Servitization in Support of Sustainable Cities: What Are Steel’s Contributions and Challenges?

Abstract

1. Introduction

1.1. Sustainable Cities: Cells of a Larger Organism

1.2. Servitization: Demand-Side Circularity from Within

1.3. The Role of a Commodity in a Service Economy

2. Methodology

2.1. Tools

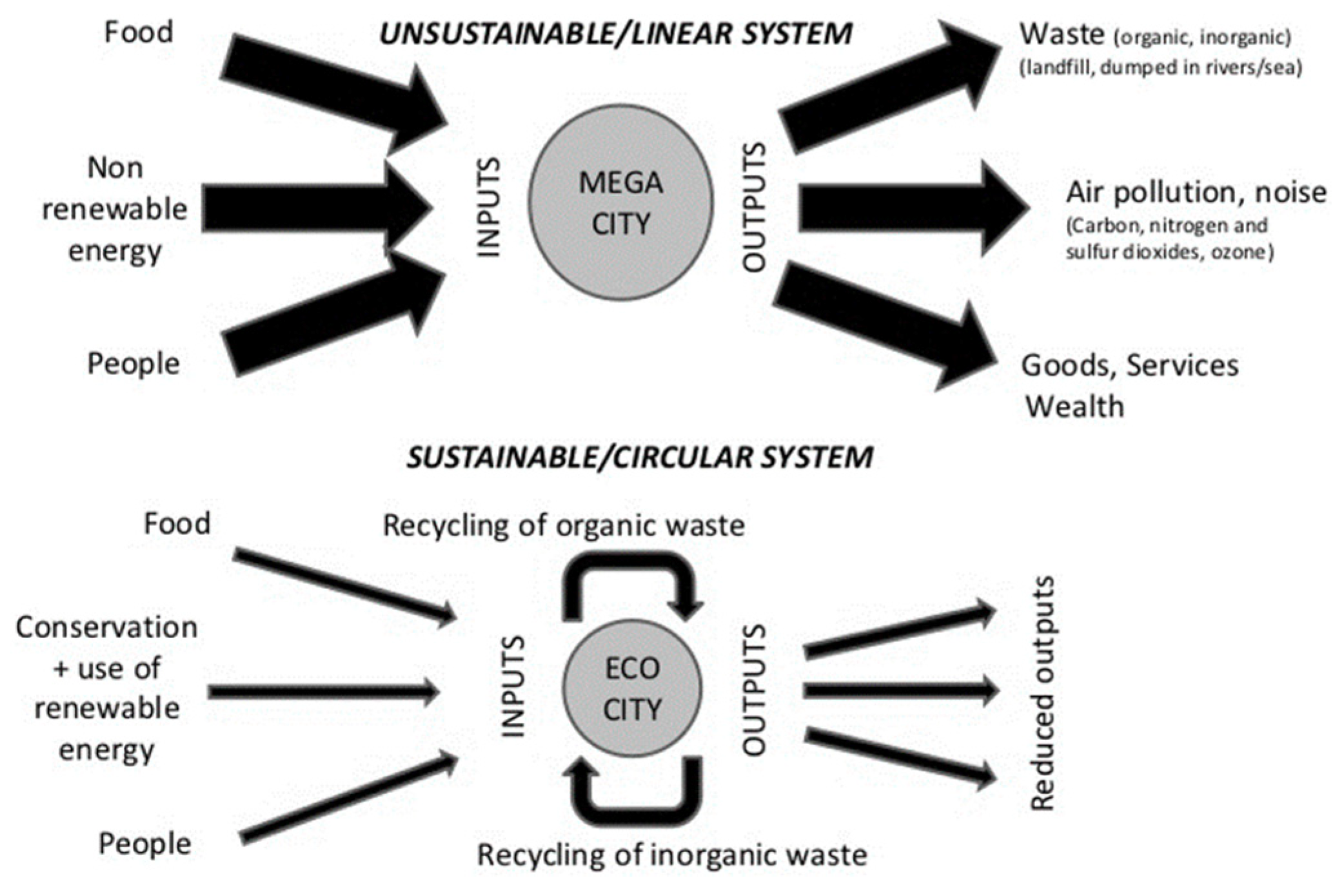

2.1.1. Sustainable Urban Metabolism

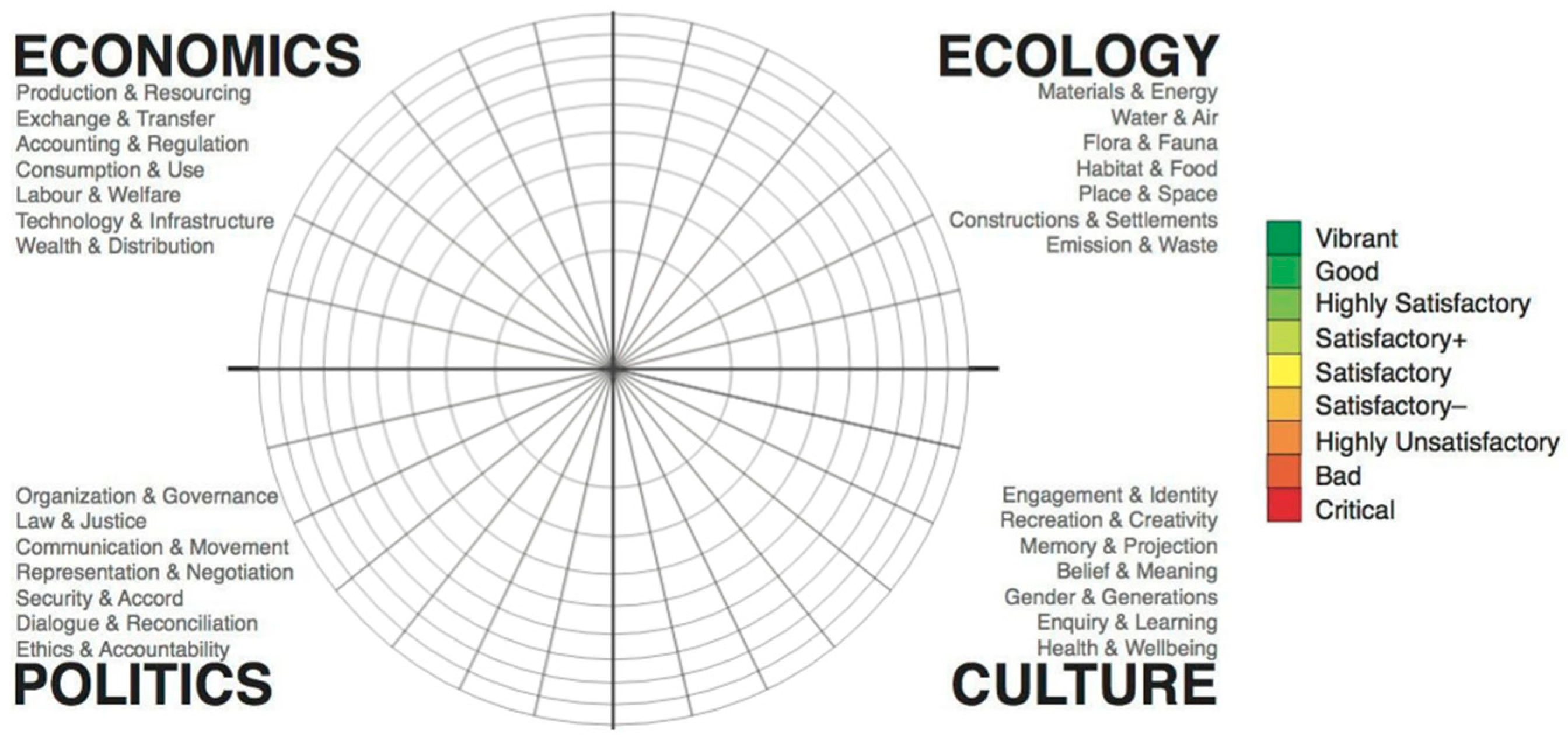

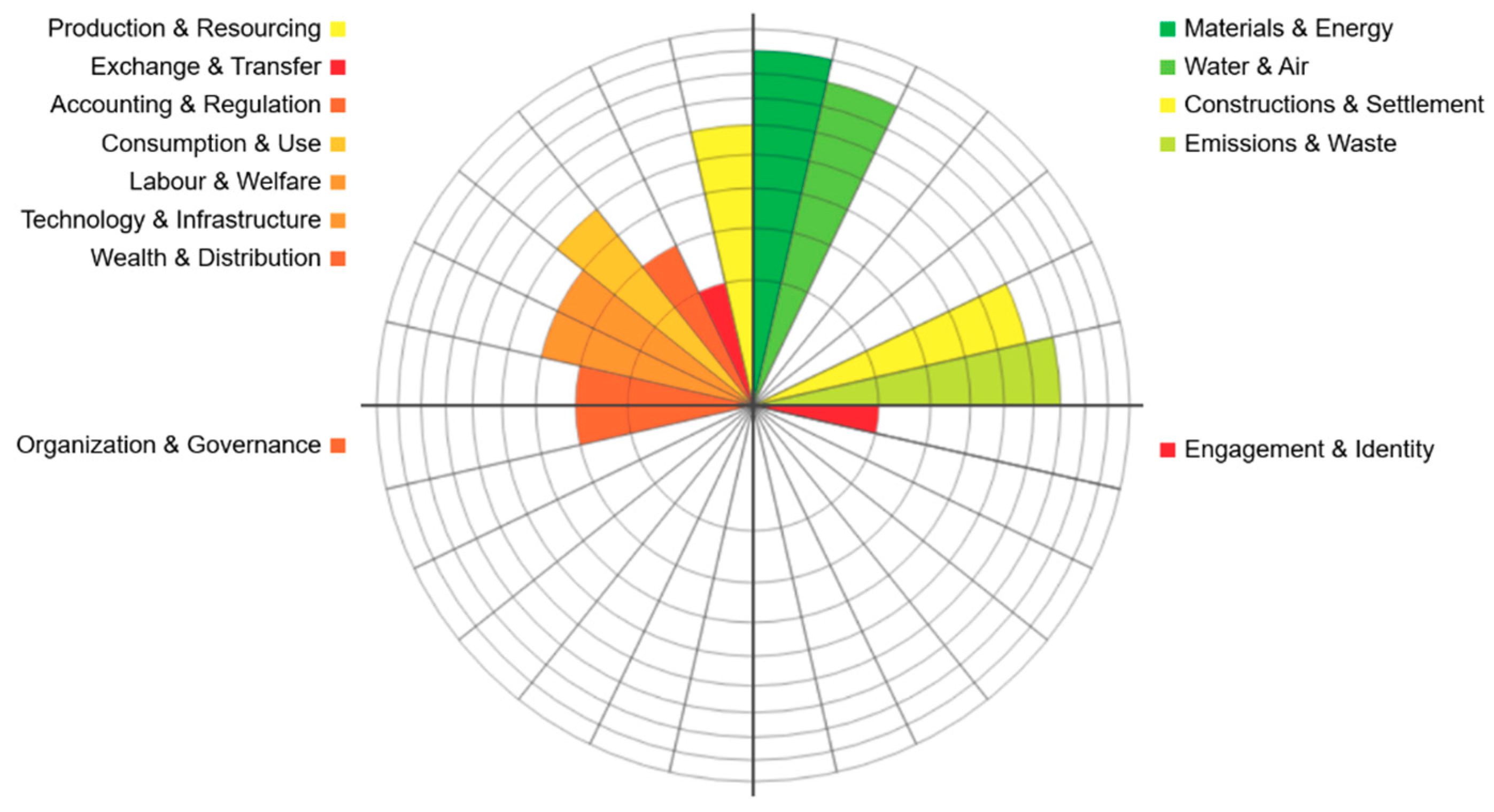

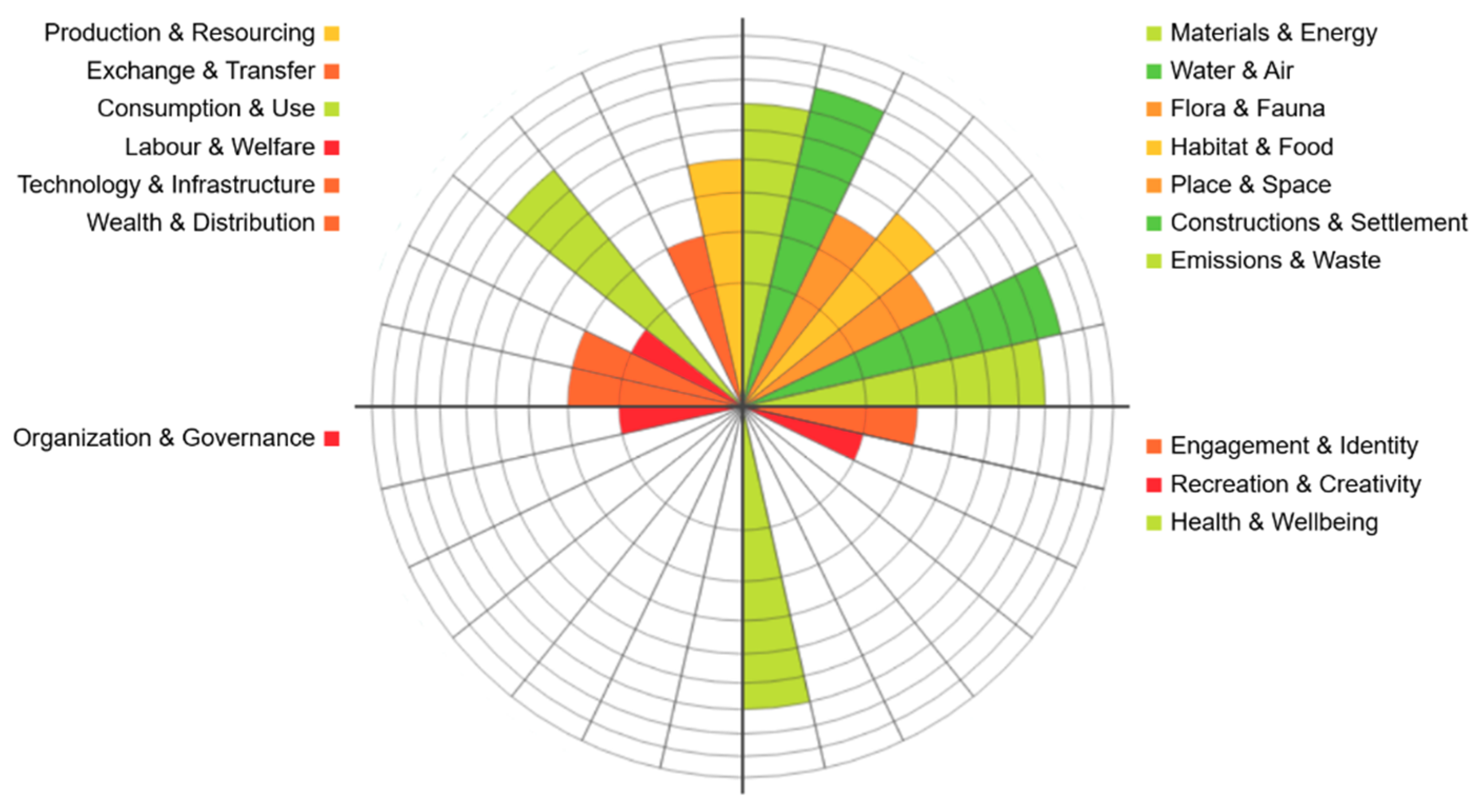

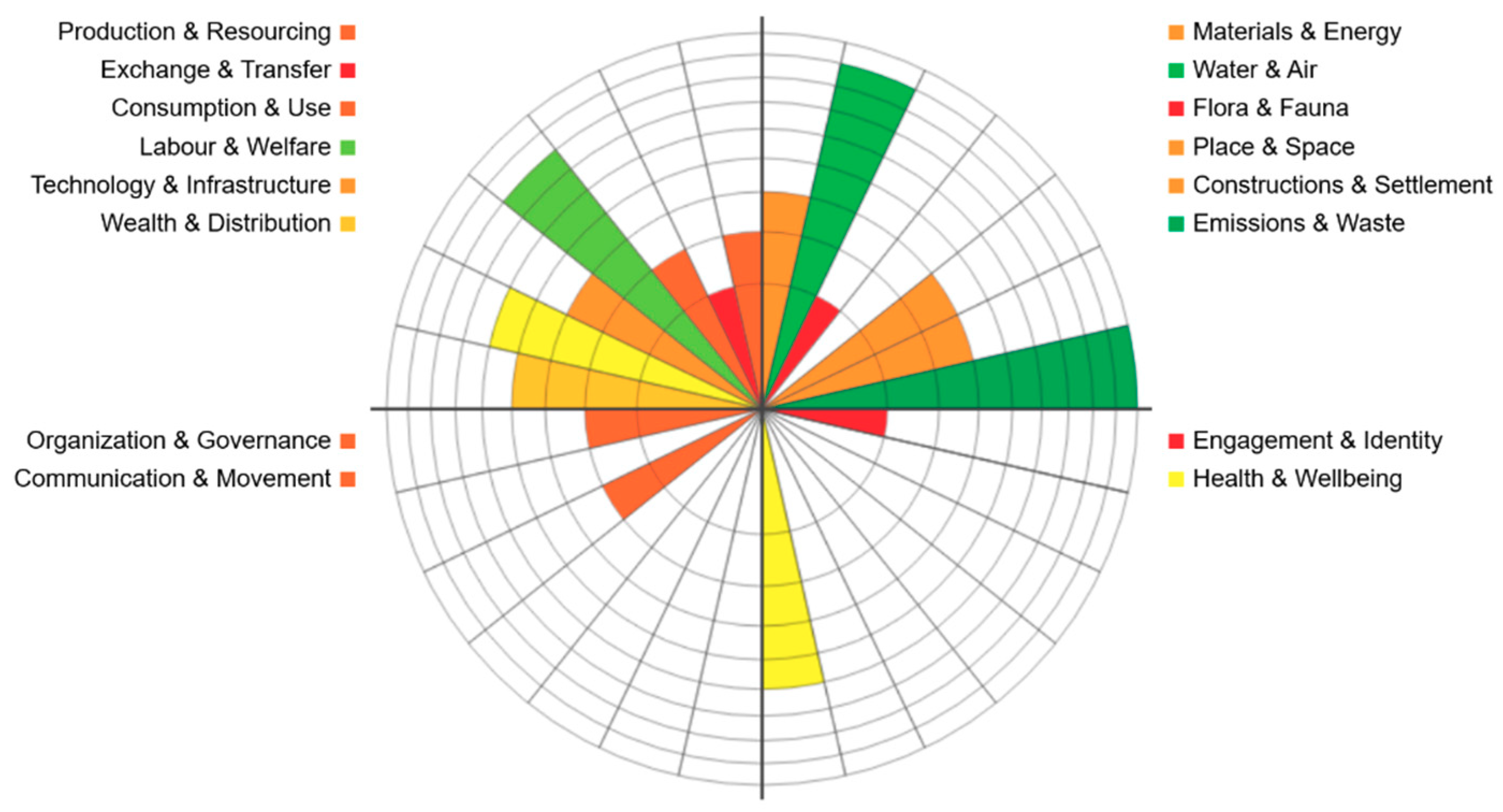

2.1.2. Circles of Sustainability

2.2. Case Studies

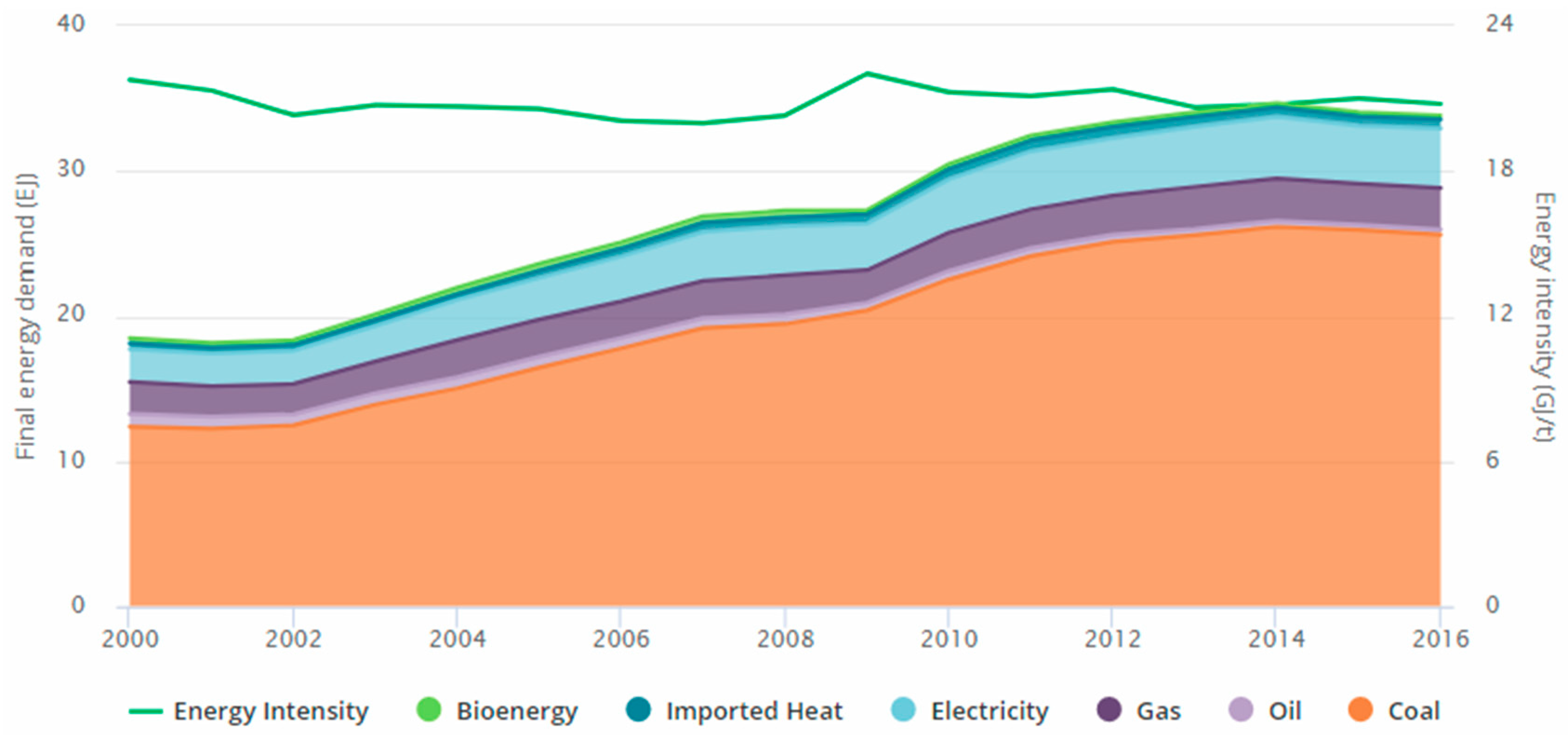

2.2.1. Energy

2.2.2. Housing

2.2.3. Mobility

3. Results

3.1. Energy

3.2. Housing

3.3. Mobility

4. Discussions and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mega, V. Towards European sustainable cities. Athens Cent. Ekistics 1996, 63, 273–288. [Google Scholar]

- Akande, A.; Cabral, P.; Gomes, P.; Casteleyn, S. The Lisbon ranking for smart sustainable cities in Europe. Sustain. Cities Soc. 2019, 44, 475–487. [Google Scholar] [CrossRef]

- Bibri, S.E.; Krogstie, J. Smart sustainable cities of the future: An extensive interdisciplinary literature review. Sustain. Cities Soc. 2017, 31, 183–212. [Google Scholar] [CrossRef]

- Albertí, J.; Balaguera, A.; Brodhag, C.; Fullana-I-Palmer, P. Towards life cycle sustainability assessment of cities. A review of background knowledge. Sci. Total Environ. 2017, 609, 1049–1063. [Google Scholar] [CrossRef] [PubMed]

- Ahvenniemi, H.; Huovila, A.; Pinto-Seppä, I.; Airaksinen, M. What are the differences between sustainable and smart cities? Cities 2017, 60, 234–245. [Google Scholar] [CrossRef]

- Green, M.H.; Davies, P.; Ng, I.C.L. Two strands of servitization: A thematic analysis of traditional and customer co-created servitization and future research directions. Int. J. Prod. Econ. 2017, 192, 40–53. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Baines, T.; Rabetino, R.; Bigdeli, A.Z. Practices and Tools for Servitization: Managing Service Transition; Palgrave Macmillan: Birmingham, UK, 2018; ISBN 9783319765167. [Google Scholar]

- Kowalkowski, C.; Gebauer, H.; Oliva, R. Service growth in product firms: Past, present, and future. Ind. Mark. Manag. 2017, 60, 82–88. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Grober, U. Deep Roots—A Conceptual History of Sustainable Development; Wissenschaftszentrum Berlin für Sozialforschung (WZB): Berlin, Germany, 2007. [Google Scholar]

- BC. Report of the World Commission on Environment and Development: Our Common Future; Brundtland, G.H.: Oslo, Norway, 1987. [Google Scholar]

- Aalborg Charter. Charter of European Cities & Towns towards Sustainability. In Proceedings of the European Conference on Sustainable Cities & Towns, Aalborg, Denmark, 27 May 1994. [Google Scholar]

- UNEP. Melbourne Principles for Sustainable Cities; United Nations Environment Programme—Division of Technology, Industry, and Economics—International Environmental Technology Center: Osaka, Japan, 2002. [Google Scholar]

- Sartori, S.; Silva, F.L.; Campos, L.M.S. Sustainability and sustainable development: A taxonomy in the field of literature. Ambient. Soc. 2014, 17, 1–22. [Google Scholar] [CrossRef]

- Meadows, D.L.; Meadows, D.H.; Randers, J. Beyond the Limits: Confronting Global Collapse, Envisioning a Sustainable Future; Green Publishing: Chelsea, MA, USA, 1993; ISBN 0930031628. [Google Scholar]

- Brugmann, J. Welcome to the Urban Revolution: How Cities Are Changing the World; Bloomsburry Press: London, UK, 2009; ISBN 9781608190928. [Google Scholar]

- Burdett, R.; Sudjic, D. Living in the Endless City; Phaidon Press: London, UK, 2011; ISBN 9780714861180. [Google Scholar]

- Rogers, R. Cities for a Small Planet; Westview: Boulder, CO, USA, 1997; ISBN 0813335531. [Google Scholar]

- De Jong, M.; Joss, S.; Schraven, D.; Zhan, C.; Weijnen, M. Sustainable-smart-resilient-low carbon-eco-knowledge cities; making sense of a multitude of concepts promoting sustainable urbanization. J. Clean. Prod. 2015, 109, 25–38. [Google Scholar] [CrossRef]

- Lay, G. Servitization in Industry; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Levitt, T. The Marketing Mode—Pathways to Corporate Growth; McGraw-Hill: New York, NY, USA, 1969. [Google Scholar]

- Vandermerwe, S.; Rada, J. Servitization of business: Adding value by adding services. Eur. Manag. J. 1988, 6, 314–324. [Google Scholar] [CrossRef]

- Matschewsky, J.; Kambanou, M.L.; Sakao, T. Designing and providing integrated product-service systems—Challenges, opportunities and solutions resulting from prescriptive approaches in two industrial companies. Int. J. Prod. Res. 2017, 56, 2150–2168. [Google Scholar] [CrossRef]

- Frambach, R.T.; Wels-Lips, I.; Gündlach, A. Proactive product service strategies—An application in the European health market. Ind. Mark. Manag. 1997, 26, 341–352. [Google Scholar] [CrossRef]

- Boyt, T.; Harvey, M. Classification of industrial services—A model with strategic implications. Ind. Mark. Manag. 1997, 26, 291–300. [Google Scholar] [CrossRef]

- Mathieu, V. Service strategies within the manufacturing sector: Benefits, costs and partnerships. Int. J. Serv. Ind. Manag. 2001, 12, 451–475. [Google Scholar] [CrossRef]

- Tukker, A. Eight types of product-service system: Eight ways to sustainability? Experiences from Suspronet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Lightfoot, H.; Baines, T.; Smart, P. The servitization of manufacturing: A systematic literature review of interdependent trends. Int. J. Oper. Prod. Manag. 2013, 33, 1408–1434. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Benedettini, O.; Kay, J.M. The servitization of manufacturing: A review of literature and reflection on future challenges. J. Manuf. Technol. Manag. 2009, 20, 547–567. [Google Scholar] [CrossRef]

- Coombs, R.; Miles, I. Innovation, Measurement and Services: The New Problematique; Kluwer Academics: Boston, MA, USA, 2000. [Google Scholar]

- Oliva, R.; Kallenberg, R. Managing the transition from products to services. Int. J. Serv. Ind. Manag. 2003, 14, 160–172. [Google Scholar] [CrossRef]

- Zhang, W.; Banerji, S. Challenges of servitization: A systematic literature review. Ind. Mark. Manag. 2017, 65, 217–227. [Google Scholar] [CrossRef]

- Burton, J.; Story, V.M.; Raddats, C.; Zolkiewski, J. Overcoming the challenges that hinder new service development by manufacturers with diverse services strategies. Int. J. Prod. Econ. 2017, 192, 29–39. [Google Scholar] [CrossRef]

- Rothenberg, S. Sustainability through servicizing. MIT Sloan Manag. Rev. 2007, 48, 82–91. [Google Scholar]

- World Steel (WS). Sustainable Steel: At the Core of a Green Economy; WorldSteel Association: Brussels, Belgium, 2012. [Google Scholar]

- World Steel (WS). World Steel in Figures 2018; WorldSteel Association: Brussels, Belgium, 2019; Available online: https://www.worldsteel.org/media-centre/press-releases/2018/world-steel-in-figures-2018.html (accessed on 18 January 2019).

- Beddows, R. Steel 2050—How Steel Transformed the World and Now Must Transform Itself; Devonian: Kingsbridge, UK, 2014; ISBN 0993038107. [Google Scholar]

- Olmez, G.M.; Dilek, F.B.; Karanfil, T.; Yetis, U. The environmental impacts of iron and steel industry: A life cycle assessment study. J. Clean. Prod. 2015, 130, 195–201. [Google Scholar] [CrossRef]

- Vaclav, S. Still the Iron Age; Butterworth-Heinemann, Elsevier: Oxford, UK, 2016; ISBN 9780128042359. [Google Scholar]

- Warrian, P. A Profile of the Steel Industry—Global Reinvention for a New Economy; Business Expert Press: New York, NY, USA, 2012; ISBN 1631573845. [Google Scholar]

- OECD. Eco-Innovation in Industry: Enabling Green Growth; Organisation for Economic Co-Operation and Development: Paris, France, 2010; ISBN 9789264077218. [Google Scholar]

- IEA. Iron and Steel: Tracking Clean Energy Progress. International Energy Agency. 2018. Available online: https://www.iea.org/tcep/industry/steel/ (accessed on 18 January 2019).

- EC. Communication from the Commission to the Parliament, the Council, the European Economic and Social Committee and the Committee of Regions: Action Plan for a Competitive and Sustainable Steel Industry in Europe. COM(2013) 407; European Commission: Strasbourg, France, 2013; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52013DC0407 (accessed on 16 January 2019).

- WS. Steel, the Permanent Material in the Circular Economy; WorldSteel Association: Brussels, Belgium, 2016. [Google Scholar]

- BIR. World Steel Recycling in Figures; Bureau of International Recycling: Brussels, Belgium, 2017. [Google Scholar]

- Eurofer. Steel, the Backbone of Sustainability in Europe; The European Steel Association, Eurofer: Brussels, Belgium, 2017. [Google Scholar]

- Centre for European Policy Studies (CEPS). Assessment of Cumulative Cost Impact for the Steel Industry; CEPS: Brussels, Belgium, 2013. [Google Scholar]

- IETD. Electric Arc Furnaces Technologies & Measures. Institute for Industrial Productivity—Industrial Efficiency Technology Database, 2018. Available online: http://ietd.iipnetwork.org/content/electric-arc-furnace (accessed on 5 May 2018).

- Waugh, R. The end of the blast furnace era? Ironmak. Steelmak. 2016, 258–263. [Google Scholar] [CrossRef]

- Material Economics. The Circular Economy—A Powerful Force for Climate Mitigation; Material Economics: Stockholm, Sweden, 2018. [Google Scholar]

- Graedel, T.E.; Allenby, B.R. Industrial Ecology; Prentice Hall: Englewood Cliffs, NJ, USA, 1995. [Google Scholar]

- James, P. Circles of Sustainability; Routledge: Abingdon-on-Thames, UK, 2015. [Google Scholar]

- Petit-Boix, A.; Llorach-Massana, P.; Sanjuan-Delmás, D.; Sierra-Pérez, J.; Vinyes, E.; Gabarrell, X.; Rieradevall, J.; Sanyé-Mengual, E. Application of life cycle thinking towards sustainable cities: A review. J. Clean. Prod. 2017, 166, 939–951. [Google Scholar] [CrossRef]

- Ferrao, P.; Fernandez, J.E. Sustainable Urban Metabolism; MIT Press: Cambridge, MA, USA, 2013; ISBN 9780262019361. [Google Scholar]

- CoS. Circles of Sustainability-Practical Tools for Creating Sustainable Cities and Communities. 2018. Available online: https://www.circlesofsustainability.org/cities/ (accessed on 5 May 2018).

- Pinto, J.T.M.; Amaral, K.J.; Janissek, P.R. Deployment of photovoltaics in Brazil: Scenarios, perspectives and policies for low-income housing. Sol. Energy 2016, 133, 73–84. [Google Scholar] [CrossRef]

- Cerón-Palma, I.; Sanyé-Mengual, E.; Oliver-Solà, J.; Montero, J.-I.; Ponce-Caballero, C.; Rieradevall, J. Towards a green sustainable strategy for social neighborhoods in Latin America: Case from social housing in Merida, Yucatan, Mexico. Habitat Int. 2013, 38, 47–56. [Google Scholar] [CrossRef]

- Diez, J.M.; Lopez-Lambas, M.E.; Gonzalo, H.; Rojo, M.; Garcia-Martinez, A. Methodology for assessing the cost effectiveness of Sustainable Urban Mobility Plans (SUMPs). The case of the city of Burgos. J. Transp. Geogr. 2018, 68, 22–30. [Google Scholar] [CrossRef]

- Sorrell, S. The Economics of Energy Service Contracts. Energy Policy 2007, 35, 507–521. [Google Scholar] [CrossRef]

- Neely, A. Servitization in Germany: An International Comparison; Cambridge Service Alliance: Cambridge, UK, 2013. [Google Scholar]

- Neely, A. Exploring the Financial Consequences of the Servitization of Manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef]

- Benedetti, M.; Cesarotti, V.; Holgado, M.; Introna, V.; Macchi, M. A Proposal for Energy Services’ Classification Including a Product Service Systems Perspective. Procedia CIRP 2015, 30, 251–256. [Google Scholar] [CrossRef]

- Hamwi, M.; Lizarralde, I.; Legardeur, J.; Technopole, I.; Birdart, F. Energy Product Service Systems as Core Element of Energy Transition in the Household Sector: The Greenplay Project. In Proceedings of the 22nd International Sustainable Development Research Society Conference, Lisbon, Portugal, 13–15 July 2016. [Google Scholar]

- Polzin, F.; von Flotow, P.; Nolden, C. Exploring the Role of Servitization to Overcome Barriers for Innovative Energy Efficiency Technologies—The Case of Public LED Street Lighting in German Municipalities; SWPS; University of Sussex: Brighton, UK, 2015. [Google Scholar]

- IEA. Projections: Energy Policies of IEA Countries Online Data Service. International Energy Agency, 2017. Available online: https://www.iea.org/classicstats/relateddatabases/projectionsenergypoliciesofieacountries/ (accessed on 21 April 2018).

- Koch-Orvad, N.; Thuesen, C. Sustainable Building in Scandinavia: Directions of Innovations for Supporting the Transition. In Proceedings of the 32nd Annual ARCOM Conference, Manchester, UK, 5–7 September 2016. [Google Scholar]

- Kibert, C.J. Green buildings: An overview of progress. J. Land Use Environ. Law 2003, 19, 491–502. [Google Scholar]

- Wu, M.H.; Ng, T.S.; Skitmore, M.R. Sustainable building envelope design by considering energy cost and occupant satisfaction. Energy Sustain. Dev. 2016, 31, 118–129. [Google Scholar] [CrossRef]

- LEED. Reference Guide for Green Building Design and Construction; U.S. Green Building Council: Washington, DC, USA, 2010. [Google Scholar]

- WEC. World Energy Trilemma Index; World Energy Council: London, UK, 2018. [Google Scholar]

- Petros-Sebhatu, S.; Enquist, B. Sustainable Public Transit Service Value Network for Building Living Cities in Emerging Economies: Multiple Case Studies from Public Transit Services. Soc. Behav. Sci. 2016, 224, 263–268. [Google Scholar] [CrossRef]

- Cerfontaine, C. Combined mobility: Public transport in synergy with car-sharing, cycling, taxis, etc., a smart way forward. In Proceedings of the 5th UITP Combined Mobility Workshop, Hannover, Germany, 20 October 2014; p. 30. [Google Scholar]

- Bringas, J.E. Handbook of Comparative World Steel Standards; ASTM International: West Conshohocken, PA, USA, 2004; ISBN 0803133626. [Google Scholar]

- Greiner, R. High strength steels for hydropower plants—A conference bringing together specialists from many disciplines. Steel Constr. Des. Res. 2013, 6, 247–248. [Google Scholar] [CrossRef]

- ANEEL. Atlas de Energia Elétrica do Brasil; Agência Nacional de Energia Elétrica: Brasilia, Brazil, 2009. [Google Scholar]

- Souliotis, M.; Arnaoutakis, N.; Panaras, G.; Kavga, A.; Papaefthimiou, S. Experimental study and Life Cycle Assessment (LCA) of Hybrid Photovoltaic/Thermal (PV/T) solar systems for domestic applications. Renew. Energy 2018, 126, 708–723. [Google Scholar] [CrossRef]

- International Stainless Steel Forum (ISSF). Stainless Steel in Solar Energy Use; International Stainless Steel Forum: Brussels, Belgium, 2015; ISBN 978-2-930069-53-1. [Google Scholar]

- Bracquene, E.; Peeters, J.R.; Dewulf, W.; Duflou, J.R. Taking Evolution into Account in a Parametric LCA Model for PV Panels. Procedia CIRP 2018, 69, 389–394. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Aden, N.; Chunxia, Z.; Xiuping, L.; Fangqin, S. Comparison of Iron and Steel Production Energy Use and Energy Intensity in China and the U.S.; Berkeley National Laboratory, U.S. Department of Energy: Washington, DC, USA, 2011. [Google Scholar]

- van Schaik, A.; Reuter, M.A. Dynamic modelling of E-waste recycling system performance based on product design. Miner. Eng. 2010, 23, 192–210. [Google Scholar] [CrossRef]

- Oguchi, M.; Murakami, S.; Sakanakura, H.; Kida, A.; Kameya, T. A preliminary categorization of end-of-life electrical and electronic equipment as secondary metal resources. Waste Manag. 2011, 31, 2150–2160. [Google Scholar] [CrossRef]

- ECO3E. Eco-Design Guide of WEEE Compliance Schemes. Product Database. 2018. Available online: http://eco3e.eu/en/ressources/eco-products/ (accessed on 28 September 2018).

- ADEME. Global Inventories of the Worldwide Fleets of Refrigerating and Air-Conditioning Equipment in Order to Determine Refrigerant Emissions; French Agency for the Environment and Energy Management (ADEME): Paris, France, 2010. [Google Scholar]

- ÖKO. Eco-Efficiency Analysis of Washing machines; Commissioned by the European Committee of Domestic Equipment Manufacturers (CECED), Öko-Institut e.v.: Freiburg, Germany, 2005. [Google Scholar]

- Kärnä, P. Carbon Footprint of the Raw Materials of an Urban Transit Bus—Case Study: Diesel, Hybrid, Electric and Converted Electric Bus; Lahti University of Applied Sciences, Programme in Environmental Technology: Lahti, Finland, 2012. [Google Scholar]

- Leuenberger, M.; Frischknecht, R. Life Cycle Assessment of Two Wheel Vehicles; ESU-Services Ltd.: Uster, Switzerland, 2010. [Google Scholar]

- WS. Steel in Automotive; WorldSteel Association: Brussels, Belgium, 2018; Available online: https://www.worldsteel.org/steel-by-topic/steel-markets/automotive.html (accessed on 28 September 2018).

| Case Study | Main Servitization Contributions According To | Steel’s | |||

|---|---|---|---|---|---|

| Sustainable Urban Metabolism | Circles of Sustainability | Presence | Contribution | Challenge | |

| Energy |

|

| Decreased | Less steel in the right places can help create more environmental value. | HOW MUCH steel to use, WHERE to use steel. |

| Housing |

|

| Steady | Different alloys used to the best of their potential can support other goods’ and services’ environmental values. | WHAT type of steel to use, HOW to use steel optimally. |

| Mobility |

|

| Increased | Regardless of quantity, optimal applications of even the simplest of steel alloys can help improve the environmental values of a service or good. | WHEN and WHERE to use steel. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinto, J.T.M.; Morales, M.E.; Fedoruk, M.; Kovaleva, M.; Diemer, A. Servitization in Support of Sustainable Cities: What Are Steel’s Contributions and Challenges? Sustainability 2019, 11, 855. https://doi.org/10.3390/su11030855

Pinto JTM, Morales ME, Fedoruk M, Kovaleva M, Diemer A. Servitization in Support of Sustainable Cities: What Are Steel’s Contributions and Challenges? Sustainability. 2019; 11(3):855. https://doi.org/10.3390/su11030855

Chicago/Turabian StylePinto, Julian T. M., Manuel E. Morales, Mariia Fedoruk, Marina Kovaleva, and Arnaud Diemer. 2019. "Servitization in Support of Sustainable Cities: What Are Steel’s Contributions and Challenges?" Sustainability 11, no. 3: 855. https://doi.org/10.3390/su11030855

APA StylePinto, J. T. M., Morales, M. E., Fedoruk, M., Kovaleva, M., & Diemer, A. (2019). Servitization in Support of Sustainable Cities: What Are Steel’s Contributions and Challenges? Sustainability, 11(3), 855. https://doi.org/10.3390/su11030855