Characterization of Bitumen Modified with Pyrolytic Carbon Black from Scrap Tires

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

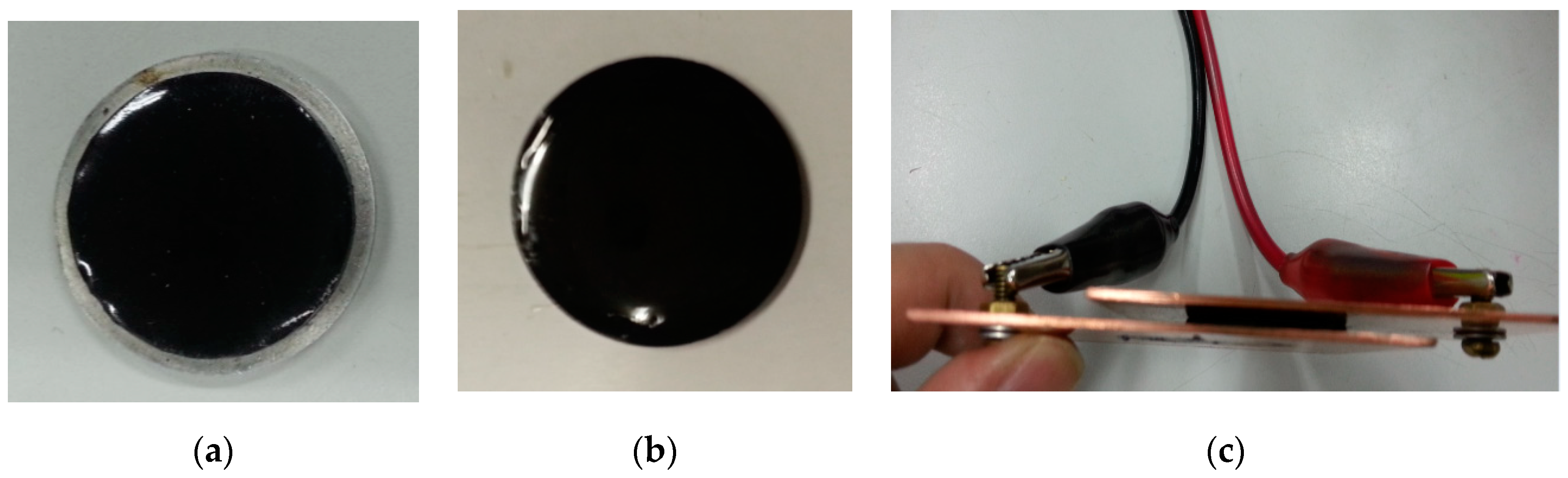

2.2. Sample Preparation

2.3. Testing Methods

2.3.1. Electrical Resistivity and Thermal Conductivity Measurement

2.3.2. Physical, Rheological, and Mechanical Properties Tests

2.3.3. Aging Procedure

2.3.4. Storage Stability Test

3. Results and Discussion

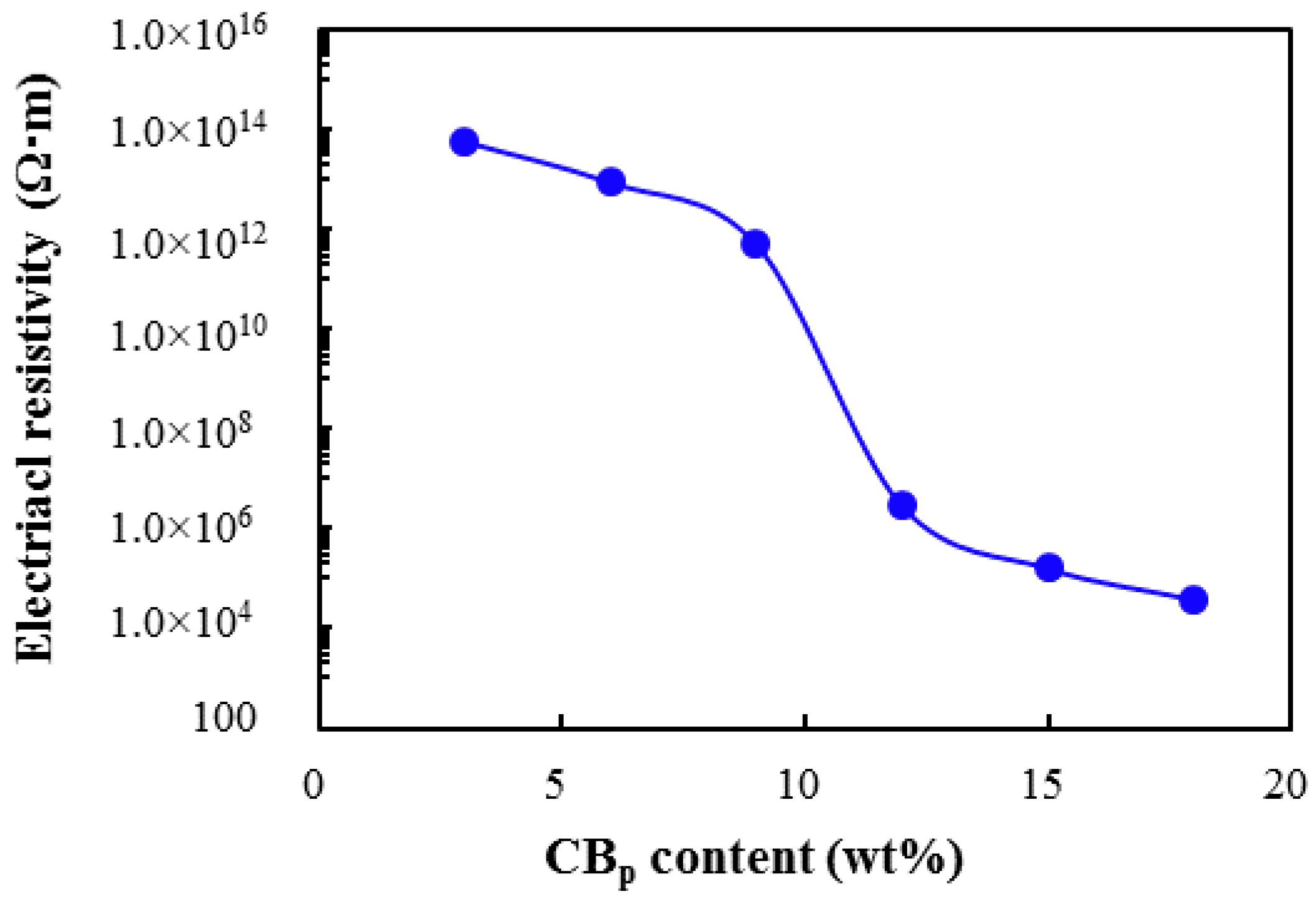

3.1. Electrothermal Properties

3.2. Conventional Physical Properties

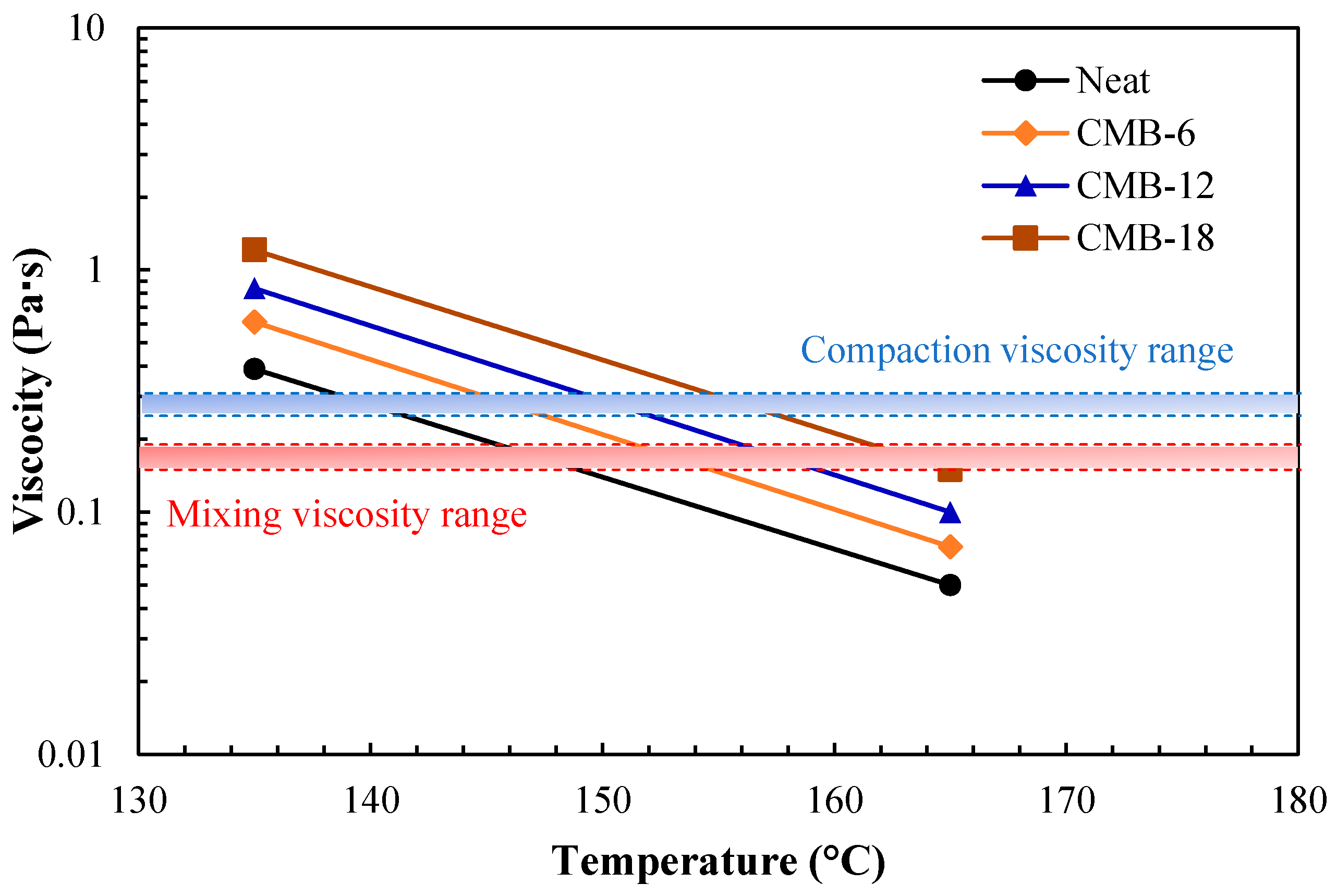

3.3. Rotational Viscosity

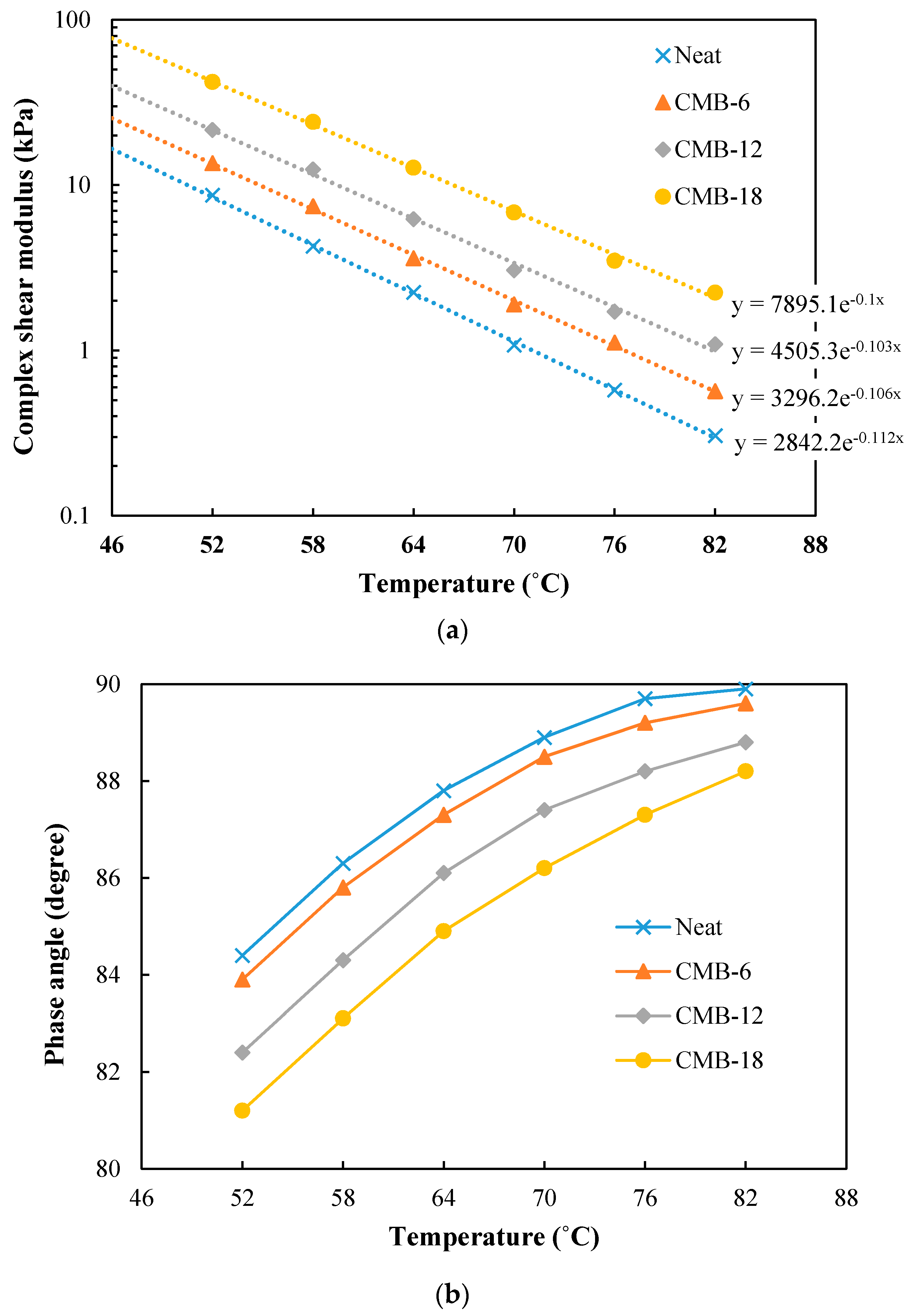

3.4. Rheological Properties

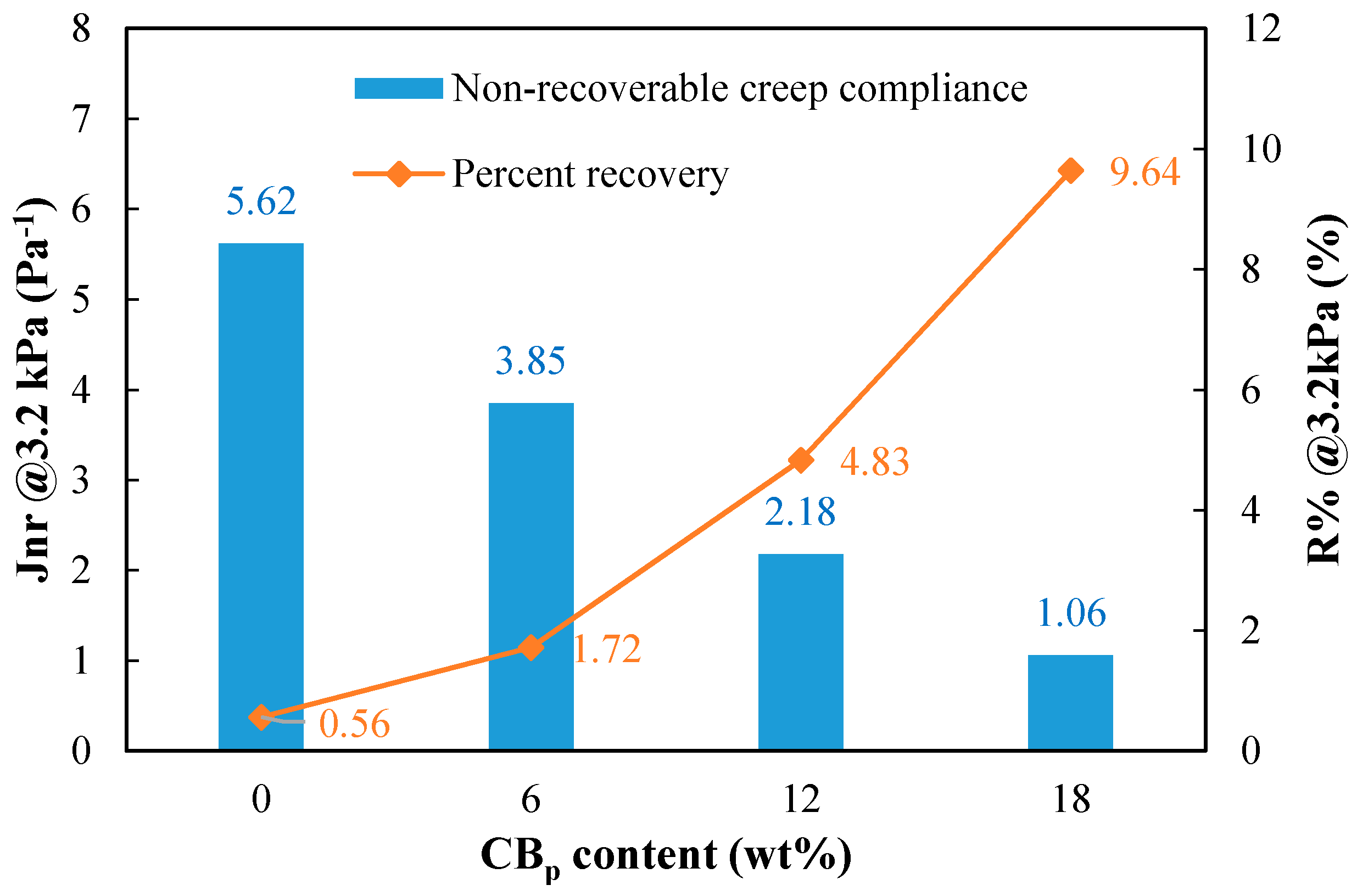

3.5. Multiple Stress Creep Recovery Test

3.6. Hot-Temperature Storage Stability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- WBCSD. End-of-Life Tires: A Framework for Effective Management Systems; World Business Council for Sustainable Development: Conches-Geneva, Switzerland, 2010. [Google Scholar]

- Stevenson, K.; Stallwood, B.; Hart, A.G. Tire rubber recycling and bioremediation: A review. Bioremediat. J. 2008, 12, 1–11. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef] [PubMed]

- Torretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Review of warm mix rubberized asphalt concrete: Towards a sustainable paving technology. J. Clean. Prod. 2018, 177, 302–314. [Google Scholar] [CrossRef]

- Roy, C.; Chaala, A.; Darmstadt, H. The vacuum pyrolysis of used tires—End-uses for oil and carbon black products. J. Anal. Appl. Pyrol. 1999, 51, 201–221. [Google Scholar] [CrossRef]

- Huang, J.-C. Carbon black filled conducting polymers and polymer blends. Adv. Polym. Technol. 2002, 21, 299–313. [Google Scholar] [CrossRef]

- Wen, S.H.; Chung, D.D.L. Effects of carbon black on the thermal, mechanical and electrical properties of pitch-matrix composites. Carbon 2004, 42, 2393–2397. [Google Scholar] [CrossRef]

- Feng, Z.-G.; Rao, W.-Y.; Chen, C.; Tian, B.; Li, X.-J.; Li, P.-L.; Guo, Q.-L. Performance evaluation of bitumen modified with pyrolysis carbon black made from waste tyres. Constr. Build. Mater. 2016, 111, 495–501. [Google Scholar] [CrossRef]

- Pal, A.; Thu, K.; Mitra, S.; El-Sharkawy, I.I.; Saha, B.B.; Kil, H.-S.; Yoon, S.-H.; Miyawaki, J. Study on biomass derived activated carbons for adsorptive heat pump application. Int. J. Heat Mass Trans. 2017, 110, 7–19. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.P.; Xiao, F.P.; Pang, L.; Xiao, Y. Conductive asphalt concrete: A review on structure design, performance, and practical applications. J. Intell. Mater. Syst Struct. 2015, 26, 755–769. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Liao, H. Advances in self-monitoring asphalt concrete. In Proceedings of the 15th COTA International Conference of Transportation Professionals, Beijing, China, 24–27 July 2015; American Society of Civil Engineers: Reston, VA, USA, 2015; pp. 810–822. [Google Scholar]

- Wang, H.; Yang, J.; Liao, H.; Chen, X. Electrical and mechanical properties of asphalt concrete containing conductive fibers and fillers. Constr. Build. Mater. 2016, 122, 184–190. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Lu, G.; Liu, X. Accelerated healing in asphalt concrete via laboratory microwave heating. J. Test. Eval. 2020, 48. [Google Scholar] [CrossRef]

- Wu, S.; Mo, L.; Shui, Z.; Chen, Z. Investigation of the conductivity of asphalt concrete containing conductive fillers. Carbon 2005, 43, 1358–1363. [Google Scholar] [CrossRef]

- Cong, P.; Xu, P.; Chen, S. Effects of carbon black on the anti aging, rheological and conductive properties of sbs/asphalt/carbon black composites. Constr. Build. Mater. 2014, 52, 306–313. [Google Scholar] [CrossRef]

- Agari, Y.; Uno, T. Thermal-conductivity of polymer filled with carbon materials—Effect of conductive particle chains on thermal-conductivity. J. Appl. Polym. Sci. 1985, 30, 2225–2235. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Non-newtonian behaviors of crumb rubber-modified bituminous binders. Appl. Sci. 2018, 8, 1760. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Gong, M. Rheological characterization of asphalt binders and mixtures modified with carbon nanotubes. In Rilem Bookser; Springer: Berlin/Heidelberg, Germany, 2016; pp. 141–150. [Google Scholar]

- Airey, G. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- D’Angelo, J.A. The relationship of the mscr test to rutting. Road Mater. Pavement Des. 2011, 10, 61–80. [Google Scholar] [CrossRef]

- Chaala, A.; Roy, C.; Ait-Kadi, A. Rheological properties of bitumen modified with pyrolytic carbon black. Fuel 1996, 75, 1575–1583. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Effect of crumb rubber modifier dissolution on storage stability of crumb rubber-modified asphalt. Trans. Res. Rec. J. Trans. Res. Board 2013, 2370, 109–115. [Google Scholar] [CrossRef]

| Properties | Unit | Value |

|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | dmm | 71 |

| Ductility (5 cm/min, 5 °C) | cm | 32.2 |

| Softening point (R&B) | °C | 47.5 |

| Flash point | °C | 272 |

| Rotational viscosity (60 °C) | Pa·s | 203 |

| Wax content | % | 1.6 |

| Density (15 °C) | g/cm3 | 1.032 |

| Properties | Unit | Value |

|---|---|---|

| Iodine absorption | g/kg | 82 |

| DPB absorption | cm3/100 g | 102 |

| DPB absorption of the compressed sample | cm3/100 g | 90 |

| CTAB surface area | cm2/100 g | 83 |

| Nitrogen absorption surface area | cm2/100 g | 79 |

| Heating loss | % | 2.3 |

| Ash content | % | 0.3 |

| Density | g/cm3 | 1.871 |

| 45-µm sieve residue | % | 0.09 |

| Tensile modulus at 300% strain | MPa | 1.8 |

| Electrical resistivity | Ω·cm | 0.472 |

| Binder Types | Rotational Viscosity (Pa·s) | Temperature Range (°C) | ||

|---|---|---|---|---|

| 135 °C | 165 °C | Mixing | Compaction | |

| Neat bitumen | 0.39 | 0.05 | 147–150 | 139–143 |

| CMB-6 | 0.61 | 0.07 | 152–155 | 145–148 |

| CMB-12 | 0.84 | 0.11 | 156–160 | 149–152 |

| CMB-18 | 1.21 | 0.15 | 162–166 | 155–158 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Lu, G.; Feng, S.; Wen, X.; Yang, J. Characterization of Bitumen Modified with Pyrolytic Carbon Black from Scrap Tires. Sustainability 2019, 11, 1631. https://doi.org/10.3390/su11061631

Wang H, Lu G, Feng S, Wen X, Yang J. Characterization of Bitumen Modified with Pyrolytic Carbon Black from Scrap Tires. Sustainability. 2019; 11(6):1631. https://doi.org/10.3390/su11061631

Chicago/Turabian StyleWang, Haopeng, Guoyang Lu, Shuyin Feng, Xiaobo Wen, and Jun Yang. 2019. "Characterization of Bitumen Modified with Pyrolytic Carbon Black from Scrap Tires" Sustainability 11, no. 6: 1631. https://doi.org/10.3390/su11061631

APA StyleWang, H., Lu, G., Feng, S., Wen, X., & Yang, J. (2019). Characterization of Bitumen Modified with Pyrolytic Carbon Black from Scrap Tires. Sustainability, 11(6), 1631. https://doi.org/10.3390/su11061631