Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study

Abstract

1. Introduction

2. Materials and Methods

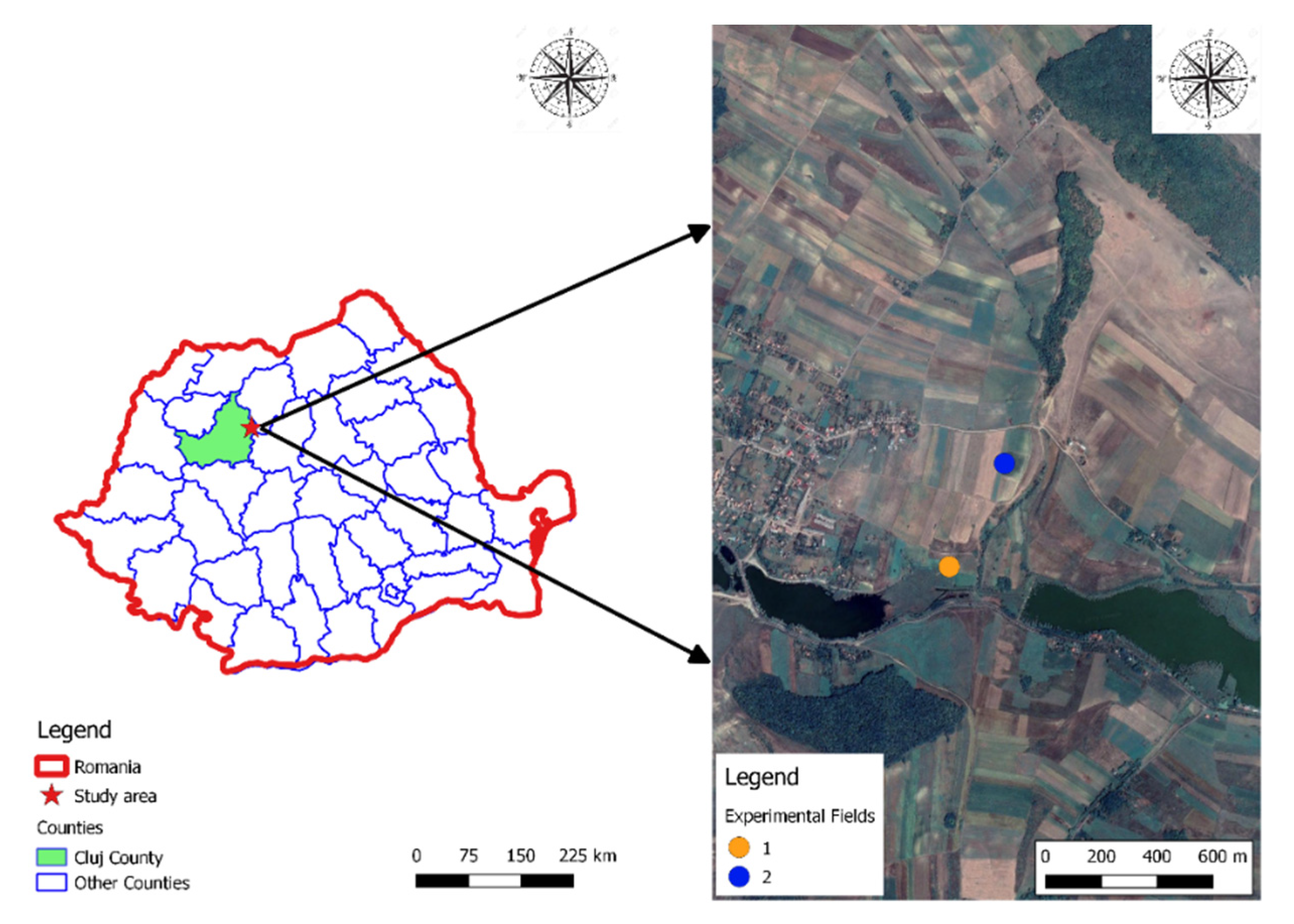

2.1. Study Sites

2.2. Crop Characteristics and Management of the by-Products

2.3. Data Sampling and Measurements

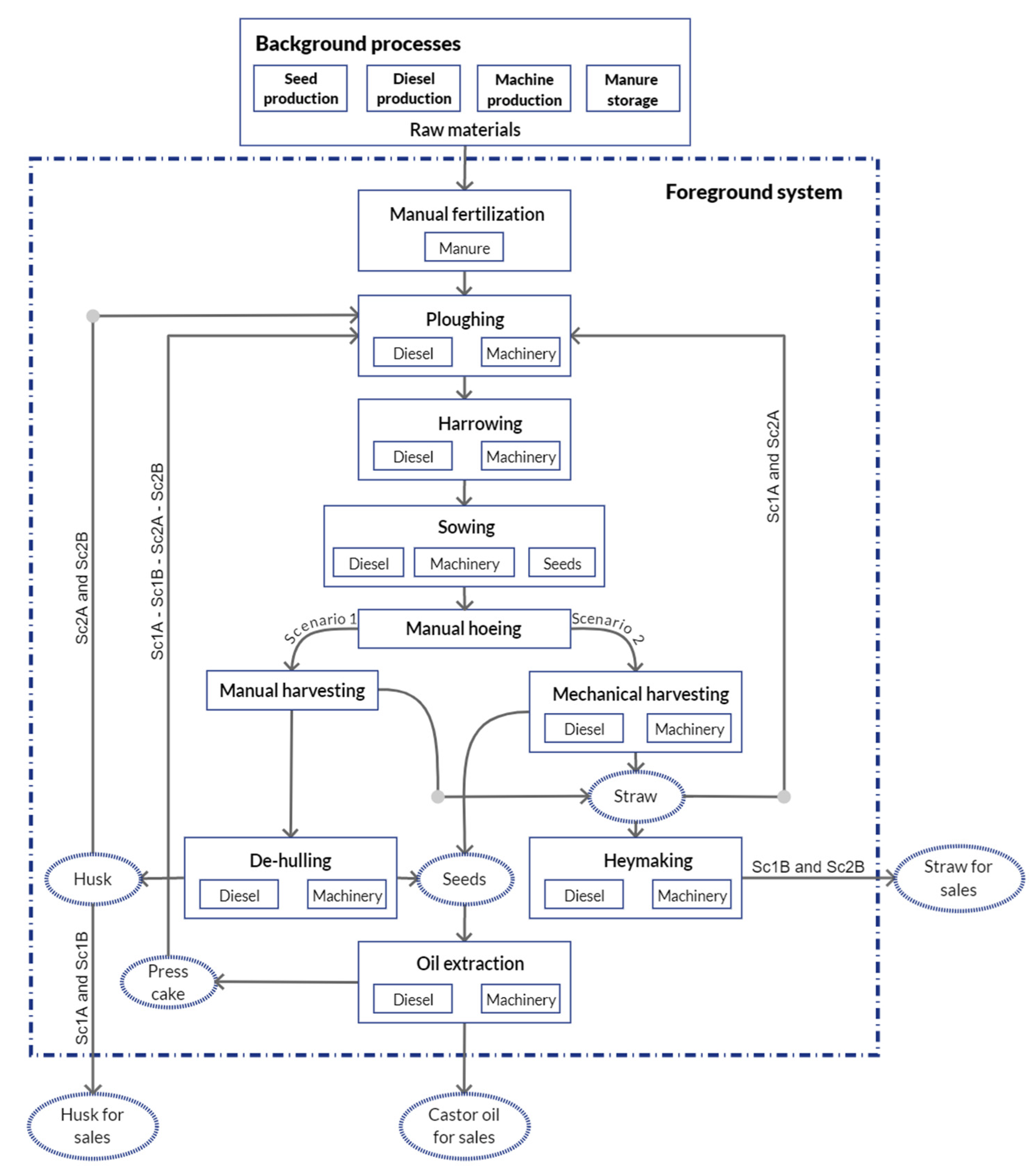

2.4. Life Cycle Assessment of Castor Oil Supply Chain

2.4.1. Goal Definition and Scoping

2.4.2. Life Cycle Inventory Analysis

2.4.3. Land Use Change (LUC)

- GHGres = Greenhouse gases emissions from soil incorporation of residue “i” per scenario (Mg CO2 ha−1)

- Resi = Amount of residue “i” incorporated into the soil (Mg ha−1)

- awCO2 = atomic weight of carbon dioxide equal to 44/12

2.4.4. Life Cycle Impact Assessment

2.5. Economic Assessment

3. Results and Discussions

3.1. LCA

3.2. Economic Assessment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAO (Food and Agriculture Organization). Global agriculture towards 2050. In Proceedings of the High Level Expert Forum—How to Feed the World, Rome, Italy, 12–13 October 2009; Volume 2050, pp. 1–4. [Google Scholar]

- IEA (International Energy Agency). World Energy Outlook—Executive Summary; IEA: Paris, France, 2018; Volume 11. [Google Scholar]

- ICCT (Internationa Council on Clean Transportation). The European Commission’s Renewable Energy Proposal for 2030; ICCT: Berlin, Germany, 2017; Volume 8. [Google Scholar]

- Zafeiriou, E.; Karelakis, C. Income volatility of energy crops: The case of rapeseed. J. Clean. Prod. 2016, 122, 113–120. [Google Scholar] [CrossRef]

- Makanju, A.; Bello, E.I. Production, characterization and evaluation of castor oil biodiesel as alternative fuel for diesel engines. J. Emerg. Trends Eng. Appl. Sci. 2011, 2, 525–530. [Google Scholar]

- Alexopoulou, E.; Papatheohari, Y.; Zanetti, F.; Tsiotas, K.; Papamichael, I.; Christou, M.; Namatov, I.; Monti, A. Comparative studies on several castor (Ricinus communis L.) hybrids: Growth, yields, seed oil and biomass characterization. Ind. Crops Prod. 2015, 75, 8–13. [Google Scholar] [CrossRef]

- Murphy, C.B. Compound Annual Growth Rate—CAGR. Available online: https://www.investopedia.com/terms/c/cagr.asp (accessed on 22 June 2020).

- Ghosal, S. Castor Oil Prices Spike 23% in Global Market. Available online: https://economictimes.indiatimes.com/markets/commodities/news/castor-oil-prices-spike-23-in-global-market/articleshow/69089709.cms (accessed on 22 June 2020).

- Bateni, H.; Karimi, K.; Zamani, A.; Benakashani, F. Castor plant for biodiesel, biogas, and ethanol production with a biorefinery processing perspective. Appl. Energy 2014, 136, 14–22. [Google Scholar] [CrossRef]

- Mensah, M.B.; Awudza, J.A.M.; O’Brien, P. Castor oil: A suitable green source of capping agent for nanoparticle syntheses and facile surface functionalization. R. Soc. Open Sci. 2018, 5, 180824. [Google Scholar] [CrossRef]

- Huang, H.; Yu, N.; Wang, L.; Gupta, D.K.; He, Z.; Wang, K.; Zhu, Z.; Yan, X.; Li, T.; Yang, X. The phytoremediation potential of bioenergy crop Ricinus communis for DDTs and cadmium co-contaminated soil. Bioresour. Technol. 2011, 102, 11034–11038. [Google Scholar] [CrossRef]

- Rajkumar, M.; Freitas, H. Influence of metal resistant-plant growth-promoting bacteria on the growth of Ricinus communis in soil contaminated with heavy metals. Chemosphere 2008, 71, 834–842. [Google Scholar] [CrossRef]

- Pandey, V.C. Suitability of Ricinus communis L. cultivation for phytoremediation of fly ash disposal sites. Ecol. Eng. 2013, 57, 336–341. [Google Scholar] [CrossRef]

- Helling, R.K.; Russell, D.A. Use of life cycle assessment to characterize the environmental impacts of polyol production options. Green Chem. 2009, 11, 380–389. [Google Scholar] [CrossRef]

- Amouri, M.; Mohellebi, F.; Zaïd, T.A.; Aziza, M. Sustainability assessment of Ricinus communis biodiesel using LCA approach. Clean Technol. Environ. Policy 2017, 19, 749–760. [Google Scholar] [CrossRef]

- Parascanu, M.M.; Puig-Gamero, M.; Soreanu, G.; Valverde, J.L.; Sanchez-Silva, L. Comparison of three Mexican biomasses valorization through combustion and gasification: Environmental and economic analysis. Energy 2019, 189, 116095. [Google Scholar] [CrossRef]

- Liang, S.; Xu, M.; Zhang, T. Life cycle assessment of biodiesel production in China. Bioresour. Technol. 2013, 129, 72–77. [Google Scholar] [CrossRef] [PubMed]

- Adewale, C.; Reganold, J.P.; Higgins, S.; Evans, R.D.; Carpenter-Boggs, L. Agricultural carbon footprint is farm specific: Case study of two organic farms. J. Clean. Prod. 2019, 229, 795–805. [Google Scholar] [CrossRef]

- Mittal, J.P.; Dhawan, K.C.; Thyagraj, C.R. Energy scenario of castor crop under dryland agriculture of Andhra Pradesh. Energy Convers. Manag. 1991, 32, 425–430. [Google Scholar] [CrossRef]

- Parascanu, M.M.; Sandoval-Salas, F.; Soreanu, G.; Valverde, J.L.; Sanchez-Silva, L. Valorization of Mexican biomasses through pyrolysis, combustion and gasification processes. Renew. Sustain. Energy Rev. 2017, 71, 509–522. [Google Scholar] [CrossRef]

- Perea-Moreno, M.-A.; Manzano-Agugliaro, F.; Hernandez-Escobedo, Q.; Perea-Moreno, A.-J. Peanut shell for energy: Properties and its potential to respect the environment. Sustainability 2018, 10, 3254. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO (International Organization for Standardization). Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO 14044:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Palmieri, N.; Forleo, M.B.; Giannoccaro, G.; Suardi, A.; Pari, L. Environmental and economic performance of cereal straw end-practices. In Proceedings of the 25th European Biomass Conference and Exhibition, Stockholm, Sweden, 12–15 June 2017; Volume 2017. [Google Scholar]

- Ekvall, T.; Azapagic, A.; Finnveden, G.; Rydberg, T.; Weidema, B.P.; Zamagni, A. Attributional and consequential LCA in the ILCD handbook. Int. J. Life Cycle Assess. 2016, 21, 293–296. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- McManus, M.C.; Taylor, C.M. The changing nature of life cycle assessment. Biomass Bioenergy 2015, 82, 13–26. [Google Scholar] [CrossRef]

- De Boer, I.J.M. Environmental impact assessment of conventional and organic milk production. Livest. Prod. Sci. 2003, 80, 69–77. [Google Scholar] [CrossRef]

- Notarnicola, B.; Salomone, R.; Petti, L.; Renzulli, P.A.; Roma, R.; Cerutti, A.K. Life Cycle Assessment in the Agri-Food Sector: Case Studies, Methodological Issues and Best Practices; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 3319119400. [Google Scholar]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.; Ventura, A. LCA allocation procedure used as an incitative method for waste recycling: An application to mineral additions in concrete. Resour. Conserv. Recycl. 2010, 54, 1231–1240. [Google Scholar] [CrossRef]

- Vásquez Lavin, F.; Barrientos, M.; Castillo, Á.; Herrera, I.; Ponce Oliva, R.D. Firewood certification programs: Key attributes and policy implications. Energy Policy 2020, 137, 111160. [Google Scholar] [CrossRef]

- Brentrup, F.; Kusters, J.; Lammel, J.; Kuhlmann, H. Methods to estimate on-field nitrogen emissions from crop production as an input to LCA studies in the agricultural sector. Int. J. Life Cycle Assess. 2000, 5, 349–357. [Google Scholar] [CrossRef]

- Dalla Riva, A.; Kristensen, T.; De Marchi, M.; Kargo, M.; Jensen, J.; Cassandro, M. Carbon footprint from dairy farming system: Comparison between Holstein and Jersey cattle in Italian circumstances. Acta Agrar. Kvár. 2014, 18, 75–80. [Google Scholar]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. IPCC Guidelines for National Greenhouse Gas Inventories; Agriculture, Forestry and Other Land Use; IPCC: Hayama, Japan, 2006; Volume 4. [Google Scholar]

- ISPRA (Istituto Superiore per la Protezione e la Ricerca Ambientale). Agricoltura—Inventario Nazionale delle Emissioni e Disaggregazione Provinciale (Agriculture—National Emission Inventory and Provincial Breakdown); Report 85/2008; ISPRA: Rome, Italy, 2008; ISBN 9788844805012.

- Falconi, F.; Neri, P.; Borsari, A.; Bombardieri, R.; Di Stefano, M.; Brambilla, C.; Querzola, F. Analisi Ambientale del Ciclo di Vita della Produzione di Latte da Allevamento Biologico e Confronto con la Convenzionale. In ENEA e UTS Protezione e Sviluppo dell’Ambiente e del Territorio; ENEA: Rome, Italy, 2005. [Google Scholar]

- Battini, F.; Agostini, A.; Tabaglio, V.; Amaducci, S. Environmental impacts of different dairy farming systems in the Po Valley. J. Clean. Prod. 2016, 112, 91–102. [Google Scholar] [CrossRef]

- Ruíz-Valdiviezo, V.M.; Mendoza-Urbina, L.D.; Luna-Guido, M.; Gutiérrez-Miceli, F.A.; Cárdenas-Aquino, M.R.; Montes-Molina, J.A.; Dendooven, L. Emission of CO2, CH4 and N2O and dynamics of mineral N in soils amended with castor bean (Ricinus communis L.) and piñón (Jatropha curcas L.) seed cake. Plant Soil Environ. 2013, 59, 51–56. [Google Scholar]

- Forleo, M.B.; Palmieri, N.; Suardi, A.; Coaloa, D.; Pari, L. The eco-efficiency of rapeseed and sunflower cultivation in Italy. Joining environmental and economic assessment. J. Clean. Prod. 2017, 172, 3138–3153. [Google Scholar] [CrossRef]

- Lal, R.; Stewart, B.A. Soil-Specific Farming: Precision Agriculture; Advances in Soil Science; CRC Press: Boca Raton, FL, USA, 2015; ISBN 9781482245349. [Google Scholar]

- Grace, P.R.; Harrington, L.; Jain, M.; Robertson, G.P. Long-Term sustainability of the tropical and subtropical rice-wheat system: An environmental perspective. Improv. Product. Sustain. Rice Wheat Syst. Issues Impacts 2003, 65, 27–43. [Google Scholar]

- Iriarte, A.; Rieradevall, J.; Gabarrell, X. Life cycle assessment of sunflower and rapeseed as energy crops under Chilean conditions. J. Clean. Prod. 2010, 18, 336–345. [Google Scholar] [CrossRef]

- Rigamonti, L.; Borghi, G.; Martignon, G.; Grosso, M. Life cycle costing of energy recovery from solid recovered fuel produced in MBT plants in Italy. Waste Manag. 2019, 99, 154–162. [Google Scholar] [CrossRef]

- Brandão, M.; Clift, R.; Milà, L.C.; Basson, L. A life-cycle approach to characterising environmental and economic impacts of multifunctional land-use systems: An integrated assessment in the UK. Sustainability 2010, 2, 3747–3776. [Google Scholar] [CrossRef]

- Koutroubas, S.D.; Papakosta, D.K.; Doitsinis, A. Adaptation and yielding ability of castor plant (Ricinus communis L.) genotypes in a Mediterranean climate. Eur. J. Agron. 1999, 11, 227–237. [Google Scholar] [CrossRef]

- Arnaud, F. The development of castor-oil crops in France. In Il Ricino: Obiettivi, Strategie e Ricerca. Agricoltura Ricerca; Ministero Agricoltura e Foreste Roma: Rome, Italy, 1990. [Google Scholar]

- Anastasi, U.; Sortino, O.; Cosentino, S.L.; Patanè, C. Seed yield and oil quality of perennial castor bean in a Mediterranean environment. Int. J. Plant Prod. 2015, 9, 99–116. [Google Scholar]

- Pari, L.; Latterini, F.; Stefanoni, W. Herbaceous Oil crops, a review on mechanical harvesting state of the art. Agriculture 2020, 10, 309. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, C. Analysis on the research status and structure characteristics of castor harvester. In Proceedings of the 2019 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4–7 August 2019; pp. 415–420. [Google Scholar]

- Palmieri, N.; Forleo, M.B.; Giannoccaro, G.; Suardi, A. Environmental impact of cereal straw management: An on-farm assessment. J. Clean. Prod. 2017, 142, 2950–2964. [Google Scholar] [CrossRef]

- Pari, L.; Palmieri, N.; Forleo, M.B.; Suardi, A.; Coaloa, D.; Friuli, V.G. Lca of oilseed rape production for energy purposes: Sensitivity analysis. In Proceedings of the 20th European Biomass Conference and Exhibition, Milan, Italy, 18–22 June 2012. [Google Scholar]

- Li, S.; Huang, B.; Zhao, F.; Lu, Z.; Wang, X.; Chen, X.; Chen, Y. Environmental impact assessment of agricultural production in Chongming ecological island. Int. J. Life Cycle Assess. 2019, 24, 1937–1947. [Google Scholar] [CrossRef]

- Chatzisymeon, E.; Foteinis, S.; Borthwick, A.G.L. Life cycle assessment of the environmental performance of conventional and organic methods of open field pepper cultivation system. Int. J. Life Cycle Assess. 2017, 22, 896–908. [Google Scholar] [CrossRef]

- Sanz Requena, J.F.; Guimaraes, A.C.; Quirós Alpera, S.; Relea Gangas, E.; Hernandez-Navarro, S.; Navas Gracia, L.M.; Martin-Gil, J.; Fresneda Cuesta, H. Life Cycle Assessment (LCA) of the biofuel production process from sunflower oil, rapeseed oil and soybean oil. Fuel Process. Technol. 2011, 92, 190–199. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Adler, P.R.; Del Grosso, S.J.; Parton, W.J. Life cycle assessment of net greenhouse gas flux for bioenergy cropping systems. Ecol. Appl. 2007, 17, 675–691. [Google Scholar] [CrossRef]

- Malça, J.; Coelho, A.; Freire, F. Environmental life-cycle assessment of rapeseed-based biodiesel: Alternative cultivation systems and locations. Appl. Energy 2014, 114, 837–844. [Google Scholar] [CrossRef]

- Aguilera, E.; Lassaletta, L.; Sanz-Cobena, A.; Garnier, J.; Vallejo, A. The potential of organic fertilizers and water management to reduce N2O emissions in Mediterranean climate cropping systems. A review. Agric. Ecosyst. Environ. 2013, 164, 32–52. [Google Scholar] [CrossRef]

- Spinelli, D.; Jez, S.; Basosi, R. Integrated Environmental Assessment of sunflower oil production. Process Biochem. 2012, 47, 1595–1602. [Google Scholar] [CrossRef]

- Silalertruksa, T.; Bonnet, S.; Gheewala, S.H. Life cycle costing and externalities of palm oil biodiesel in Thailand. J. Clean. Prod. 2012, 28, 225–232. [Google Scholar] [CrossRef]

| Experimental Field | Prevalent Slope [%] | Minimum Slope [%] | Maximum Slope [%] | Prevalent Exposition | Prevalent Altitude [m a.s.l.] | Surface [ha] |

|---|---|---|---|---|---|---|

| 1 | 8.5 | 7.9 | 8.7 | South | 294 | 0.25 |

| 2 | 5.7 | 4.1 | 7.2 | South | 313 | 0.47 |

| Hybrid Cultivar | Height of Plants [cm] | Husks [Mg ha−1] | Seed [Mg ha−1] | Straw Fresh Weight [Mg ha−1] | Harvest Index [%] | |

|---|---|---|---|---|---|---|

| d.w. | ssf.w. | f.w. | d.w. | |||

| C-856 | 74.4 c | 1.40 | 2.80 a | 4.13 b | 0.87 b | 52.5 a |

| C-1030 | 112.8 a | 1.60 | 2.90 a | 8.35 a | 1.61 a | 43.4 b |

| Harvesting Systems | Manual Harvesting | Mechanical Harvesting | |||

|---|---|---|---|---|---|

| Scenarios | Sc1A | Sc1B | Sc2A | Sc2B | |

| Products and co-products | Straw | Soil incorporation | Sale | Soil incorporation | Sale |

| Husk | Sale | Sale | Soil incorporation | Soil incorporation | |

| Press cake | Soil incorporation | Soil incorporation | Soil incorporation | Soil incorporation | |

| Castor oil | Sale | Sale | Sale | Sale | |

| Phases | Product and by-Products | Cultivar Hybrids | |

|---|---|---|---|

| C-856 | C-1030 | ||

| Agricultural phases | Husks with seed | 97.50% | 95.84% |

| Straw | 2.50% | 4.16% | |

| Total | 100.00% | 100.00% | |

| Dehulling | Castor seed | 86.96% | 85.80% |

| Husks | 13.04% | 14.20% | |

| Total | 100.00% | 100.00% | |

| Oil extraction phase | Castor oil | 99.93% | 99.93% |

| Press cake | 0.07% | 0.07% | |

| Total | 100.00% | 100.00% | |

| Agricultural Operation | Manual Fert. | Plough. | Harr. | Sow. | Manual Hoeing | Manual Harv.* | Mech Harv.** | Dehull. | Oil Extrac. |

|---|---|---|---|---|---|---|---|---|---|

| Machinery | |||||||||

| Machinery power (kW) | - | 78 | 78 | 78 | - | - | 146 | 7.7 | 3 |

| Machinery weight (kg) | - | 3750 | 3750 | 3750 | - | - | 10700 | 250 | 1900 |

| Fuel consumption (l ha−1) | - | 45 | 15 | 5 | - | - | 25 | 5.1 | - |

| Lubrificant consumption (l ha−1) | 0.10 | 0.07 | 0.03 | - | - | 0.05 | 0.18 | - | |

| Lifetime (h ha−1) | - | 12,000 | 12,000 | 12,000 | - | - | 3000 | 2000 | - |

| Instrument used (type) | Shovel | Moldboard plow | Rolmako | Row planter | - | - | - | - | - |

| Instrument power (kW) | 66 | 63 | 44 | - | - | - | - | - | |

| Weight instruments (kg) | 1.5 | 795 | 2860 | 830 | - | - | - | - | - |

| Lifetime (h) | 4000 | 2000 | 2000 | 1500 | - | - | - | - | - |

| Product utilized (type) | Manure | - | - | Seeds | - | - | - | - | - |

| Quantity (kg ha−1) | 6000 | - | - | 15 | - | - | - | - | - |

| Emissions | Source |

|---|---|

| Manure storage emissions | |

| Emissions of methane (CH4) and nitrous oxide (N2O) | [33,34,35] |

| Ammonia (NH3) emissions due to manure storage | [35,36] |

| Nitrogen oxides (NOx) emissions | [37], using the factor by [34] |

| Emissions related to soil incorporation different combinations of by-products | |

| CO2 emissions | [6,38] |

| N2O emissions | [32] |

| Emissions due to soil incorporation of manure | |

| N2O, NH3, NOx and nitrate leaching | [32] |

| Emission factor of Potassium, Copper and Zinc | [36] |

| Cultivar Hybrids | ||

|---|---|---|

| Costs (€/Year) | C-856 | C-1030 |

| Manual fertilization | 200.00 | 200.00 |

| Ploughing | 120.00 | 120.00 |

| Harrowing | 60.00 | 60.00 |

| Sowing | 60.00 | 60.00 |

| Manual hoeing | 375.00 | 375.00 |

| Manual harvesting | 625.00 | 625.00 |

| Mechanical harvesting | 180.00 | 180.00 |

| Dehulling | 150.00 | 150.00 |

| Oil extraction | 390.00 | 390.00 |

| Revenues (€/year) | ||

| Straw for sales | 49.5 | 88.00 |

| Husks for sales | 255.00 | 288.00 |

| Castor oil for sales | 26,206.32 | 27,142.26 |

| Cultivar Hybrid: C-856 | Cultivar Hybrid: C-1030 | |||||||

|---|---|---|---|---|---|---|---|---|

| Scenarios | Scenarios | |||||||

| Manual | Mechanical | Manual | Mechanical | |||||

| Sc1A | Sc1B | Sc2A | Sc2B | Sc1A | Sc1B | Sc2A | Sc2B | |

| Costs (€/Mg) * | ||||||||

| Manual fertilization | 72.42 | 71.42 | 71.42 | 71.42 | 68.96 | 68.96 | 68.96 | 68.96 |

| Ploughing | 42.85 | 42.85 | 42.85 | 42.85 | 41.38 | 41.38 | 41.38 | 41.38 |

| Harrowing | 21.43 | 21.43 | 21.43 | 21.43 | 20.69 | 20.69 | 20.69 | 20.69 |

| Sowing | 21.43 | 21.43 | 21.43 | 21.43 | 20.69 | 20.69 | 20.69 | 20.69 |

| Manual hoeing | 133.93 | 133.93 | 133.93 | 133.93 | 129.31 | 129.31 | 129.31 | 129.31 |

| Harvesting | 223.21 | 223,21 | 64.28 | 64.28 | 215.52 | 215.52 | 62.07 | 62.07 |

| Dehulling | 53.57 | 53.57 | - | - | 51.72 | 51.72 | - | - |

| Oil extraction | 139.28 | 139.28 | 139.28 | 139.28 | 134.48 | 134.48 | 134.48 | 134.48 |

| Total Costs (€/Mg) | 708.12 | 708.12 | 494.62 | 494.62 | 682.75 | 682.75 | 477.58 | 477.58 |

| Revenues (€/Mg) | ||||||||

| Straw for sales | - | 4,58 | - | 4,58 | - | 7.61 | - | 7.61 |

| Husks for sales | 76.24 | 76.24 | - | - | 81.57 | 81.57 | - | - |

| Castor oil for sales | 31,166 | 31,166 | 31,166 | 31,166 | 31,166 | 31,166 | 31,166 | 31,166 |

| Total Revenues (€/Mg) | 31,242 | 31,246 | 31,166 | 31,170 | 31,247 | 31,255 | 31,166 | 31,173 |

| Gross Margin (€/Mg) | 30,533 | 30,537 | 30,671 | 30,675 | 30,564 | 30,572 | 30,688 | 30,695 |

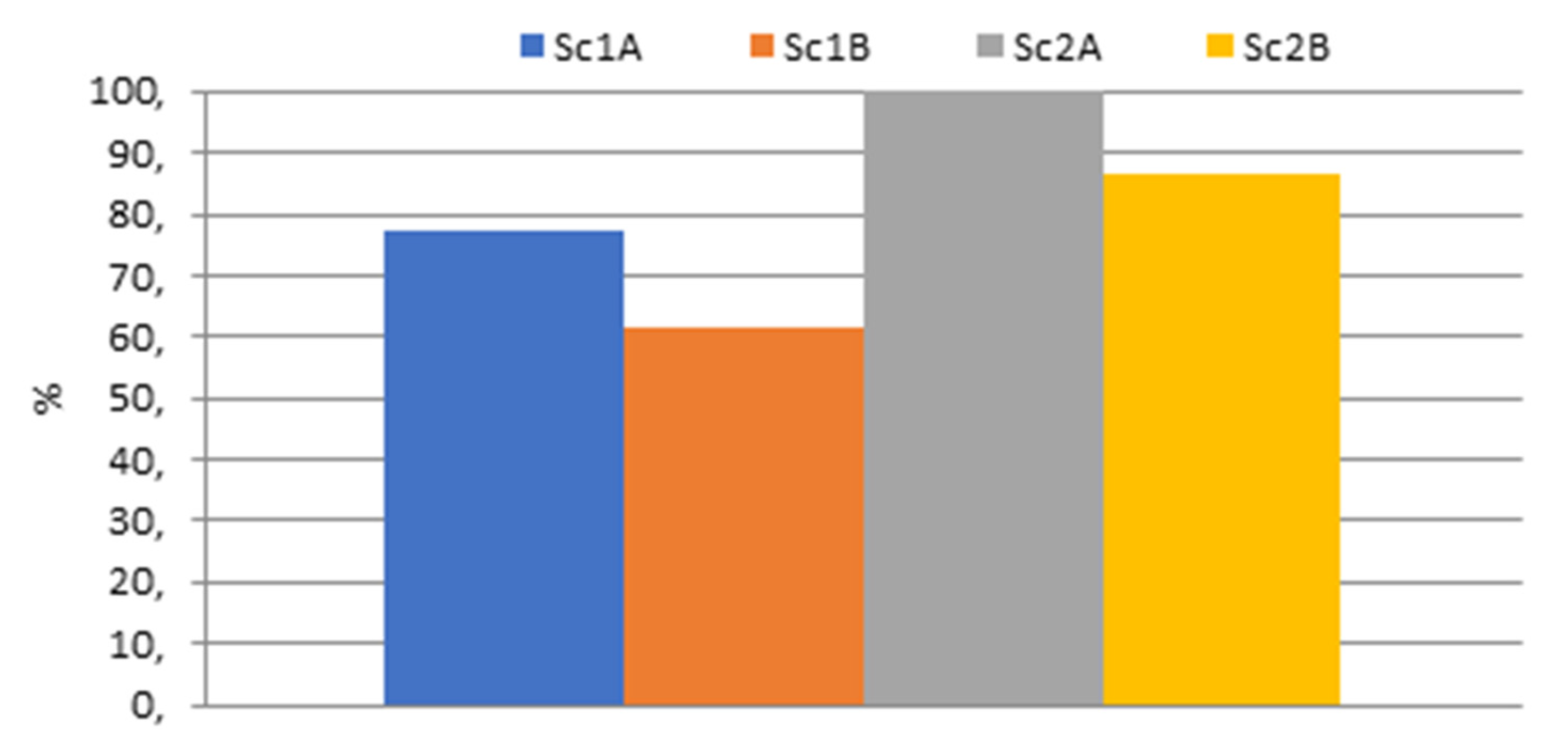

| Cultivar Hybrid: C-856 | Cultivar Hybrid: C-1030 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Scenarios | Scenarios | ||||||||

| Unit | Manual | Mechanical | Manual | Mechanical | |||||

| Sc1A | Sc1B | Sc2A | Sc2B | Sc1A | Sc1B | Sc2A | Sc2B | ||

| Gross Margin | (€/FU) | 30,533 | 30,537 | 30,671 | 30,675 | 30,564 | 30,572 | 30,688 | 30,695 |

| GWP | (kg CO2 eq/FU) | 9070 | 8140 | 18,100 | 15,800 | 14,600 | 11,600 | 18,900 | 16,300 |

| Gross Margin/GWP ratio | (%) | 3.37 | 3.75 | 1.69 | 1.94 | 2.09 | 2.63 | 1.62 | 1.88 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study. Sustainability 2020, 12, 6339. https://doi.org/10.3390/su12166339

Pari L, Suardi A, Stefanoni W, Latterini F, Palmieri N. Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study. Sustainability. 2020; 12(16):6339. https://doi.org/10.3390/su12166339

Chicago/Turabian StylePari, Luigi, Alessandro Suardi, Walter Stefanoni, Francesco Latterini, and Nadia Palmieri. 2020. "Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study" Sustainability 12, no. 16: 6339. https://doi.org/10.3390/su12166339

APA StylePari, L., Suardi, A., Stefanoni, W., Latterini, F., & Palmieri, N. (2020). Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study. Sustainability, 12(16), 6339. https://doi.org/10.3390/su12166339