Selection of Sustainable Short-Span Bridge Design in Brazil

Abstract

1. Introduction

2. Multi-Criteria Decision-Making

3. Materials and Methods

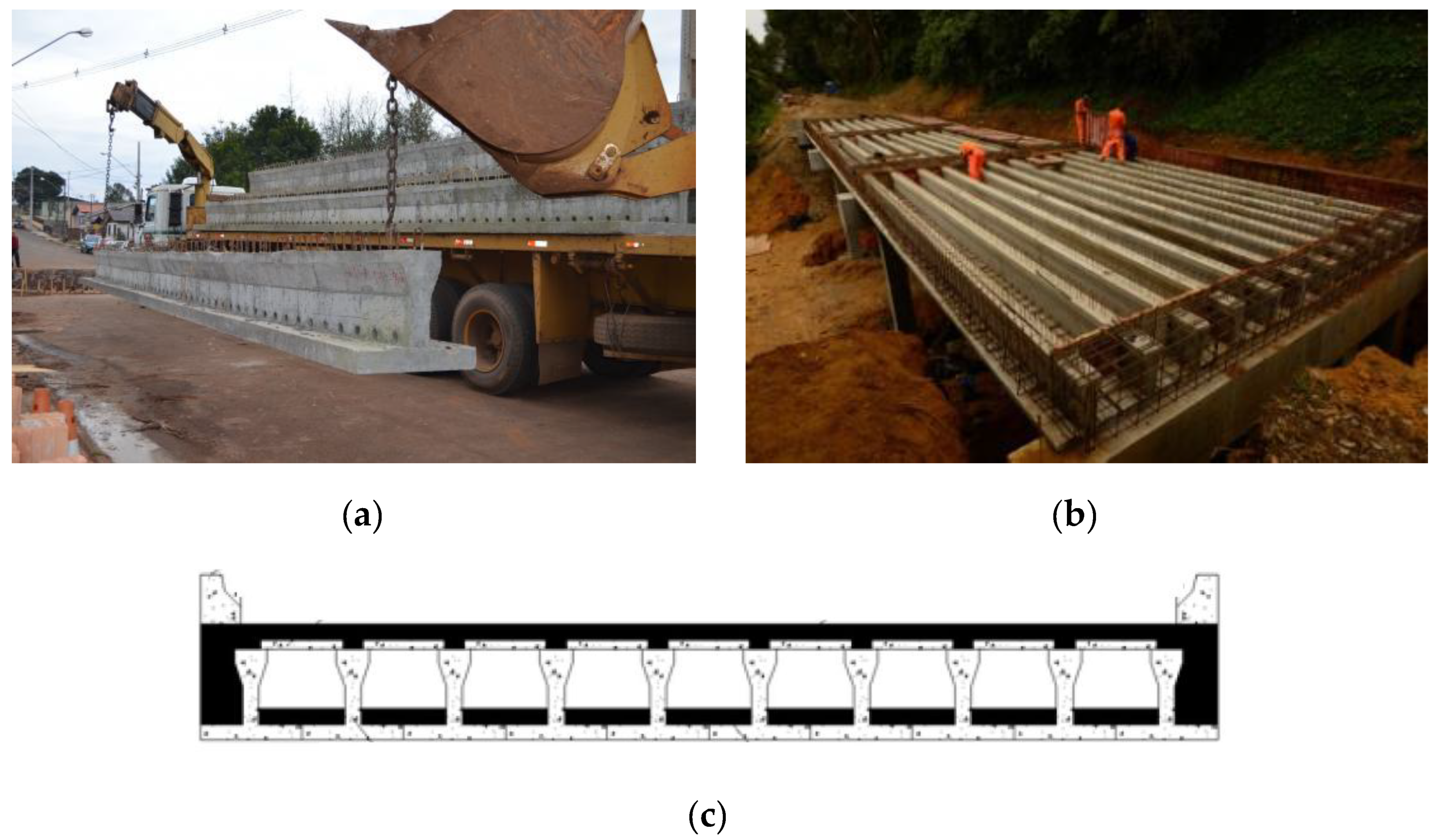

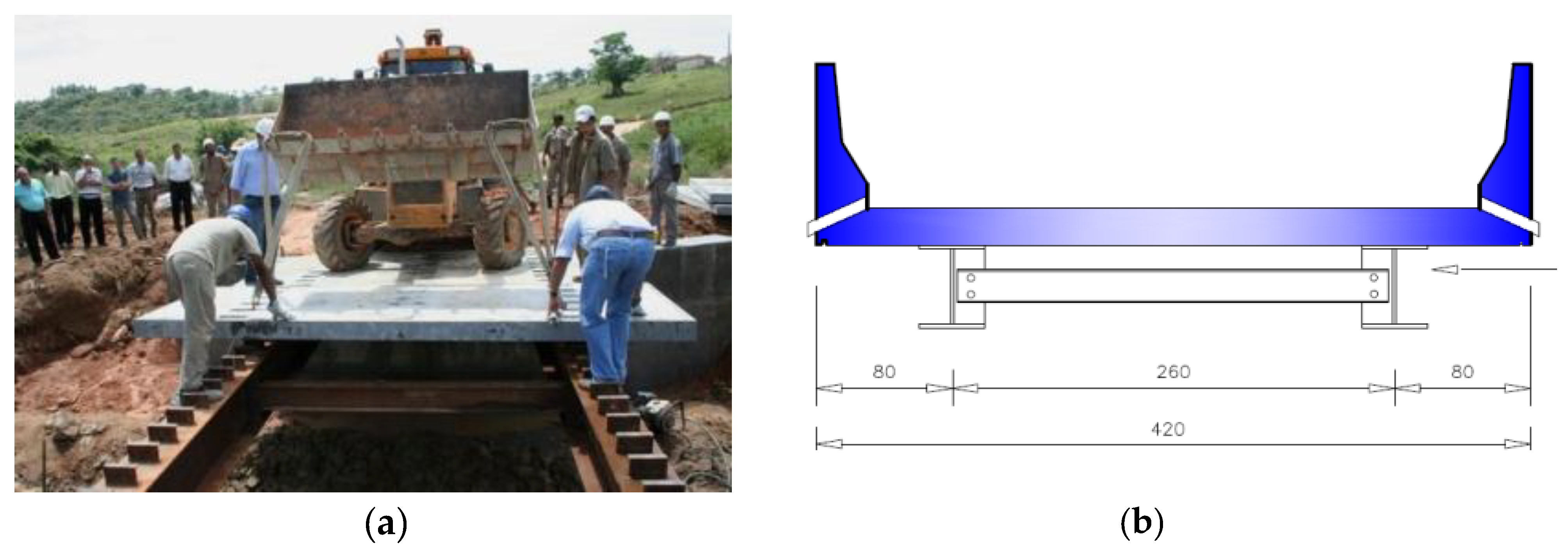

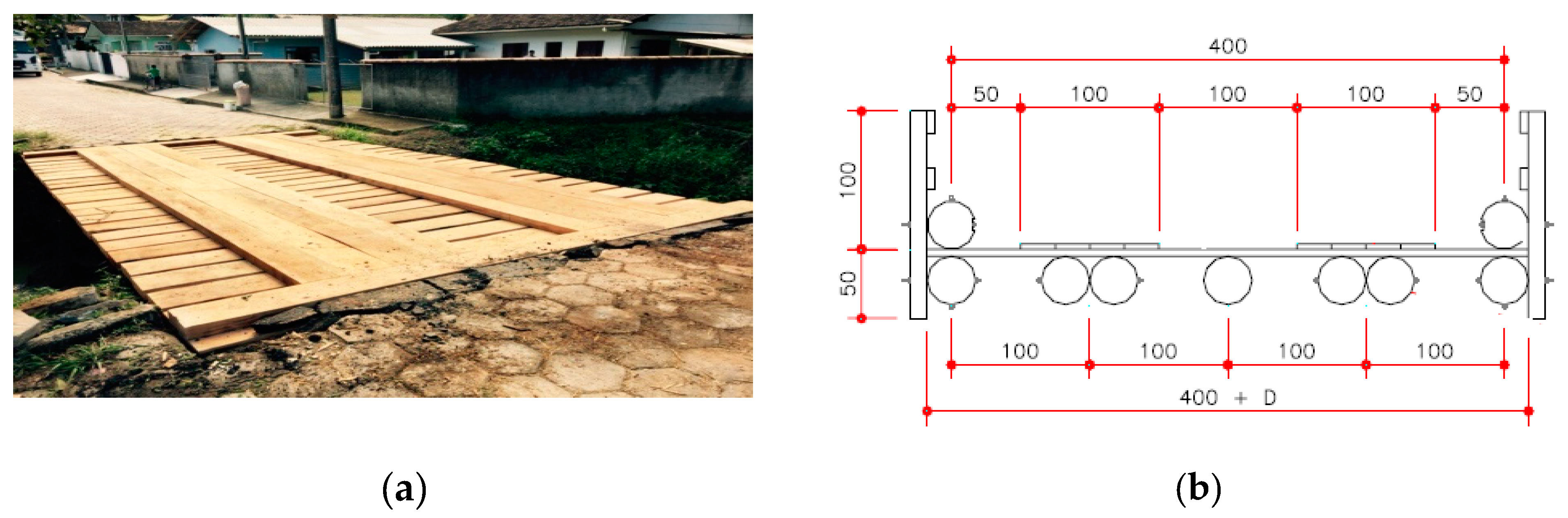

3.1. Bridges Studied

3.2. Criteria Adopted

3.2.1. Costs of Construction/Assembly and Transportation

3.2.2. Lifespan

3.2.3. Environmental Impact

3.2.4. Architecture and Security Sensation

4. Results and Discussion

5. Conclusions and Final Considerations

- Much work has been done regarding the application of MCDM methods to bridges, especially focusing on maintenance. Alternatively, more efforts could be made to design small-span bridges to fulfill the needs of infrastructure, especially in developing countries. It is important that these new structures not only have the least cost but also consider other important aspects, such as their impact on the environment.

- Both the MCDM methods considered led to similar results, identifying the mixed steel/concrete bridge as the most suitable option, despite its higher construction and assembly cost. Even when considering the impact caused by the production of steel, its elevated relation between the strength and own weight led to a relatively low transportation cost. Precast concrete bridges presented the worst results when considering the environmental impacts.

- Although less expensive, timber bridges cannot be considered a good alternative, owing to their transportation cost, architecture, security sensation, and lifespan. It is important to stress that the costs and impacts needed to guarantee the durability of timber were not considered. A study including the treatment and maintenance aspects of timber bridges could be a possible direction in future works.

- Among several possible configurations, the timber bridge selected was one of the most used in Brazil. Its simplicity explained the worst evaluation in terms of the architecture and security sensation. The consideration of other alternatives, such as glue-laminated timber bridges, can allow the construction of more aesthetically pleasant (but more expensive) bridges. In this sense, the evaluation of other timber bridge configurations could be interesting.

- Aiming to study the influence of several aspects such as relative cost variations and the weights of the subjective criteria on the results, additional simulations were performed. It was seen that these considerations did not alter the final weights significantly.

Author Contributions

Funding

Conflicts of Interest

References

- Karas, S.; Bohatkiewicz, J. Sustainable Bridge Design. Probl. Ekorozw./Probl. Sustain. Dev. 2015, 10, 123–132. [Google Scholar]

- Fonte, T.F.; Calil, C., Jr. Pontes protendidas de madeira: Alternativa técnico—Econômica para vias rurais. Artig. Técnico-Eng. Agríc. Jaboticabal 2007, 27, 2. [Google Scholar] [CrossRef]

- Milani, C.J.; Kripka, M. Diagnosis of Pathologies in Bridges of the Road System in Brazil. Constructii 2012, 13, 26–34. [Google Scholar]

- Hurd, M.K. Economical Short Span Concrete Bridges. 1985. Available online: https://www.concreteconstruction.net/how-to/construction/economical-short-span-concrete-bridges_o (accessed on 13 December 2018).

- Vitório, J.A.P.; Barros, R.M.M.C. Análise dos danos estruturais e das condições de estabilidade de 100 pontes rodoviárias no Brasil. In Segurança, Conservação e Reabilitação de Pontes; Cruz, P.J.S., Calçada, R., Mendonça, T., Eds.; Associação Portuguesa para a Segurança e Conservação de Pontes: Lisbon, Portugal, 2013; pp. 62–70. [Google Scholar]

- Vladimir, M.; Mihai, V. Economical Solutions for Short-span Bridges Using Reinforced Glue Laminated Timber and Steel. Procedia Eng. 2016, 156, 227–232. [Google Scholar] [CrossRef]

- Ricardo, F.; Kripka, M.; Pravia, Z.M.C. Composite bridges: Study of parameters of optimized design. Int. J. Bridge Eng. 2017, 5, 1–20. [Google Scholar]

- Calmon, N.; da Gama, J.; Vieira, D.; Coutinho, S. Perceptions of Sustainability in Civil Construction Projects: Analysis of Brazilian Construction Sites. J. Mod. Proj. Manag. N. Am. 2014, 2. Available online: http://www.mundopm.com.br/jmpm/index.php/jmpm/article/view/66 (accessed on 21 December 2018).

- García-Segura, T.; Penadés-Plá, V.; Yepes, V. Sustainable bridge design by metamodel-assisted multi-objective optimization and decision-making under uncertainty. J. Clean. Prod. 2018, 202, 904–915. [Google Scholar] [CrossRef]

- Yepes, V.; Martí, J.V.; García-Segura, T. Cost and CO2 emission optimization of precast-prestressed concrete U-beam road bridges by a hybrid glowworm swarm algorithm. Autom. Constr. 2015, 49, 123–134. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V. Multiobjective optimization of post-tensioned concrete box-girder road bridges considering cost, CO2 emissions, and safety. Eng. Struct. 2016, 125, 325–336. [Google Scholar] [CrossRef]

- Ardeshir, A.; Mohseni, N.; Behzadian, K.; Errington, M. Selection of a bridge construction site using fuzzy analytical hierarchy process in geographic information system. Arab. J. Sci. Eng. 2014, 39, 4405–4420. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Martí, J.V.; Alcalá, J. Optimization of concrete I beams using a new hybrid glowworm swarm algorithm. Lat. Am. J. Solid. Struct. 2014, 11, 1190–1205. [Google Scholar] [CrossRef]

- Gervasio, H.; Simões da Silva, L. A probabilistic decision-making approach for the sustainable assessment of infrastructures. Expert Syst. Appl. 2012, 39, 7121–7131. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; García-Segura, T.; Yepes, V. An optimization-LCA of a prestressed concrete precast bridge. Sustainability 2018, 10, 685. [Google Scholar] [CrossRef]

- Zukhsh, Z.A.; Stipanovic, I.; Klanker, G.; O’ Connor, A.; Doree, A.G. Network level bridges maintenance planning using Multi-Attribute Utility Theory. Struct. Infrastruct. Eng. 2018. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; García-Segura, T.; Martí, J.; Yepes, V. A review of multi-criteria decision-making methods applied to the sustainable bridge design. Sustainability 2016, 8, 1295. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Antucheviciene, J.; Vilutiene, T.; Adeli, H. Sustainable Decision-Making in Civil Engineering, Construction and Building Technology. Sustainability 2018, 10, 14. [Google Scholar] [CrossRef]

- Du, G.; Karoumi, R. Life cycle assessment framework for railway bridges: Literature survey and critical issues. Struct. Infrastruct. Eng. 2014, 10, 277–294. [Google Scholar] [CrossRef]

- Du, G.; Karoumi, R. Environmental life cycle assessment comparison between two bridge types: Reinforced concrete bridge and steel composite bridge. In Proceedings of the SCMT3, International Conference on Sustainable Construction Materials & Technologies, Kyoto, Japan, 18–21 August 2013. [Google Scholar]

- Mara, V.; Haghani, R.; Sagemo, A.; Storck, L.; Nilsson, D. Comparative study of different bridge concepts based on life-cycle cost analyses and life-cycle assessment. In Proceedings of the 4th Asia-Pacific Conference on FRP in Structures (APFIS 2013), Melbourne, Australia, 11–13 December 2013. [Google Scholar]

- Gervasio, H.; Simões da Silva, L. Comparative life-cycle analysis of steel-concrete composite bridges. Struct. Infrastruct. Eng. 2008, 4, 251–269. [Google Scholar] [CrossRef]

- Hammervold, J.; Reenaas, M.; Brattebø, H. Environmental life cycle assessment of bridges. J. Bridge Eng. 2011, 18, 153–161. [Google Scholar] [CrossRef]

- Itoh, Y.; Kitagawa, T. Using CO2 emission quantities in bridge lifecycle analysis. Eng. Struct. 2003, 25, 565–577. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making with the Analytic Hierarchy Process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Zamarrón-Mieza, I.; Yepes, V.; Moreno-Jiménez, J.M. A systematic review of application of multi-criteria decision analysis for aging-dam management. J. Clean. Prod. 2017, 47, 217–230. [Google Scholar] [CrossRef]

- Milani, C.J. Sustainability Assessment as One of the Indicators to Bridge Designs for Rural and Secondary Roads; Research report; Universidade de Passo Fundo: Passo Fundo, Brazil, 2018. (In Portuguese) [Google Scholar]

- Júnior, C.C.; Dias, A.A.; Góes, J.L.N.d.; Cheung, A.B.; Stamato, G.C.; Pigozzo, J.C.; Okimoto, F.S.; Logsdon, N.B.; Brazolin, S.; Lana, E.L. Manual de projeto e construção de pontes de madeira. 2006. Available online: http://www.usp.br/agen/wp-content/uploads/Manual-de-Pontes-de-Madeira.pdf (accessed on 13 December 2018).

- Vincentsen, L.J.; Hendricksen, K.R. The Great Belt Link—Built to Last. Concr. Int. 1992, 14, 30–33. [Google Scholar]

- AASHTO LRFD Bridge Design Specifications, 4th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007.

- British Standards Institution (BSI). Guide to Durability of Buildings and Building Element, Products and Components, BS 7543; British Standards Institution (BSI): London, UK, 2003. [Google Scholar]

- EN (European Standard). EN 206-1 2013. Concrete—Part 1: Specification, Performance, Production and Conformity; European Committee for Standarization (CEN): Brussels, Belgium, 2013. [Google Scholar]

- Ritter, M.A. Timber Bridges; Forest Products Laboratory—Forest Service: Madison, WI, USA, 1992.

- Santoro, J.F.; Kripka, M. Studies on Environmental Impact Assessment of Reinforced Concrete in Different Life Cycle Phases. Int. J. Struct. Glass Adv. Mater. Res. 2017, 1, 32–40. [Google Scholar] [CrossRef]

- Zuo, J.; Pullen, S.; Rameezdeen, R. Green building evaluation from a life-cycle perspective in Australia: A critical review. Renew. Sustain. Energy Rev. 2017, 70, 358–368. [Google Scholar] [CrossRef]

- Mahnert, K.C.; Hundhausen, U. A review on the protection of timber bridges. Wood Mater. Sci. Eng. 2018, 13, 152–158. [Google Scholar] [CrossRef]

- National Ready Mixed Concrete Association. Concrete CO2 Fact Sheet. 2008. Available online: www.nrmca.org/greenconcrete/concrete%20co2%20fact%20sheet%20june%202008.pdf (accessed on 10 February 2019).

| Alternative | Total Cost (US$) | Total Area (m2) | Unit Cost (Construction /Assembly, US$/m2) | Unit Cost (Transportation, US$/m2) | Unit Cost (Construction /Assembly and Transportation, US$/m2) |

|---|---|---|---|---|---|

| Precast Concrete | 11,326.04 | 36.00 | 312.07 | 2.54 | 314.61 |

| Mixed Steel/concrete | 11,831.53 | 33.60 | 350,42 | 1.71 | 352.13 |

| Timber | 8,419.84 | 33.60 | 238.24 | 12.35 | 250.59 |

| Alternative | GWP (kgCO2eq/m2) |

|---|---|

| Precast Concrete | 296.00 |

| Mixed Steel/concrete | 194.00 |

| Timber | 174.00 |

| Precast Concrete | Mixed Steel/Concrete | Timber | |

|---|---|---|---|

| Precast Concrete | 1 | 1 | 3 |

| Mixed Steel/concrete | 1 | 1 | 3 |

| Timber | 0.3333 | 0.3333 | 1 |

| Precast Concrete | Mixed Steel/Concrete | Timber | |

|---|---|---|---|

| Precast Concrete | 1 | 0.3333 | 3 |

| Mixed Steel/concrete | 3 | 1 | 5 |

| Timber | 0.3333 | 0.2 | 1 |

| Alternative | Cost (US$/m2) | Lifespan (Years) | Environmental Impact (kgCO2eq/m2) | Architecture | Security Sensation |

|---|---|---|---|---|---|

| Min | Max | Min | Max | Max | |

| Precast Concrete | 314.61 | 100 | 296.00 | 0.4286 | 0.2583 |

| Mixed Steel/concrete | 352.13 | 100 | 194.00 | 0.4286 | 0.6370 |

| Timber | 250.59 | 50 | 174.00 | 0.1429 | 0.1047 |

| Alternative | Cost | Lifespan | Environmental Impact | Architecture | Security Sensation | Final |

|---|---|---|---|---|---|---|

| Precast Concrete | 0.318 | 0.400 | 0.237 | 0.4286 | 0.2583 | 0.3232 |

| Mixed Steel/concrete | 0.284 | 0.400 | 0.361 | 0.4286 | 0.6370 | 0.3823 |

| Timber | 0.399 | 0.200 | 0.402 | 0.1429 | 0.1047 | 0.2958 |

| Alternative | Cost | Lifespan | Impact | Architecture | Security Sensation |

|---|---|---|---|---|---|

| Precast Concrete | 0.128 | 0.000 | 0.030 | 0.000 | 0.297 |

| Mixed Steel/concrete | 0.204 | 0.000 | 0.005 | 0.000 | 0.000 |

| Timber | 0.000 | 0.306 | 0.000 | 0.043 | 0.417 |

| Alternative | Sj | Rj |

|---|---|---|

| Precast Concrete | 0.455 | 0.297 |

| Mixed Steel/concrete | 0.209 | 0.204 |

| Timber | 0.767 | 0.417 |

| Alternative | Original | Variation 1 | Variation 2 |

|---|---|---|---|

| Precast Concrete | 0.3232 | 0.3213 | 0.3273 |

| Mixed Steel/concrete | 0.3823 | 0.3459 | 0.3725 |

| Timber | 0.2958 | 0.3339 | 0.3010 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kripka, M.; Yepes, V.; Milani, C.J. Selection of Sustainable Short-Span Bridge Design in Brazil. Sustainability 2019, 11, 1307. https://doi.org/10.3390/su11051307

Kripka M, Yepes V, Milani CJ. Selection of Sustainable Short-Span Bridge Design in Brazil. Sustainability. 2019; 11(5):1307. https://doi.org/10.3390/su11051307

Chicago/Turabian StyleKripka, Moacir, Victor Yepes, and Cleovir José Milani. 2019. "Selection of Sustainable Short-Span Bridge Design in Brazil" Sustainability 11, no. 5: 1307. https://doi.org/10.3390/su11051307

APA StyleKripka, M., Yepes, V., & Milani, C. J. (2019). Selection of Sustainable Short-Span Bridge Design in Brazil. Sustainability, 11(5), 1307. https://doi.org/10.3390/su11051307