology Assessment (CTA), input-output analysis, LCC, Cost-Benefit Analysis (CBA) |

| [15] | LCA, Material Reutilization Score (MRS), MCI |

| [59] | LCA, MFA, LCC, S-LCA |

| [46] | LCA, Material Flow Cost Accounting (MFCA) |

| [42] | LCA, E-factor |

| [60] | LCA, Net Present Value, Internal Rate of Return, questionnaire on stakeholder perception |

| [61] | LCA, Environmental Product Declaration |

| References | Environment | Economic | Social | Circular | Number of Approaches |

|---|---|---|---|---|---|

| [47,52,58,59,66,67,68,69,70,71,72,73,74,75,76,77,78,79] | X | X | X | X | 18 |

| [55,60] | X | X | X | 2 | |

| [61,80,81,82] | X | X | X | 4 | |

| [46,54,83] | X | X | 3 | ||

| [15,42,44,45,48,84,85,86,87,88,89] | X | X | 11 | ||

| [50] | X | X | 1 | ||

| [56,90,91,92,93,94,95] | X | 7 | |||

| [13,96,97] | X | 3 | |||

| [43,51,53,57,62,63,64,65,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114] | X | 25 | |||

| 45 | 31 | 20 | 59 | 74 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roos Lindgreen, E.; Salomone, R.; Reyes, T. A Critical Review of Academic Approaches, Methods and Tools to Assess Circular Economy at the Micro Level. Sustainability 2020, 12, 4973. https://doi.org/10.3390/su12124973

Roos Lindgreen E, Salomone R, Reyes T. A Critical Review of Academic Approaches, Methods and Tools to Assess Circular Economy at the Micro Level. Sustainability. 2020; 12(12):4973. https://doi.org/10.3390/su12124973

Chicago/Turabian StyleRoos Lindgreen, Erik, Roberta Salomone, and Tatiana Reyes. 2020. "A Critical Review of Academic Approaches, Methods and Tools to Assess Circular Economy at the Micro Level" Sustainability 12, no. 12: 4973. https://doi.org/10.3390/su12124973

APA StyleRoos Lindgreen, E., Salomone, R., & Reyes, T. (2020). A Critical Review of Academic Approaches, Methods and Tools to Assess Circular Economy at the Micro Level. Sustainability, 12(12), 4973. https://doi.org/10.3390/su12124973