Abstract

In this study a systematic literature review was carried out to analyze the characteristics, indicators, limitations, benefits, and conclusions of scientific productions on industrial sustainability to propose a set of generic sustainability indicators for industrial organizations. The identification of the scientific productions occurred through the use of key words, in addition, the snowballing technique was also used, which resulted in a final set of 24 papers from 1998 to 2018. The technique used to select the indicators was the text mining with the help of NVivo Software. Finally, the multiple advisor method was applied. The main results show that the studies on sets of indicators with a Triple Bottom Line approach began in 1998. In addition, the papers show studies that analyze the industries generally being published by journals with a high impact factor, with authors from universities in Europe, from America and Asia, which use an average set of 30 indicators, with the lowest percentage of studies using mixed and mixed-scale approaches. The limitations revealed by the papers are the lack of initiative and actions of organizations for the adoption of sustainability. The benefits are linked to the informational assistance they provide to managers in decision-making, and the conclusions reveal a lack of research on the use of the praxis of the set of sustainability indicators in industrial organizations. In this sense, we conclude that the set of indicators suggested in this study is in line with the theoretical findings of the reviewed literature, with a balance between the Triple Bottom Line aspects and the synthetic number of indicators that provide the ease of its application and analysis.

1. Introduction

The terrestrial globe is undergoing changes that show the environmental imbalance, revealing the human being as the main cause of these changes through consumption and production reflected in deforestation, endangered plant and animal species, air and water pollution, greenhouse effect, among others [1]. Consumption and production comprise the vestiges that our development is unsustainable and threatens the balance of the planet and the existence of human beings, already evidenced almost two decades ago by Veleva and Ellenbecker [2], and reaffirmed by Büyüközkan and Karabulut [3].

Sustainable development can be achieved through a new vision attributed to industrial processes in relation to the control of emissions of gases, reuse and recycling of wastes, types and quantities of environmental resources, among others [4]. This vision is not considered an easy task to achieve since it involves high levels of corporate management, production, and consumption by society. In this sense, ecological, social, and economic pressure is increasing in industrial organizations [3], as the pollution generated by them has increased to levels never reached before [5].

Determining the direction of most industrial organizations in relation to the level of sustainability is subjective and difficult to implement. However, a possible solution for this definition of the direction to be simple, fast, and accessible can be performed using sustainability indicators [6]. The measurement and monitoring of sustainability in industrial organizations based on indicators promote the simplification and quantification of information on Triple Bottom Line aspects [7].

The benefits of using sustainability indicators refer to possible anticipation of conditions and trends, provision of warnings of possible occurrences and situations that prevent damage to the Triple Bottom Line aspects, and assistance with the processes of managing industrial operations [8]. Therefore, the process of selection and identification of sustainability indicators is essential in the efficiency of their use in determining the direction of sustainability [1].

A set of generalist (standard) sustainability indicators that can be used in industries, in general, is not feasible due to differences in activities and size [2]. In this sense, the existing frameworks—Global Reporting Initiative (GRI), Commission on Sustainable Development (CSD), Institution of Chemical Engineers (ICHEME), The Organization for Economic Co-operation and Development (OECD) and others—suggest the use of a large number of main indicators, elaborated by the top-down approach, which need adaptation, that is, the selection and identification of specific indicators which are facilitated by the bottom-up approach for a given industry [9]. In addition, these authors point out that there is insufficient knowledge about the adequate selection and identification of compatible sustainability indicators for sustainability assessment of Triple Bottom Line aspects.

In this sense, a systematic review of the literature was carried out to analyze the characteristics, indicators, limitations, benefits, and conclusions of the scientific productions on industrial sustainability to propose a framework of indicators of generic sustainability to industry. This study aims to help define a set of main sustainability indicators (top-down approach), organized in a small number of indicators, that can be used in industries in general. Lee and Saen [10] stated that there is an urgent need to develop tools for evaluating sustainability in organizations in general, since the existing ones represent mere suggestions and recommendations for specific companies. Chen et al. [11] also reinforced that there is a lack of tools to assess the state of sustainability through performance indicators.

2. Theoretical Background

2.1. Brief Review about Sustainable Development and Sustainability

Sustainability and sustainable development in this study have different conceptions and characteristics, but they cover the Triple Bottom Line aspect and complement each other in theoretical and practical use. Sustainable development is “... one that meets the needs of the present without compromising the ability of future generations to meet their own needs” [12]. This development is the key to ensuring the control of risks and pollution from traditional activities in organizations, among others [5]. In this sense, it is pointed out that sustainable development can be operationalized through strategies (actions) that are elaborated based on the measurement of the sustainability level.

Sustainability, in turn, “... expresses concern about the quality of a system that relates to inseparable integration (environmental and human), and evaluates its properties and characteristics, encompassing environmental, social, and economic aspects” [13]. Sustainability has many perspectives; for example, it covers environmental protection, ecosystem services, economic and financial issues, social issues, operating licenses, among others [14]. Büyüközkan and Karabulut [3] emphasized that sustainability begins to extend towards a more holistic, integrated, and methodological understanding. Lobos and Partida [15] contributed to the assertion that decision-makers are aware of the need for sustainability to evaluate complex systems to replace linear solutions.

Sustainability assessment “[...] is operationalized through indicators or indexes, and results in quantitative information, enabling the establishment of objectives or goals to be achieved through long-term strategies ...” [13], which are implemented by sustainable development. In this logic, sustainable development represents the path (process) to achieve sustainability, focusing systemic well-being, while sustainability is the expected long-term result, consisting of the qualitative aspect of the system, which is monitored by the operationalization of indicators and indexes [7].

The actions used for sustainable development relate to the technical, financial, managerial, and, in particular, strategic skills to achieve sustainability [16]. In this sense, these actions to achieve sustainable development can alter the trajectory of the system quality, that is, they may allow interventions at the level of sustainability. Sustainability consists of a goal, or parameter (final objective), defined through scientific criteria, which measures and tracks the results generated by the use of sustainable development strategies. In summary, in this study, the idea of sustainability is linked to the measurement of the quality of the industrial system that seeks to measure all aspects of the Triple Bottom Line, using indicators.

2.2. Sustainability in Industrial Organizations

Corporate sustainability can be considered an invaluable tool in the analysis of cost reduction, risk management, development of new products and promotion of internal, cultural and structural changes [17]. The growing pressures on organizations to increase the focus of sustainability derive from environmental demands, from shareholders and other stakeholders, regulations, fears of loss of the consumer market, decline in corporate reputation, among others [10,18]. Therefore, the challenge of corporations is contributing to the wellbeing of the current generations, without harming the quality of life of future generations [19].

Most industrial practices are not sustainable due to the excessive consumption needs of nonrenewable natural resources [4]. These authors also emphasize that the solution to this is sustainable growth, without the destructive consumption, Triple Bottom Line aspects that must be integrated into the corporate culture and business planning, thus, requiring a new drastic look at industrial practices of productive processes. Tonelli et al. [20] pointed out that the direction for industrial sustainability is linked to the attitude towards the consumption of materials, products, processes, and the production system.

Sustainable production means producing less, with higher quality and durability, lower environmental impacts and higher profitability [21]. Lowell Center [22] stated that industrial sustainability is represented by the manufacture of products with processes and systems that use clean technologies. Veleva and Ellenbecker [2] suggested a set of conditions necessary for the industries to comply to be sustainable: (a) reduction of the use of natural materials and energy; (b) conservation and avoid waste of materials; (c) prevention of waste, reuse and recycling of products; (d) disposal of non-recyclable and environmentally acceptable waste products; (e) use of clean technologies in the production process and the product life cycle; (f) reduction of transport requirements; (g) planning of products that are easy to repair, adaptable, and durable; (h) support social issues; and (i) economic feasibility, among others.

The evaluation of sustainability performance in industrial organizations is as important as the use of the set of sustainable conditions, since it can help in decision making and organizational performance management to decide future actions [23]. The measurement of the sustainability of industrial organizations includes measuring the extent of incorporation of environmental, social, and economic factors into their activities, that is, measuring the impact of their activities on their endogenous and exogenous environment [24].

The model for measuring the sustainability of industrial organizations must meet the conditions suggested by Dočekalová and Kocmanova [23]: (a) integrate the Triple Bottom Line aspects; (b) be based on financial and non-financial indicators; (c) reflect the particularities of the activities of the industry; (d) ease of interpretation of results; (e) include the principle of benchmarking; (f) availability of the data for the calculations; and (g) simple calculations. Tokos et al. [9] emphasized that the main obstacles are the availability of reliable data and the information needed for evaluation.

The difficulties of measuring sustainability in industrial organizations are related to the high levels of sustainability uncertainties and impacts that may be difficult to quantify [10] and highly subjective in nature [3]. Li and Mathiyazhagan [5] complemented that companies are not concerned with updating and maintaining sustainability performance. Luthra et al. [25] emphasized that most industries are unwilling to incorporate sustainable practices. Krajnc and Glavič [4] recalled the determination of which directions the changes must be made to lead to sustainability.

Lucato et al. [18] pointed out that current sustainability assessment tools have limitations, such as (a) appropriateness to cover the corporation as a whole, thus, presenting difficulties in the application of the productive process; (b) lack of integration between the Triple Bottom Line aspects, damaging the methodology if the indicators advance in different directions; and (c) complexity of tools to be used in the productive process of industries. In this logic, Büyüközkan and Karabulut [3] emphasized that the structure of the evaluation of the performance of the sustainability must be generic and adaptable.

2.3. Sustainability Indicators

The sustainability indicator is a measure or set of measures that provide information on pre-defined variables [26]. In this sense, these indicators aim to quantify, analyze, and communicate complex information in a simple way [7], through systematic, precise, consistent, and transparent measures of the Triple Bottom Line aspects [6]. The simplification of complex processes, regardless of the number of indicators used, implies the reduced capacity of translation of all the information collected in the field, generating, consequently, a variable margin of loss of the quality of the information about the phenomenon investigated [27].

The objectives of sustainability indicators include (a) increase awareness and sustainable understanding; (b) inform concise data on the current state and performance trends for decision making; (c) measure progress toward established goals; (d) promote organizational learning; (e) provide a tool to measure the organization’s achievements against sustainability goals; and (f) provide a tool that encourages stakeholder involvement in decision making, among others. In this sense, the indicators should reflect the reality of the organization’s business, values, and culture to be efficient and consistent [28].

Sustainability indicators should be identified and selected by observing the desirable qualities [2,29], and the essential characteristics [2,4], as presented in Table 1.

Table 1.

Qualities and characteristics of sustainability indicators.

Sustainability indicators can be identified and selected based on the top-down (main ones), and bottom-up (complementary or specific) approaches. The top-down approach allows experts and researchers to define a set of indicators at the macro level, while the bottom-up approach allows the systematic participation of local stakeholders, at a micro level, in defining this framework of specific indicators [31].

The number of indicators used should not be high, only sufficient to provide manageable analysis [6]. Singh et al. [19], Krajnc and Glavič [34], Veleva and Ellenbecker [2] and Tokos et al. [9] understood that it is difficult to evaluate performance with a high number of sustainability indicators. Bui et al. [35] argued that the number of indicators selected depends on the specific interests and goals of organizations. Nordheim and Barrasso [32] suggested not more than 30 indicators in total considering the Triple Bottom Line aspects; but Kinderyté [36] developed a set of 42 sustainability indicators to assess sustainability in companies. Rahdari and Rostamy [37] emphasized that there is widespread confusion about the definition of sustainability indicators that reflect on the organizational performance and represent sustainability guidelines in terms of high available quantity. In this sense, it is noticed that there is no consensus on an ideal number of sustainability indicators, but these must meet the objectives they were created for.

3. Methodological Procedures

The typification of this research is qualitative based on a systematic review of the literature on sustainability indicators used in industrial organizations. The systematic review is recommended because it is a rigorous and verifiable methodology, thus, reducing the likely bias of the research results [38]. These authors suggest the following steps in conducting the research: (a) definition of the research aim; (b) choice of keywords and database; (c) selection of studies evaluating titles and abstracts; (d) tabulation of the information of the selected articles; and (e) presentation of the results. In this sense, the information regarding each of these stages is presented in the sequence.

The aim of this review is the identification of the characteristics, indicators, limitations, benefits, and conclusions of scientific publications on industrial sustainability, to propose a framework of generic sustainability indicators to industrial organizations. The keywords used as a basis for consultation correspond to “Indicators of sustainability”, “economic”, “social”, “environmental”, “industry”. These keywords were defined as a keyword for research since they were those that presented the most scientific titles in the databases consulted, that is, other pre-queries were also performed with keywords similar to these but did not return with a quantity of titles as officially defined. These words were used in the English language since about 85% of scientific publications are in this language at a global level [39]. The keywords were inserted into the reference journals’ databases with double quotes, so each title should have all the expressions in its full text and not only in the title or abstract; and returned with the following results: Springerlink (108), Pubmed (10), Meraldinsight (4), Science direct (130), Wiley Online Library (26), Scopus (339), Scielo (0), and Google Scholar (3310).

The search in these search bases took place in July 2018, collecting 3927 scientific titles from which the titles, abstracts, and keywords were read. The reading of the title and the abstract was done with the intention of selecting the scientific publications potentially adhering to the following inclusion criteria: (a) covering the three aspects of the Triple Bottom Line; (b) presenting a set of sustainability indicators; (c) being linked to industrial sustainability; and (d) be the result of only scientific article publications with the process of blind review. After defining these selection criteria, the articles found were distributed among the five authors of this study to carry out the initial screening, that is, the reading of the title and the abstract and to separate those that have adherence to the predetermined criteria. This initial screening stage lasted from July 2018 to October 2018.

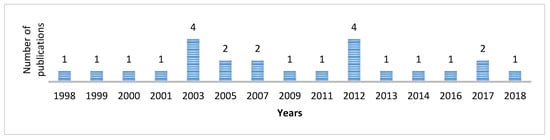

This reading identified 82 scientific publications, which were read in full, including the references of each paper. The references were analyzed using the snowballing technique, which, according to Jalali and Wohlin [40], rescues the publications that did not appear in the collection of initial scientific titles. In this work, the technique rescued 32 papers, bringing the total to 118. After the reading of these publications, there were found a total of 24 scientific articles that meet the inclusion criteria and cover the period from 1998 to 2018 (Figure 1).

Figure 1.

Scientific publications.

The tabulation of the 24 papers occurred concomitantly with the reading through a spreadsheet containing the following information to be collected: (a) author and year; (b) title; (c) objective; (d) type of activity of the industrial organization; (e) number of indicators per Triple Bottom Line; (f) description of the indicators by aspect; g) approach of indicators (main or complementary); (h) type of scale (qualitative, qualitative or financial); (i) limitations/difficulties/disadvantages; (j) advantages/benefits; (k) application of the results (generic or punctual); (l) quick application; (m) main conclusions; (n) published journal; (o) number of citations; (p) Country/State of authors; and (q) University/institutions of the authors.

The description of indicators by aspect provided a total of 753 sustainability indicators, distributed in environmental (348), social (244), and economic (161). The technique used to identify indicators more frequently in each aspect was text mining as suggested by Feldman and Sanger [41], with the help of NVivo© Software. Thus, the 753 indicators collected from the papers were inserted in the NVivo © Software, and text mining generated a list of words in order of frequency, that is, of repeated expressions. A new set of sustainability indicators has been carefully developed from this list of words.

The presentation of the results was carried out through tables previously organized and the textual analysis linked to the objective, limitations/difficulties/disadvantages, advantages/benefits, and the main conclusions occurred through the interpretative analysis, as suggested by Severino [42]. Interpretive analysis, according to this author, has the purpose of synthesizing the textual information to assist in the in-depth understanding of the results. Finally, the multiple advisor method, as suggested by Gast et al. [43], was applied to increase quality (validity and reliability) of the analysis, which involved the participation of all authors of this study in the reading of articles independently by organizing and collecting the same information from the collection table. In the sequence, the independent collections were compared and discussed to reach a consensus in the collection, analysis, and results.

4. Results and Analyses

4.1. General Characteristics

The characteristics of the studies revealed a problem with the elaboration of a set of indicators from the triple point of view, starting with the research by Fiksel et al. [44] (Table 2). An idea of sustainability allied with the Triple Bottom Line was developed by Elkington [45] and then became a research on the academic environment and an industrial practice, suggesting tools and sets of indicators to evaluate the performance of business sustainability.

Table 2.

General characteristics of the papers.

The activity studied is focused on the industry sector, that is, without mentioning any specific activity (50.0%), Steel, mechanical, and aluminum, and electronics with 12.5% each, mining (8.3%), and brewing, milling, automotive components, and detergent products with 4.2% each. The academic researches are pursuing a set of indicators that can be applied to the industries in general, being approached by several authors, especially Parris and Kates [55].

The articles were published in particular in Ecological Economics, Journal of Cleaner Production, Clean Technologies, and Environmental Policy and Process Safety and Environmental Protection, which cover 45.8% of the publications identified in this research. These scientific journals are among the most qualified in the areas of environmental sciences and interdisciplinary (Qualis classification with strata A1 and A2) according to Sucupira Capes [56], which demonstrates the importance currently attributed to the measurement and evaluation of sustainability with the use of indicators.

The most cited publications are related to the study by Azapagic and Perdan [47] and Krajnc and Glavič [34]. These authors developed the initial idea of the measurement and management of industrial sustainability through sustainability indicators. Articles published and linked to universities in Europe account for 50.0%, North American countries and Asia with 29.2% each. These results are corroborated by the Environmental Performance Index (EPI) ranking of 2018 which presents the 18 highest performing European countries [57].

4.2. Analysis of the Measurement Structure

The analysis of the number of total indicators and by aspect did not present a consistent arithmetic mean, that is, the coefficient of variation is higher than 0.6, representing high dispersion and low precision (Table 3). This result shows that the used number of indicators does not have a standard, even though the total average of indicators is 31.4, which corroborates with the literature that the number of indicators should be close to 30, as suggested by Nordheim and Barrasso [32]. It should be noted that the peculiarity of each segment or industrial activity contributes to a greater or lesser number of indicators used.

Table 3.

Sustainability indicators and their characteristics.

The top-down approaches were used in 62.5%, the joint (mixed) approach in 37.5% of the studies, therefore, the set of indicators suggested by the surveys are generic in 50% of the cases, that is, that can be used for industries of different activities. This finding demonstrates the alignment with the demand to elaborate a set of sustainability indicators that can be used generically by most industrial organizations to facilitate the development of benchmarks, comparisons of results, and continuous improvements in the activity, which is corroborated by Büyüközkan and Karabulut [3].

The indicators are measured by quantitative (financial, kg, liters) by 41.7%, qualitative (37.5%) and mixed (qualitative) by 20.8%. The literature suggests that one of the desirable qualities of indicators is that the metrics are mixed, that is, qualitative and quantitative [2]. Thus, it is noticed that the minority (five studies) presents this desirable quality and focuses on publications from 2012.

4.3. Analysis of the Difficulties, Benefits, and Conclusions of the Studies

The difficulties in the measurement and management of sustainability in industrial organizations, in short, are related to the business positioning regarding sustainability, considering that the organizational culture, the subjectivity, the vision and the implementation of sustainable tools, are linked to the actions taken by the industries to achieve sustainability (Table 4). In this sense, the path to corporate sustainability depends on the action element (attitudes) on the part of the decision makers (managers), considering the advances in the literature in the suggestions of tools of management and measurement of the sustainability and the report of successful practices would not justify non-adherence, corroborated by Tonelli et al. [20].

Table 4.

Main difficulties, benefits, and conclusions.

The benefits that the tools of sustainability (set of indicators) can provide industries are summed up in the generation of information for a level of management beyond the traditional one. Niemeijer and Groot [8] interpreted these benefits as a generation of information that helps in anticipating conditions and trends, and Li and Mathiyazhagan [5] affirmed that industries differentiate with this element to increase their competitiveness because they allow to develop social capacities and environmental problems, and there would be difficulties in being imitated by competitors.

The conclusions of the studies are limited to analysis of the use of sets of sustainability indicators in industries and lack evidence and arguments of practical improvements and their reflexes for growth and organizational development. Evans et al. [58] already argued that a sufficient theoretical literature existed, but in practice few tools were available.

4.4. Set of Sustainability Indicators for Industrial Organizations

The set of sustainability indicators presented in Table 5 shows a compilation of environmental indicators in 93.7%, social indicators with 91.8%, and economic indicators with 91.3%, that is, the total of 753 indicators derived from the 24 studies were reduced, on average, to 92.3%, without losing the essence of the information. This result means that there is a high homogeneity of the sets of sustainability indicators of the 24 studies analyzed, pointing to the coherence in the choice of indicators, even though it was done in different countries, authors, and industries with different activities, as discussed in Section 4.1.

Table 5.

Set of sustainability indicators for industries.

The environmental aspect of sustainability is related to energy, water, waste, emissions, product, resources (materials), effluent ts, labels and certificates, logistics, environmental expenditures/investments, impacts/environmental degradation, and soil. These environmental aspects are in line with the requirements that industries must meet to become sustainable, according to Veleva and Ellenbecker [2]; and the essential conditions to achieve industrial sustainability as described by Krajnc and Glavic [4]. However, in terms of sustainability indicators in each environmental aspect, there are weaknesses, such as the emphasis on reuse and recycling of water, consumption of hazardous materials, reuse and recycling of products, reverse logistics, environmental fines, and concerns about the origin of natural resources. This fact reveals that there is an inconsistency in the product lifecycle span, that is, from the source of the material to the reverse logistics of the packaging, although not satisfying the lifecycle comprehension, in most of the sets of indicators of sustainability used in the industries, in contradiction to the principle defended by Mayyas et al. [59].

The social aspects are related to employees, work, clients/consumers, community, stakeholders, and ethics, which are consistent with the social criteria defended by Lowell Center for Sustainable Production (LCSP) [22] to make industries more sustainable. However, in terms of indicators, there is little emphasis on specific aspects of social dimension, such as discrimination, career and stability, involvement in management, complaints from employees and consumers/customers, i.e., a large number of indicators do not present this information when the frequency number is analyzed. This reveals that there is a fragility in these sets and that they are not adherent with GRI instructions, among others.

The economic aspects consider cost/expense, profit, investments, suppliers, revenue, shareholders/board and institutional, and are adherent to the main aspects of sustainable production presented by Veleva and Ellenbecker [2] and Tonelli, Evans and Taticchi [20]. Thus, it is possible to affirm that they represent an efficient structure for the measurement of sustainable economic performance. However, as in other dimensions, some indicators, that are important for economic aspects, were analyzed considering frequency presented in the research, such as return on assets, business with local suppliers, concern with competitiveness and market, and expenses with taxes. In this perspective, the sets of the analyzed and compiled economic indicators, are not coherent, at all, with the suggestions of economic indicators, as suggested by GRI.

The set of indicators, presented in Table 5, can be used as a model to measure the sustainable performance of industries, but it may be necessary to adjust the number of indicators in relation to the size of the industry, type of the economic activity, among others. The criteria defined by the literature that must be observed in defining the number of indicators are [35]: (a) be enough to support the managerial analysis; (b) dependency on their managers’ interests and industries’ workers; and (c) dependency on the specific objectives of the organization. In this sense, the definition or suggestion of an exact, or ideal, number of sustainability indicators is difficult, confusing, and it is not possible to reach a consensus, according to Rahdari and Rostamy [37]. Moreover, it is considered that the number of indicators is not a decisive factor, but rather the quality of the indicators, or set of sustainability indicators, that will be used to measure the positive and negative aspects of the industrial complex, as cited by Erol et al. [60]. Veleva and Ellenbecker [2] have mentioned that the absence of one, or more fundamental aspects would make the set of indicators incomplete. In this way, industrial sustainability may be considered effective, and valid, once organizations take responsibility for the impacts of their activities on the economy, the environment, and society, corroborating Li et al. [51] and Tonelli, Evans and Taticchi [20].

The compiled sustainability indicators, described in Table 5, can be considered a complete and consistent set of indicators to be used in assessing sustainability performance in industries in terms of the Triple Bottom Line concept, confirmed through consensus of 93.2% (mean) in relation to the indicators presented by the 24 scientific studies. In this sense, the set of indicators, presented in Table 5, can be considered a backbone, because from them complementary indicators can be developed by managers and industries’ stakeholders. This means that there is an emerging consensus of a set of sustainability indicators used in industries, which meets the demands of Lee and Saen [10] concerning the existence of a set of sustainability indicators that can be used in industries in general; and by making one more contribution in the literature as called by Chen et al. [11].

Business managers, when using the sustainability indicators for measurement and performance evaluation considering the Triple Bottom Line aspects, should be aware that there may be informational losses in the process. However, these managers should use them anyway, as it is a meager tool, but available for that purpose. In this perspective, previous intellectuals have already argued that it is necessary to “Measure what can be measured, and to make measurable what cannot be measured” (Galileo Galilei, 1564–1642), and Vollmann [61] tool with the understanding that “... it is better to measure the right things roughly than the wrong ones with great accuracy and precision.”

These reflections reinforce that ideal tools can be difficult to formulate and, thus, industrial organizations should use existing tools and over time to improve them more efficiently. Managers should use the set of indicators, even if not ideal, because industries are, thus, starting a solution to Li and Mathiyazhagan [5] criticisms that point to a lack of concern on the part of industries to use the performance of sustainability, and that for Luthra et al. [25] industries are unwilling to use sustainable practices. The use of the set of sustainability indicators in the assessment of business performance (Table 5) is also justified by the characteristics that Büyüközkan and Karabulut [3] defines as being a generic and adaptable set.

5. Final Considerations

Industrial sustainability lacks research and publications on the set of indicators, despite the effort made since 1998, are still scarce and present theoretical and practical limitations. In this sense, a systematic literature review was carried out, to analyze the characteristics, indicators, limitations, benefits and conclusions of the scientific productions on industrial sustainability to propose a set of indicators of generic sustainability to the industries.

The analysis of the literature revealed that the previous papers have the following general characteristics: (a) publications began in 1998; (b) the activity of the industry was general and the activity with a high environmental impact; (c) published in journals with Qualis A (45.8%); (d) the papers with the highest citation date from 2000 and 2005; (e) are linked to European, American and Asian universities; (f) an average of 31.4 indicators in each set; (g) low emphasis on the joint approach (top-down + bottom-up); and (h) the mixed measurement method (qualitative + quantitative) appear in only 20.8%.

The analysis of the difficulties presented by the studies indicates the weak actions or posture of the managers of the industrial organizations before incorporating the idea of sustainability. The benefits mentioned refer to the informational generation that can help the most assertive decision making by the diversified data that the industry has and that is generated by the use of the sustainability indicators. The papers point to the conclusion that there are limitations regarding the practical use of the set of sustainability indicators and their effects on the management of the industries.

The compiled set of sustainability indicators can be considered as a consistent and coherent representation of the 24 sets of indicators of the analyzed studies so the indicators of each dimension (environmental, social, and economic) can be considered valid when considering the information they relate to. However, the frequency of some indicators, such as, for example, reverse logistics, employee complaints, and dealings with local suppliers related to environmental, social, and economic aspects, respectively, showed that most of the indicator sets of the analyzed studies did not use them, but are important in building a sustainable awareness by the industries. This compiled set of indicators consistently represents the backbone of sustainability indicators that can be expanded and reduced as needed by industry managers.

The compiled set of sustainability indicators has contributions to: (a) literature: emphasizing the possibility of a consensus of set of sustainability indicators that can be used in industries, independently of economic activity, due to the homogeneity presented by the sets of indicators in the literature; and (b) practice: industry managers can use the set of indicators to assess sustainability performance and to report them for internal and external disclosure. In this sense, this study updates and complements efforts made by previous studies on a set of sustainability indicators. In addition, it can be highlighted that this research tried to transcend the current literature on the subject, providing a set of sustainability indicators with consistency and considering the 24 studies previously analyzed.

The limitations of this study are related to the fact that the set of indicators can be used only in industries with a productive process, without differentiation in relation to the size and or activity of the industry. Another limitation related to the method is that many practices carried out in industries related to the measurement of sustainability through the use of a set of indicators may not be disseminated in papers and could contribute to the qualification of this set of indicators.

Author Contributions

Conceptualization, A.A.F., D.S., C.H. and V.J.S.; methodology, A.A.F., D.S., C.H., V.J.S. and C.L.B.; software, A.A.F..; validation, A.A.F., D.S., C.H., V.J.S. and C.L.B; formal analysis, A.A.F., D.S., C.H., V.J.S.; investigation, A.A.F. and C.L.B.; writing—original draft preparation, A.A.F.; writing—review and editing, A.A.F., D.S., C.H., V.J.S. and C.L.B.; project administration, A.A.F.

Funding

This work was supported by the Fundação de Amparo a Pesquisa do Estado do Rio Grande do Sul (Fapergs), Edital 01/2017—Auxílio Recém Doutor (ARD), Termo de Outorga: 17/2551-0000. Brazil.

Acknowledgments

We thank the Fapergs for funding our research, the anonymous reviewers and the editor of the Issue, for their most valuable contributions to improving the quality of this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bork, C.A.; de Souza, J.F.; de Oliveira Gomes, J.; Canhete, V.V.; De Barba, D.J. Methodological tools for assessing the sustainability index (SI) of industrial production processes. Int. J. Adv. Manuf. Technol. 2016, 87, 1313–1325. [Google Scholar] [CrossRef]

- Veleva, V.; Ellenbecker, M.J. Indicators of sustainable production. J. Clean. Prod. 2001, 9, 447–452. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Karabulut, Y. Sustainability performance evaluation: Literature review and future directions. J. Environ. Manag. 2018, 217, 253–267. [Google Scholar] [CrossRef]

- Krajnc, D.; Glavič, P. Indicators of sustainable production. Clean Technol. Environ. Policy 2003, 5, 279–288. [Google Scholar] [CrossRef]

- Li, Y.; Mathiyazhagan, K. Application of DEMATEL approach to identify the influential indicators towards sustainable supply chain adoption in the auto components manufacturing sector. J. Clean. Prod. 2018, 172, 2931–2941. [Google Scholar] [CrossRef]

- Linke, B.S.; Corman, G.J.; Dornfeld, D.A.; Tönissen, S. Sustainability indicators for discrete manufacturing processes applied to grinding technology. J. Manuf. Syst. 2013, 32, 556–563. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2012, 15, 281–299. [Google Scholar] [CrossRef]

- Niemeijer, D.; Groot, R.S. A conceptual framework for selecting environmental indicator sets. Ecol. Indic. 2008, 8, 14–25. [Google Scholar] [CrossRef]

- Tokos, H.; Pintarič, Z.N.; Krajnc, D. An integrated sustainability performance assessment and benchmarking of breweries. Clean Technol. Environ. Policy 2012, 14, 173–193. [Google Scholar] [CrossRef]

- Lee, K.H.; Saen, R.F. Measuring corporate sustainability management: A data envelopment analysis approach. Int. J. Prod. Econ. 2012, 140, 219–226. [Google Scholar] [CrossRef]

- Chen, D.; Thiede, S.; Schudeleit, T.; Herrmann, C. A holistic and rapid sustainability assessment tool for manufacturing SMEs. Cirp Ann. Manuf. Technol. 2014, 63, 437–440. [Google Scholar] [CrossRef]

- World Commission on Environment and Development (WCED). Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Feil, A.A.; Schreiber, D. Sustentabilidade e desenvolvimento sustentável: Desvendando as sobreposições e alcances de seus significados. Cad. EBAPE BR 2017, 15, 667–681. [Google Scholar] [CrossRef]

- Bartelmus, P. Use and usefulness of sustainability economics. Ecol. Econ. 2010, 69, 2053–2055. [Google Scholar] [CrossRef]

- Lobos, V.; Partidario, M. Theory versus practice in strategic environmental assessment (SEA). Environ. Impact Assess. Rev. 2014, 48, 34–46. [Google Scholar] [CrossRef]

- Dempsey, N.; Bramley, G.; Power, S.; Brown, C. The Social Dimension of Sustainable Development: Defining Urban Social Sustainability. Sustain. Dev. 2011, 19, 289–300. [Google Scholar] [CrossRef]

- Azapagic, A. Systems approach to corporate sustainability: A general management framework. Process Saf. Environ. Prot. 2003, 81, 303–316. [Google Scholar] [CrossRef]

- Lucato, W.C.; Santos, J.C.S.; Pacchini, A.P.T. Measuring the Sustainability of a Manufacturing Process: A Conceptual Framework. Sustainability 2017, 10, 81. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. Development of composite sustainability performance index for steel industry. Ecol. Indic. 2007, 7, 565–588. [Google Scholar] [CrossRef]

- Tonelli, F.; Evans, S.; Taticchi, P. Industrial sustainability: Challenges, perspectives, actions. Int. J. Bus. Innov. Res. 2013, 7, 143–163. [Google Scholar] [CrossRef]

- Welford, R.; Young, W.; Ytterhus, B. Toward sustainable production and consumption: A conceptual framework. Eco-Manag. Audit. 1998, 5.1, 38–56. [Google Scholar] [CrossRef]

- Lowell Center for Sustainable Production (LCSP). Lowell Center for Sustainable Production. What Is Sustainable Production? 2015. Available online: http://www.sustainableproduction.org/abou.what.php (accessed on 13 October 2018).

- Dočekalová, M.P.; Kocmanova, A. Composite indicator for measuring corporate sustainability. Ecol. Indic. 2016, 61, 612–623. [Google Scholar] [CrossRef]

- Artiach, T.; Lee, D.; Nelson, D.; Walker, J. The determinants of corporate sustainability performance. Acc. Financ. 2010, 50, 31–51. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Mangla, S.K. Structural model for sustainable consumption and production adoption-a grey-DEMATEL based approach. Resour. Conserv. Recycl. 2017, 125, 198–207. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2012, 24, 148–157. [Google Scholar] [CrossRef]

- Lodhia, S.; Martin, N. Corporate Sustainability Indicators: An Australian mining case study. J. Clean. Prod. 2014, 84, 107–115. [Google Scholar] [CrossRef]

- Keeble, J.J.; Topiol, S.; Berkeley, S. Using indicators to measure sustainability performance at a corporate and project level. J. Bus. Ethics 2003, 44, 149–158. [Google Scholar] [CrossRef]

- Azapagic, A. Developing a framework for sustainable development indicators for the mining and minerals industry. J. Clean. Prod. 2004, 12, 639–662. [Google Scholar] [CrossRef]

- Patlitzianas, K.D.; Doukas, H.; Kagiannas, A.G.; Psarras, J. Sustainable energy policy indicators: Review and recommendations. Renew. Energy 2008, 33, 966–973. [Google Scholar] [CrossRef]

- Tahir, A.C.; Darton, R.C. The process analysis method of selecting indicators to quantify the sustainability performance of a business operation. J. Clean. Prod. 2010, 18, 1598–1607. [Google Scholar] [CrossRef]

- Nordheim, E.; Barrasso, G. Sustainable development indicators of the European aluminium industry. J. Clean. Prod. 2007, 15, 275–279. [Google Scholar] [CrossRef]

- Malkina-Pykh, I.G. Integrated assessment models and response function models: Pros and cons for sustainable development indices design. Ecol. Indic. 2002, 2, 93–108. [Google Scholar] [CrossRef]

- Krajnc, D.; Glavič, P. A model for integrated assessment of sustainable development. Resour. Conserv. Recycl. 2005, 43, 189–208. [Google Scholar] [CrossRef]

- Bui, N.T.; Kawamura, A.; Kim, K.W.; Prathumratana, L.; Kim, T.H.; Yoon, S.H.; Jang, M.; Amaguchi, H.; Du Bui, D.; Truong, N.T. Proposal of an indicator-based sustainability assessment framework for the mining sector of APEC economies. Resour. Policy 2017, 52, 405–417. [Google Scholar] [CrossRef]

- Kinderytė, L. Methodology of sustainability indicators determination for enterprise assessment. Environ. Res. Eng. Manag. 2010, 52, 25–31. [Google Scholar]

- Rahdari, A.H.; Rostamy, A.A.A. Designing a general set of sustainability indicators at the corporate level. J. Clean. Prod. 2015, 108, 757–771. [Google Scholar] [CrossRef]

- Sampaio, R.E.; Mancini, M.C. Estudos de revisão sistemática: Um guia para a síntese criteriosa da evidência científica. Rev. Bras. Fisioter. 2007, 11, 83–89. [Google Scholar] [CrossRef]

- Schütz, R.E. O Inglês como Língua Internacional. English Made in Brazil. 2018. Available online: http://www.sk.com.br/sk-ingl.html (accessed on 29 May 2018).

- Jalali, S.; Wohlin, C. Systematic literature studies: Database searches vs. backward snowballing. In Proceedings of the ACM-IEEE International Symposium on Empirical Software Engineering and Measurement (ESEM), Lund, Sweden, 20–21 Sepember 2012; pp. 29–38. [Google Scholar]

- Feldman, R.; Sanger, J. The Text Mining Handbook: Advanced Approaches in Analyzing Unstructured Data; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Severino, A.J. Metodologia do Trabalho Científico, 23rd ed.; Cortez: São Paulo, Brazil, 2007. [Google Scholar]

- Gast, J.; Gundolf, K.; Cesinger, B. Doing business in a green way: A systematic review of the ecological sustainability entrepreneurship literature and future research directions. J. Clean. Prod. 2017, 147, 44–56. [Google Scholar] [CrossRef]

- Fiksel, J.; Mcdaniel, J.; Spitzley, D. Measuring product sustainability. J. Sustain. Prod. Des. 1998, 6, 7–18. [Google Scholar]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997. [Google Scholar]

- Callens, I.; Tyteca, D. Towards indicators of sustainable development for firms: A productive efficiency perspective. Ecol. Econ. 1999, 28, 41–53. [Google Scholar] [CrossRef]

- Azapagic, A.; Perdan, S. Indicators of sustainable development for industry: A general framework. Process Saf. Environ. Prot. 2000, 78, 243–261. [Google Scholar] [CrossRef]

- Seuring, S.A.; Koplin, J.; Behrens, T.; Schneidewind, U. Sustainability assessment in the German detergent industry: From stakeholder involvement to sustainability indicators. Sustain. Dev. 2003, 11, 199–212. [Google Scholar] [CrossRef]

- Labuschagne, C.; Brent, A.C.; Van Erck, R.P. Assessing the sustainability performances of industries. J. Clean. Prod. 2005, 13, 373–385. [Google Scholar] [CrossRef]

- Delai, I.; Takahashi, S. A proposed model of reference for measuring corporate sustainability. Rev. Gest. Soc. Ambient. 2008, 2, 19–40. [Google Scholar]

- Arbačiauskas, V.; Staniškis, J. Sustainability performance indicators for industrial enterprise management. Environ. Res. Eng. Manag. 2009, 48, 42–50. [Google Scholar]

- Zhou, L.; Tokos, H.; Krajnc, D.; Yang, Y. Sustainability performance evaluation in industry by composite sustainability index. Clean Technol. Environ. Policy 2012, 14, 789–803. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H.; Yuan, C.; Liu, Z.; Fan, C. A PCA-based method for construction of composite sustainability indicators. Int. J. Life Cycle Assess. 2012, 17, 593–603. [Google Scholar] [CrossRef]

- Mota, J.A.; Maneschy, M.C.; Souza-Filho, P.W.; Navarro Torres, V.F.; de Siqueira, J.O.; dos Santos, J.F.; Matlaba, V. Uma nova proposta de indicadores de sustentabilidade na mineração. Sustentabilidade em Debate 2017, 8, 15–29. [Google Scholar] [CrossRef]

- Parris, T.M.; Kates, R.W. Characterizing and measuring sustainable development. Annu. Rev. Environ. Resour. 2003, 28, 559–586. [Google Scholar] [CrossRef]

- Sucupira Capes. Plataforma Capes. 2018. Available online: https://sucupira.capes.gov.br/sucupira/Acesso em (accessed on 15 November 2018).

- Yale Center. Global Metrics for the Environment: Ranking Country Performance on High-Priority Environmental Issues; Yale Center for Environmental Law & Policy, Yale University: New Haven, CT, USA, 2018; Available online: https://epi.envirocenter.yale.edu/downloads/epi2018policymakerssummaryv01.pdf (accessed on 26 October 2018).

- Evans, S.; Bergendahl, M.N.; Gregory, M.; Ryan, C. Towards a Sustainable Industrial System, International Manufacturing Professors Symposium, Cambridge. 2009. Available online: https://www.ifm.eng.cam.ac.uk/uploads/Resources/Reports/industrial_sustainability_report.pdf. (accessed on 13 October 2018).

- Mayyas, A.; Qattawi, A.; Omar, M.; Shan, D. Design for sustainability in automotive industry: A comprehensive review. Renew. Sustain. Energy Rev. 2012, 16, 1845–1862. [Google Scholar] [CrossRef]

- Erol, I.; Cakar, N.; Erel, D.; Sari, R. Sustainability in the Turkish retailing industry. Sustain. Dev. 2009, 17, 49–67. [Google Scholar] [CrossRef]

- Vollmann, T. The Transformation Imperative: Achieving Market Dominance through Radical Change; Harvard Business School Press: Boston, MA, USA, 1996. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).