Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis

Abstract

1. Introduction

1.1. Framework

1.2. Main Chaff Utilization

2. Materials and Methods

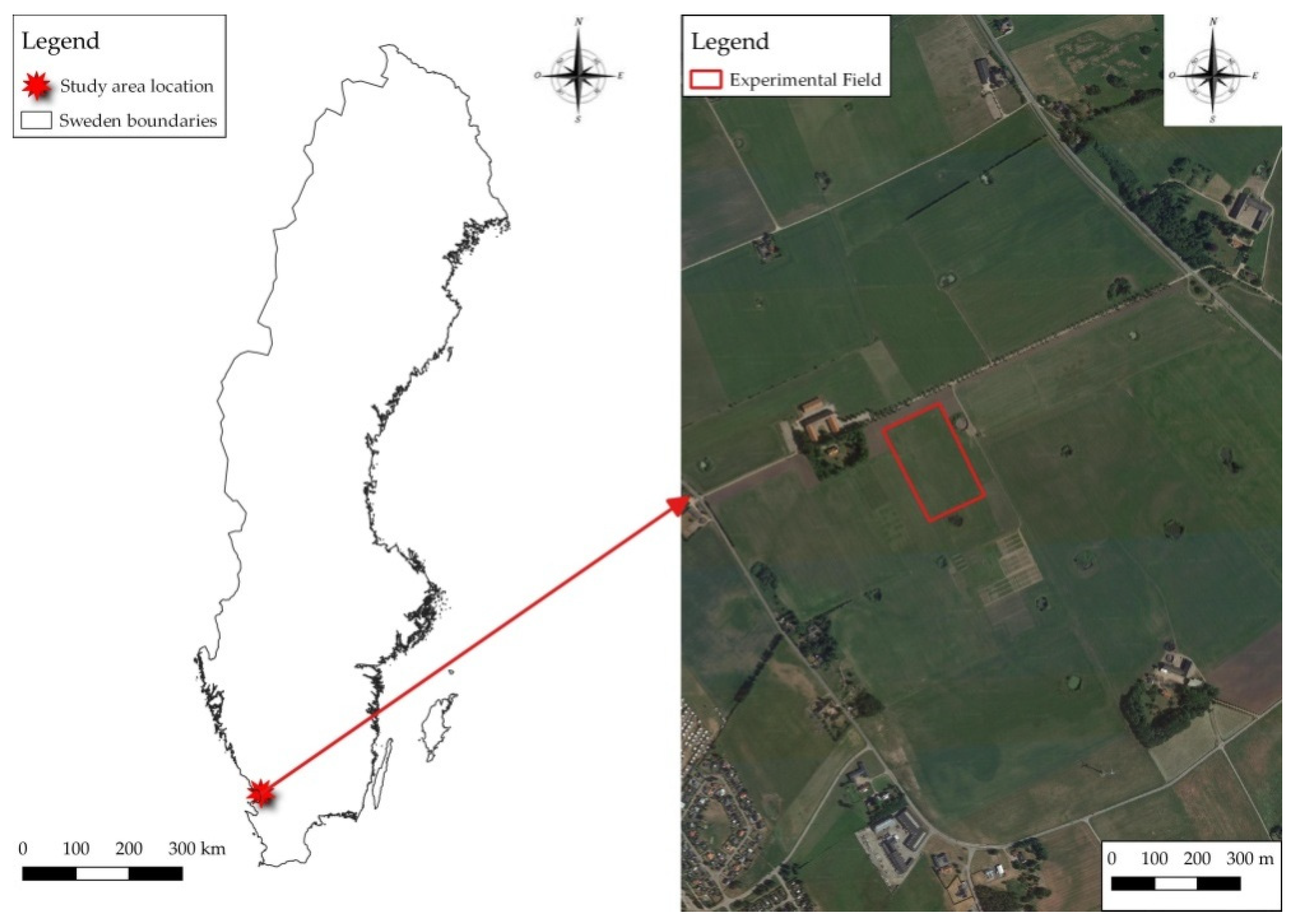

2.1. Field Site and Experimental Design

2.2. Pre-Harvest Tests: Theoretical Biomass Assessment

2.3. Equipment

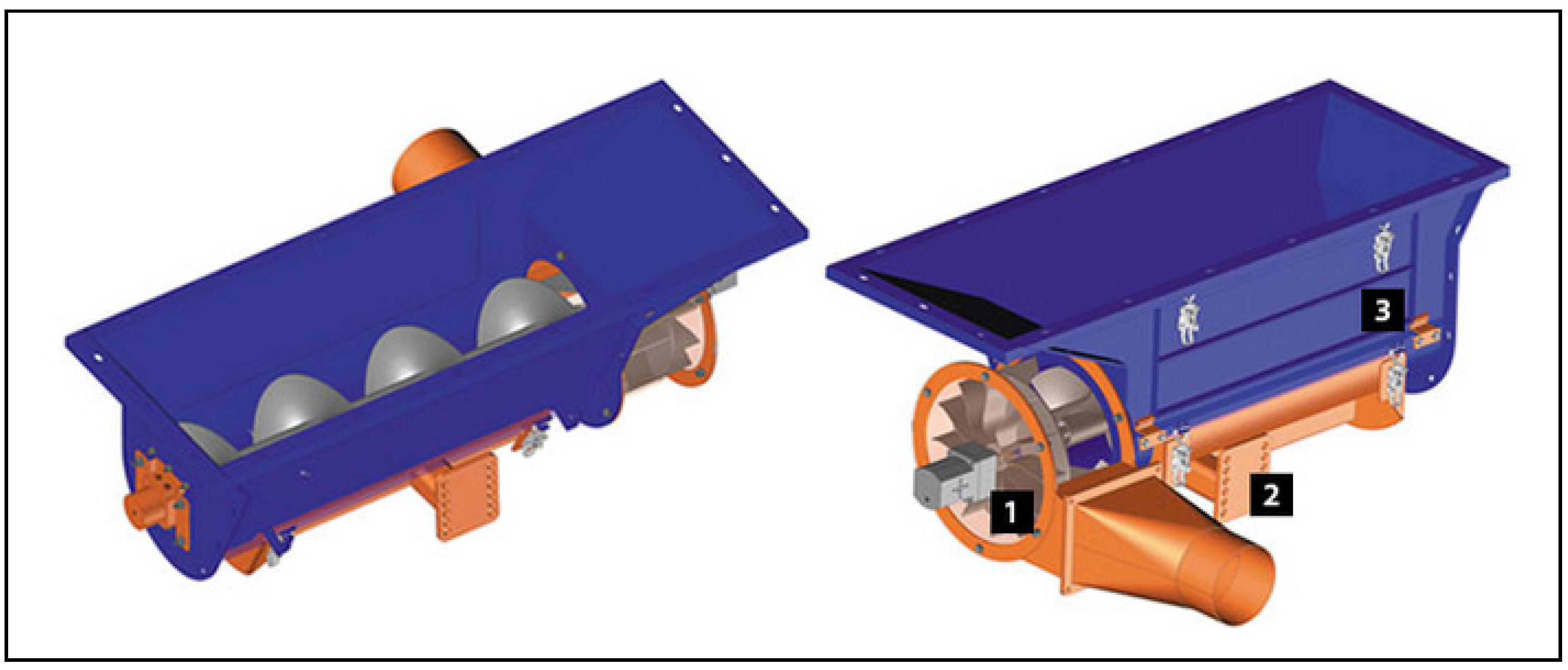

2.3.1. Combine Harvester and Recovery System

2.3.2. Residual Biomass Harvesting

2.4. Harvesting and Baling Performance

2.5. Post-Harvesting Test: Biomass Collected, Losses and Bulk Density

2.6. Cost Analysis

- Ea = Economic allocation of each product or co-product (i.e., grain seed, straw, or chaff) per harvesting phase (combine harvesting or baling)

- Mp = Market price of each product or co-product (i.e., grain seed, straw, or chaff)

- Yi = Yield of each product or co-product (i.e., grain seed, straw, or chaff)

- Ri = Revenue obtained by multiplying Mp × Yi

2.7. Statistical Analysis

3. Results and Discussions

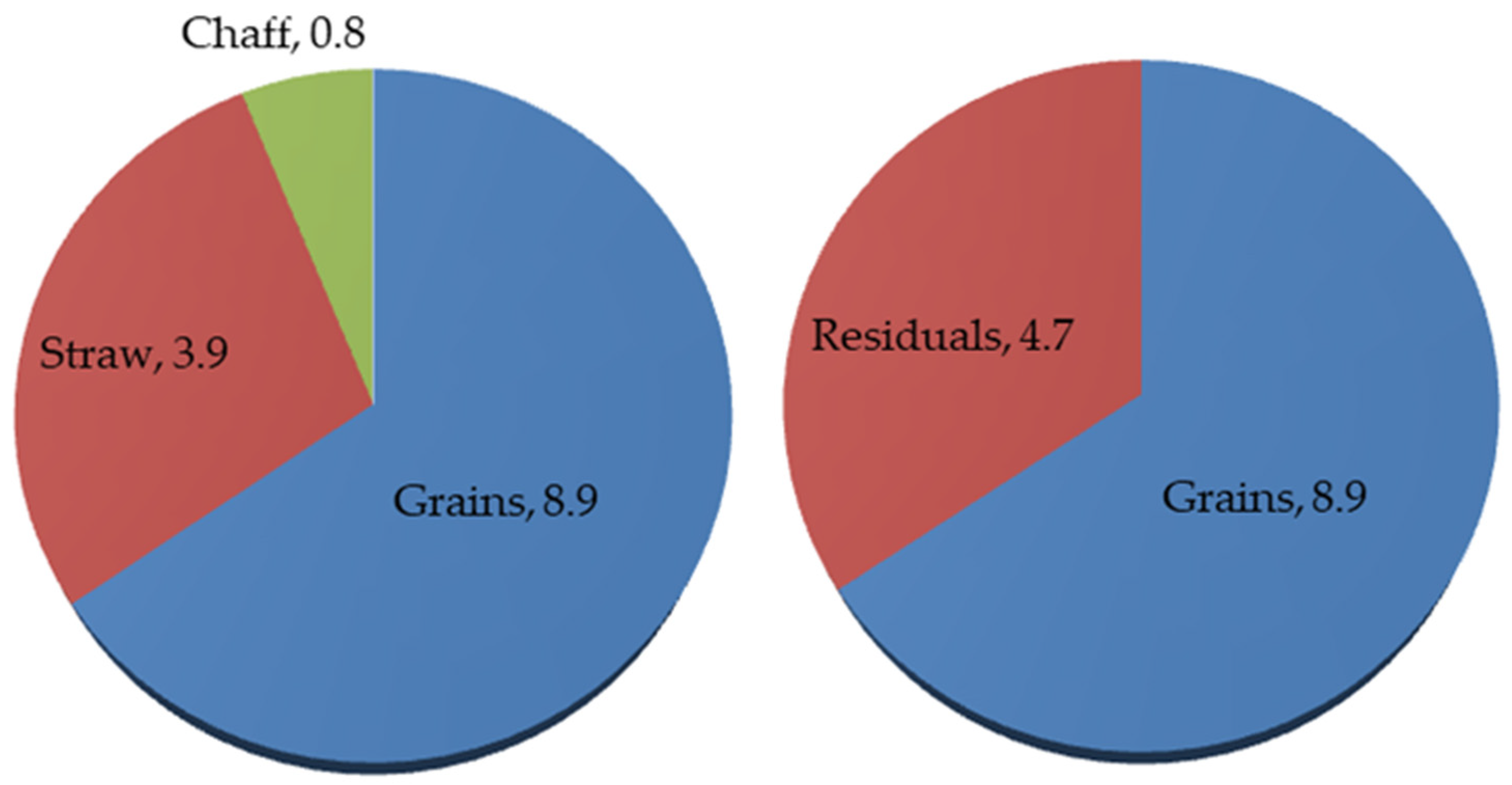

3.1. Biomass Fractions

3.2. Performance of the Combine

3.3. Performance of the Baler

3.4. Losses of Biomass during the Baling Stage

3.5. Cost Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Eise, J.; Foster, K. How to Feed World; Island Press Center for Resource Economics: Washington, DC, USA, 2018; pp. 1–250. [Google Scholar]

- European Parliament. DIRECTIVE (EU) 2015/1513 of the european parliament and of the council of 9 September 2015 amending Directive 98/70/EC relating to the quality of petrol and diesel fuels and amending Directive 2009/28/EC on the promotion of the use of energy from renewabl. Off. J. Eur. Union 2015, L239/1, 20–30. [Google Scholar]

- EU. A 2030 Framework for Climate and Energy Policies. European Parliament Resolution of 5 February 2014 on a 2030 Framework for Climate and Energy Policies (2013/2135(INI)). 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52014IP0094&from=EN (accessed on 18 January 2020).

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar]

- Paiano, A.; Lagioia, G. Energy potential from residual biomass towards meeting the EU renewable energy and climate targets. The Italian case. Energy Policy 2016, 91, 161–173. [Google Scholar] [CrossRef]

- Mann, M.E.; Cohen, R.D.H.; Kernan, J.A.; Nicholson, H.H.; Christensen, D.A.; Smart, M.E. The feeding value of ammoniated flax straw, wheat straw and wheat chaff for beef cattle. Anim. Feed Sci. Technol. 1988, 21, 57–66. [Google Scholar] [CrossRef]

- Ionel, I.; Cioablǎ, A.E. Biogas production based on agricultural residues. From history to results and perspectives. WSEAS Trans. Environ. Dev. 2010, 6, 591–603. [Google Scholar]

- Fang, G.; Shen, K. Wheat straw pulping for paper and paperboard production. In Global Wheat Production; InTech Open: London, UK, 2018; pp. 223–240. [Google Scholar]

- Hýsek, Š.; Čermák, J.; Lexa, M. Influence of lignocellulosic waste pre-treatment on the characteristics of bond rupture. Sustainability 2019, 11, 4784. [Google Scholar] [CrossRef]

- Swain, M.R.; Singh, A.; Sharma, A.K.; Tuli, D.K. Bioethanol production from rice—And wheat straw: An overview. In Bioethanol Production from Food Crops; Ray, R.C., Ramachandran, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 213–231. ISBN 978-0-12-813766-6. [Google Scholar]

- Yang, Y.; Ma, S.; Zhao, Y.; Jing, M.; Xu, Y.; Chen, J. A field experiment on enhancement of crop yield by rice straw and corn stalk-derived biochar in Northern China. Sustainability 2015, 7, 13713–13725. [Google Scholar] [CrossRef]

- Seglah, P.A.; Wang, Y.; Wang, H.; Bi, Y. Estimation and efficient utilization of straw resources in Ghana. Sustainability 2019, 11, 4172. [Google Scholar] [CrossRef]

- McCartney, D.H.; Block, H.C.; Dubeski, P.L.; Ohama, A.J. Review: The composition and availability of straw and chaff from small grain cereals for beef cattle in western Canada. Can. J. Anim. Sci. 2006, 86, 443–455. [Google Scholar] [CrossRef]

- EU. Eurostat Database, Cereals for the Production of Grain (Including Seed) by Area, Production and Humidity. 2019. Available online: https://ec.europa.eu/eurostat/databrowser/view/tag00027/default/table?lang=en (accessed on 18 January 2020).

- Rönnbäck, M.; Lundin, G. Simultaneous harvesting of straw and chaff for energy purposes-influence on bale density, yield, field drying process and combustion characteristics. In Proceedings of the XVIIth World Congress of the International Commission of Agricultural and Biosystems Engineering (CIGR) Hosted by the Canadian Society for Bioengineering (CSBE/SCGAB), Québec City, QU, Canada, 13–17 June 2010. [Google Scholar]

- Weiß, B.D.; Glasner, C. Evaluation of the process steps of pretreatment, pellet production and combustion for an energetic utilization of wheat chaff. Front. Environ. Sci. 2018, 6, 1–10. [Google Scholar] [CrossRef]

- Zhang, H.; Lopez, P.C.; Holland, C.; Lunde, A.; Ambye-Jensen, M.; Felby, C.; Thomsen, S.T. The multi-feedstock biorefinery—Assessing the compatibility of alternative feedstocks in a 2G wheat straw biorefinery process. GCB Bioenergy 2018, 10, 946–959. [Google Scholar] [CrossRef]

- Shirtliffe, S.J.; Entz, M.H. Chaff collection reduces seed dispersal of wild oat (avena fatua) by a combine harvester. Weed Sci. 2005, 53, 465–470. [Google Scholar] [CrossRef]

- Uardi, A.; Saia, S.; Stefanoni, W.; Gunnarsson, C.; Sundberg, M.; Pari, L. Admixing chaff with straw increased the residues collected without compromising machinery efficiencies. Energie 2020, 13, 1766. [Google Scholar]

- Walsh, M.; Newman, P.; Powles, S. Targeting weed seeds in-crop: A new weed control paradigm for global agriculture. Weed Technol. 2013, 27, 431–436. [Google Scholar] [CrossRef]

- Jacobs, A.; Kingwell, R. The harrington seed destructor: Its role and value in farming systems facing the challenge of herbicide-resistant weeds. Agric. Syst. 2016, 142, 33–40. [Google Scholar] [CrossRef]

- Walsh, M.J.; Harrington, R.B.; Powles, S.B. Harrington seed destructor: A new nonchemical weed control tool for global grain crops. Crop Sci. 2012, 52, 1343–1347. [Google Scholar] [CrossRef]

- Unger, J.S.; Glasner, C. Cost analysis of chaff harvesting concepts in Germany. Agronomy 2019, 9, 579. [Google Scholar] [CrossRef]

- Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a combine harvester with turbine technology increases the recovery of residual biomass from cereal crops via the collection of chaff. Energies 2020, 13, 1572. [Google Scholar] [CrossRef]

- Pari, L.; Toscano, G.; Suardi, A.; Bergonzoli, S.; Lopez, E.; Scarfone, A.; Alfano, V. Maize cob and cereal chaff: Feedstocks for energy production. Eur. Biomass Conf. Exhib. Proc. 2018, 2018, 279–282. [Google Scholar]

- Bergonzoli, S.; Suardi, A.; Rezaie, N.; Alfano, V.; Pari, L. An innovative system for maize cob and wheat chaff harvesting: Simultaneous grain and residues collection. Energies 2020, 13, 1265. [Google Scholar] [CrossRef]

- Gerling, M.; Dickey, P.C. Absorbant Animal Bedding. U.S. Patent No 5,878,696, 9 March 1999. Available online: https:/patentimages.storage.googleapis.com/aa/1d/1d/5d9a9f2a556454/US5878696.pdf (accessed on 25 February 2020).

- Anisuzzaman, M.; Chowdhury, S.D. Use of four types of litter for rearing broilers. Br. Poult. Sci. 1996, 37, 541–545. [Google Scholar] [CrossRef] [PubMed]

- Swain, B.K.; Sundaram, R.N.S. Effect of different types of litter material for rearing broilers. Br. Poult. Sci. 2000, 41, 261–262. [Google Scholar] [CrossRef] [PubMed]

- Shishkin, V.; Shulzhenko, E. The study of soybean chaff pressing process depending on its fractional composition and humidity. Bull. Sci. Pract. 2019, 5, 160–164. [Google Scholar] [CrossRef] [PubMed]

- Trinh Van, Q.; Nagy, S. The influence of temperature on the briquetting of ground post agglomerated spelt chaff. Mech. Hulladékkezeles 2019, 13, 13–18. [Google Scholar]

- EU. Agroinlog—Integrated Biomass Logistic Centres fo the Agro-Industry. Available online: https://ec.europa.eu/eip/agriculture/en/news/agroinlog-integrated-biomass-logistics-centres (accessed on 26 May 2020).

- Thiérart Etude. Conception et Réalisation de Machines Spéciales. Available online: https://www.thierart.fr/ (accessed on 17 January 2020).

- NSAI. ISO. ISO 18134-2:2017 Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method 2017. Available online: https://www.iso.org/standard/71536.html (accessed on 6 March 2020).

- Assirelli, A.; Croce, S.; Acampora, A.; Civitarese, V.; Suardi, A.; Santangelo, E.; Pari, L. An innovative system for conditioning biomass [sorghum bicolo (l.) moench.]. Am. Soc. Agric. Biol. Eng. 2013, 56, 829–837. [Google Scholar]

- ISO 17828:2015 Solid Biofuels—Determination of Bulk Density. 2015. Available online: https://www.iso.org/obp/ui/#iso:std:iso:17828:ed-1:v1:en (accessed on 23 December 2015).

- American society of agricultural engineers agricultural machinery management. Agricultural Machinery Management; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2000; pp. 344–349. [Google Scholar]

- Assirelli, A.; Pignedoli, S. Costo di esercizio delle macchine agricole. Boll. CRPA Not. 2005, 5, 1–10. [Google Scholar]

- Banca d’Italia. Banca d’Italia Lending Rate. Available online: https://www.bancaditalia.it/ (accessed on 11 November 2019).

- Camera di Commercio di Modena (Chamber of Commerce of Modena). Listino dei prezzi all’ingrosso rilevati sul mercato di Modena nella settimana dal 16 luglio al 22 luglio 2019 (List of Wholesale Prices Recorded on the Modena Market in the Week from 16 July to 22 July 2019). 2019. Available online: https://www.mo.camcom.it/tutela-del-mercato/borsamerci/listini/listino-dei-prezzi-allingrosso-rilevati-sul-mercato-di-modena-nella-settimana-dal-16-al-22-luglio-2019 (accessed on 6 March 2020).

- R Development Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2008; ISBN 3-900051-07-0. [Google Scholar]

- Glasner, C.; Vieregge, C.; Robert, J.; Fenselau, J.; Bitarafan, Z.; Andreasen, C. Evaluation of new harvesting methods to reduce weeds on arable fields and collect a new feedstock. Energies 2019, 12, 1688. [Google Scholar] [CrossRef]

- INRA. Recuperateur de Menues Pailles «turbo Paille de Thievin». Mignaloux-Beauvoir. 2011. Available online: https://geco.ecophytopic.fr/documents/20182/21720/upload_00011189_pdf (accessed on 6 March 2020).

- CUMA. Journée Technique: Récuperation des Menues Pailles. 2015. Available online: http://draaf.normandie.agriculture.gouv.fr/IMG/pdf/6_Powerpoint_journee_menues_pailles_FRCUMA_cle0bd622.pdf (accessed on 6 March 2020).

- Mesterházy, A.; Oláh, J.; Popp, J. Losses in the grain supply chain: Causes and solutions. Sustainability 2020, 12, 2342. [Google Scholar] [CrossRef]

| Unit | Harvesting | Baling | |||||

|---|---|---|---|---|---|---|---|

| Machine | Combine harvester | Tractor | |||||

| Power | [kW] | 208.8 | 115.6 | ||||

| Operating machine | Thierart | Trailer | Baler | ||||

| Financial cost | Investment | [€] | 230,980 | 10,000 | 7000 | 110,127 | 30,463 |

| Service life | [y] | 10 | 10 | 10 | 10 | 8 | |

| Service life | [h] | 3000 | 3000 | 3000 | 14,000 | 2500 | |

| Resale | [%] | 19 | 18 | 18 | 32 | 23 | |

| Resale | [€] | 44,139 | 1768 | 1238 | 40,524 | 6878 | |

| Depreciation | [€] | 186,841 | 8232 | 5762 | 69,603 | 23,585 | |

| Annual usage | [h·y−1] | 480 | 480 | 480 | 307 | 307 | |

| Interest rate | [%] | 3 | 3 | 3 | 3 | 3 | |

| Workers | [n] | 1 | - | - | 1 | - | |

| Fixed costs | Ownership costs | [€·y−1] | 18,684.09 | 823.16 | 576.21 | 11,009.49 | 2948.11 |

| Interests | [€·y−1] | 4126.79 | 176.53 | 123.57 | 1652.39 | 560.12 | |

| machine shelter | [m2] | 62.30 | 0.00 | 10.20 | 9.12 | 6.93 | |

| Value of the shelter | [€·m−2] | 100.00 | 0.00 | 100.00 | 100.00 | 100.00 | |

| Value of the shelter | [€·y−1] | 124.59 | 0.00 | 30.60 | 27.36 | 20.79 | |

| Insurance (0.25%) | [€·y−1] | 577.45 | 0.00 | 17.50 | 275.32 | 76.16 | |

| Variable costs | Repair factor | [%] | 40.00 | 45.00 | 80.00 | 80.00 | 90.00 |

| Repairs and maintenance | [€·h−1] | 49.28 | 2.40 | 2.99 | 1.38 | 10.78 | |

| Fuel cost | [€·l−1] | 0.57 | 0.57 | ||||

| Fuel consumption | [L·h−1] | 32.51 | 11.60 | ||||

| Fuel cost | [€·h−1] | 18.66 | 6.66 | ||||

| Lubricant cost | [€·l−1] | 3.03 | 3.03 | ||||

| Lubricant consumption | [L·h−1] | 0.14 | 0.09 | ||||

| Lubricant consumption | [€·h−1] | 0.44 | 0.27 | ||||

| Worker salary | [€·h−1] | 11.50 | 11.50 | ||||

| Cost of baling string | [€·h−1] | 32.32 | |||||

| Unit | Harvesting | Baling | ||||

|---|---|---|---|---|---|---|

| Machine | Combine harvester | Tractor | ||||

| Power | [kW] | 208.8 | 115.6 | |||

| Operating machine | Thierart | Baler | ||||

| Financial cost | Investment | [€] | 230,980 | 10,000 | 110,127 | 30,463 |

| Service life | [y] | 10 | 10 | 10 | 8 | |

| Service life | [h] | 3000 | 3000 | 14,000 | 2500 | |

| Resale | [%] | 19 | 18 | 32 | 23 | |

| Resale | [€] | 44,139 | 1768 | 40,524 | 6878 | |

| Depreciation | [€] | 186,841 | 8232 | 69,603 | 23,585 | |

| Annual usage | [h·y−1] | 480 | 480 | 307 | 307 | |

| Interest rate | [%] | 3 | 3 | 3 | 3 | |

| Workers | [n] | 1 | 1 | |||

| Fixed costs | Ownership costs | [€·y−1] | 18,684.09 | 823.16 | 11,009.49 | 2948.11 |

| Interests | [€·y−1] | 4126.79 | 176.53 | 1652.39 | 560.12 | |

| Machine shelter | [m2] | 62.30 | 9.12 | 9.89 | ||

| Value of the shelter | [€·m−2] | 100.00 | 100.00 | 100.00 | ||

| Value of the shelter | [€·y−1] | 124.59 | 27.36 | 29.67 | ||

| Insurance (0.25%) | [€·y−1] | 577.45 | 275.32 | 76.16 | ||

| Variable costs | Ownership costs | [%] | 40.00 | 45.00 | 80.00 | 90.00 |

| Repairs and maintenance | [€·h−1] | 49.28 | 2.40 | 1.38 | 10.78 | |

| Fuel cost | [€·L−1] | 0.57 | 0.57 | |||

| Fuel consumption | [L·h−1] | 32.51 | 10.7 | |||

| Fuel cost | [€·h−1] | 18.66 | 6.14 | |||

| Lubricant cost | [€·L−1] | 3.03 | 3.03 | |||

| Lubricant consumption | [L·h−1] | 0.14 | 0.09 | |||

| Lubricant consumption | [€·h−1] | 0.44 | 0.27 | |||

| Worker salary | [€·h−1] | 11.50 | 11.50 | |||

| Cost of baling string | [€·h−1] | 32.32 | ||||

| Treatment | Product | Market Price | Yield | Revenue | Economic Allocation | |

|---|---|---|---|---|---|---|

| [€·t−1] | [t·ha−1] | [€·ha−1] | Harvesting [%] | Baling [%] | ||

| CoT | Grain | 198.5 1 | 9.83 | 1951.26 | 89.2 | 0.0 |

| Straw | 50 1 | 3.88 | 194 | 8.9 | 100.0 | |

| Chaff | 50 1 | 0.84 | 42 | 1.9 | 0.0 | |

| Total | 2187.26 | 100.0 | 100.0 | |||

| CoS | Grain | 198.5 | 9.5 | 1881.78 | 88.9 | 0.0 |

| Straw | 50 | 3.9 | 194 | 9.2 | 83.0 | |

| Chaff | 0 | 0.8 | 40 | 1.9 | 17.0 | |

| Total | 2115.78 | 100.0 | 100.0 | |||

| Treatment | TFC | EFC | FE | MC | |

|---|---|---|---|---|---|

| [ha·h−1] | [ha·h−1] | [%] | [tgrain·h−1] | [tresidue·h−1] | |

| CoT | 2.17 ± 0.20 | 1.02 ± 0.18 | 47 ± 5 | 9.87 ± 0.82 | 0.84 ± 0.05 |

| CoS | 2.34 ± 0.43 | 1.71 ± 0.36 | 73 ± 8 | 16.22 ± 3.49 | - |

| ANOVA | ns | * | ** | * | |

| Treatment | TFC | EFC | FE | MC |

|---|---|---|---|---|

| [ha·h−1] | [ha·h−1] | [%] | [t·h−1] ⸸ | |

| CoT | 2.86 ± 0.43 | 1.92 ±0.09 | 68 ± 7 | 7.47 ± 0.85 |

| CoS | 2.21 ± 0.25 | 1.57 ± 0.15 | 71 ± 2 | 7.37 ± 0.38 |

| ANOVA | ns | * | ns | ns |

| Treatment | Machine | Yield | ||||

|---|---|---|---|---|---|---|

| Grain | Residue | Bale Weight | Bale Density | Chaff Bulk Density | ||

| [t·ha−1] | [t·ha−1] | [kg] | [kg·m−3] | [kg·m−3] | ||

| CoT | Combine | 9.83 ± 1.26 | 0.84 ± 0.12 | - | - | 41.75 ± 3.30 |

| Baling | - | 3.88 ± 0.06 | 184.6 ± 4.41 | 76.78 ± 1.83 | - | |

| CoS | Combine | 9.48 ± 0.45 | - | - | - | - |

| Baling | - | 4.68 ± 0.23 | 198.4 ± 3.14 | 82.22 ± 1.33 | - | |

| ANOVA | ns | ns ⸸ | * | * | ||

| Unit | Grain | Straw | Chaff | Total Harvesting Costs | ||

|---|---|---|---|---|---|---|

| Market price | [€·t−1] | 198.5 | 50 | 50 | ||

| Yield | [t·ha−1] | 9.83 | 3.88 | 0.84 | ||

| Harvesting | Cost allocation | [%] | 89% | 9% | 2% | 100% |

| Combine harvester + Twin stage turbine + Wagon | [€·h−1] | 123.01 | 12.23 | 2.65 | 137.89 | |

| [€·ha−1] | 120.6 | 11.99 | 2.6 | 135.18 | ||

| [€·t−1] | 12.27 | 3.09 | 3.09 | 18.45 | ||

| Baling | Cost allocation | [%] | 0% | 100% | 0% | 100% |

| Tractor + Baler | [€·h−1] | 116.85 | 116.85 | |||

| [€·ha−1] | 60.86 | 60.86 | ||||

| [€·t−1] | 15.69 | 15.69 | ||||

| Total cost of the harvesting system | [€·h−1] | 123.01 | 129.08 | 2.65 | 254.74 | |

| [€·ha−1] | 120.6 | 72.85 | 2.6 | 196.04 | ||

| [€·t−1] | 12.27 | 18.78 | 3.09 | |||

| Unit | Grain | Straw | Chaff | Total Harvesting Costs | ||

|---|---|---|---|---|---|---|

| Market price | [€·t−1] | 198.5 | 50 | 50 | ||

| Yield | [t·ha−1] | 9.48 | 3.88 | 0.8 | ||

| Harvesting | Cost allocation | [%] | 89% | 9% | 2% | 100% |

| Combine harvester + Twin stage turbine | [€·h−1] | 118.59 | 12.23 | 2.52 | 133.34 | |

| [€·ha−1] | 69.35 | 7.15 | 1.47 | 77.98 | ||

| [€·t−1] | 7.32 | 1.84 | 1.84 | 11 | ||

| Baling | Cost allocation | [%] | 83% | 17% | 100% | |

| Tractor + Baler | [€·h−1] | 96.47 | 19.89 | 116.36 | ||

| [€·ha−1] | 61.45 | 12.67 | 74.12 | |||

| [€·t−1] | 15.84 | 15.84 | 31.67 | |||

| Total cost of the harvesting system | [€·h−1] | 118.59 | 108.7 | 22.41 | 249.7 | |

| [€·ha−1] | 69.35 | 68.6 | 14.14 | 152.09 | ||

| [€·t−1] | 7.32 | 17.68 | 17.68 | |||

| Treatment | Product | Yield | Market Price | Revenue | Harvesting Costs | Net Gain |

|---|---|---|---|---|---|---|

| [t·ha−1] | [€·t−1] | [€·ha−1] | [€·ha−1] | [€·ha−1] | ||

| CoT | Seed | 9.83 | 198.50 | 1951.26 | 120.60 | 1830.66 |

| Straw | 3.88 | 50.00 | 194.00 | 72.85 | 121.15 | |

| Chaff | 0.84 | 50.00 | 42.00 | 2.60 | 39.40 | |

| Total | 14.55 | - | 2187.26 | 196.05 | 1991.21 | |

| CoS | Seed | 9.48 | 198.50 | 1881.78 | 69.35 | 1812.43 |

| Straw | 3.88 | 50.00 | 194.00 | 68.60 | 125.40 | |

| Chaff | 0.80 | 50.00 | 40.00 | 14.14 | 25.86 | |

| Total | 14.16 | 2115.78 | 152.09 | 1963.69 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suardi, A.; Stefanoni, W.; Bergonzoli, S.; Latterini, F.; Jonsson, N.; Pari, L. Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability 2020, 12, 4936. https://doi.org/10.3390/su12124936

Suardi A, Stefanoni W, Bergonzoli S, Latterini F, Jonsson N, Pari L. Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability. 2020; 12(12):4936. https://doi.org/10.3390/su12124936

Chicago/Turabian StyleSuardi, Alessandro, Walter Stefanoni, Simone Bergonzoli, Francesco Latterini, Nils Jonsson, and Luigi Pari. 2020. "Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis" Sustainability 12, no. 12: 4936. https://doi.org/10.3390/su12124936

APA StyleSuardi, A., Stefanoni, W., Bergonzoli, S., Latterini, F., Jonsson, N., & Pari, L. (2020). Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability, 12(12), 4936. https://doi.org/10.3390/su12124936