Increasing Energy Efficiency in the Food and Beverage Industry: A Human-Centered Design Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. INDUCE Methodology Overview

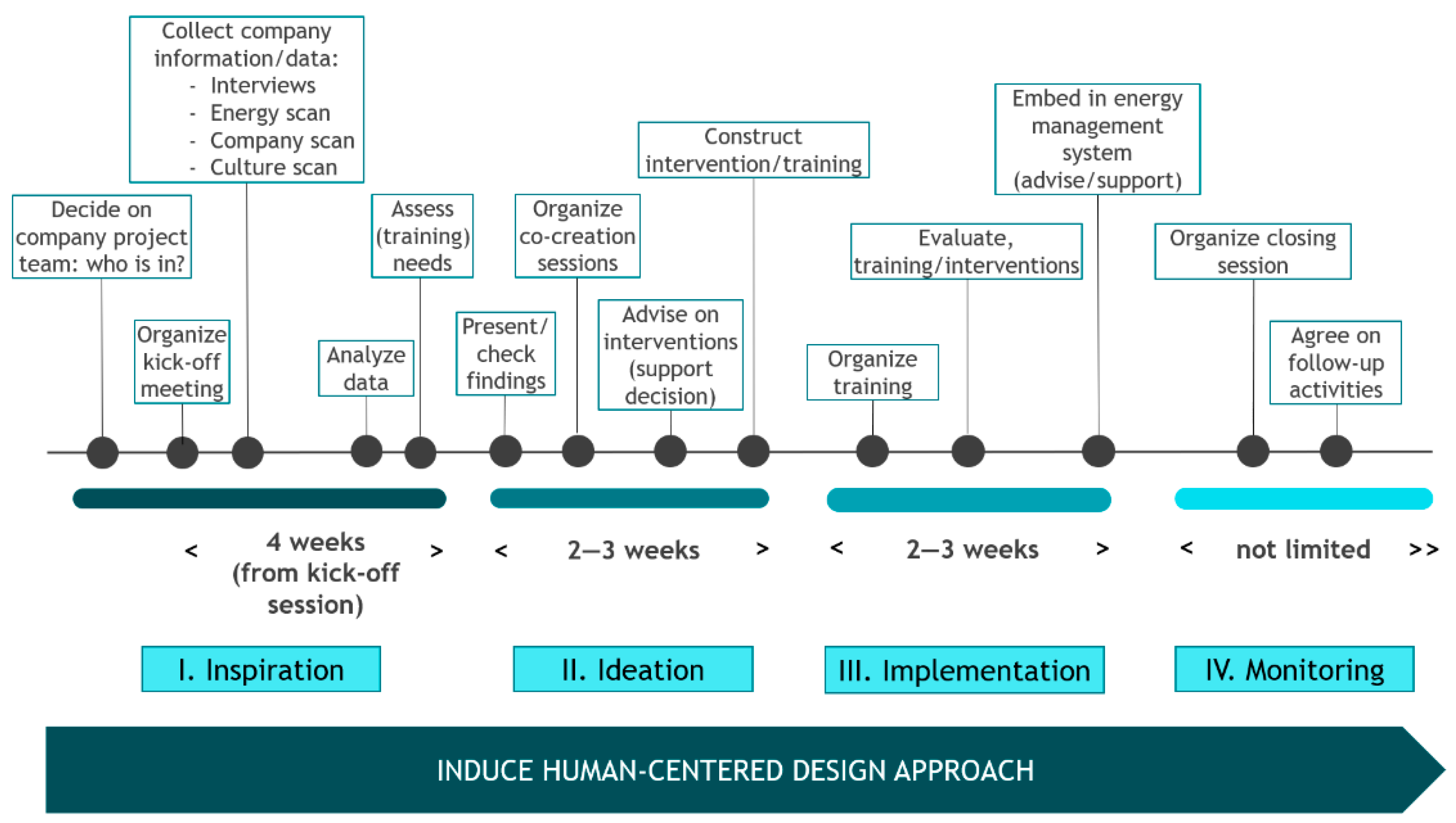

2.2. INDUCE Methodology

- Inspiration: In this phase, the key actors are observed to identify their ideas, opinions, desires, expectations, etc., regarding the challenge needing to be solved.

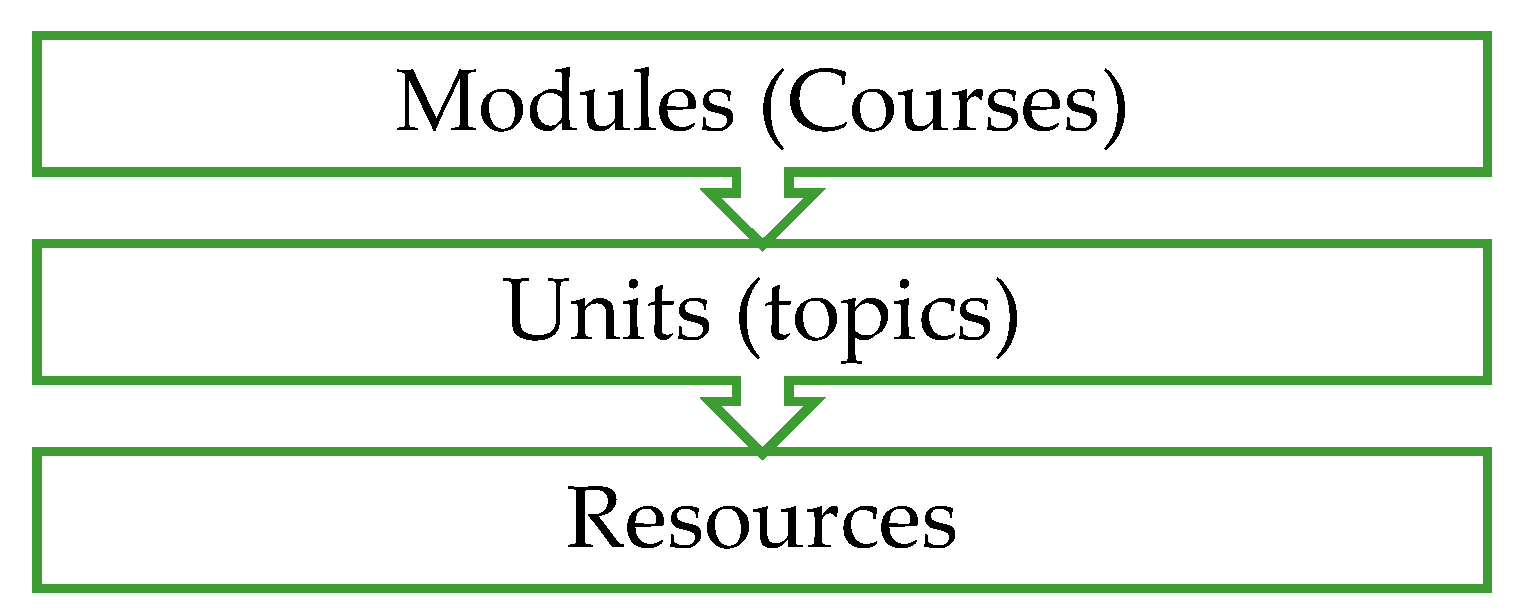

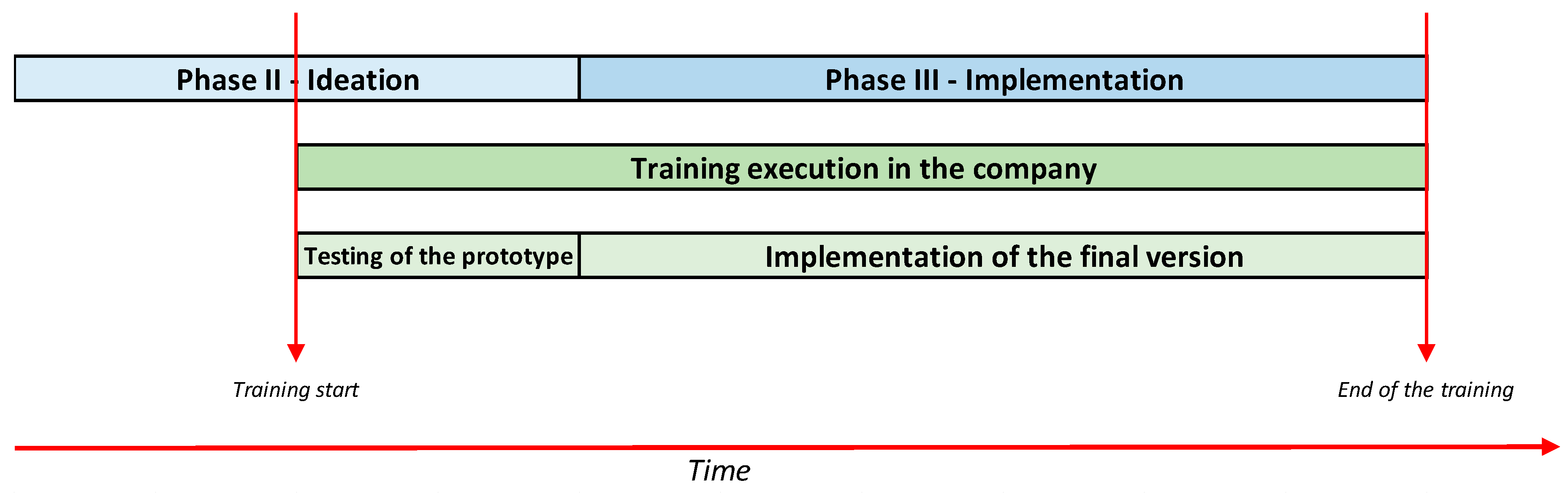

- Ideation: Here, the opportunities are identified, the ideas are generated, and prototypes of the hypothetical solution are made. The prototypes are tested, receiving feedback, and being adjusted to generate more sophisticated prototypes until the final version of the solution is achieved.

- Implementation: In this phase, the solution is implemented in the market in real life.

- (1)

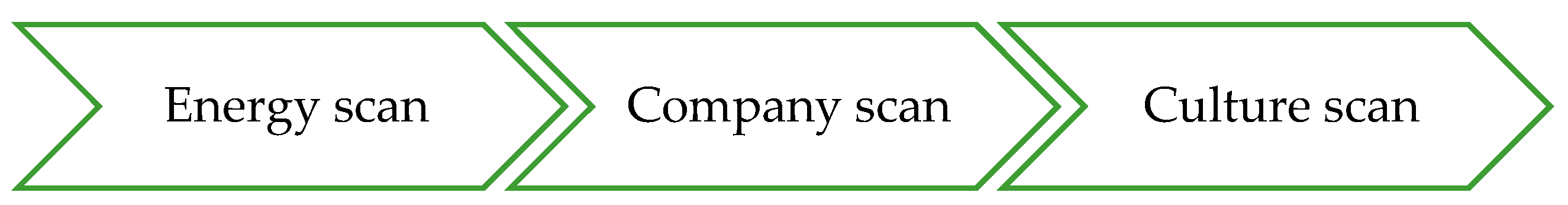

- At the company level, the barriers and opportunities of the entity are identified, as well as the characteristics of the organization, its structure, the roles of the different actors, etc. All of these aspects are key points in this methodology, which considers that technical and non-technical aspects have the same importance. The key point here is to receive all of the necessary insights for obtaining a realistic picture of the situation of the company, being fully aware of the technical points but also of those phenomena caused by organizational culture, as well as the relationship among the workers. These inputs are mainly obtained thanks to different actions, listed chronologically as: first contact, discuss benefits, agreement, energy scan, interviews, and culture scan (Figure 1). The project also performs—and encourages future replicators to perform—meetings with key people and managers, as well as to observe carefully the reality of the organization, trying to comprehend the real hopes, expectations, needs, and interest of the members of the company. In this first part, it is also crucial to determine who the managers and the members of the direction department are, as well as to identify who should be involved in the project—who will support the INDUCE experts in their labors and who will be the future trainees?

- (2)

- Technically speaking, the INDUCE methodology considers the energy performance of a company in depth. Because this methodology did not foresee direct energy assessments, the insights in this respect are obtained by taking into account energy audits and energy assessments performed in the past, energy-efficiency measures already developed or planned, data obtained from internal diagnosis, or daily maintenance tasks, etc.

- (3)

- As a unique feature, the INDUCE methodology includes cultural analysis of the entities: their habits, daily routines, informal roles, the nature of their relationships and, ultimately, all those non-technical aspects that explain the reason why a company is the way it is. Here, the key point in the work of the INDUCE experts or those replicators of the INDUCE methodology is to develop an empathic and open-minded approach. Based on the study developed within the INDUCE project, it was determined that these experts must understand the opinions, wishes, hopes, expectations, etc., of future trainees, as well as to comprehend a company’s social structure, the relationship between the departments, and the general organization culture.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CO2 | Carbon dioxide |

| EED | European Energy Efficiency Directive 2012/27/EU |

| EEOSs | Energy efficiency obligation schemes |

| EMS | Energy management system |

| EU | European Union |

| GHG | Greenhouse gas |

| HCD | Human-centered design |

| ISO | International Standard Organization |

| NACE | Nomenclature of Economic Activities |

| SMEs | Small and medium enterprises |

References

- European Parliament. EED. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency. Off. J. Eur. Union 2012, 315, 1–56. [Google Scholar]

- European Parliament. Directive 2018/2002/EU amending Directive 2012/27/EU on Energy Efficiency. Off. J. Eur. Union 2018, 328, 210–230. [Google Scholar]

- Chan, Y.; Kantamaneni, R. Study on Energy Efficiency and Energy Saving Potential in Industry and on Possible Policy Mechanisms; ICF Consult. Ltd.: London, UK, 2015; pp. 1–461. [Google Scholar]

- Monforti-Ferrario, F. Energy Use in the EU Food Sector: State of Play and Opportunities for Improvement; European Union; Joint Research Centre; Institute for Energy and Transport and Institute for Environment and Sustainability: Ispra, Italy, 2015. [Google Scholar]

- Blasco Hedo, E. Real Decreto 56/2016, de 12 de febrero, por el que se transpone la Directiva 2012/27/UE del Parlamento Europeo y del Consejo, de 25 de octubre de 2012, relativa a la eficiencia energética, en lo referente a auditorías energéticas, acreditación de proveedo. Actual. Jurídica Ambient. 2016, 55, 39–41. [Google Scholar]

- European Commission. Good Practice in Energy Efficiency—Clean Energy for all Europeans; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- European Commission; Eurostat. Small and Medium-Sized Enterprises: An Overview; Eurostat Press Centre: Luxembourg, 2018; pp. 1–2. [Google Scholar]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- 785047 INDUCE. Towards a Sustainable Agro-Food Industry: Capacity Building Programmes in Energy Efficiency—785047. 2017. Available online: https://cordis.europa.eu/project/id/785047 (accessed on 1 June 2020).

- Wohlfarth, K.; Eichhammer, W.; Schlomann, B.; Mielicke, U. Learning networks as an enabler for informed decisions to target energy-efficiency potentials in companies. J. Clean. Prod. 2016, 163. [Google Scholar] [CrossRef]

- Burk, A.; Baker, R. Measuring End-Use Technological and Behavioral Waste to Prioritize and Improve Program Design; International Energy Program Evaluation Conference: Chicago, IL, USA, 2013. [Google Scholar]

- Jollands, N.; Tanaka, K.; Gasc, E.; Wescott, W. Energy Management Action NetworK (EMAK)-A Scoping Study Investigating the Establishment and Support of an International and Domestic Action Network of Energy Management in Industry; International Energy Agency: Paris, France, 2009. [Google Scholar]

- Granade, C.; Creyts, J.; Derkach, A.; Farase, P.; Nyquist, S.; Ostrowski, K. Unlocking Energy Efficiency in the U.S. Economy; McKinsey & Company: NewYork, NY, USA, 2009. [Google Scholar]

- Fraunhofer ISI. Deliverable 2.4—Benchmarking Baseline Report Project Factsheet; 785047 INDUCE, European Union’s H2020 Coordination Support Action; Fraunhofer ISI: Karlsruhe, Germany, 2018. [Google Scholar]

- Kooger, R.S.M.; Reffeltrath, P. D2.2 Best Practice Guideline; 785047 INDUCE, European Union’s H2020 Coordination Support Action: Amsterdam, The Netheralands, 2018. [Google Scholar]

- Fraj, I.; Hermans, L. D2.1 Overview of Capacity Building and Training Programmes; 785047 INDUCE, European Union’s H2020 Coordination Support Action: Amsterdam, The Netheralands, 2018. [Google Scholar]

- IDEO.org. The Field Guide To Human-Centered Design, 1st ed.; IDEO.org: Palo Alto, CA, USA, 2015. [Google Scholar]

- Fernandez, C. Learning from Japanese approaches to professional development: The case of lesson study. J. Teach. Educ. 2002, 53, 393–405. [Google Scholar] [CrossRef]

- Hiles, J.B. Teacher Learning Through the Dialogic Space of a Lesson Study Cycle; University of Pittsburgh School of Education: Pittsburgh, PA, USA, 2018. [Google Scholar]

- Elliott, J. What is Lesson Study? Eur. J. Educ. 2019. Available online: https://lessonresearch.net/about-lesson-study/what-is-lesson-study/ (accessed on 1 June 2020).

- Javied, T.; Rackow, T.; Franke, J. Implementing energy management system to increase energy efficiency in manufacturing companies. Procedia CIRP 2015, 26, 156–161. [Google Scholar] [CrossRef]

- ISO. ISO 50001-2018: Energy Management Systems—Requirements with Guidance for Use; International Organization for Standardization: Geneva, Switzerland, 2018; p. 47. [Google Scholar]

| Sector | Energy Intensity (2015) | Energy Intensity (2050) | Energy Intensity Ratio Variation 2015–2050 |

|---|---|---|---|

| Food and beverage | 0.023 ktoe/MioEUR | 0.007 ktoe/MioEUR | −70.6% |

| Machinery | 0.012 ktoe/MioEUR | 0.006 ktoe/MioEUR | −51.6% |

| Pulp, paper, and paperboard | 0.389 toe/ton | 0.292 toe/ton | −24.9% |

| Non-ferrous metals | 0.078 ktoe/MioEUR | 0.065 ktoe/MioEUR | −17.1% |

| Iron and steel | 0.341 toe/ton | 0.299 toe/ton | −12.3% |

| Chemical and pharmaceutical | 0.08 ktoe/MioEUR | 0.076 ktoe/MioEUR | −5% |

| Non-metallic minerals | 0.118 toe/ton | 0.115 toe/ton | −2.5% |

| Coke and refined petroleum | 0.066 toe/ton | 0.068 toe/ton | 3% |

| Energy, Economic, and Environmental Impact of the INDUCE Project | ||

|---|---|---|

| Impact | Value/Enterprise | Unit |

| Investment | 68,824 | EUR/year/enterprise |

| Energy savings (final energy) | 1,296,882 | kWh/year/enterprise |

| Electricity | 254,478 | kWh/year/enterprise |

| Natural gas | 1,042,405 | kWh/year/enterprise |

| Energy savings (primary energy) | 1,800,000 | kWh/year/enterprise |

| Energy costs avoided | 63,501 | EUR/year/enterprise |

| Electricity costs avoided | 34,746 | EUR/year/enterprise |

| Natural gas costs avoided | 28,755 | EUR/year/enterprise |

| Greenhouse gas (GHG) avoided (EU electricity mix) | 329,672 | kgCO2/year/enterprise |

| GHG avoided due to electricity | 75,325 | kgCO2/year/enterprise |

| GHG avoided due to natural gas | 254,347 | kgCO2/year/enterprise |

| (Nomenclature of Economic Activities) NACE | Employees (Number) | Enterprises (Number) | Value Added (MioEUR) | Production Value (MioEUR) | Turnover (MioEUR) |

|---|---|---|---|---|---|

| C10—Manufacture of food products | 4,120,893 | 265,094 | 199,000 | 931,000 | 1,026,033 |

| C11—Manufacture of beverages | 448,146 | 31,000 | 47,210 | 168,000 | 174,963 |

| TOTAL | 4,569,039 | 296,094 | 246,210 | 1,099,000 | 1,200,997 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Millán, G.; Llano, E.; Globisch, J.; Durand, A.; Hettesheimer, T.; Alcalde, E. Increasing Energy Efficiency in the Food and Beverage Industry: A Human-Centered Design Approach. Sustainability 2020, 12, 7037. https://doi.org/10.3390/su12177037

Millán G, Llano E, Globisch J, Durand A, Hettesheimer T, Alcalde E. Increasing Energy Efficiency in the Food and Beverage Industry: A Human-Centered Design Approach. Sustainability. 2020; 12(17):7037. https://doi.org/10.3390/su12177037

Chicago/Turabian StyleMillán, Gema, Erudino Llano, Joachim Globisch, Antoine Durand, Tim Hettesheimer, and Eduardo Alcalde. 2020. "Increasing Energy Efficiency in the Food and Beverage Industry: A Human-Centered Design Approach" Sustainability 12, no. 17: 7037. https://doi.org/10.3390/su12177037

APA StyleMillán, G., Llano, E., Globisch, J., Durand, A., Hettesheimer, T., & Alcalde, E. (2020). Increasing Energy Efficiency in the Food and Beverage Industry: A Human-Centered Design Approach. Sustainability, 12(17), 7037. https://doi.org/10.3390/su12177037