Requirements for the Construction of New Desalination Plants into a Framework of Sustainability

Abstract

1. Introduction

- The desalination technology, the necessary energy, and its production;

- The environmental impact and measures to neutralize it;

- The management of the construction and smooth running of the plants.

2. Desalination Technology

- Multi-stage evaporation or multi-stage flash distillation, known by its acronym MSF;

- Multi-effect evaporation (MED);

- Mechanical Vapor Compression (MVC).

- Design;

- Equipment and materials, especially highlighting membranes and pumps;

- Energy recovery systems.

3. Environmental Impact of Desalination Plants

The environmental impact assessment procedure tries to establish the minimum thresholds under which alterations to the environment caused by an action would or would not be acceptable, paying attention not only to the characteristics of the action involved, but also to the environmental conditions–broadly understood- of the area on which action might be needed.

And in this sense, it has to be underlined that the impact of a desalination plant is not at all more than the residual impact of previous larger human actions, such as the urbanization and extensive occupation of thousands of hectares which lack water resources in quantity and quality enough to meet the demand typical for this accelerated building process.

- Starting from the study phase, the representatives of the communities that live near or within the catchment area of a possible plant location should be included in the decision process that may affect these communities;

- The location of the plant and its integration into the environment. This is always difficult because the plant will necessarily always be situated near the coastline;

- The areas affected by work installations, quarries, landfill sites, etc., in order to consider restoration measures;

- The seawater intake area and its connection to the plant;

- The marine and land fauna which might be either temporarily or permanently affected, which would require studies for corrective measures;

- The marine and land flora affected by the works;

- The connections of the plant with the nearby road network and the effects construction vehicles have on it;

- The connections with the electricity grid and its possible environmental impact;

- The piping connections with the general system supply network.

- Maintenance of the adopted measures for the environmental integration of the plant;

- Brine discharge control measures to preserve the marine flora and fauna in the area;

- Purification of reject waters resulting from the treatment of drinking water supplied to the network;

- Conservation and maintenance of the adopted measures not to harm or damage the marine and land fauna;

- Conservation and maintenance of the road network due to the deterioration by the vehicles from the plant;

- Adequate surveillance of the plant’s connection pipe network.

- (a)

- Water quality and marine biota—impacts from construction and operation of the desalination plant;

- (b)

- Terrestrial fauna—impacts from clearing of habitat;

- (c)

- Terrestrial vegetation and wetlands—impacts from clearing during infrastructure construction;

- (d)

- Greenhouse gas emissions—proposed no net greenhouse gas emissions.

- (a)

- The precautionary principle;

- (b)

- The principle of inter-generational equity;

- (c)

- The principle of conservation of biological diversity and ecological integrity; and

- (d)

- The principle of waste minimization.

- (1)

- Water quality and marine biota;

- (2)

- Marine fauna;

- (3)

- Terrestrial fauna;

- (4)

- Terrestrial flora and vegetation;

- (5)

- Wetlands; and

- (6)

- Greenhouse gas emissions.

The unprecedented marine monitoring program has included computer modelling for diffuser design and validation, rhodamine dye tracer tests, extensive far field dissolved oxygen tests, a water quality monitoring program, diffuser performance monitoring program, WET testing and Macrobenthic surveys. All studies have proven that the PSDP is having negligible impact on the surrounding environment. Impacts on seawater habitat are limited by a validated diffuser design and treatment of suspended solids.

The power consumption of RO plants is decreasing due to increasing technological gains in plant design, membrane design and energy recovery. RO plants can also easily be powered (offset) by renewable energies. Energy recovery systems such as that used at the PSDP (ERI) are now extremely efficient at recovering energy from the brine wastewater (greater than 96% efficiency). Sourcing power from renewable energy (albeit offset) is an important sustainability principal employed by the PSDP, which is also now being applied by other large-scale Australian desalination plants.

- Environmental factors, risks, and impacts;

- Environmental monitoring plan;

- Environmental behavior;

- Value comparison, best available technology, and improvements in environmental management.

Monitoring results indicate that the SSDP is operating effectively and that the Environmental Quality Objectives for the marine environment are being maintained. Water Corporation has demonstrated that the SSDP has met MS792 criteria for salinity and dissolved oxygen and is achieving the required diffuser performance to meet 99% species protection at the LEPA boundary”.

“Seagrass Health Monitoring continues and while a decline in seagrass shoot density was recorded post construction, we have seen a recovery and stabilization of seagrass shoot density over the last three-years of monitoring”.

“Water Corporation is in the process of developing a strategy for the purchase of renewable energy and/or carbon offsets for the SSDP”.

“Water Corporation and SSWA plan to undertake the following:

4. Decision Support System and Type of Contract

- There is a single contractor responsible for design and work, so that engineering and construction can be developed in parallel, thus shortening deadlines;

- The dialogue is limited to client/contractor;

- The global assumption of responsibility includes not only the quality requirements established by contract, but also the proposed new technological developments, and consequently, changed or modified orders which generate deviations of deadlines and budget are eliminated or reduced.

5. Conclusions

- The technology to adopt for desalination is reverse osmosis, considering the several stages and energy recovery measures and opportunities available along the process. In addition, adopting the latest generation membranes is essential to achieve the best efficiency;

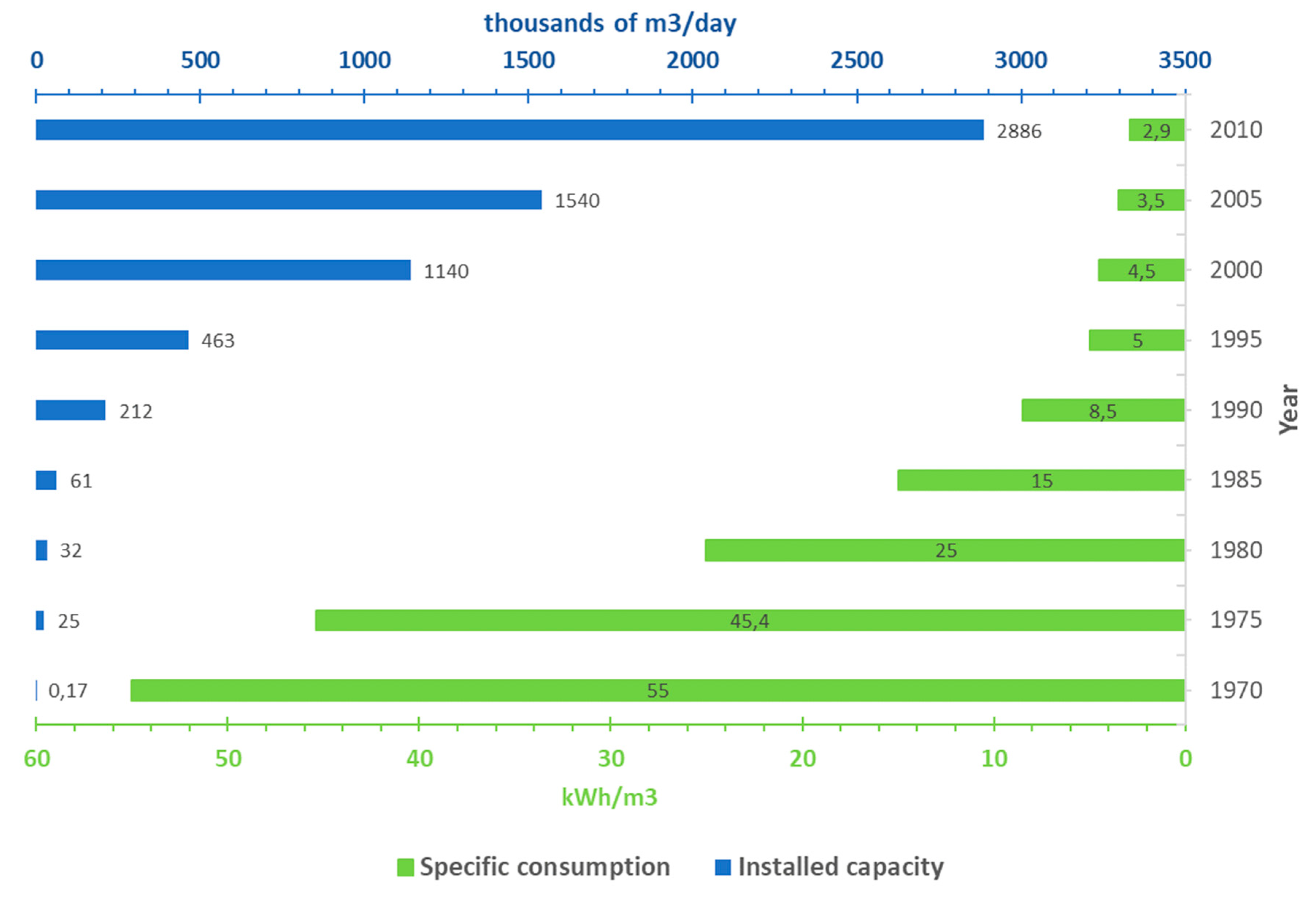

- Regarding the consumption and production of the energy necessary for desalination, the proposed technology, including all the measures to improve efficiency, offers the safest possible means for desalination. Consumption is getting below 2.7 kWh/m3 through reverse osmosis. It is recommended to associate with the construction of these large desalination plants renewable energy production parks, fundamentally solar or wind farms; even if it is utopian to think of a plant today producing hundreds of thousands of cubic meters a day, through the exclusive supply of renewable energies;

- From the environmental point of view, it is essential that the construction of any desalination plant, wherever it may be, should include an environmental impact study during the construction of said plant, and also include a monitoring plan that guarantees the corrective measures and the possibility of adopting new ones if impacts on the environment were detected. This monitoring must be guaranteed by an independent body from the plant operating company and must be published regularly with the supporting documentation of the results obtained during the follow-up.

- As for the development management of these large infrastructures, it is recommended to use one of the decision support systems that justifies the chosen contractual modality for the project and construction. Today, the best contract to achieve the objective of big, complex, and expensive projects is the turnkey contract. The advantages are mainly that turnkey contracts shorten deadlines when combining design and construction and avoid or even reduce extra costs because of the closed price formula. It is, however, advisable to have an Open Book Estimation (OBE) phase before finally agreeing the binding contract.

- A significant cost reduction in RO is possible in the short term if the working pressure can be reduced without the membranes losing efficiency.

Author Contributions

Funding

Conflicts of Interest

References

- Brundtland Commission. The World Commission on Environment and Development. In Our Common Future; Hauff, V., Ed.; Oxford University Press: Oxford, New York, NY, USA, 1987; ISBN 9780192820808. [Google Scholar]

- Jonker, G.; Harmsen, J. Engineering for Sustainability. A Practical Guide for Sustainable Design; Elsevier BV: Amsterdam, The Netherlands, 2012; ISBN 9780444538468. [Google Scholar]

- Siegel, S.M. Let There Be Water. Israel’s Solution for a Water-Starved World; Thomas Dunne Books: New York, NY, USA, 2015; ISBN 978-1250073952. [Google Scholar]

- Bates Ramírez, V. Inching towards Abundant Water: New Progress in Desalination Tech, Singularity Hub. Available online: https://singularityhub.com/2019/06/18/inching-towards-abundant-water-new-progress-in-desalination-tech/ (accessed on 30 January 2020).

- Universidad Complutense de Madrid. El Agua en la Tierra. Available online: https://webs.ucm.es/info/diciex/proyectos/agua/El_agua_en_la_tierra.html (accessed on 19 June 2020).

- AQUASTAT FAO’s Global Information System on Water and Agriculture. Available online: http://www.fao.org/aquastat/en/overview/methodology/water-use (accessed on 20 May 2020).

- International Desalination Association. Desalination by the Numbers. Available online: https://idadesal.org/ (accessed on 20 May 2020).

- Urrutia, F. Evolución Global de la Capacidad Instalada de Plantas Desalinizadoras. Ingeniería y Territorio 2005, 72, 68. [Google Scholar]

- Torres Corral, M. Avances Técnicos en la Desalación de Aguas; Ambienta, Ministerio de Medio Ambiente: Madrid, Spain, 2004; pp. 18–19. [Google Scholar]

- Stover, R.L. Innovation Leads the Way to Solving Desalination Challenges. Water Online. Available online: https://www.wateronline.com/doc/innovation-leads-the-way-to-solving-desalination-challenges-0001 (accessed on 23 May 2020).

- Scott, K. Handbook of Industrial Membranes; Elsevier Advanced Technology: Oxford, UK, 1995. [Google Scholar]

- Ibáñez Mengual, J.A. Desalación de Aguas. Aspectos Tecnológicos, Medioambientales, Jurídicos y Económicos; Editorial Fundación Instituto Euromediterráneo del Agua: Espinardo, Murcia, Spain, 2009; ISBN 978-84-936326-6-3. [Google Scholar]

- Voutchkov, N. Desalination-Past, Present and Future. Available online: https://iwa-network.org/desalination-past-present-future/ (accessed on 19 May 2020).

- Lattemann, S.; Höpner, T. Environmental impact and impact assessment of seawater desalination. Desalination 2008, 220, 1–15. [Google Scholar] [CrossRef]

- Kämpf, J.; Clarke, B. How robust is the environmental impact assessment process in South Australia? Behind the scenes of the Adelaide seawater desalination project. Mar. Policy 2013, 38, 500–506. [Google Scholar]

- Fuentes-Bargues, J.L. Analysis of the Process. of environmental impact assessment for seawater desalination plants in Spain. Desalination ELSEVIER 2014, 347, 166–174. [Google Scholar] [CrossRef]

- Shemer, H.; Semiat, R. Sustainable RO desalination—Energy demand and environmental impact. Desalination 2017, 242, 10–16. Available online: https://doi.org/10.1016/j.desal.2017.09.021 (accessed on 19 May 2020). [CrossRef]

- Saracco, R. Desalination Plants Ask for Tech Evolution. Available online: https://cmte.ieee.org/futuredirections/2019/01/19/desalination-plants-ask-for-tech-evolution/ (accessed on 20 May 2020).

- Parlar, I.; Hacıfazlıoğlu, M.; Kabay, N.; Pek, M.; Yüksel, M. Performance comparison of reverse osmosis (RO) with integrated nanofiltration (NF) and reverse osmosis process for desalination of MBR effluent. J. Water Process. Eng. 2019, 29, 100640. Available online: https://doi.org/10.1016/j.jwpe.2018.06.002 (accessed on 20 May 2020). [CrossRef]

- Lee, J.J.; Kang, J.S. Treatment of reverse osmosis concentrate by electrolysis and MBR process. Desalination Water Treat. 2015, 57, 1–9. [Google Scholar] [CrossRef]

- Asociación Española de Desalación y Reutilización, AEDyR. Desalination Figures in Spain; AEDyR: Madrid, Spain, 2019; Available online: http://www.aedyr.com (accessed on 20 February 2020).

- Urban, J.; Chao, J. Moving Forward on Desalination. Lawrence Berkeley National Laboratory (Berkeley Lab) 2019. Available online: https://newscenter.lbl.gov/2019/07/31/moving-forward-on-desalination/ (accessed on 20 February 2020).

- De Luis López, M.; Gómez Benítez, M.A. La desalación mediante energía solar como fuente de recursos hídricos. Colección Informes 2015, 111, 6. [Google Scholar]

- Subramani, A.; Jacangelo, J.G. Emerging desalination technologies for water treatment: A critical review. Water Res. 2015, 75, 164–187. Available online: https://doi.org/10.1016/j.watres.2015.02.032 (accessed on 21 May 2020). [CrossRef]

- Estevan, A.; García, M. El consumo de energía en la desalación de agua de mar por ósmosis inversa: Situación actual y perspectivas. Ing. Civ. 2007, 148, 113–121. [Google Scholar]

- Jia, X.; Jaromír, J.; Sabev, P.; Wan Alwi, S.R. Analysing the Energy Consumption, GHG Emission, and Cost of Seawater Desalination in China. Energies 2019, 12, 463. [Google Scholar] [CrossRef]

- Water Corporation. Southern Seawater Desalination Project; Geon: Perth, Australia, 2011; p. 9. ISBN 1-74043-726-8. [Google Scholar]

- Kalogirou, S.A. Seawater desalination using renewable energy sources. Prog. Energy Combust. Sci. 2005, 31, 242–281. [Google Scholar] [CrossRef]

- Charcosset, C. A review of membrane processes and renewable energies for desalination. Desalination 2009, 245, 214–231. [Google Scholar] [CrossRef]

- Eltawil, M.; Zhengming, Z.; Yuan, L. A review of renewable energy technologies integrated with desalination systems. Renew. Sustain. Energy Rev. 2009, 13, 2245–2262. [Google Scholar] [CrossRef]

- Petersen, G.; Fries, S.; Mohn, J.; Müller, A. Wind and solar-powered reverse osmosis desalination units-description of two demonstration projects. Desalination 1979, 31, 501–509. [Google Scholar] [CrossRef]

- Lindermann, J.H. Wind and solar powered seawater desalination applied solutions for the Mediterranean, the Middle East. and the Gulf countries. Desalination 2004, 168, 73–80. [Google Scholar] [CrossRef]

- Ghermandi, A.; Messalem, R. Solar-driven desalination with reverse osmosis: The state of the art. Desalination Water Treat. 2009, 7, 285–296. [Google Scholar] [CrossRef]

- Palenzuela, P.; Zaragoza, G.; Alarcon-Padilla, D.C.; Guillen, E.; Ibarra, M.; Blanco, J. Assessment of different configurations for combined parabolic-trough (PT) solar power and desalination plants in arid regions. Energy 2011, 36, 4950–4958. [Google Scholar] [CrossRef]

- ACWA Power. Taweelah Independent Water Plant (IWP). Available online: https://www.acwapower.com/news/taweelah-iwp-obtains-the-first-ever-sustainable-loan-qualification-for-a-desalination-project/ (accessed on 22 May 2020).

- ACWA Power. Jubail 3A Independent Water Plant (IWP). Available online: https://www.acwapower.com/en/projects/jubail-3a-iwp/ (accessed on 22 May 2020).

- Water Corporation. Southern Seawater Desalination Project. Social Impact Management Plan. 2009. Available online: https://pw-cdn.watercorporation.com.au/-/media/WaterCorp/Documents/Our-Water/Desalination/ssdp-social-impact-management-plan.pdf?rev=d58321c9628441909baa0697213a8e33&hash=CCCACB07C0537EDB352A8183369198CB (accessed on 19 June 2020).

- Mumbida Wind Farm. Available online: https://mumbidawindfarm.com.au/ (accessed on 20 May 2020).

- Greenough Solar Farm. Available online: https://www.brightenergyinvestments.com.au/greenough-river-solar-farm (accessed on 20 May 2020).

- Raluy, G.; Serra, L.; Uche, J. Life cycle assessment of MSF, MED and RO desalination technologies. Energy 2006, 31, 2361–2372. [Google Scholar] [CrossRef]

- Mezher, T.; Fath, H.; Abbas, Z.; Khaled, A. Techno-economic assessment and environmental impacts of desalination technologies. Desalination 2011, 266, 263–273. [Google Scholar] [CrossRef]

- Van der Bruggen, B.; Vandecasteele, C. Distillation vs. membrane filtration: Overview of Process. evolutions in Seawater desalination. Desalination 2002, 143, 207–2018. [Google Scholar] [CrossRef]

- Najafi, F.T.; Alsaffar, M.; Schwerer, S.C.; Brown, N. Environmental Impact Cost Analysis of Multi-Stage Flash, Multi-Effect Distillation, Mechanical Vapor Compression, and Reverse Osmosis Medium-Size Desalination Facilities. In Proceedings of the ASEE’s 123rd annual Conference & Exposition, New Orleans, LA, USA, 26–29 June 2016. [Google Scholar]

- Jones, E.; Qadir, M.; van Vliet, M.T.H.; Kang, S.-M. The state of desalination and brine production: A global outlook. Sci. Total Environ. 2019, 657, 1343–1356. Available online: https://doi.org/10.1016/j.scitotenv.2018.12.076 (accessed on 21 May 2020). [CrossRef] [PubMed]

- Ley 21/2013 de Evaluación Ambiental. B.O.E. nº 296. Available online: https://www.boe.es/eli/es/l/2013/12/09/21/con (accessed on 19 June 2020).

- Martínez de la Vallina, J.J. Evaluación del Impacto Ambiental de las Desaladoras. Congreso Nacional del Medio Ambiente; Cumbre del Desarrollo Sostenible: Madrid, Spain, 2008; pp. 5–17. [Google Scholar]

- Environmental Protection Authority EPA. Southern Seawater Desalination Project. Report and Recommendations of the EPA. 2008. Available online: http://www.epa.wa.gov.au/sites/default/files/EPA_Report/2797_Rep1302Desal_61008.pdf (accessed on 22 May 2020).

- Christie, S.; Bonnélye, V. Two-year Feed Back on Operation and Environmental Impact. In Proceedings of the IDA World Congress, Atlantis, Dubai, UAE, 7–12 November 2009; p. 14. [Google Scholar]

- Water Corporation. Southern Seawater Desalination Project. 2018 Performance Review Report. Available online: https://www.watercorporation.com.au/Our-water/Desalination/Southern-Seawater-Desalination-Plant (accessed on 19 June 2020).

- Water Corporation. Perth Seawater Desalination Plant. Compliance Assessment Report Ministerial Statements 655 & 832, 01 July 2017 to 30 June 2018. Available online: https://www.watercorporation.com.au//media/files/residential/watersupply/desalination/psdp/psdp-compliance-assessment-report-2017-18.pdf (accessed on 21 May 2020).

- Water Corporation. Southern Seawater Desalination Plant. Performance and Compliance Report 14 April 2018–13 April 2019. Available online: https://www.watercorporation.com.au/-/media/files/residential/watersupply/desalination/ssdp/ssdp-performance-compliance-report-2018-2019.pdf (accessed on 21 May 2020).

- Gordon, C.M. Choosing Appropriate Construction Contracting Method. J. Constr. Eng. Manag. (ASCE) 1994, 120, 196. [Google Scholar] [CrossRef]

- Bennett, J.; Pothecary, E.; Robinson, G. Designing and Building a World-Class Industry; University of Reading: Reading, UK, 1996; ISBN 9780704911703. [Google Scholar]

- Molenaar, K.R. Public Sector Design-Build: A Model. for Project Selection; University of Colorado, Civil Engineering: Boulder, CO, USA, 1997. [Google Scholar]

- Konchar, M.D.; Sanvido, V.E. Comparison of U.S. Project Delivery Systems. J. Constr. Eng. Manag. (ASCE) 1998, 124, 435–444. [Google Scholar] [CrossRef]

- Ibbs, C.W.; Wong, C.K.; Kwak, Y.H.; Ng, T. Project Delivery Systems and Project Change: Quantitative Analysis. J. Constr. Eng. Manag. (ASCE) 2003, 129, 328–386. [Google Scholar] [CrossRef]

- Gransberg, D.D.; Koch, J.E.; Molenaar, K.R. Preparing for Design-Build Projects: A Primer for Owners, Engineers, and Contractors; American Society of Civil Engineers ASCE: Reston, VA, USA, 2006; pp. 13–16. [Google Scholar]

- Hale, D.R.; Shrestha, P.P.; Gibson, G.E.; Migliaccio, G.C. Empirical Comparison of Design/Build. and Design/Bid/Build. Project Delivery Methods. J. Constr. Eng. Manag. (ASCE) 2009, 135, 579–587. [Google Scholar] [CrossRef]

- Touran, A.; Gransberg, D.D.; Molenaar, K.R.; Ghavamifar, K.; Mason, D.J.; Fithian, L.A. A Guidebook for the Evaluation of Project Delivery Methods; TCRP Report 131; Transportation Research Board, Transit Cooperative Research Program: Washington, DC, USA, 2009. [Google Scholar]

- Park, J.; Kwak, Y.H. Design-bid-build (DBB) vs. design-build (db) in the U.S. public transportation projects: The choice and consequences. Int. J. Proj. Manag. 2019, 35, 280–295. [Google Scholar] [CrossRef]

- Sullivan, J.; El Asmar, M.; Chalhoub, J.; Obeid, H. Two decades of performance comparisons for Design-Build., Construction Manager at Risk and Design-Bid-Build.: Quantitative analysis of the state of knowledge about cost, schedule, and project quality. J. Constr. Eng. Manag. (ASCE) 2019, 143, 04017009. [Google Scholar] [CrossRef]

- Jiyong, D.; Wang, N.; Hu, L. Framework for Designing Project Delivery and Contract Strategy in Chinese Construction Industry Based on Value-Added Analysis. Adv. Civ. Eng. 2018, 12, 1–14. [Google Scholar]

- Berenguel-Felices, F.; Lara-Galera, A.; Guirao-Abad, B.; Galindo-Aires, R. Contracting Formulas for Large Engineering Projects. The Case of Desalination Plants. Sustainability 2020, 12, 219. Available online: https://doi.org/10.3390/su12010219 (accessed on 20 May 2020). [CrossRef]

- El-Wardani, M.; Messner, J.I.; Horman, M.J. Comparing Procurement Methods for Design-Build Projects. J. Constr. Eng. Manag. (ASCE) 2005, 132, 230–238. [Google Scholar] [CrossRef]

- Ohrn, L.G.; Rogers, T. Defining Project Delivery Methods for Design, Construction, and Other Construction-Related Services in the United States; Northern Arizona University: Flagstaff, AZ, USA, 2008; p. 5. [Google Scholar]

- Hinze, J. Construction Contracts 3rd Edition; McGraw-Hill: Columbus, OH, USA, 2010; ISBN 978-0073397856. [Google Scholar]

- Chamarro, I. Contratos internacionales de construcción llave en mano. 2012. Available online: http://www.interempresas.net (accessed on 6 May 2020).

- Franz, B.; Leicht, R.; Molenaar, K.R.; Messner, J. Impact of team integration and group cohesion on project delivery performance. J. Constr. Eng. Manag. 2016, 143, 04016088. [Google Scholar] [CrossRef]

- Farnsworth, C.B.; Warr, R.O.; Weidman, J.E.; Hutchings, D.M. Effects of CM/GC project delivery on managing process risk in transportation construction. J. Constr. Eng. Manag. 2016, 142, 04015091. [Google Scholar] [CrossRef]

- Hernández Rodríguez, A. Los Contratos Internacionales de Construcción «Llave en Mano». Cuad. Derecho Transnacional 2014, 6, 161–235. [Google Scholar]

- Gad, G.M.; Davis, B.; Shrestha, P.P.; Harder, P. Lessons Learned from Progressive Design-Build. Implementation on Airport Projects. J. Leg. Aff. Disput. Resolut. Eng. Constr. ASCE 2019, 11, 8. [Google Scholar] [CrossRef]

- Gransberg, D.D.; Molenaar, K.R. Critical Comparison of Progressive Design-Build and Construction Manager/General Contractor Project Delivery Methods. Transp. Res. Record J. Transp. Res. Board Natl. Acad. 2019, 261–268. [Google Scholar] [CrossRef]

| Agricultural | Municipal | Industrial | |

|---|---|---|---|

| World | 69 | 19 | 12 |

| Europe | 21 | 57 | 22 |

| Americas | 51 | 34 | 15 |

| Oceania | 60 | 15 | 25 |

| Asia | 81 | 10 | 9 |

| Africa | 82 | 5 | 13 |

| Desalination Technology | Energy Requirement (kWh/m3) |

|---|---|

| MSF | 21–58 |

| MED | 15–58 |

| MVC | 7–12 |

| RO | 3–5 |

| Desalination Technology | UPC (USD in 2016) |

|---|---|

| RO | 0.8 to 1.3 |

| MED | 2.0 |

| MSF | 3.6 |

| ED | 3.0 |

| Component | MSF | RO |

|---|---|---|

| Recovery percentage | 10–20% | 30–50% |

| Investment ($/m3.day) | 1000–1500 | 1500–7000 (Including 10% for membranes) |

| Chemicals $/m3 | 0.03 to 0.05 | 0.06 to 0.10 |

| Brine Quality | Chemicals and Heat | Chemicals |

| Robustness | High | Medium (Problems: fouling sensitive and feed water monitoring) |

| Improvement Potential | Low | High |

| Water Type | Salinity (gr/l) |

|---|---|

| Freshwater | Less than 1 gr/l |

| Sea water average salinity | 35 |

| Sea water | 35–45 |

| Brackish water | 3–25 |

| Red Sea | 42–46 |

| Persian Gulf | 40–44 |

| Mediterranean Sea | 36–39 |

| Caribbean Sea | 34–38 |

| Indian Ocean | 33–37 |

| Pacific Ocean | 33–36 |

| Atlantic Ocean | 33–36 |

| Baltic Sea | 6–18 |

| Caspian Sea | 12 |

| Dead Sea | 350–370 |

| Element | Description |

|---|---|

| General | |

| Capacity | 50 Gigalitres per year initial capacity 100 Gigalitres per year ultimate capacity |

| Power requirement | 50 Megawatts annual average |

| Power source | 100% renewable energy from Western Power Grid |

| Clearing of vegetation required | Not more than 20 hectares (at plant site) |

| Rehabilitation | 7 hectares minimum |

| Offset (rehabilitation) | 13 hectares minimum |

| Seawater intake | |

| Intake volume | Average 722 Megaliters per day |

| Length (indicative) | Extending from 400 to 600 m offshore |

| Number | Up to 4 pipes |

| Diameter | Up to 3 m |

| Concentrated seawater discharge | |

| Discharge volume | 418 Megaliters per day (average) |

| Salinity | Up to 65,000 milligrams per liter |

| Temperature | Not more than 2 °C above/below ambient seawater |

| pH | 6–8 |

| Length (indicative) | Extending not more than 1100 m offshore |

| Number | Up to 4 pipes |

| Diameter | Up to 3 m |

| Diffuser | Located between 600 and 1100 m offshore and up to 450 m in total length |

| Sludge | |

| Sludge production | 30 tons per day (approximately) |

| Water Transfer Pipeline | |

| Length | 30 km (approximately) |

| Diameter | 1400 mm |

| Destination | Harvey Summit Tank Site |

| Clearing of native vegetation | Not more than 7 hectares (in pipeline corridor) |

| Rehabilitation | 7 hectares minimum |

| Harvey Summit Tank Site | |

| Number of tanks | Up to 4 |

| Capacity of each tank | 32 Megaliters |

| Sump size | 2 Megaliters (upgradeable to 5 Megaliters) |

| Clearing of native vegetation | Not more than 0.1 hectares |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berenguel-Felices, F.; Lara-Galera, A.; Muñoz-Medina, M.B. Requirements for the Construction of New Desalination Plants into a Framework of Sustainability. Sustainability 2020, 12, 5124. https://doi.org/10.3390/su12125124

Berenguel-Felices F, Lara-Galera A, Muñoz-Medina MB. Requirements for the Construction of New Desalination Plants into a Framework of Sustainability. Sustainability. 2020; 12(12):5124. https://doi.org/10.3390/su12125124

Chicago/Turabian StyleBerenguel-Felices, Francisco, Antonio Lara-Galera, and María Belén Muñoz-Medina. 2020. "Requirements for the Construction of New Desalination Plants into a Framework of Sustainability" Sustainability 12, no. 12: 5124. https://doi.org/10.3390/su12125124

APA StyleBerenguel-Felices, F., Lara-Galera, A., & Muñoz-Medina, M. B. (2020). Requirements for the Construction of New Desalination Plants into a Framework of Sustainability. Sustainability, 12(12), 5124. https://doi.org/10.3390/su12125124