Food Waste Management with Technological Platforms: Evidence from Indian Food Supply Chains

Abstract

:1. Introduction

1.1. Conceptual Framework

1.2. Technological Platforms

- i.

- Internet-based data monitoring and communication.

- ii.

- Enterprise Resource Planning (ERP), i.e., software that helps integrate components of a company, including supply chain, by sharing and organizing information among participants at different levels [23].

- iii.

- iv.

- v.

- Electronic Data Interchange (EDI), i.e., computer-to-computer exchange of documents for order processing, transactions, accounting, production, and distribution [23].

- vi.

- Programmable Logic Controller (PLC), i.e., a control system to monitor parameters of input devices and to generate decisions-based output parameters [23].

- vii.

- Cloud computing, i.e., an internet-based system to access a shared pool of computing resources (Mell & Grance, 2011).

- viii.

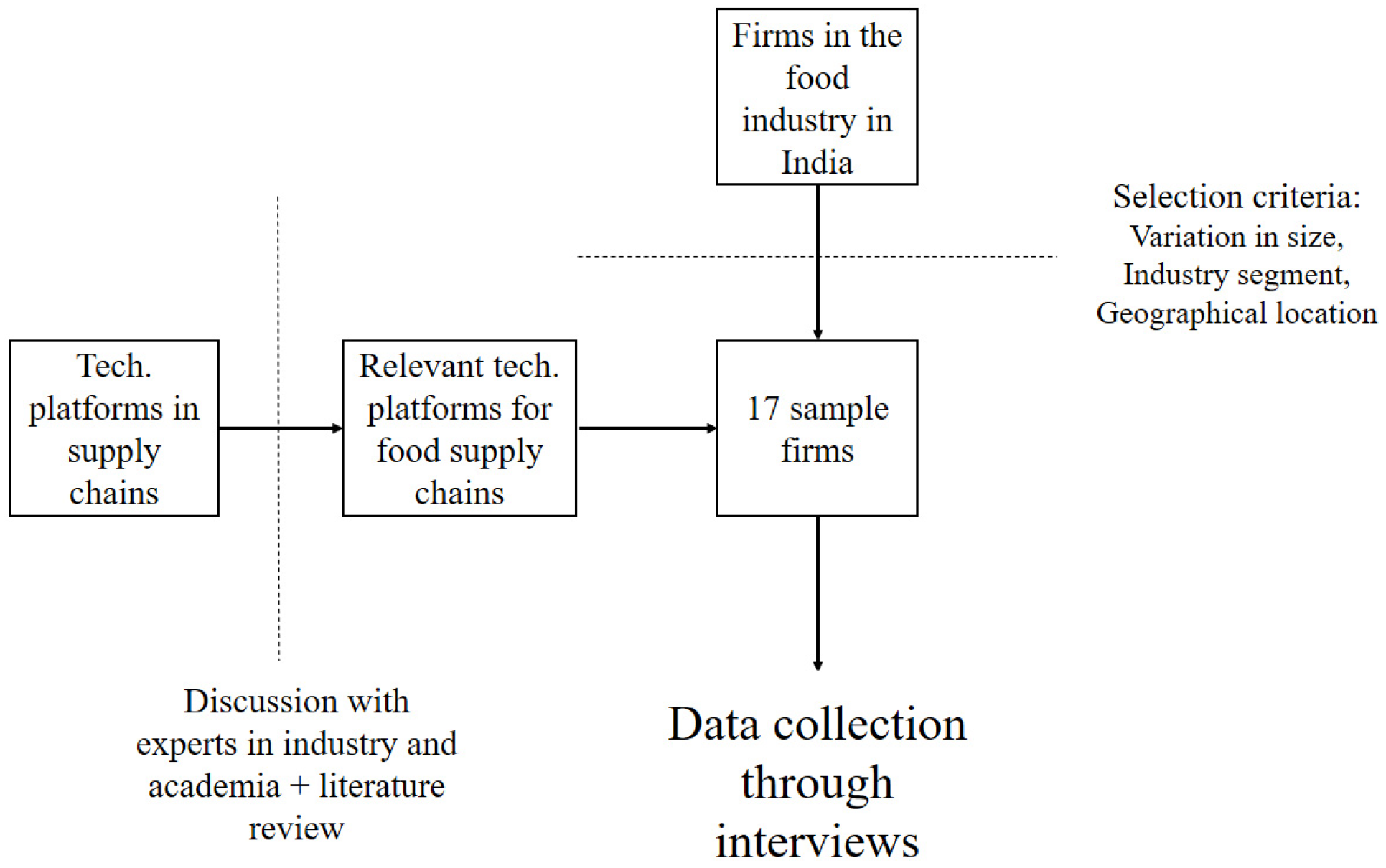

2. Materials and Methods

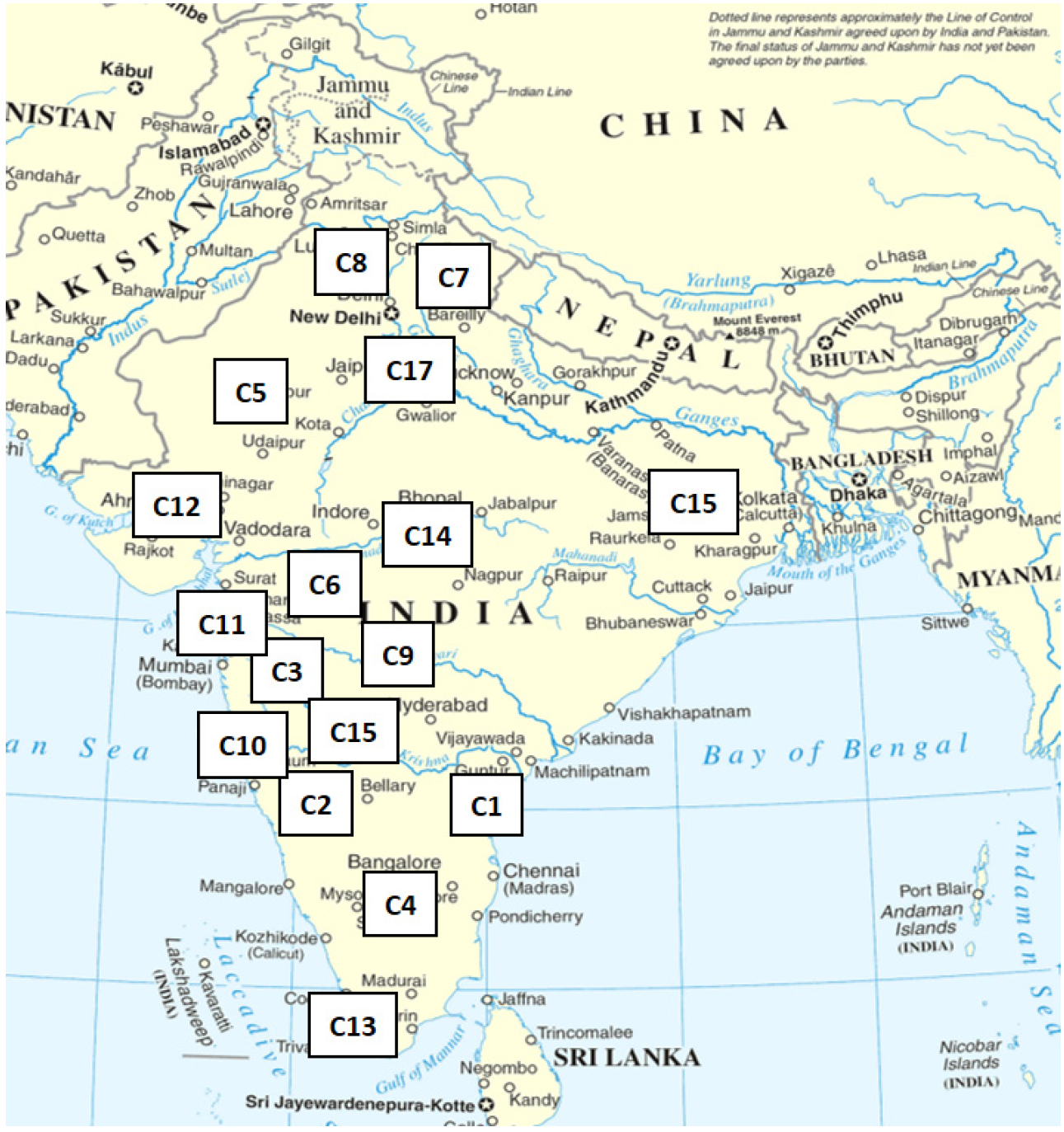

2.1. Sample Overview

2.2. Data

2.3. Analysis

- i.

- Supply chain complexity: Milgate (2001) [41] describes supply chain complexity as the uncertainty, technological intricacy, and organizational systems required to manage it. In other words, supply chain complexity refers to the number of production processes and needs for stringent control of processing and storage conditions [12,15]. From the interview responses, the author evaluated how complex the supply chains of each organization was. The author rated the sample firms on these parameters on three levels. For example, if the uncertainty in the processes (e.g., seasonality, reliance on weather), technological intricacy (need for advanced technology), and requirement of organizational systems were high (e.g., manual monitoring and supervision), the author classified supply chains as highly complex and rated as “5”. This took into account the number of production processes and need for stringent control for processing and storage conditions. Similarly, if the processes did not have a high level of uncertainty, technological intricacy, and need for organizational systems, the supply chain was classified as “moderately complex” and rated as “3”. Finally, if the processes had very low uncertainty, technological intricacy, and need for organizational systems, the supply chains were classified as “less complex” and rated as “1”. Supply chains falling between these three levels were rated at 4 and 2, respectively. These ratings allowed us to evaluate the supply chains in a comparative manner and study the differences.

- ii.

- Perishability of raw material and product. According to the US Department of Agriculture [42], there is a likelihood for food to spoil, decay, or become unsafe for consumption if not maintained at specific conditions. Rahman (2005) and Singh and Heldman (2001) describe the criteria for the perishability of food products [12,43]. Based on these explanations, and based on the responses about the perishability of the raw material and final product as described by our respondents, they gave the following ratings:

- Perishable: shelf-life of 1–2 days, rated 5.

- Semi-perishable: shelf-life of up to 1–2 weeks, rated 4.

- Less perishable: shelf-life of 3–4 weeks, rated 3.

- Shelf-stable: shelf-life of >1 month, rated 2.

- Non-perishable: shelf-life of 12 months, rated 1 (Rahman, 2005).

- i.

- Low: < 2% of production volume.

- ii.

- Medium-low: 2–4% of production volume.

- iii.

- Medium: 4–6% of production volume.

- iv.

- Medium-high: 6–9%.

- v.

- High: > 9%.

3. Results

- i.

- Out of the 17 firms studied in the sample, 13 firms showed similar actual food loss as predicted in the propositions. A majority of the firms support the predicted propositions. Thus, the overall findings suggest that platforms can help prevent food wastage in supply chains.

- ii.

- Four companies, namely, C3, C10, C13, and C17, did not have actual loss as predicted by the propositions. The author studied them in further detail to understand the conditions in which technological platforms do not help in preventing food wastage, or are not required to avoid food loss. The following are the conclusions based on these four anomalous firms where the technological deployment did not show any relationship with the waste levels.

- iii.

- At C3, food loss levels are higher than expected despite having a high technological infrastructure in their supply chain. The respondent shared that the firm had not efficiently installed technologies, and there were “gaps [they] needed to fill”. C3 was planning to initiate “process intensification” to explore how they could use “technological platforms to reduce food loss.” The interviewee shared that they were “planning to use data from ERP to identify the areas of supply chain having higher wastage” and then “improve them for future”.

- iv.

- At C10, actual food loss levels are lower than expected. The interviewee shared that “the highest chances of food loss are in the raw material storage, which requires temperature and humidity controls”. The staff of C10 is trained to monitor the temperature and humidity regularly. “At the raw material warehouse, the likelihood of wastage is high.” Hence, “the air-handling units [there] are automated”. C10 also implements lean manufacturing, which ensures low wastage levels despite limited use of technology.

- v.

- At C13, the waste is mainly the residue left after the flavors have been extracted from spices. However, C13 has been able to convert this “waste” into a by-product. They found alternate use of the residue as a “filler” in spice-blends. C13 sells the residue to spice mix companies. Hence, their wastage levels are very low, despite having a reasonably low technological infrastructure and high production sensitivity.

- vi.

- At C17, the food wastage levels are very low despite having limited technology and moderate production sensitivity. This low wastage level is because the company relies on manual observation and checks. However, the interviewee shared that “in future, implementation of technological platforms can reduce manual work, improve efficiency, and reduce errors”.

4. Discussion

5. Policy Implications

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Interview Questionnaire

- What are the products manufactured by your firm?

- What is the scale of production in your company? Please specify whether this scale is for one facility and if there are multiple facilities owned by your firm.

- Please describe the SC of your main products in brief.(The remaining questions can be answered specifically for one or two major products produced by your firm)

- What is its shelf-life?

- Are there any special requirements of your food product? (In terms of pressure/temperature/humidity or storage)

- At the time of production

- At the time of transportation

- How are these ensured during the processing stage/transportation?

- How often is there a failure? (as an approximate estimate from your experience)

- In case of a failure, how are the personnel notified? How is the corrective action then taken?

- At what stage(s) of the production process/transport as the product susceptible to contamination?

- What the ways by which any contamination can be detected? How is the personnel notified and corrective action taken?

- 11.

- What are the raw materials used? What is their shelf life?

- 12.

- What the requirements of surrounding conditions (temperature, pressure, humidity)?

- 13.

- In case of a situation wherein the requirements are not met, how are the personnel notified? How is the corrective action then taken?

- 14.

- What kind of technological platforms are set up in your firm? Since when?

- 15.

- Is any technology which uses integrated within the supply chain? For example: SAP, Enterprise Resource Planning etc. (Please specify which)

- 16.

- Are Dashboard Analytics and Control Tower used in any part of your supply chain?[Explanation if needed: Dashboard Analytics is an overview on performance of various parameters displaying summaries of different reports as widgets on a single page. It enables simultaneous monitoring of many metrics. Control Tower is a concept derived from airport management and now being used by logistics service providers. This technology comprises of a telecommunications tower, such as that for televisions, to monitor the movement of vehicles or goods.]

- 17.

- Is M2M communication used in the supply chain?[Explanation if needed: M2M refers to machine-to-machine communication. Here, a machine, such as a temperature sensor communicates about parameters like surrounding conditions or others. This information is communicated directly to the enterprise monitoring system where corrective action is taken in case of a failure without human involvement. M2M communication also has other applications like inventory replenishment and others, which need to be considered of this answer.]

- 18.

- If any of the above methods is used, since when it is used?

- 19.

- What were the key objectives with which these were installed? (E.g.: Improvement of productivity, efficiency, reduction of wastage etc.)

- 20.

- Was prevention of wastage a reason for which these systems were installed?

- 21.

- Has there been any change in product wastage because of these systems? (either in terms of percentage, quantity, volume or value)

- 22.

- Are the wastages being tracked? What method is used?

- 23.

- What are the levels of wastage of food products (raw material or final product) in your company/in the immediate transportation? (In percentage terms or absolute figures, preferably for products requiring cold storage. If there are no such products, then for any other key raw material or product)

- 24.

- To what levels can these be related to absence of proper infrastructure (such as cold storage)?

- 25.

- In case proper technological facilities are available, does it so happen that due of certain fluctuation in the conditions, the quality of the product is hampered? Can it lead to a substantial wastage?

- 26.

- Do you see any correlation between implementation of technological information platforms and reduction in wastage?

Appendix B. Case-Study of Each Sample Firm

References

- Gustafson, S. FAO SOFA Report 2019: New Insights into Food Loss and Waste; IFPRI Blog: Issue Post. 2019. Available online: https://www.ifpri.org/blog/fao-sofa-report-2019-new-insights-food-loss-and-waste#:~:text=Fourteen%20percent%20of%20the%20food,and%20Agriculture%20(SOFA)%20report (accessed on 7 June 2020).

- FAO. The State of Food and Agriculture 2019. In Moving Forward on Food Loss and Waste Reduction; Food and Agricultural Organisation of the United Nations: Rome, Italy, 2019; Available online: http://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 13 July 2020).

- Huber, C. World’s Food Waste Could Feed 2 Billion People. Field Report. 2017. Available online: https://www.worldvision.org/hunger-news-stories/food-waste#:~:text=As%20American%20families%20prepare%20to,of%20the%20global%20food%20supply (accessed on 13 July 2020).

- Kim, S. Global Food Waste: A Problem for the Society. 2020. Available online: https://www.arcgis.com/apps/Cascade/index.html?appid=5235a8d8c6014e44ac8723f14540ce31 (accessed on 14 July 2020).

- Gustavson, J.; Cederberg, C.; Sonesson, U.; Otterdijk, V.; Meybeck, A. Global Food Loss and Waste: Extent, Causes and Prevention. FAO: Study Conducted for the International Congress. 2011. Available online: http://www.fao.org/3/a-i2697e.pdf (accessed on 13 July 2020).

- Stuart, T. Waste—Uncovering the Global Food Scandal; Penguin Books: London, UK, 2009. [Google Scholar]

- FAO. Food Loss Index. Online Statistical Working System for Loss Calculations. 2019. Available online: http://www.fao.org/food-loss-and-food-waste/flw-data (accessed on 14 July 2020).

- Heblikar, A. India Wastes as Much Food as the UK Consumes. 2019. Available online: https://www.deccanchronicle.com/nation/in-other-news/230219/india-wastes-as-much-food-as-the-uk-consumes.html (accessed on 14 July 2020).

- Thacker, H. Food Wastage in India. 2018. Available online: https://thecsrjournal.in/food-wastage-india/ (accessed on 12 August 2020).

- Perappadan, B.S. Donate Excess Food, Says Health Ministry. 2019. Available online: https://fssai.gov.in/upload/media/FSSAI_News_Donate_Hindu_11_06_2019.pdf (accessed on 13 July 2020).

- Chowdhuri, J.P. Food Security and Food Wastage in India and Around the World. 2020. Available online: https://easychair.org/publications/preprint/wtkg (accessed on 14 July 2020).

- Rahman, M.S. Purpose of Food Preservation and Processing. In Handbook of Food Preservation; Marcel Dekker: New York, NY, USA, 2005; pp. 1–10. [Google Scholar]

- Singh, R. Scientific Principles of Shelf-Life Evaluation; Man, C., Jones, A., Eds.; Blackie Academic and Professional: Glasgow, Scotland, 1994. [Google Scholar]

- Gebresenbet, G.; Bosona, T. Logistics and Supply Chains in Agriculture and Food. In Pathways to Supply Chain Excellence; Groznik, D.A., Ed.; IntechOpen: London, UK, 2012. [Google Scholar]

- Russell, R.S.; Taylor, B.W. Operations and Supply Chain Management; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kummu, M.; de Moel, H.; Prokka, M.; Siebert, S.; Varis, O.; Ward, P. Lost food, wasted resources: Global food supply chain loss and their impacts. Sci. Total Environ. 2012, 438, 478–479. [Google Scholar]

- HLPE; United Nations; Nutrition and Food Systems. A Report by the High-Level Panel of Experts on Food Security and Nutrition; HLPE Report 12; HLPE: Rome, Italy, 2017; Available online: http://www.fao.org/3/a-i7846e.pdf (accessed on 2 August 2020).

- Hawkes, C.; Ruel, M.T. Value chains for nutrition. In Reshaping Agriculture for Nutrition and Health; Fan, S., Pandya-Lorch, R., Eds.; IFPRI: Washington, DC, USA, 2012; pp. 73–82. [Google Scholar]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Glaser, B.; Strauss, A. The Discovery of Grounded Theory; Weidenfield & Nicolson: London, UK, 1967; pp. 1–19. [Google Scholar]

- Coyle, J.J.; Gibson, B.J.; Langley, C.J.; Novack, R.A. Managing Supply Chains: A Logistics Approach; South-Western Cengage Learning: Boston, MA, USA, 2013. [Google Scholar]

- Pullman, M.; Wu, Z. Food supply Chain Management: Economic, Social and Environmental Perspectives; Routledge: New York, NY, USA, 2012. [Google Scholar]

- Bourlakis, M.A.; Weightman, P.W. Food Supply Chain Management; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Chopra, S.; Meindl, P. Strategy, Planning, and Operation. In Supply Chain Management; Pearson: London, UK, 2001. [Google Scholar]

- Vlahakis, G.; Apostolou, D.; Kopanaki, E. Enabling situation awareness with supply chain event management. Expert Syst. Appl. 2018, 93, 86–103. [Google Scholar] [CrossRef]

- Christopher, M. Logistics and Supply Chain Management, 4th ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Bozarth, C.C.; Handfield, R.B. Introduction to Operations and Supply Chain Management, 2nd ed.; Pierson Education: London, UK, 2006. [Google Scholar]

- Domdouzis, K.; Kumar, B.; Anumba, C. Radio-Frequency Identification (RFID) applications: A brief introduction. Adv. Eng. Inform. 2007, 21, 350–355. [Google Scholar] [CrossRef]

- Meera, K.; Rajan, H. Infosys: Machine-to-Machine: A Fresh Approach to Profits from Perishables; Infosys Perspective: Bangalore, India, 2007. [Google Scholar]

- West, S.; Gencheva, N. Overcoming the Challenges with M2M Device Lifecycle Management. Report on Joint Project of Deutsche Telekom, Blackberry and QNX. 2013. Available online: https://www.meetup.com/de-DE/bbdevla/messages/boards/thread/35400092 (accessed on 13 August 2020).

- Barley, S.R. Images of imaging: Notes on doing longitudinal field work. Organ. Sci. 1990, 1, 220–247. [Google Scholar] [CrossRef]

- Denzin, N.K.; Lincoln, Y.S. (Eds.) The Sage Handbook of Qualitative Research; Sage Publications: Thousand Oaks, CA, USA, 2011. [Google Scholar]

- Strauss, A.; Corbin, J.M. Grounded Theory in Practice; Sage Publications: Thousand Oaks, CA, USA, 1997. [Google Scholar]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking qualitative rigor in inductive research: Notes on the Gioia methodology. Organ. Res. Methods 2013, 16, 15–31. [Google Scholar] [CrossRef]

- Strauss, A.; Corbin, J. Basics of Qualitative Research Techniques; Sage Publications: Thousand Oaks, CA, USA, 1998. [Google Scholar]

- Corbin, J.M.; Strauss, A. Grounded theory research: Procedures, canons, and evaluative criteria. Qual. Sociol. 1990, 13, 3–21. [Google Scholar] [CrossRef]

- Bull, E.; Rapport, L.; Lockwood, B. What is a nutraceutical? Pharm. J. 2000. Available online: https://www.pharmaceutical-journal.com/1-what-is-a-nutraceutical/20002095.article?firstPass=false (accessed on 13 July 2020).

- FDA. FDA 101: Dietary Supplements. 2015. Available online: https://www.fda.gov/consumers/consumer-updates/fda-101-dietary-supplements (accessed on 19 August 2020).

- Bandopadhyay, S. Why Is Economic Growth across Indian States Uneven? London School of Economics Blog. 18 February 2013. Available online: https://blogs.lse.ac.uk/southasia/2013/02/18/why-is-economic-growth-across-indian-states-uneven/ (accessed on 14 July 2020).

- Indian Economic Strategy State Snapshots—Explanatory Note. 2018. Available online: https://www.dfat.gov.au/geo/india/ies/appendix-1.html (accessed on 8 August 2020).

- Milgate, M. Supply chain complexity and delivery performance: An international exploratory study. Supply Chain Manag. Int. J. 2001, 6, 106–118. [Google Scholar] [CrossRef]

- USDA. What Foods Are Perishable? 2019. Available online: https://ask.usda.gov/s/article/What-foods-are-perishable (accessed on 7 July 2020).

- Singh, R.P.; Heldman, D.R. Introduction to Food Engineering; Gulf Professional Publishing: Houston, TX, USA, 2001. [Google Scholar]

| Firm | Company Description | Respondent | Location |

|---|---|---|---|

| C1 | Indian FMCG (fast-moving consumer goods) conglomerate. Key products: wheat flour and snacks. | Sales manager | Tamil Nadu |

| C2 | A subsidiary of a European FMCG giant. Key product: instant noodles. | Quality executive | Goa |

| C3 | A subsidiary of an American MNC (multi-national company). Key product: tomato ketchup. | R&D manager | Maharashtra |

| C4 | A subsidiary of an American MNC. Key products: pizza and desserts. | Production manager | Karnataka |

| C5 | A subsidiary of a European brewery. Key product: beer. | Quality executive | Rajasthan |

| C6 | A subsidiary of a European FMCG giant. Key product: chocolate and other confectioneries. | R&D manager | Maharashtra |

| C7 | A subsidiary of European FMCG. Key product: candy and other confectioneries firm. | Trade manager | Haryana |

| C8 | Traditional snack-foods manufacturer. Key product: snack foods, meals for same-day consumption. | Quality auditor | Haryana |

| C9 | Indian dairy company. Key product: ice-cream. | Quality executive | Maharashtra |

| C10 | Subsidiary for European flavor manufacturer. Key products: flavors for industrial use. | Production executive | Maharashtra |

| C11 | Indian conglomerate. Key products: tea, coffee, and soup premixes. | Supply chain manager | Maharashtra |

| C12 | A subsidiary of a Canadian MNC. Key products: frozen snack foods. | Quality executive | Gujarat |

| C13 | Indian spice manufacturer and exporter. Key products: spices, spice blends, and extracts. | Production head | Kerala |

| C14 | Indian nutraceuticals (nutraceutical is a substance that may be considered food and provides medical or health benefits, including the prevention and treatment of disease [37]) for dietary supplements (a dietary supplement is a product containing a “dietary ingredient” intended to add further nutritional value to (supplement) the diet. A “dietary ingredient” may be one or a combination of substances [38]). Key products: lutein extract, capsaicin extract. | Production executive | Maharashtra |

| C15 | Contract manufacturing unit for an Indian FMCG manufacturer. Key product: biscuits. | Quality executive | Maharashtra |

| C16 | Indian manufacturer of traditional remedial formulations sold in the retail market. Key products: dietary supplements. | Production manager | West Bengal |

| C17 | Manufacturer to several prominent companies in the Indian healthcare industry. Key products: Indian traditional dietary supplements. | Senior manager | Delhi |

| i | ii | iii | iv | v | vi | vii | viii | Comment | TR | |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | Y | Y | Y | Y | N | Y | N | N | PLC for automation, backward integrated | 7 |

| C2 | Y | Y | Y | N | Y | O | O | N | PLC for automation | 5 |

| C3 | Y | N | Y | Y | Y | N | O | N | 4.5 | |

| C4 | Y | Y | N | Y | O | N | O | N | Air humidifiers are automated | 4 |

| C5 | Y | Y | Y | O | Y | N | Y | O | PLC present but not for automation | 6 |

| C6 | Y | Y | N | Y | N | N | N | N | PLC present but not for automation | 3 |

| C7 | Y | Y | Y | N | Y | N | N | N | PLC for automation | 4 |

| C8 | Y | N | Y | N | N | N | N | N | Barcode used until central location | 2 |

| C9 | Y | N | N | N | N | N | N | N | No ERP until franchisee location. Used thereafter | 1.5 |

| C10 | Y | N | O | O | N | O | N | N | ERP integrated with the suppliers | 2.5 |

| C11 | Y | N | Y | N | N | N | N | N | 2 | |

| C12 | Y | Y | Y | O | O | O | O | N | Air humidifiers automated by tech. platforms | 5 |

| C13 | Y | N | N | N | N | N | N | N | 1 | |

| C14 | Y | N | N | N | N | N | N | N | 1 | |

| C15 | Y | Y | Y | N | N | N | N | N | PLC present but not for automation | 3 |

| C16 | Y | N | Y | N | N | N | N | N | 2 | |

| C17 | N | N | N | N | N | N | N | N | 0 |

| Proposition | Production Sensitivity | Technology Deployment | Expected Food Wastage |

|---|---|---|---|

| 1 | High | High | Medium-low |

| 2 | High | Low | High |

| 3 | Low | Low | Medium-low |

| 4 | Low | High | Low |

| PS | TR | Expected Food Wastage | Actual Food Wastage | Comments | |

|---|---|---|---|---|---|

| C1 | 8 | 7 | Medium-low | Low | Food wastage reduced from 3–4% to 0.7% with tech. systems; major decrease in back-end |

| C2 | 8 | 5 | Medium-low | Medium | Raw material loss reduced by 20–30% with tech. systems |

| C3 | 6 | 4.5 | Medium-low | Medium-high | Process intensification with ERP helped reduce wastage overall, tech. platforms and wastage found to be unrelated |

| C4 | 6 | 3.5 | Medium | Medium-high | Automation and ERP reduced wastage |

| C5 | 6 | 4 | Medium | Medium-high | Wastage reduced through computerized palletization and other processes |

| C6 | 8 | 6 | Medium-low | Low | Yield improvement observed after tech. deployment |

| C7 | 3 | 3 | Low | Low | Tech. systems reduced manual error |

| C8 | 10 | 4 | High | High | Use of some tech. systems reduced wastage by 8–10% |

| C9 | 7 | 1 | High | High | The use of some tech. systems reduced the wastage of the final product, though raw material wastage is still high |

| C10 | 8 | 2.5 | Medium-high | Low | Tech. platforms and wastage found to be unrelated |

| C11 | 3 | 2 | Medium-low | Low | Marginal waste reduction observed after installing ERP |

| C12 | 7 | 5 | Medium-high | High | Raw material wastage decreased with automated air-conditioned storage |

| C13 | 6 | 1 | High | Low | Tech. platforms and wastage found to be unrelated |

| C14 | 3 | 1 | Medium-low | Low | Tech. supported cold-chains may improve the yield |

| C15 | 2 | 3 | Medium-low | Low | Automation reduced wastage in baking process |

| C16 | 2 | 2 | Medium-low | Medium-low | Loss is mostly due to physical damage and not production sensitivity |

| C17 | 4 | 0 | Medium-low | Low | Manual monitoring ensures low wastage in absence of tech. platforms. Tech. platforms and wastage found to be unrelated |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chauhan, Y. Food Waste Management with Technological Platforms: Evidence from Indian Food Supply Chains. Sustainability 2020, 12, 8162. https://doi.org/10.3390/su12198162

Chauhan Y. Food Waste Management with Technological Platforms: Evidence from Indian Food Supply Chains. Sustainability. 2020; 12(19):8162. https://doi.org/10.3390/su12198162

Chicago/Turabian StyleChauhan, Youthika. 2020. "Food Waste Management with Technological Platforms: Evidence from Indian Food Supply Chains" Sustainability 12, no. 19: 8162. https://doi.org/10.3390/su12198162

APA StyleChauhan, Y. (2020). Food Waste Management with Technological Platforms: Evidence from Indian Food Supply Chains. Sustainability, 12(19), 8162. https://doi.org/10.3390/su12198162