1. Introduction

Compared with the traditional method of housing construction, prefabricated housing has the advantages of increasing design and production efficiency, improving construction quality, and ensuring housing quality [

1]. In the process of housing industrialization and modernization, developing prefabricated houses can help save energy, reduce consumption, improve construction efficiency, and so on [

2]. It has been widely used in a lot of countries due to the benefits [

3]. Prefabricated buildings are also very popular in China [

4]. However at present, the floor plan design of the prefabricated house in China still follows the traditional house floor plan design method, and even applies the traditional house plane directly, resulting in problems in the market such as an unreasonable distribution of the suite types of the fabricated house, a low utilization rate of the space of the suite types, an unreasonable plan size with too much variation, a lack of flexibility in the space design, etc. For the floor plan design of prefabricated housing, we must find a unique design method to meet the requirements of its industrial production and construction, and finally, realize the standardization and diversity of the design results.

The modular building is assembled from many pre-production modules which are produced in an off-site fabrication center [

5]. The modular construction method can improve construction safety and efficiency [

6,

7]. The modular design is still in the primary stage of development in China’s architectural design community. It is the development trend of housing industrialization and standardization [

8,

9], in which the modular design method is used in the floor plan design of prefabricated housing [

10]. With modular design theory, the plan is divided into modular parts and the module library is established; then the modules are recombined into new monomer according to certain logic [

11], which can obtain a standardization of results and diversity [

12].

Building information modeling (BIM) technology is an architectural design method emphasizing a whole process and life-cycle [

13,

14], which is another significant change in the construction industry after the transition from manual drawing to computer aided design [

15,

16]. The development of BIM technology can provide more comprehensive information [

17]. It can realize the design and management during the whole life cycle of the building [

18,

19]. However, how to apply BIM technology to the floor plan design of prefabricated housing is still lacking research. Based on the theory of modular design and the BIM technology platform [

20,

21], this paper discusses a new method for floor plan designs of prefabricated houses, and diversified designs have also been considered. In the floor plan designs of prefabricated houses, guided by the theory of modular design method and using BIM technology as a means of implementation [

22,

23], the plane module libraries of prefabricated houses are preliminarily established.

At present, architects still use traditional design methods [

24]. In order to meet the characteristics of industrialization, an information conversion process is required, which disconnects the design stage and production stage and increases the workload. Perhaps some companies form a collection of residential planes, but these products are basically messy because there is no clear system. In some collections, the hierarchical relationship is not clear, and in other collections the attributes are crossed to make the objects unrepresentative. It is likely that many objects are duplicated and redundant, and it is difficult for designers to quickly select the ones that meet the requirements. Using plane module libraries based on BIM to design the plane for the prefabricated houses can result in the informatization and visualization of every module in the whole life cycle [

25,

26]. BIM gives modules three-dimensional characteristics, so it can help give a more intuitive feel to the space, with quicker module selection and modifications. It is very feasible and also of great benefit to improve the design efficiency and meet the design and construction requirements [

27,

28].

The problem of this research is how to find a suitable floor plan design method for prefabricated houses. The purpose of the research is to improve the efficiency and standardization of floor plan designs of prefabricated houses, and to meet the diversified needs of residents. In addition, the research line of this paper consists of three steps. First, the modular design theory is used to systematically separate the residential plan to establish a clear modular system. Then, the concept of a module library corresponding to each level of the module system is established, and the principles of module selection and the method of creating information based on BIM are discussed. The module library is initially established in this step. The establishment of module libraries is the core of the floor plan design method for prefabricated houses. They are selected to combine into a new plane, and can be replaced with each other. There will be many different results under the same combinatorial logic, which will definitely improve design efficiency. Finally, the plane combination and diversified design methods based on module libraries are studied. Moreover, this article innovatively applies the modular design theory to floor plan designs of prefabricated houses, which helps to establish a clear plane modular system. Furthermore, a concept of module libraries corresponding to the plane modular system is creatively proposed, and it is initially established using BIM. Compared with traditional design methods it is more orderly, and can greatly improve design efficiency. The contribution of this research is to provide a new idea for the floor plan designs of prefabricated houses. The new method can not only greatly improve the efficiency of designs of prefabricated houses and meet the diverse needs of users, but also improve the level of information in the design process and promote the industrialization of the housing industry. This study also has reference significance for the design of facades and parts of prefabricated houses. The research can be applied to floor plan designs of prefabricated houses in design institutes to help save time and improve design quality. It can also promote the industrial development of housing.

2. Building Modular Library Method for Prefabricated Houses

The establishment of the BIM plane module library is the core of the floor plan design method for prefabricated houses [

29]. The floor plan design method based on plane module libraries can improve the design efficiency and the degree of refined design. The establishment of the plane module library is divided into three steps: module classification and selection, module coding, and module information creation.

In the module classification stage, the modular design method is used to systematically separate residential planes to establish a plane modular system. The key at this stage is to choose an appropriate separated point. The results of structural systems will be very different if the separated points are different. In addition, planes cannot be separated in a too fragmented manner. It will increase the design steps and reduce the design efficiency if the modular system has too many levels. After establishing the plane module system and the concept of corresponding module libraries, guidelines of selecting modules to be included in module libraries must be discussed, which guarantees that the modules in module libraries are representative and standard. The setting of the principle of storage should ensure that the modules in the module library are representative and standard. In the module coding stage, the technical point to be resolved is to determine which feature attributes of modules are extracted to form coding structures. It is necessary to solve this problem by considering what the architects’ needs are in the design phase and what the residents’ requirements are in the selection phase. The points of interest for both are extracted to make up the coding structure. After completing the above steps, module information can be created based on BIM technology. The information creation process must be checked repeatedly. Only qualified modules can enter the module library.

2.1. The Classification and Selection of Plane Modules for Prefabricated Housing

2.1.1. Classification of the Plane Modules

Completely individual modular systems will be different if they are formed through different methods of decomposition [

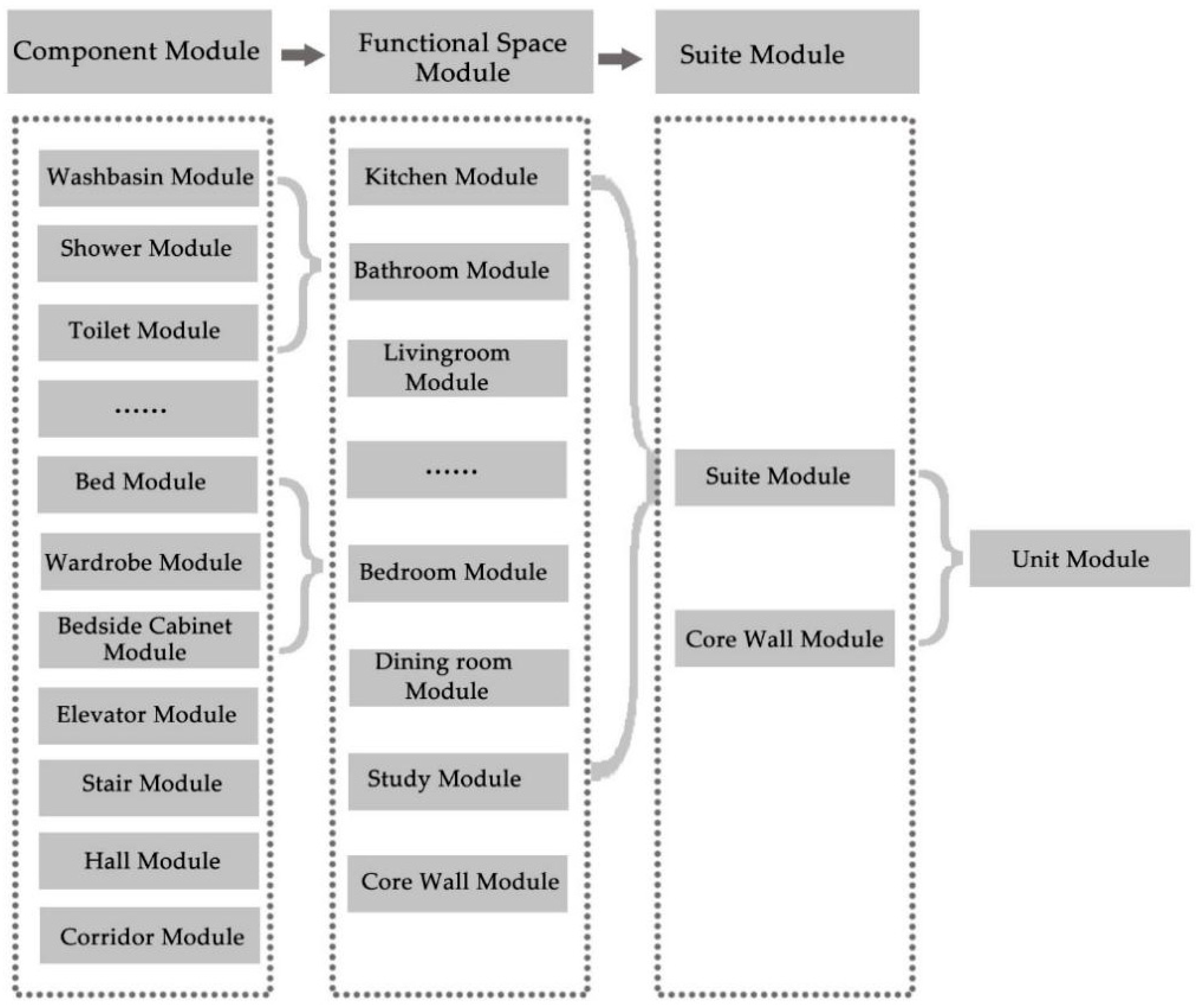

30]. In order to facilitate research on the architectural design of residential plans of the prefabricated housing, the plan systems are divided by the decomposition of the functions into three levels of modules [

31]: the first-level suite-type module, the second-level functional space module, and the third-level component module.

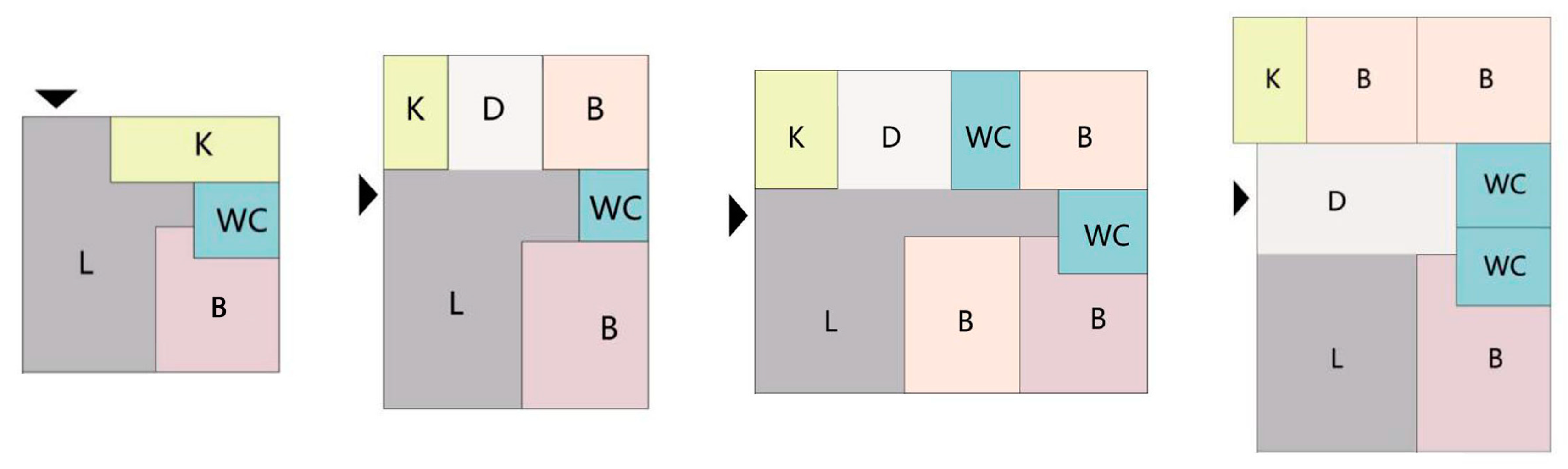

Figure 1 shows the combination of modules between the levels. The third-level component module and its use spaces form the second-level functional space module, and the third-level washbasin module, the shower module, and the toilet module together form a second-level bathroom module. The different functional space modules form the first-level suite module, just like the kitchen module, the bathroom module, the living room module, and the other functional space module together constitute a suite module. In addition, the suite module can be combined with other suite modules or core wall module to form a larger residential unit module.

According to these hierarchical relationships of levels, the corresponding module libraries are established, that is, the third-level component module library, the second-level functional space module library, and the first-level suite-type module library. Each library represents a collection of the same type of module, and the modules in each library have the same properties. In the case of the same combination logic, content-rich module libraries can achieve the aim of diversity of design, which plays an important role in improving design efficiency [

32].

2.1.2. Selection of Inputting Plane Modules into the Libraries

There are two requirements for selecting modules into the libraries. The first one is to ensure that the selected module conforms to the properties of the module library type. Another one is to ensure that the selected module is standard and universal, so as to ensure that the module conforms to the standardized production and the number of the types are within a certain controllable range. The selection process of each plane module has four steps. Firstly, the plan of a prefabricated house is to be separated according to a suitable system. Secondly, the modules must be classified. Thirdly, the main control factors are to be grasped, the secondary factors are to be ignored, and the modules of the same type in the module library are to be merged as possible, so as to reduce the excessive types of components caused by too detailed division of the main control factors, in order to obtain the modules with high standard and generality. Fourthly, it must be checked if the modules are standard and versatile. However, the types of modules should not be too few, so as to avoid not meeting the requirements of floor plan design diversity [

33].

The establishment of module libraries is the core of the floor plan design method for prefabricated houses based on BIM. Based on the module libraries, the modules that meet the requirements are to be selected and combined into new individuals, which not only improves the design efficiency and the degree of defined design, but also the richer the module libraries, the higher the degree of diversification of design results under the same combination logic.

2.2. Coding of Plane Modules

The coding of modules should not only reflect the classification of objects but also show their characteristics [

34]. When coding, the following principles should be followed. First, the uniqueness principle: each code can only correspond to a single module. Second, the rationality principle: any code should correspond to certain corresponding classification of modules. Third, the simplicity principle: the coding should use as few characters as possible for identifying which module it belongs to. Fourth, the integrity principle: the coding must be complete without lack of corresponding information. Fifth, the standardization principle: all the coding must use the same formal specification. Sixth, the practicality principle: the coding should be as convenient as possible for the use and management of professionals.

The general coding structure is shown in

Table 1: Letter groups X1 and X2 usually stand for the module classification. X3 generally stands for the basic properties of an object by using digit or alphanumeric mixture. X4 can be added when the previous three encodings are all the same. For example, when coding the second-level function module, X1 stands for the names of various function rooms, such as “Bedroom”, “Living Room”, “Bathroom”, etc., which are represented by “BD”, “L”, and “BT”, respectively. The areas of the same functional rooms vary from small to large. In the design of the suite and functional space, the design institutes, real estate developers, and users always classify and select the suites by the size of the area. Therefore, in order to facilitate the search of the suite types in the module libraries, the author classifies the functional spaces and suite modules into three types: economic type, comfortable type, and higher comfort level type, according to the size of the area, which are coded respectively with “E-”, “C-”, “HC-”. The coding principle of the suite type module is the same as above. For example, “E-51.7-2BD1L1K1BT” indicates that the size of the suite area belongs to the economic type of suite just meeting the basic use demand, with a suite area of 51.7 m

2, and the residential unit is equipped with two bedrooms, one living room, one kitchen, and one bathroom.

2.3. Creation of Module Information

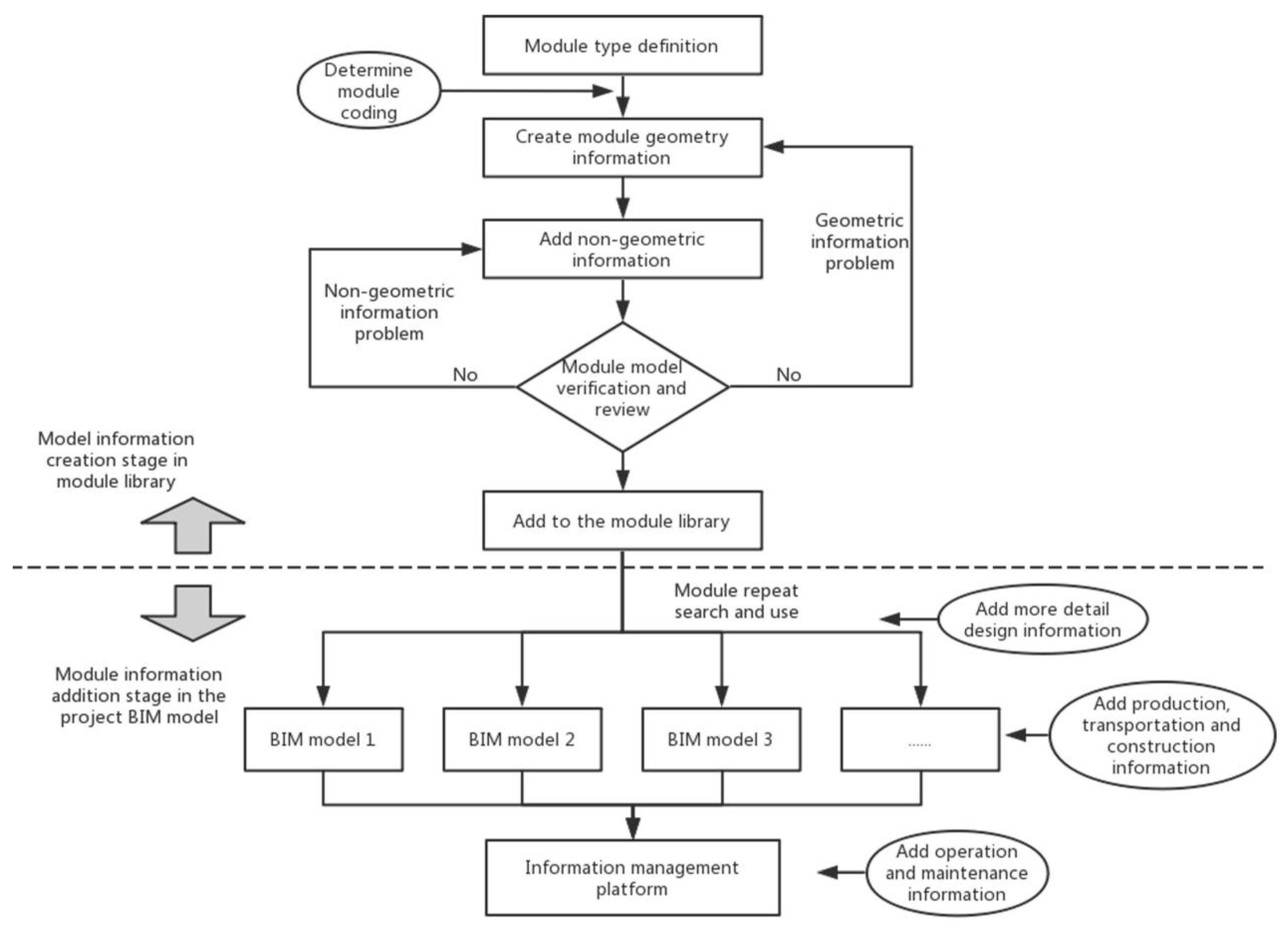

In the whole life cycle of the building, the information creation of the models is divided into two stages: information creation of modules in the module library and information addition to project BIM model [

35]. As shown in

Figure 2, in the first stage the module is classified firstly; then the module is coded according to the type and characteristics, and then the geometric information of the module is created. After that, the non-geometric information of the module is added. Next, the model information should be verified and reviewed. If the model geometry information has problems, the model should be returned to correct the geometric information. If the non-geometric information is checked out, the non-geometric information should also be re-edited. After checking, the model without any problems can enter the corresponding type of module library for later use. In the project, the original module that is closest to our needs is chosen, then detailed information to the selected modules is added and the detailed design of the BIM model is carried out. Then the BIM model is to be submitted to the next level of construction organization after passing the review to guide the organization for production and construction. The subsequent information addition is a dynamic process, adding what is not included in the module libraries. When establishing the module libraries, some blank space should be reserved for BIM model information addition. For example, when building the “bed module”, after the bed form is determined, the length, width, and height are to be set as parameters in the BIM model, which will be convenient for change and application in different functional spaces. After the module is given a parameter, it has the characteristics of the BIM family, but they are different from those families because its shape parameters can only be changed in a certain range, and they also have many limitations.

After module decomposition, selection, coding, and information model creation, the first-level suite module library, the second-level function space module library, and the third-level component module library are established.

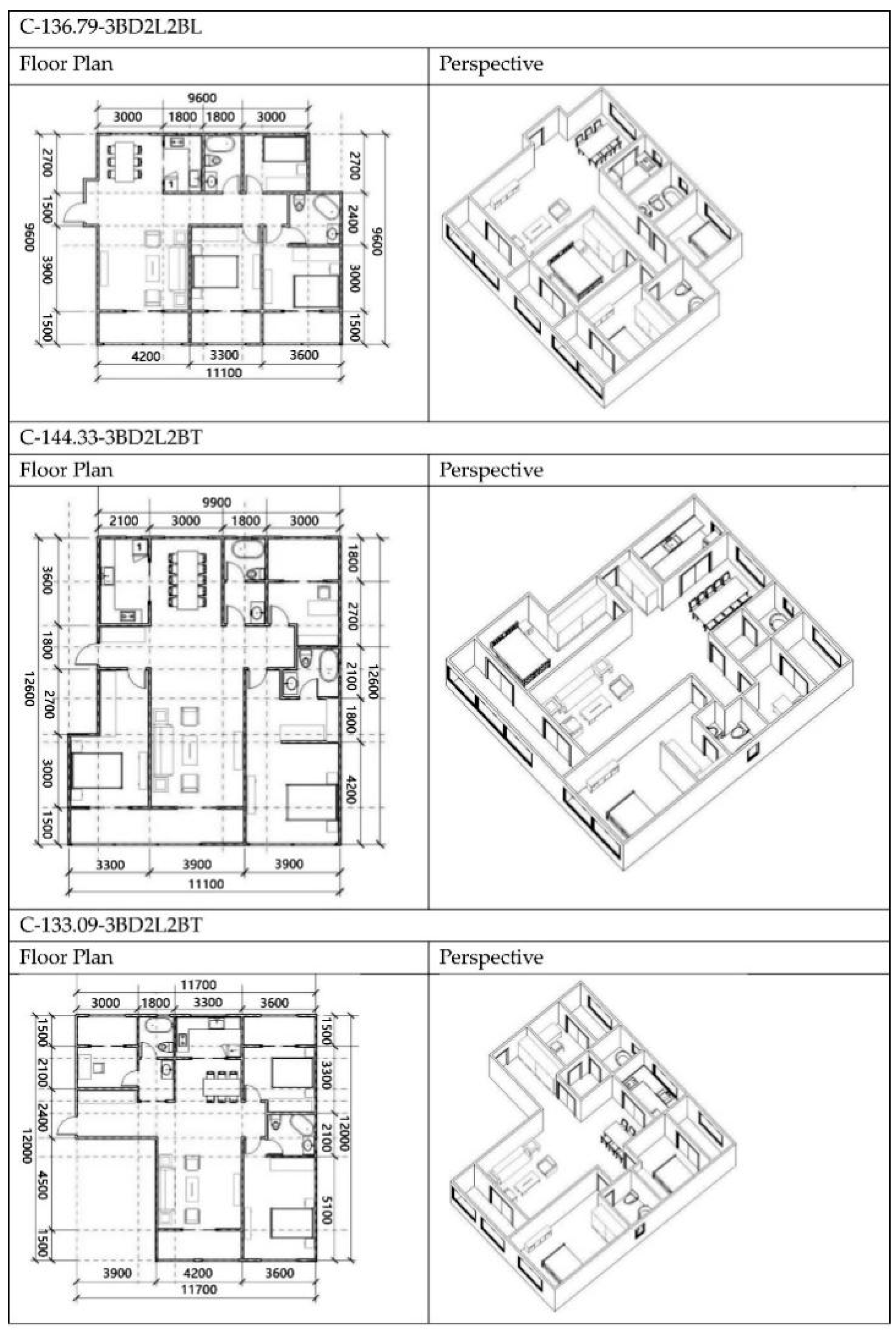

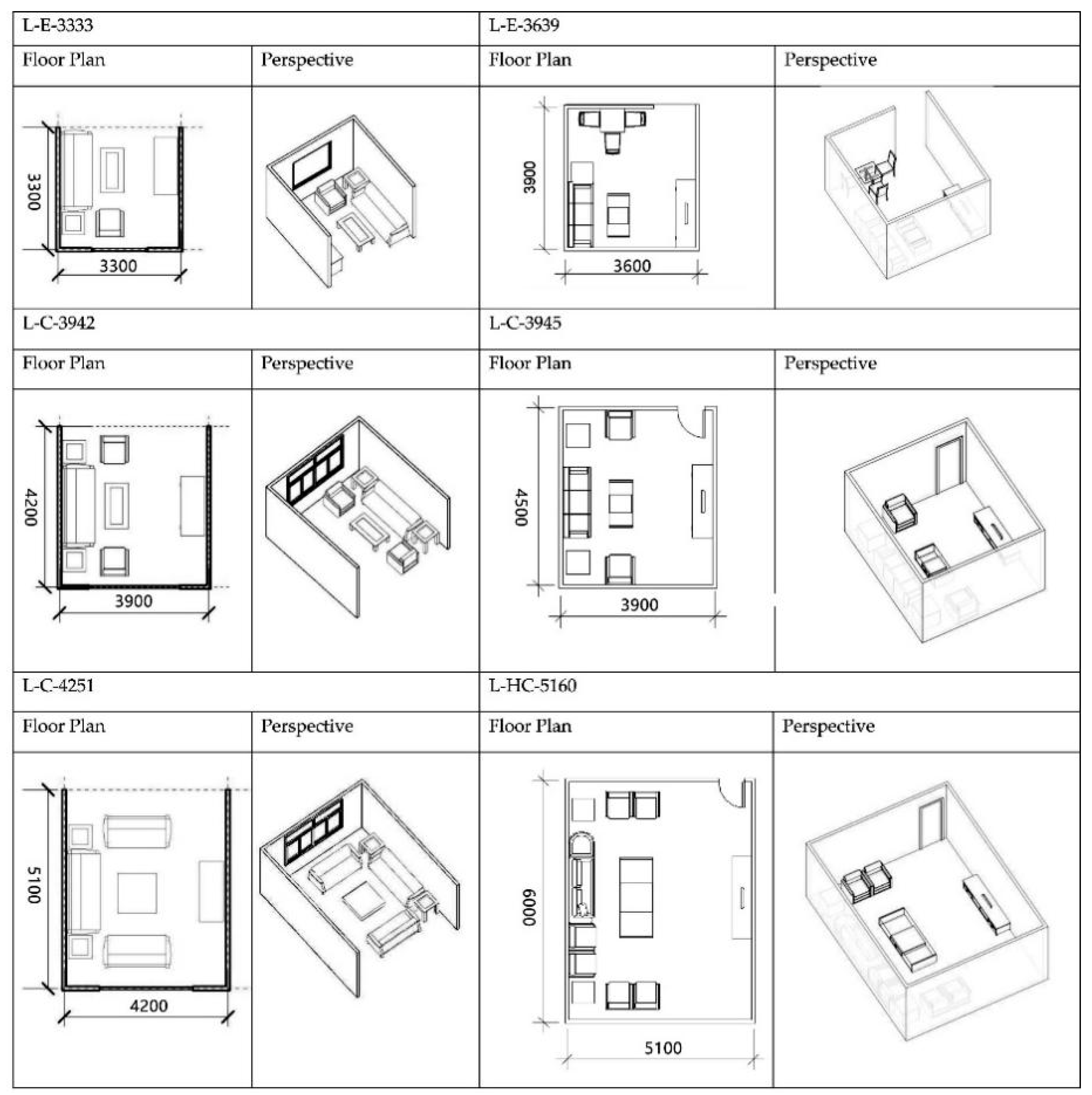

Figure 3,

Figure 4 and

Figure 5 show some parts of the module libraries.

Figure 3 describes some comfortable suites of the suite module library. The code simply describes the composition of the set, which helps to quickly find the desired set.

Figure 4 illustrates living room modules from small to large, from comfort to super comfort. The size of the plan on the left is in accordance with the modulus system, which is a multiple of three. The perspective on the right gives an intuitive feeling of space.

Figure 5 shows the sofa modules. Their styles are different, and the length, width and height of each style of sofa are set to changeable parameters. In the application process, a style of sofa is selected according to the needs, and then the parameters such as length and width are adjusted according to the size of the functional space.

A three-dimensional effect has been applied to the module library based on BIM, which makes it more intuitive than the traditional atlas, and conducive to the refined design of the house. The establishment of model information with a complete system will promote the use of modular design methods in practical engineering and improve design and production efficiency. Factories can prefabricate standardized modules and the entire industry chain will become more robust [

36].

3. The Application of Plane Module Library for Prefabricated Housing

Based on the module library, the modules that meet the requirements are to be selected and then to be combined into new individuals, which can not only improve the design efficiency and the degree of refined design, but also meet the needs of users for the variety of suite types and units by using certain design methods [

37,

38]. In the following, the application method of module libraries and diversification of floor plan designs are probed.

3.1. Application Method of Plane Module Libraries

For most residences, a complete suite consists of bedrooms, living rooms, kitchens, dining rooms, bathrooms, study rooms, entrance halls, balconies, storage, and other functional spaces. There are one-bedroom, two-bedroom, three-bedroom, and multi-bedroom suites. People usually choose a right type according to their use needs and economic capabilities. The floor plan designs of houses should conform to the principles of economy, adaptability, comfort and diversity. In the combination of spaces, the most important work is to perform functional partitioning. For example, it is necessary to consider activity zoning and clean-dirt partition, not only to ensure that the space is independent and free of interference, but also to ensure that the spaces need to be connected to each other to improve the use efficiency.

Figure 6 shows the common space combination relationship of one-bedroom, two-bedroom, and three-bedroom suites. When designing other suites, designer can make topology changes according to the combination relationship of each type to achieve reasonable design of other suites.

Based on the above architectural background knowledge, when carrying out the floor plan design of prefabricated residence it is necessary to first query the required suite type in the module library according to the architectural design and the user’s needs. Then it is necessary to combine the suite module with the public transport module to form the unit module, and finally combine the unit module to achieve the initial design. The completed initial BIM model needs to be analyzed and optimized. When there is no problem, it means that the BIM model meets the user’s needs of use and comfort, and then the floor plan design scheme is basically determined and can be delivered to other disciplines to continue design and input model information. When the BIM model does not meet the use requirements, modules can be selected from the module library for replacement. When the modules that meet the requirements cannot be found from the module library, it is necessary to design new modules according to the requirements and input the representative new modules into the libraries for future use. Due to the existence of the module library, some universal modules can be manufactured in advance to improve the production and construction efficiency. The richness of the module library determines the feasibility and applicability of the BIM-based prefabricated residential floor plan design method. When the module libraries are not perfect, it is difficult to design a residential unit that meets the needs of users. Therefore, it is very important to enrich the module libraries in the early stage, and it is necessary to continuously improve them by adding representative modules that are not included in them.

As the modules in the module library all meet the requirements of standardization and generalization, users can select modules from the functional space module library to replace other functional space modules in a suite module according to their needs, so as to achieve diverse designs. In addition, selecting different furniture from the component module library to replace parts in a functional space can realize different layout forms. The diversified combination of modules enables a wide range of design results.

In the following, this article chooses three typical residential plans to explore the flexibility and variability of floor plan designs based on module libraries. These three cases all conform to the basic principles of residential designs, with clear functional partitioning, reasonable space organization, and modular size. The suites belong to the comfortable type with the largest market demand, and the functional space configuration is reasonable. It has reference significance for flexible and variable designs of other prefabricated houses through the case study.

3.2. Flexible and Variable Design of the Suite

Flexible and variable design of the suite based on the above said three-level module libraries can adapt to the long-term needs of family so that the residential units can also “continue to grow” to extend their service lives [

39], and become real sustainable development buildings, mainly through the method of replacement of the spaces within a suite or between the suites.

3.2.1. Space Replacement within a Suite

There are two ways to replace the spaces within a suite: the diversified combination of functional space modules, and the large-space design. The suite is composed of many functional space modules, so the change of a suite type can be realized through different combinations of functional space modules.

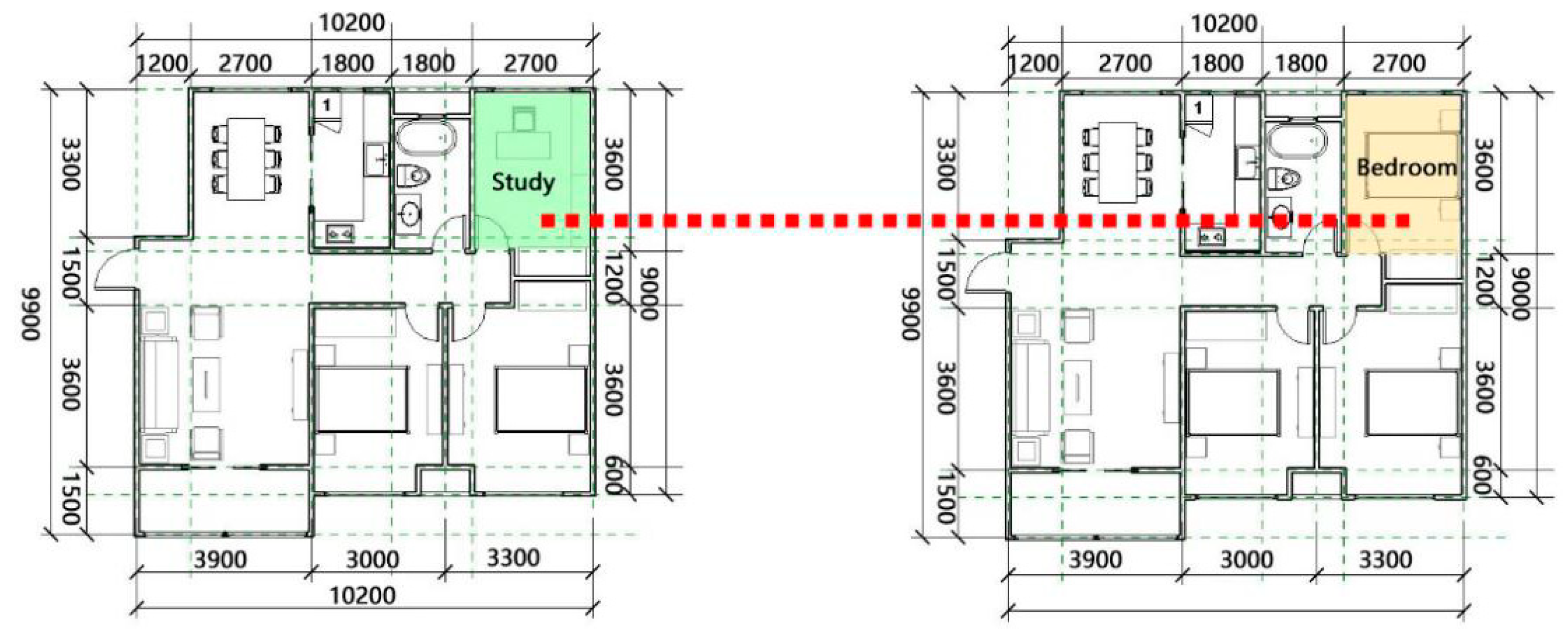

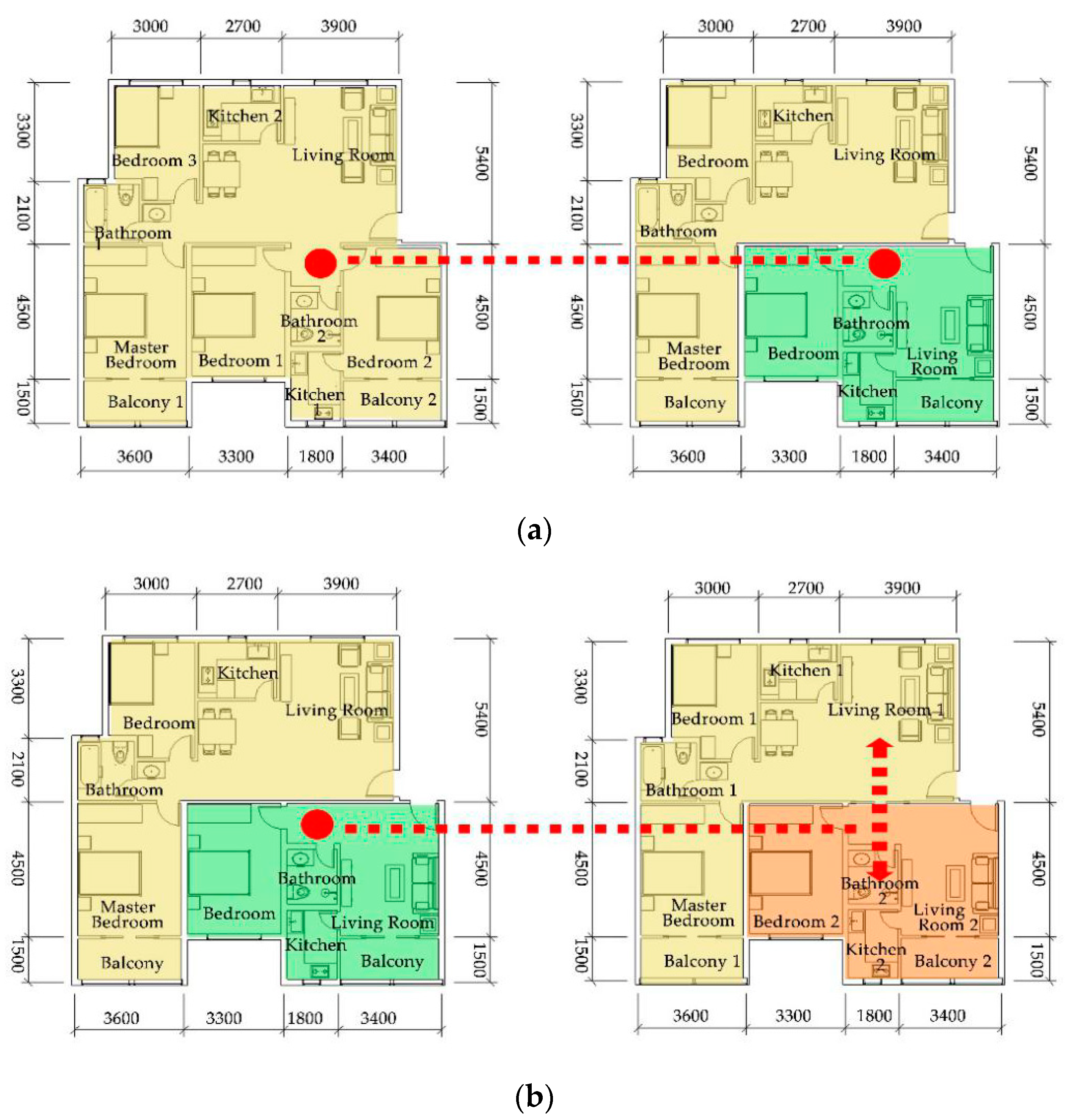

As shown in

Figure 7, it is a scheme of diversified combination of function modules inside a suite. The change of the whole suite can be realized by replacing the function space module of the “Study” with the function space module of the “Bedroom”. For the family with a large population, the latter can be selected, When the two spaces are replaced, the other spaces are not affected at all.

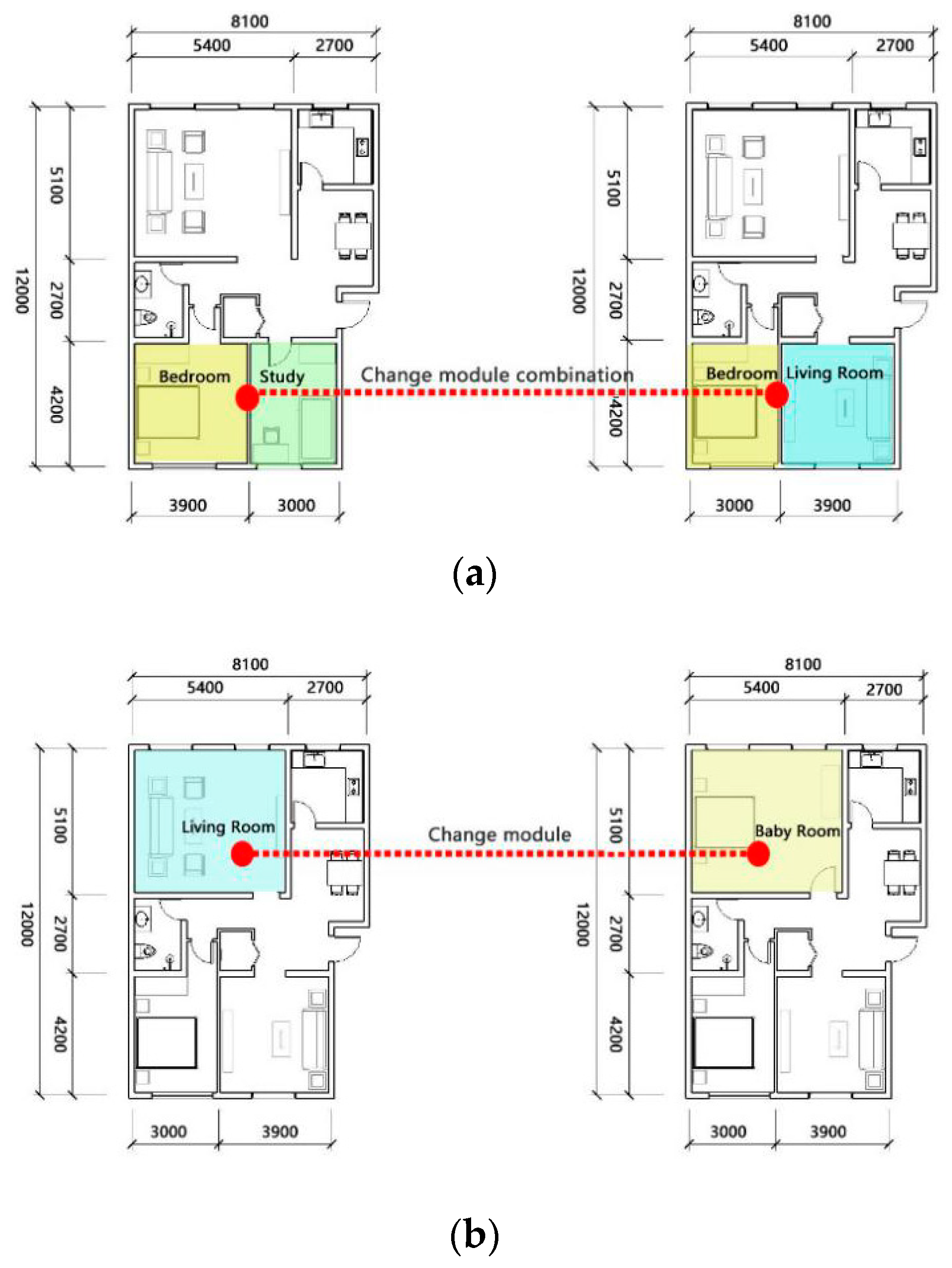

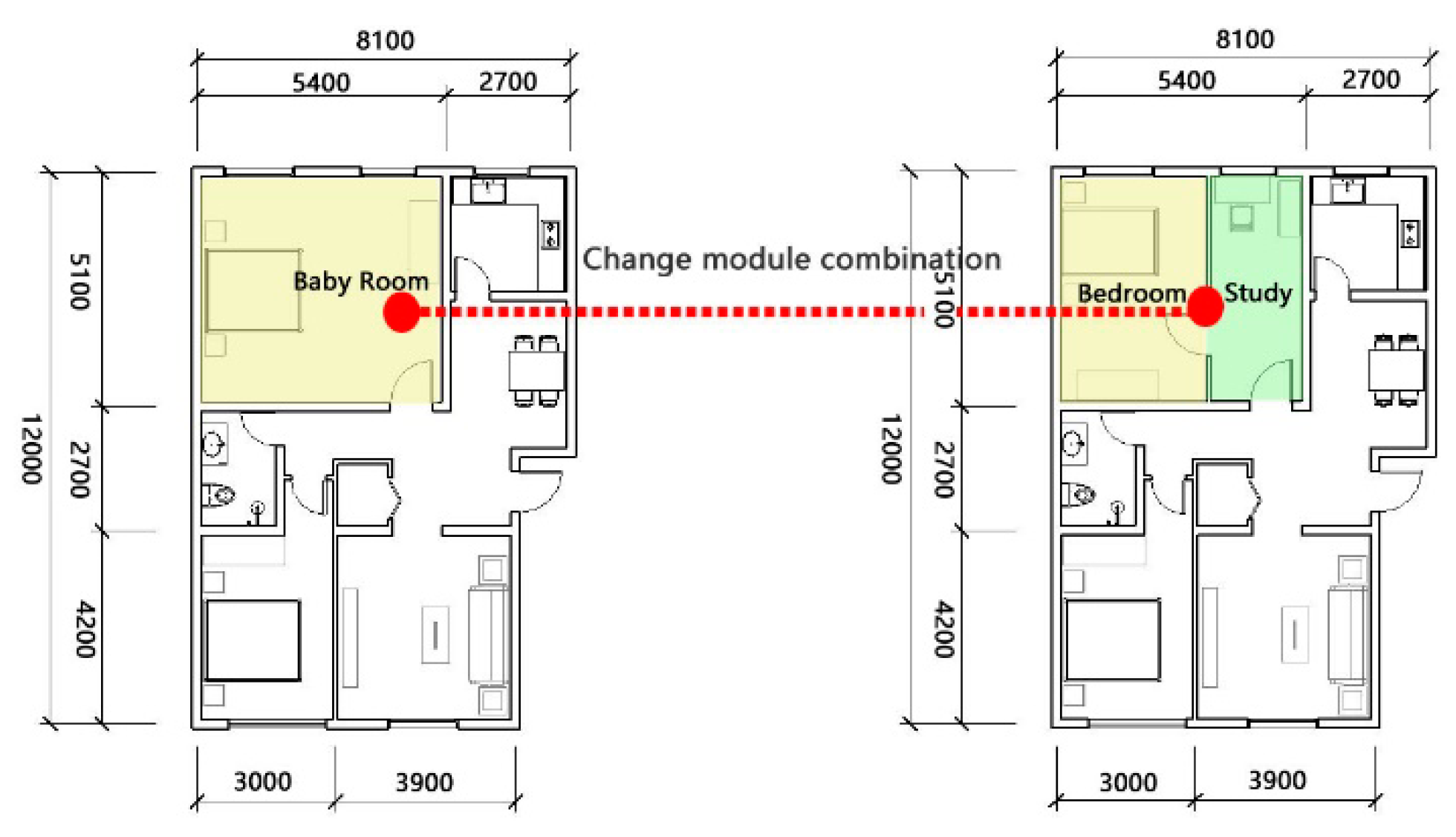

Figure 8,

Figure 9 and

Figure 10 show a scheme of large space design in a suite type. In the newly married stage, the family structure is a family of two, and young couples usually focus on work. Therefore, the large space in the south is composed of a master bedroom module with a width of 3.9 m and a study module with a width of 3.0 m. The living room with a width of 5.4 m is designed to the north of the suite. During the baby-rearing stage, the living room on the north side of the suite is changed to the baby room, and the large space on the south side is changed from the original module to bedroom module with a width of a 3.3 m, with the remaining space for living room module with a width of 3.6 m (

Figure 8) [

40]. At the school-age stage of the child, the original nursery room can be divided into “Bedroom module” + “Study module” to meet the learning needs of the child under the condition that other rooms remained unchanged (

Figure 9). In the elderly care stage, the family structure has become a two-person structure, but the children will occasionally go back home to live, so the large space on the north side can be divided into two independent spaces consisting of a bedroom module and a nanny room module (

Figure 10). From the above changes, thanks to the use of large space design techniques, the replacement of functional spaces inside the suite can meet the needs of life for decades from newlyweds to the elderly, which greatly improves the service life of the suite.

3.2.2. Space Replacement between Suite Types

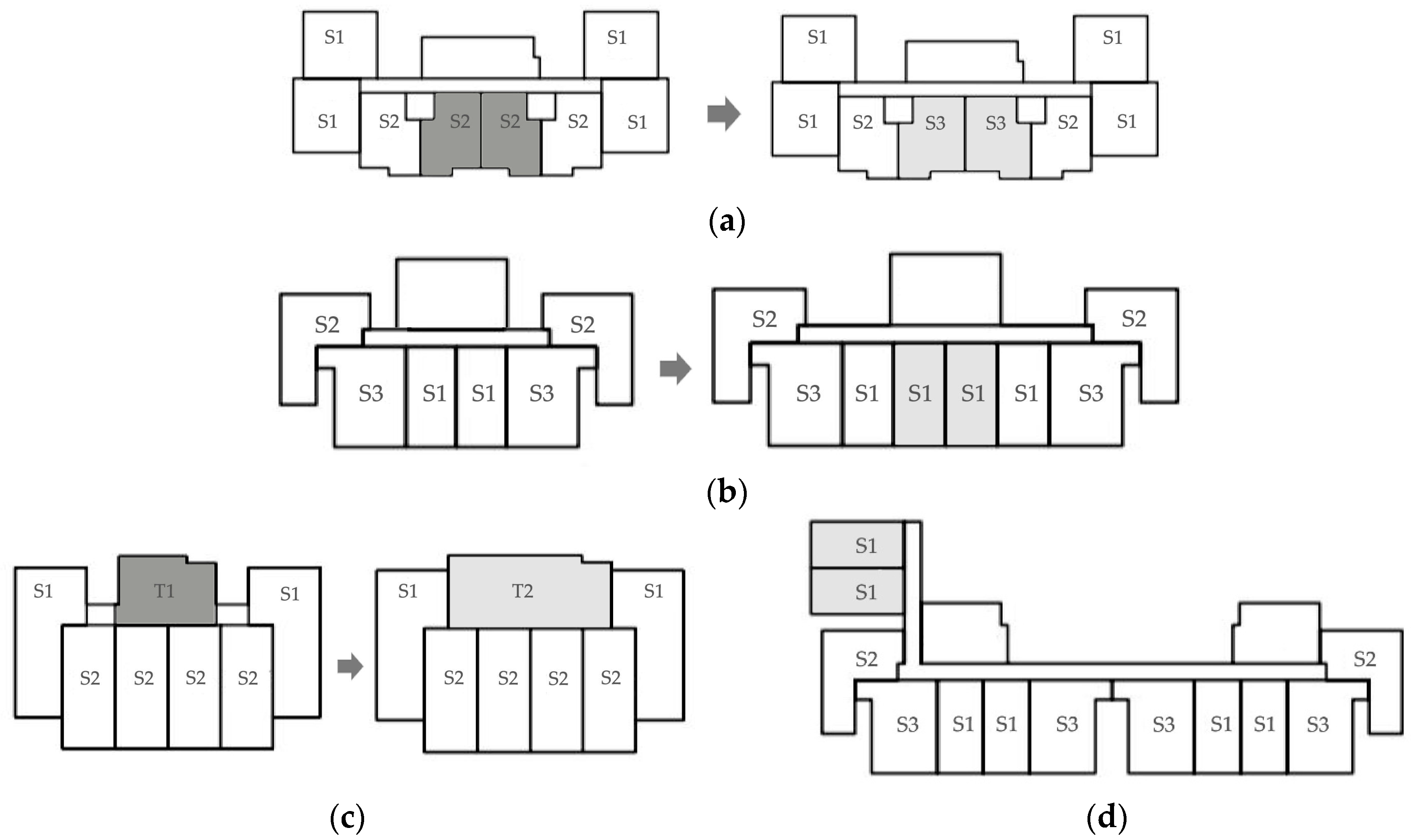

The division and combination of the functional space between the suites can result in the diversification of the suite types without changing the building structure, and the suite types can be flexibly determined to meet the demand of the users. In

Figure 11 a flexible design example of space division and combination between two adjacent suites is presented. At first, in

Figure 11a, the four-room suite A1 is divided into two independent suites B and C by connecting walls and adding an entry door to separate spaces. Type B has two rooms, one bathroom and one hall, and type C has one room, one bathroom, and one hall. The spaces of the two suites are completely separated. As shows in

Figure 11b, by inserting a sliding door on the adjacent wall interface, the two independent suites can be changed into two relatively independent suites. The two spaces can be connected when the sliding door is opened, but when the sliding door is closed, the two spaces are independent. Since there are two entry doors, mutual interference can be completely avoided between the two sets. The suite A2 is suitable for families of three generations, with the elderly living in the middle suite, which means they not only get the care from their children but also have relative privacy in the two spaces. Through the method of space replacement between suites, the diversity of suites can be realized. The number of each type of suite in a unit is flexibly determined according to the customer’s demand, which greatly improves the flexibility of the suite design.

3.3. Diversified Combination Design of Suite Modules

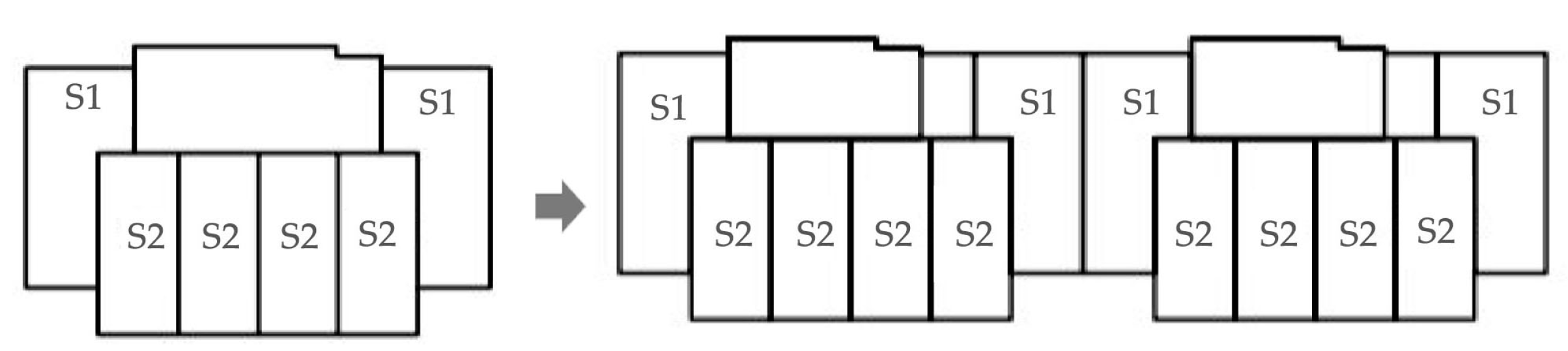

Based on the selection of standardized suite type, the residential unit can be combined into tower-type or slab-type residence according to the requirements and consideration of the volumetric rate [

41]. There are various methods of combination. The author summarizes the following methods: First, for a single residential unit, the unit form can be changed by changing the suite type. As shown in

Figure 12a, the original four type S2 suites facing south have been changed to the form of type 2S2 + 2S3. Second, the unit form can be changed by increasing the number of a certain suite type. As shown in

Figure 12b, the unit form is changed by adding two southward S1-type units. Third, for the same suite combination plan, the whole unit form can be changed through changing the traffic cores to adapt to the floor change, as shown in

Figure 12c. Fourth, the unit form can be changed through the vertical splicing of the unit. As shown in

Figure 12d, the unit plan changes the original unit form by adding two S1-type suites longitudinally.

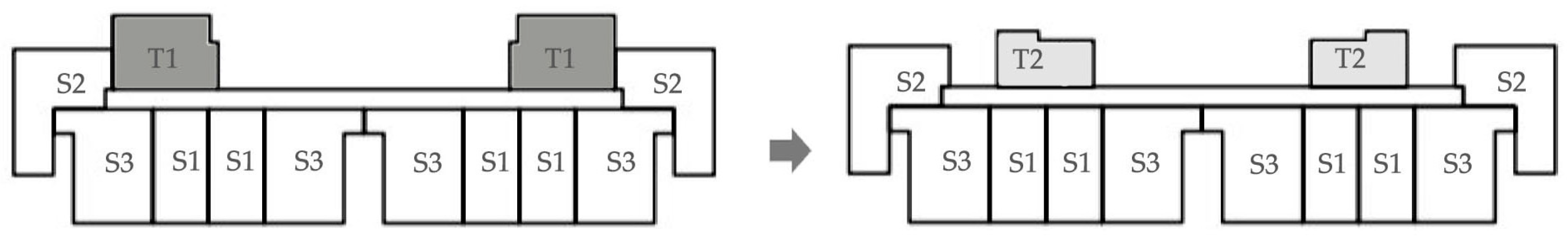

3.4. Diversified Combination Method of Unit Modules

For the combination of multiple units, first, a new unit can be formed by combining two units in parallel (

Figure 13). Second, the unit form can be changed by changing the traffic box, as shown in

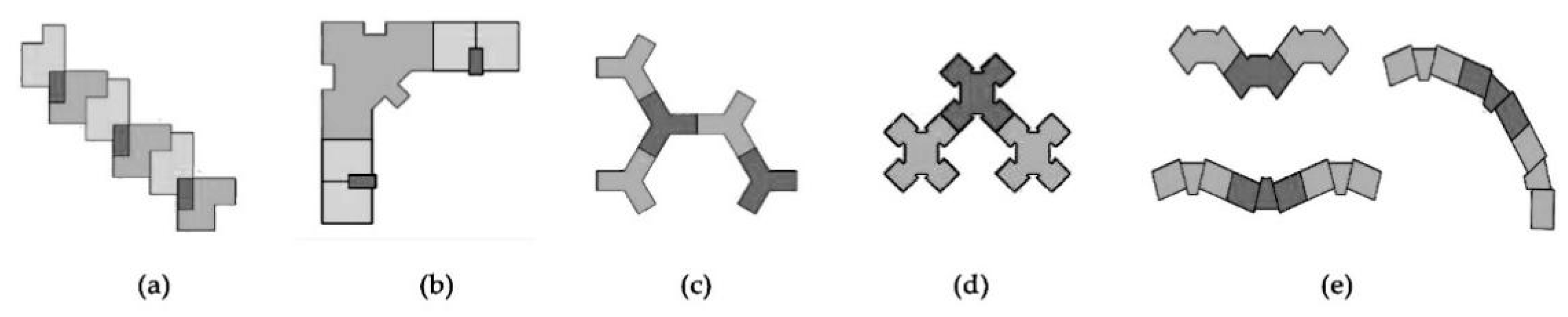

Figure 14. In addition, the unit module also has the methods of one-direction splicing, two-direction splicing, three-direction splicing, multiple directions splicing, and heteromorphic splicing. As shown in

Figure 15, the one-direction splicing means the splicing in a single direction, which can be spliced into strip-type or oblique serration shape according to the land conditions or terrain constraints. Two-direction splicing means that the unit at the corner has a certain degree of closure, which is formed in the horizontal or vertical directions. The three-direction splicing means the splicing is made in three directions, and its form has more changes. Multiple direction splicing means the splicing in multiple directions to form the I-shape, X-shape, frog shape, and other shapes of the plan. The splicing in multiple directions can not only obtain rich architectural forms but also obtain a good orientation. In order to make plan shapes of houses better adapt to the terrain and can utilize the land in an efficient way, heteromorphic splicing can also be applied. The heteromorphic splicing can be carried to break the monotonous layout and provide more possibilities for getting good orientation.

The above said unit module combination methods should be judged according to the specific project situation, and BIM simulation software can be used for ventilation and sunshine analysis to meet the residential use demand [

42].

4. Discussion and Implications

4.1. Method and Application

Modular theory can be applied to industrial production. The method of building modular libraries for floor plan design of prefabricated housing in this paper is also a specific application of modular theory. BIM technology can realize the informatization of buildings in the whole life cycle. This paper embodies the application method of BIM technology in the stage of floor plan designs of prefabricated houses as well. Based on the design method of this paper, we can also explore the modular design of facades and components for prefabricated houses. In practical engineering applications, the architectural design institute can apply the modular design method to separate prefabricated house planes, and then use BIM technology to build information module libraries. When the types of modules in module libraries are rich enough, the modules that meet the requirements can be selected quickly and combined from the module libraries according to the needs of the owner, which can greatly improve the design efficiency. In addition, for real estate companies and residents, the module library is like a menu. People can search modules according to their requirements. The information of each module is comprehensive and intuitive. Due to the benefits of modular design, the modules can be replaced to realize personalized design. Compared with the traditional floor plan design method, this method combined with the information technology and modular design concept can greatly improve the degree of spatial design refinement and efficiency of design and production. This method can not only improve design quality but can also reduce the investment cost.

4.2. Strengths and Limitations

The research method in this paper can improve the design efficiency of prefabricated houses from the following aspects: First, the modules in the module library all meet the requirements of modularization, so they meet the requirements of industrialized production and can avoid repeatedly adjusting the plane size to meet industrial requirements which often occurs using traditional design methods. Second, the modules in the module library have been carefully designed, so designers can directly select them, which saves design time from the beginning. Third, because there is a clear and scientific system classification, users can quickly and accurately find the required module in the corresponding hierarchy which helps save a lot of search time. Fourth, the module has three-dimensional features and can be viewed intuitively and clearly because BIM technology is used. The application of BIM technology avoids repeated revisions in traditional designs due to unclear space perception.

This study also has some limitations. First, when discussing the flexible and variable design of the suite, this paper discusses two methods. One is the space replacement within a suite, which is mainly changed by functional space module replacement. The other is the replacement of spaces between suites, which can change the types and proportions of residential units. These two methods can help change configuration of suite space to meet the needs of different periods of time, and extend the service life without changing the structure of the house. However, the space design of house should be more flexible in architecture although it is affected by many complex factors. In addition to the methods proposed in this article, more residential space design methods based on module libraries should be explored in the future. The new method should be more concerned with residential space configuration and combined with user needs to better help achieve the goal of diversity and flexibility of the prefabricated house. Second, only the preliminary creation of the module library is carried out; the research on the refined design of each module is insufficient, and the types are not rich enough. The follow-up research should continue to further optimize each functional space module to ensure the quality of the modules in the module library and improve the richness, so as to provide more choices for subsequent prefabricated residential floor plan designs based on the modular libraries. Third, due to the lack of knowledge in the development of computer software, there is no secondary development of BIM software. In order to achieve the search function of the BIM platform module library, the secondary development of BIM software needs to be further studied.

5. Conclusions

The development of prefabricated buildings has the advantage of saving energy and reducing consumption, improving production efficiency and project quality. Firstly, this paper has put forward the method for floor plan designs of prefabricated houses with plane module libraries as the core. The floor plan of the prefabricated house has been divided into three-level modules, and has initially established the first-level suite module library, the second-level functional space module library, and the third-level component module library. It has probed into the combination relationship, entering conditions, coding, and information creation methods of the modules. Secondly, the application method of the module library and the diversified floor plan design method of the prefabricated residence with the module library as the core are probed, including the flexible design of the suite through the space replacement inside and outside the suite, and the diversified splicing design of the unit modules through the splicing of different directions. According to the characteristics of prefabricated house, based on the theory of modular design, this paper studies the design method of plane diversification with the establishment of plane module libraries as the core, which provides new ideas for floor plan designs of prefabricated houses and is of great significance for the development of standardization and diversification of prefabricated house.