Advancing Pervious Pavements through Nomenclature, Standards, and Holistic Green Design

Abstract

1. Introduction

2. Materials and Methods

3. Results

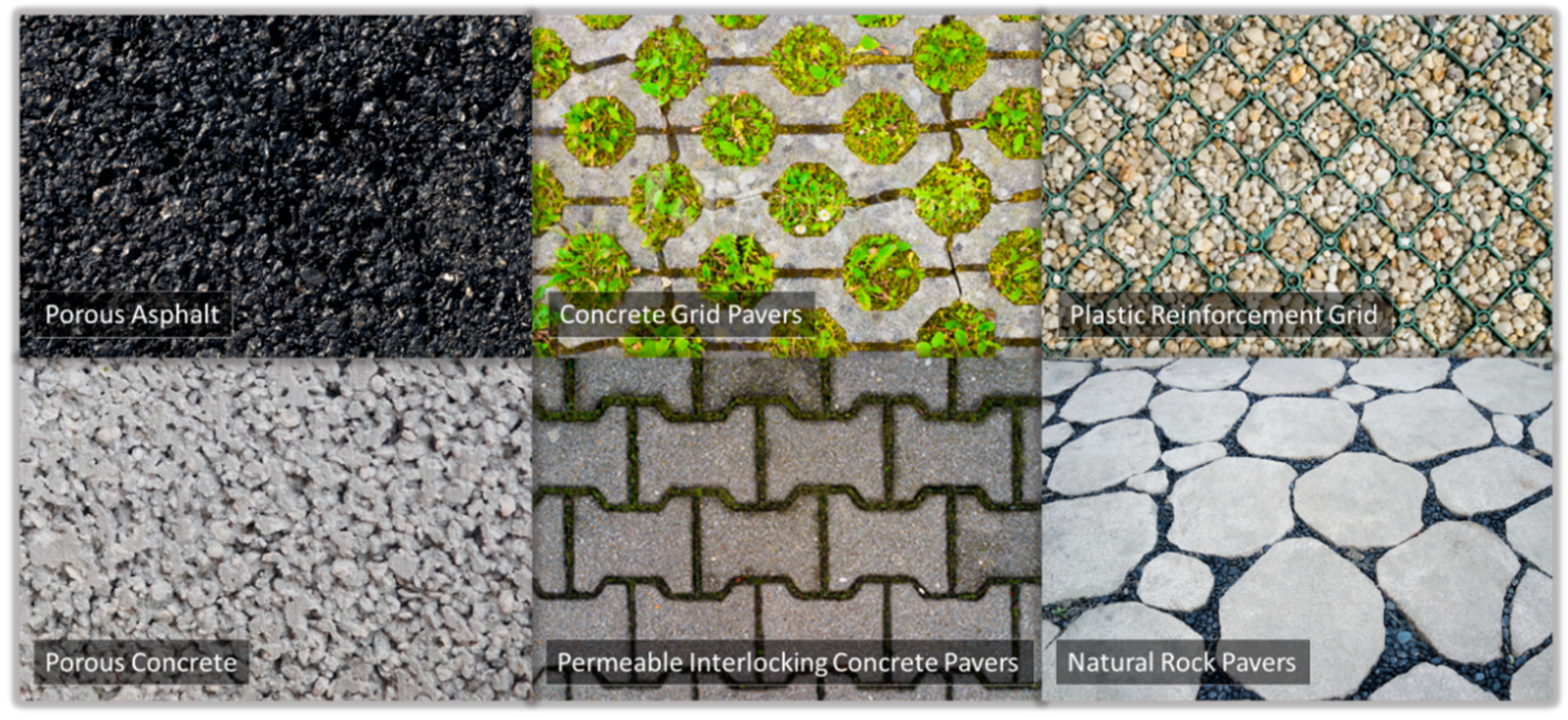

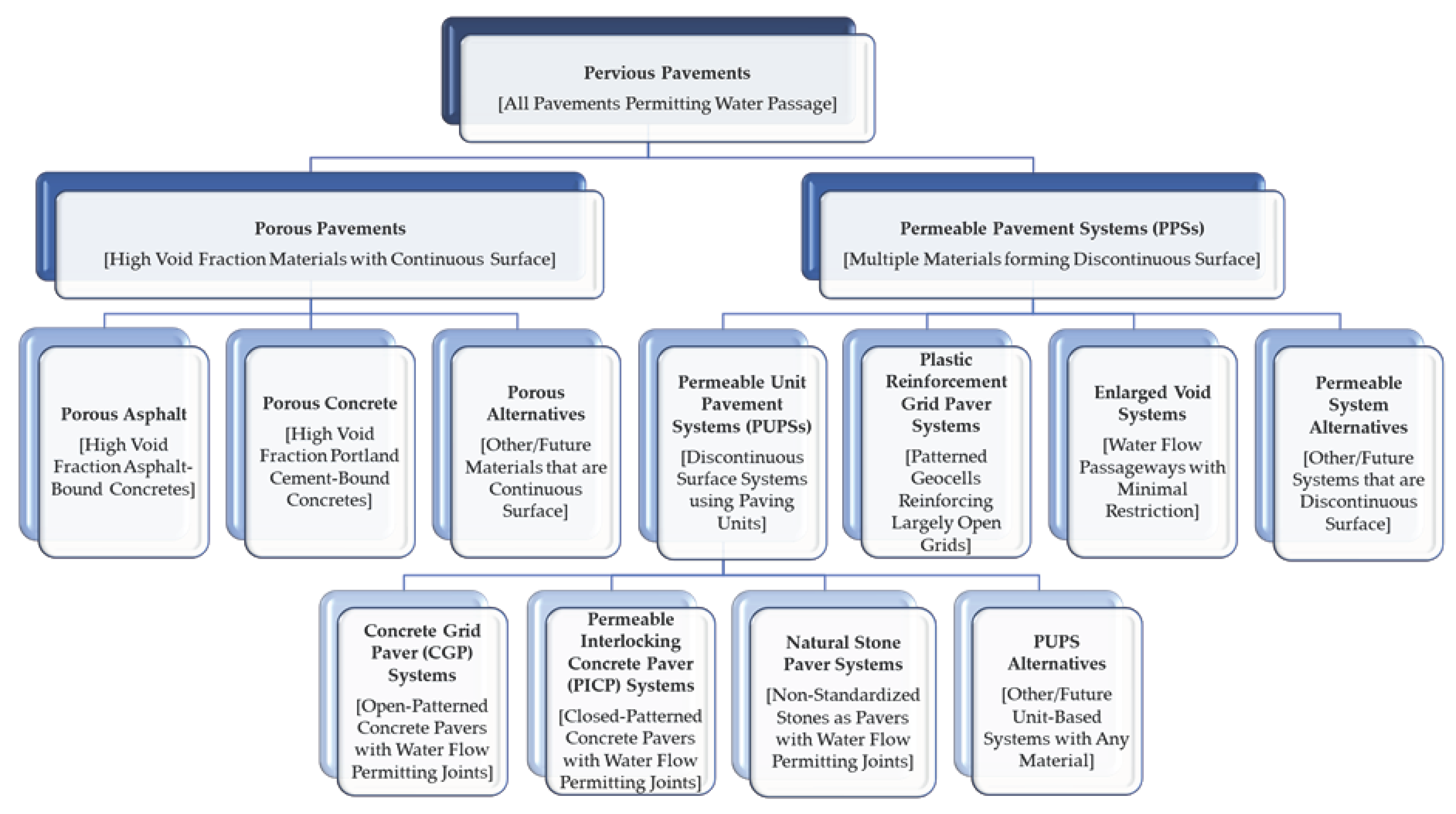

3.1. Resolving Terminology of Porous, Permeable, and Pervious Pavements

3.2. Improving Testing Standards

3.2.1. ASTM International C1232-17 on Terminology

3.2.2. ASTM International C1701/C1701M-17a and C1781/C1781M-18 on Water Infiltration

3.2.3. ASTM International C936/C936M-18, D4832-16, and C1319-17 on Properties and Inspection

3.3. Framework for Holistic Green Design

3.3.1. Functional Surface for Travel

3.3.2. Environmental Harmony of Appearance and Noise

3.3.3. Durability in Operating Environment

3.3.4. Initial Hydraulic Performance

3.3.5. Maintenance of Hydraulic Performance

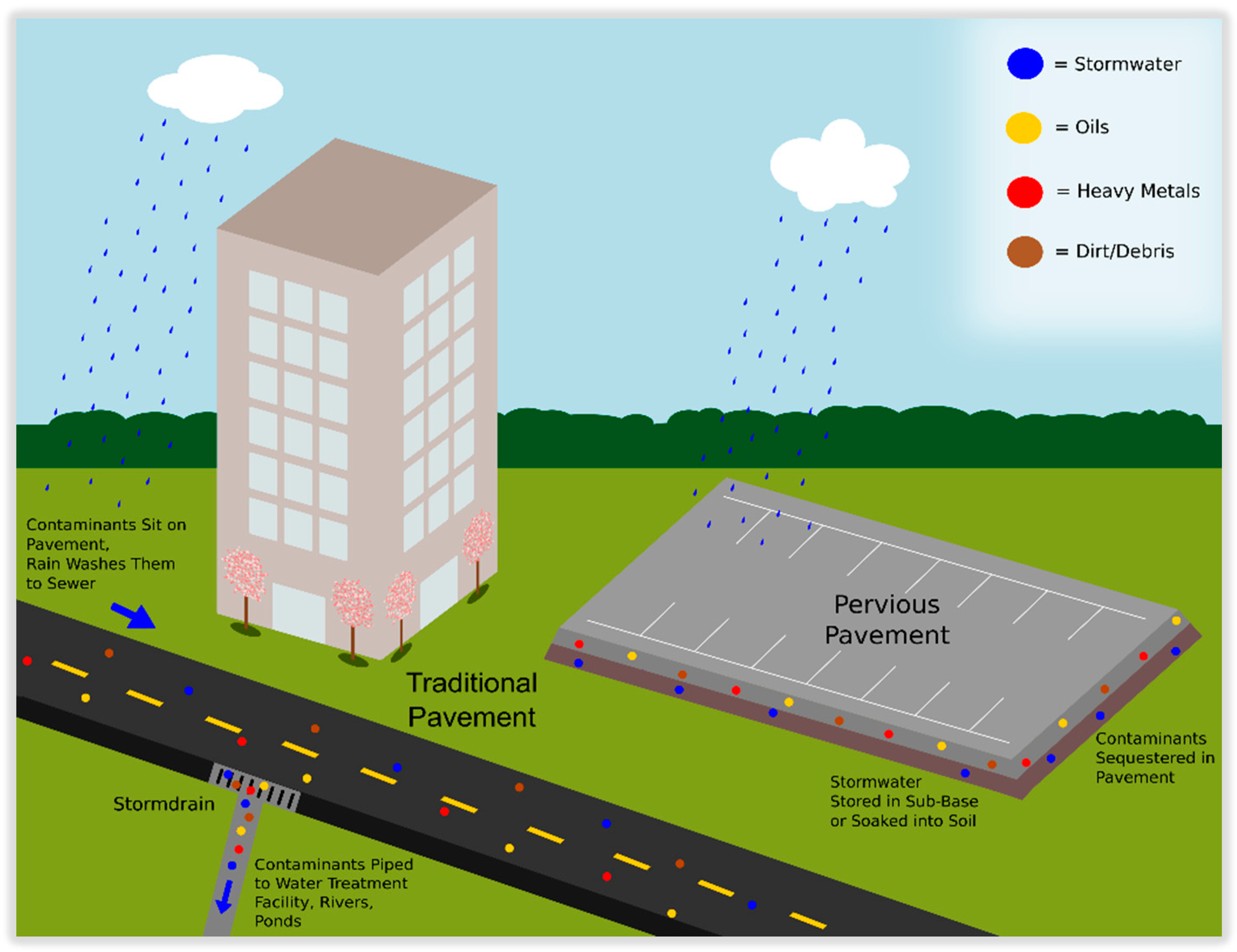

3.3.6. Pollution Sequestration and Remediation

3.3.7. Impact of Manufacturing and Installation

3.3.8. Urban Heat Island Effect Mitigation

3.3.9. End of Life

3.3.10. Sustainable or Restorative

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Ghafoori, N.; Dutta, S. Laboratory Investigation of Compacted No-Fines Concrete for Paving Materials. J. Mater. Civ. Eng. 1995, 7, 183–191. [Google Scholar] [CrossRef]

- Thelen, E.; Howe, L.F. Porous Pavement: Including the Principles of Development and a Porous Pavement Design Manual; The Franklin Institute Press: Philadelphia, PA, USA, 1978. [Google Scholar]

- U.S. Green Building Council. About (USGBC). Available online: https://www.usgbc.org/about/brand (accessed on 29 June 2020).

- Jacob Kriss—U.S. Green Building Council. Narrative of the history of LEED’s development. In Proceedings of the Greenbuild International Conference and Expo, Philadelphia, PA, USA, 20–22 November 2013. [Google Scholar]

- U.S. Green Building Council. LEED 2009 (LEED v3); Green Building Council: Washington, DC, USA, 2009. [Google Scholar]

- U.S. Green Building Council. LEED 2009 (LEED v3). Addenda 100001374. Available online: https://www.usgbc.org/leedaddenda/100001374 (accessed on 11 September 2020).

- U.S. Environmental Protection Agency—Office of Water. Low Impact Development (LID): A Literature Review; U.S. Environmental Protection Agency: Washington, DC, USA, 2000.

- 110th United States Congress. Energy Independence and Security Act of 2007; U.S. Government Publishing Office (GPO): Washington, DC, USA, 2007.

- U.S. Environmental Protection Agency. Technical Guidance on Implementing the Stormwater Runoff Requirements for Federal Projects under Section 438 of the Energy Independence and Security Act; Office of Water: Washington, DC, USA, 2009.

- Ashley, E. Using Pervious Concrete to Achieve LEED Points; Concrete Infocus: Alexandria, VA, USA, 2008. [Google Scholar]

- United States Green Building Council. LEED v4.1. Available online: https://www.usgbc.org/leed/v41 (accessed on 18 May 2020).

- Ferguson, B.K. Porous Pavements; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- U.S. Environmental Protection Agency. Reducing Urban Heat Islands: Compendium of Strategies—Chapter 5: Cool Pavements. 2012. Available online: https://www.epa.gov/heat-islands/heat-island-compendium (accessed on 27 May 2020).

- Zanoni, L. The Benefits of Using Porous Asphalt Pavement in Comparison with Other Forms of Pervious Pavements; University of Illinois at Chicago: Chicago, IL, USA, 2019. [Google Scholar]

- Siegel, R.P. Cutting the carbon from concrete. Mech. Eng. 2020, 142, 38–43. [Google Scholar] [CrossRef][Green Version]

- U.S. Environmental Protection Agency. Technical Guidance on Implementing the Stormwater Runoff Requirements for Federal Projects. December 2009. Available online: https://www.epa.gov/sites/production/files/2015-08/documents/epa_swm_guidance.pdf (accessed on 29 May 2020).

- Hunt, W.F.; Collins, K.A. Permeable Pavement: Research Update and Design Implications; North Carolina Cooperative Extension Service: Raleigh, NC, USA, 2006. [Google Scholar]

- Xie, N.; Akin, M.; Shi, X. Permeable concrete pavements: A review of environmental benefits and durability. J. Clean. Prod. 2019, 210, 1605–1621. [Google Scholar] [CrossRef]

- Brown, R.A.; Borst, M. Evaluation of surface infiltration testing procedures in permeable pavement systems. J. Environ. Eng. 2014, 140, 04014001. [Google Scholar] [CrossRef]

- West, D.; Kaye, N.B.; Putman, B.J.; Clark, R. Quantifying the non-linear hydraulic behavior of pervious concrete. J. Test Eval. 2016, 44, 20150054. [Google Scholar] [CrossRef]

- Ullman, D. The Mechanical Design Process; McGraw-Hill: New York, NY, USA, 2017. [Google Scholar]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design; McGraw-Hill: New York, NY, USA, 2016. [Google Scholar]

- Mihelcic, J.R.; Zimmerman, J.B. Environmental Engineering: Fundamentals, Sustainability, Design; John Wiley & Sons: New York, NY, USA, 2014. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Schulze, P.C.; Cairns, J., Jr.; Holling, C.; Borton, B.G.; Herman, R.; Costanza, R.; Karr, J.R. Engineering Within Ecological Constraints; National Academy Press: Washington, DC, USA, 1996. [Google Scholar]

- Gunn, A.S.; Vesilind, P.A. Environmental Ethics for Engineers; Lewis Publishers: Chelsea, MI, USA, 1986. [Google Scholar]

- Intergovernmental Panel on Climate Change. Global Warming of 1.5 degrees Celsius; Cambridge University Press: Cambridge, UK, 2018. [Google Scholar]

- Pope Francis, I. Laudato Si’: On Care for Our Common Home; Libreria Editrice Vaticana: Vatican City, Vatican, 2015. [Google Scholar]

- Scholz, M.; Grabowiecki, P. Review of permeable pavement systems. Build Environ. 2007, 42, 3830–3836. [Google Scholar] [CrossRef]

- Jayasuriya, N.; Kadrupokune, N. Comparative Performance of Permeable and Porous Pavements. In Proceedings of the International Conference on Sustainable Built Environment, Kandy, Sri Lanka, 13–14 December 2010. [Google Scholar]

- Online Etymology Dictionary (Douglas Harper). Porous. Available online: https://www.etymonline.com/word/porous (accessed on 25 May 2020).

- Houghton Mifflin Harcourt Publishing Company. American Heritage Dictionary of the English Language; Houghton Mifflin Harcourt Publishing Company: Boston, MA, USA, 2016. [Google Scholar]

- Online Etymology Dictionary (Douglas Harper). Permeable. Available online: https://www.etymonline.com/word/permeable (accessed on 25 May 2020).

- Online Etymology Dictionary (Douglas Harper). Pervious. Available online: https://www.etymonline.com/word/pervious (accessed on 25 May 2020).

- Hunt, W.F.; Szpir, L.L. Permeable Pavements, Green Roofs, and Cisterns; North Carolina Cooperative Extension Service: Raleigh, NC, USA, 2006. [Google Scholar]

- North Carolina Department of Environmental Quality. Stormwater Injection. Available online: https://deq.nc.gov/about/divisions/water-resources/water-resources-permits/wastewater-branch/ground-water-protection/stormwater-injection (accessed on 23 May 2020).

- CTC & Associates LLC. Comparison of Permeable Pavement Types: Hydrology, Design, Installation, Maintenance and Cost; Wisconsin Department of Transportation: Madison, WI, USA, 2012.

- State of New Jersey Department of Environmental Protection. New Jersey Stormwater Best Management Practices Manual (Chapter 9.7 Standard for Pervious Paving Systems); State of New Jersey Department of Environmental Protection: Trenton, NJ, USA, 2004.

- City of Duluth. Pervious Pavements. Lake Superior Streams: Community Partnerships for Understanding Water Quality and Stormwater Impacts and the Head of the Great Lakes, 2011. Available online: https://www.lakesuperiorstreams.org/stormwater/toolkit/paving.html (accessed on 23 May 2020).

- Selbig, W.R.; Buer, N. Hydraulic, Water-Quality, and Temperature Performance of Three Types of Permeable Pavemet under High Sediment Loading Conditions; U.S. Geological Survey—U.S. Department of the Interior: Reston, VA, USA, 2018.

- Permeable Pavements Task Committee. Permeable Pavements; American Society of Civil Engineers: Reston, VA, USA, 2015. [Google Scholar]

- ASTM International. Standard Terminology for Masonry (C1232-17); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM International. Standard Test Method for Surface Infiltration Rate of Permeable Unit Pavement Systems (C1781/C1781M—18); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. Test Method for Infiltration Rate of in Place Pervious Concrete (C1701/C1701M-17); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Chen, L.-M.; Chen, J.-W.; Chen, T.-H.; Lecher, T.; Davidson, P.C. Measurement of permeability and comparison of pavements. Water 2019, 11, 444. [Google Scholar] [CrossRef]

- Li, H.; Kayahanian, M.; Harvey, J.T. Comparative field permeability measurement of permeable pavements using ASTM C1701 and NCAT permeameter methods. J. Environ. Manag. 2013, 118, 144–152. [Google Scholar] [CrossRef]

- Pantsi, C.; Wright, G.B.; Alsubih, M. Permeable Pavement Systems: State of the Art. In Proceedings of the ICUD Conference, Prague, Czech Republic, 10–15 September 2017. [Google Scholar]

- Alsubih, M. Understanding the Hydrological Performance of Permeable Pavement; Heriot-Watt University: Edinburgh, UK, 2016. [Google Scholar]

- Konstandopoulos, A.G.; Kostoglou, M.; Housiada, P. Spatial non-uniformities in diesel particulate trap regeneration. SAE Tech. Pap. Ser. 2001. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Solid Concrete Interlocking Paving Units (C936/C936M); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. Standard Test Method for Preparation and Testing of Controlled Low Strength Material (CLSM) Test Cylinders (D4832-16); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM International. Standard Specification for Concrete Grid Paving Units (C1319-17); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Dhanagar, G.S.; Kumbar, P.D. Strength and durability properties of cncrete with recycled plastic aggregate: A review. Int. J. Innov. Res. Technol. 2019, 6, 271–275. [Google Scholar]

- Chen, Y.; Wang, K.; Wang, X.; Zhou, W. Strength, fracture and fatigue of pervious concrete. Constr. Build. Mater. 2013, 42, 97–104. [Google Scholar] [CrossRef]

- Khankhaje, E.; Salim, M.R.; Mirza, J.; Hussin, M.W.; Rafieizonooz, M. Properties of sustainable lightweight pervious concrete containing oil palm kernel shell as coarse aggregate. Constr. Build. Mater. 2016, 126, 1054–1065. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A Comprehensive Review on the Applications of Waste Tire Rubber in Cement Concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Volz, J.S.; Khayat, K.H.; Arezoumandi, M.; Drury, J.; Sadati, S.; Steele, S. A Recycled Concrete Aggregate (RCA) for Infrastructure Elements (NUTC R312); National University Transportation Center at Missouri University of Science and Technology: Rolla, MO, USA, 2014. [Google Scholar]

- Kevern, J.T.; Schaefer, V.R.; Wang, K. Mixture proportion development and performance evaluation of pervious concrete for overlay applications. ACI Mater. J. 2011, 108, 439–448. [Google Scholar]

- Mounika, P.; Srinivas, K. Mechanical Properties of no Fines Concrete for Pathways. Int. J. Eng. Technol. 2018, 4, 68–81. [Google Scholar]

- Davis, A.P. Green engineering: Promote low (impact development). Environ. Sci. Technol. 2005, 39, 338A–344A. [Google Scholar] [CrossRef]

- Interlocking Concrete Pavement Institute. A Comparison Guide to Porous Asphalt and Pervious Concrete. 2016. Available online: https://www.icpi.org/sites/default/files/PICP%20Comparison%20brochure%20Final%202016.pdf (accessed on 27 May 2020).

- Tang, T.; Anupam, K.; Kasbergen, C.; Scarpas, A.; Erkens, S. A finite element study of rain intensity on skid resistance. Constr. Build. Mater. 2019, 220, 464–475. [Google Scholar] [CrossRef]

- Parris, K.M. Chapter 16: Ecological Impacts of Road Noise and Options for Mitigation; Clean Air and Urbal Landscapes Hub: Parkville, Victoria, Australia, 2020. [Google Scholar]

- Bichajlo, L.; Kolodziej, K. Porous asphalt pavement for traffic noise reduction and pavement dewatering—The pollution problem. In Proceedings of the E3S Web of Conferences—Infraeko, Krakow, Poland, 7–8 June 2018. [Google Scholar]

- U.S. Environmental Protection Agency. Porous Asphalt Pavement; National Pollutant Discharge Elimination System of the U.S. EPA: Washington, DC, USA, 2009.

- Chai, C.; Cheng, Y.-C.; Zhang, Y.; Zhu, B. Experimental study on the performance decay of permeable asphalt mixture in seasonally frozen regions under freeze-thaw cycles. Sustainability 2020, 12, 2966. [Google Scholar] [CrossRef]

- Newman, A.P.; Coupe, S.J.; Puehmeier, T.; Morgan, J.A.; Henderson, J.; Pratt, C.J. Microbial ecology of oil degrading porous pavement structures. In Proceedings of the Global Solutions for Urban Drainage/ICUD, Portland, OR, USA, 8–13 September 2002. [Google Scholar]

- Bean, E.Z.; Hunt, W.F.; Bidelspach, D.A. Study on the Surface Infiltration Rate of Permeable Pavements. In Proceedings of the American Society of Civil Engineers—World Water Congress 2004, Salt Lake City, UT, USA, 19–24 September 2004. [Google Scholar]

- Anastas, P.T.; Zimmerman, J.B. Design through the 12 principles of green engineering. Environ. Sci. Technol. 2003, 37, 5349–5353. [Google Scholar] [CrossRef]

- Cahill, M.; Godwin, D.C.; Sowles, M. Porous Pavement: Low Impact Development Fact Sheet; Oregon State Unviersity, Oregon Sea Grant: Corvallis, OR, USA, 2011. [Google Scholar]

- McCain, G.N.; Dewoolkar, M.M. An Investigation into Porous Concrete Pavements for Northern Communities; University of Vermont & Vermont Agency of Transportation: Burlington, VT, USA, 2010. [Google Scholar]

- Gerrits, C.; James, W. Restoration of Infiltration Capacity of Permeable Pavers; University of Guelph: Guelph, ON, Canada, 1993. [Google Scholar]

- Minesota Pollution Control Agency. Minnesota Stormwater Manual. 2018. Available online: https://stormwater.pca.state.mn.us/index.php?title=Operation_and_maintenance_of_permeable_pavement (accessed on 28 May 2020).

- Oregon Department of Transportation. Pavement Design Guide; Oregon Department of Transportation: Salem, OR, USA, 2019.

- Balades, J.D.; Legret, M.; Madiec, H. Permeable pavements: Pollution management tools. Water Sci. Technol. 1995, 32, 49–56. [Google Scholar] [CrossRef]

- Colandini, V.; Legret, M.; Brosseaud, Y.; Balades, J.D. Metallic pollution in clogging materials of urban porous pavements. Water Sci. Technol. 1995, 32, 57–62. [Google Scholar] [CrossRef]

- Jakubiak, M.; Giska, I.; Asztemborska, M. Bioaccumulation and biosorption of inorganic nanoparticles: factors affecting the efficiency of nanoparticle mycoextraction by liquid-grown mycelia of pleurotis eryngii and trametes versicolor. Mycol. Prog. 2014, 13, 525–532. [Google Scholar] [CrossRef]

- Brattebo, B.O.; Booth, D.B. Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Barrett, M.E. Performance, cost, and maintenance requirements of Austin sand filters. J. Water Resour. Plan. Manag. 2003, 129, 234–242. [Google Scholar] [CrossRef]

- Building Products & Materials Today. Materials and embodied carbon. Eng. News Rec. 2019, 48. Available online: http://digitaladmin.bnpmedia.com/publication/?m=38305&i=583640&p=2 (accessed on 18 May 2020).

- Gaedicke, C.; Marines, A.; Mata, L.; Miankodila, F. Effect of Recycled Materials and Compaction Methods on the Mechanical Properties and Solar Reflectance Index of Pervious Concrete. Revista Ingeniería de Construcción 2015, 30, 159–167. [Google Scholar] [CrossRef][Green Version]

| LEED v2009 Credit | Simplified Description |

|---|---|

| Sustainable Sites: SS-C6.1 Stormwater Design-Quantity Control | Credit for limiting stormwater runoff (for primarily impervious areas, reduce stormwater runoff by ≥25% from the two-yr, 24-hr design storm). |

| Sustainable Sites: SS-C6.2 Stormwater Design-Quality Control | Credit for filtering post-development total suspended solids (treats ≥90% of rainfall and removes ≥80% of solids). |

| Sustainable Sites: SS-C7.1 Heat Island Effect-Non-Roof | Credit for shading, unbounded loose substrates, or materials reflecting incident sunlight (Solar Reflectance Index (SIR) ≥29). |

| Water Efficiency: WE-C1.1 Water Efficient Landscaping | Credit for reducing landscaping water usage by storing and using stormwater (≥50% reduction by using water from pervious concrete sub-base). |

| Materials and Resources: MR-C4.1, MR-C4.2 Recycled Content | Credit for using materials with recycled content (postconsumer + one-half preconsumer ≥10% for one point, ≥20% for two points-by cost). |

| Materials and Resources: MR-C5.1, MR-C5.2 Regional Materials | Credit for using materials sourced within ≤500 mi (805 km) radius (≥10% for one point, ≥20% for two points-by cost). |

| Aspect of Framework | Description of Framework Aspect |

|---|---|

| Functional Surface for Travel | Pleasant travel experience. Evenness for wheelchairs/high heels, offering sufficient wet/dry skid resistance, cushioning jogging impact, dull edges for avoiding tire/foot punctures, offering a “touch” connection surface that connects travelers to nature. |

| Environmental Harmony of Appearance and Noise | Preference for natural materials, shapes, patterns, and lifeforms. Environment (e.g., plants, wildlife) flourishes when needs are met; perspective of plants, birds, rabbits, worms all considered. Prevention of excessive road noise from intended modes of travel. |

| Durability in Operating Environment | Move lifespans from decades into centuries. Strength to support loads and retain passageways, UV resistance, freeze/thaw resistance, hardness for long wear life and abrasion resistance, impact resistance for drops, crashes, and rapid acceleration/deceleration, and chemical compatibility for deicing and leaks/spills. |

| Initial Hydraulic Performance | Hydraulic conductivity to support local “design storms”, retention of water for irrigation. Driven by local hydraulic needs and goals, sub-grade characteristics (e.g., clay helps reservoiring). |

| Maintenance of Hydraulic Performance | Effective and affordable maintenance, passive failures, infrequent maintenance requirements with accessible machinery, recovery of high percentage of initial hydraulic conductivity. |

| Pollution Sequestration and Remediation | Effective capture of suspended solids, retention of road runoff pollution such as lubricating oils, remediation through maintenance or other/biological reclamation processes. Consider local pollution types/levels and water needs. |

| Impact of Manufacturing and Installation | Low impact manufacturing to produce low cost materials with easy installation. Consider locally available materials, soil conditions, and technologies. |

| Urban Heat Island Effect Mitigation | High solar reflectance index and enabling evaporative cooling. Consider local environment holistically, especially population density and weather. |

| End of Life | Prefer plentiful (non-depleting), non-toxic, separable, and reusable or recyclable materials. Move to “repair in place”. |

| Sustainable or Restorative | Satisfy sustainability triad and look for ways to restore nature, improve livability for wildlife, improve beauty, facilitate social interaction, decrease pollution. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sprouse, C.E., III; Hoover, C.; Obritsch, O.; Thomazin, H. Advancing Pervious Pavements through Nomenclature, Standards, and Holistic Green Design. Sustainability 2020, 12, 7422. https://doi.org/10.3390/su12187422

Sprouse CE III, Hoover C, Obritsch O, Thomazin H. Advancing Pervious Pavements through Nomenclature, Standards, and Holistic Green Design. Sustainability. 2020; 12(18):7422. https://doi.org/10.3390/su12187422

Chicago/Turabian StyleSprouse, Charles E., III, Conrad Hoover, Olivia Obritsch, and Hannah Thomazin. 2020. "Advancing Pervious Pavements through Nomenclature, Standards, and Holistic Green Design" Sustainability 12, no. 18: 7422. https://doi.org/10.3390/su12187422

APA StyleSprouse, C. E., III, Hoover, C., Obritsch, O., & Thomazin, H. (2020). Advancing Pervious Pavements through Nomenclature, Standards, and Holistic Green Design. Sustainability, 12(18), 7422. https://doi.org/10.3390/su12187422