An Intelligent Framework for the Evaluation of Compliance with the Requirements of ISO 9001:2015

Abstract

1. Introduction

2. Concepts and Related Works

2.1. Overview of ISO 9001:2015

- ISO 9000. Quality Management Systems—Basic Principles and Vocabulary.

- ISO 9001. Quality Management Systems—Requirements.

- ISO 9004. Quality Management Systems—Guidelines for Improving Performance.

- Internal: benefits such as improved product quality, better process performance, short delivery times, cost reductions, improved system documentation, higher quality awareness.

- External: benefits such as improved customer satisfaction, better market image, and stronger competitive position.

- Leadership: ISO 9001:2015 reinforces the commitment to quality through strong leadership and eliminates the figure of the management representative. It extends leadership to all levels of the organization.

- Risk-Based Thinking is also one of the main changes in the new version of ISO 9001. The standard does not include the concept of preventive action and is replaced by a way of thinking, adding some systematic assessment of potential and actual issues with the aim of making processes more robust and capable.

- Interested parts: The identification of the needs and expectations of interested parts (stakeholders) is one of the new requirements of ISO 9001 2015, in point 4.2. Stakeholders are, among others, internal and external customers, shareholders, owners, employees, suppliers, and partners, as well as society.

- Change control: Point 6.3 clearly details the need for change planning and control, something not very clear in the current version of ISO, and that in an environment like the current one (where change is a constant), it is essential.

- Strategic Directions: This requirement has been added to the management review to try to meld business and quality systems.

- Knowledge Management: It requires organizations to consider knowledge to ensure the quality of the goods and services produced. These requirements, referring to organizational knowledge, are included in order to avoid loss of knowledge or mistakes in knowledge capture and distribution. They can stimulate the acquisition of knowledge by the organization, for example, through, experiential learning, mentoring, or benchmarking.

2.2. Expert Systems

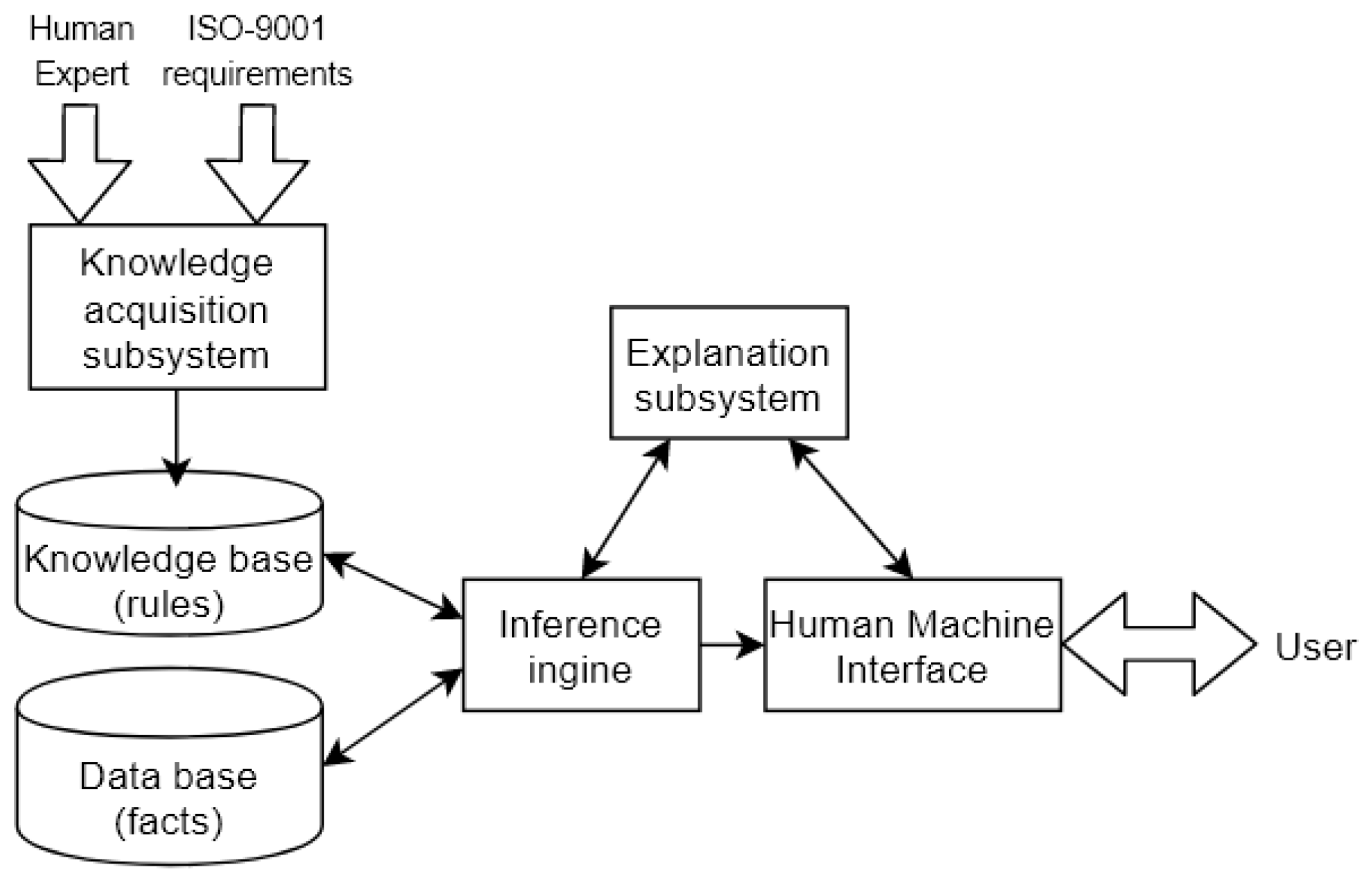

- Knowledge Base: It contains the knowledge necessary to understand, formulate, and solve problems.

- Inference Engine: A rules interpreter that determines which rules are applicable at any given moment and that oversees their execution.

- Fact Base: work memory with the facts about a problem.

- Knowledge Acquisition: It allows the acquisition of knowledge and stores it in its knowledge base in an automated way.

- User Interface: It allows interaction between the ES and the user, presenting and facilitating the management of information.

- Explanation Subsystem: explains the lines of action followed by the ES.

2.3. Expert Systems Applied to Quality Systems

2.4. Ontologies

- Provides a way to represent and share knowledge using a common vocabulary.

- Allows the use of a knowledge-sharing format.

- Provides a specific communication protocol.

- Step 1—Specification. The goal is a document describing the ontology.

- Step 2—Conceptualization. It is aimed at organizing and structuring the acquired knowledge using an external representation language that is independent of implementation languages and environments.

- Step 3—Implementation. It is focused on implementing the conceptual model into a formal language like Ontolingua, Resource Description Framework Schema (RDF/S), or Web Ontology Language (OWL).

- Step 4—Evaluation. It is basically a technical judgment of the ontology, its software environment, and the documentation regarding a frame of reference.

3. Methodology

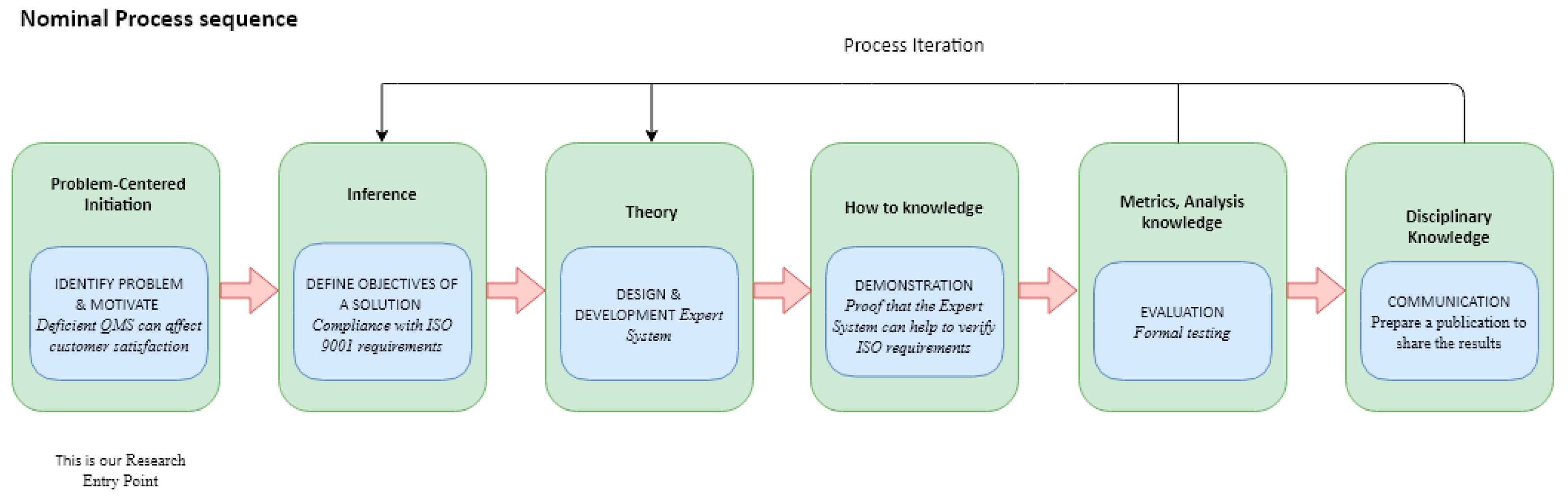

- Identify Problem and Motivate: The researcher must identify the problem and the motivation to understand the context of the problem and thus define the objectives to be achieved. Following the proposed methodology, the first step is identifying the problem and motivation reflected in the introduction. Since a deficient QMS can affect customer satisfaction, the knowledge of the degree of compliance with the requirements demanded by ISO 9001 can improve this aspect—this is our objective and motivation.

- Define Objectives of a Solution: The researcher must consult several sources, both from industry and from academia, to suggest a design to achieve and test the proposed objectives. In Section 2, we consulted a set of sources to contextualize the problem, choosing the design of an ES. This will be the artefact used to help the organization to verify the degree of compliance with the requirements proposed by ISO 9001, providing information on the set of processes and on each of the processes individually.

- Design and Development: The researcher must develop an artefact for the suggested identified solution that best adapts to the business domain. The details of this step are presented in Section 4, where ISO 9001:2015 is discussed in detail (Section 4.1). The basis for developing the ES is presented (Section 4.2), explaining how knowledge of the standard is extracted by generating a formalized data structure. The architecture of the ES is explained, detailing how the user interfaces. It also specifies the programming language, as well as the different libraries and tools (Section 4.3).

- Demonstration: The researcher must demonstrate the use of the artefact to solve one or more instances of the problem. Section 4.3 explains how the system is verified.

- Evaluation: The researcher must conduct an evaluation, which may be based on a formal evaluation, test activities, simulations, usability studies, and/or a case study. Details of this step can be found in Section 5.

- Communication: Finally, the researcher must provide a conclusion related to the evaluation of the results of the process by communicating the results. This information is detailed in Section 6.

4. Design and Development of the Artefact

4.1. System Analysis

- Planning Processes. These are those that are directly related to the responsibilities of senior management and that establish the objectives and quality policy to be carried out by the organization.

- Resource management processes. These provide, manage, and maintain the necessary resources for the production of the product or service within the organization.

- Product realization processes. They oversee the production or provision of the service of the organization.

- Measurement and analysis processes. They are responsible for monitoring and evaluating the rest of the processes, measuring, and suggesting improvements.

4.2. System Development

- Phase 1

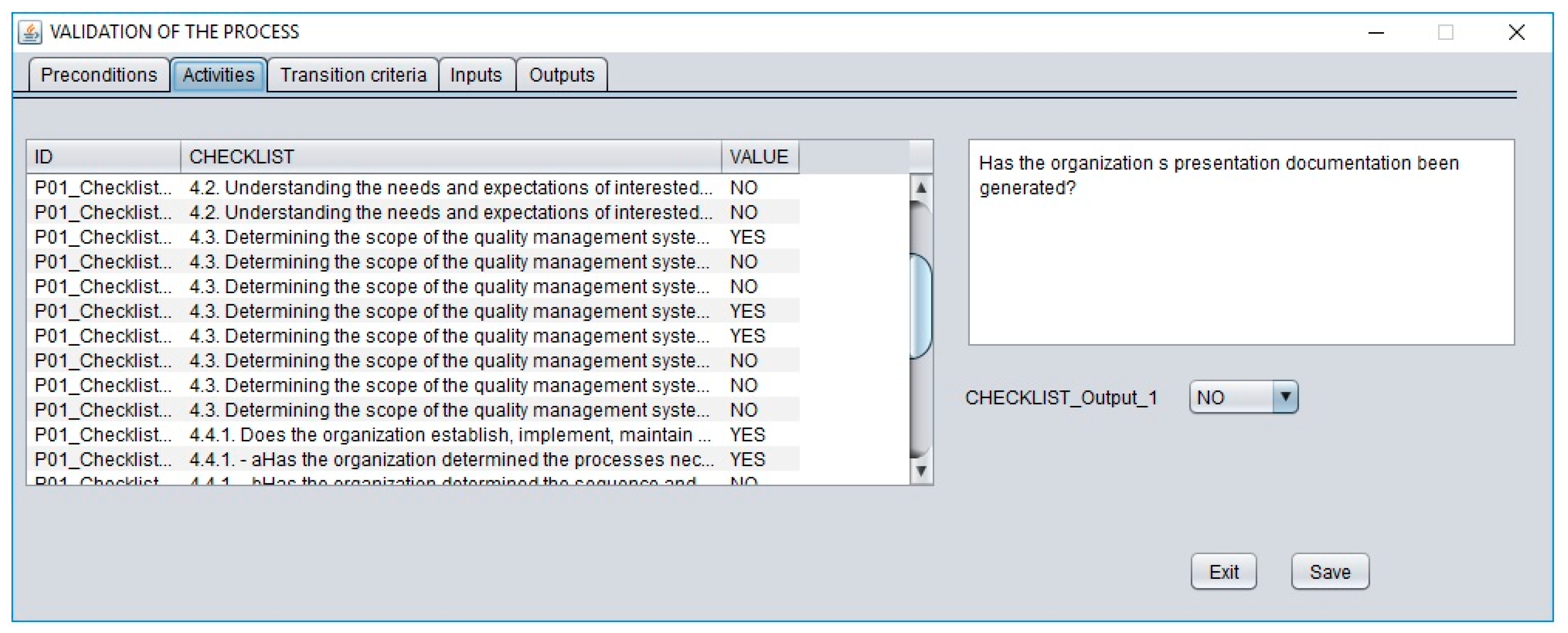

- —Knowledge Base. Constructed through 7 steps. It explains (1) how the process map is obtained from the standard, (2) how traceability of the processes and subprocesses is generated, (3) how to identify the set of requirements applicable to each process that will later be evaluated by the ES, (4) how to verify that all the requirements are perfectly identified, (5) how these requirements are transformed into checklists, (6) details of how the set of rules is generated from all this information, which forms the knowledge base, and (7) how the knowledge structure is transformed into a standardized format that will be used by the ES.

- Phase 2

- —System Design. Proposing an architecture to support the ES, showing how each process defined by the standard is going to be evaluated, indicating what information needs to be entered, and what is going to result as output. It also shows the most important aspects to configure the ES to evaluate the whole defined map of processes. Finally, it summarizes all the premises to develop the system, such as the use of technologies, type of architecture, authentication requirements, and profile management.

- Phase 3

- —Design Interface. Defining the graphic aspect of the system, acting as a human–machine interface (HMI).

4.2.1. Phase 1—Knowledge Base

- Each of the processes of the QMS. All these processes are reviewed by the domain expert.

- Each of the requirements for each of the processes. All these requirements are reviewed by the domain expert.

- The input and output items required by each process. The domain expert defined, according to his experience and knowledge, a series of specific inputs and outputs for each process, a total of 69. The knowledge engineer, through different interviews with the expert, created a map showing each defined element, the process to which it corresponds, and whether it is an output or an input.

- The transition criteria for each process defined by the domain expert. This includes the entry criteria and exit criteria for each process. With this information, the human expert verifies that each of the proposed processes is achieved. At the end of the evaluation, if the end-user expects to meet all the requirements, all the transition criteria of each phase must be satisfied.

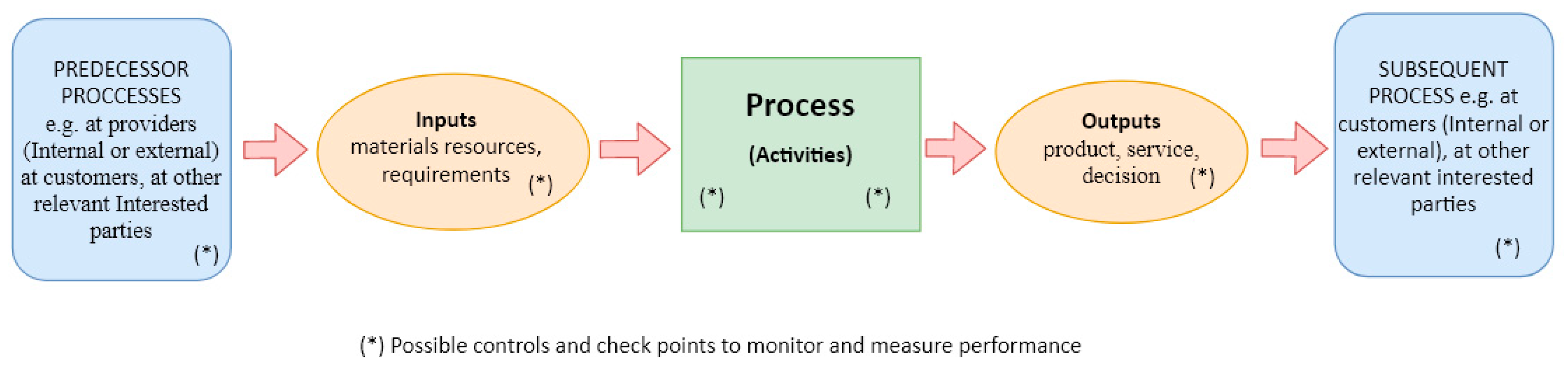

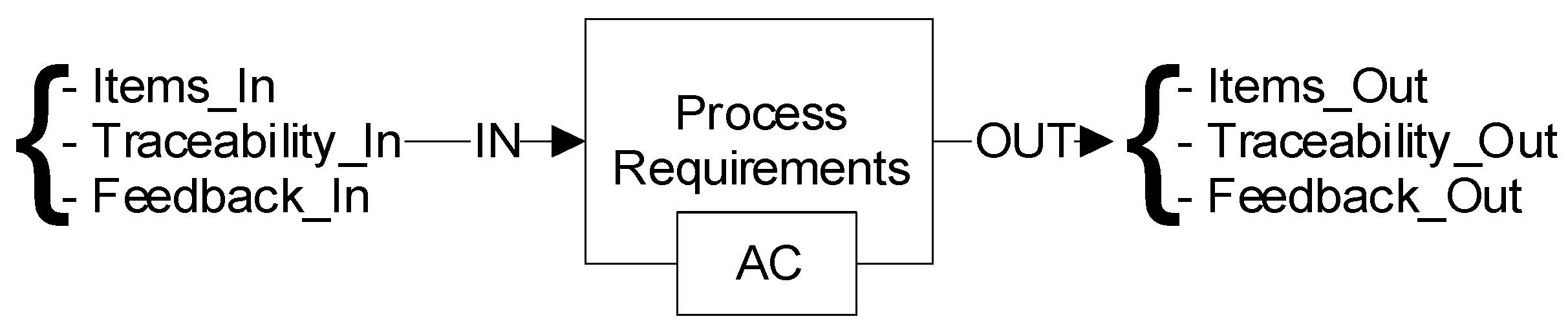

- Inputs (IN): a series of documents or feedback from other processes. The inputs will be processed by a process or activity.

- Activities: provides traceability between processes. They are the requirements that the process has to comply with.

- Outputs (OUT): the expected or intended result of a process, e.g., documents or feedback to other processes.

- Acceptance Criteria (AC): used to determine if a process can be considered completed or requires rework and new review.

- A global configuration file defining the 19 processes identified by the standard and intended to be evaluated, as well as the inputs and outputs of each of these processes.

- A configuration file for each process, specifying the rules to be applied by the inference engine, and the variables to be handled by these rules depending on the phase of the process being evaluated (e.g., preconditions, activities, transition criteria).

- Step 1.

- Obtaining the ISO 9001 process map. The identification of the process map is explained in Section 4.1 “System Analysis”.

- Step 2.

- Traceability of the corresponding subprocesses (clauses of the standard) to the previously identified processes. This traceability is reviewed by the domain expert based on the process map he has previously identified. All subprocesses have been tagged in a specific order from P01_xx to P019_xx and are mapped to each specific section of the regulation.Example:

- P01_xx; “Identification and context of the organization interested parties and the QMS” -> chapter 4.

- P08_xx; “Determination of objectives” -> Chapter 6.2, where XX will include the number of requirements mapped.

- Step 3.

- Identification of the set of requirements applicable to each subprocess. The standard requires the compliance of all the requirements mentioned in the standard when they are applicable. It is not possible to exclude any requirement unless it is not applicable to the QMS and you have an acceptable justification. For example, if you are not purchasing any services or goods from an external provider, there is no need to develop quality management tools and controls for those areas [64]. With the help of the knowledge engineer, the domain expert checks that all those requirements that are identified from the standard are completely represented, and, in those cases where it is necessary to qualify or expand, he decides based on his experience. This way, the data extracted from the standard are transformed into knowledge.

- REQ_01:The organization shall determine external and internal issues that are relevant to its purpose and its strategic direction and that affect its ability to achieve the intended result(s) of its quality management system.

- REQ_02:The organization shall monitor and review information about these external and internal issues.

- Step 4.

- Verification of requirements to ensure that all the requirements have been correctly identified, labeled, and mapped to a specific process. Following the requirements capture guidelines, these will be unambiguous, comprehensible, internally consistent, feasible, valid, and verifiable.

- Step 5.

- Step 6.

- Generation of the set of rules for the knowledge base. Both the requirements and the checklists have become a set of rules for the ES when evaluating the fulfillment of each process, and therefore, of the life cycle. The process for transforming these checklists into production rules is the following one:

- Each of the requirements of the ISO 9001:2015 is assigned to a checklist. That, together with the domain expert, has allowed us to obtain the rules of the system. For each checklist, a set of at least three rules are defined:

- ○

- Rule 1: Indicate to the user what to do based on initial conditions.

- ○

- Rule 2: If the user has not performed the action, it shows “how to” perform it.

- ○

- Rule 3: If the user has performed the action, it shows “how to evidence it”.

Requirement: 4.1.ISO-9001:2015. Checklists: Has the organization determined the external and internal issues that are relevant to its purpose and strategic direction?

- ○

- RULE 1: IF P01_Requirement_1=YES THEN The organization shall determine external and internal issues that are relevant to its purpose and its strategic direction and that affect its ability to achieve the intended result(s) of its quality management system, according to the 4.1. ISO 9001:2015 paragraph.

- ○

- RULE 2: IF P01_Requirement_1=YES AND P01_Checklist_001=NO THEN If we have not done so, redetermine internal and external issues.

- ○

- RULE 3: IF P01_Requirement_1=YES AND P01_Checklist_001=YES THEN If we have done so, document internal and external issues.

- Step 7.

- Generation of a standardized data structure that later becomes an XMLS.

4.2.2. Phase 2—System Design

- Java has been selected as the programming language, adding specific libraries for implementation.

- JruleEngine [70], as the inference engine based on Java Specification Request 94, version 1.111, is considered as a sophisticated IF/ELSE sentence interpreter, which acts on input objects (facts) to produce output objects (conclusions or inferences). It is based on a direct chaining algorithm using XMLS syntax. The set of rules has been adapted to an XMLS format that allows the use of the knowledge base by JruleEngine.

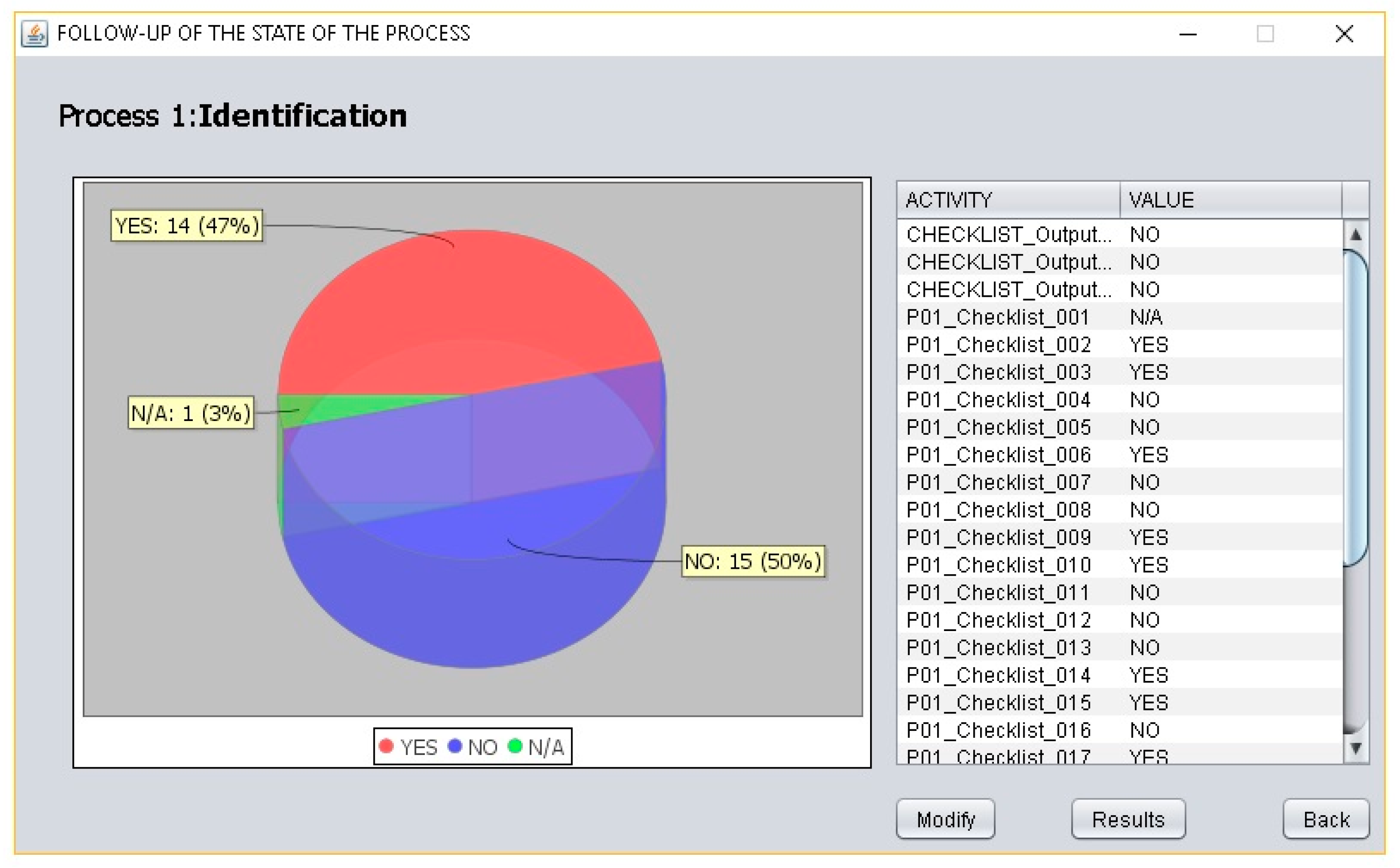

- JfreeChart [71] offers different tools to implement all types of diagrams and graphics elements that are very useful for the preparation of reports and dashboards.

- MySQL [72] is the selected database management system. Workbench has been selected for its capacity for the management of tables and the application of tables.

- Use of free software technologies. The system has been developed with nonproprietary development environments. In addition, the system components which are intrinsic to an ES, such as the knowledge base and the inference engine, have also been developed with free software technologies.

- The system architecture will be restricted to a local/business network environment, not allowing any external connection to the application for security reasons.

- The system has an authentication module and a hierarchy of roles so that each type of user in the application has a series of specific permissions to perform specific actions and to evaluate a series of processes according to their area of knowledge.

- The application has two distinct user profiles: the administrator and the standard user. The administrator profile can do maintenance and system management operations, such as updating the knowledge base and registering new users and projects. The standard user profile can do the evaluation of the processes of a project and the monitoring of its evolution through different graphical tools of analysis.

4.2.3. Phase 3—Design Interface

4.3. Testing

5. Validation and Evaluation of the System

- Accuracy = (TP+TN)/(TN+TP+FN+FP)

- Positive Predictive Value = TP/(TP+FP)

- Negative Predictive Value = TN/(FN+TN)

- Sensitivity = TP/(TP+FN)

- Specificity = TN/(TP+VN)

- Accuracy (%) = 87.96%

- Sensitivity (%) = 84.50%

- Specificity (%) = 96.36%

- Positive predictive value (%) = 98.26%

- Negative predictive value (%) = 71.95%

- Accuracy (%) = 100%

- Sensitivity (%) = 100%

- Specificity (%) = 100%

- Positive predictive value (%) = 100%

- Negative predictive value (%) = 100%

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bassi, E. Globalización de Negocios: Construyendo Estrategias Competitivas; Limusa: Mexico City, Mexico, 2003. [Google Scholar]

- Porter, M.E. Estrategia Competitiva: Técnicas para el Análisis de Industrias y Competidores; CECSA: Mexico City, Mexico, 1998. [Google Scholar]

- Zaidi, A. QFD: Despliegue de la Función de Calidad; Díaz de Santos: Madrid, Spain, 1993. [Google Scholar]

- Prieto, J. El Servicio en Acción: La Única Forma de Ganar a Todas; ECOE Ediciones: Bogota, Colombia, 2005. [Google Scholar]

- Hill, N.; Alexander, J. Manual de Satisfacción del Cliente y Evaluación de la Fidelidad; AENOR: Madrid, Spain, 2001. [Google Scholar]

- Martínez, S.; Ortiz, I.; Juan, J.; Lázaro, F. Using Certification as a Tool to Develop Sustainability in Project Management. Sustainability 2018, 10, 1408. [Google Scholar] [CrossRef]

- ISO-9001:2015. Sistemas de Gestión de Calidad. Requisitos; AENOR: Madrid, Spain, 2015. [Google Scholar]

- Strenitzerová, M.; Gaňa, J. Customer satisfaction and loyalty as a part of customer-based corporate sustainability in the sector of mobile communications services. Sustainability 2018, 10, 1657. [Google Scholar] [CrossRef]

- Consejería de Economía, Empresas y Empleo-JCCM, Orden 123/2017, de 28 de Junio, por la Que se Establecen las Bases Reguladoras de las Ayudas-Adelante Inversión-, para el Fomento de la Inversión y la Mejora de la Productividad Empresarial en Castilla-La Mancha, Cofinanciables en un 80% por el Fondo Europeo de Desarrollo Regional. 2018. Available online: http://www.jccm.es (accessed on 29 November 2018).

- JCCM. Junta de Comunidades de Castilla la Mancha. El Plan Adelante 2016–2019 es la Estrategia de Fortalecimiento Empresarial de Castilla-La Mancha. 2018. Available online: http://adelante-empresas.castillalamancha.es/comercializacion (accessed on 29 November 2018).

- ISO. Encuesta ISO 2017. 2018. Available online: http://www.iso.org/iso/home/standards/certification/iso-survey.htm (accessed on 29 November 2018).

- ONTSI. Informe ePyme, Análisis Sectorial de Implantación de las TIC en la Pyme Españolas. 2018. Available online: https://www.ontsi.red.es/es/estudios-e-informes/Empresas/e-Pyme-17%2C-Analisis-Sectorial-de-Implantacion-de-las-TIC-en-la (accessed on 26 November 2018).

- AMETIC. Las Tecnologías de la Información en España 2017. 2018. Available online: https://ametic.es/es/publicaciones/las-tecnologias-de-la-informacion-en-espana-2017 (accessed on 27 November 2018).

- Ministerio de Industria, Turismo y Comercio. La Convocatoria 3/2007 del Programa Avanza PYME. 2008. Available online: https://www.mincotur.gob.es (accessed on 27 November 2018).

- Ministerio de Energía, Turismo y Agenda Digital. Agenda Digital para España 2015–2020. 2013. Available online: https://avancedigital.gob.es/planes-TIC/agenda-digital/Paginas/agenda-digital-para-Espana.aspx (accessed on 27 November 2018).

- Zhang, H.; Song, M.; He, H. Achieving the Success of Sustainability Development Projects through Big Data Analytics and Artificial Intelligence Capability. Sustainability 2020, 12, 949. [Google Scholar] [CrossRef]

- Ștefănescu, L.; Ștefănescu, A.; Ungureanu, L.; Constantinescu, M.; Barbu, C. Expert system and its applications for a sustainable environment management. J. Environ. Prot. Ecol. JEPE 2011, 12, 1582–1592. [Google Scholar]

- AI: Built to Scale from Experimental to Exponential. Available online: https://www.accenture.com/_acnmedia/Thought-Leadership-Assets/PDF-2/Accenture-Built-to-Scale-PDF-Report.pdf#zoom=50 (accessed on 13 February 2020).

- Gartner Says AI Technologies will be in almost Every New Software Product by 2020. Available online: https://www.gartner.com/en/newsroom/press-releases/2017-07-18-gartner-says-ai-technologies-will-be-in-almost-every-new-software-product-by-2020 (accessed on 13 February 2020).

- Artificial Intelligence Decoded. Available online: https://www.capgemini.com/es-es/wp-content/uploads/sites/16/2018/07/dtr-11_final1-2.pdf (accessed on 14 February 2020).

- Tarí, J.J. Calidad Total: Fuente de Ventaja Competitiva; Universidad de Alicante, Servicio de Publicaciones: Alicante, Spain, 2000; Available online: http://rua.ua.es/dspace/handle/10045/13445 (accessed on 6 July 2020).

- Baeza, M.; Mertens, L. La Norma ISO 9000 y la Competencia Laboral; CONOCER: Mexico City, Mexico, 2000. [Google Scholar]

- Fonseca, L.M. From Quality Gurus and TQM to ISO 9001:2015: A review of several quality paths. Int. J. Qual. Res. 2015, 9, 167–180. [Google Scholar]

- Fonseca, L.M.; Domingues, J.P.; Baylina, P.; Calderón, M. Management system certification benefits: Where do we stand? J. Ind. Eng. Manag. 2017, 10, 476–494. [Google Scholar]

- Zimon, D.; Zimon, G. The Impact of Implementation of Standardized Quality Management Systems on Management of Liabilities in Group Purchasing Organizations. Qual. Innov. Prosper. 2019, 23, 60–73. [Google Scholar] [CrossRef]

- Domingues, J.P.T.; Reis, A.M.; Fonseca, L.M.; Ávila, P.; Putnik, G. The added value of the ISO 9001:2015 International standard from an auditors’ perspective: A CB-SEM based evaluation. Int. J. Qual. Res. 2019, 13, 967–986. [Google Scholar] [CrossRef]

- ISO-9001:2008. Sistemas de Gestión de Calidad. Requisitos; AENOR: Madrid, Spain, 2008. [Google Scholar]

- Sirvent, S.; Gisbert, V.; Perez, E. Seven Principles of quality management in ISO 9001. 3C Empresa 2017, 1, 10–18. Available online: https://dialnet.unirioja.es/descarga/articulo/6300060.pdf (accessed on 6 July 2020).

- Alzate, A.M. ISO 9001:2015 base para la sostenibilidad de las organizaciones en países emergentes. Rev. Venez. Gerenc. 2017, 22, 576–592. [Google Scholar] [CrossRef][Green Version]

- Castillo, E.; Gutiérrez, J.M.; Hadi, A.S. Sistemas Expertos y Modelos de Redes Probabilísticas; Editorial Academia de Ingeniería (España): Madrid, Spain, 1998; ISBN 84-600-9395-6. [Google Scholar]

- Giarratano, J.; Riley, G. Expert Systems: Principles and Programming; PWS-KENT Publishing Co.: Boston, MA, USA, 1998; p. 632. [Google Scholar]

- Gipe, J.; Jasinski, N. Expert system applications in quality assurance. In ASQ Quality Congress Transactions; American Society for Quality Control, Inc.: Anaheim, CA, USA, 1986; Volume 40, pp. 280–284. [Google Scholar]

- Evans, J.; Lindsay, W. Expert systems for statistical quality control. In Annual International Industrial Engineering Conference Proceedings; American Institute of Industrial Engineers: Washinton, DC, USA, 1987; pp. 131–136. [Google Scholar]

- Hosni, Y.A.; Elshennavy, A.K. Quality control and inspection. Knowledge-based quality control system. Comput. Ind. Eng. 1988, 15, 331–337. [Google Scholar] [CrossRef]

- Pfeifer, T. Knowledge based fault detection in quality inspection. Softw. Manuf. IFIP 1989, 467–476. [Google Scholar]

- Ntuen, C.; Park, H.; Kim, J. KIMS a knowledge based computer vision system for production line inspection. Comput. Ind. Eng. 1989, 16, 491–508. [Google Scholar] [CrossRef]

- Lee, N.; Phadke, M.; Keny, R. An expert system for experimental design in off-line quality control. Quality control and inspection. Expert Syst. 1989, 6, 238–249. [Google Scholar] [CrossRef]

- Crawford, K.; Eyada, O. A Prolog based expert system for the allocation of quality assurance program resources. Comput. Ind. Eng. 1989, 17, 298–302. [Google Scholar] [CrossRef]

- Eyada, O. An expert system for quality assurance auditing. In ASQ Quality Congress Transactions; American Society for Quality Control, Inc.: Milwaukee, WI, USA, 1990; Volume 44, pp. 613–619. [Google Scholar]

- Brink, J.R.; Mahalingam, S. An expert system for quality control in manufacturing. In Handbook of Expert System in Manufacturing; Maus, R., Keyes, J., Eds.; McGraw Hill: New York, NY, USA, 1991; pp. 455–465. [Google Scholar]

- Fard, N.; Sabuncuoglu, H. An expert system for selecting attribute sampling plans. Int. Comput. Integr. Manuf. 1990, 3, 364–372. [Google Scholar] [CrossRef]

- Ohta, H.; Kanagawa, A. A design for single sampling attribute plan based on fuzzy sets theory. Fuzzy Sets Syst. 1990, 37, 173–181. [Google Scholar]

- Allen, B.; Kathawala, Y. Expert systems applications in quality management: An integrative approach. ISA Trans. 1992, 31, 19–25. [Google Scholar] [CrossRef]

- Rehbein, D.; Thorp, S.; Deitz, D.; Schultz, L. Expert systems in process control. ISA Trans. 1992, 31, 49–55. [Google Scholar] [CrossRef]

- Moore, R. Expert systems for process control. TAPPI J. 1995, 6, 64–67. [Google Scholar]

- Paladini, E. An expert system approach to quality control. Expert Syst. Appl. 2000, 18, 133–151. [Google Scholar] [CrossRef]

- Liao, H.; Enke, D.; Wiebe, H. An expert advisory system for the ISO 9001 quality system. Expert Syst. Appl. 2004, 27, 313–322. [Google Scholar] [CrossRef]

- Reffat, R.; Harkness, E. Expert System for Environmental Quality Evaluation. J. Perform. Constr. Facil. 2001, 15, 109–114. [Google Scholar] [CrossRef]

- Liukkonen, M.; Havia, E.; Leinonen, H.; Hiltunen, Y. Expert system for analysis of quality in production of electronics. Expert Syst. Appl. 2011, 38, 8724–8729. [Google Scholar] [CrossRef]

- Ling-Zhong, L. A perceptual measure of trade shows using fuzzy quality deployment development. Expert Syst. Appl. 2010, 37, 3921–3933. [Google Scholar]

- Behbahani, M.; Saghaee, A.; Noorossana, R. A case-based reasoning system development for statistical process control: Case representation and retrieval. Comput. Ind. Eng. 2012, 63, 1107–1117. [Google Scholar] [CrossRef]

- Andrade, J.; Ares, J.; García, R.; Rodríguez, S.; Suárez, S. An expert system for ISO 9001 certification pre-audit. In Proceedings of the 2nd international conference on Circuits, Systems, Communications & Computers, Tenerife, Spain, 10–12 December 2011; pp. 273–278. [Google Scholar]

- Bewoor, A.K.; Bewoor, L.A.; Pawar, M.S. An expert advisory system for ISO 9001 based QMS of manufacturing environment. In Proceedings of the 2012 International Conference on Communication, Information & Computing Technology (ICCICT), Mumbai, India, 19–20 October 2012; pp. 1–5. [Google Scholar]

- Herghiligiu, I.V.; Robu, I.B.; Pislaru, M.; Vilcu, A.; Asandului, A.L.; Avasilcăi, S.; Balan, C. Sustainable Environmental Management System Integration and Business Performance: A Balance Assessment Approach Using Fuzzy Logic. Sustainability 2019, 11, 5311. [Google Scholar] [CrossRef]

- Gruber, T.R. Toward principles for the design of ontologies used for knowledge sharing? Int. J. Hum. Comput. Stud. 1995, 43, 907–928. [Google Scholar] [CrossRef]

- Gruber, T. Ontology. In Encyclopedia of Database Systems; Liu, L., Özsu, M.T., Eds.; Springer: New York, NY, USA, 2008. [Google Scholar]

- Hernández, D.R.; Labrada, J.V.; Hernández, M.R. Ontologías. Integración De Esquemas. Tlatemoani 2014, 17, 16–32. [Google Scholar]

- Al Balushi, T.H.; Sampaio, P.R.F.; Dabhi, D.; Loucopoulos, P. ElicitO: A quality ontology-guided NFR elicitation tool. In Proceedings of the International Working Conference on Requirements Engineering: Foundation for Software Quality, Trondheim, Norway, 11–12 June 2007; pp. 306–319. [Google Scholar]

- Sapkota, K.; Aldea, A.; Duce, D.A.; Younas, M.; Bañares-Alcántara, R. Semantic-art: A framework for semantic annotation of regulatory text. In Proceedings of the Fourth Workshop on Exploiting Semantic Annotations in Information Retrieval; Association for Computing Machinery: New York, NY, USA, 2011; pp. 23–24. [Google Scholar]

- Fernández, M.; Gómez-Pérez, A.; Juristo, N. METHONTOLOGY: From Ontological Art towards Ontological Engineering. In Proceedings of the AAAI Symposium; University of Stanford: Palo Alto, CA, USA, 1997; pp. 33–40. Available online: http://oa.upm.es/5484/ (accessed on 6 July 2020).

- Peffers, K.; Tuunanen, T.; Rothenberger, M.A.; Chatterjee, S. A design science research methodology for information systems research. J. Manag. Inf. Syst. 2007, 24, 45–77. [Google Scholar] [CrossRef]

- Kuechler, W.; Vaishnavi, V. The Emergence of Design Research in Information Systems in North America. J. Des. Res. 2008, 7, 1–16. [Google Scholar] [CrossRef]

- Winter, R. Design Science Research in Europe. Eur. J. Inf. Syst. 2008, 17, 470–475. [Google Scholar] [CrossRef]

- Abuhav, I. ISO 9001:2015—A Complete Guide to Quality Management Systems; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- IBM Rational RequisitePro. Available online: Ftp://ftp.software.ibm.com/software/rational/web/datasheets/reqpro.pdf (accessed on 22 May 2020).

- Shishko, R.; Aster, R. NASA Systems Engineering Handbook; NASA Special Publication: Washington, DC, USA, 1995; p. 6105. [Google Scholar]

- Laitenberger, O.; DeBaud, J.M. An encompassing life cycle centric survey of software inspection. J. Syst. Softw. 2000, 50, 5–31. [Google Scholar] [CrossRef]

- Brykczynski, B. A survey of software inspection checklists. ACM SIGSOFT Softw. Eng. Notes 1999, 24, 82. [Google Scholar] [CrossRef]

- Andres, J.; Medina, J.A.; Fernandez, L. Checklists for compliance to DO-178C and DO-278A standards. Comput. Stand. Interfaces 2017, 52, 41–50. [Google Scholar]

- JRuleEngine. Available online: http://jruleengine.sourceforge.net (accessed on 16 October 2019).

- Jfreechart. Available online: http://www.jfree.org/jfreechart/ (accessed on 18 October 2019).

- MySql. Available online: https://www.mysql.com/ (accessed on 18 October 2019).

- Godara, S.; Singh, R. Evaluation of predictive machine learning techniques as expert systems in medical diagnosis. Indian J. Sci. Technol. 2016, 9, 1–14. [Google Scholar]

| Authors | Year Pub. | Soundest Conclusions |

|---|---|---|

| Gipe and Jasinski [32] | 1986 | An ES was developed to solve problems in quality systems, such as the detection of significant variations in process production, the diagnosis of out-of-control events using a rule base, and the analysis of undiagnosed out-of-control events using additional process data or process knowledge. |

| Evans and Lindsay [33] | 1987 | An ES of statistics applied to quality control was developed. This system not only selects the experience in the control table, but it rather offers interpretations of such graphs, providing conclusions about the control process. |

| Elshennavy and Hosni [34] | 1988 | A knowledge-based quality control system was developed that is suitable for variable-specific inspection procedures and for the selection of control charts. |

| Pfeifer [35] | 1989 | The successful results of an ES applied to the detection of defects during the production process in Germany were described. |

| Ntuen, et al. [36] | 1989 | An ES was developed and, by applying pattern recognition, it was able to inspect manufacturing processes. |

| Lee, et al. [37] | 1989 | The development of an ES to evaluate quality controls was reported. |

| Crawford and Eyada [38] | 1989 | This ES was developed for the purpose of planning the allocation of resources for the quality assurance program. |

| Eyada [39] | 1990 | This ES was developed for the evaluation of procedures within the quality control audit, considering the process for suppliers and products. |

| Brink and Mahalingam [40] | 1990 | This ES evaluates the quality of production level, making it possible to detect and correct defects that are produced during the production process. |

| Fard and Sabuncuoglu [41] | 1990 | An ES was developed to select, through attribute sampling, the most appropriate type of sampling for each case: single, double, or multiple. |

| Ohta and Kanagawa [42] | 1990 | A project of sampling by attributes based on fuzzy logic was proposed. |

| Allen and Kathawala [43] | 1992 | It presents a summary of several current ES used in quality management. It also shows a framework for selecting suitable application candidates and a guide for integrating ES technology into these applications. Following the framework will significantly improve the chances of a successful ES implementation. |

| Rehbein et al. [44] | 1992 | Different applications in the process control industry are analyzed. It also includes several case studies that discuss the justification, development, and implementation of ES applications in this field. |

| Moore [45] | 1995 | An ES for process control at a general level was developed. |

| Paladini [46] | 2000 | The development of an ES for quality inspection evaluation was published. |

| Liao et al. [47] | 2004 | An expert advisory system (in the shape of an ES) for ISO 9001 was proposed. This system integrated the ISO 9001 quality system guidelines and an evaluation approach based on the criteria of the Malcolm Baldrige National Quality Award (MBNQA) into a knowledge-based ES. |

| Reffat and Harkness [48] | 2001 | It proposes the development of an ES to assess the effects on the environmental quality of proposed modifications to an office building following a post-occupancy assessment. This model was called the Expert System for the Evaluation of Environmental Quality (ESEQE). |

| Liukkonen et al. [49] | 2011 | It presents works focused on controlling production rather than managing it. It also explains how a system can exploit actual production data and use them to diagnose and optimize manufacturing processes. |

| Ling-Zhong [50] | 2010 | It explains how an ES uses fuzzy quality and entropy function deployment logic to determine the intensity of criteria at trade fairs to develop a fuzzy decision support system. The resulting fuzzy values can be used to analyze the variance and importance of criteria at trade fairs more effectively compared to sharp values. |

| Behbahani et al. [51] | 2012 | The use of a knowledge-based system (KBS) for statistical process control (SPC) was proposed to organize this area of knowledge using a case study through case-based reasoning (CBR). |

| Andrade et al. [52] | 2011 | It presents an ES oriented towards the ISO 9001, which facilitates audit organization processes while preparing the organization for possible audits. |

| Bewoor et al. [53] | 2012 | It presents another solution to advise on compliance by providing preventive and corrective actions to the organization. |

| Herghiligiu et al. [54] | 2019 | It presents the modeling with fuzzy logic of the influence of the integration of an environmental management system (EMS), which can support sustainable development and value creation. |

| ID | Name | Global Process | Prev. Process | Next. Process |

|---|---|---|---|---|

| 1 | Identification and context of the organization interested parties and the QMS | 1 | 0 | 0 |

| 2 | Determination and commitment of senior management | 1 | 0 | 0 |

| 3 | Establishment of the quality policy | 1 | 0 | 0 |

| 4 | Evaluation of risks and opportunities | 1 | 0 | 0 |

| 5 | Identification and traceability | 1 | 0 | 0 |

| 6 | Documented Information | 1 | 0 | 0 |

| 7 | Communication | 1 | 0 | 0 |

| 8 | Determination of objectives | 1 | 0 | 0 |

| 9 | Design and development | 1 | 0 | 10 |

| 10 | Projects control | 0 | 9 | 11 |

| 11 | Sales | 0 | 10 | 12 |

| 12 | Shopping | 0 | 11 | 13 |

| 13 | Production | 0 | 12 | 14 |

| 14 | Packing, packaging, and shipping | 0 | 13 | 0 |

| 15 | Human Resources | 1 | 0 | 0 |

| 16 | Infrastructure management and maintenance | 1 | 0 | 0 |

| 17 | Monitoring and evaluation | 1 | 0 | 0 |

| 18 | Nonconformity, corrective action and improvement | 1 | 0 | 0 |

| 19 | Internal audit | 1 | 0 | 0 |

| Actual | Prediction—First Test | ||

|---|---|---|---|

| Positives | Negatives | Total | |

| Positives | True-Positive (TP) = 338 | False-Negative (FN) = 62 | 400 |

| Negatives | False-Positive (FP) = 0 | True-Negative (TN) = 159 | 165 |

| Total | 344 | 221 | 565 |

| Actual | Prediction—Last Set of Tests | ||

|---|---|---|---|

| Positives | Negatives | Total | |

| Positives | True-Positive (TP) = 338 | False-Negative (FN) = 0 | 388 |

| Negatives | False-Positive (FP) = 0 | True-Negative (TN) = 177 | 177 |

| Total | 388 | 177 | 565 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andres-Jimenez, J.; Medina-Merodio, J.-A.; Fernandez-Sanz, L.; Martinez-Herraiz, J.-J.; Ruiz-Pardo, E. An Intelligent Framework for the Evaluation of Compliance with the Requirements of ISO 9001:2015. Sustainability 2020, 12, 5471. https://doi.org/10.3390/su12135471

Andres-Jimenez J, Medina-Merodio J-A, Fernandez-Sanz L, Martinez-Herraiz J-J, Ruiz-Pardo E. An Intelligent Framework for the Evaluation of Compliance with the Requirements of ISO 9001:2015. Sustainability. 2020; 12(13):5471. https://doi.org/10.3390/su12135471

Chicago/Turabian StyleAndres-Jimenez, Jose, Jose-Amelio Medina-Merodio, Luis Fernandez-Sanz, Jose-Javier Martinez-Herraiz, and Estefania Ruiz-Pardo. 2020. "An Intelligent Framework for the Evaluation of Compliance with the Requirements of ISO 9001:2015" Sustainability 12, no. 13: 5471. https://doi.org/10.3390/su12135471

APA StyleAndres-Jimenez, J., Medina-Merodio, J.-A., Fernandez-Sanz, L., Martinez-Herraiz, J.-J., & Ruiz-Pardo, E. (2020). An Intelligent Framework for the Evaluation of Compliance with the Requirements of ISO 9001:2015. Sustainability, 12(13), 5471. https://doi.org/10.3390/su12135471