1. Introduction

The development of the modern manufacturing industry, in terms of today’s characteristic productivity, quality, and profitability, has been driven by the availability and massive use of cheap energy sources. Bearing in mind the planetary boundaries, while also considering the impacts of a growing population and advancing industrialization, which have led to the steady increase in well-known environmental problems, currently, governments around the world have adopted restrictive regulations to reduce CO

2 emissions, making energy increasingly more expensive and thus a significant production factor [

1]. With regard to current environmental concerns and the corresponding development of energy and climate policies, as well as from an economic viewpoint, a sustainable orientation of the production lines and an on-going enhancement of all manufacturing sectors must be considered indispensable, given the current and future international competitiveness [

2]. As one of the most energy-intensive manufacturing industries, foundry processes are particularly affected. However, not only the casting procedure itself offers significant potential for increasing energy efficiency. In the production of aluminium casting components, next to melting and the casting operation, which account for around 55% of the energy demand, heat treatment requires about 15–20% of the total energy consumed in a foundry. Hence, heat treatment is a cost-intensive process within a foundry. Measured energy values of the project partner, LGL GmbH, Germany, bear out this statement in good accordance with [

3]. Simultaneously, heat treatment is indispensable for achieving the required mechanical properties in many aluminium-based light metal components.

In general, energy saving in heat treatment processes can be achieved through various approaches, namely, the development of new plant technologies, as described, e.g., in [

4], through the reuse of waste heat [

5] and/or through the search for efficient operating modes. Whereas the former is often difficult to implement owing to the high investment required for new equipment, harnessing the potential for greater process efficiency through optimized process parameters has proven to be a challenge. In the past, numerous important studies on this subject have been published, some of them for special components [

6,

7], but they all lack a concrete result for a universal practical application with regard to the course of the mechanical properties. In this context, the present paper addresses the development of a more sustainable and universally applicable configuration of the heat treatment operation mode for the aluminium casting alloy, A356 (AlSi7Mg0.3). The chosen alloy system has extensive application, e.g., within the production of automotive chassis components, and is used for safety-related structural body parts. In addition, the alloy has been very well researched and is ideally suited for verifying the innovative procedure for a systematic parameter finding.

2. Problem Description

The most common heat treatment process for the alloy chosen is the precipitation hardening (technical term: T6), which mainly aims for the maximum tensile strength of the alloy and its casts. During treatment, the castings are subjected to a series of thermal processing steps, which finally result in an increase of tensile strength and modification of mechanical properties in general. Typically, precipitation hardening comprises three stages: solution annealing, quenching, and (artificial) ageing. With regard to the alloy A356, the first process step, the solution annealing, is required to dissolve Mg-rich phases formed during solidification to homogenize the alloying elements such as Mg and Si and to change the morphology of eutectic Si in the treated alloys as well. As described also by [

7,

8,

9], the intention is to create a supersaturated, metastable mixed crystal. To obtain a maximum solution of the constituents, the solution annealing should be performed as close as possible to the solidus temperature. The second step, quenching, is carried out to maintain a supersaturated solid solution of solute atoms and vacancies even at room temperature as well as to achieve a further increase in strength during the subsequent ageing. Despite the fact that the best mechanical properties can be achieved through high quenching rates, it must be considered that rapid quenching can also lead to unacceptable distortions or even cracks in the treated components [

10]. Artificial ageing, the third and last step, consists of a new heating of castings in a temperature range between 150 °C and 200 °C. Since the alloy strives to its energetic equilibrium, the dissolved elements start to precipitate due to the supplied heat energy. Over different precipitation states, material strengthening can be achieved, which ideally results in the maximum tensile strength (T6). Regarding the considered alloy, the precipitation of the supersaturated solution begins with the clustering of Si atoms. This clustering in turn leads to the formation of coherent spherical GP zones, consisting of an enrichment of Mg and Si atoms, which leads to the development of stable β-Mg

2Si phases formed as incoherent platelets in the α-Al matrix [

8]. In summary, the proper heat treatment of aluminium alloys is a very sensitive process that requires, along with precise plant technology, expert knowledge of the alloy being treated, and its phase transformation processes.

Although the success of the treatment depends substantially on the exact adherence of the selected processing parameters, the current standards, such as DIN EN 1706 [

11], do not provide any predefined obligatory data on the process parameters of the heat treatment of aluminium alloys. Consequently, in contrast to the previously valid standard [

12], there are no standard specifications that determine the parameters to be selected. Rather, individual institutions have developed various operation modes (different combinations of temperatures and times). These modes are used in foundries depending on the casting process, alloy type, and casting requirements.

Table 1 shows a selection of the corresponding recommendations and guidelines for T6 heat treatment of alloy A356.3.

Although the physical, material–technological processes applied during treatment are well known, it must be stated that the existing recommendations are still based solely on empirical values and vary greatly. In addition, other authors already made comprehensive investigation for an optimization of the heat treatment process, e.g., [

6,

7], but these investigations were all verified on a single component. An application-oriented transfer of the results to other components is not possible. Against the background of steadily rising energy prices, high demand for component properties, and increasing alloy diversity, this fact becomes more and more problematic, particularly for small and medium-sized foundries. Therefore, the aim of the present research was the development and investigation of a simulation-assisted procedure for a systematic identification of suitable heat treatment parameters by analysing the development of the mechanical properties under various heat treatment parameters. The overall objective of this new approach was to open up the potential of universal and thus more efficient heat treatment practices for industrial application. The basic approach to reach this goal was to develop an alloy- and application-specific parameter catalogue using existing knowledge of the phase transformation kinetics for calculating the necessary temperature ranges.

3. Numerical Pre-Investigation

For simulation-assisted preliminary examination and in front of any experiments, the software Thermo-Calc was used to gather information regarding the phase formation during solidification, as well as the phase transformation during reheating for the selected alloy. The adopted approach was to use the simulation to receive specific information on the temperatures that must be set during the heat treatment. In particular, a calculation of the solution kinetics and phase transformations that are important for solution annealing should be helpful in finding potentially ideal temperature levels for setting an optimally supersaturated α-mixed crystal. In contrast to the usual trial and error method, this approach allows a scientifically sound and efficient parameter setting. The calculated chemical composition of the alloy corresponds to that used for the experiments and can be taken from

Table 2.

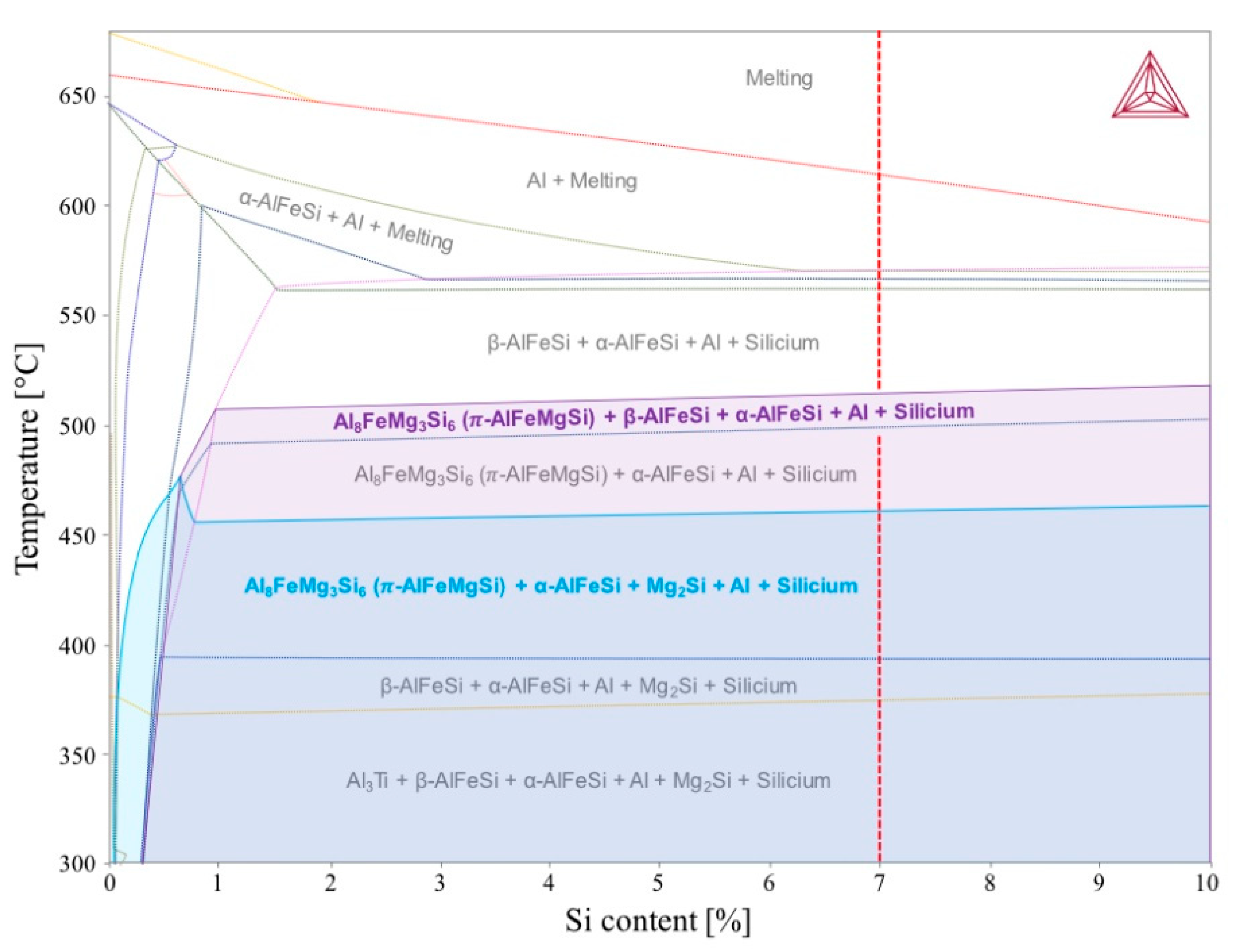

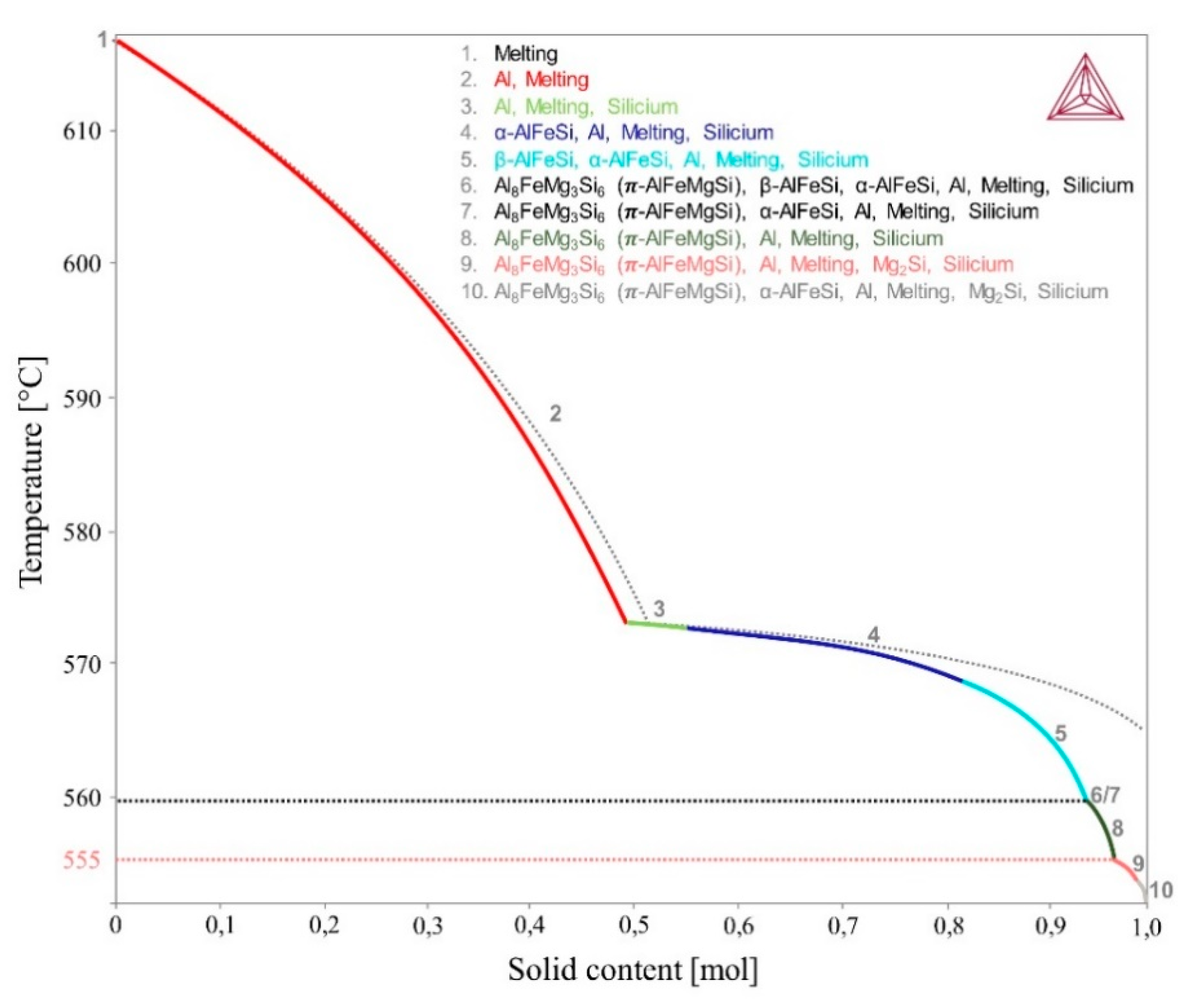

For a precise determination of the temperature range for the formation of the strength-relevant phases Mg

2Si and π-AlFeMgSi, simulations based on the equilibrium model as well as the Scheil–Gulliver model (with an assumed imbalance) were carried out. The results of both solidification simulation can be seen in

Figure 1 and

Figure 2. In adopting these simulation results to the aimed phase transformation during the heat treatment, it can be stated that the temperature should not be higher than 555 °C (based on the Scheil–Gulliver model). Otherwise, the danger of an incipient melting of the strength-related Mg

2Si phases and other alloy elements will exist.

On the other hand, the temperature should not be lower than 540 °C (based on the equilibrium model), to enable the necessary alloy elements to solute in the matrix. Thus, the optimal temperature for a solution annealing of an A356 alloy could be limited to a relevant range of 540–555 °C.

4. Experimental Procedure

4.1. Specimen Production

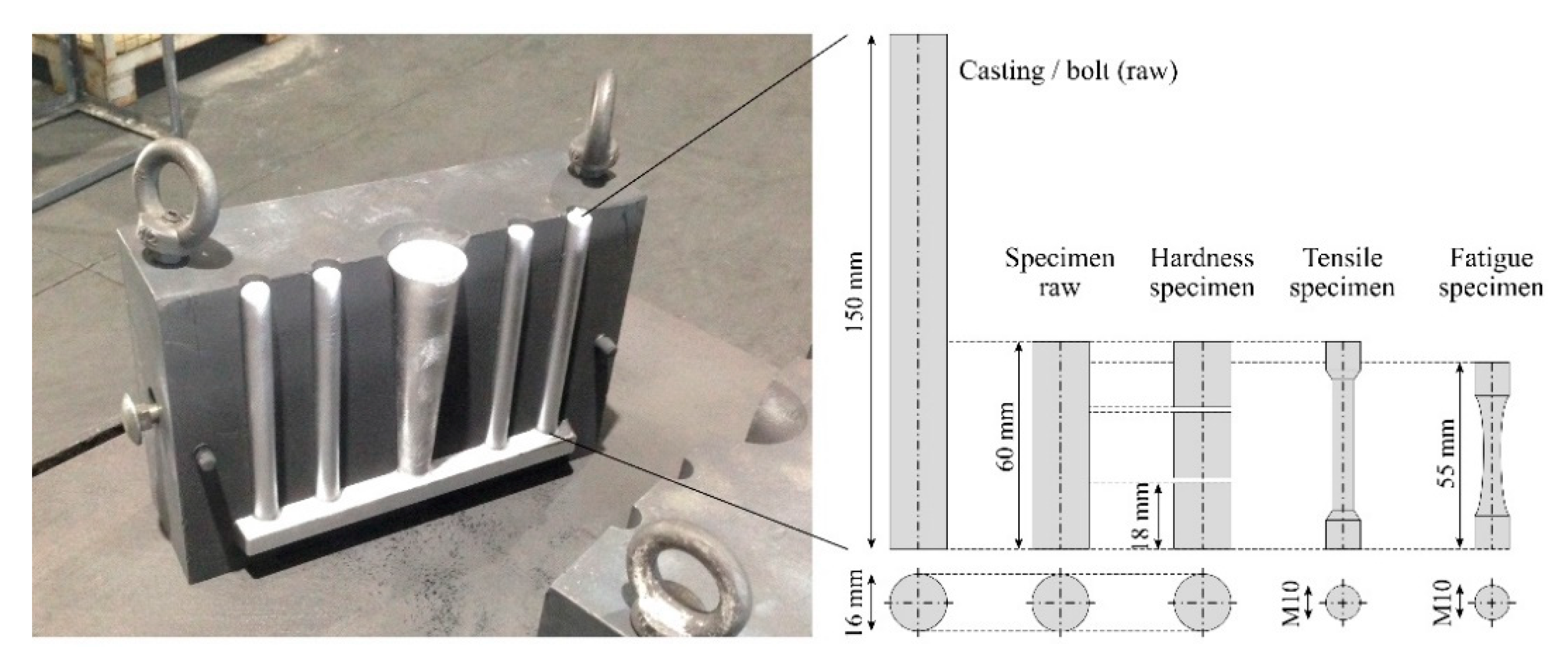

The experimental investigations started with the casting of cylindrical samples using a so-called bolt mould, which can be seen in

Figure 3. The mould allowed for the preparation of specimens with consistent quality. To achieve reproducible results, for all castings, the mould temperature was set to 330 °C, whereas the casting temperature was maintained at 735 °C. For the casting process, a basic coat (Dycote ESS34) and a work coat (Wagras KS20) were applied to the mould. The latter was renewed after every work piece removal.

Detailed results from the spectral analysis are demonstrated in

Table 1 as they were used for the Thermo-Calc calculations, as well. As can be seen, the alloy used was a strontium-refined system with a mass fraction of 200 to 250 ppm strontium. Furthermore, the alloy was subjected to grain refining using a Tiboral 6 tablet. To remove dissolved hydrogen from the melt and reduce the gas porosity, chemical melt cleaning was also carried out using Nitral 10 nitrogen tablets. Additionally, the melt was stirred using an impeller for a period of 6 min to keep the density index of the melt at constantly below 4%. The cast microstructures produced were characterized as having an average secondary dendrite arm spacing (SDAS) of 20 μm. This specimen was then used for the further heat treatment investigations.

4.2. Experimental Heat Treatment Procedure

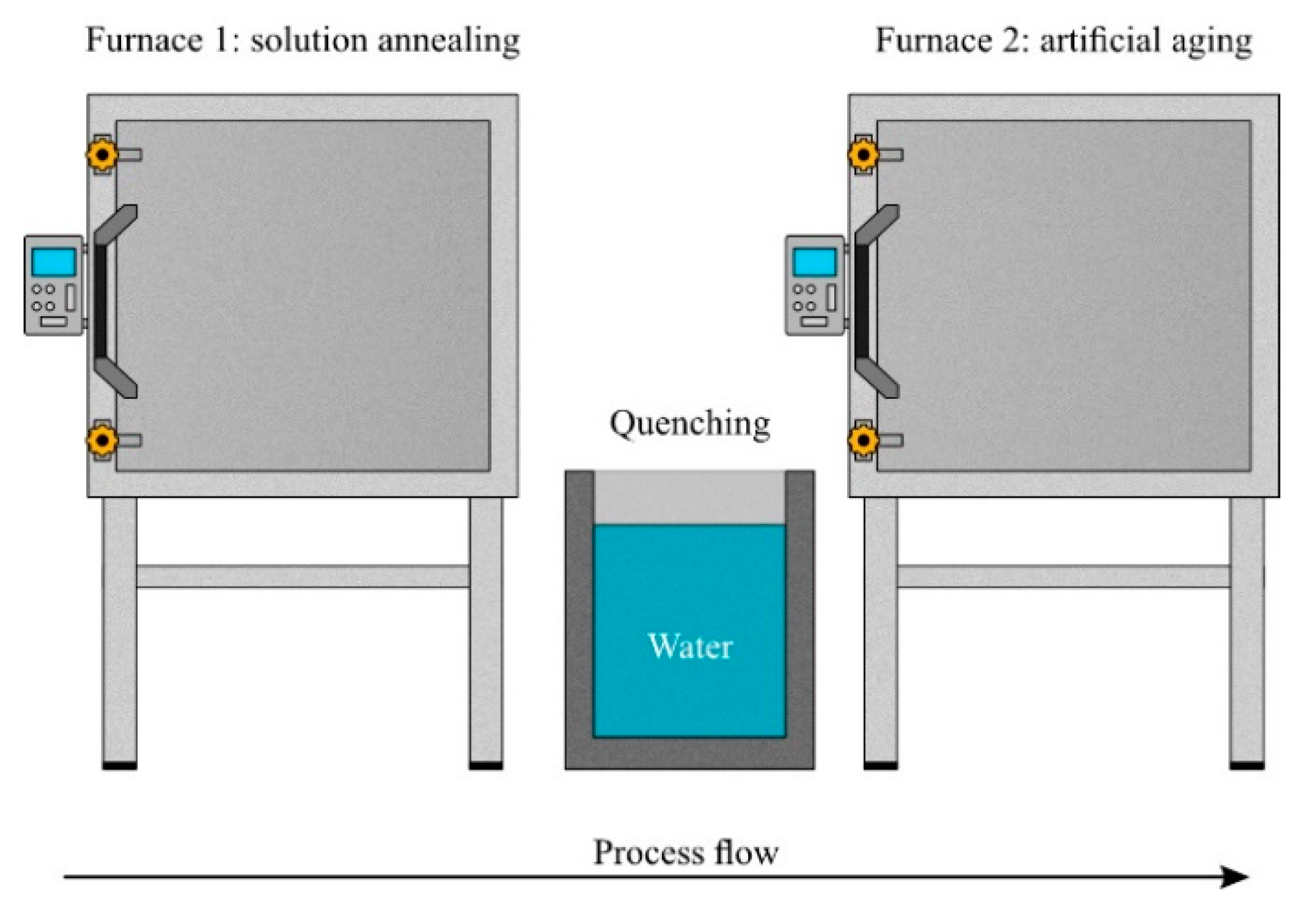

The experimental heat treatment procedures were carried out using two electrically heated convection chamber furnaces, N 500/65 HA and N 250/65 HA, from Nabertherm and a quenching basin with water at 20 °C. Initially, the times required for warming the specimens were determined by measuring the centre temperature with a K-type thermocouple. All treatment times shown below are based on completely and homogeneously warmed components. The experimental setup can be seen in

Figure 4.

4.2.1. Solution Annealing Investigations

Based on the numerical results described above, the solution annealing was carried out for temperatures at 540, 550 and 555 °C. All three test series were conducted over a period of 8 h. Every 0.5 h specimens were taken from the furnaces and then quenched in the water bath. To avoid cold ageing effects, the quenched specimens subsequently were subjected to an immediate artificial ageing at 165 °C for 6 h within the next ten minutes after quenching. Each measuring point was tested using two hardness specimens, since hardness tests can indicate whether the solution annealing was completed as described by [

19].

4.2.2. Artificial Ageing Investigations

After an evaluation of the first series of experiments, a second series of tests concerning the artificial ageing were conducted using the determined optimum solution annealing parameters from the test series before and immediate quenching. The selected temperature levels for the ageing process were 160 °C, 170 °C, 180 °C, and 190 °C over a period of 8 h. Whereas the lowest ageing temperature of 160 °C was representative for the recommended values found in the literature (see

Table 1), higher temperature levels of up to 190 °C were chosen to investigate the influence of a faster and thus possibly more efficient ageing process. With reference to previous research activities ([

8,

20]), temperature ranges of above 190 °C have been avoided owing to a decrease in strength and reduced process safety. For these investigations, the measuring points were analysed using two hardness samples, five tensile samples and five fatigue samples. Because a faster attainment of the maximum plateaus (hardness, tensile strength, and yield strength) is to be expected with an increase in ageing temperature, in particular during the first four hours of the test series specimens were re-moved from the furnaces every 0.5 h. Later the samples were only taken out of the furnace every hour. After the completion of the experiments, the treated raw specimens were used for manufacturing of the final sample geometries for the various investigations in according to

Figure 3.

All experiments were accompanied by energetic consumption measurements, where the energy usage of the two furnaces were recorded during several long-term measurements to document the potential savings using a three-phase power meter, type Easycount 3.

5. Results

5.1. Solution Annealing

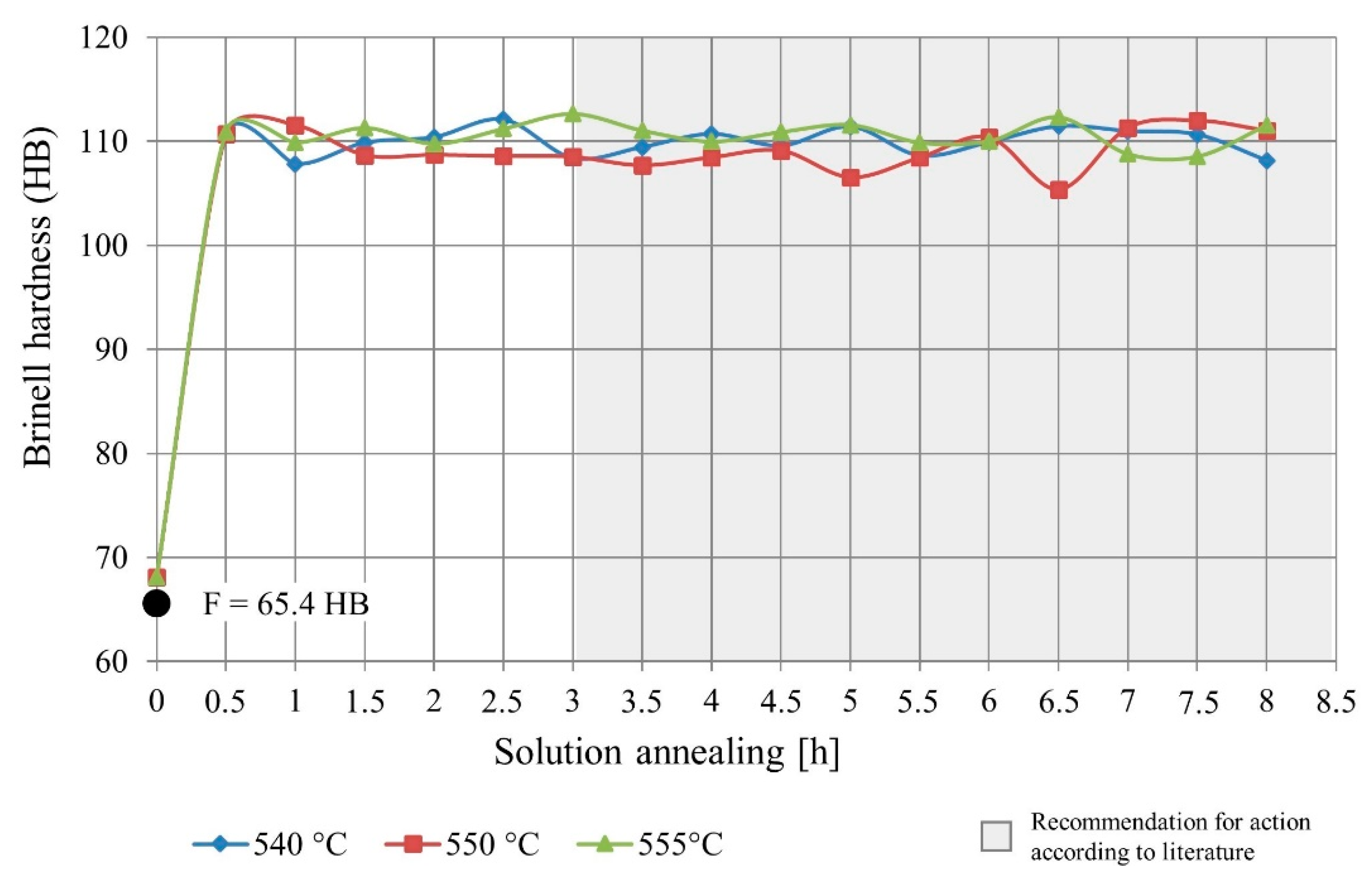

Based on the temperatures for the transformation of the strength-relevant phases resulting from the Thermo-Calc calculations, the process step solution annealing was first considered. As shown in

Figure 5, the samples under as-cast condition “F” had a Brinell hardness of 65.4 HBW. The hardness increased during all temperature scenarios after only a 0.5 h solution annealing treatment to 110.9 HBW. As can also be seen, in the further course of all temperature scenarios, no significant increase in the hardness values was observed later on. The maximum 112.6 HBW reached (after 3 h at 555 °C) is only slightly (1.8%) above the values already reached after 0.5 h. An increase in the solution annealing temperature to 550 °C or 555 °C also showed no significant effects. These results therefore confirm the findings of Lu et al. [

6] and Menargues et al. [

7].

5.2. Artificial Ageing

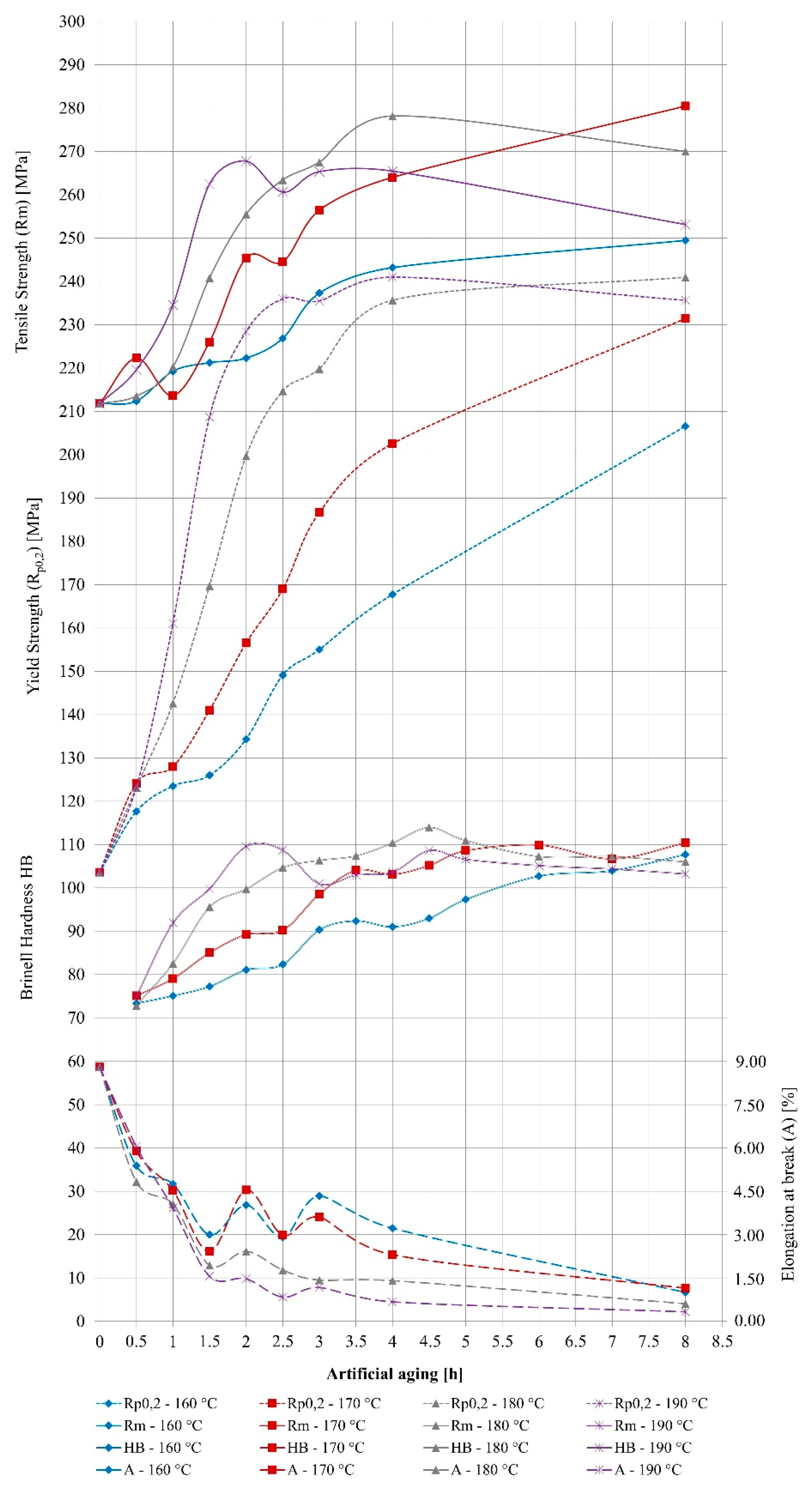

In the second series of experiments, the influence of artificial ageing parameters on the achievable mechanical properties was investigated. Based on the optimum solution annealing parameters determined in the first experimental series (0.5 h at 540 °C), targeted time–temperature combinations of the artificial ageing were examined for their strength-increasing effect. The specified measured values represent the mean value of the measuring point-specific samples. For the sake of clarity, an error bar specification was omitted in

Figure 6.

Based on the results obtained, it can be seen that an increase in the selected ageing temperatures leads to a shift in both the temperature-specific hardness and maximum strength toward shorter treatment times. The ageing curve for 180 °C, for example, achieves a tensile strength of 278.2 MPa after only 4 h of artificial ageing, as compared to the equivalent result of 280.5 MPa for the ageing curve at 170 °C achieved after 8 h. At the same time, it can be stated that, with an increase in temperature, the treated components undergo a significantly faster loss of ductility, which results in a corresponding reduction in the elongation at break.

5.3. Real Case Application and Energy Consumption

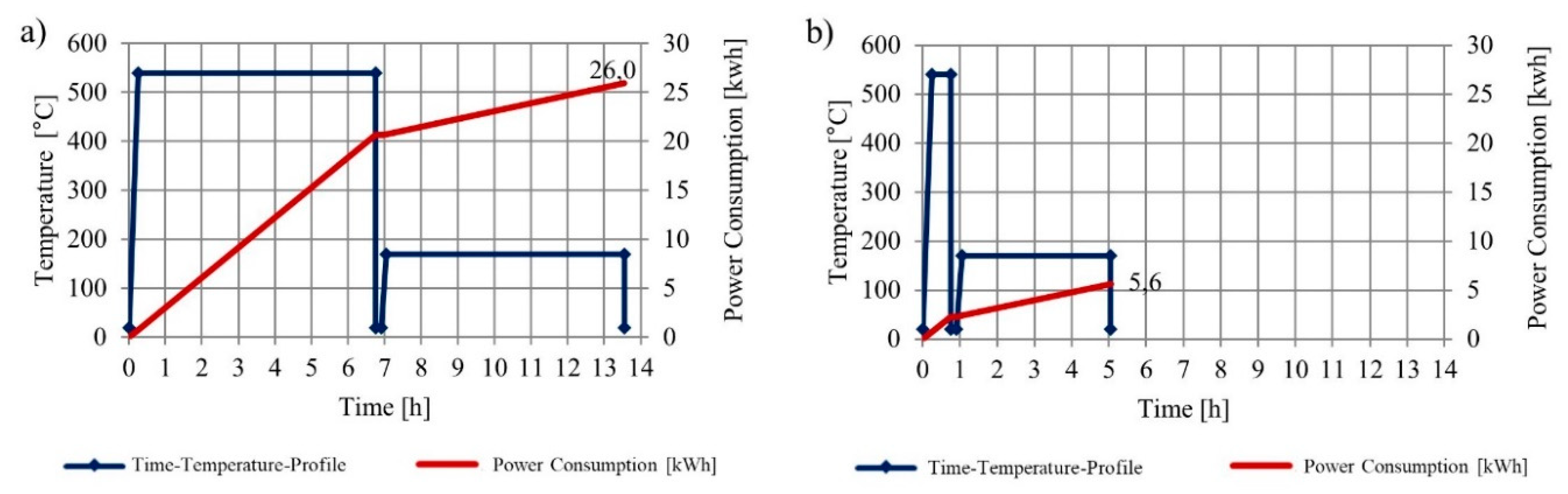

In this context, the applicability of the investigated operation modes and the achievable saving potentials were analysed based on a close-to-series case study. Using the required mechanical properties of a casting for the automotive industry produced at the project partners foundry with a minimum tensile strength of 220 MPa, yield strength of 180–210 MPa, and minimum elongation at break of 3%. To achieve these goals, the foundry chose the following parameters: solution annealing 540 °C for 6.5 h, artificial aging 160 °C for 6.5 h. The previously selected heat-treatment procedure was compared with the shortened process parameters based on the research described above. Using the parameter catalogue and thus a new operation mode (solution annealing 540 °C for 0.5 h, artificial ageing 170 °C for 4 h), the required properties could also be fully achieved (Rm = 264.2 MPa, Rp0.2 = 202.6 MPa, and A = 3.4%).

The process parameters to date used to meet these requirements as well as the new parameters applied can be taken from

Table 3. As can be seen in

Figure 7 and

Table 3, this way, the total process time could be lowered from 13 h to 4.5 h (∆ 8.5 h/−65.4%) with a corresponding reduction in energy usage from almost 26 kWh to 5.6 kWh (∆ 20.4 h/−78.4%).

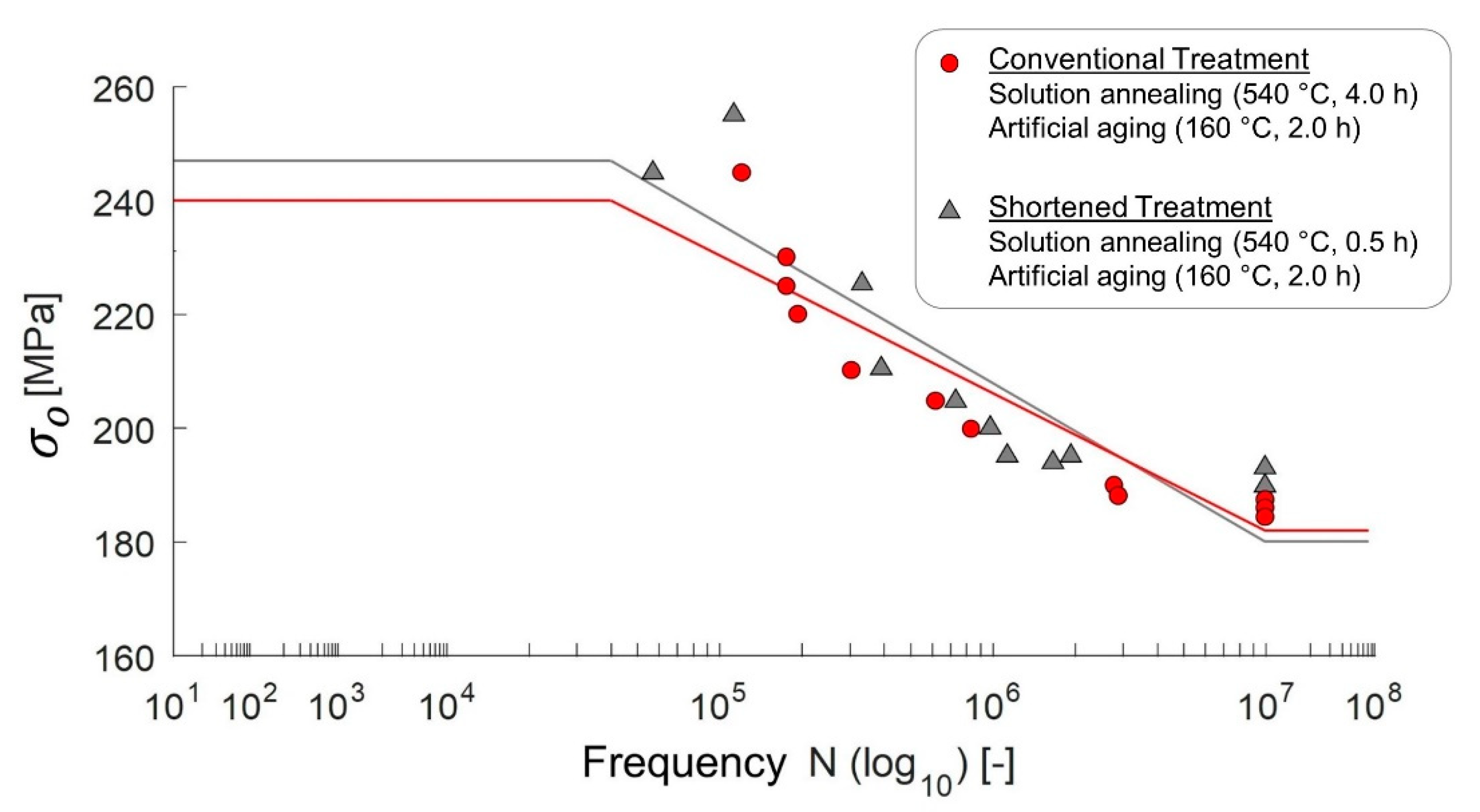

5.4. Fatigue Analyses

Finally, low-cycle fatigue analyses were conducted to investigate the effects of a shortened solution annealing on the fatigue life behaviour of the material. Referring to

Figure 8, it can be noted that the parameter modification (particularly with respect to the shortened solution annealing) shows the same developments with regard to the curve as the conventional treatment. For both the conventional and shortened treatment, the transition to the endurance limit was reached after 10

7 cycles and an applied stress of about 180 MPa.

6. Discussion

In all phases of the investigations, it could be shown that the currently known process parameters for the heat treatment of A356 can be reduced, in this way tapping the potential for high energy saving. The presented procedure for application-oriented parameter determination proved to be particularly effective. In identifying suitable solution heat treatment parameters, the calculation/simulation of the alloy-dependent phase formation made it possible to determine the required temperature window very precisely. The targeted experimental execution of simple hardness measurements made it possible to determine the required treatment duration systematically. The evaluation of the determined hardness values points out that after only 0.5 h of solution annealing, the solution of the alloying elements magnesium and silicon, which are important for curing, was completed and the eutectic silicon was sufficiently reformed. These results are in excellent agreement with former investigations on microstructural characteristics, e.g., [

6,

7]. It should also be emphasized at this point that the reduction of the solution heat treatment has no negative effects on the dynamic fatigue strength of the components, which could be proven here for the first time. Taking into account the existing recommendations for action (

Table 1), considerable potential for saving energy has already been demonstrated at this point.

With regard to the determination of optimal parameters for the artificial aging process step, the novel approach also proved to be very practical and suitable. By creating an alloy-specific parameter atlas, the user is now able to read off the precisely fitting process parameters depending on the product requirements. In this way, a further savings potential of approx. 40% was demonstrated in a practical example close to series production.

However, it must be considered in all studies and results that the casting geometry has a significant impact on the heat treatment result. Particularly for larger castings where some time is required for the casting to reach the process temperatures completely and homogeneously, the dissolution and precipitation processes take place earlier than in the center of the castings, which makes it difficult to produce consistent mechanical properties over the entire casting. However, this problem for both the conventional and the optimized process and most of the recommended parameters to date also refers to completely warmed castings. With this in mind, the optimized parameters represent a great advantage and the results obtained show the high potential of new process parameters as well as of the reinvestigation of traditional process operations.

7. Conclusions

In many cases, the heat treatment process is essential to guarantee the required component properties. At the same time, heat treatment is one of the largest energy consumers in a light metal foundry, accounting for approx. 15–20% of the total energy requirement.

However, since the parameters to be set vary greatly not only in terms of the alloy, but also, and in particular, the areas of application of the treated components, the determination of suitable parameters is still carried out by means of complex test series according to the trial and error principle. This method is not only cost-intensive, but also extremely inefficient, as each component requires its own series of tests. The presented approach to a systematic parameter determination should at this point show a practical and flexible possibility for a sustainable and energy-efficient process control. This approach has proven to be very target-oriented and flexible within the scope of the presented test series.

The initial solution annealing studies have shown that half an hour of solution annealing is sufficient to dissolve the required alloying elements in the matrix. Based on this result, investigations on artificial ageing were carried out over a process period of 8h. The resulting curves, combined to a parameter atlas, provide a holistic picture of the development of the mechanical properties. This detailed analysis enables the selection of suitable process parameters depending on the requirements placed on a casting. By testing the shortened process duration to meet the requirements of a concrete casting at the project partners foundry, the required mechanical properties could be fully met. Compared to the conventional process, the process time required for this was reduced by 65% and the associated energy input by 78%. Additional fatigue tests show that the shortened process times have no negative influence on the fatigue behaviour of the castings.

Author Contributions

Conceptualization, S.S.; Methodology, S.S., N.B. and E.R.; Software, N.B. and E.R.; Validation, S.S., N.B. and E.R.; Formal analysis, S.S., N.B. and E.R.; Investigation, N.B., E.R., H.R. and N.S.; Resources, S.S., N.B., E.R., H.R. and N.S.; Data curation, N.B., E.R. and H.R.; Writing—original draft preparation, S.S. and E.R.; Writing—review and editing, S.S. and E.R.; Visualization, S.S., N.B. and E.R.; Supervision, S.S.; Project administration, S.S.; Funding acquisition, S.S. and N.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Allianz Industrie Forschung, grant number KF 2292043LL4.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Dornfeld, D.A. Green Manufacturing; Springe: Boston, MA, USA, 2013; ISBN 978-1-4419-6015-3. [Google Scholar]

- Federal Ministry for Economic Affairs and Energy BMWi. Energiekosten für die Herstellung von Metallerzeugnissen bis 2017 (Energy Costs for the Production of Metal Products until 2017). Available online: https://de.statista.com/statistik/daten/studie/250683/umfrage/energiekosten-fuer-die-herstellung-von-metallerzeugnissen-in-deutschland/ (accessed on 10 January 2020).

- Pagone, E.; Jolly, M.; Salonitis, K. The Development of a Tool to Promote Sustainability in Casting Processes. Procedia CIRP 2016, 55, 53–58. [Google Scholar] [CrossRef]

- Scharf, S.; Dischinger, N.; Ates, B.; Schlegel, U.; Stein, N.; Stein, H. New Plant-Technologies for Reducing Carbon Emissions and Costs in Heat Treatment Processes of Aluminium Castings. Procedia CIRP 2018, 69, 283–287. [Google Scholar] [CrossRef]

- Kurle, D.; Schulze, C.; Herrmann, C.; Thiede, S. Unlocking Waste Heat Potentials in Manufacturing. Procedia CIRP 2016, 48, 289–294. [Google Scholar] [CrossRef]

- Lu, S.-P.; Du, R.; Liu, J.-P.; Chen, L.-C.; Wu, S.-S. A new fast heat treatment process for cast A356 alloy motorcycle wheel hubs. China Foundry 2018, 15, 11–16. [Google Scholar] [CrossRef]

- Menargues, S.; Martín, E.; Baile, M.T.; Picas, J.A. New short T6 heat treatments for aluminium silicon alloys obtained by semisolid forming. Mater. Sci. Eng. A 2015, 621, 236–242. [Google Scholar] [CrossRef]

- Manente, A.; Timelli, G. Optimizing the Heat Treatment Process of Cast Aluminium Alloys. In Recent Trends in Processing and Degradation of Aluminium Alloys; InTechOpen: London, UK, 2011. [Google Scholar] [CrossRef]

- Macherauch, E.; Zoch, H.-W. Praktikum in Werkstoffkunde (Materials Science Internship), 11th ed.; Vieweg+Teubner Verlag/Springer Fachmedien Wiesbaden GmbH Wiesbaden: Wiesbaden, Germany, 2011; ISBN 978-3-8348-0343-6. [Google Scholar]

- Weißbach, W. Werkstoffkunde (Materials Technology). Strukturen, Eigenschaften, Prüfung (Structures, Properties, Testing), 16th ed.; Friedr. Vieweg & Sohn Verlag | GWV Fachverlage GmbH Wiesbaden: Wiesbaden, Germany, 2007; ISBN 9783834802958. [Google Scholar]

- DIN. Aluminium and Aluminium Alloys—Castings—Chemical Composition and Mechanical Properties; Beuth Verlag GmbH: Berlin, Germany, 2013; DIN EN 1706:2013-12. [Google Scholar]

- DIN. Aluminium Alloys, Casting Alloys; Sand Casting, Gravity Die Casting, Pressure Die Casting, Investment Casting; Beuth Verlag GmbH: Berlin, Germany, 1986; DIN 1725-2. [Google Scholar]

- Finkelnburg, W.-D. Wärmebehandlung von Aluminium-Legierungen (Heat Treatment of Aluminium Alloys); GDA: Düsseldorf, Germany, 2007; ISBN 9783937171197. [Google Scholar]

- Hesse, W. Aluminium-Werkstoff-Datenblätter (Aluminium Material Data Sheets), 7th ed.; Beuth Verlag GmbH: Berlin, Germany, 2016; ISBN 9783410268758. [Google Scholar]

- Rheinfelden ALLOYS. Anticorodal-70 (AlSi7Mg0,3)—Anticorodal-72 (Al-Si7Mg0,6): Die Eisenarme Universallegierung für den Sand- und Kokillenguss (Anticorodal-70 (AlSi7Mg0.3)—Anticorodal-72 (Al-Si7Mg0.6): The Low-Iron Universal Alloy for Sand and Gravity die Casting).: Anwendungsmerkblatt Code Ac-70/501. Available online: http://rheinfelden-alloys.eu/wp-content/uploads/2016/01/Ac-70_Anwendungsmerkblatt-501_RHEINFELDEN-ALLOYS.pdf (accessed on 10 February 2020).

- Klan, S. Beitrag zur Evolution von Aluminium-Gusslegierungen für Warmfeste Anwendungen (Contribution to the Evolution of Aluminium Casting Alloys for Heat Resistant Applications). Ph.D. Thesis, TU Bergakademie Freiberg, Freiberg, Sachsen, Germany, 2004. [Google Scholar]

- Totten, G.E. Heat Treating of Nonferrous Alloys; ASM International: Materials Park, OH, USA, 2016; ISBN 978-1-62708-112-2. [Google Scholar]

- Rose, A. Verzugsreduzierung beim Wärmebehandeln von Bauteilen aus Sprühkompaktierten und Gießtechnisch Hergestellten Aluminiumlegierungen durch Gasabschrecken (Distortion Reduction during Heat Treatment of Components Made of Spray-Compacted and Cast Aluminium Alloys by Gas Quenching). Ph.D. Thesis, Universität Bremen, Bremen, Germany, 2014. [Google Scholar]

- Kohtz, D. Wärmebehandlung Metallischer Werkstoffe (Heat Treatment of Metallic Materials). Grundlagen und Verfahren (Principles and Procedures); Springer: Berlin/Heidelberg, Germany, 1994; ISBN 9783540621652. [Google Scholar]

- Dambauer, G.; Pabel, T.; Schumacher, P. Einsparpotentiale durch eine modifizierte Wärmebehandlung für untereutektische Aluminium-Silizium Legierungen (Savings potentials through a modified heat treatment for hypoeutectic aluminium-silicon alloys). Gießerei-Praxis (Giessereipraxis) 2009, 294–300. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).