1. Introduction

Buildings with smooth concrete or glass surfaces, without openings or any greenery are nowadays state-of-the-art in contemporary architecture. An increase of sealed and built-up areas, as well as high-tech and smart buildings, are existing long-term trends which require many resources and are usually neither sustainable nor biodiversity-friendly. The Intergovernmental Platform on Biodiversity and Ecosystem Services’ (IPBES) Global Assessment Report on Biodiversity and Ecosystem Services, published in 2019, calculates that about one million species are threatened worldwide. These calculations include nearly 550,000 threatened insects which account for 75% of all species [

1]. In Germany, another published study on insect loss aroused a lot of interest. Scientists in Krefeld found that the biomass of flying insects has declined by more than 75% between 1989 and 2016 [

2].

Climate and culture responsive buildings is a research field that comprises many disciplines. It includes the issues of building physics, sustainable buildings with nature-based solutions [

3], as well as the requirements of society, such as an optimal indoor climate (temperature, moisture, acoustics, light, and emissions), building materials, energy efficiency in the building sector (use of renewable thermal energy sources [

4]), but also the aesthetics of buildings and built environments that are part of people’s cultural identity. The contents of culture are discrete and difficult to define. In the wide range of its topic, biodiversity is one of the main parts to be handled within this field of research, as explained below.

The causes of insect loss are diverse. Among other things, the increasing use of big agricultural machinery and chemicals like fertilizers and pesticides, cultivation in monocultures, mass livestock farming with the use of animal medicine, the increase of sealed soil and many more aspects reduce the insect species and habitats in the “wild” nature. A recent study, published in October 2019, concludes that the main drivers of arthropod decline are related to agriculture at the landscape level, at least for grassland [

5]. At the same time, the number of people and species living in cities is growing. Sealed soil goes along with increasing construction volume and the use of vertical façades. There is a kind of rural exodus for people and species. This increasing number of citizens and decreasing number of species requires solutions for the built environment.

Up to now, the impact of the built environment and the vertical surfaces in particular, are highly underestimated in case of supporting measures for biodiversity. Walls are vertical components, classified and specified based on their design, location, construction, function, use and material. Walls protect (e.g., against the weather) and support (e.g., transmission of forces). A general subdivision of exterior wall constructions is made into single- and double-shell constructions. Single-shell walls usually consist of exterior and interior plaster layers with a load-bearing wall in between. Double-shell constructions usually have a rear ventilation, thus a weather-protecting layer or a thermal insulating layer in between two heavy walls (which acts as feather-mass-system) [

6]. Similar to green ground or roofs (horizontal surfaces) walls can (as vertical surfaces) also be greened. Greened surfaces have beneficial effects, e.g., on the micro- and indoor climate or the reduction of pollutants [

7,

8,

9,

10,

11,

12,

13,

14,

15]. Nevertheless, the vast majority of buildings is still not biodiversity-friendly. There are, for example, artificial nesting boxes for birds and bats, which can be integrated into the building envelope and help the animals to adapt to changes in their habitats to a certain extent (e.g.,

Figure 1).

In Germany, they appear occasionally due to a federal law, the so-called “Bundesnaturschutzgesetz”—The Act on Nature Conservation and Landscape Management (Federal Nature Conservation Act-BNatSchG), especially due to article 44: provisions for specially protected fauna and flora species, and certain other fauna and flora species, are relevant. This law prohibits a significant disturbance of wild animals, of strictly protected species and of European bird species during their breeding, rearing, hibernation, and migration periods. However, many urban planners and architects are not yet aware of this law, so that it often remains unconsidered. Artificial ways of habitats for bats and birds are nothing new (but still not common and rarely built). There are many places and ways, where and how such artificial habitats can be built to support bats and birds. There are diverse installation possibilities (e.g., directly into the exterior wall (

Figure 2), or at attic level) and built-in multi-systems for swifts, sparrows, or bats.

However, insects in façades are rather a novelty in this area. Artificial habitats for insects are limited to gardens (insect hotels,

Figure 2) or forests.

The integration of habitat systems into constructions and already in the planning phase is a possible measure. Technically, it is feasible [

17]. As different as the aspects for insect losses are, so too are their consequences. The role of insects in ecosystems is not just limited to pollination services, but they also provide a nutritional basis for many other species [

18,

19,

20]. For this reason, supporting their living conditions is an urgent need in the interest of humankind.

Thus, a holistic view of integrating insect habitats into the built environment considers a subdivision of this research field of climate and culture responsive buildings. The subdivided parts are synergies with the urban climate, the needs of humans and animals (particularly insects) and the fulfillment of standards with regard to the building sector. It addresses interactions of people, animals, and constructions. This research sees great potential, especially for vertical surfaces, because there are conflicts in the use of horizontal surfaces in cities. As a result, this study focuses on a way of creating habitats, especially for insects, by integrating them into urban vertical walls while maintaining the construction’s function (e.g., indoor comfort and energy efficiency). A first estimation on the cultural issue of people’s awareness of the importance of insects is given in an extract of first surveys. A major role for the sustainable integration of insect habitat systems in society is the scientific research including participation and education. The aim of this research was to investigate possibilities to integrate biodiversity-friendly modules (e.g., in case of renovation or new constructions) into exterior wall constructions.

2. Methods and Materials

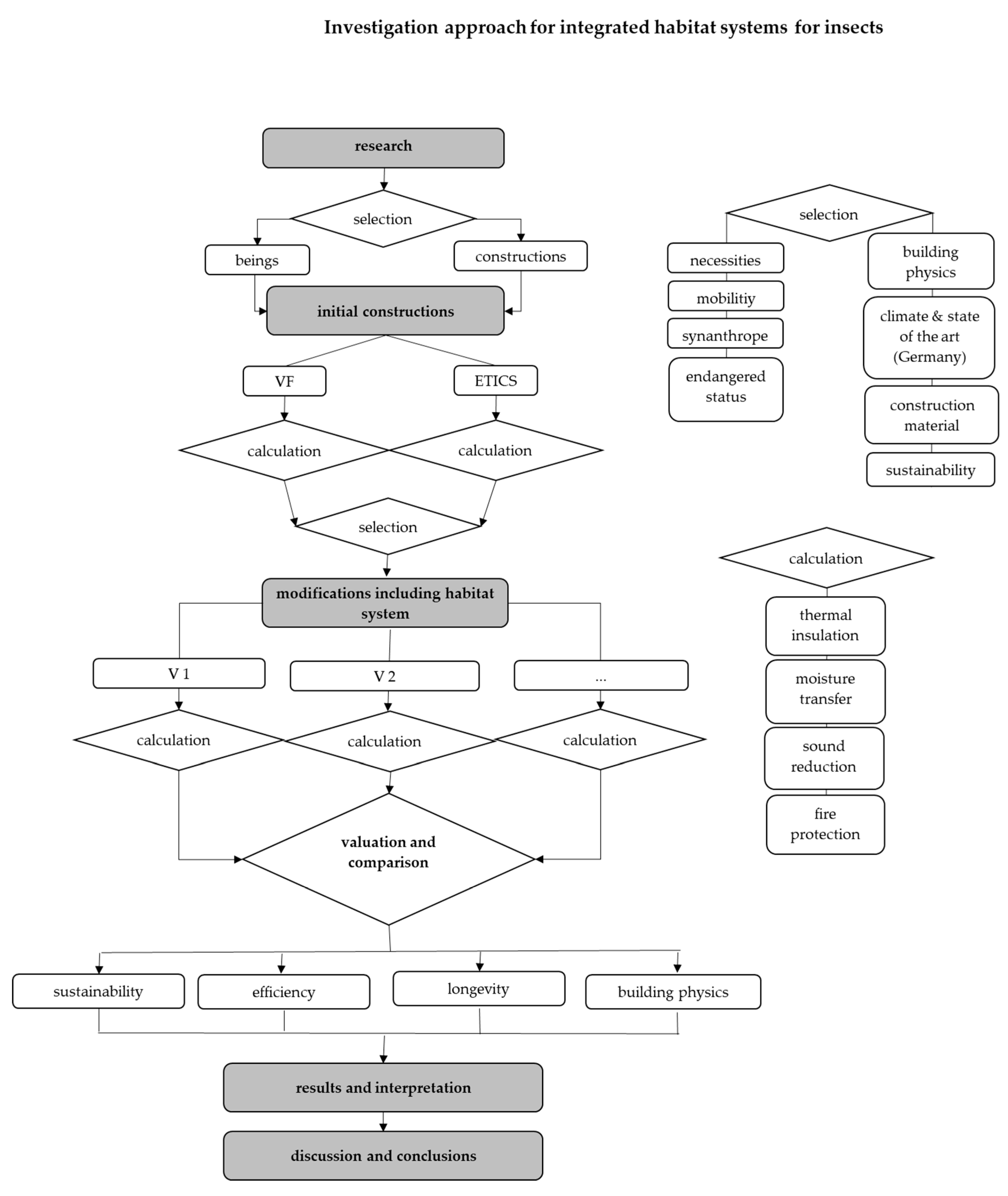

First, this large research field was subdivided.

Figure 3 points out the single steps of this approach: literature research, initial constructions, modifications, and results with conclusions. Target figures of research were insects and their living conditions, different aspects of structural design, such as façade building materials and building physic aspects. Due to the topic of insects, people’s awareness and willingness to act plays an important role. This work presents the first findings of an online questionnaire answered by 185 participants.

To narrow down the choice for the initial construction variants, the selection criteria of living beings (including humans) and constructions (function and sustainability) were weighed. Considering the animals’ needs (e.g., their mobility: winged or wingless) and the ecosystem services meeting these needs, the species was selected to be focused on primarily in this work. Consequently, the target species were wild bees due to their pollinator function, their extinction rate and their mobility. Wild bees can easily reach nesting clays in up to 3 m height. Thus, suggestions as to which nesting clay to choose and where to place it were among the initial considerations. In addition, the function of the construction was important. Building physical aspects and standards, building materials (preferably sustainable ones) and building properties were also considered for choosing suitable façades. Furthermore, climatic parameters are significant. All of the mentioned aspects and the climatic conditions in Germany (moderate climate with cold winters and warm summers) resulted in the selection of two initial constructions. They are designed without integrated habitat systems, serving as reference for further investigation. The initial constructions (

Figure 4) consisted of single and double-shell exterior wall constructions. A ventilated façade (VF) and an external thermal insulation composite system (ETICS) are the references. A ventilated façade consists out of an external cladding, which is not mounted directly on the wall structure. Like this an air space is present behind the cladding. Air circulates in this rear ventilation to provide the vapour and moisture exchange. ETICS is a multi-layer construction. The single layers are fixed in-between without gaps and supplement each other building physically. ETICS must be used as one system per manufacturer. Mixed systems with components from other manufacturers are forbidden. Analyzing the individual design and investigation steps will explain the method of this approach.

Table 1 lists the considered materials of the initial VF construction. In

Table 2 the materials of the ETICS are presented. All calculation values in this work are based on common databases or component catalogues and product declarations of the manufacturers. For reasons of sustainability, the substructure material of VF was wood. Fiber cement panels were used because of their resistance, longevity and the possibilities of reusing them. Due to its good material properties (for example water absorbency), mineral wool as simulated insulating material was chosen which is also easy to process. It has a low thermal conductivity and is non-combustible. Mineral wool enables a consistent temperature profile and thus prevents cracks caused by strain. Its low diffusion resistance allows moisture from the building component and the interior of the building to diffuse through the insulation layer into the rear ventilation. In this way, the construction can dry out.

The insulation layer of the investigated ETICS composite system also consisted of mineral wool.

For receiving reference values, international standards for thermal insulation and sound reduction as well as for humidity and fire protection were taken into account. Extracts of the used standards and guidelines for calculations and simulations were among others:

DIN EN ISO 6946, DIN 4108, EnEV:2007 [

21,

22], DIN EN ISO 13789 for thermal insulation,

DIN 4108-3 for protection against moisture [

23],

DIN 4109 for sound reduction [

24] and

§28 MBO:2016 (Model Building Regulation, Germany), DIN EN 13501for fire protection [

25].

Calculation and simulation for each building physical aspect were carried out as follows. The last methodological step consisted of variants with integrated biodiversity-friendly measures.

2.1. Building Physical Criteria

(a) Thermal Insulation

Calculations according to DIN EN ISO 6946 (taking into account possibilities of transverse heat flows), with the materials in

Table 1 lead to the initial VFs’ heat transfer coefficient (U-value) of 0.23 W/m

2K. Following these standards, the construction is a highly ventilated variant where only the layers up to the rear ventilation are decisive. Dowels for fixing the mineral wool were neglected according to DIN EN ISO 6946 to punctual thermal bridge χ ≤ 0.0005 W/K. By using a grid size of 625 mm (distance between main battens and counter battens), the construction fulfills the demands of EnEV (

Table 3). The simulation tool used for thermal bridges was ZUB Argos.

The ZUB software (from ZUB Systems GmbH, Kassel, Germany) provides support in energy consulting and the implementation of the EnEV in planning practice. Products are ZUB Helena and ZUB Argos [

27,

28,

29,

30]. With ZUB Argos 2D thermal bridges and surface temperatures for moisture protection analyses on any connection details for use in the context of EnEV and KfW proofs as well as for expert examination of condensation and the risk of mold can be simulated. Calculations are performed according to DIN EN ISO 10211, optionally with boundary conditions according to DIN 4108 Supplement 2. With ZUB Helena is an EnEV balance also possible. Proofs of minimum thermal insulation as well as summer thermal insulation are further simulation aspects. ZUB Helena was developed in cooperation with Univ.-Prof. Dr.-Ing. Gerd Hauser, the Fraunhofer Institute for Building Physics Holzkirchen, the University of Kassel and ebz süd (Energieberatungszentrum Süd Ingenieurgesellschaft mbH) [

31,

32,

33,

34].

Same calculations (as before) for ETICS lead to a U-value for the initial variant of 0.21 W/m

2K, which is a better value than in case of VF. The demands of EnEV (

Table 3) are fulfilled. Other criteria regarding thermal aspects are thermal bridges, which were simulated with ZUB Argos. The planned integration of nesting boxes into the reference systems probably will cause material-related thermal bridges (occur if construction elements consist of heterogenic materials). Thermal bridges differ in building physical properties (e.g., thermal conductivity, raw density and specific heat capacity) which leads to varying heat flows and a significantly higher heat transmission through the surface of the thermal bridge. Therefore, a special focus lies on the investigation of thermal bridges in the area of integrated habitat systems. There may also be some exceptions of the EnEV proof. §9(2) of EnEV. If less than 10% of the total façade surface is changed or renovated, an EnEV proof is not necessary, as specified in §9(2) of EnEV. When being integrated into existing buildings, the surface of habitat systems is therefore relevant, too.

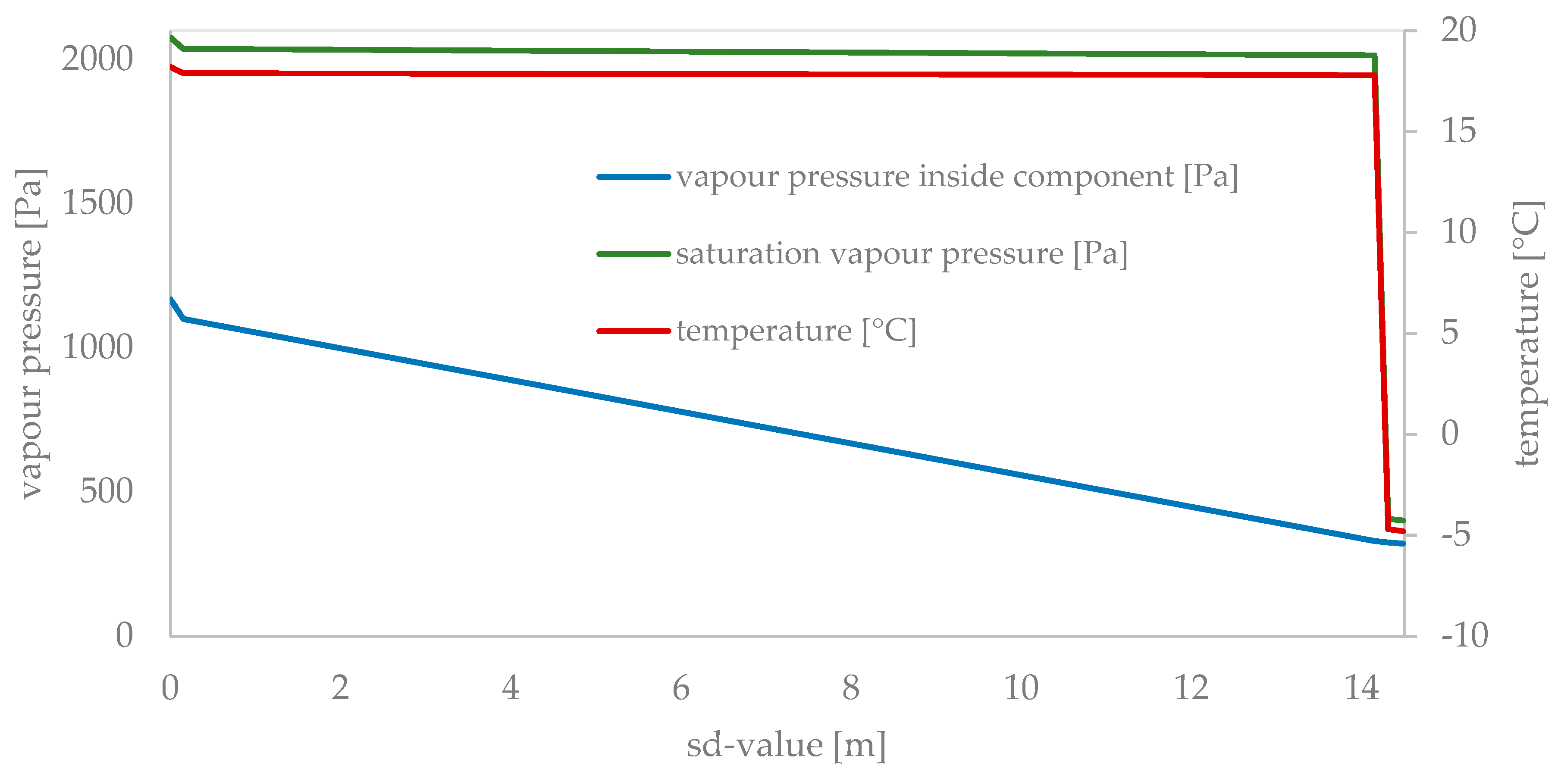

(b) Moisture Transfer

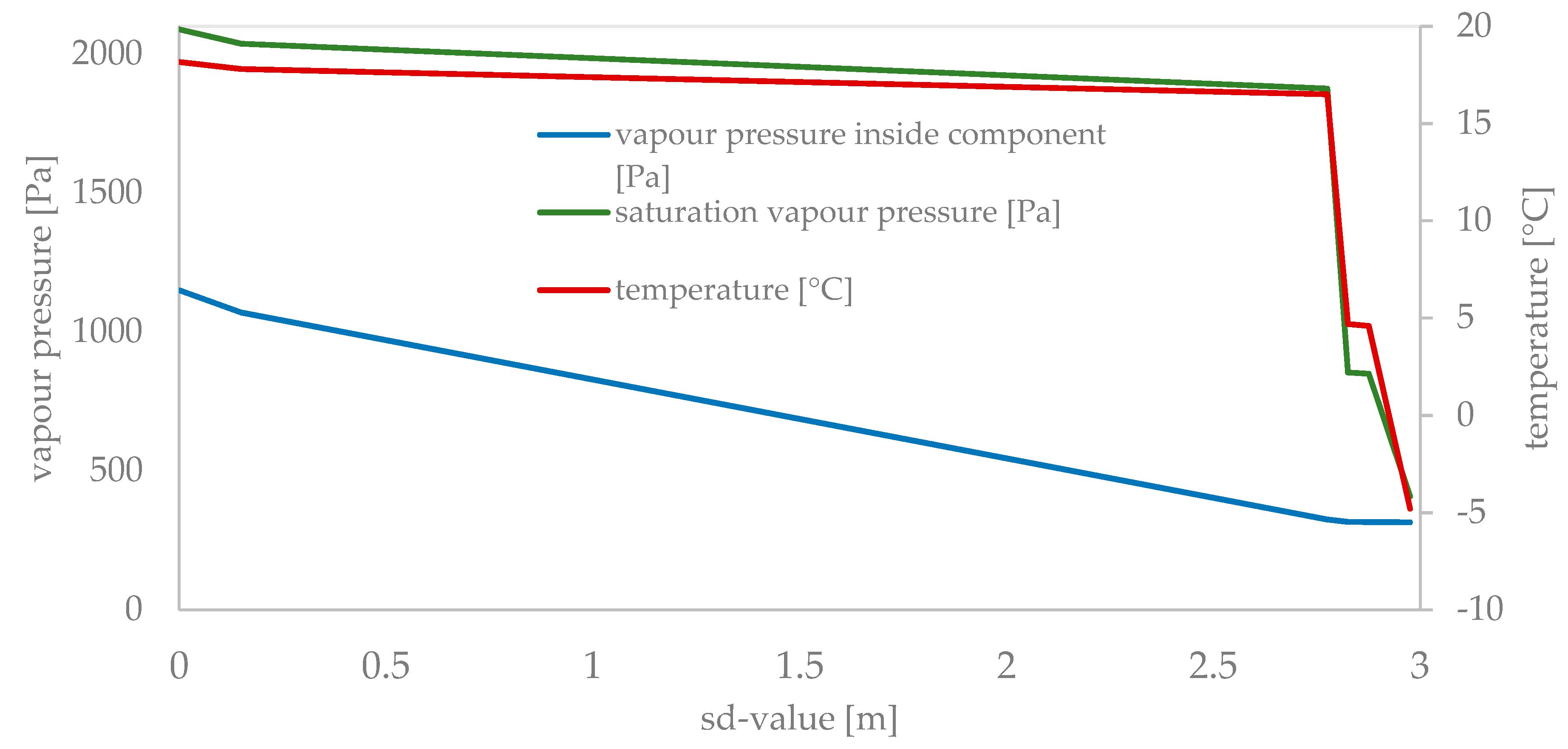

Calculation for VF is not necessary because there is no risk of condensate. The so-called “Glaser” diagram demonstrates the risk of condensate inside the construction in case of ETICS. The diagram was plotted in ZUB Helena.

Figure 5 shows the curve progression of the initial construction of ETICS.

For the Glaser-graphic and the calculations, inner and outer humidity conditions are fixed (outer: −5 °C, 80% relative humidity (RH) and inner: 20 °C, 50% RH). In this way, a particular layer temperature can be determined by means of the heat transmission resistances. The sd-values are plotted on x-axes (position) and the two y-axes describe the values for vapour pressure and temperature inside the construction.

(c) Sound Reduction

In the following, the façade is examined with regard to its sound reduction and external noise [

35]. The VF is not sealed acoustically, so in the following only the sound reduction index (DIN 4109-32) of the basic supporting structure consisting of interior plaster and reinforced concrete were calculated. Part 4.8 of DIN 4109-34 points out that investigations into the exact calculation method are still being carried out here. According to DIN 4109-2, flanking transmission is negligible for the investigation of external noise.

The sound reduction index (DIN 4109-32) is calculated according to Equation (1):

with:

RW: evaluated sound reduction index [dB];

mges’: mass per unit area [kg/m2];

m0’: reference mass, 1.0 [kg/m2].

The total sound reduction index for ETICS is calculated with an improvement measure ΔR

w,ETICS according to DIN 4109-34/A1. ΔR

w,ETICS is calculated via the resonance frequency (f

0) and correction terms according Equations (2)–(8):

with:

: improvement of airborne sound reduction through ETICS according to reference conditions [dB];

f0: resonance frequency [Hz];

a, b: factors Tab. A1.1 DIN 4109-34/A1;

s’: dynamic stiffness [MN/m3];

m’: mass per unit area [kg/m2];

KD: correction term due to dowels [dB];

KK: correction term due to adhesive surface percentage [dB];

F: adhesive surface percentage [%];

KS: correction term due to length related current resistance [dB];

r: length-related current resistance [kPa s/m2];

Rw,0: sound reduction index basic component [dB];

KTW: correction term for evaluated sound reduction index of supporting structure [dB].

(d) Fire Protection

The requirements for fire protection in buildings in Germany are divided into building classes (GK) according to county guidelines. They are related to building type, area, and height. Depending on the building classes, the fire protection requirements (highly fire-resistant, fire-resistant, fireproof, and flame-retardant) for building components differ. According to §28 MBO, buildings other than GK1 to GK3, surfaces of external walls and external wall claddings must be flame-retardant, including insulating materials and substructures. For the VF, there are additional requirements for GK4 and 5. In §28 (4) MBO, special precautions against fire spread are specified which apply to external wall constructions if they consist of cavities or air spaces over more than one floor. Precautionary measures can be, e.g., fire barriers preventing the spread of fire in the rear ventilation space by interrupting or reducing the cross-section over a sufficiently long period. The cross-section must be reduced to a total of 100 cm2/m of the wall. If the insulation is dimensionally stable in the event of fire and characterized by a melting point of more than 1000 °C, the fire barrier can be arranged between the insulation material and the cladding. Vertical fire barriers must be installed in the area of fire walls to prevent fire spread in the rear ventilation space. The approach of fire protection in this work concerned individual materials of the façade construction and later of the nesting box or the previously listed criteria. A qualitative estimation of the fire protection resulted.

2.2. Integration of Biodiversity Measures

In the next step, artificial habitats for wild bees were integrated into the reference constructions in various ways as a biodiversity-friendly measure.

The selection criteria for the variants were the functional maintenance of the construction, a manageable installation and aesthetic dimensions. Position (

Figure 6) and color are important as design elements. The habitat system can occupy a projecting position on the façade surface or/and be colorful. If desired, a more hidden implementation, e.g., behind the weather protection layer, is possible. Like this, several modifications for each reference system resulted with a total of 13 different construction variants and 2 references. The eight construction variants for VF and five construction variants for ETICS consisted in each case of either sand-lime bricks or reinforced concrete as load-bearing layer. The thicknesses of the insulation layers in the area behind the nesting box varied. The thickness of the insulation layer of the VF varied in this area from 0.1 cm to 5 cm, whereas the ETICS consisted of 1.5 cm, 3.5 cm or 4 cm thick insulation layers. The insulating layer of the undisturbed wall was 16 cm. In case of the VF, some variants were hidden behind the weather protection layer, some were installed projecting on the weather protection layer, and some were installed flush in the covering. The installations of the ETICS were either flush or projecting.

The following characteristic values for the building physical aspects heat and fire protection, as well as moisture and sound reduction were examined by calculating and simulating the same parameters as for the initial constructions. The new values have been compared with international standards and with the initial constructions, and will be presented in the results and validated. For a holistic comparison, assumptions were made about longevity, sustainability, and economical aspects. In the end, all results lead to an evaluated comparison, taking into account the advantages and disadvantages.

2.3. Valuation and Comparison

The last step before the results of this investigation (

Figure 3) is the valuation and comparison of the selected variants. Therefore, aspects of “longevity”, “efficiency”, and sustainability” were (beside the already mentioned building physical aspects) defined and treated very superficially. This study’s significance is therefore limited to the investigated factors. Assumptions and simplifications were taken as follows:

The field of sustainability is very complex. It includes nearly every individual topic named in this chapter. It is divided into three subject areas: social, economic, and ecological area. The criteria in the area of social affairs are in this research due to heating costs and good living conditions inside of a building, primarily the listed building physical criteria. Results of chapter 5 are also linked to the social side of sustainability;

Efficiency means, how efficient the buildings’ envelope works as protection layer. Therefore, it is linked to the building physical (e.g., heat losses and sound reduction) and economic criteria (material costs along average lifetime);

Environmental impacts from building ecology demonstrate the ecological and sustainable aspects. The average lifetime with its environmental impacts along lifecycle steps (life cycle assessment) are considered roughly. More detailed investigations are planned;

The economic issues are analyzed roughly based on the longevity and recyclability of the variants and costs of used materials. Environmentally friendly variants have to be economically expedient.

3. Results

First, the building physical aspects of selected examples will be given in this chapter. Due to the number of variants, two examples will clarify the approach of this theoretical research. Besides a hidden variant of the VF construction with a habitat system, a possible integration of the habitat system into the ETICS is demonstrated. The latter is a projecting variant which is not flush-mounted in the façade surface due to the thickness of the isolation layer. Furthermore, the variants will be compared according to building physics aspects and with regard to longevity, sustainability, and economical aspects. The first findings of a survey on sociological aspects then complete the results.

3.1. Building Physical Aspects of Chosen Variants

Referring to the materials and methods, this chapter presents selected VF and ETICS variants and compares their building physical aspects.

3.1.1. Hidden VF-Variant

This VF variant made of sand-lime brick as load-bearing wall and a 5 cm insulating layer (behind the nesting clay) is a hidden variant of the habitat system. The fiber cement panels have little gaps allowing wild bees to enter in the rear ventilation layer, which is located behind. The nesting box interrupts the insulating layer and the rear ventilation, thus creating a thermal bridge, which has to be investigated. The frame of the nesting box consists of cement-bonded wood wool and is filled with loam and reed as nesting tubes. In addition, the frame works as a barrier towards the rear-ventilation area, thus preventing the wild bees from entering. Construction details are demonstrated in

Figure 7.

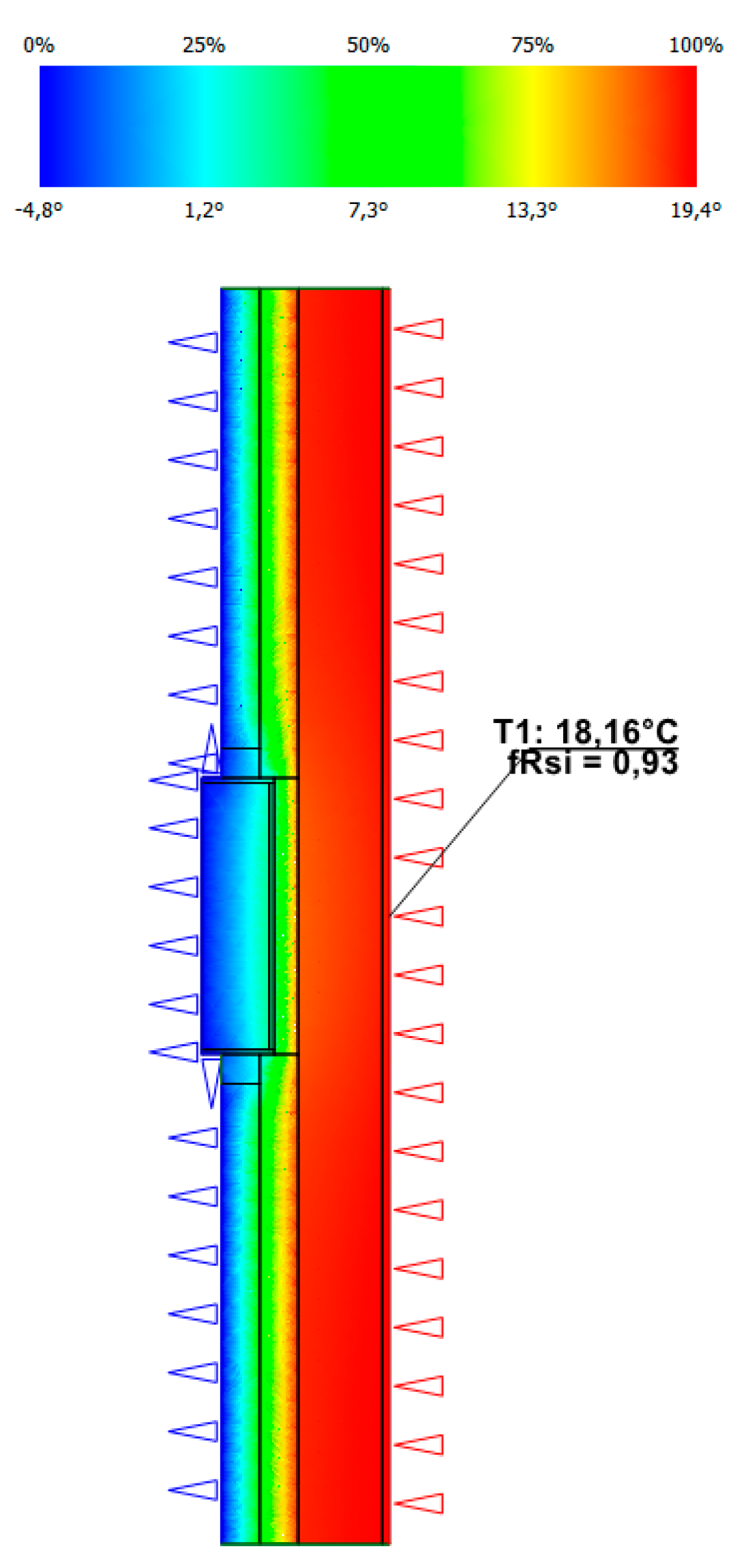

(a) Thermal Insulation

Figure 8 demonstrates the temperature profile (vertical section) through the nesting box including one meter above and below the nesting box. The cladding is not relevant for the temperature profile (because of rear ventilation). The blueish color in the area of the nesting box shows that there is a small reduction of the temperature of approximately 3 °C. The surface temperature inside is 18.2 °C. The U-value is 0.34 W/m

2K.

The length-related heat transfer coefficient (Ψ-value, describing the additional transmission heat losses of the linear thermal bridge) was also calculated. According to DIN EN ISO 10211, the Ψ-value is determined by the difference between the disturbed and the undisturbed thermal guide value. In this variant, the Ψ-value of 0.093 presents a good value because the smaller the value, the lower the additional energy loss via the thermal bridge. Furthermore, due to the novelty of the habitat systems, there is no value for nesting boxes in the standards supplement. As reference value, roller shutter boxes were approximated. Therefore, a criterion for validating the results was the compliance of Ψ-nominal value (DIN 4108 Supplement 2) ≤ 0.23 W/mK (

Table 4).

An improvement of these values and thus a reduction of the energy loss due to thermal bridge would be an increase of the insulation layer in the area behind the nesting clay. A reduction of the depth of the nesting clay and consequently an increase of the insulating layer thickness to 10 cm, improves the Ψ-value to 0.03 W/mK.

(b) Moisture Transfer

Figure 8 also demonstrates the temperature factor (f

Rsi) at the nesting clay level. It is 0.93. To avoid a risk of mold, the interior surface temperature should be higher than 12.6 °C and f

Rsi should be higher than 0.7. Both is reached in the investigated construction. The minimal requirements on the thermal insulation are thus fulfilled. As the nesting box interrupts the rear ventilation, a Glaser diagram (

Figure 9) is necessary. The material properties of the calculated single layers are listed in

Table 5.

There is no condensate inside the building component. In the condensate period, the condensate potential is 4692 g/m2, opposed to an evaporation potential of 5459 g/m2.

(c) Sound Reduction

With the properties presented in

Table 6 a resonance frequency (Equation (4)) of 108 Hz results. The sound reduction improvement is according to Equation (3) 6 dB. The resulting total reduction index is 62 dB.

(d) Fire Protection

This work regards individual materials of the façade construction, and the previously listed fire protection criteria for the modifications of the nesting box materials. Wood cement used as frame material is a composite material (cement, wood fibers and water). It is wood lightweight concrete with a mass percentage of wood of less than 20%. Thus, it fits into building material class A2 (not combustible with combustible materials, DIN 4102) and does not cause any extra fire protection criteria. The nesting box filling (reed and loam), on the contrary, is an organic material. Loam fits into building material class A1 as not combustible (without combustible materials), but reed fits into B2 with a normal flammability. A qualitative estimation on the fire protection resulted as described: the hidden variant as VF must be flame-retardant. Fire spread over the floors must be prevented. Therefore, the arrangement and the proportion of combustible façade elements are important. One possibility of prevention could be a fire barrier (non-combustible strip) with a height of one meter, installed above the nesting boxes.

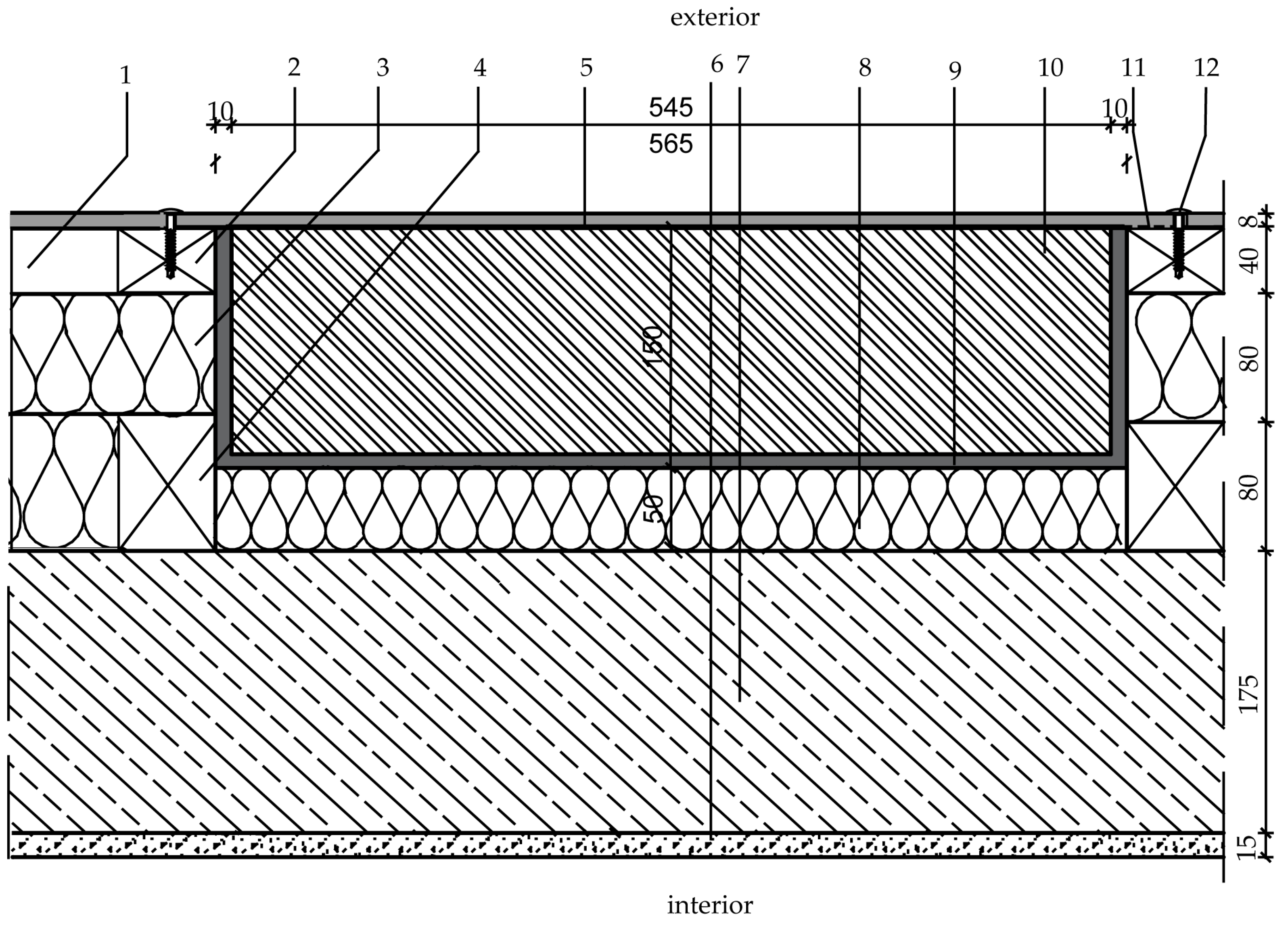

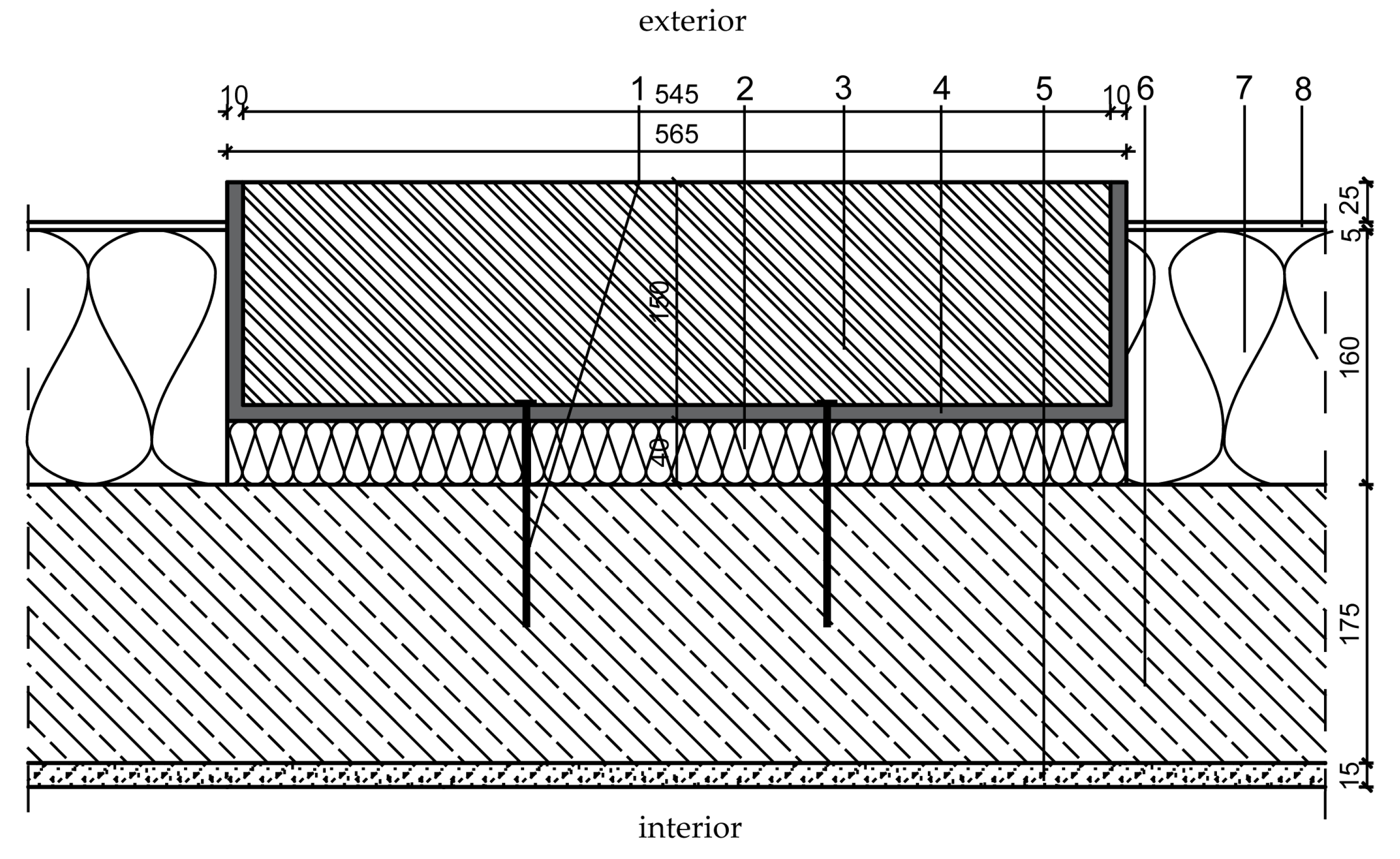

3.1.2. Projecting ETICS Variant

Due to a thicker insulation layer behind the nesting clay, this module is not installed flush with the façade surface. Thus, it offers wild bees the opportunity to build their nesting tubes which are requiring a certain depth (15 cm). It also complies with a better thermal insulation (4 cm behind nesting clay). Besides, it is a design element. As the nesting box is not installed flush in the wall surface, a water drainage plate should be integrated with this variant. Construction details are demonstrated in

Figure 10.

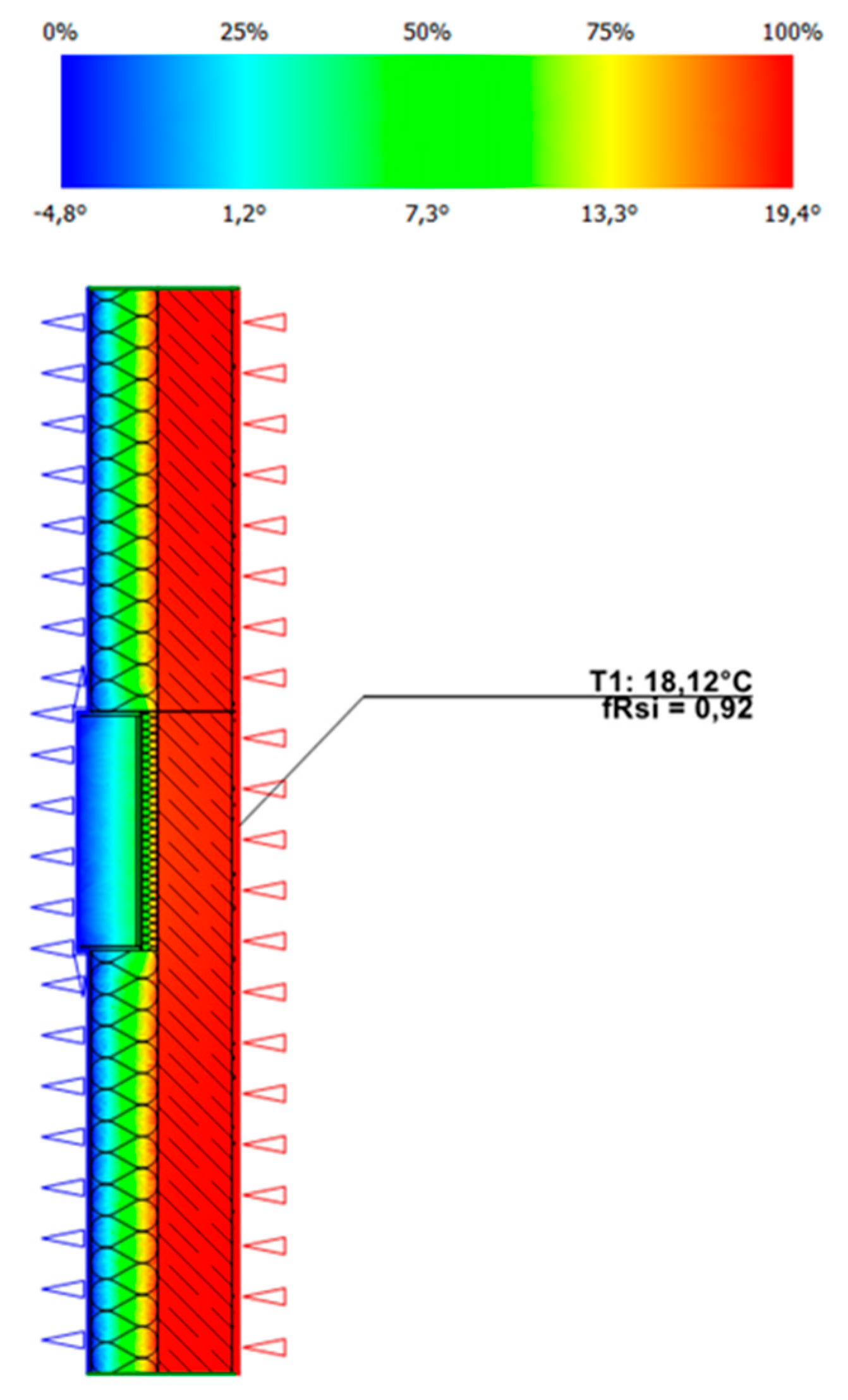

(a) Thermal Insulation

The nesting clay reduces the insulation layer in the area behind the nesting clay from 16 cm to 4 cm. An investigation of the thermal bridges is necessary. A Ψ-value of 0.135 W/mK results. The resulting U-value is 0.41 W/m2K.

Table 7 demonstrates the temperature profile (vertical section) through the nesting box including one meter above and below the nesting box. The blueish color in the area of the nesting box shows that there is a small reduction of temperature of approximately 3.0 °C. The surface temperature inside is 18.1 °C. An increase of the insulating layer to 20 cm improves the Ψ-value to 0.074 W/(mK).

(b) Moisture Transfer

Figure 11 also demonstrates the temperature factor (f

Rsi) at the level of nesting clay. There is no risk of condensate, due to an interior surface temperature of 18.1 °C and a f

Rsi–value of 0.92. The minimal requirements on thermal insulation are thus fulfilled.

The Glaser diagram (

Figure 12) shows that there is no risk of condensate inside the construction.

Table 8 lists the material properties of the calculated single layers.

(c) Sound Reduction

With the properties of

Table 9 a resonance frequency of 120.5 Hz results. The improvement is 5 dB, whereas the total reduction index results as quite 59 dB accordingly (Equations (1)–(4)).

(d) Fire Protection

Same requirements as for the VF-variant result (

Section 3.1.1 d)).

3.2. Summary of Selected Variants

The initial constructions (reference constructions without habitat system) are solid constructions. For this reason, the acoustic effects of installing the modules are minimal. Regarding the building physical evaluation, thermal insulation and thermal bridge calculation are therefore decisive. The aim of this research was to investigate possibilities to integrate biodiversity-friendly modules (e.g., in case of renovation or new constructions) into exterior wall constructions. This study found, that an integration is possible in either VF or ETICS. There is only an insignificant deterioration in building physics. For instance, the presented variants hardly differ in the Ψ-value, with results of 0.093 (VF) to 0.135 W/mK (ETICS), while both fulfilling the requirements of DIN 4108 Supplement 2 (Ψ-nominal value ≤ 0.23 W/mK). Furthermore, the temperature profiles (related to the climatic conditions in winter) are similar. With 18.1 °C or rather 18.2 °C the critical condensation temperature is exceeded by nearly 6 degrees Celsius.

differs for both variants only in one decibel. The sound reduction indexes of the presented variants are high enough for external noise until noise level range IV.

Table 10 demonstrates a summary of the two presented façade variants of this work.

4. Assumptions on Longevity, Sustainability and Economic Aspects

Aspects of longevity, sustainability and economic were treated very superficially. This study’s significance is therefore limited to the investigated factors. From today’s perspective, VF is the ecological choice over the average service life. Reuse and recycling of all components are possible. Further detailed investigations are planned.

The field of sustainability is divided into three subject areas (Chapter 2.3): social, economic, and ecological area. Sustainable materials were already selected during the design phase. Exemplarily for the VF, a wooden substructure was chosen instead of a metal one. By using modern, synthetic insulating materials such as polystyrene foam (EPS or XPS), the thermal conductivity can be reduced (by up to 0.23 W/mK). The aspect of sustainability is, however, guaranteed better by the use of mineral insulation materials than with synthetic insulation materials due to their manufacturing and recycling process.

The individual variants differ in the use of the ETICS or VF. A qualitative comparison with LCA-values [

36] for different façade constructions shows that the ETICS have a higher global warming potential (ETICS: 70.7 to VF: 44.5kg CO

2-eq./m

2 wall) and nearly a doubled primary energy content for non renewable resources. Reinforced concrete (e.g., as load-bearing wall) has more ecological impact than sand-lime bricks. The use of a VF thus achieves ecologically better values over a period of 50 years than comparable ETICS. An exact LCA is already planned. Comparing the investigated variants (hidden VF and projecting ETICS), however, VF and sand-lime brick as load-bearing wall perform best.

The average expected lifetime of ETICS is 30 years. For VF there are no exact values, as it depends on the components used. For a VF-construction existing out of cladding with fiber cement panels, an insulating layer and the substructure of the facing shell, the average service life is expected to be over 50 years [

37]. Thus, the VF lifetime is longer and causes less environmental impacts. In addition, deconstruction and recyclability of ETICS is still a controversial issue. At present, the raw materials made of plasters, fabrics, mortars, dowels etc. are incinerated, without returning waste to the recycling cycle.

Economic systems, that are easier to disassemble by using alternative joining techniques as a replacement for current bonding techniques, are still in research [

38]. Currently, however, the recyclability of VF is less complicated than that of ETICS. For example, the fiber cement boards can be directly reused. According to a producing company, nesting boxes are maintenance-free and do not require cleaning [

39]. An exact statement regarding the longevity of the installation modules does not yet exist. Further analysis will take place. However, the installation modules must be installed in a maintenance-suitable location. Thermal bridges lead to increased heat flow and thus to increased heating costs and energy consumption. The lower the thermal bridge, i.e., the less heat gets lost and the better the construction can be evaluated from an ecological and economic point of view. For economics, the additional costs have to be calculated by taking into account the actual energy mix for heating. The application of ETICS costs between EUR 100 and 160 per m

2 [

40]. In comparison, a VF costs between EUR 150 and 275 [

41]. The VF is more expensive to manufacture, but in case of longevity more cost-effective. VF is less susceptible to damage and requires less maintenance. In the event of damage, the VF can also be easily repaired. Since the installation module as used in this work does not yet exist, estimations of the costs are made. The standard installation module costs about 50€. A larger module costs correspondingly more. The installation of nesting boxes is comparable to an installation of a window. The expenditure in mounting plaster strips or joints is similarly high.

5. Human Awareness and Willingness to Act

An empirical study, based on online surveys, resulted in first findings about the awareness of insect loss and the willingness of citizens to counteract [

42]. It shows a sample at a certain time and a certain group of people (so-called “onliner”). The average age of the N = 185 participants was 37 years, and about 64.0% had a higher education degree. Thus, this group is overrepresented in comparison with the German resident population aged 18+. This study’s significance is therefore limited.

57.3% were female participants, 41.6% were male and 1.1% were other gender. About 48% of participants were aged between 18 and 39 years, about 43% were between 40 and 59 years old and about 9.0% were 60+. In general, most participants confirmed the benefits of insects for nature. The question related to the presented results in

Figure 13 was “What do you associate with insects in general?”. Multiple choice answers were permitted. At the same time, about 23% did not know anything about insect loss. About half of the 52.0%, were aware of insect loss, and indicated their engagement with insect protection.

Almost 95.0% of the participants thought everyone could do something to support insects; in turn, 13.4% believed in politics as the exclusive solution. In total, 8.0% confirmed that measures could only support insects outside urban areas (

Figure 14). These results indicate the difference between awareness and action. The majority knows about the problem but does not counteract actively.

Further findings imply that certain risks would inhibit participants to implement insect habitat systems in their own façade. Nearly 93.0% of the participants who could not imagine insect habitat systems in their own building fear risks. These people (N = 94) with fears were asked about their reasons. It was possible to answer more than once. Risks, based on their frequency (relatively to the 94 cases) in this survey, were:

Building damage due to pests (78.7%);

Maintenance and cleansing efforts (68.1%);

Building physical damage (42.6%);

Allergies (40.4%).

These feared risks explain why people support the test of habitat systems for insects in public buildings (e.g., car parks, town halls, etc.) or offices. The majority of participants were open minded to the suggestion of habitat systems in these kinds of buildings. The survey shows that, in general, biodiversity-(fauna-) friendly measures in façades depend on the species. Most people preferred butterflies, bees, or birds to other insects. Especially ants and wasps did not find approval. Measures to support animals such as birdhouses or bat boxes are known, but are rarely used due to varying reasons.

Results of a first online survey showed that people do care about insects but hesitate to act in their own place because of certain risks. The findings imply that people need best practice objects to lose their prejudices. The most frequent fears were building damages due to pests (78.7%), physical building damages (42.6%), increased maintenance and cleansing efforts (68.1%), or fear of allergies (40.4%). First results show that the species influences people’s attitude towards biodiversity protection. People do care more about “favored” insects like butterflies or bees. All listed aspects of have to be analyzed and weighed before installing habitat systems for insects.

6. Discussion and Conclusions

This work points out that integrated habitat systems, both in the VF and in the ETICS, are building physically possible. The requirements on indoor comfort, energy efficiency, a good sound reduction index, and a low risk of mold were met for all variants. The integrated insect habitat systems have the largest building physical impact on the construction in terms of thermal insulation and acoustics. With regard to fire protection and moisture, similar findings apply for all variants. These findings are, with the restrictions described in this paper, that all variants meet the fire protection (qualitative approach) and moisture transfer requirements (steady state approach). Due to the combustibility of reed as a filling material for the installation modules, all variants can only be installed in building classes 1 to 3 (up to 7 m height and up to two utilization units). For other building classes, additional measures (e.g., fire barriers) are needed. A risk of mold can be excluded for all selected variants.

Simplifications and assumptions were made, which have to be metrologically checked in the future. For example, a thermal conductivity of 0.14 W/mK was assumed for the nesting box filling, based on empirical values. The mixing ratio, as well as the air exchange through the openings of the reed pipes, was neglected. In order to reduce the thermal bridge effect, edge insulation strips and insulation materials with lower thermal conductivity can be used. A more precise simulation is necessary to get a temperature profile inside the nesting clay. The summer case will have to be investigated, too.

The acoustic calculations of this work were carried out frequency-independently. The current legal requirements for sound reduction are based on the evaluated sound reduction index. The sound reduction index is limited to the range of high frequencies. However, external noise, such as road traffic, is usually in the lower frequency range. Therefore, the sound reduction index does not investigate this aspect sufficiently. A low stiffness usually results in a low resonant frequency. Consequently, there is a high degree of improvement of airborne sound reduction, which has a good effect on the evaluated sound reduction index but can lead to deterioration in the lower frequency range. In order to ensure the most effective noise protection, an additional calculation should be carried out using the spectrum adjustment values. Another noise source is the bees themselves and possible other predators which will be attracted. This aspect needs further investigations of acoustic influences inside the house. Next to a busy road, the hum will have less impact compared to the noise level of traffic than in a quiet residential area. Measurements and field trials are necessary. It is likely that the habitat systems can act as a point mass in the ETICS variants. The weight of the systems influences the oscillations. Thus, compared to same façade construction without nesting boxes, an improvement can be achieved. This also applies to the module filling which can have positive effects (e.g., absorption).

First sociological findings of N = 185 participants imply that people need best practice objects to lose their prejudices. Although the survey was limited due to its online format and thus an average age of 37 years, first implications can be made. The most common concerns of participants were damage to buildings caused by pests, physical damage to buildings, increased maintenance and cleaning efforts, or fear of allergies. This skepticism may originate because of people’s knowledge gaps concerning insects and the novelty of insect habitat systems into façades. People are reminded in some cases of building damage due to insects or birds (e.g., ants, termites, and woodpeckers). They also may not know a lot about the way of life of certain insects (for example, that wild bees usually are not aggressive). Another result of the survey was that species influence people’s attitude towards biodiversity protection. People do care more about “favored” insects like butterflies or bees. Thus, further building physical examinations on real test subjects are necessary. Additionally, static issues, e.g., the installation method, longevity, and maintenance intensity of the created systems, have to be investigated in practice.

The findings reveal a big research gap. Further research studies will focus more on the socio-ecological and technical levels (field studies). Awareness of insect loss is no guarantee for actions. Acceptance is very important, whether addressing people or insects.

It is not certain that animals will live in the offered systems. It depends on different issues, e.g., the ecological niche, orientation of the façade, and the environment of the buildings (water, plants, soil, and air-qualities). Temperature, humidity, wind speed, and radiation influence human comfort zones, which can be simulated. Current investigations pursue a categorization for insect comfort zones by using adapted, modified methods. Building physical investigations of comfort needs of insects in habitat systems is essential. Individual isolated solutions in a city do not make sense. It may be possible though to link biotopes with integrated habitat systems. Field studies are indispensable and already planned. In order to meet the demands of society and reduce reservations, it is necessary to prove in a holistic, scientific way, that nature and cities are not contradictory.