Determination of the Optimal Operative Conditions for the Torrefaction of Olive Waste Biomass

Abstract

1. Introduction

2. Materials and Methods

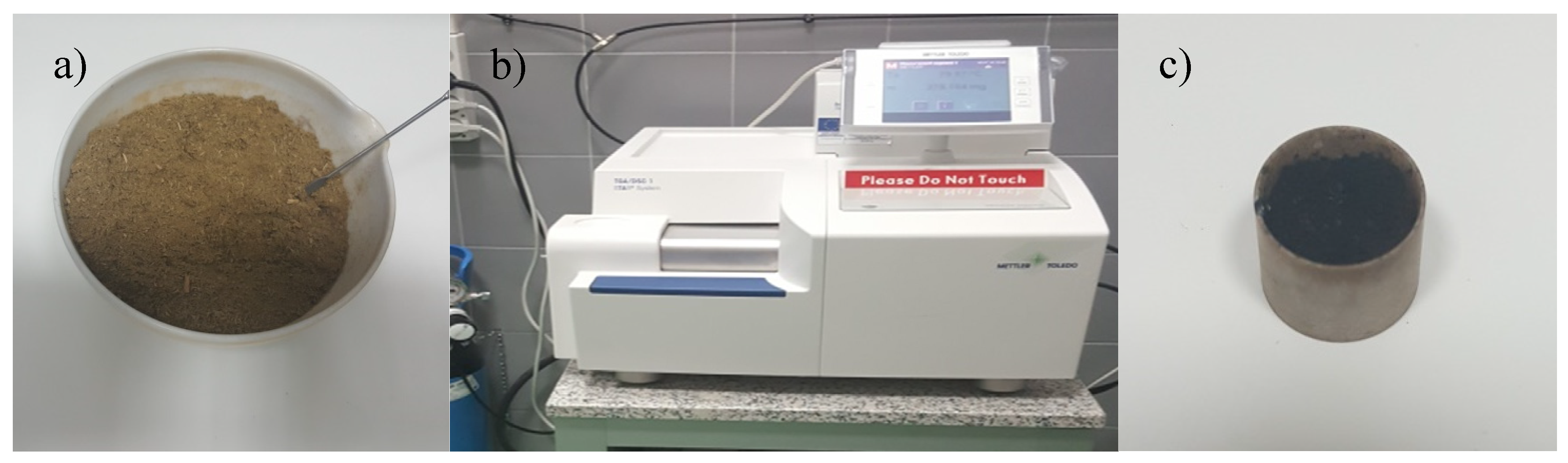

2.1. Characteristics of the Biomass

2.2. Torrefaction Process

2.3. Moisture and Ash Content

2.4. Determination of Higher Heating Value (HHV)

2.5. Statistical Analysis

2.6. Numerical Model

3. Results and Discussion

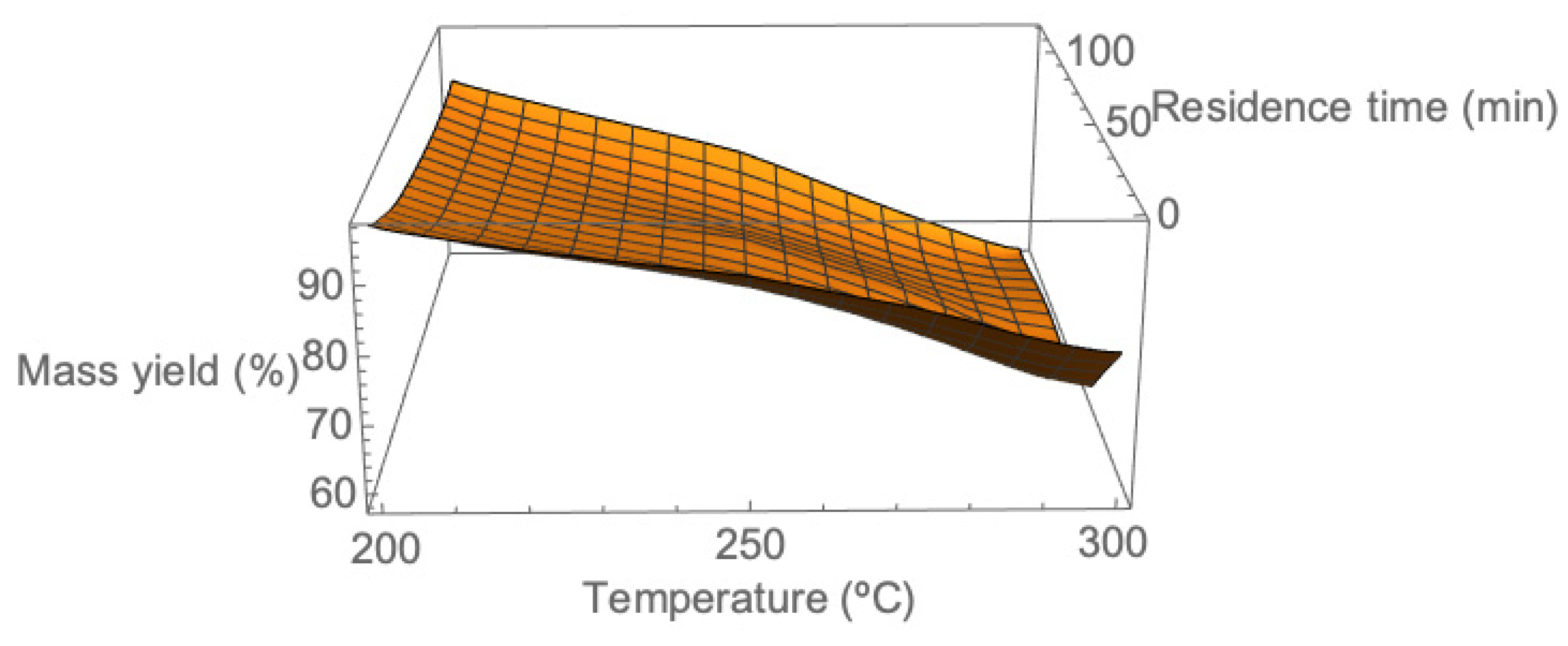

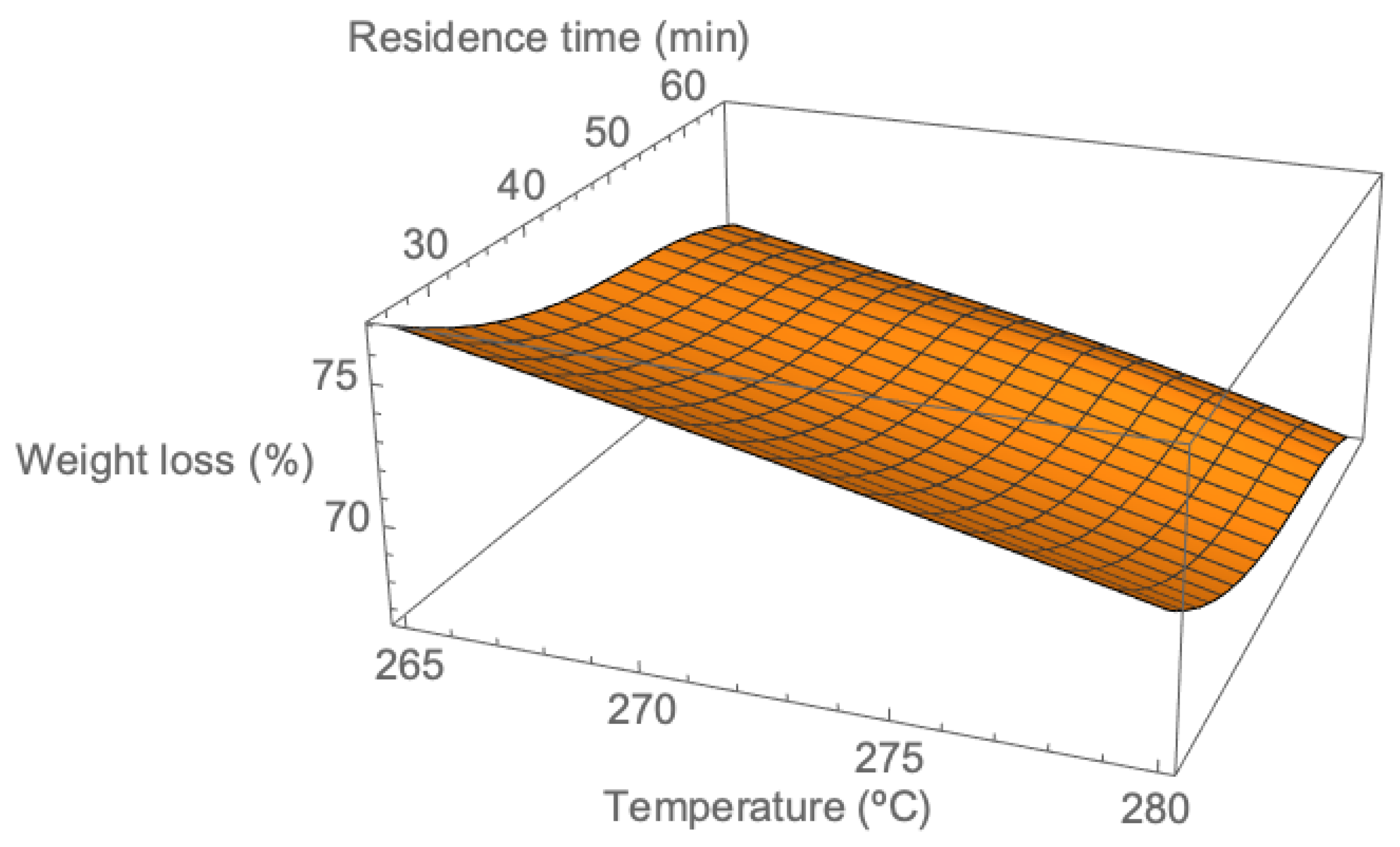

3.1. Weight Loss of Torrefied Biomass

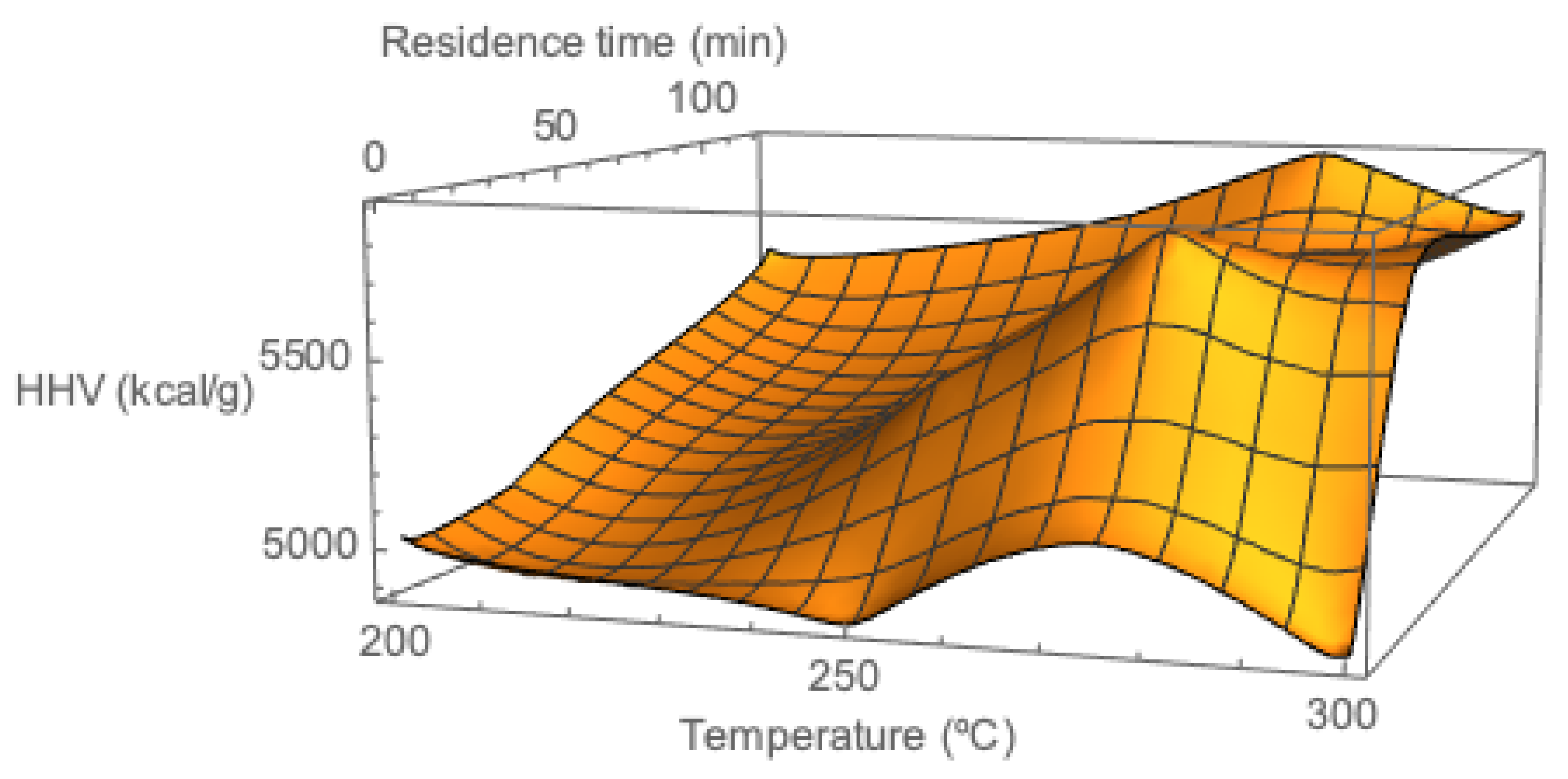

3.2. Higher Heating Value (HHV)

3.3. Numerical Model

4. Conclusions

- (1)

- The mass yield of the tested biomass varied between 97.48% and 57.61%, decreasing with the residence time and temperature. However, the ash content of the torrefied biomass increased with respect to the raw material up to a maximum of 73.32%, so the problem inherent in biomass combustion of ash could be increased.

- (2)

- The HHV of the torrefied biomass varied from 4884.14 ± 36.45 to 5893 ± 68.83 kcal/g. In the best case (275 °C and 120 min), a 19.47% increase in the HHV was achieved. The results of the mathematical model showed that the optimal conditions for torrefaction of olive tree waste are approximately 275 °C and 30 min.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Volpe, M.; Wüst, D.; Merzari, F.; Lucian, M.; Andreottola, G.; Kruse, A.; Fiori, L. One stage olive mill waste streams valorisation via hydrothermal carbonization. Waste Manag. 2018, 80, 224–234. [Google Scholar] [CrossRef] [PubMed]

- Lenis, Y.A.; Agudelo, A.; Pérez, J.F. Analysis of statistical repeatability of a fixed bed downdraft biomass gasification facility. Appl. Therm. Eng. 2013, 51, 1006–1016. [Google Scholar] [CrossRef]

- Ramos-Carmona, S.; Martínez, J.D.; Pérez, J.F. Torrefaction of patula pine under air conditions: A chemical and structural characterization. Ind. Crops Prod. 2018, 118, 302–310. [Google Scholar] [CrossRef]

- Benavente, V.; Fullana, A. Torrefaction of olive mill waste. Biomass Bioenergy 2015, 73, 186–194. [Google Scholar] [CrossRef]

- Ibrahim, R.H.H.; Darvell, L.I.; Jones, J.M.; Williams, A. Physicochemical characterization of torrefied biomass. J. Anal. Appl. Pyrolysis 2013, 103, 21–30. [Google Scholar] [CrossRef]

- Chin, K.L.; H’ng, P.S.; Go, W.Z.; Lim, T.W.; Maminski, M.; Paridah, M.T. Optimization of torrefaction conditions for high energy density solid biofuel from oil palm biomass and fast growing species available in Malaysia. Ind. Crops Prod. 2013, 49, 768–774. [Google Scholar] [CrossRef]

- Berndes, G.; Hoogwijk, M.; van den Broek, R. The contribution of biomass in the future global energy supply: A review of 17 studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

- Zheng, A.; Zhao, Z.; Chang, S.; Huang, Z.; He, F.; Li, H. Effect of torrefaction temperature on product distribution from two-staged pyrolysis of biomass. Energy Fuels 2012, 26, 2968–2974. [Google Scholar] [CrossRef]

- Da Silva, C.M.S.; Vital, B.R.; Carneiro, A.D.C.O.; Costa, E.V.; De Magalhães, M.A.; Trugilho, P.F. Structural and compositional changes in eucalyptus wood chips subjected to dry torrefaction. Ind. Crops Prod. 2017, 109, 598–602. [Google Scholar] [CrossRef]

- Matos, M.; Barreiro, M.F.; Gandini, A. Olive stone as a renewable source of biopolyols. Ind. Crops Prod. 2010, 32, 7–12. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Loureiro, L.M.E.F.; Sá, L.C.R.; Silva, H.F. Thermochemical Conversion of Olive Oil Industry Waste: Circular Economy through Energy Recovery. Recycling 2020, 5, 12. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Zamorano, M.; Ramos-Ridao, A.; Díaz, L.F. Analysis of olive grove residual biomass potential for electric and thermal energy generation in Andalusia (Spain). Renew. Sustain. Energy Rev. 2012, 16, 745–751. [Google Scholar] [CrossRef]

- Mei, Y.; Che, Q.; Yang, Q.; Draper, C.; Yang, H.; Zhang, S.; Chen, H. Torrefaction of different parts from a corn stalk and its effect on the characterization of products. Ind. Crops Prod. 2016, 92, 26–33. [Google Scholar] [CrossRef]

- Li, M.F.; Li, X.; Bian, J.; Xu, J.K.; Yang, S.; Sun, R.C. Influence of temperature on bamboo torrefaction under carbon dioxide atmosphere. Ind. Crops Prod. 2015, 76, 149–157. [Google Scholar] [CrossRef]

- Martín-Lara, M.; Ronda, A.; Zamora, M.C.; Calero, M. Torrefaction of olive tree pruning: Effect of operating conditions on solid product properties. Fuel 2017, 202, 109–117. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinki, K.J.; Jansen, F.J.J.G. Torrefaction of wood Part 2. Analysis of products. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Yan, W.; Acharjee, T.C.; Coronella, C.J.; Vasquez, V.R. Vásquez, Thermal pretreatment of lignocellulosic biomass. Environ. Prog. Sustain. Energy 2009, 28, 435–440. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.; Rubiera, F.; Pis, J.J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Chen, W.-H.; Kuo, P.-C. Torrefaction and co-torrefaction characterization of hemicellulose, cellulose and lignin as well as torrefaction of some basic constituents in biomass. Energy 2011, 36, 803–811. [Google Scholar] [CrossRef]

- Park, S.-W.; Jang, C.-H.; Baek, K.-R.; Yang, J.-K. Torrefaction and low-temperature carbonization of woody biomass: Evaluation of fuel characteristics of the products. Energy 2012, 45, 676–685. [Google Scholar] [CrossRef]

- Van Der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lu, K.-M.; Liu, S.-H.; Tsai, C.-M.; Lee, W.-J.; Lin, T.-C. Biomass torrefaction characteristics in inert and oxidative atmospheres at various superficial velocities. Bioresour. Technol. 2013, 146, 152–160. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Skreiberg, Ø. Upgrading biomass fuels via wet torrefaction: A review and comparison with dry torrefaction. Renew. Sustain. Energy Rev. 2016, 54, 665–677. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Tran, K.-Q.; Skreiberg, Ø.; Trinh, T.T. Effects of wet torrefaction on pyrolysis of woody biomass fuels. Energy 2015, 88, 443–456. [Google Scholar] [CrossRef]

- Wannapeera, J.; Worasuwannarak, N. Upgrading of woody biomass by torrefaction under pressure. J. Anal. Appl. Pyrolysis 2012, 96, 173–180. [Google Scholar] [CrossRef]

- Simonec, M.; Goricanec, D.; Urbancl, D. Impact of torrefaction on biomass properties depending on temperature and operation time. Sci. Total Environ. 2020, 740, 140086. [Google Scholar] [CrossRef]

- Harun, N.H.H.M.; Samad, N.A.F.A.; Saleh, S. Development of kinetics model for torrefaction of empty fruit bunch from palm oil waste. Energy Procedia 2017, 105, 744–749. [Google Scholar] [CrossRef]

- Nakason, K.; Pathomrotsakun, J.; Kraithong, W.; Khemthong, P.; Panyapinyopol, B. Torrefaction of Agricultural Wastes: Influence of Lignocellulosic Types and Treatment Temperature on Fuel Properties of Biochar. Int. Energy. J. 2019, 19, 253–266. [Google Scholar]

- Burden, A.; Burden, R.; Faires, J. Numerical Analysis, 10th ed.; Cengage: New York, NY, USA, 2016. [Google Scholar]

- Buhmann, M.D. Radial Basis functions; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar] [CrossRef]

- Fasshauer, G.E. Meshfree Approximation Methods with Matlab; World Scientific Publishing: Singapore, 2007. [Google Scholar] [CrossRef]

- Phanaphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Nimlos, M.R.; Brooking, E.; Michael, J. Biomass torrefaction studies with a molecular beam mass spectrometer. Am. Chem. Soc. Div. Fuel Chem. 2003, 48, 590–591. [Google Scholar]

- García-Maraver, A.; Terron, L.C.; Ramos-Ridao, A.; Zamorano, M. Effects of mineral contamination on the ash content of olive tree residual biomass. Biosyst. Eng. 2014, 118, 167–173. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Williams, A.; Waldron, D.J. An investigation of the grindability of two torrefied energy crops. Fuel 2010, 89, 3911–3918. [Google Scholar] [CrossRef]

- Pinchuai, A.; Dutta, A.; Basu, P. Torrefaction of Agriculture Residue to Enhance Combustible Properties. Energy Fuels 2010, 24, 4638–4645. [Google Scholar] [CrossRef]

- García-Maraver, A.; Mata-Sánchez, J.; Carpio, M.; Pérez-Jiménez, J.A. Critical review of predictive coefficients for biomass ash deposition tendency. J. Energy Inst. 2017, 90, 214–228. [Google Scholar] [CrossRef]

- Zamorano, M.; Popov, V.; Rodríguez, M.L.; García-Maraver, A. A comparative study of quality properties of pelletized agricultural and forestry lopping residues. Renew. Energy 2011, 36, 3133–3140. [Google Scholar] [CrossRef]

- Chiou, B.-S.; Valenzuela-Medina, D.; Bilbao-Sainz, C.; Klamczynski, A.P.; Avena-Bustillos, R.J.; Milczarek, R.R.; Du, W.-X.; Glenn, G.M.; Orts, W.J. Torrefaction of almond shells: Effects of torrefaction conditions on properties of solid and condensate products. Ind. Crops Prod. 2016, 86, 40–48. [Google Scholar] [CrossRef]

| Temperature (°C) | Residence Time (min) | |||||

|---|---|---|---|---|---|---|

| 0 | 30 | 120 | ||||

| 200 | 97.48 ± 0.69 | A | 92.20 ± 0.65 | B | 89.48 ± 0.22 | C |

| 250 | 90.53 ± 0.54 | B,C | 79.87 ± 0.44 | E | 75.71 ± 0.82 | F |

| 275 | 84.57 ± 1.14 | D | 72.01 ± 0.55 | G | 66.49 ± 1.35 | G |

| 300 | 78.89 ± 0.84 | E | 62.38 ± 1.86 | H | 57.61 ± 0.80 | H |

| Temperature (°C) | Residence Time (min) | |||||

|---|---|---|---|---|---|---|

| 0 | 30 | 120 | ||||

| 200 | 5028.19 ± 102.76 | B | 5053.42 ± 33.27 | B | 5527.34 ± 68.97 | C,D |

| 250 | 5129.31 ± 59.75 | B | 5409.52 ± 26.03 | C | 5679.21 ± 69.72 | D,E |

| 275 | 4884.14 ± 36.45 | A | 5830.70 ± 44.31 | E,F | 5893.45 ± 68.83 | F |

| 300 | 4895.61 ± 57.65 | A,B | 5679.08 ± 66.34 | D,E | 5725.33 ± 21.23 | D,E,F |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Pascual, J.; Jódar, J.; Rodríguez, M.L.; Zamorano, M. Determination of the Optimal Operative Conditions for the Torrefaction of Olive Waste Biomass. Sustainability 2020, 12, 6411. https://doi.org/10.3390/su12166411

Martín-Pascual J, Jódar J, Rodríguez ML, Zamorano M. Determination of the Optimal Operative Conditions for the Torrefaction of Olive Waste Biomass. Sustainability. 2020; 12(16):6411. https://doi.org/10.3390/su12166411

Chicago/Turabian StyleMartín-Pascual, Jaime, Joaquín Jódar, Miguel L. Rodríguez, and Montserrat Zamorano. 2020. "Determination of the Optimal Operative Conditions for the Torrefaction of Olive Waste Biomass" Sustainability 12, no. 16: 6411. https://doi.org/10.3390/su12166411

APA StyleMartín-Pascual, J., Jódar, J., Rodríguez, M. L., & Zamorano, M. (2020). Determination of the Optimal Operative Conditions for the Torrefaction of Olive Waste Biomass. Sustainability, 12(16), 6411. https://doi.org/10.3390/su12166411