Postcollection Separation of Plastic Recycling and Design-For-Recycling as Solutions to Low Cost-Effectiveness and Plastic Debris

Abstract

1. Introduction

2. Facts and Figures

2.1. Plastic Recycling in the Netherlands

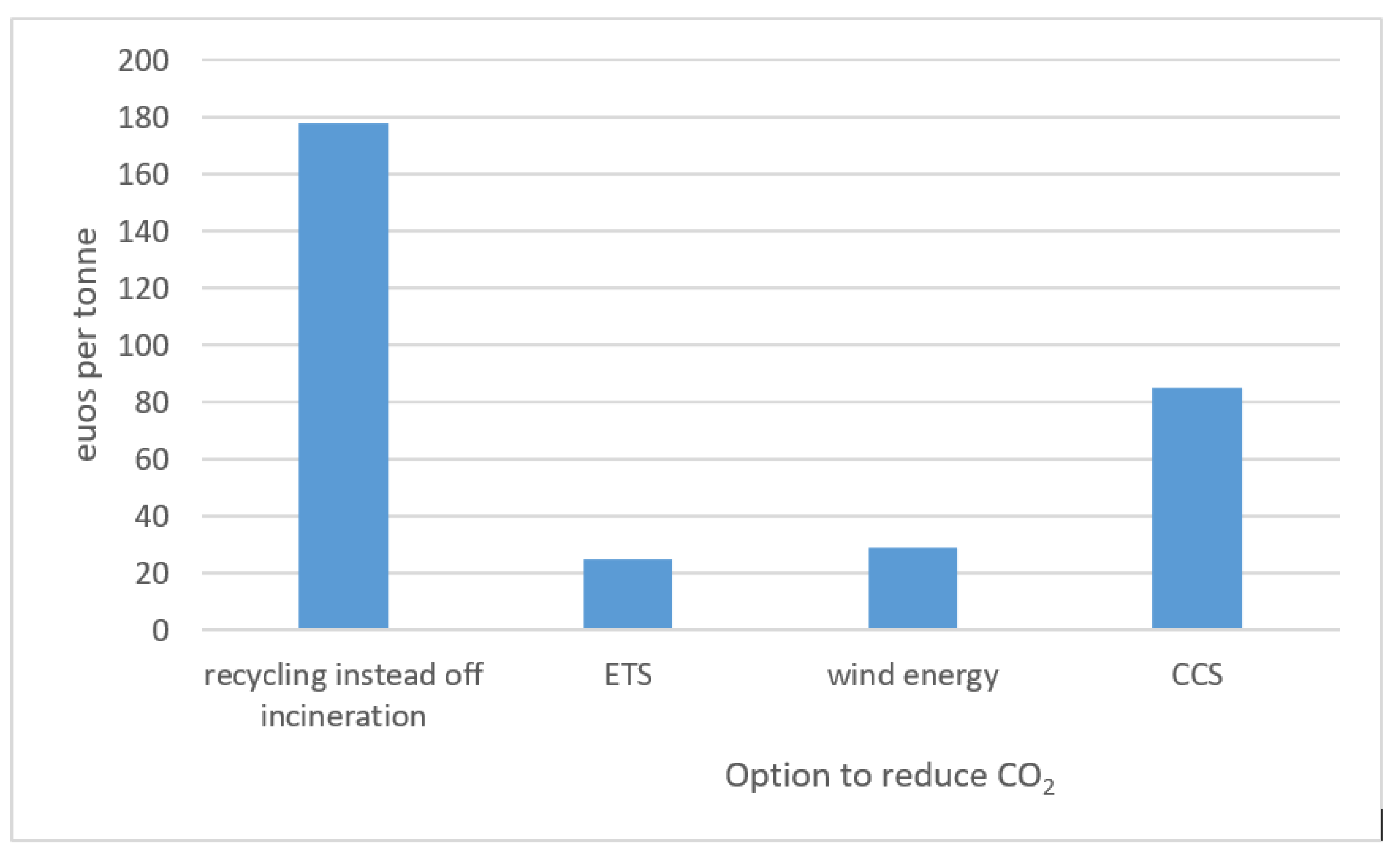

2.2. Cost-Effectiveness of Plastic Recycling vs. Incineration

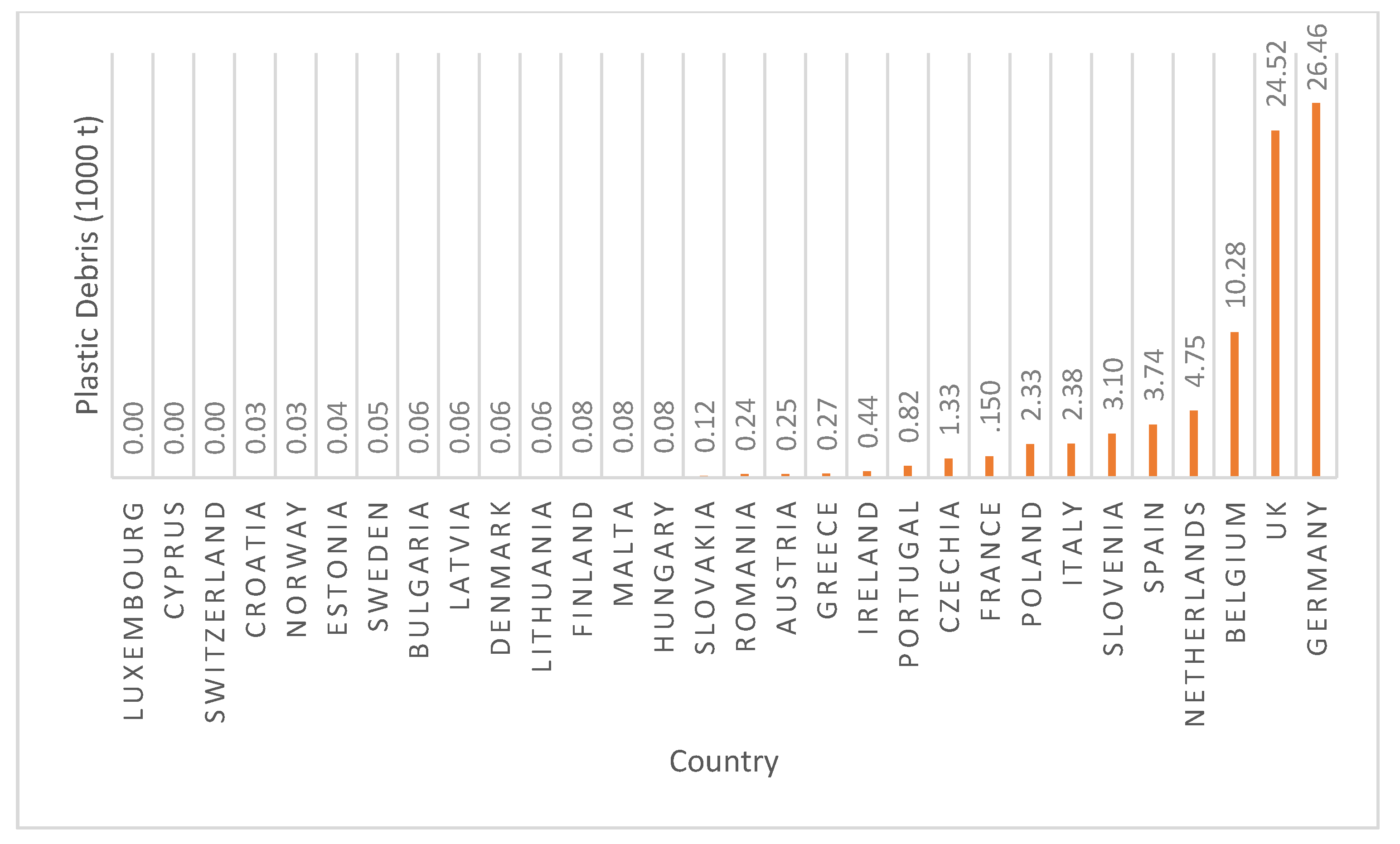

2.3. Recycling as a Pathway to Plastic Debris in the Ocean

3. How to Bring about Less Plastic Debris and a More Cost-Effective System

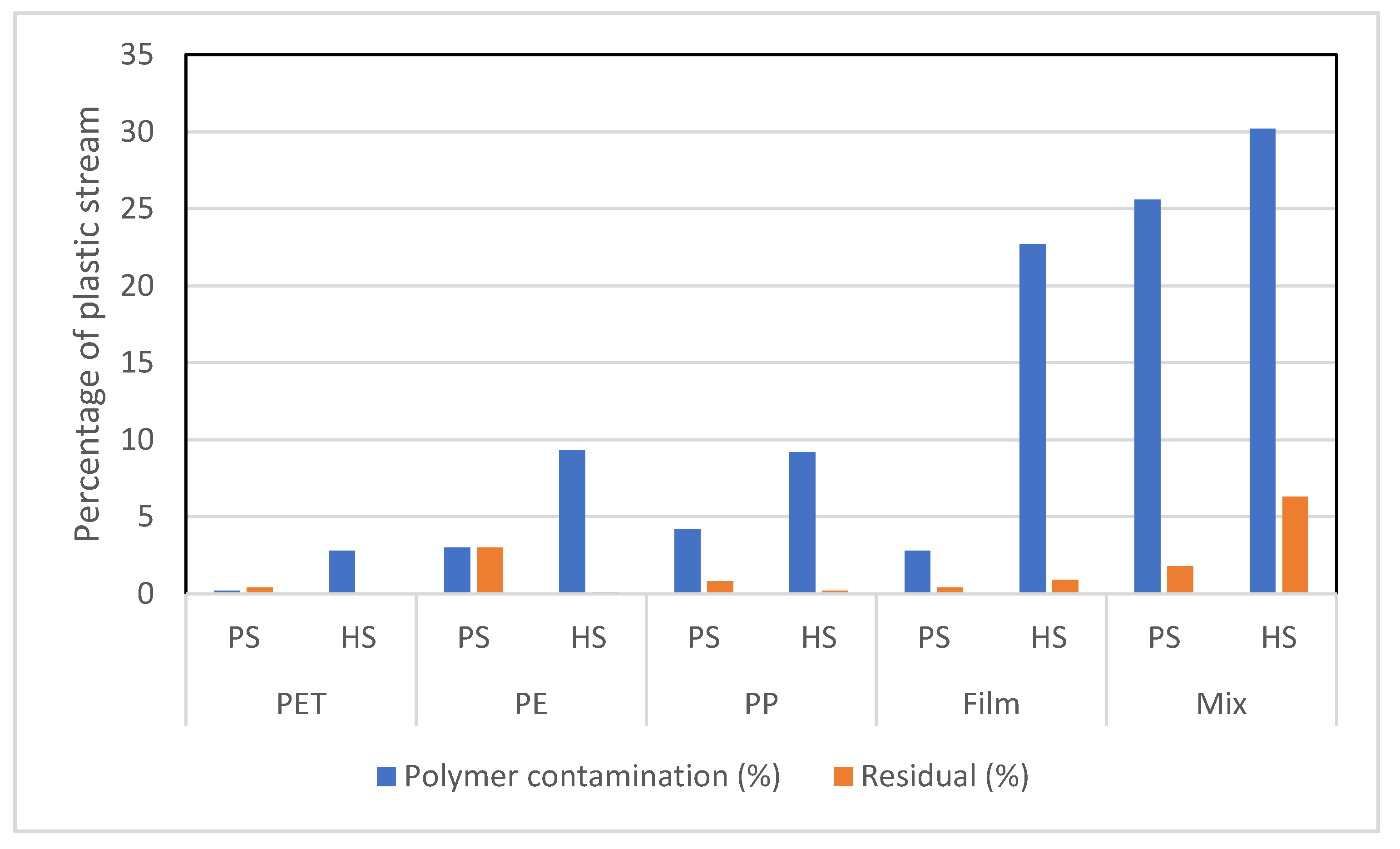

3.1. Postseparation Is a Serious Alternative Resulting in Better Quality of Separated Plastics

3.2. Postseparation Leads to Lower Costs as Well

3.3. Design-For-Recycling

4. Discussion and Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Brouwer, M.; Picuno, C.; Thoden van Velzen, E.U.; Kucha, K.; De Meester, S.; Rageart, K. The impact of collection portfolio expansion on key performance indicators of the Dutch recycling system for Post-Consumer Plastic Packaging Waste, a comparison between 2014 and 2017. Waste Manag. 2019, 100, 112–121. [Google Scholar] [PubMed]

- Seyring, N.; Dollhofer, M.; Weissenbacher, J.; Bakas, I.; McKinnon, D. Assessment of collection schemes for packaging and other recyclable waste in European Union-28 Member States and capital cities. Waste Manag. Res. 2016, 34, 947–956. [Google Scholar] [CrossRef] [PubMed]

- Gradus, R.H.J.M.; Nillesen, P.H.L.; Dijkgraaf, E.; Koppen, R.J.van. A cost-effectiveness analysis for incineration or recycling of Dutch household plastic waste. Ecol. Econ. 2017, 135, 22–28. [Google Scholar] [CrossRef]

- Brouwer, M.; Thoden van Velzen, E.U.; Augustinus, A.; Soethoudt, H.; De Meester, S.; Rageart, K. Predictive model for the Dutch post-consumer plastic packaging recycling system and implications for the circular economy. Waste Manag. 2018, 71, 62–85. [Google Scholar] [CrossRef] [PubMed]

- Bishop, G.; Styles, D.; Lens, P.N.L. Recycling of European plastic is a pathway for plastic debris in the ocean. Environ. Int. 2020. [Google Scholar] [CrossRef] [PubMed]

- Dijkgraaf, E.; Gradus, R.H.J.M. Post separation of plastic waste: Better for the environment and lower collection costs? Environ. Resour. Econ. 2020, 77, 127–142. [Google Scholar]

- Feil, A.; Pretz, T.; Jansen, M.; Thoden van Velzen, E.U. Separate collection of plastic waste better than technical sorting from municipal solid waste? Waste Manag. Res. 2017, 35, 172–180. [Google Scholar] [CrossRef] [PubMed]

- JMA. Gemeente Hengelo: Evaluatie Afvalinzameling En Mogelijkheden Nascheiding; JMA (De Jonge Milieu Advies): Zeist, The Netherlands, 2019. [Google Scholar]

- Afvalfonds verpakkingen. Tariefdifferentiatie Kunststof. Available online: afvalfondsverpakkingen.nl/en/ (accessed on 22 July 2020).

- Dijkgraaf, E.; Gradus, R.H.J.M. An EU recycling target: What does the Dutch evidence tell us? Environ. Resour. Econ. 2017, 68, 501–526. [Google Scholar] [CrossRef]

- Dijkgraaf, E.; Gradus, R.H.J.M. Waste management in the Netherlands. In Handbook on Waste Management; Kinnaman, T., Takeuchi, K., Eds.; Edward Elgar Publishers: Cheltenham, UK, 2014; pp. 287–315. [Google Scholar]

- Gradus, R.H.J.M.; Dijkgraaf, E. Poorer and less political fragmented Dutch municipalities take tighter waste reduction decisions. Waste Manag. 2019, 88, 328–336. [Google Scholar] [CrossRef]

- Fullerton, D.; Kinnaman, T.C. Household responses to pricing garbage by the bag. Am. Econ. Rev. 1996, 86, 971–984. [Google Scholar]

- Heller, M.; Vatn, A. The divisive and disruptive effect of a weight-based waste fee. Ecol. Econ. 2017, 131, 275–285. [Google Scholar] [CrossRef]

- Marques, R.; da Cruz, N. Recycling and Extended Producer Responsibility: The European Experience; Ashgate: Dorchester, UK, 2015. [Google Scholar]

- Bel, G.; Joseph, S. Emissions abatement: Untangling the impacts of the EU ETS and the economic crisis. Energy Econ. 2015, 49, 531–539. [Google Scholar] [CrossRef]

- Gemeente Gooise Meren. Beantwoording Vragen Gemeenteraad over PMD Inzameling. Available online: https://bestuur.gooisemeren.nl/fileadmin/user_upload/191209_VVD_Beantwoording_vragen_Gooise_Meren_aan_AB_Regio_-_GAD.pdf (accessed on 29 July 2020).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Thoden van Velzen, E.U.; Brouwer, M.; Molenveld, K. White Paper: Kwaliteit Van Gerecyclede Huishoudelijke Kunststofverpakkingen; Wageningen University & Research: Wageningen, The Netherlands, 2018. [Google Scholar]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the loop for PET, PE and PP waste from households: Influence of material properties and product design for plastic recycling. Waste Manag. 2019, 100, 75–85. [Google Scholar]

- Dirksen, M.; van Zutphen, L.; Bergsma, A. Doorbraak in Recycling Van Kunststof Verpakkingen: Polypropyleen Uit Nascheiding Opgewerkt Tot Virgin Kwaliteit; Omrin: Heereveen, The Netherlands, 2020. [Google Scholar]

- Attero. Pmd: Er zit Meer Vervuiling in Dan je op Het Eerst Oog Ziet! Available online: attero.nl (accessed on 28 August 2020).

- Gradus, R.H.J.M.; Prast, H. EU’s Proposed Tax on Burning Plastic Waste is Counter-Productive. Available online: https://www.euractiv.com/section/energy-environment/opinion/eus-proposed-tax-on-burning-plastic-waste-is-counter-productive/ (accessed on 1 August 2020).

- Afvalfonds verpakkingen. Verpakkingen in De Circulaire Economie, Recycling Verpakkingen Nederland 2018; AfvalfondsVerpakkingen: Leidschendam-Voorburg, The Netherlands, 2019. [Google Scholar]

- Bruinsma, J. Zo Groot is de Rotzooi in Arnhemse Wijken: Troep Bij Bijna één op de Vijf Containers. De Gelderlander. Available online: https://www.gelderlander.nl/arnhem/zo-groot-is-de-rotzooi-in-arnhemse-wijken-troep-bij-bijna-een-op-de-vijf-containers~ad62e3ee/ (accessed on 7 October 2020).

- CPB. De Circulaire Economie Van Kunststof: Van Grondstoffen Tot Afval; CPB: Den Haag, The Netherlands, 2017. [Google Scholar]

| System | 2013 | 2014 |

|---|---|---|

| Kerbside | 32% | 28% |

| Kerbside and drop-off | 24% | 23% |

| Drop-off | 22% | 18% |

| Post | 11% | 11% |

| Post and kerbside | 4% | 7% |

| Post, kerbside, and drop-off | 4% | 7% |

| Post and drop-off | 1% | 4% |

| Plastic Polymer, etc. | Tonne | Share | Effectiveness of Recycling | Destination |

|---|---|---|---|---|

| PET 90/10 | 172 | 4% | High | Netherlands |

| PET trays | 81 | 2% | Complex | Netherlands |

| HDPE | 185 | 4% | Complex, HDPE bottles, high | Netherlands |

| LDPE | 497 | 11% | Poor | Netherlands |

| PP | 275 | 6% | Potentially High | Netherlands |

| Mixed plastics | 1279 | 28% | Very Poor | Germany |

| Beverage cartons | 229 | 5% | Poor | n.a. |

| Tin | 312 | 7% | High | n.a. |

| Aluminium | 86 | 2% | High | n.a. |

| Residue | 1431 | 31% | Incinerator | n.a. |

| Country | Tonne | Share |

|---|---|---|

| China | 52,342 | 34% |

| Germany | 25,016 | 16% |

| Belgium | 24,001 | 16% |

| India | 9923 | 6% |

| United Kingdom | 6908 | 4% |

| France | 6673 | 4% |

| Hong Kong | 6018 | 4% |

| Italy | 3813 | 2% |

| Turkey | 3300 | 2% |

| Viet Nam | 2850 | 2% |

| Poland | 1958 | 1% |

| Other Europe | 6943 | 5% |

| Other Asia | 1987 | 1% |

| Company | Place | Province | Capacity (Kilotonnes) |

|---|---|---|---|

| Omrin | Heerenveen | Friesland | 300 |

| AEB | Amsterdam | Noord-Holland | 300 |

| Attero | Wijster | Drenthe | 280/280 |

| Groningen | Groningen | 140 | |

| AVR | Rotterdam | Zuid-Holland | 200 |

| HVC | Alkmaar | Noord-Holland | 140 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gradus, R. Postcollection Separation of Plastic Recycling and Design-For-Recycling as Solutions to Low Cost-Effectiveness and Plastic Debris. Sustainability 2020, 12, 8415. https://doi.org/10.3390/su12208415

Gradus R. Postcollection Separation of Plastic Recycling and Design-For-Recycling as Solutions to Low Cost-Effectiveness and Plastic Debris. Sustainability. 2020; 12(20):8415. https://doi.org/10.3390/su12208415

Chicago/Turabian StyleGradus, Raymond. 2020. "Postcollection Separation of Plastic Recycling and Design-For-Recycling as Solutions to Low Cost-Effectiveness and Plastic Debris" Sustainability 12, no. 20: 8415. https://doi.org/10.3390/su12208415

APA StyleGradus, R. (2020). Postcollection Separation of Plastic Recycling and Design-For-Recycling as Solutions to Low Cost-Effectiveness and Plastic Debris. Sustainability, 12(20), 8415. https://doi.org/10.3390/su12208415