An Effects Analysis of Logistics Collaboration: The Case of Pharmaceutical Supplies in Seoul

Abstract

1. Introduction

2. Literature Review

3. Description of the Case-Study Area and Assumptions

4. Methodology

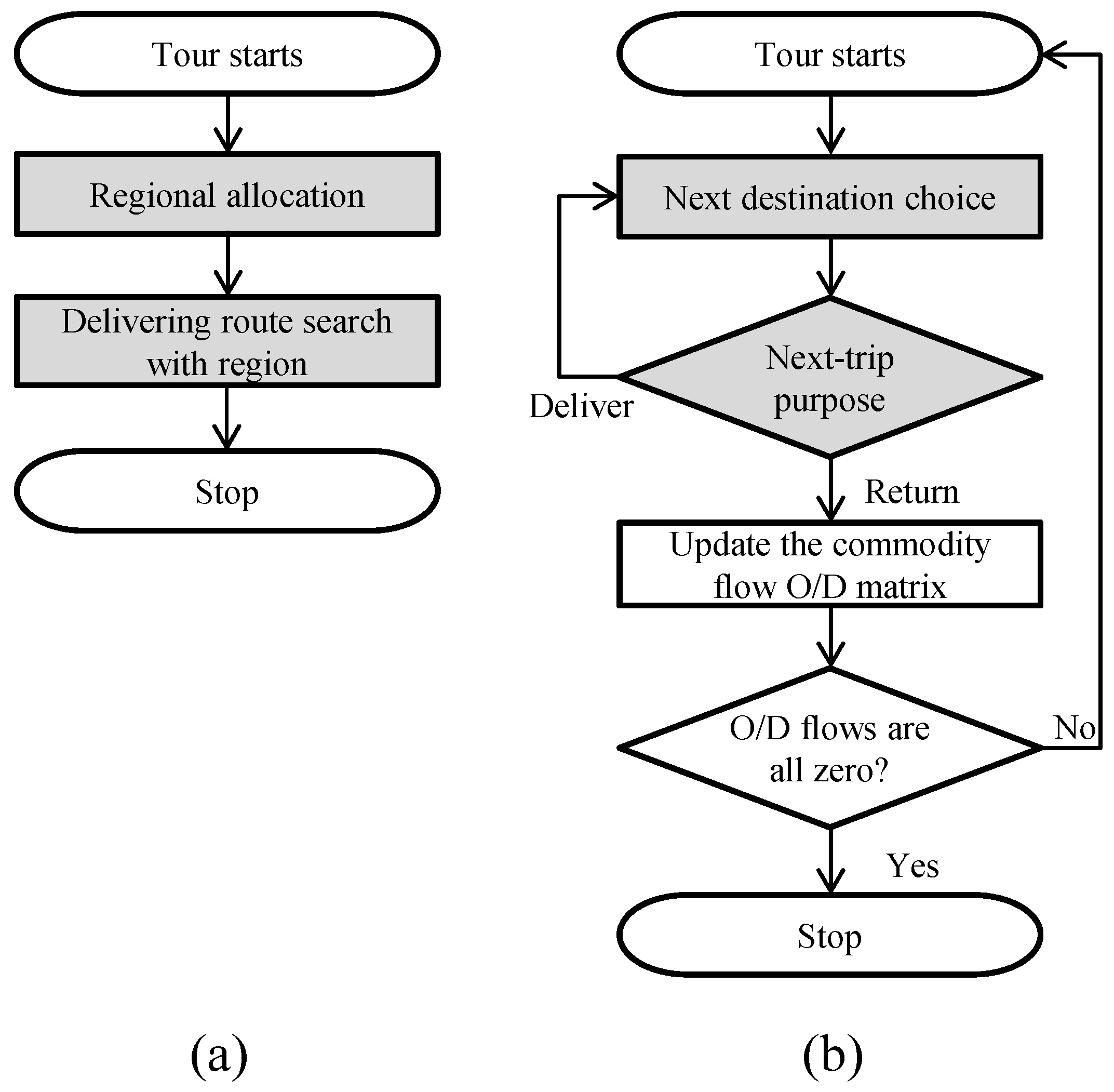

4.1. Major Company Truck Routing Model

4.1.1. Regional Allocation

4.1.2. Delivery Route Search

- : index for each zone in region h

- : index for delivery region

- : set of each zone with delivery demand of more than 1 in region h including depot (i = 0)

- : total delivery cost in region h

- : delivery cost from zone i to zone j

- : capacity of truck for delivery

- : the available truck load after it visits zone i

- : demand at each zone i

- : binary variable indicating whether a truck goes from zone i to zone j

4.2. Minor Company Truck Routing Model

4.2.1. Selecting Next Destination

- : The distance from current location to next destination i.

- : The amount of freight demand available to deliver in the next destination i

- : probability of truck driver n selecting zone i from choice zone set D

- : coefficient of the distance attribute

- : value of the distance attribute of truck driver n selecting zone i

- : size measure of zone i

- : coefficient of size measures

- : truck driver n’s choice zone set

- : number of zone alternatives in the subset region

4.2.2. Determining the Purpose of Next-Trip

- : Alternative specific constant for delivery

- : Returning distance from the current location to base

- : The cumulative distance up to the current location

5. Findings and Discussion

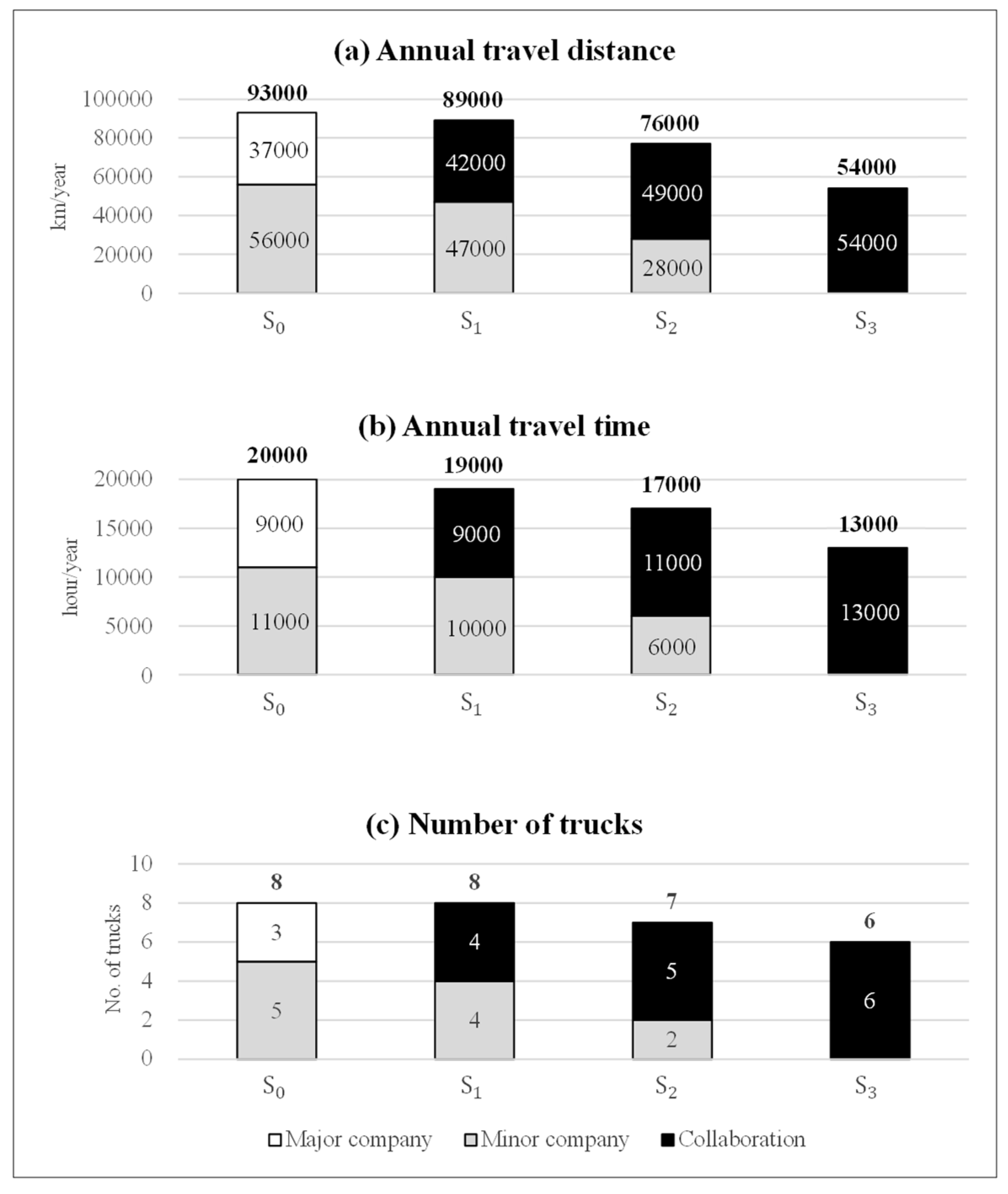

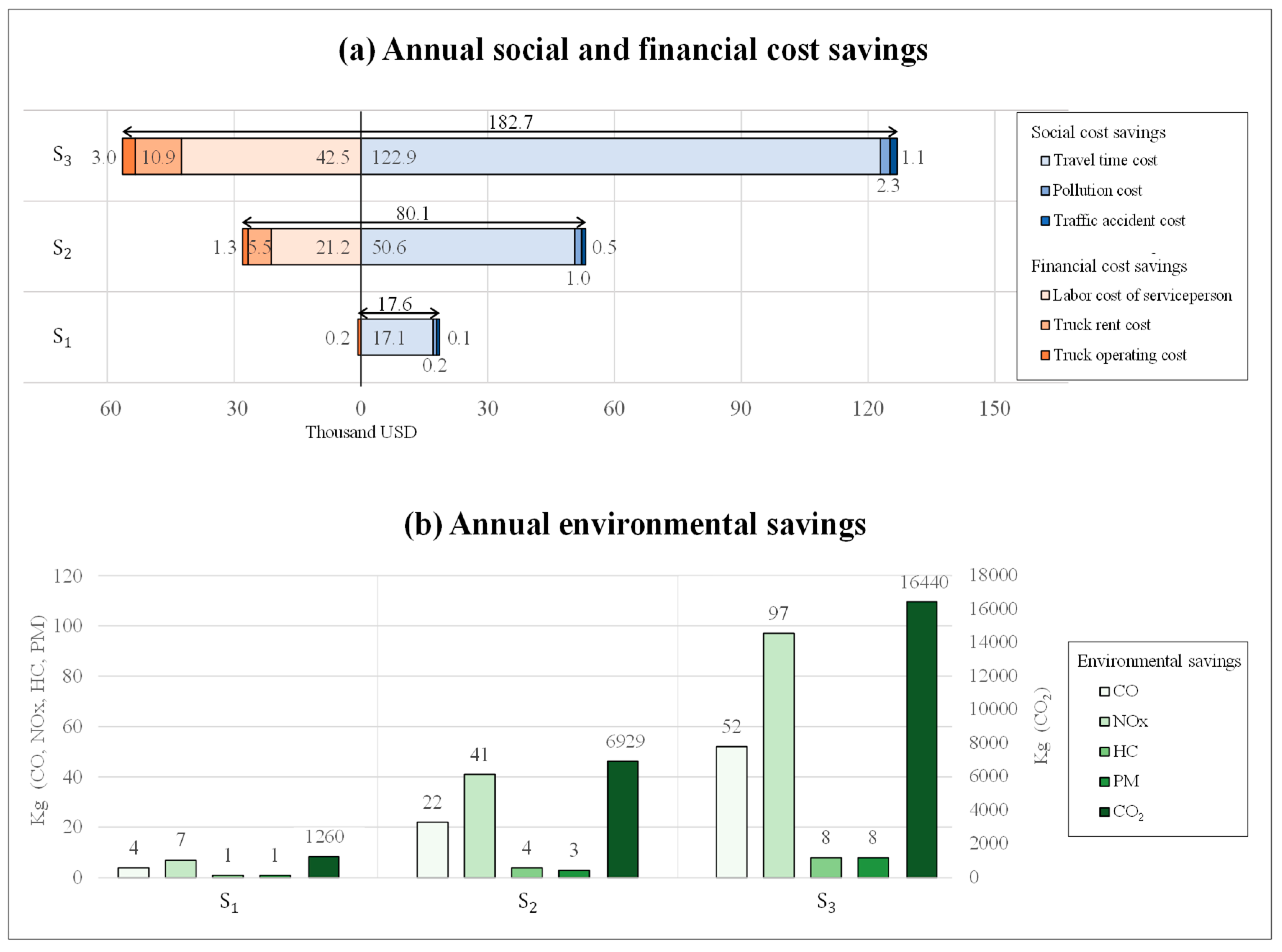

5.1. Findings

5.2. Discussion and Policy Implications

6. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Boerkamps, J.; Van Binsbergen, A. GoodTrip—A new approach for modelling and evaluation of urban goods distribution. City Logist. I 1999, 175–186. [Google Scholar]

- Anand, N.; van Duin, R.; Tavasszy, L. Ontology-based multi-agent system for urban freight transportation. Int. J. Urban Sci. 2014, 18, 133–153. [Google Scholar] [CrossRef]

- Teo, J.; Taniguchi, E.; Qureshi, A. Multi-agent systems modelling approach to evaluate urban motorways for city logistics. Int. J. Urban Sci. 2014, 18, 154–165. [Google Scholar] [CrossRef]

- Russo, F.; Comi, A. City sustainability and urban freight transport: Environmental evidences from the cities. In Proceedings of the 2011 NUF-4th METRANS National Urban Freight Conference, Long Beach, CA, USA, 12–14 October 2011. [Google Scholar]

- Lindholm, M.; Behrends, S. Challenges in urban freight transport planning—A review in the Baltic Sea Region. J. Transp. Geogr. 2012, 22, 129–136. [Google Scholar] [CrossRef]

- Dolati Neghabadi, P.; Samuel, K.E.; Espinouse, M.-L. Systematic literature review on city logistics: Overview, classification and analysis. Int. J. Prod. Res. 2018, 1–23. [Google Scholar] [CrossRef]

- Nuzzolo, A.; Comi, A.; Rosati, L. City logistics long-term planning: Simulation of shopping mobility and goods restocking and related support systems. Int. J. Urban Sci. 2014, 18, 201–217. [Google Scholar] [CrossRef]

- Lindawati; van Schagen, J.; Goh, M.; de Souza, R. Collaboration in urban logistics: Motivations and barriers. Int. J. Urban Sci. 2014, 18, 278–290. [Google Scholar] [CrossRef]

- Ergun, Ö.; Kuyzu, G.; Savelsbergh, M. Shipper collaboration. Comput. Oper. Res. 2007, 34, 1551–1560. [Google Scholar] [CrossRef]

- Cruijssen, F.; Cools, M.; Dullaert, W. Horizontal cooperation in logistics: Opportunities and impediments. Transp. Res. Part E Logist. Transp. Rev. 2007, 43, 129–142. [Google Scholar] [CrossRef]

- Park, D.; Kim, N.S.; Park, H.; Kim, K. Estimating trade-off among logistics cost, CO2 and time: A case study of container transportation systems in Korea. Int. J. Urban Sci. 2012, 16, 85–98. [Google Scholar] [CrossRef]

- Allen, G.; Sioutas, C.; Koutrakis, P.; Reiss, R.; Lurmann, F.W.; Roberts, P.T. Evaluation of the TEOM® method for measurement of ambient particulate mass in urban areas. J. Air Waste Manag. Assoc. 1997, 47, 682–689. [Google Scholar] [CrossRef]

- Gehring, U.; Gruzieva, O.; Agius, R.M.; Beelen, R.; Custovic, A.; Cyrys, J.; Eeftens, M.; Flexeder, C.; Fuertes, E.; Heinrich, J.; et al. Air pollution exposure and lung function in children: The ESCAPE project. Environ. Health Perspect. 2013, 121, 1357–1364. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, L.K.d.; Pereira, L.d.S.F. An estimation of freight flow using secondary data: A case study in Belo Horizonte (Brazil). Int. J. Urban Sci. 2014, 18, 291–307. [Google Scholar] [CrossRef]

- Yilmaz, O.; Savasaneril, S. Collaboration among small shippers in a transportation market. Eur. J. Oper. Res. 2012, 218, 408–415. [Google Scholar] [CrossRef]

- Zhou, G.; van Hui, Y.; Liang, L. Strategic alliance in freight consolidation. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 18–29. [Google Scholar] [CrossRef]

- Köhler, U. New ideas for the city-logistics project in Kassel. In Logistics Systems for Sustainable Cities, Proceedings of the 3rd International Conference on City Logistics, Madeira, Portugal, 25–27 June 2003; Emerald Group Publishing Limited: Bingley, UK, 2004. [Google Scholar]

- KITA. A Survey on Current Status of Third Party and Logistics Collaboration; Korea International Trade Association: Seoul, Korea, 2014. [Google Scholar]

- Allen, J.; Browne, M.; Woodburn, A.; Leonardi, J. The role of urban consolidation centres in sustainable freight transport. Transp. Rev. 2012, 32, 473–490. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R.; Muñoz-Villamizar, A.; Vega-Mejía, C.A. On the impact of collaborative strategies for goods delivery in city logistics. Prod. Plan. Control 2016, 27, 443–455. [Google Scholar] [CrossRef]

- Muñoz-Villamizar, A.; Montoya-Torres, J.R.; Vega-Mejía, C.A. Non-collaborative versus collaborative last-mile delivery in urban systems with stochastic demands. Procedia CIRP 2015, 30, 263–268. [Google Scholar] [CrossRef]

- Park, H.; Park, D.; Jeong, I.-J. An effects analysis of logistics collaboration in last-mile networks for CEP delivery services. Transp. Policy 2016, 50, 115–125. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Haijema, R.; van der Vorst, J.G. Modeling a green inventory routing problem for perishable products with horizontal collaboration. Comput. Oper. Res. 2018, 89, 168–182. [Google Scholar] [CrossRef]

- Gordon, A. Classification; C&H/CRC Monographs on Statistics & Applied Probability; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Bramel, J.; Simchi-Levi, D. The Logic of Logistics: Theory, Algorithms, and Applications for Logistics Management; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Qureshi, A.G.; Taniguchi, E.; Thompson, R.G.; Teo, J.S. Application of exact route optimization for the evaluation of a city logistics truck ban scheme. Int. J. Urban Sci. 2014, 18, 117–132. [Google Scholar] [CrossRef]

- Sungur, I.; Ordónez, F.; Dessouky, M. A robust optimization approach for the capacitated vehicle routing problem with demand uncertainty. IIE Trans. 2008, 40, 509–523. [Google Scholar] [CrossRef]

- Kim, S.; Park, D.; Kim, S.; Park, H. Modeling Courier Vehicles’ Travel Behavior: Case of Seoul, South Korea. Transp. Res. Rec. 2014, 2410, 67–75. [Google Scholar] [CrossRef]

- Kuppam, A.; Lemp, J.; Beagan, D.; Livshits, V.; Vallabhaneni, L.; Nippani, S. Development of a Tour-Based Truck Travel Demand Model Using Truck GPS Data; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2014. [Google Scholar]

- Nuzzolo, A.; Comi, A. Urban freight demand forecasting: A mixed quantity/delivery/vehicle-based model. Transp. Res. Part E Logist. Transp. Rev. 2014, 65, 84–98. [Google Scholar] [CrossRef]

- Park, H.; Park, D.; Kim, C.; Kim, H.; Park, M. A comparative study on sampling strategies for truck destination choice model: Case of Seoul Metropolitan Area. Can. J. Civ. Eng. 2012, 40, 19–26. [Google Scholar] [CrossRef]

- Roca-Riu, M.; Estrada, M. An evaluation of urban consolidation centers through logistics systems analysis in circumstances where companies have equal market shares. Procedia-Soc. Behav. Sci. 2012, 39, 796–806. [Google Scholar] [CrossRef][Green Version]

- Lin, J.; Chen, Q.; Kawamura, K. Sustainability SI: Logistics cost and environmental impact analyses of urban delivery consolidation strategies. Netw. Spat. Econ. 2016, 16, 227–253. [Google Scholar] [CrossRef]

- Van Heeswijk, W.; Larsen, R.; Larsen, A. An Urban Consolidation Center in the City of Copenhagen: A Simulation Study; Technical Report; TU Eindhoven, Research School for Operations Management and Logistics (BETA): Eindhoven, The Netherlands, 2017. [Google Scholar]

- Dablanc, L.; Giuliano, G.; Holliday, K.; O’Brien, T. Best practices in urban freight management: Lessons from an international survey. Transp. Res. Rec. 2013, 2379, 29–38. [Google Scholar] [CrossRef]

- Macharis, C.; Melo, S. City Distribution and Urban Freight Transport: Multiple Perspectives; Edward Elgar Publishing: Bingley, UK, 2011. [Google Scholar]

- Wang, X.C.; Zhang, D. Truck freight demand elasticity with respect to tolls in New York State. Transp. Res. Part A Policy Pract. 2017, 101, 51–60. [Google Scholar] [CrossRef]

- Brunekreef, B.; Janssen, N.A.; de Hartog, J.; Harssema, H.; Knape, M.; van Vliet, P. Air pollution from truck traffic and lung function in children living near motorways. Epidemiology 1997, 298–303. [Google Scholar] [CrossRef] [PubMed]

- Small, K.A.; Kazimi, C. On the costs of air pollution from motor vehicles. J. Transp. Econ. Policy 1995, 7–32. [Google Scholar]

- Roorda-Knape, M.C.; Janssen, N.A.; De Hartog, J.J.; Van Vliet, P.H.; Harssema, H.; Brunekreef, B. Air pollution from traffic in city districts near major motorways. Atmos. Environ. 1998, 32, 1921–1930. [Google Scholar] [CrossRef]

- Seoul Metropolitan Government. National Symposium for Better Air-Quality of South Korea; Seoul Metropolitan Government: Seoul, Korea, 2017.

- OECD. Better Life Index; OECD Publishing: Paris, France, 2017. [Google Scholar]

- Statistical Geographic Information Service. 2014. Available online: https://sgis.kostat.go.kr/view/index (accessed on 4 March 2015).

- Duque, J.C.; Church, R.L.; Middleton, R.S. The p-Regions Problem. Geogr. Anal. 2011, 43, 104–126. [Google Scholar] [CrossRef]

- Cliff, A.D.; Haggett, P.; Ord, J.K.; Bassett, K.A.; Davies, R.; Bassett, K.L. Elements of Spatial Structure: A Quantative Approach; Cambridge University Press: Cambridge, UK, 1975; Volume 6. [Google Scholar]

- Keane, M. The size of the region-building problem. Environ. Plan. A 1975, 7, 575–577. [Google Scholar] [CrossRef]

- Toth, P.; Vigo, D. Models, relaxations and exact approaches for the capacitated vehicle routing problem. Discret. Appl. Math. 2002, 123, 487–512. [Google Scholar] [CrossRef]

- Chang, T.-S.; Yen, H.-M. City-courier routing and scheduling problems. Eur. J. Oper. Res. 2012, 223, 489–498. [Google Scholar] [CrossRef]

- Christofides, N. The Vehicle Routing Problem; RAIRO—Operations Research—Recherche Opérationnelle: Paris, France, 1976; Volume 10, pp. 55–70. [Google Scholar]

- Gliebe, J.; Cohen, O.; Hunt, J. Dynamic choice model of urban commercial activity patterns of vehicles and people. Transp. Res. Rec. J. Transp. Res. Board 2007, 2003, 17–26. [Google Scholar] [CrossRef]

- Hunt, J.D.; Stefan, K. Tour-based microsimulation of urban commercial movements. Transp. Res. Part B Methodol. 2007, 41, 981–1013. [Google Scholar] [CrossRef]

- Waddell, P. UrbanSim: Modeling urban development for land use, transportation, and environmental planning. J. Am. Plan. Assoc. 2002, 68, 297–314. [Google Scholar] [CrossRef]

- Korea-Development-Institute. A Study on Standard Guidelines for Pre-Feasibility Study on Road and Railway Projects; KDI Public & Private Infrastructure Investment Management Center Seoul: Seoul, Korea, 2008. [Google Scholar]

- Basso, F.; D’Amours, S.; Rönnqvist, M.; Weintraub, A. A survey on obstacles and difficulties of practical implementation of horizontal collaboration in logistics. Int. Trans. Oper. Res. 2019, 26, 775–793. [Google Scholar] [CrossRef]

- Nimtrakool, K.; Gonzalez-Feliu, J.; Capo, C. Barriers to the adoption of an urban logistics collaboration process: A case study of the Saint—Etienne urban consolidation centre. City Logist. 2 Modeling Plan. Initiat. 2018, 313–332. [Google Scholar]

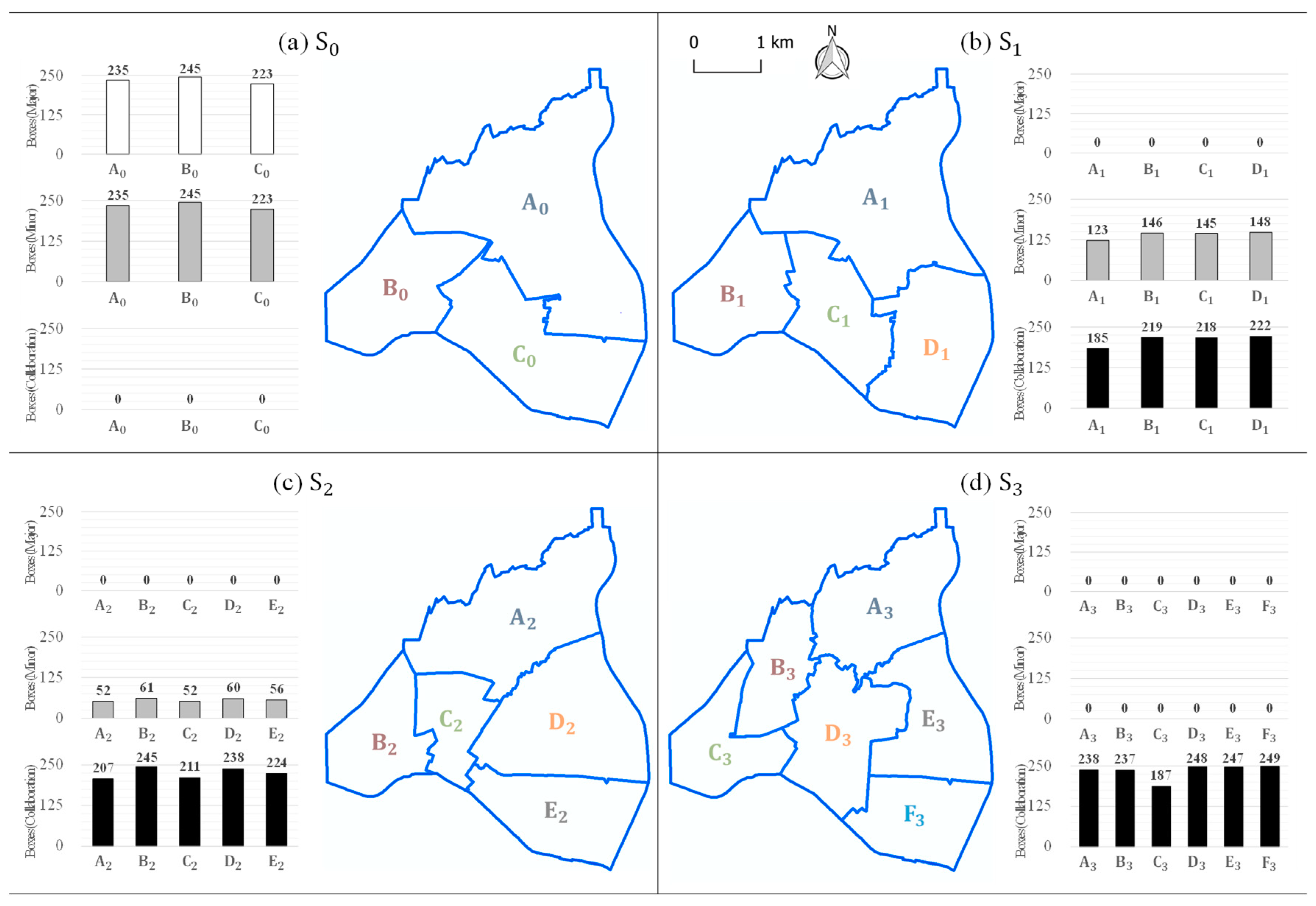

| Scenario | Classification | Allocated Region | Sum | Market Share | |||||

|---|---|---|---|---|---|---|---|---|---|

| Baseline Scenario, S0 | No. of boxes | 235 | 245 | 223 | - | - | - | 703 | 50% |

| No. of zones | 42 | 14 | 25 | - | - | - | 81 | ||

| Scenario 1, S1 | No. of boxes | 185 | 219 | 218 | 222 | - | - | 844 | 60% |

| No. of zones | 33 | 12 | 15 | 21 | - | - | 81 | ||

| Scenario 2, S2 | No. of boxes | 207 | 245 | 211 | 238 | 224 | - | 1125 | 80% |

| No. of zones | 28 | 10 | 7 | 20 | 16 | - | 81 | ||

| Scenario 3, S3 | No. of boxes | 238 | 237 | 187 | 248 | 247 | 249 | 1406 | 100% |

| No. of zones | 22 | 7 | 10 | 13 | 15 | 14 | 81 | ||

| Classification | Definition | Coefficient | t-Statistic |

|---|---|---|---|

| Next destination choice | Distance from current location to next destination | −0.00246 | −5.3721 |

| The freight demand available to deliver to next destination | 0.048410 | 7.6832 |

| Classification | Definition | Coefficient | t-Statistic |

|---|---|---|---|

| Deliver | Alternative specific constant | 4.85312 | 7.4568 |

| Return | The distance from current location to origin | −0.009123 | −2.1934 |

| The cumulative distance up to the current location | 0.003132 | 5.0546 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Do, W.; Park, H.; Chung, K.; Park, D. An Effects Analysis of Logistics Collaboration: The Case of Pharmaceutical Supplies in Seoul. Sustainability 2019, 11, 2442. https://doi.org/10.3390/su11082442

Do W, Park H, Chung K, Park D. An Effects Analysis of Logistics Collaboration: The Case of Pharmaceutical Supplies in Seoul. Sustainability. 2019; 11(8):2442. https://doi.org/10.3390/su11082442

Chicago/Turabian StyleDo, Wooseok, Hyeongjun Park, Koohong Chung, and Dongjoo Park. 2019. "An Effects Analysis of Logistics Collaboration: The Case of Pharmaceutical Supplies in Seoul" Sustainability 11, no. 8: 2442. https://doi.org/10.3390/su11082442

APA StyleDo, W., Park, H., Chung, K., & Park, D. (2019). An Effects Analysis of Logistics Collaboration: The Case of Pharmaceutical Supplies in Seoul. Sustainability, 11(8), 2442. https://doi.org/10.3390/su11082442