Sustainable Perspective of Low-Lime Stabilized Fly Ashes for Geotechnical Applications: PROMETHEE-Based Optimization Approach

Abstract

1. Introduction

2. Methodology

2.1. Materials Used

2.2. Experimental Testing Methodology

3. Experimental Results

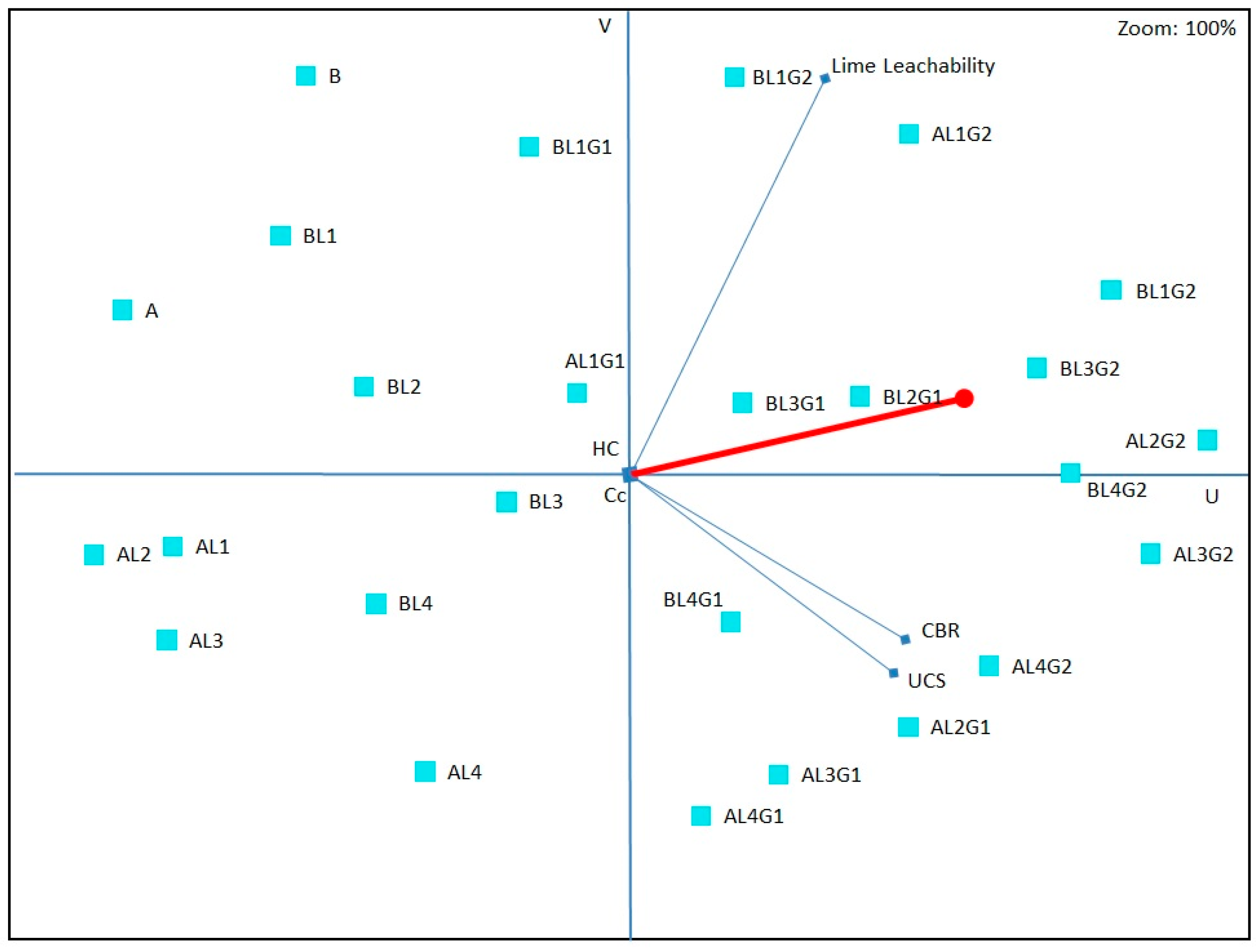

4. MCDM Model: Based on PROMETHEE and GAIA

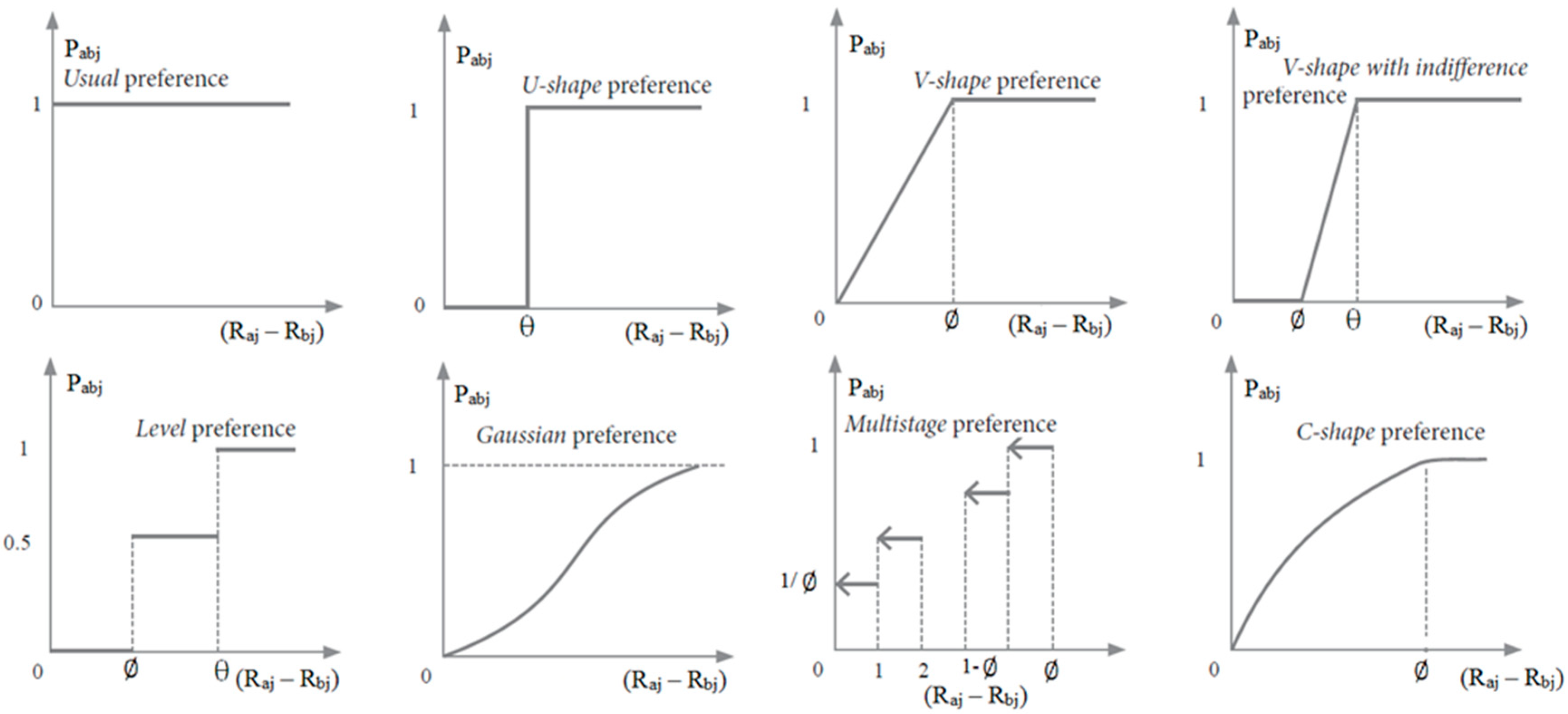

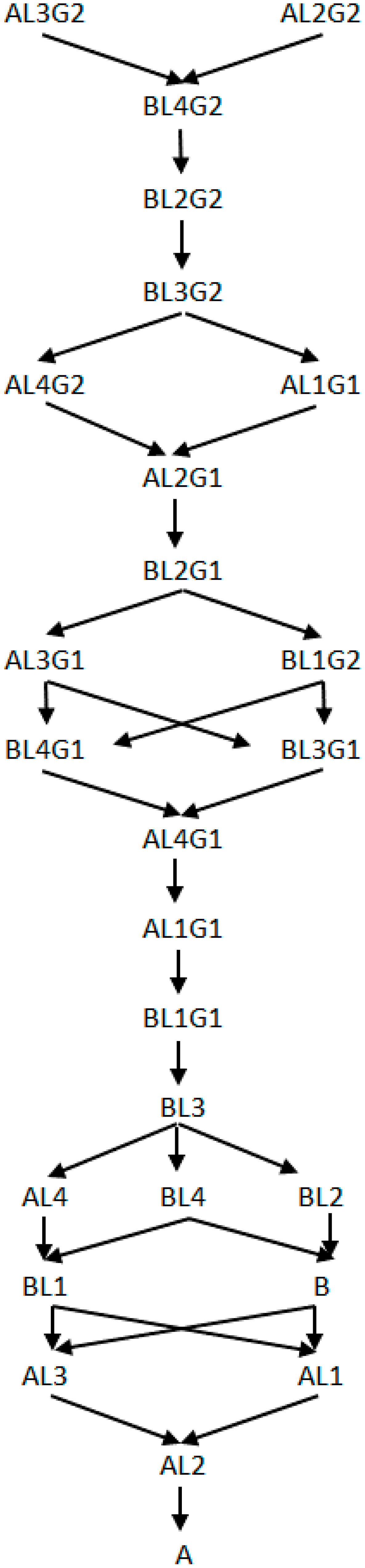

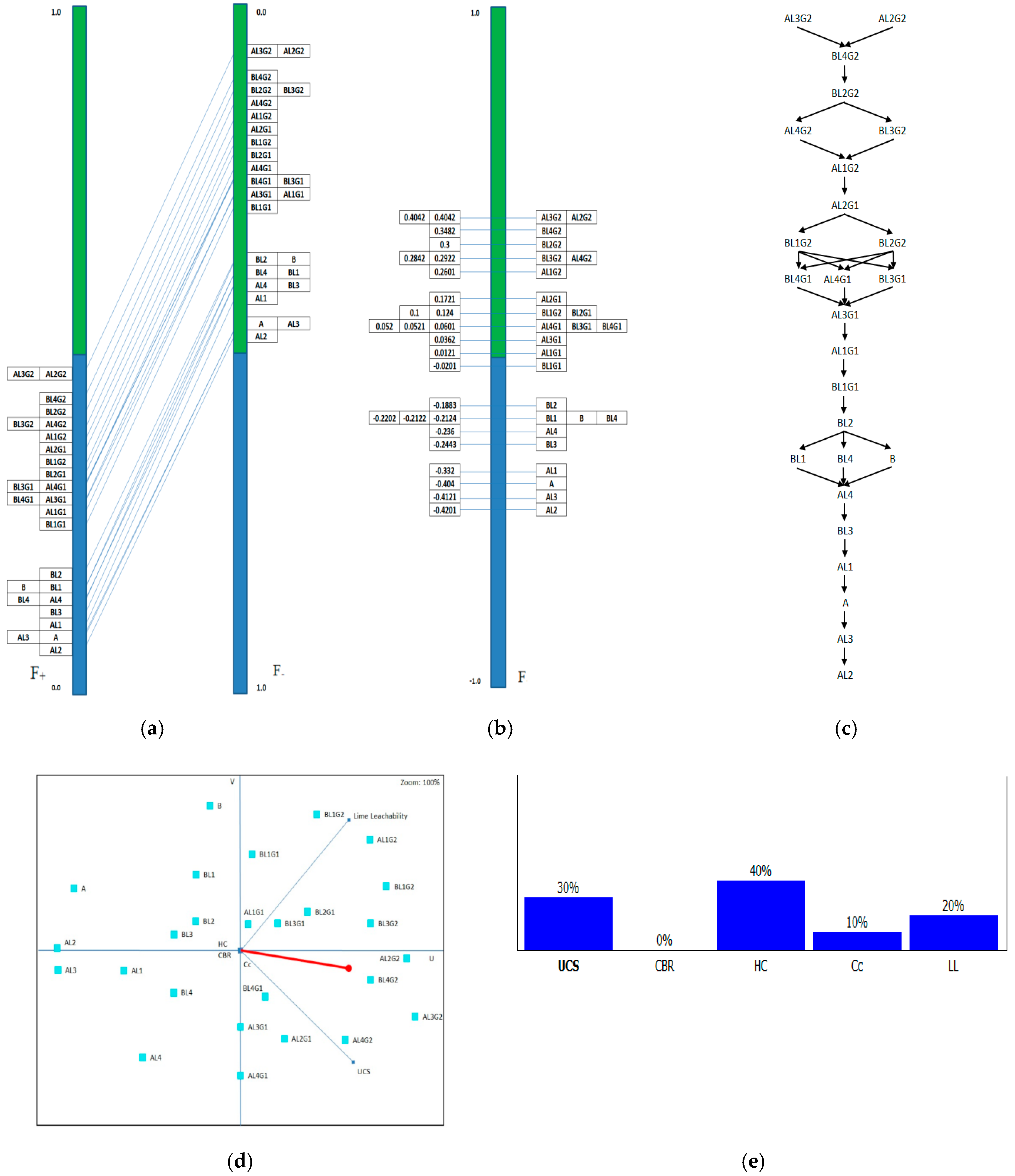

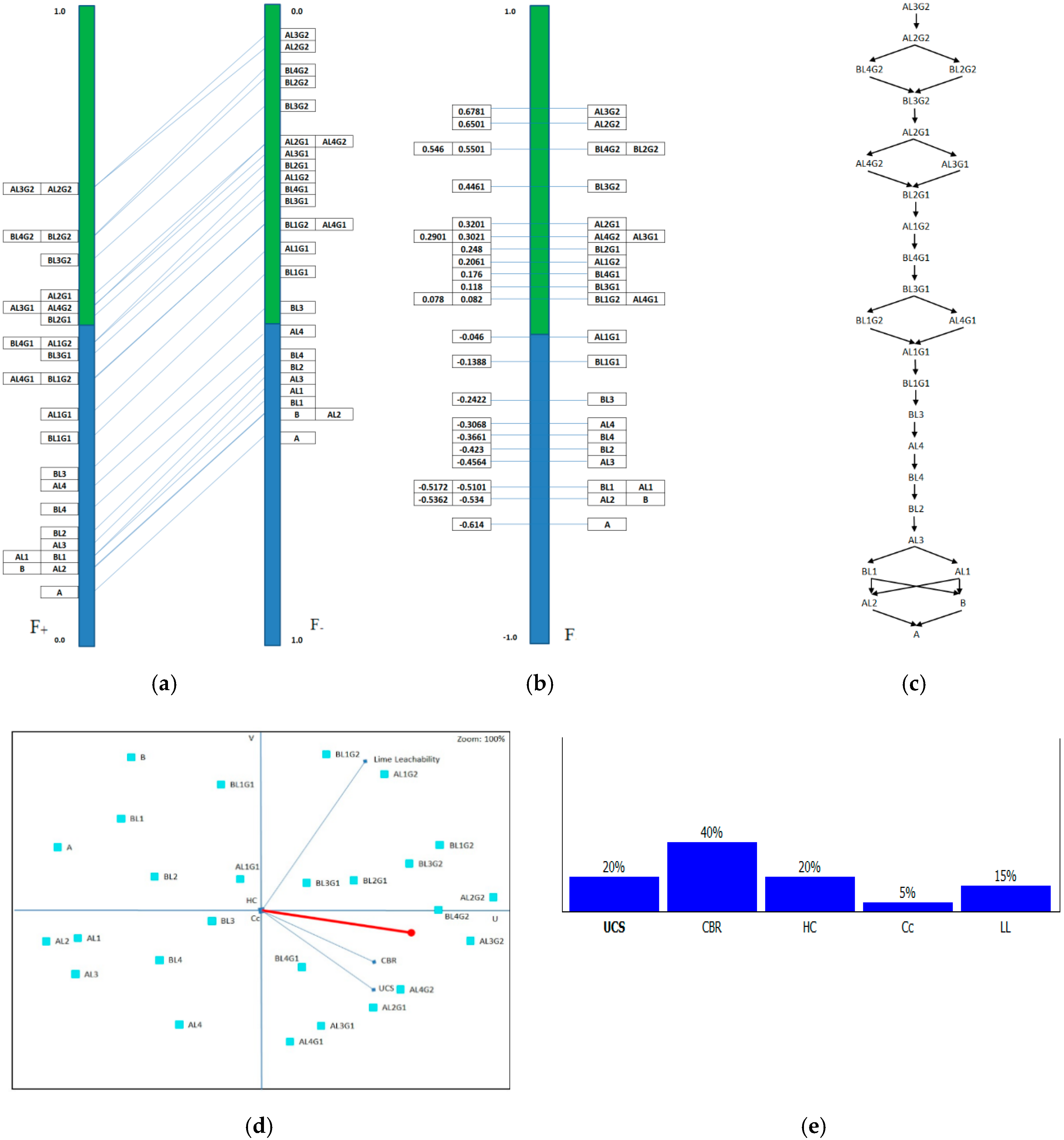

4.1. PROMETHEE Partial Ranking

- Pabj ≈ one, indicates acceptable preference for strategy Ta over strategy Tb.

- Pabj ≈ zero, indicates a weak preference for strategy Ta over strategy Tb.

- Pabj = zero, indicates no preference for strategy Ta over strategy Tb for a given j performance measure.

- Pabj = one, indicates a higher preference for strategy Ta over Tb.

- If F+a > F+b, the outranking relationship is D+ab (i.e., treatment strategy Ta is dominating Tb).

- If F−a < F−b, the outranking relationship is D−ab (i.e., treatment strategy Ta is not dominating Tb).

- If F+a = F+b, the outranking relationship is ED+ab (i.e., both treatment strategies Ta and Tb equally dominate (ED) the other “n − 2” treatment strategies).

- If F-a = F-b, the outranking relationship is ED-ab (i.e., both treatment strategies Ta and Tb are equally dominated (ED) by the other “n − 2” treatment strategies).

- If (D+ab and D−ab)/(D+ab and ED−ab)/(ED+ab and D−ab) are true, it indicates that treatment strategy Ta has a higher preference over Tb.

- If ED+ab and ED−ab are true, it indicates that treatment strategy Ta is no different to Tb.

- If (D+ab and D−ba)/(D+ba and D−ab) are true, it indicates that treatment strategy Ta is in contrast to Tb. Specifically, on a set of geotechnical performance measures, Ta exhibits the best performance over Tb, which exhibits a low response and vice versa.

4.2. PROMETHEE Complete Ranking

- If Fa > Fb is true, it indicates that treatment strategy Ta is preferred over treatment strategy Tb.

- If Fa = Fb is true, there is no difference between treatment strategies Ta and Tb.

- If Fa < Fb is true, it indicates that there is no preference of treatment strategy Ta over treatment strategy Tb.

5. Application of PROMETHEE

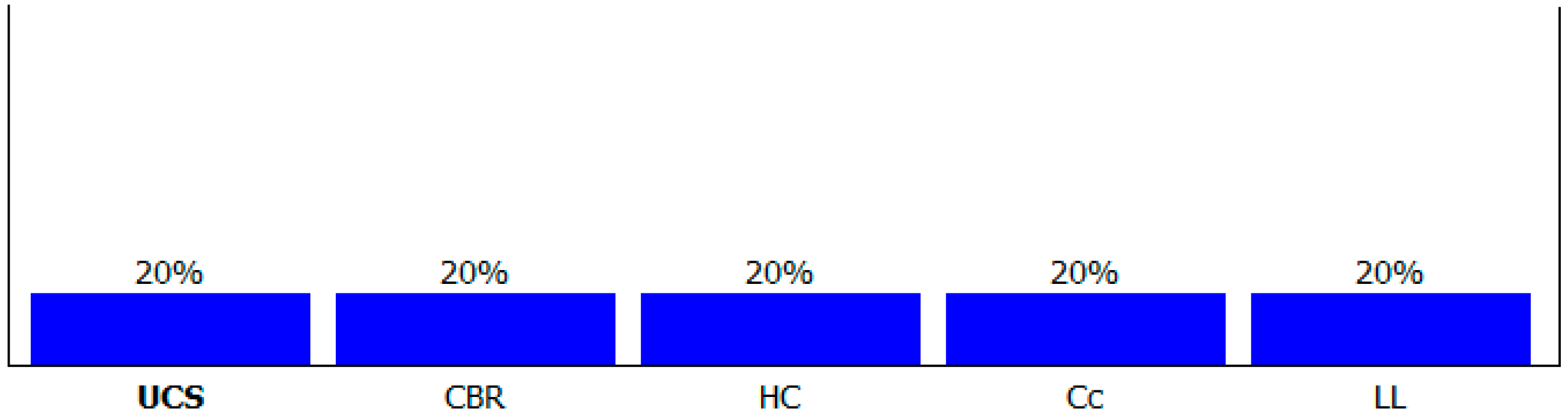

Sensitivity Analysis Using Walking Weights

6. Conclusions

- For liner applications, fly ash type A, treated with a 2.5% dosage of lime and 2.5% dosage of gypsum, is preferred.

- For pavement applications, fly ash type A, treated with a 5% dosage of lime and a 2.5% dosage of gypsum, is preferred.

- When equal walking weights were assigned to all response measures, irrespective of the nature of application, fly ash type A, treated with either a 2.5% or 5% dosage of lime and a 2.5% dosage of gypsum, should be the first choice.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Example Calculation for AL3G2

- Raj and Rbj are the performance measures for treatment strategies Ta and Tb, respectively;

- Wj is the weight assigned to each performance measure j; and

- Pabj is a preference function allocated to a pair of treatment strategies Ta and Tb for each j.

- R11 1 = 6842 and R1 1 = 173.1 are the performance measures for j = 1;

- R11 2 = 409.2 and R1 2 = 55.5 are the performance measures for j = 2;

- R11 3 = 0.016 × 10−4 and R1 3 = 6.52 × 10−4 are the performance measures for j = 3;

- R11 4 = 0.0023 and R1 4 = 0.0099 are the performance measures for j = 4;

- R11 5 = 210 and R1 5 = 630 are the performance measures for j = 5, respectively.

References

- British Petroleum. Statistical Review of World Energy; Workbook, BP: London, UK, 2018. [Google Scholar]

- Cherian, C.; Siddiqua, S. Pulp and Paper Mill Fly Ash: A Review. Sustainability 2019, 11, 4394. [Google Scholar] [CrossRef]

- Ashfaq, M.; Heeralal, M.; Moghal, A.A.B. Characterization studies on coal gangue for sustainable geotechnics. Innov. Infrastruct. Solut. 2020, 5, 15. [Google Scholar] [CrossRef]

- Mehta, P.K. Influence of fly ash characteristics on the strength of portland-fly ash mixtures. Cem. Concr. Res. 1985, 15, 669–674. [Google Scholar] [CrossRef]

- Singh, S.R.; Panda, A.P. Utilization of fly ash in geotechnical construction. In Proceedings of the Indian Geotechnical Conference, Chennai, India, 14–16 December 1996; pp. 547–550. [Google Scholar]

- Palmer, B.G.; Edil, T.B.; Benson, C.H. Liners for waste containment constructed with class F and C fly ashes. J. Hazard. Mater. 2000, 76, 193–216. [Google Scholar] [CrossRef]

- Antiohos, S.; Tsimas, S. Activation of fly ash cementitious systems in the presence of quicklime: Part, I. Compressive strength and pozzolanic reaction rate. Cem. Concr. Res. 2004, 34, 769–779. [Google Scholar] [CrossRef]

- Kim, B.; Prezzi, M.; Salgado, R. Geotechnical Properties of Fly and Bottom Ash Mixtures for Use in Highway Embankments. J. Geotech. Geoenviron. Eng. 2005, 131, 914–924. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Mohan, J. Compressive strength of fiber reinforced highly compressible clay. Constr. Build. Mater. 2006, 20, 1063–1068. [Google Scholar] [CrossRef]

- Sekhar, M.R.; Madhav, M.R.; Puppala, A.J.; Ghosh, A. Compressibility and Collapsibility Characteristics of Sedimented Fly Ash Beds. J. Mater. Civ. Eng. 2008, 20, 401–409. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Baig, M.A.A. Gypsum treated fly ash as a liner for waste disposal facilities. Waste Manag. 2011, 31, 359–369. [Google Scholar] [CrossRef] [PubMed]

- Moghal, A.A.B.; Sivapullaiah, P.V. Characterization of Lime and Gypsum Amended Class F Fly Ashes as Liner Materials. Geo Front. 2011, 1162–1171. [Google Scholar] [CrossRef]

- Moghal, A.A.B. A state-of-the-art review on the role of fly ashes in geotechnical and geoenvironmental applications. J. Mater. Civ. Eng. 2017, 29, 04017072. [Google Scholar] [CrossRef]

- Xu, P.; Zhao, Q.; Qiu, W.; Xue, Y.; Li, N. Microstructure and Strength of Alkali-Activated Bricks Containing Municipal Solid Waste Incineration (MSWI) Fly Ash Developed as Construction Materials. Sustainability 2019, 11, 1283. [Google Scholar] [CrossRef]

- DiGioia, A.M.; Nuzzo, W.L. Fly Ash as Structural Fill. J. Power Div. 1972, 98, 77–92. [Google Scholar]

- Edil, T.B.; Berthouex, P.M.; Vesperman, K.D. Fly Ash as a Potential Waste Liner; ASCE, Geotechnical Practice for Waste Disposal ’87, University of Michigan: Ann Arbor, MI, USA, 15–17 June 1987; pp. 447–461. [Google Scholar]

- Nhan, C.T.; Graydon, J.W.; Kirk, D.W. Utilizing coal fly ash as a landfill barrier material. Waste Manag. 1996, 16, 587–595. [Google Scholar] [CrossRef]

- Mollamahmutoğlu, M.; Yilmaz, Y. Potential use of fly ash and bentonite mixture as liner or cover at waste disposal areas. Environ. Earth Sci. 2001, 40, 1316–1324. [Google Scholar] [CrossRef]

- Rostami, H.; Brendley, W. Alkali Ash Material: A Novel Fly Ash-Based Cement. Environ. Sci. Technol. 2003, 37, 3454–3457. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K. Fly Ash as a Barrier Material. Geo Front. 2012, 947–956. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Sivapullaiah, P.V. Effect of Pozzolanic Reactivity on Compressibility Characteristics of Stabilised Low Lime Fly Ashes. Geotech. Geol. Eng. 2011, 29, 665–673. [Google Scholar] [CrossRef]

- Moghal, A.; Sivapullaiah, P. Role of lime leachability on the geotechnical behavior of fly ashes. Int. J. Geotech. Eng. 2012, 6, 43–51. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Moghal, A.A.B. CBR and strength behavior of class F fly ashes stabilized with lime and gypsum. Int. J. Geotech. Eng. 2011, 5, 121–130. [Google Scholar] [CrossRef]

- Ghosh, A.; Subbarao, C. Strength Characteristics of Class F Fly Ash Modified with Lime and Gypsum. J. Geotech. Geoenvironmental Eng. 2007, 133, 757–766. [Google Scholar] [CrossRef]

- Moghal, A.A.B. Geotechnical and Physico-Chemical Characterization of Low Lime Fly Ashes. Adv. Mater. Sci. Eng. 2013, 2013, 1–11. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Moghal, A.A.B. Role of Gypsum in the Strength Development of Fly Ashes with Lime. J. Mater. Civ. Eng. 2011, 23, 197–206. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Antuchevičienė, J.; Kapliński, O. Multi-criteria decision making in civil engineering: Part I—A state-of-the-art survey. Eng. Struct. Technol. 2015, 7, 103–113. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Antuchevičienė, J.; Kapliński, O. Multi-criteria decision making in civil engineering. Part II—Applications. Eng. Struct. Technol. 2015, 7, 151–167. [Google Scholar] [CrossRef]

- Rousta, B.A.; Araghinejad, S. Development of a Multi Criteria Decision Making Tool for a Water Resources Decision Support System. Water Resour. Manag. 2015, 29, 5713–5727. [Google Scholar] [CrossRef]

- Haralambopoulos, D.A.; Polatidis, H. Renewable energy projects: Structuring a multi-criteria group decision-making framework. Renew Energy 2003, 28, 961–973. [Google Scholar] [CrossRef]

- Fiorucci, P.; Minciardi, R.; Robba, M.; Sacile, R. Solid waste management in urban areas: Development and application of a decision support system. Resour. Conserv. Recycl. 2003, 37, 301–328. [Google Scholar] [CrossRef]

- Vego, G.; Kučar-Dragičević, S.; Koprivanac, N. Application of multi-criteria decision-making on strategic municipal solid waste management in Dalmatia, Croatia. Waste Manag. 2008, 28, 2192–2201. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Khalifah, Z.; Jusoh, A.; Md Nor, K. Multiple criteria decision-making techniques in transportation systems: A systematic review of the state of the art literature. Transport 2016, 31, 359–385. [Google Scholar] [CrossRef]

- Malindu, S.; Chamila, G.; David, L.; Guomin, Z.; Sujeeva, S.; Dennis, W. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Xu, J.; Deng, Y.; Shi, Y.; Huang, Y. A bi-level optimization approach for sustainable development and carbon emissions reduction towards construction materials industry: A case study from China. Sustain. Cities Soc. 2020, 53, 101828. [Google Scholar] [CrossRef]

- Behzadian, M.; Kazemzadeh, R.B.; Albadvi, A.; Aghdasi, M. PROMETHEE: A comprehensive literature review on methodologies and applications. Eur. J. Oper. Res. 2010, 198–215. [Google Scholar] [CrossRef]

- Rehman, A.U.; Moghal, A.A.B. The Influence & Optimisation of Treatment Strategy in Enhancing Semi-Arid Soil Geotechnical Properties. Arab. J. Sci. Eng. 2018, 43, 5129–5141. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Rehman, A.U.; Chittoori, B. Optimizing Fiber Parameters Coupled with Chemical Treatment: Promethee Approach. In Proceedings of the Geotechnical Frontiers 2017: Geotechnical Materials, Modeling and Testing: Selected Papers from Sessions of Geotechnical Frontiers, Orlando, FL, USA, 12–15 March 2017; pp. 30–41. [Google Scholar] [CrossRef]

- ASTM D2166 A. Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Indian Standards IS 2720-16: Methods of Test for Soils, Part 16: Laboratory Determination of CBR; Bureau of Indian Standards: New Delhi, India, 1987.

- D1883 A. Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- D5856 A. Standard Test Method for Measurement of Hydraulic Conductivity of Porous Material Using a Rigid-Wall, Compaction-Mold Permeameter; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Indian Standards IS 2720-15: Method of Test for Soils–Determination of Consolidation Properties; Bureau of Indian Standards: New Delhi, India, 1986.

- ASTM D2435 A Standard, Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading; ASTM International: West Conshohocken, PA, USA, 2004.

- Brans, J.P.; Mareschal, B. Promethee Methods. In Multiple Criteria Decision Analysis: State of the Art Surveys; Figueira, J., Greco, S., Ehrogott, M., Eds.; Springer: New York, NY, USA, 2005; Volume 200, pp. 163–186. [Google Scholar]

| Type of Fly Ash and Properties Studied | Potential Sustainable Applications | Reference |

|---|---|---|

| Fly ash compacted under controlled test conditions indicated an increase in Φ from 30° to 40° (from DST and Triaxial shear test). Average Cc was 0.2. | Satisfied embankment-fill material criteria. | DiGioia and Nuzzo [15] |

| Class C fly ash and sand mixtures; 10% bentonite; HC increased by a factor of 1000. | Satisfied liner material criteria for hazardous waste. | Edil et al. [16] |

| Coal fly ash with lime dust and bentonite (7:2:1 ratio) decreased HC by a factor of 1000, compared to fly ash alone. Migration of heavy metals (Pb, Zn, and Fe) was estimated to be less than 0.10 m (under MSW landfill conditions) over 15 years of service. | Satisfied landfill-barrier material criteria | Nhan et al. [17] |

| Class C fly ash (20% by weight) with Class F fly ash reduced HC value by a factor of 100. Durability studies revealed HC value increased by a factor between 2 and 3 for wetting and drying cycles. | Satisfied the requirements of liner for waste-containment facilities. | Palmer et al. [6] |

| The average HC values of Class F fly ash with 30% bentonite reduced by a factor of 10,000. Significant increase in Φ (33° to 42°) and C (36 to 54 kN/m2) from a Triaxial shear test (CU) was observed. | Satisfied the requirements of liner and cover materials for waste-disposal sites. | Mollamahmutoğlu and Yilmaz [18] |

| UCS increased by a factor of 2.2 for alkali-activated Class F fly ash. Percentage weight loss decreased by a factor of 5, compared to PCC subjected to acid immersion (at specified curing periods). | Satisfied the requirement of PCC used for construction purpose. | Rostami and Brendley [19] |

| The HC value of Class F and bottom ashes decreased by a factor of 10 with an increase in Class F fly ash content. | Satisfied the requirements of highway-embankment material. | Kim et al. [8] |

| The Cc of sedimented class F fly ash deposits was relatively higher (by 3%) when compared to compacted conditions. | Satisfied the requirements of sub-base material and lightweight infrastructure. | Sekhar et al. [10] |

| With an increase in compaction energy, HC values of Class F fly ash decreased by a factor of 1000. At each compaction energy, a higher CBR value was observed for a water content equal to or slightly less than OMC. | Satisfied the requirements of barrier material for landfill applications. | Zabielska-Adamska [20] |

| The HC values of Class F fly ashes reduced by a factor of 1000 and the Cc value was reduced by a factor between 6 and 10 due to the addition of lime (at 10%) and gypsum (at 2.5%). | Satisfied the liner material requirements. | Moghal and Sivapullaiah [21]; Moghal and Sivapullaiah [22] |

| UCS values and the CBR of Class F fly ashes increased by a factor of 20 and 7.5, respectively, due to the addition of lime (at 2.5%) and gypsum (at 2.5%). | Satisfied the requirements of sub-base material in road construction. | Sivapullaiah and Moghal [23] |

| Factor | Levels | Selected Alternative Treatment Strategies for Different Factors and Their Corresponding Levels | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Fly Ash Type | A | B | A | AL1 | AL2 | AL3 | AL4 | ||

| Lime Dosage (%) | L1 | L2 | L3 | L4 | AL1G1 | AL1G1 | AL2G1 | AL2G2 | AL3G1 |

| Gypsum Dosage (%) | G1 | G2 | AL3G2 | AL4G1 | AL4G2 | ― | ― | ||

| Objective | Liner Application | Pavement Application | B | BL1 | BL2 | BL3 | BL4 | ||

| Response measures (Units) | BL1G1 | BL1G1 | BL2G1 | BL2G2 | BL3G1 | ||||

| UCS (kPa) | Maximize | Maximize | BL3G2 | BL4G1 | BL4G2 | ― | ― | ||

| CBR (%) | Maximize | Maximize | |||||||

| HC (cm/sec) | Minimize | Maximize | |||||||

| Cc (kPa) | Minimize | Minimize | |||||||

| LL (ppm) | Minimize | Minimize | |||||||

| Constituent | % Based on Fly Ash Type | Constituent | % Based on Fly Ash Type | ||

|---|---|---|---|---|---|

| A | B | A | B | ||

| Sodium (Na2O) | 0.18 | 0.19 | Calcium (CaO) | 9.00 | 3.62 |

| Potassium (K2O) | 0.21 | 0.27 | Ferric (Fe2O3) | 16.61 | 6.28 |

| Titanium (TiO2) | 0.26 | 0.31 | Alumina (Al2O3) | 18.81 | 27.65 |

| Magnesium (MgO) | 1.41 | 0.34 | Silica (SiO2) | 50.97 | 56.88 |

| Loss on ignition | 2.55 | 4.46 | |||

| Strategy No. | Treatment Strategy | “j” Response Measures | ||||

|---|---|---|---|---|---|---|

| UCS (kPa) | CBR (%) | HC (cm/s) × 10−4 | Cc (kPa) | LL (ppm) | ||

| 1 | A | 173.1 | 55.5 | 6.52 | 0.0099 | 630 |

| 2 | AL1 | 790.3 | 58.5 | 1.57 | 0.0082 | 790 |

| 3 | AL2 | 532 | 63 | 1.22 | 0.0082 | 860 |

| 4 | AL3 | 689.3 | 79.3 | 0.69 | 0.0087 | 910 |

| 5 | AL4 | 1287 | 80.7 | 0.54 | 0.007 | 1010 |

| 6 | AL1G1 | 1796.3 | 88.1 | 0.97 | 0.0055 | 360 |

| 7 | AL1G2 | 2408 | 120.2 | 0.61 | 0.0043 | 70 |

| 8 | AL2G1 | 4500 | 218 | 0.096 | 0.004 | 440 |

| 9 | AL2G2 | 5181 | 360.6 | 0.08 | 0.0038 | 130 |

| 10 | AL3G1 | 3192 | 276.4 | 0.02 | 0.0034 | 510 |

| 11 | AL3G2 | 6842 | 409.2 | 0.016 | 0.0023 | 210 |

| 12 | AL4G1 | 4137.5 | 128.5 | 0.0011 | 0.0049 | 650 |

| 13 | AL4G2 | 6435 | 180 | 0.0007 | 0.0023 | 370 |

| 14 | B | 391.6 | 43.7 | 4.96 | 0.0156 | 270 |

| 15 | BL1 | 765.2 | 47.4 | 3.81 | 0.0128 | 390 |

| 16 | BL2 | 905 | 57.9 | 1.01 | 0.0129 | 480 |

| 17 | BL3 | 794 | 87.1 | 2.01 | 0.0136 | 610 |

| 18 | BL4 | 1193 | 72.5 | 0.91 | 0.0109 | 770 |

| 19 | BL1G1 | 1112 | 80.7 | 0.97 | 0.0086 | 260 |

| 20 | BL1G2 | 1204.7 | 117 | 0.89 | 0.0066 | 80 |

| 21 | BL2G1 | 2204.3 | 211.2 | 0.24 | 0.0063 | 270 |

| 22 | BL2G2 | 3496.3 | 320.7 | 0.1 | 0.0059 | 110 |

| 23 | BL3G1 | 1950 | 145.5 | 0.067 | 0.0052 | 330 |

| 24 | BL3G2 | 3790.4 | 238.9 | 0.028 | 0.0036 | 160 |

| 25 | BL4G1 | 2642 | 188.3 | 0.0021 | 0.0076 | 440 |

| 26 | BL4G2 | 4987.3 | 319.2 | 0.0001 | 0.0036 | 180 |

| Rank | Treatment Strategy Due to Factor Combination | Outranking Flow | Rank | Treatment Strategy Due to Factor Combination | Outranking Flow | ||||

|---|---|---|---|---|---|---|---|---|---|

| F | F+ | F− | F | F+ | F− | ||||

| 1 | AL3G2 | 0.5045 | 0.5525 | 0.0480 | 14 | AL4G1 | 0.0242 | 0.3123 | 0.2880 |

| 2 | AL2G2 | 0.5044 | 0.5524 | 0.0480 | 15 | AL1G1 | −0.0118 | 0.2922 | 0.3041 |

| 3 | BL4G2 | 0.4264 | 0.5124 | 0.0860 | 16 | BL1G1 | −0.0506 | 0.2697 | 0.3203 |

| 4 | BL2G2 | 0.4221 | 0.5102 | 0.0881 | 17 | BL3 | −0.2287 | 0.1840 | 0.4127 |

| 5 | BL3G2 | 0.3604 | 0.4804 | 0.1200 | 18 | AL4 | −0.2904 | 0.1498 | 0.4401 |

| 6 | AL4G2 | 0.2485 | 0.4245 | 0.1760 | 19 | BL2 | −0.2910 | 0.1520 | 0.4430 |

| 7 | AL1G2 | 0.2483 | 0.4243 | 0.1760 | 20 | BL4 | -0.2964 | 0.1521 | 0.4484 |

| 8 | AL2G1 | 0.2083 | 0.4004 | 0.1920 | 21 | B | −0.3209 | 0.1360 | 0.4569 |

| 9 | BL2G1 | 0.1761 | 0.3842 | 0.2081 | 22 | BL1 | −0.3286 | 0.1360 | 0.4646 |

| 10 | AL3G1 | 0.1364 | 0.3684 | 0.2320 | 23 | AL1 | −0.4137 | 0.0905 | 0.5042 |

| 11 | BL1G2 | 0.1361 | 0.3682 | 0.2321 | 24 | AL3 | −0.4194 | 0.0881 | 0.5075 |

| 12 | BL4G1 | 0.0960 | 0.3441 | 0.2482 | 25 | AL2 | −0.4561 | 0.0721 | 0.5282 |

| 13 | BL3G1 | 0.0882 | 0.3443 | 0.2561 | 26 | A | −0.4723 | 0.0641 | 0.5364 |

| Criterion Weight | UCS (%) | CBR (%) | HC (%) | Cc (%) | LL (%) | |

|---|---|---|---|---|---|---|

| For liner applications | Objective | Max | Max | Min | Min | Min |

| Set 1 * | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Set 2 | 0.3 | 0.0 | 0.4 | 0.1 | 0.2 | |

| For pavement application | Objective | Max | Max | Max | Min | Min |

| Set 1 * | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Set 2 | 0.2 | 0.4 | 0.2 | 0.05 | 0.15 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moghal, A.A.B.; Rehman, A.U.; Vydehi, K.V.; Umer, U. Sustainable Perspective of Low-Lime Stabilized Fly Ashes for Geotechnical Applications: PROMETHEE-Based Optimization Approach. Sustainability 2020, 12, 6649. https://doi.org/10.3390/su12166649

Moghal AAB, Rehman AU, Vydehi KV, Umer U. Sustainable Perspective of Low-Lime Stabilized Fly Ashes for Geotechnical Applications: PROMETHEE-Based Optimization Approach. Sustainability. 2020; 12(16):6649. https://doi.org/10.3390/su12166649

Chicago/Turabian StyleMoghal, Arif Ali Baig, Ateekh Ur Rehman, K Venkata Vydehi, and Usama Umer. 2020. "Sustainable Perspective of Low-Lime Stabilized Fly Ashes for Geotechnical Applications: PROMETHEE-Based Optimization Approach" Sustainability 12, no. 16: 6649. https://doi.org/10.3390/su12166649

APA StyleMoghal, A. A. B., Rehman, A. U., Vydehi, K. V., & Umer, U. (2020). Sustainable Perspective of Low-Lime Stabilized Fly Ashes for Geotechnical Applications: PROMETHEE-Based Optimization Approach. Sustainability, 12(16), 6649. https://doi.org/10.3390/su12166649