RETRACTED: Sustainable Use of Waste Polypropylene Fibers and Palm Oil Fuel Ash in the Production of Novel Prepacked Aggregate Fiber-Reinforced Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions

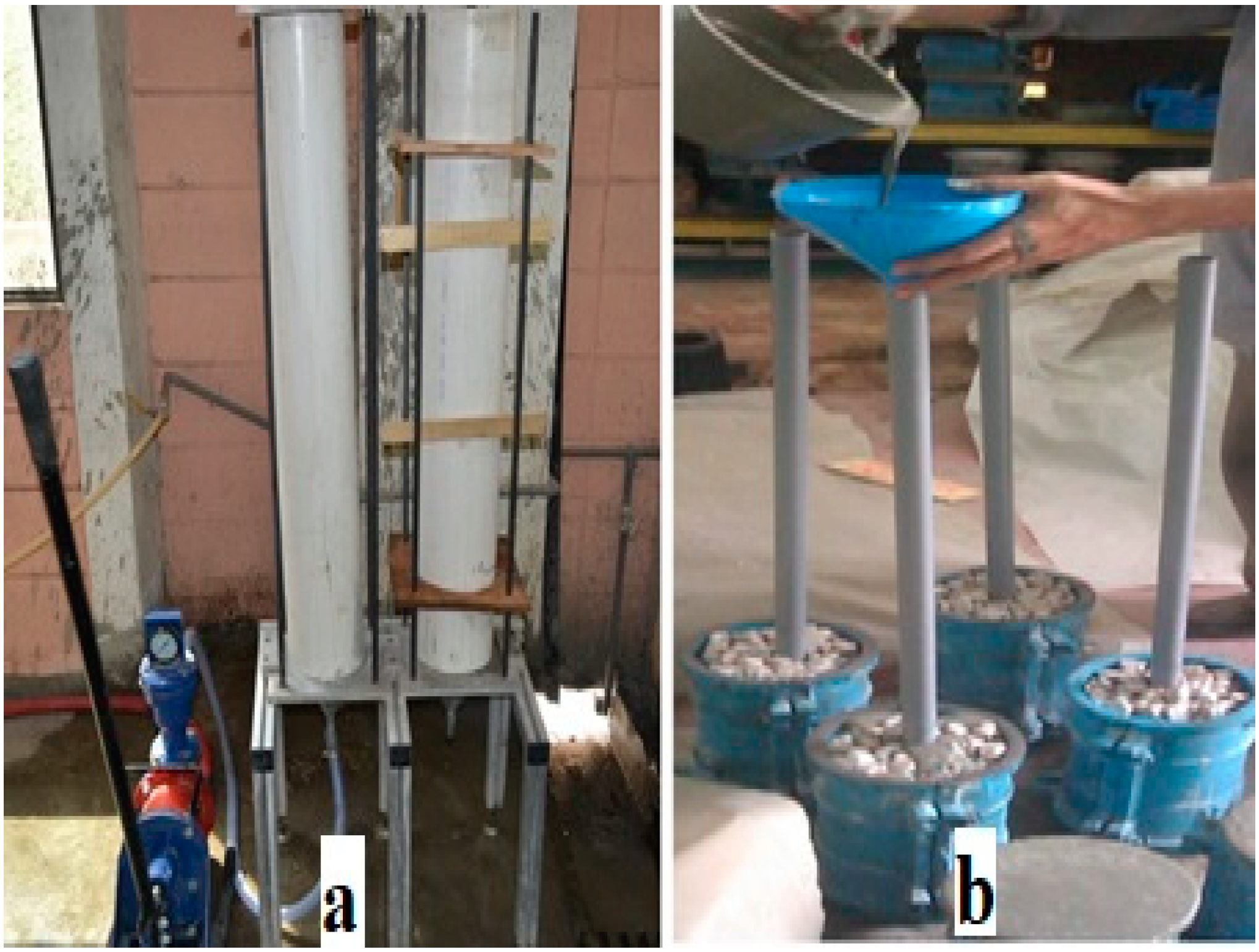

2.3. Sample Preparation

2.4. Testing Methods

3. Results and Discussion

3.1. Compressive Strength

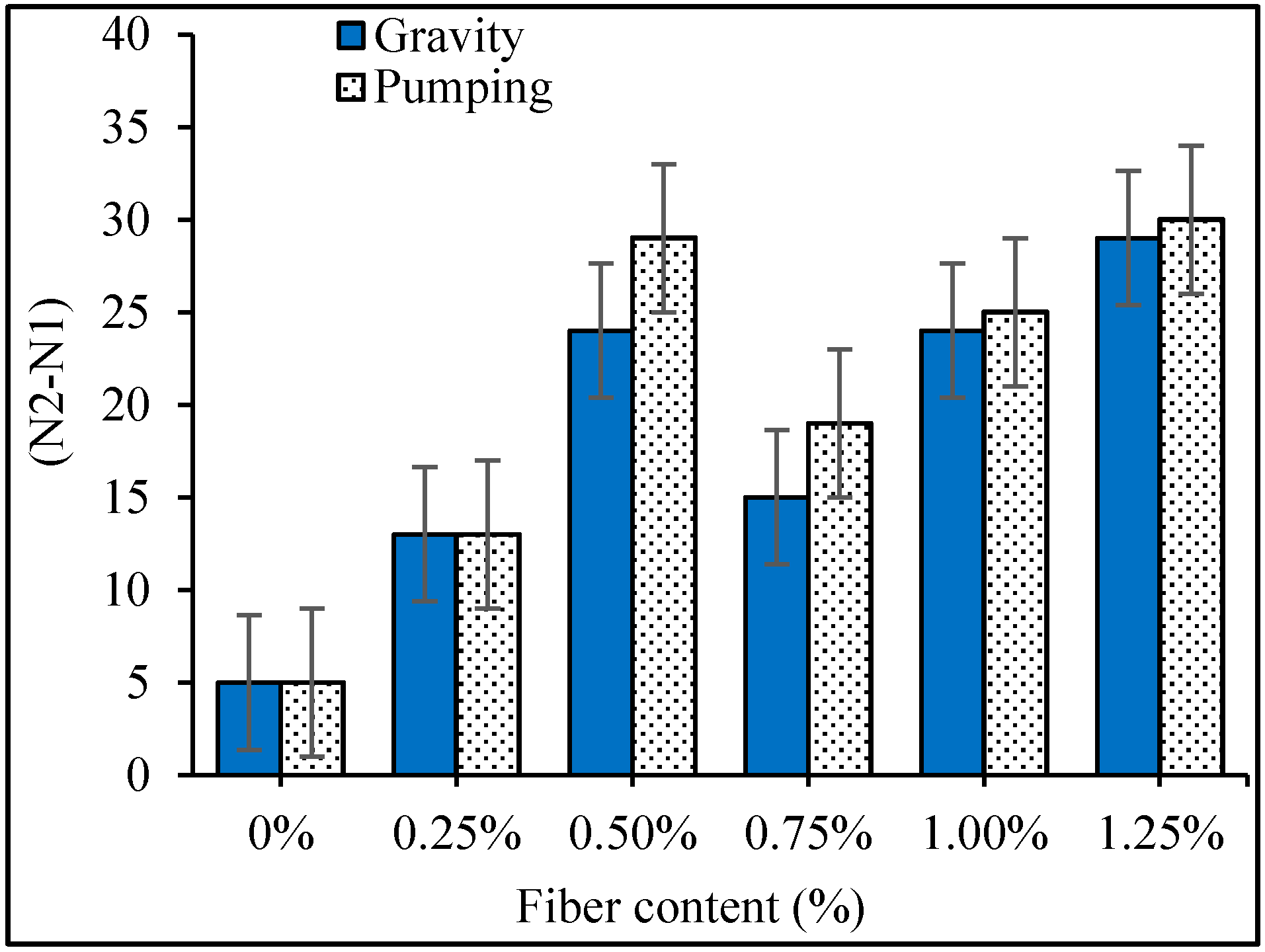

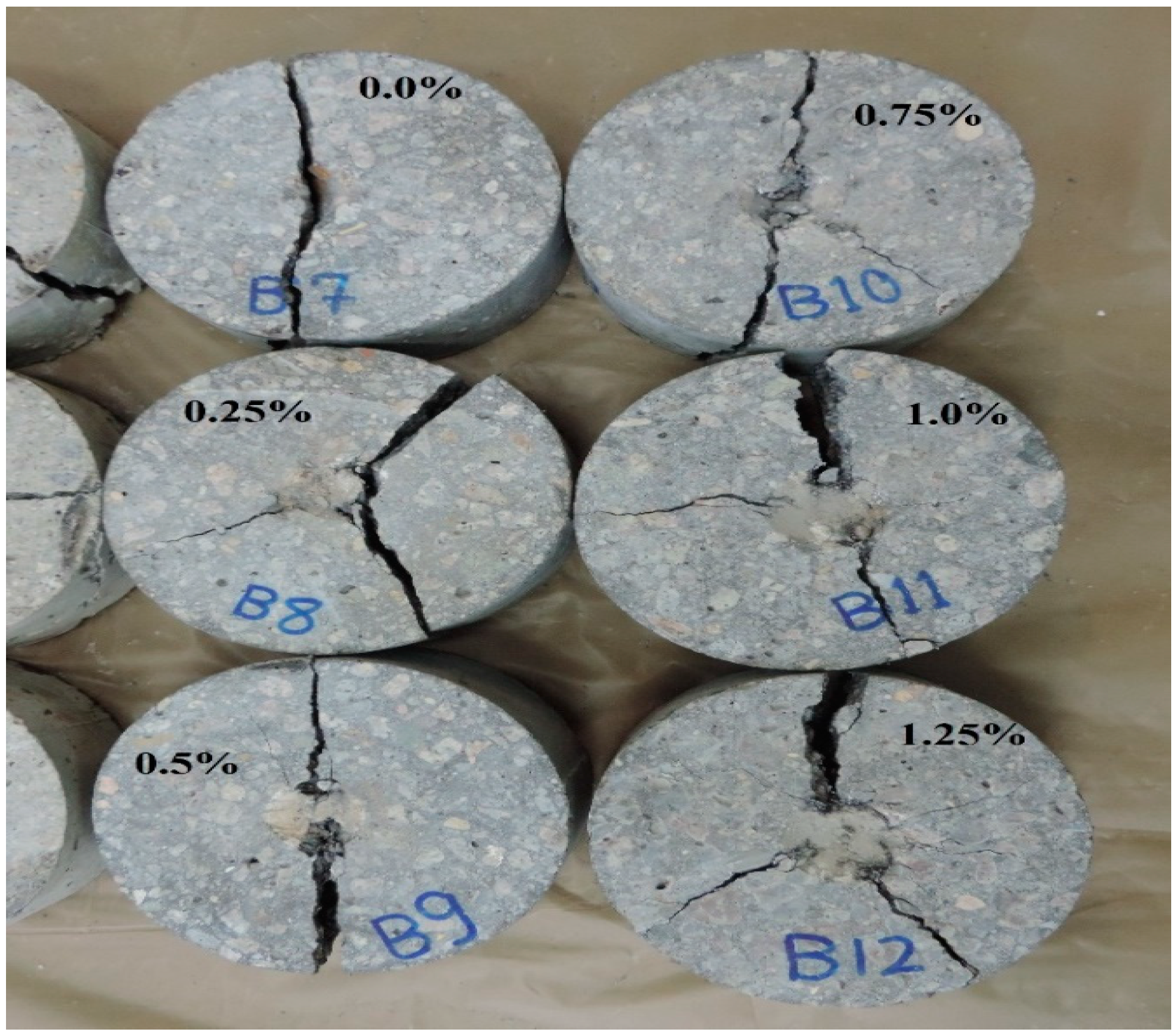

3.2. Impact Resistance

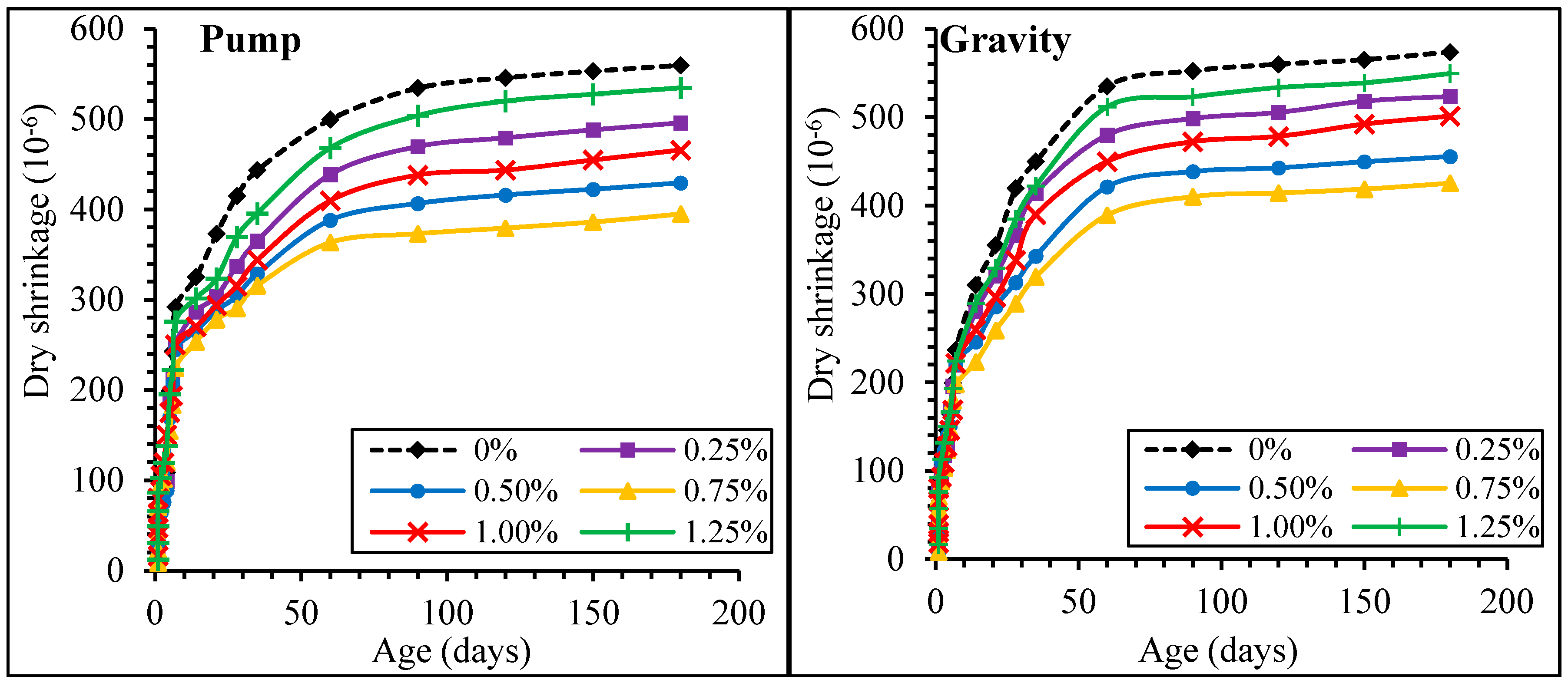

3.3. Drying Shrinkage Development

3.4. Microstructural Analysis

4. Conclusions

- (1)

- The inclusion of waste PP fibers into the mixture results in the reduction of the compressive strength of PAFRC specimens. Initially, in the early curing periods, owed to the slow pozzolanic reaction of POFA, the strength improvement of PAFRC mixtures was marginally lesser than that of the plain PAC mix with OPC. However, at the age of 90 days, the obtained strength values were greater than those of the OPC mixes. The rate of strength enhancement was more remarkable in the pumping technique PAFRC mixtures, as associated with those of gravity technique samples.

- (2)

- A remarkable rise in the number of blows under impact load for the first and ultimate cracks impact strength was detected for PAFRC samples reinforced with PP carpet fibers. Besides, the highest impact resistance values were recorded for PAFRC specimens reinforced with 1.25% fibers. In general, pumping method specimens obtained higher values than those of the gravity method.

- (3)

- The results of the impact resistance test revealed that the PAFRC specimens reinforced with waste PP fibers are highly potential to resist against impact loads through the bridging action of fibers, and consequently, reduced the brittleness and delayed the sudden failure of the PAFRC specimens.

- (4)

- The drying shrinkage values of all PAFRC specimens reinforced with waste polypropylene fibers were comparatively lower than those of plain PAC specimens. The highest reduction in drying shrinkage was noted for the PAFRC mix of pumping method containing 0.75% fibers, which were 29.5% lower than that of the plain mix.

- (5)

- The analysis of the microstructure of the grout paste indicated that the existence of POFA results in enhanced performance of PAFRC specimens by providing a dense microstructure and filled up the voids with additional hydration products, particularly at the ultimate ages.

- (6)

- The new method of reinforcing prepacked aggregates concrete has delivered a technique to move from conventional FRC to novel PAFRC, which also provides new considerations for the future sorts of FRC.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Performance of waste based alkaline mortars submitted to accelerated carbon dioxide curing. Resour. Conserv. Recycl. 2018, 129, 12–19. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Dalvand, A. Comparative Study on the Effects of Recycled Glass–Fiber on Drying Shrinkage Rate and Mechanical Properties of the Self-Compacting Mortar and Fly Ash–Slag Geopolymer Mortar. J. Mater. Civ. Eng. 2017, 29, 04017076. [Google Scholar] [CrossRef]

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Carbon dioxide sequestration of fly ash alkaline-based mortars containing recycled aggregates and reinforced by hemp fibres. Constr. Build. Mater. 2018, 160, 48–56. [Google Scholar] [CrossRef]

- Abdelgader, H.S. How to design concrete produced by a two-stage concreting method. Cem. Concr. Res. 1999, 29, 331–337. [Google Scholar] [CrossRef]

- Najjar, M.F.; Soliman, A.; Nehdi, M. Critical overview of two-stage concrete: Properties and applications. Constr. Build. Mater. 2014, 62, 47–58. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Alaskar, A.; Alabduljabbar, H.; Alyousef, R. Enhancement of strength and transport properties of a novel preplaced aggregate fiber reinforced concrete by adding waste polypropylene carpet fibers. J. Build. Eng. 2020, 27, 101003. [Google Scholar] [CrossRef]

- Swaddiwudhipong, S.; Zhang, J.; Lee, S.L. Prepacked Grouting Process in Concrete Construction. J. Mater. Civ. Eng. 2003, 15, 567–576. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.M.; Alabduljabbar, H.; Mohamed, A.M. Creep and drying shrinkage performance of concrete composite comprising waste polypropylene carpet fibres and palm oil fuel ash. J. Build. Eng. 2020, 30, 101250. [Google Scholar] [CrossRef]

- Najjar, M.F.; Nehdi, M.; Soliman, A.; Azabi, T. Damage mechanisms of two-stage concrete exposed to chemical and physical sulfate attack. Constr. Build. Mater. 2017, 137, 141–152. [Google Scholar] [CrossRef]

- Mastali, M.; Naghibdehi, M.G.; Naghipour, M.; Rabiee, S. Experimental assessment of functionally graded reinforced concrete (FGRC) slabs under drop weight and projectile impacts. Constr. Build. Mater. 2015, 95, 296–311. [Google Scholar] [CrossRef]

- Murali, G.; Ramprasad, K. A feasibility of enhancing the impact strength of novel layered two stage fibrous concrete slabs. Eng. Struct. 2018, 175, 41–49. [Google Scholar] [CrossRef]

- Ong, K.; Basheerkhan, M.; Paramasivam, P. Resistance of fibre concrete slabs to low velocity projectile impact. Cem. Concr. Compos. 1999, 21, 391–401. [Google Scholar] [CrossRef]

- Abdelgader, H. Concrete repair using two-stage concrete method. MATERIAŁY BUDOWLANE 2015, 1, 68–70. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high strength concrete containing steel and polypropylene fibres. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of the reinforced self-compacting concrete incorporating recycled CFRP fibre with different lengths and dosages. Compos. Part B Eng. 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Domski, J.; Zakrzewski, M. Deflection of Steel Fiber Reinforced Concrete Beams Based on Waste Sand. Materials 2020, 13, 392. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental Study on Basic Mechanical Properties of Basalt Fiber Reinforced Concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Mater. 2020, 13, 1827. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M.; Sam, A.R.M.; Awal, A.A. Durability performance of green concrete composites containing waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Sotayo, A.; Green, S.; Turvey, G. Carpet recycling: A review of recycled carpets for structural composites. Environ. Technol. Innov. 2015, 3, 97–107. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Sam, A.R.M.; Lim, N.H.A.S.; Samadi, M. Enhanced performance for aggressive environments of green concrete composites reinforced with waste carpet fibres and palm oil fuel ash. J. Clean. Prod. 2018, 185, 252–265. [Google Scholar] [CrossRef]

- Le Tang, W.; Lee, H.-S.; Vimonsatit, V.; Htut, T.; Singh, J.K.; Hassan, W.N.F.W.; Ismail, M.A.; Seikh, A.H.; Alharthi, N. Optimization of Micro and Nano Palm Oil Fuel Ash to Determine the Carbonation Resistance of the Concrete in Accelerated Condition. Mater. 2019, 12, 130. [Google Scholar] [CrossRef] [PubMed]

- Mohammadhosseini, H.; Tahir, M.; Sayyed, M. Strength and transport properties of concrete composites incorporating waste carpet fibres and palm oil fuel ash. J. Build. Eng. 2018, 20, 156–165. [Google Scholar] [CrossRef]

- Awal, A.A.; Mohammadhosseini, H. Green concrete production incorporating waste carpet fiber and palm oil fuel ash. J. Clean. Prod. 2016, 137, 157–166. [Google Scholar] [CrossRef]

- Chandara, C.; Azizli, K.A.M.; Ahmad, Z.; Hashim, S.F.S.; Sakai, E. Heat of hydration of blended cement containing treated ground palm oil fuel ash. Constr. Build. Mater. 2012, 27, 78–81. [Google Scholar] [CrossRef]

- Lim, N.H.A.S.; Mohammadhosseini, H.; Tahir, M.; Samadi, M.; Sam, A.R.M. Microstructure and Strength Properties of Mortar Containing Waste Ceramic Nanoparticles. Arab. J. Sci. Eng. 2018, 43, 5305–5313. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Utilization of high-volume treated palm oil fuel ash to produce sustainable self-compacting concrete. J. Clean. Prod. 2016, 137, 982–996. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Elgalhud, A.A. Effect of grout proportions on strength of two-stage concrete. Struct. Concr. 2008, 9, 163–170. [Google Scholar] [CrossRef]

- Khankhaje, E.; Hussin, M.W.; Mirza, J.; Raieizonooz, M.; Salim, M.R.; Siong, H.C.; Warid, M.N.M. On blended cement and geopolymer concretes containing palm oil fuel ash. Mater. Des. 2016, 89, 385–398. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.M.; Alabduljabbar, H.; Mohamed, A.M.; Samadi, M. Waste metalized film food packaging as low cost and ecofriendly fibrous materials in the production of sustainable and green concrete composites. J. Clean. Prod. 2020, 258, 120726. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A.S.M.A.; Yatim, J.B.M. The impact resistance and mechanical properties of concrete reinforced with waste polypropylene carpet fibres. Constr. Build. Mater. 2017, 143, 147–157. [Google Scholar] [CrossRef]

- Havlásek, P.; Jirásek, M. Multiscale modeling of drying shrinkage and creep of concrete. Cem. Concr. Res. 2016, 85, 55–74. [Google Scholar] [CrossRef]

- Karahan, O.; Atiş, C.D. The durability properties of polypropylene fibre reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A.S.M.A.; Sam, A.R.M. Mechanical and thermal properties of prepacked aggregate concrete incorporating palm oil fuel ash. Sadhana 2016, 41, 1235–1244. [Google Scholar] [CrossRef]

- Huseien, G.F.; Tahir, M.; Mirza, J.; Ismail, M.; Shah, K.W.; Asaad, M.A. Effects of POFA replaced with FA on durability properties of GBFS included alkali activated mortars. Constr. Build. Mater. 2018, 175, 174–186. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M. Microstructure and residual properties of green concrete composites incorporating waste carpet fibers and palm oil fuel ash at elevated temperatures. J. Clean. Prod. 2017, 144, 8–21. [Google Scholar] [CrossRef]

| Composition | OPC (%) | POFA (%) |

|---|---|---|

| SiO2 | 20.40 | 62.60 |

| Al2O3 | 5.20 | 4.65 |

| Fe2O3 | 4.19 | 8.12 |

| CaO | 62.39 | 5.70 |

| MgO | 1.55 | 3.52 |

| K2O | 0.005 | 9.05 |

| SO3 | 2.11 | 1.16 |

| LOI | 2.36 | 6.25 |

| Physical properties | ||

| Specific gravity | 3.15 | 2.42 |

| Blaine fineness (cm2/g) | 3990 | 4930 |

| Soundness (mm) | 1.0 | 2.0 |

| Waste Carpet Fiber | Length (mm) | Diameter (mm) | Density (kg/m3) | Melting Point (°C) | Tensile Strength (MPa) | Reaction with Water |

|---|---|---|---|---|---|---|

Multi-filament polypropylene | 30 | 0.45 | 910 | 170 | 400 | Hydrophobic |

| Mix | Water (kg/m3) | Cement (kg/m3) | POFA (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Vf (%) |

|---|---|---|---|---|---|---|

| P0 | 186 | 304 | 76 | 545 | 1320 | - |

| P1 | 186 | 304 | 76 | 545 | 1320 | 0.25 |

| P2 | 186 | 304 | 76 | 545 | 1320 | 0.50 |

| P3 | 186 | 304 | 76 | 545 | 1320 | 0.75 |

| P4 | 186 | 304 | 76 | 545 | 1320 | 1.00 |

| P5 | 186 | 304 | 76 | 545 | 1320 | 1.25 |

| G0 | 186 | 304 | 76 | 545 | 1320 | - |

| G1 | 186 | 304 | 76 | 545 | 1320 | 0.25 |

| G2 | 186 | 304 | 76 | 545 | 1320 | 0.50 |

| G3 | 186 | 304 | 76 | 545 | 1320 | 0.75 |

| G4 | 186 | 304 | 76 | 545 | 1320 | 1.00 |

| G5 | 186 | 304 | 76 | 545 | 1320 | 1.25 |

| Mix | Impact Resistance | N2-N1 | (N2-N1/N1)(100) | |

|---|---|---|---|---|

| First Crack (N1) | Failure (N2) | |||

| G0 | 16 | 21 | 5 | 31.3 |

| G1 | 28 | 41 | 13 | 46.4 |

| G2 | 45 | 74 | 29 | 64.4 |

| G3 | 63 | 82 | 19 | 30.2 |

| G4 | 84 | 108 | 24 | 28.6 |

| G5 | 102 | 131 | 29 | 28.4 |

| P0 | 20 | 25 | 5 | 25.0 |

| P1 | 38 | 51 | 13 | 34.2 |

| P2 | 63 | 87 | 24 | 38.1 |

| P3 | 84 | 99 | 15 | 17.9 |

| P4 | 101 | 126 | 25 | 24.8 |

| P5 | 131 | 161 | 30 | 22.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alrshoudi, F.; Mohammadhosseini, H.; Md. Tahir, M.; Alyousef, R.; Alghamdi, H.; Alharbi, Y.R.; Alsaif, A. RETRACTED: Sustainable Use of Waste Polypropylene Fibers and Palm Oil Fuel Ash in the Production of Novel Prepacked Aggregate Fiber-Reinforced Concrete. Sustainability 2020, 12, 4871. https://doi.org/10.3390/su12124871

Alrshoudi F, Mohammadhosseini H, Md. Tahir M, Alyousef R, Alghamdi H, Alharbi YR, Alsaif A. RETRACTED: Sustainable Use of Waste Polypropylene Fibers and Palm Oil Fuel Ash in the Production of Novel Prepacked Aggregate Fiber-Reinforced Concrete. Sustainability. 2020; 12(12):4871. https://doi.org/10.3390/su12124871

Chicago/Turabian StyleAlrshoudi, Fahed, Hossein Mohammadhosseini, Mahmood Md. Tahir, Rayed Alyousef, Hussam Alghamdi, Yousef R. Alharbi, and Abdulaziz Alsaif. 2020. "RETRACTED: Sustainable Use of Waste Polypropylene Fibers and Palm Oil Fuel Ash in the Production of Novel Prepacked Aggregate Fiber-Reinforced Concrete" Sustainability 12, no. 12: 4871. https://doi.org/10.3390/su12124871

APA StyleAlrshoudi, F., Mohammadhosseini, H., Md. Tahir, M., Alyousef, R., Alghamdi, H., Alharbi, Y. R., & Alsaif, A. (2020). RETRACTED: Sustainable Use of Waste Polypropylene Fibers and Palm Oil Fuel Ash in the Production of Novel Prepacked Aggregate Fiber-Reinforced Concrete. Sustainability, 12(12), 4871. https://doi.org/10.3390/su12124871