1. Introduction

The constant increase in light and heavy vehicle traffic throughout the years causes increasing asphalt pavement deterioration, with a consequent reduction in asphalt’s useful life.

Asphalt mixtures in road pavements are materials with viscoelastic behaviour, so their mechanical properties depend to a large extent on the operating temperature and frequency of load applications. At high temperatures and/or low load frequencies, asphalt mixes behave more viscously and less rigidly (ductile behaviour), resulting in plastic deformation. Conversely, under low operating temperatures or high frequencies loads, these materials have almost completely elastic behaviour with less deformation, albeit with a greater possibility of fatigue cracking.

To reduce the effects of temperature and load frequency on asphalt pavement and thereby increase the useful life of the pavement, non-traditional additives and materials have been used for several years, both in the bitumen and in the aggregate mix, to modify and improve the asphalt’s mechanical behaviour.

The use of recycled additives and non-traditional materials is emerging as an interesting alternative to reduce the production costs of bituminous mixtures while at the same time improving their mechanical performance, thereby increasing the useful life of the pavement. The use of such non-traditional materials makes it possible to recycle materials that would otherwise have to be landfilled, with all the related economic costs and environmental impacts.

There are two primary techniques used for adding additives to a mixture: the “wet” method and the “dry” method. In the “wet” method, additives are added directly into the bitumen at high temperatures before the bitumen is mixed with the aggregates; thus, chemical and physical changes are made to the binder, which will then lead to a change in the mechanical performance of the mixture. In the dry method, additives are added to the aggregates together with the bitumen or mixed with the aggregates before the bitumen is added. The choice of method depends on the type of additive to be used. In principle, however, the dry method is simpler and less expensive since it does not require any special equipment.

This research evaluated the influence of using recycled tyre rubber in the production of asphalt concrete for road pavements that were also produced with aggregates made from steel slag to evaluate the possible improvements in paving life.

Every year, more than one billion tyres are disposed of worldwide (a total of almost 17 million tons). Most of these tyres are recycled, while the remaining portion is disposed of in landfills (when not illegally dumped) [

1]. The most common applications of recycled tyres include the production of new tyres (retreaded tyres), fuel, civil engineering applications and products, agricultural uses, recreational and sports applications, and road pavement construction [

2]. In the field of road pavements, the advantages of using crumb rubber have been acknowledged in several studies, and it is likely that the use of crumb rubber will increase in the coming years.

Tyre rubber (and consequently crumb rubber) is an elastomer, a polymer capable of deforming significantly when subjected to stress and recovering its initial shape as soon as stress ceases. Crumb rubber can be added to bituminous conglomerates through both wet and dry processes. The choice of process depends on the amount of crumb rubber used, its size, the required function, and the type of plants available.

Although the dry process has some advantages over the wet process, especially in terms of cost and the greater amount of rubber that can be used, research worldwide has focused mainly on the wet process. This is because the performance obtained with the dry process is not always uniform. Such uncertainties stem from the poor adhesion between crumb rubber and bitumen since the short mixing phase does not allow for their complete interaction [

3]. This is not the case in the wet process, which yields more satisfactory results, as the wet process has the advantage of being able to better control the modified properties of the binder through sophisticated mixing plants [

4]. The wet method, however, also has disadvantages. In general, it is necessary to use specialized plants where high temperatures and stirring processes are required; this method is, therefore, less viable economically and, in some cases, may present hardships in separating the crumb rubber and bitumen phases during storage [

5]. Optimizing the dry method to achieve consistent performance for different types of aggregates could prove more promising in both economic and environmental terms.

In the “wet” method, the added amounts of crumb rubber can vary between 1.75% and 25.0% with respect to the weight of bitumen, although the top-performing amounts lie between 10% and 15% by weight, while the particle size of the crumb rubber varies between 0.15 mm and 0.60 mm. The mixing temperatures can vary between 140 °C and 195 °C (or in some cases, even higher).

Using a percentage by weight of crumb rubber of around 10% (in relation to the bitumen), the following results were obtained [

6]:

a reduction in penetration, varying between 12% and 37%;

an increase in softening temperature of between 9% and 23%, depending on the type of basic bitumen used;

a significant reduction in ductility at 15° and an increase in viscosity, which remained below 3 (Pa⋅s) at 135 °C, as required by SHRP specifications [

7,

8,

9].

Comparing the original bitumen with the bitumen resulting from the addition of about 10% by weight of crumb rubber bitumen, the complex modulus of the bituminous mix was increased in the latter mixture, and the phase angle was reduced at high and medium temperatures. At the same time, however, the complex modulus—the “creep stiffness” and the “m” parameter (slope of the straight-line tangent to the stiffness logarithm versus the logarithm of time)—was reduced at lower temperatures; the first two decreases are beneficial, while the decrease in the “m” parameter represents an inconvenience. The mixtures produced with the crumb-rubber-modified bitumen presented a higher value of recoverable deformations and a minimum area within the stress–strain curve, which indicates a better ability to dissipate energy [

7,

8,

10,

11,

12,

13,

14,

15]. The addition of this additive to bitumen, therefore, seems to increase the stiffness of asphalt concretes at high temperatures, as is the case with other additives, such as plastomers (which would reduce the excessive fragility of the bitumen and, therefore, the risk of cracking at low temperatures, thereby increasing the useful life of the pavement).

Unlike the wet method, for which there are many studies using crumb rubber, the dry method has rarely been investigated, especially for non-traditional aggregates. In the dry method, the crumb rubber can perform a double function based on the size of the particles. If coarse particle sizes of crumb rubber are used, their function is to replace a part of the coarse aggregate with an elastic aggregate to increase the mixture’s flexibility under load. If fine particle sizes are used instead, the crumb rubber will react more intensively with the bitumen by changing its viscosity. In the latter case, the rubber particles will absorb the lighter fractions (oils) of the maltenes present in the bitumen, which are the fractions that influence the viscous properties of the material, leaving a higher percentage of the asphaltenes in bitumen. The adsorption of the maltene fractions causes the swelling of the rubber particles, which is influenced by the temperature and bitumen-to-rubber contact time, the chemical composition of the bitumen, and the size and quantity of the crumb rubber [

16].

In the “dry” method, the crumb rubber normally varies between 0.5% and 10% of the total weight of the mixture, with the most common percentage being 1%. The sizes of the granules generally range from 0.6 mm to 3.0 mm [

17,

18,

19,

20], although higher particle sizes have been used in some experiments. The mixing temperatures range between 180 °C and 190 °C [

21]. Compared to mixtures without crumb rubber, the optimal bitumen content in this mixture is 0.5% higher. Indeed, the introduction of crumb rubber leads to a lower workability of the mixture [

22].

At medium–high temperatures (20–70 °C), with the addition of modest quantities of crumb rubber, both the creep modulus and the stiffness modulus increase, thus reducing permanent deformations and increasing the load-bearing capacity, while higher percentages do not always improve the mixtures’ mechanical characteristics. The percentage of crumb rubber needed to obtain the best results in terms of stiffness depends on the types of aggregates and bitumen and can vary from 1.5% to 12% of the weight of the mixture [

17,

18,

20,

21].

Da Silva et al. [

23] indicated that the addition of crumb rubber to the asphalt concrete produced an increase in service life of 10 times for fatigue strength and of 2.5 times for resistance to permanent deformation.

Farouk et al. [

24] highlighted the poor interactions between bitumen and crumb rubber as one of the major drawbacks of the dry method. This drawback causes the same crumb rubber to swell in bituminous mixes after compaction to three to five times its original size. This, in turn, hampers the achievement of the optimum mixture density if compaction takes place before the crumb rubber swelling is complete. Farouk et al. also suggest that it is preferable to use a smaller size of crumb rubber, which facilitates swelling in a short period of time before the mixture is put into operation. The authors also suggest that the percentage of bitumen should be increased to compensate for the amount absorbed by the crumb rubber. Finally, large particle sizes of crumb rubber produce a reduction in the resilient and creep modulus, even at medium–high temperatures.

Arabani et al. [

25] noted that percentages of crumb rubber up to 3% (by weight of the mixture) increase the stiffness modulus and reduce permanent deformations, while percentages higher than 3% negatively affect the mechanical parameters of the mixture, thus reducing its useful life due to the poor adhesion between the bitumen and aggregates in the presence of high percentages of crumb rubber.

Sangiorgi et al. [

26] analysed the behaviour of a porous bituminous mixture with the addition of crumb rubber at 1% by weight of the mixture and a fine grain size less than 1 mm, finding that, at low temperatures, the stiffness modulus, evaluated by an indirect tensile test, was lower than that of the control mixture, while at high and medium temperatures, there was no significant difference between the two.

Lastra-Gonzales et al. [

5] indicated that, by using 1% by weight crumb rubber in the mixture with a grain size of less than 1 mm, there was a 30% increase in plastic deformation resistance at 60 °C and a 50% increase in stiffness (dynamic modulus) at 20 °C compared to the unmodified mixture with the crumb rubber.

Hassan et al. [

16], drawing on an extensive literature review, outlined guidelines for the use of the dry method, including recommendations for the grain-size composition of the aggregates, the physical properties of the binder, and the mixing and packaging conditions of the mixtures. In summary:

The grain size curves of the aggregates must be such that some of the aggregates are replaced by crumb rubber of the same size for mixtures of a closed type to fill the voids in the gap-graded mixtures.

It is preferable to use bitumen with a higher degree of penetration than traditional mixtures with increased bitumen content from 1 to 2%.

A combination of coarse and fine particle sizes is desirable to achieve better performance.

Mixtures with lower residual vacuum values (<3%) are preferable to traditional mixtures.

To use higher mixing temperatures, the aggregates and crumb rubber should be mixed first and the bitumen should be added afterward.

Mixture paving and compacting should occur 1–2 h after mixing. Stirring should occur before paving, and compacting should occur as soon as possible after paving.

Moreno-Navarro et al. [

18] evaluated the effects of adding crumb rubber to mixes made with high modulus bitumen, finding that this addition slightly reduced the mechanical resistance to indirect traction but increased the resistance to plastic deformation and stiffness.

Moreno et al. [

17] compared mixtures of bituminous conglomerates, made via both the wet and dry methods using crumb rubber, with other mixtures made with polymer modified bitumens. The results of the experiment show that the dry method offers the best performance in both permanent deformations and stiffness.

Moreno et al. [

27] analysed the behaviour of asphalt mixtures modified with the addition of crumb rubber via the dry method in terms of their sensitivity to humidity and resistance to plastic deformation, finding that the most influential factor on the mixtures’ behaviours was the percentage of crumb rubber, while the digestion time (i.e., the time between mixing and compaction) was barely significant. In particular, the best results were obtained with percentages varying between 0.5% and 1.0% of crumb rubber (compared to the weight of the mixture) and a digestion time of 45 min.

Cao [

4] evaluated the behaviour of gap-grade asphalt mixtures achieved via the addition of different percentages of crumb rubber, from 1 to 3% of the weight of the mixture, using the dry method. Cao found that mixtures with higher percentages of crumb rubber offered the best behaviour, both for permanent deformation at high temperatures and for cracking at low temperatures.

The analysis of previous studies shows that the addition of crumb rubber can certainly yield benefits. Uncertainties remain, however, for the dry method, as the different variables involved, such as the size, percentage, and type of crumb rubber, the bitumen quality, the mixing time, and the temperature, affect the performance of the mixture, especially when using artificial aggregates, such as steel slag, that have a higher bulk specific gravity (>3.40 g/cm3) than natural aggregates and have a very porous surface that allows for a different interaction with the bitumen and the crumb rubber compared to traditional aggregates.

Although a considerable amount of research has been conducted in the past on the use of crumb rubber in asphalt concrete made with natural aggregates, little to no research has been done on crumb rubber used with artificial aggregates, in particular with the dry method.

The goal of this research, different from what is present in the literature, is to evaluate the influence of using recycled tyre rubber in the construction of asphalt concretes for road pavements produced using artificial aggregates (steel slag) that have very different characteristics compared to traditional aggregates.

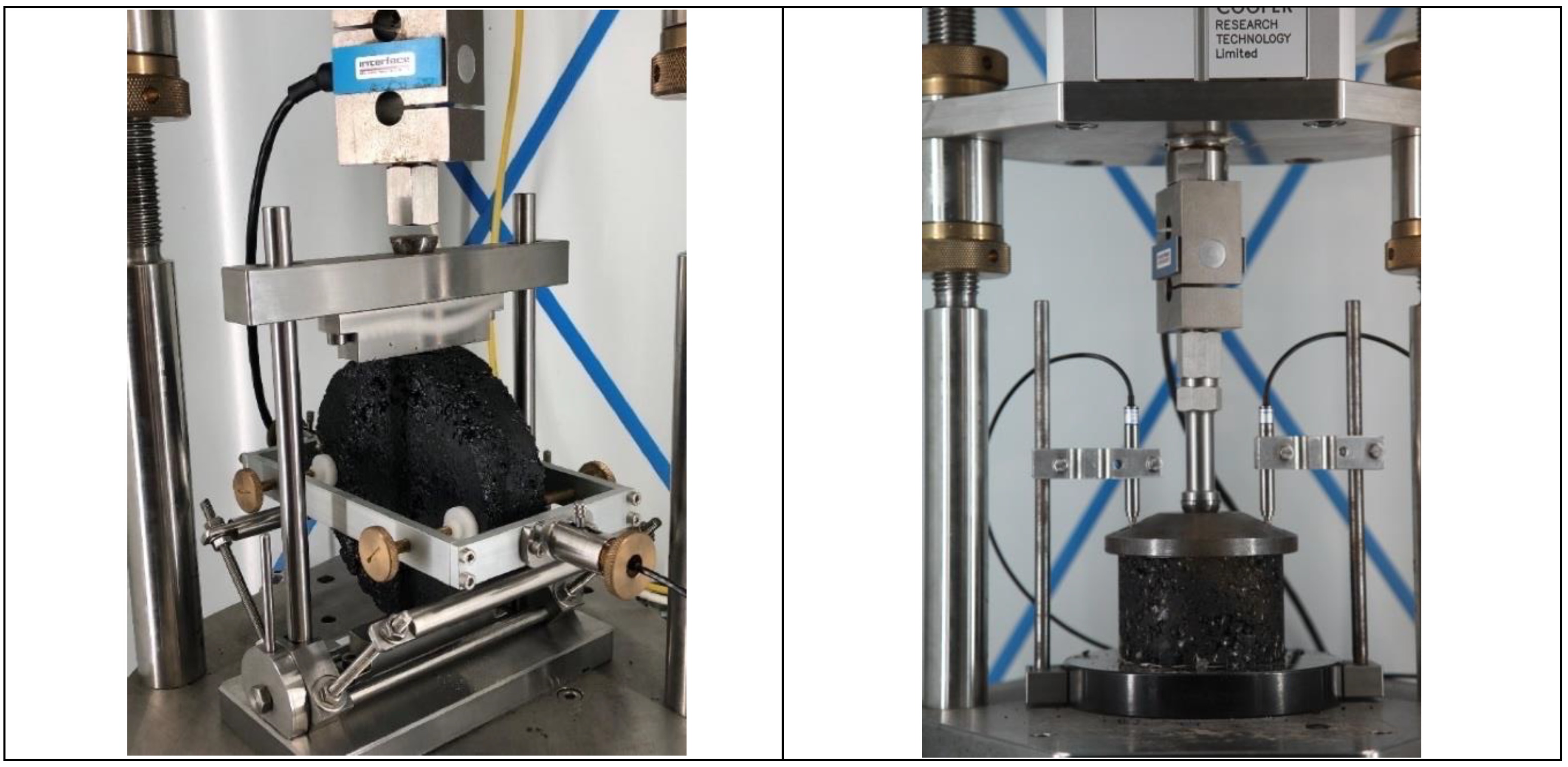

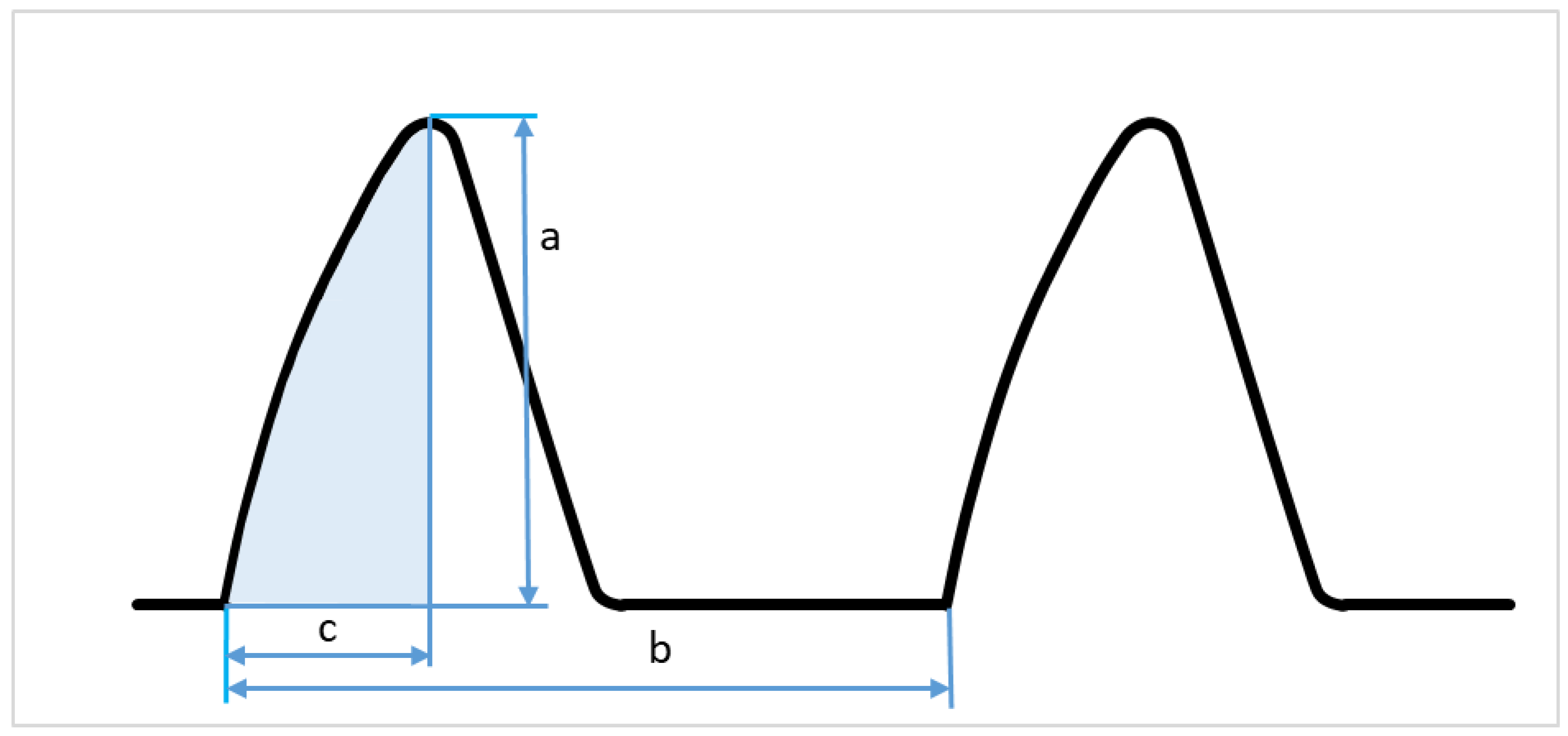

Two mixtures of bituminous conglomerates made from steelwork slag were compared, and one of these mixtures was modified using the “dry” technique by adding a percentage by weight of crumb rubber. Cyclical indirect tensile tests were carried out at different temperatures and load frequencies to evaluate the viscoelastic responses of the mixtures (resilient and dynamic modulus), and cyclic compression tests (dynamic creep) were carried out to evaluate the accumulation of permanent deformations (rutting).

4. Conclusions

This study highlighted how mixtures of aggregates (natural and artificial) and bitumen with the addition of crumb rubber obtained from end-of-life tyres provide an appealing alternative to traditional formulations. This study addressed the use of artificial aggregates to produce an asphalt concrete using steel slag together with recycled tyre rubber. These two materials correlate to several environmental concerns related to the disposal of waste resulting from their processing. The use of these materials in road pavements as secondary raw materials is an example of applying the concept of a circular economy. The use of these materials in pavements has not only provided environmental benefits but has also led to improvements in the mechanical properties of the mixtures. The benefits of using steel slag have already been highlighted elsewhere [

33], such as their lower abrasion over time, which increases the life of the pavement surface course. The addition of crumb rubber leads to further improvements in structural performance considering the stresses of road loads.

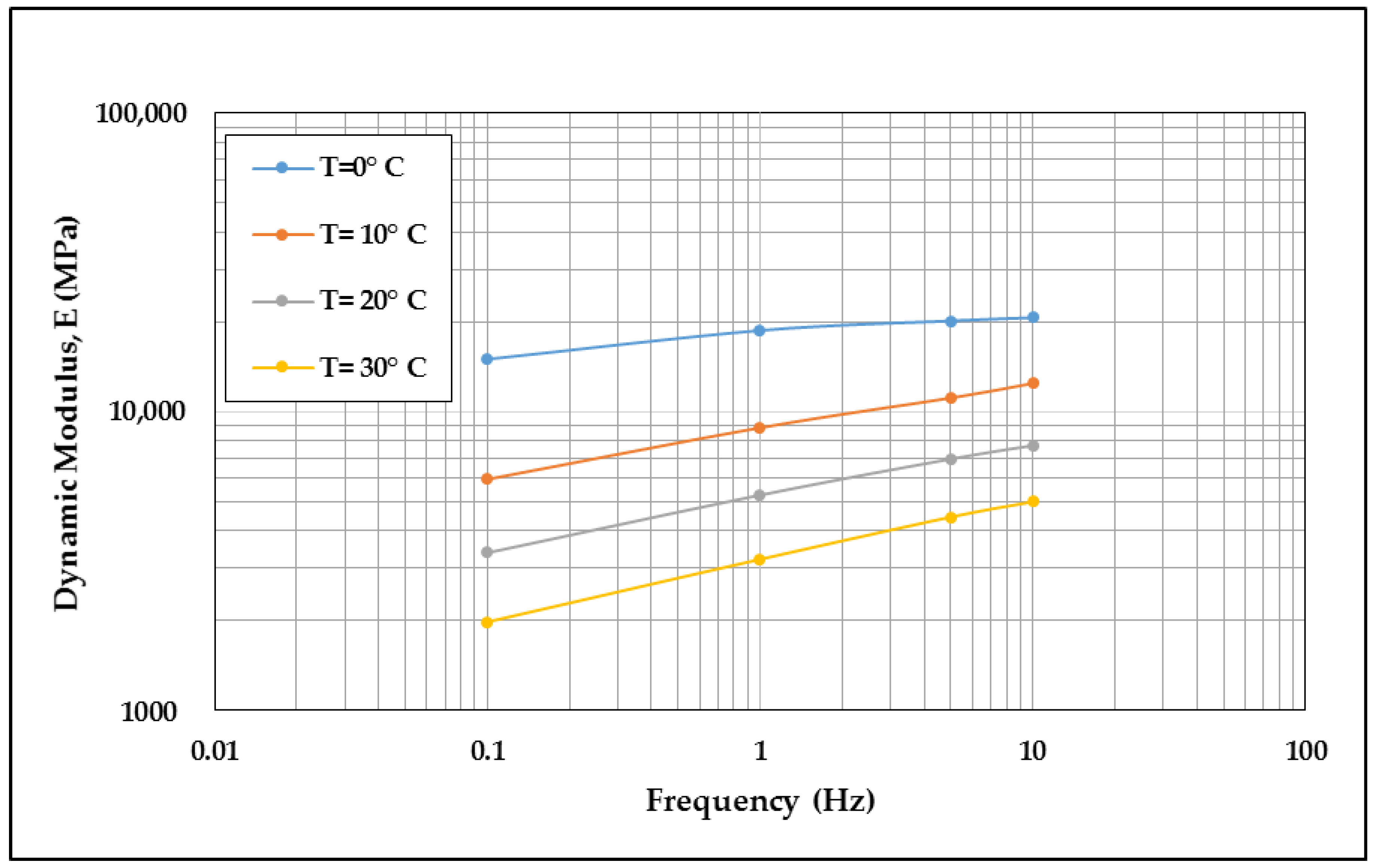

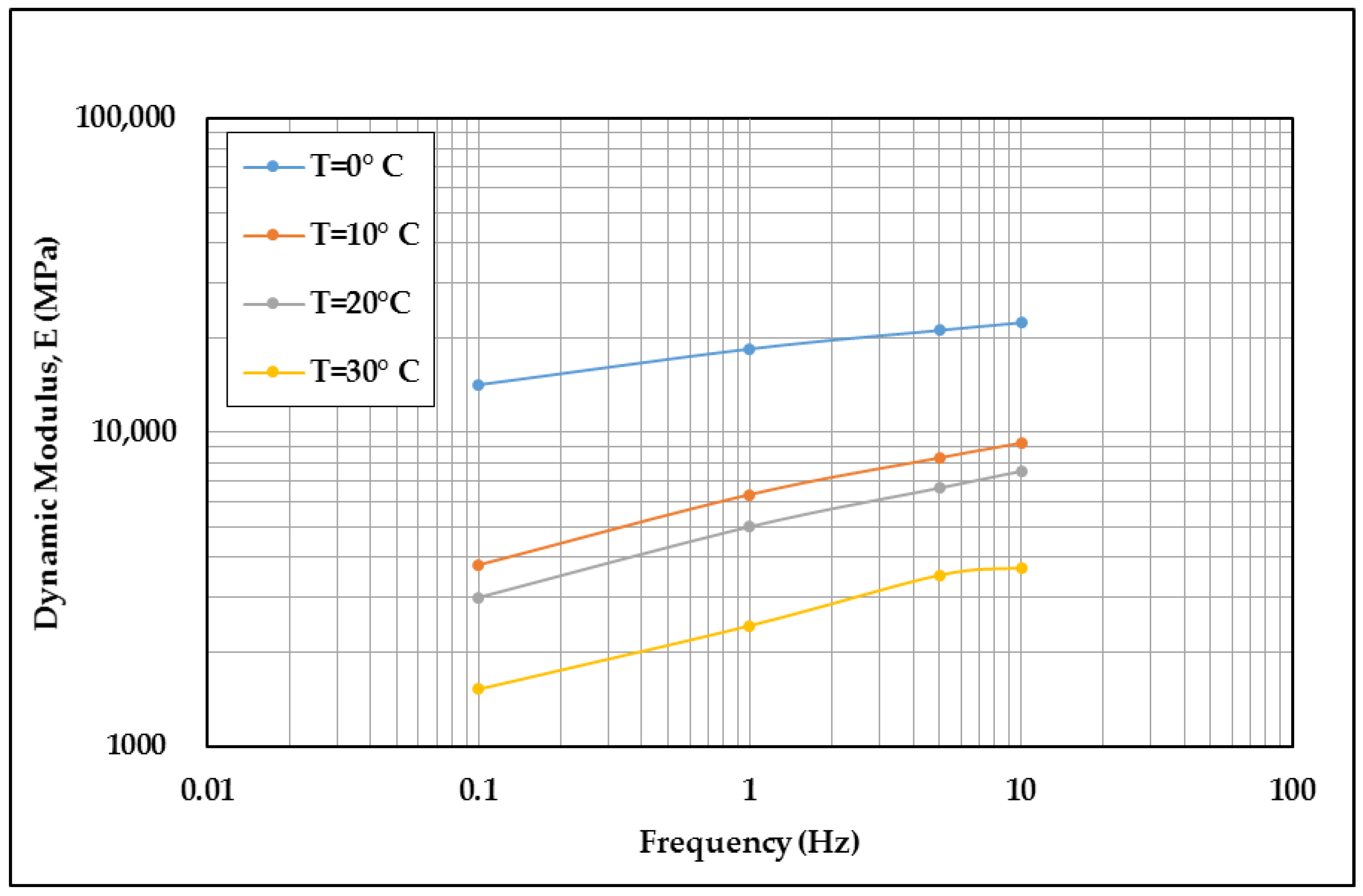

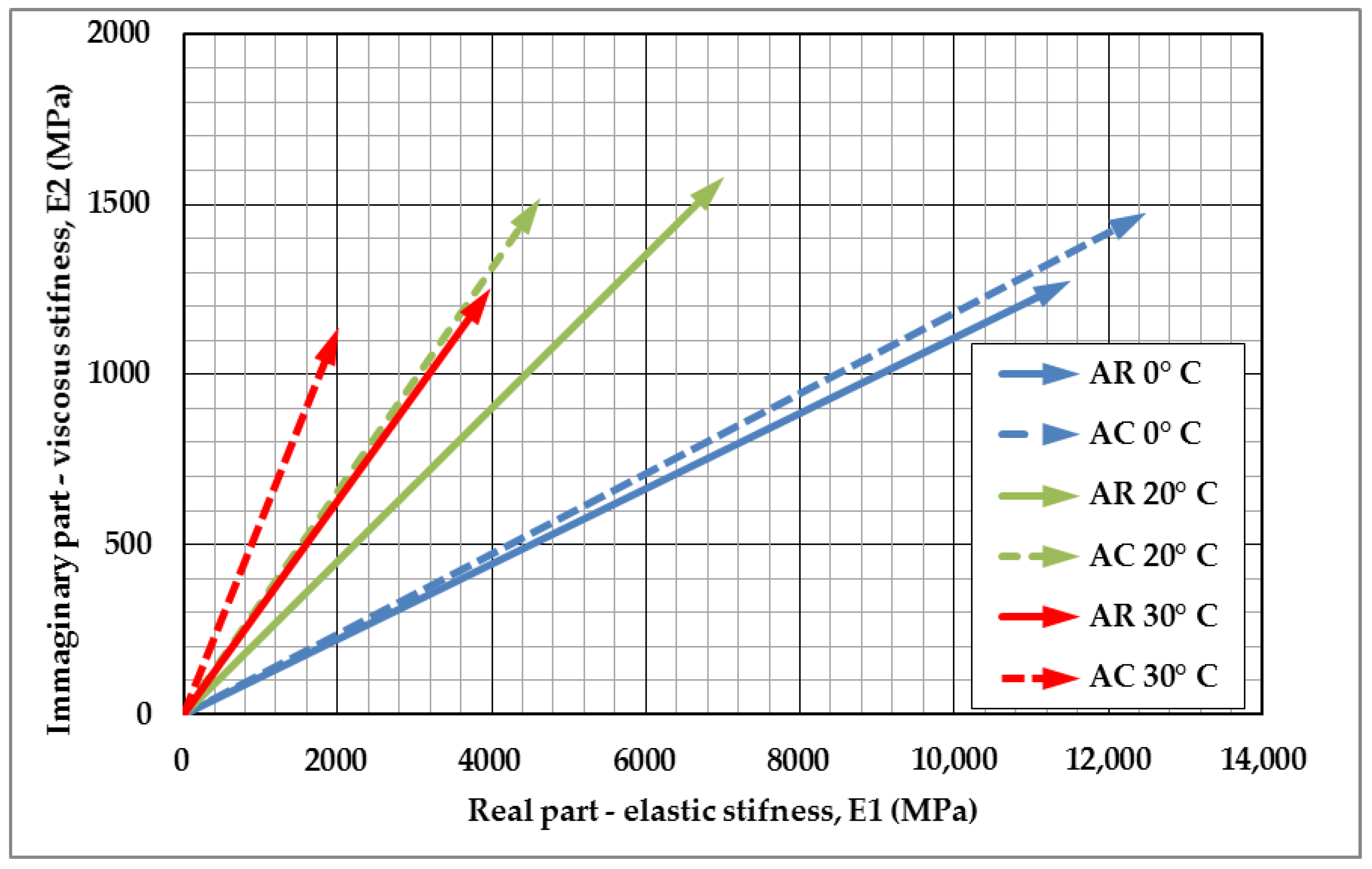

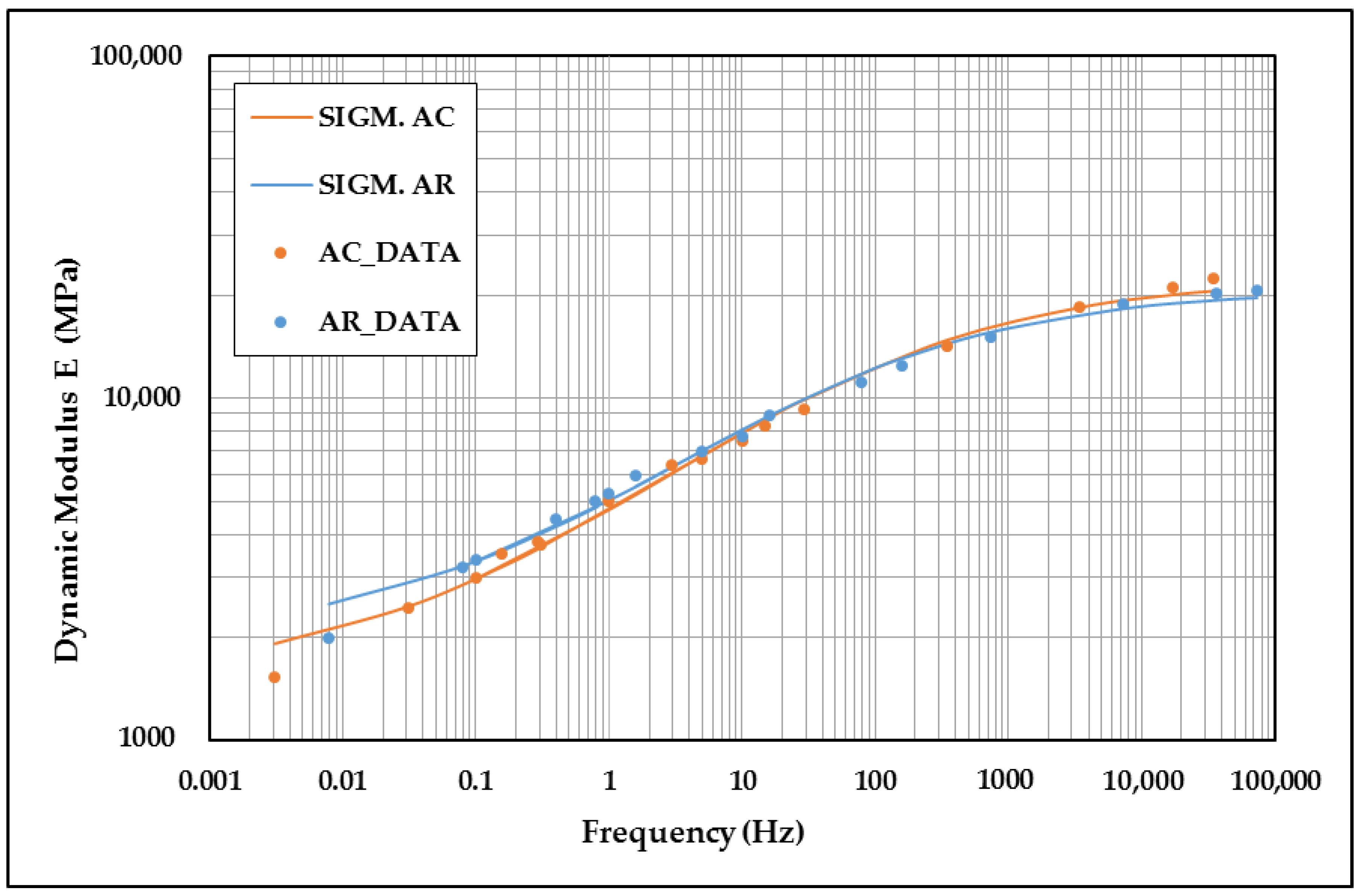

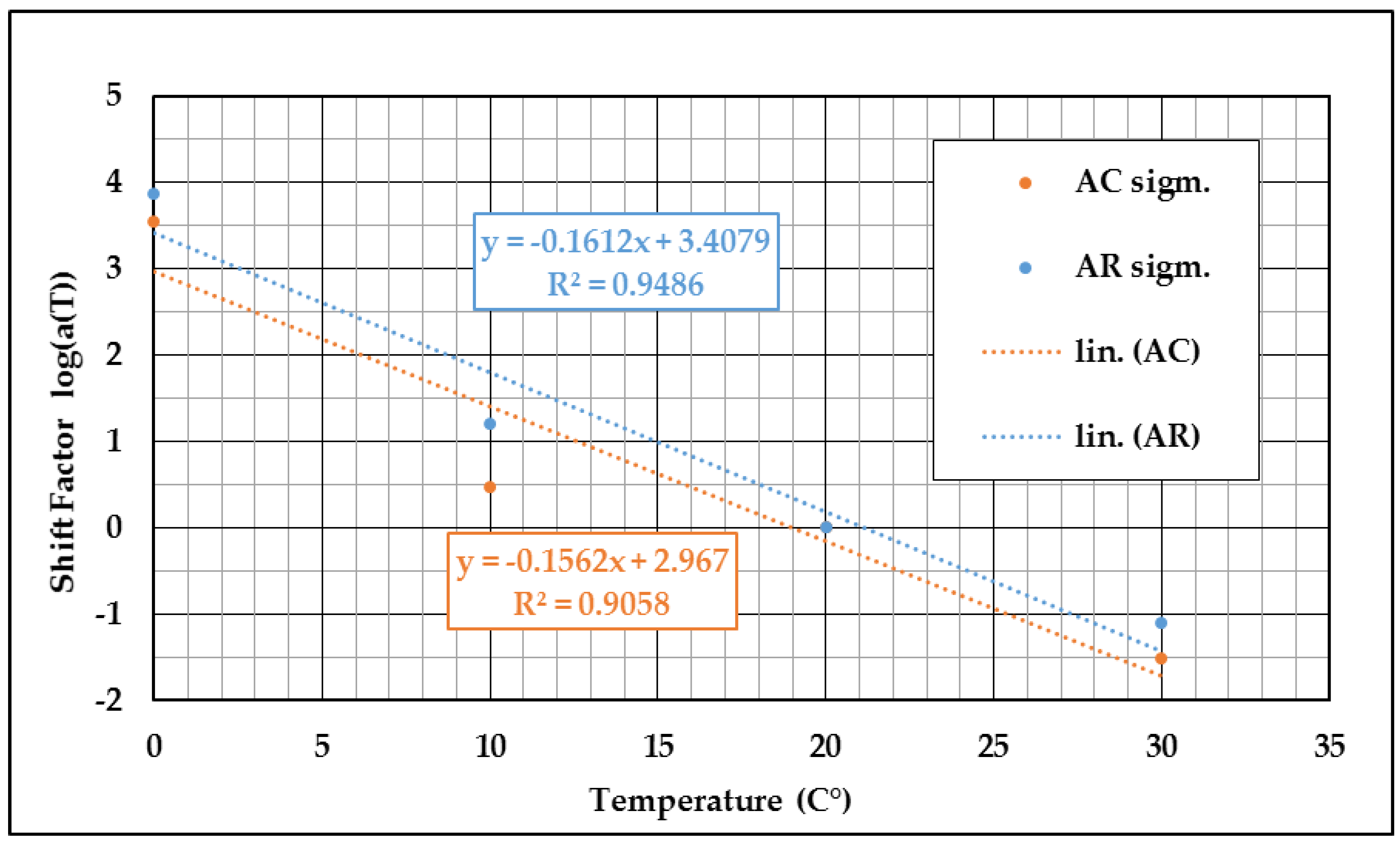

Notably, our comparative analysis of the experimental results showed different mechanical behaviours under different test temperatures and frequencies. In particular, we observed variations in the dynamic modulus with temperature under a given frequency value in the two mixtures. It is also possible to identify the temperature value that will invert this behaviour. At high temperatures, the dynamic modulus of AR is always greater (up to 30%) than that of AC, while at low temperature, the dynamic modulus of AR is lower (up to 8%) than that of AC. This result is clear when comparing the master curves of the two thickened mixtures with the same volumetric properties.

Moreover, the phase angle is always lower in the AR mixture (up to 41%). This reveals more elastic behaviour compared to the traditional mixture.

The increase in stiffness at high temperatures found in the mixture containing the recycled tyre rubber led to a significant reduction in maximum tensile stress, thereby improving performance due to fatigue degradation. To accurately quantify this advantage, further laboratory tests will be needed to fully compare the fatigue degradation laws of the two mixtures.

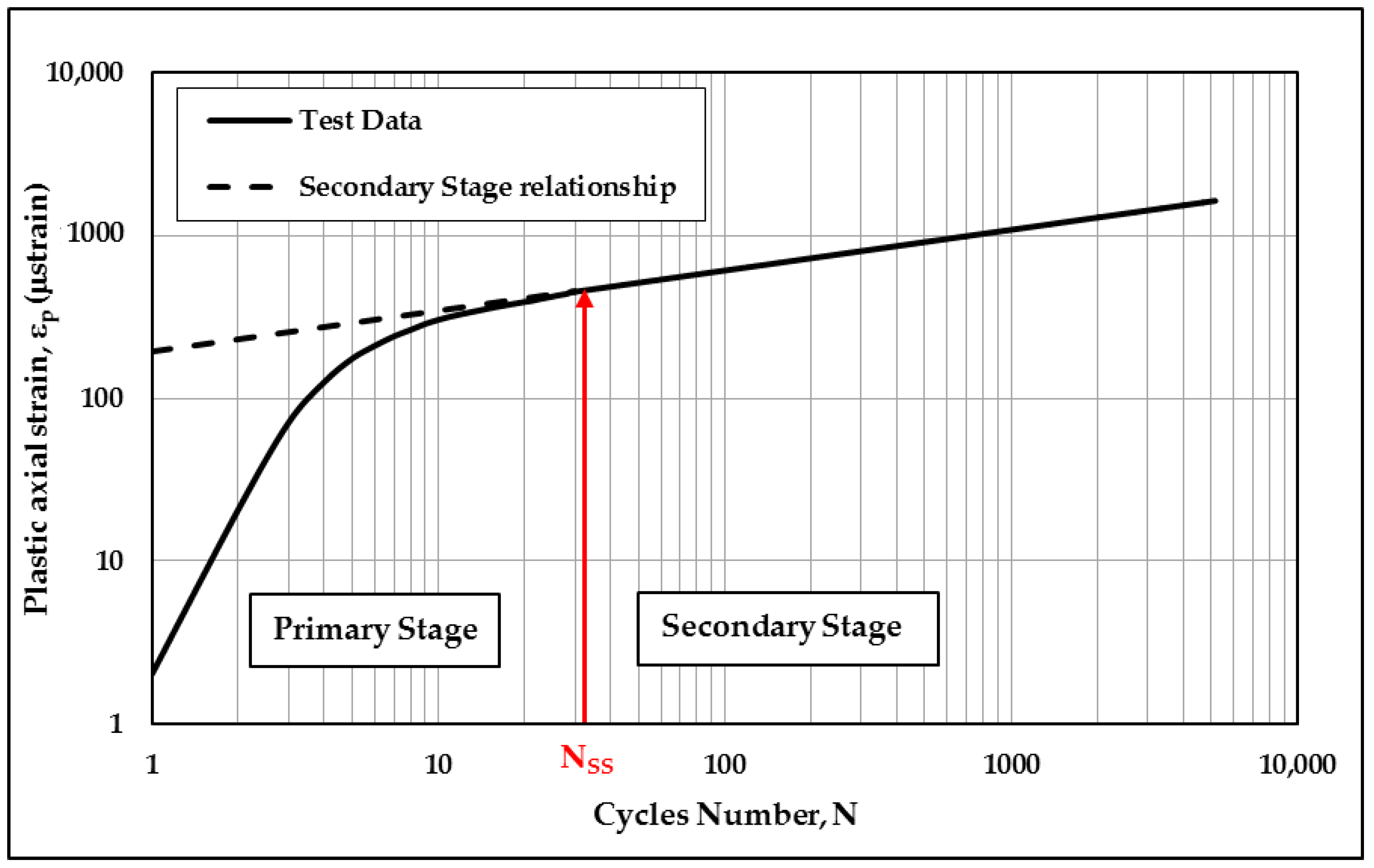

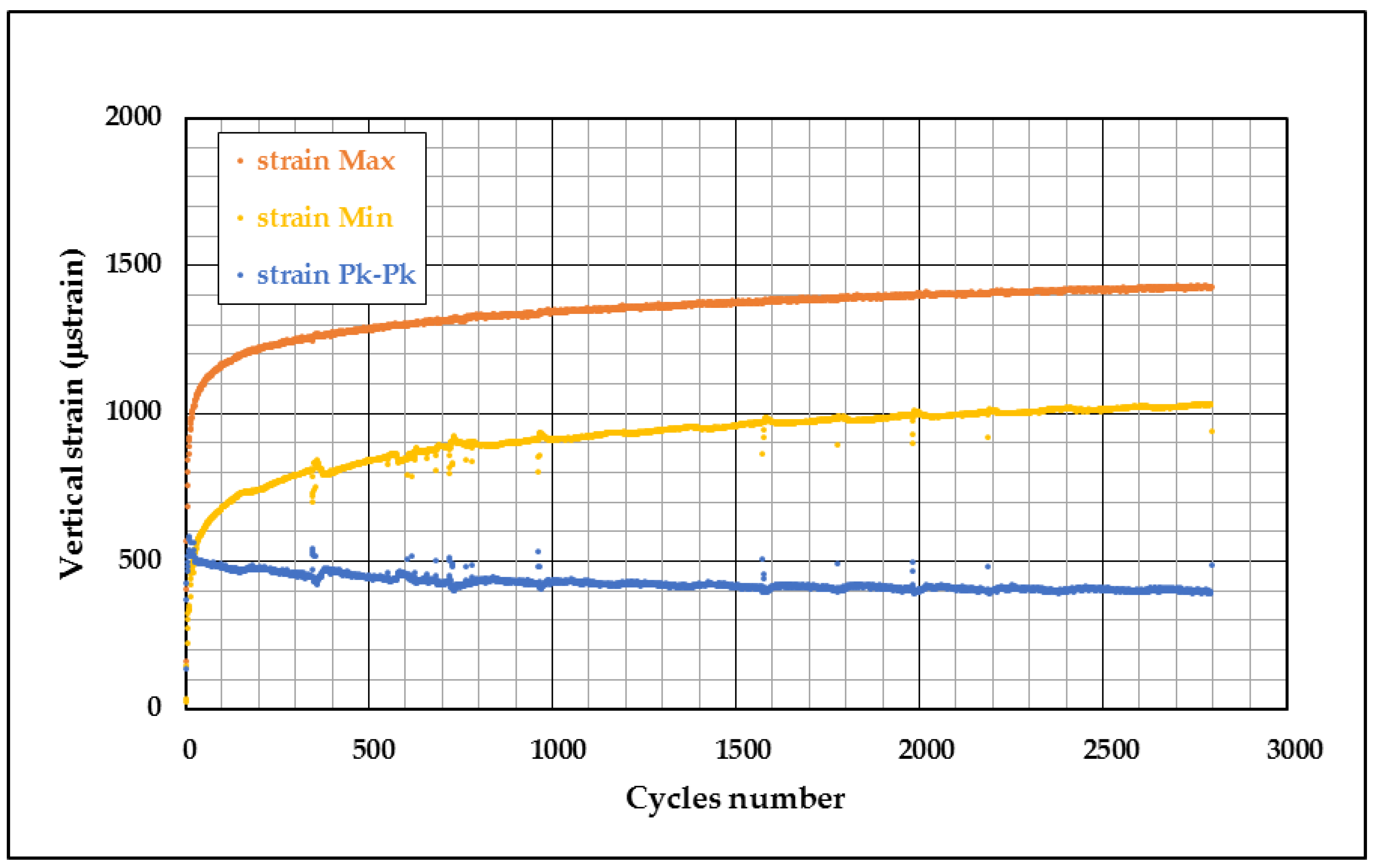

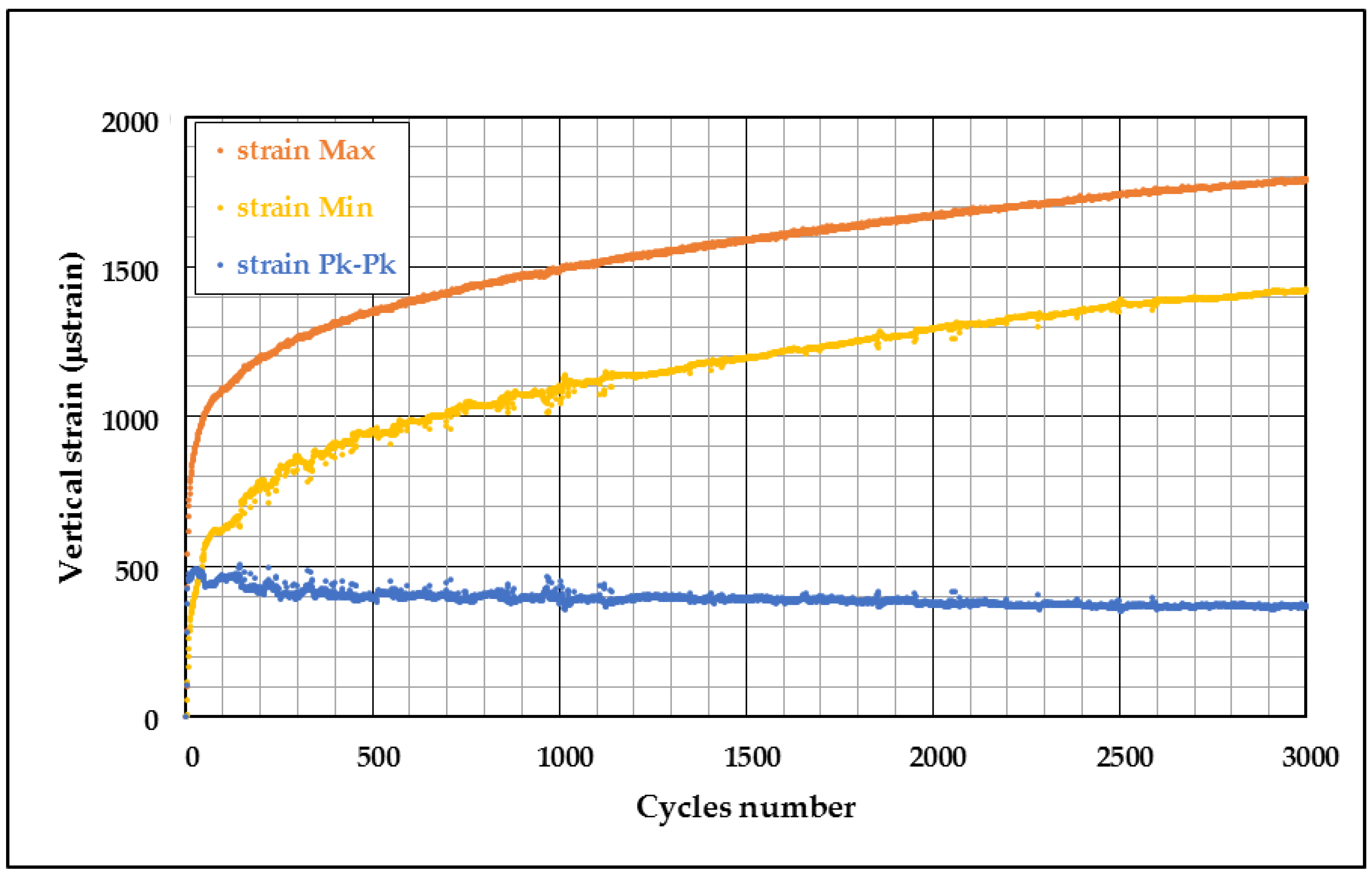

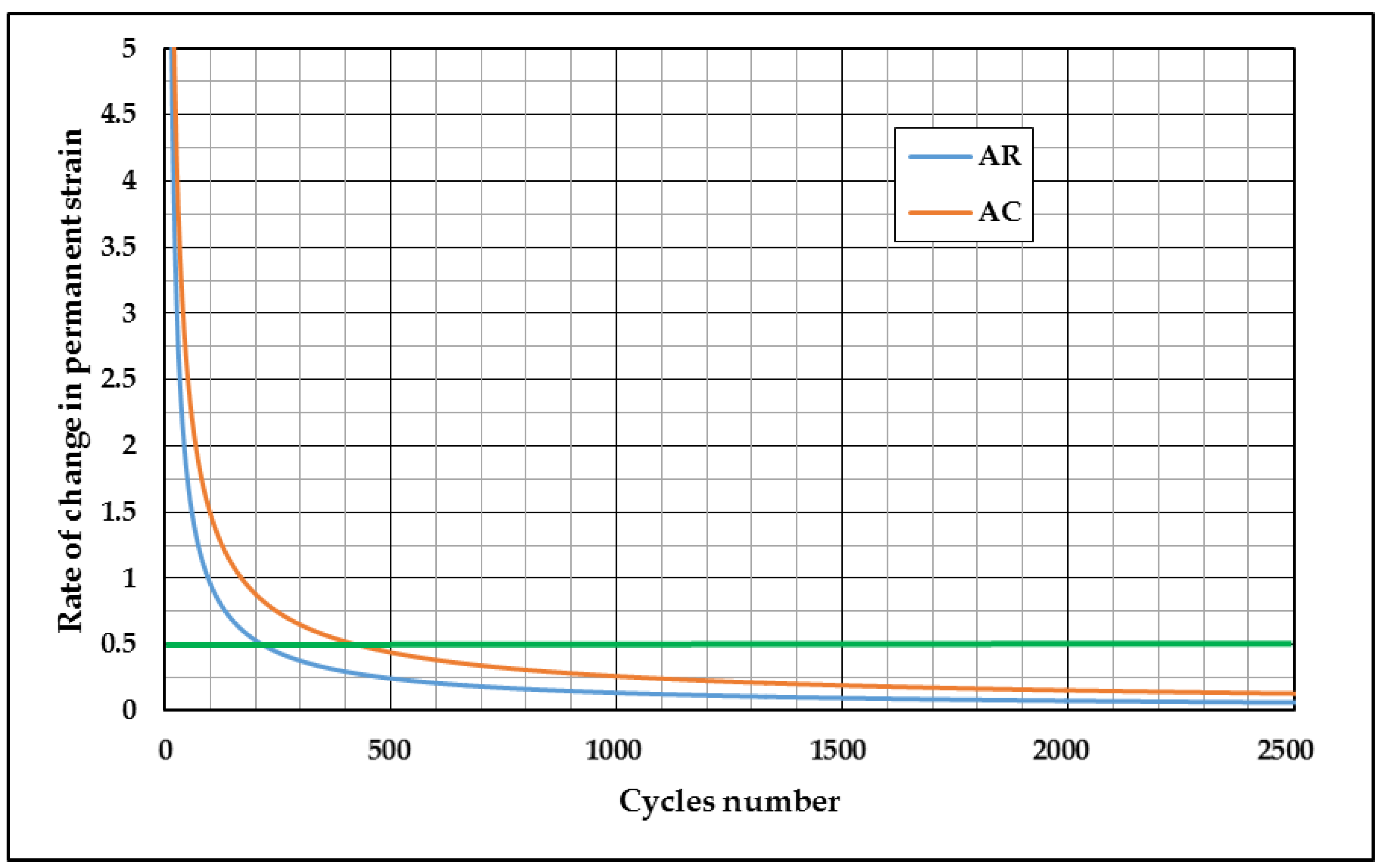

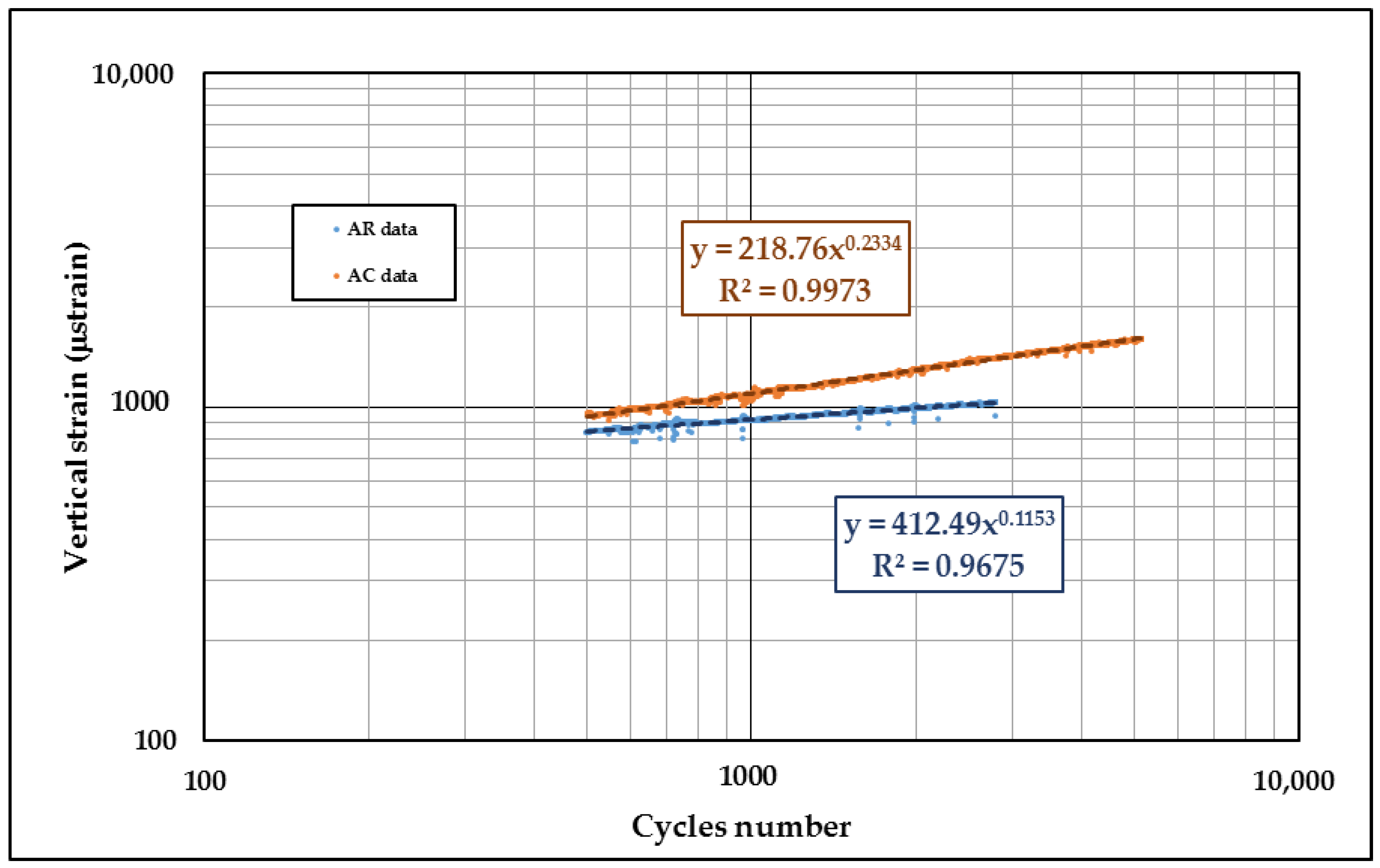

Similar results emerge when comparing the accumulation of permanent deformation between the two mixtures. Laboratory tests have shown a better response from mixtures with crumb rubber. For such mixtures, the slope of the straight line for the accumulation of permanent deformation in the secondary creep is lower. The higher stiffness of the AR mixture at high temperatures reduces the unit compression deformations in the bitumen bonded layers and, consequently, reduces the accumulation of permanent deformations.

On the basis of the results of this research, a field experiment on road pavement that aims to verify the optimal behaviour of mixtures with crumb rubber and steel slag is underway.

In the future, it will be important to evaluate the performance of this mixture, which can be largely prepared with recovered products, scrap from metallurgical processes, and end-of-life tyres, relative to the amount of crumb rubber added. The future objective will be to identify the optimal quantities of crumb rubber and binder, with the latter being different from traditional blends, for use in very porous steel slag.