Energy and Economic Analysis of Tropical Building Envelope Material in Compliance with Thailand’s Building Energy Code

Abstract

1. Introduction

2. Literature Review

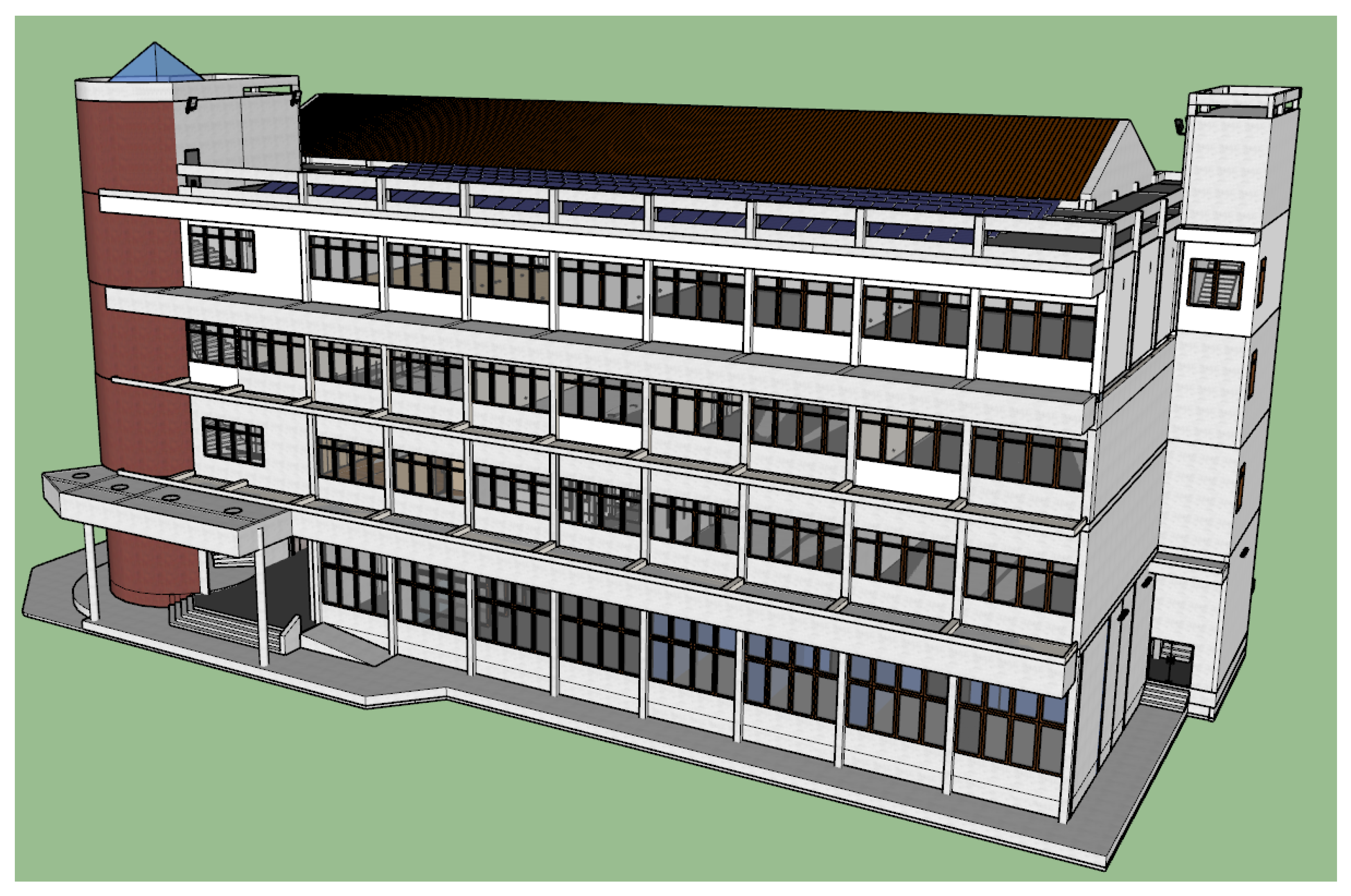

3. Thermal Calculation and Case Study

3.1. Thermal Transfer Calculation

- = Overall thermal transfer value of the building (W/m2);

- = Overall thermal transfer value of the considered side (W/m2);

- = Heat transfer coefficient of the opaque wall (W/m2·°C);

- = Window to wall ratio of the considered side;

- = Differential value of the equivalent temperature (°C);

- = Heat transfer coefficient of the transparent wall or window (W/ m2·°C);

- = Differential temperature between the interior and exterior of the building (°C);

- = Solar heat gain coefficient;

- = Shading coefficient;

- = Effective solar radiation (W/m2);

- = Area in each section of the wall (m2).

- = Roof thermal transfer value of the building (W/m2);

- = Roof thermal transfer value of the considered side (W/m2);

- = Heat transfer coefficient of the opaque roof (W/m2·°C);

- = Skylight to roof ratio;

- = Heat transfer coefficient of the transparent roof or skylight (W/m2·°C);

- = Area of the wall on the considered side (m2).

- = Heat resistance of the material (m2·k/W);

- = Total heat resistance the composition (m2·k/W);

- = Heat resistance of the air film for the inside wall = 0.12 m2·k/W;

- = Heat resistance of the air film for the outside wall = 0.044 m2·k/W;

- = Thickness of the considered material (m);

- = Thermal conductivity coefficient of the considered material (W/m2·K).

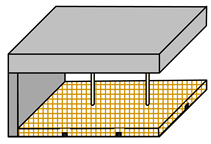

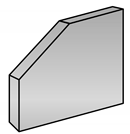

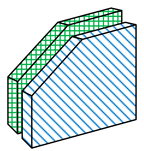

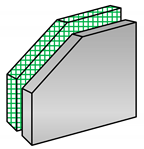

3.2. Opaque Material

3.3. Transparent Material

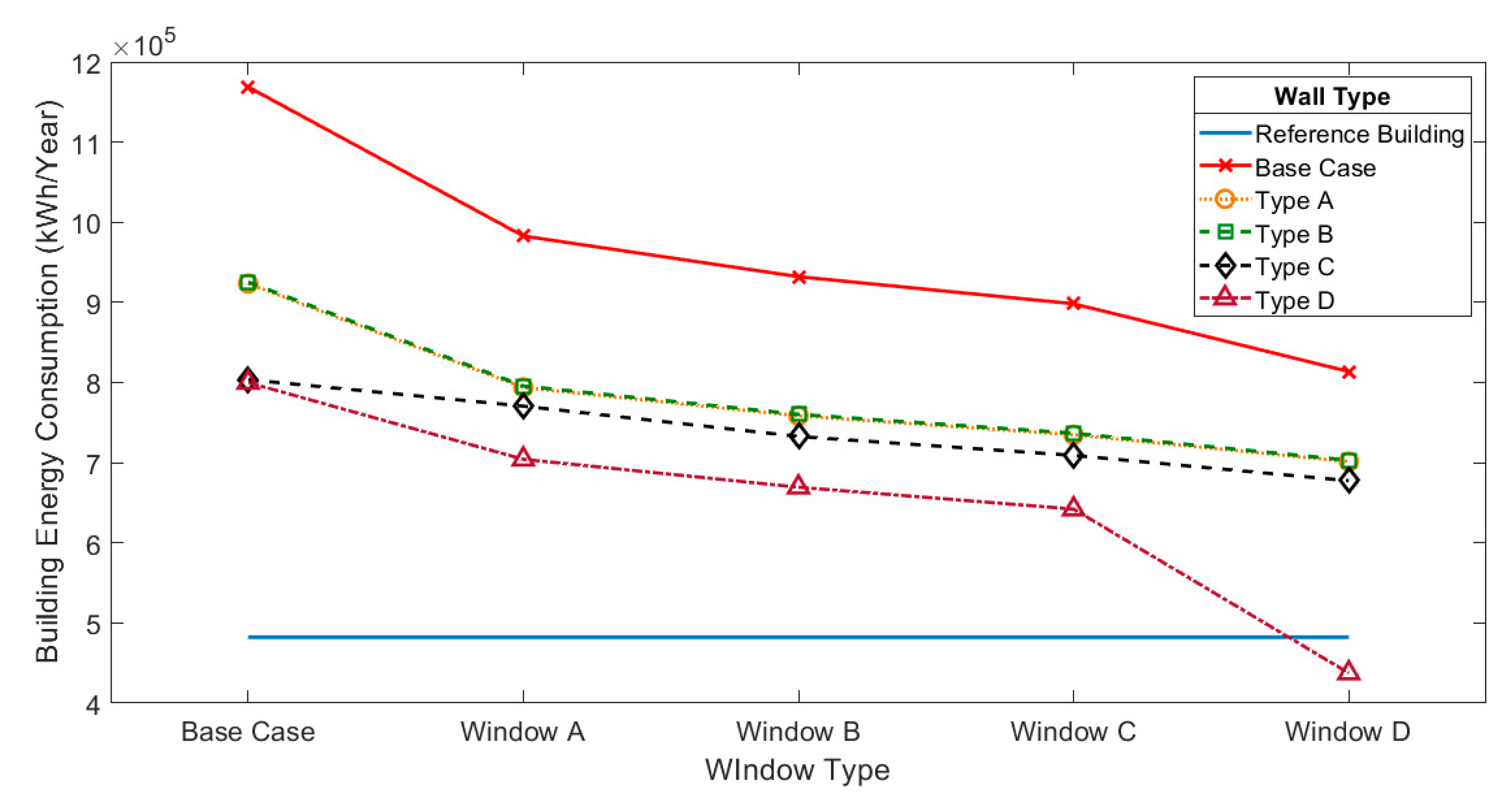

4. Energy Performance

4.1. Overall Thermal Transfer Value

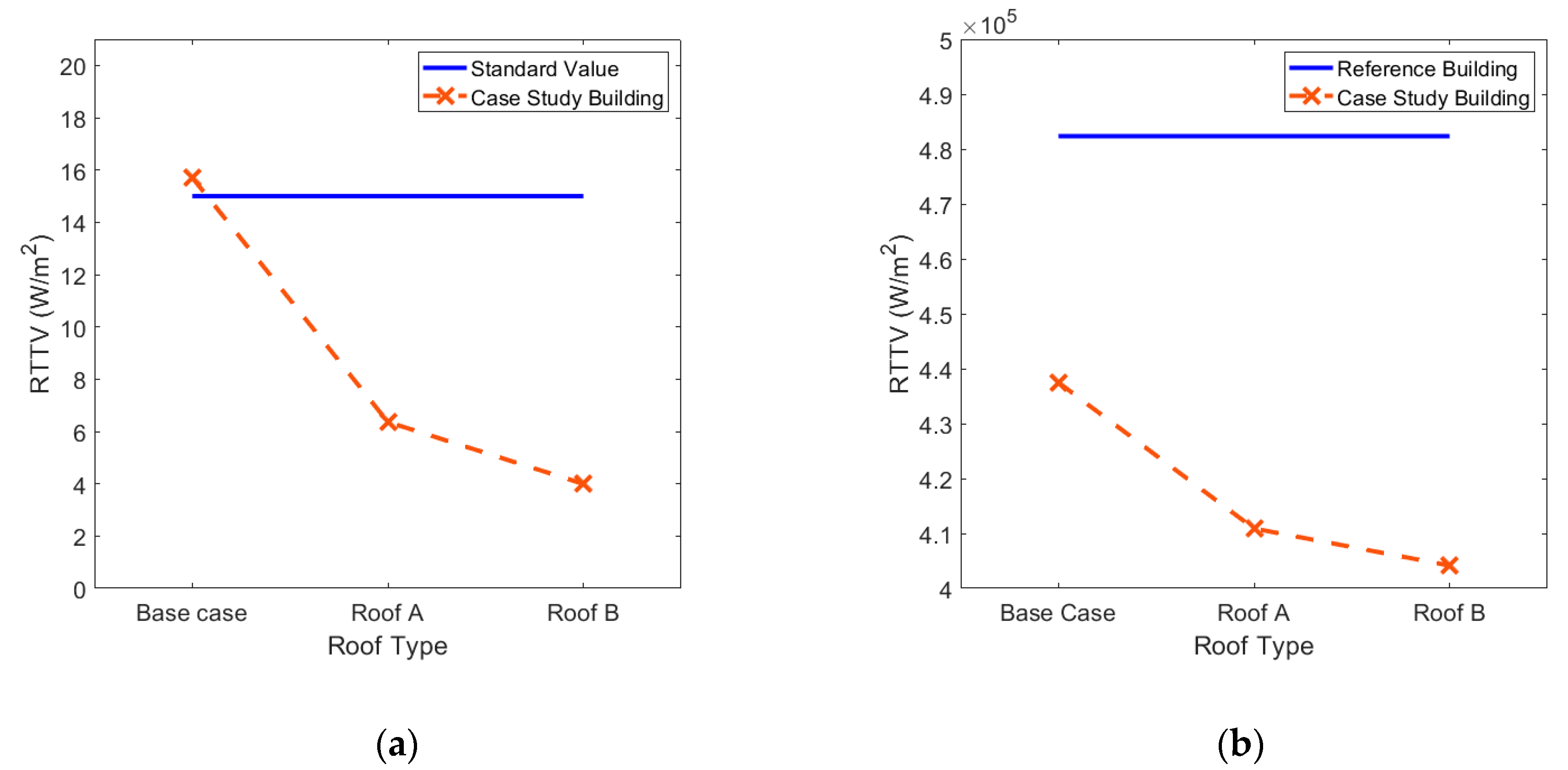

4.2. Roof Thermal Transfer Value

5. Economic Analysis

5.1. Economic Indicators

- = Rate of interest to determine the present value of the future cash flow;

- = Period to which the cash inflow relates;

- = Last period with a negative discounted cumulative cash flow;

- = Absolute value of the discounted cumulative cash flow at the end of period A;

- = Discounted cash flow during the period after A.

- = Net cash inflow during the period t;

- = Total initial investment costs;

- = The number of time periods;

- = Discounted rate.

5.2. Building Envelope Cost

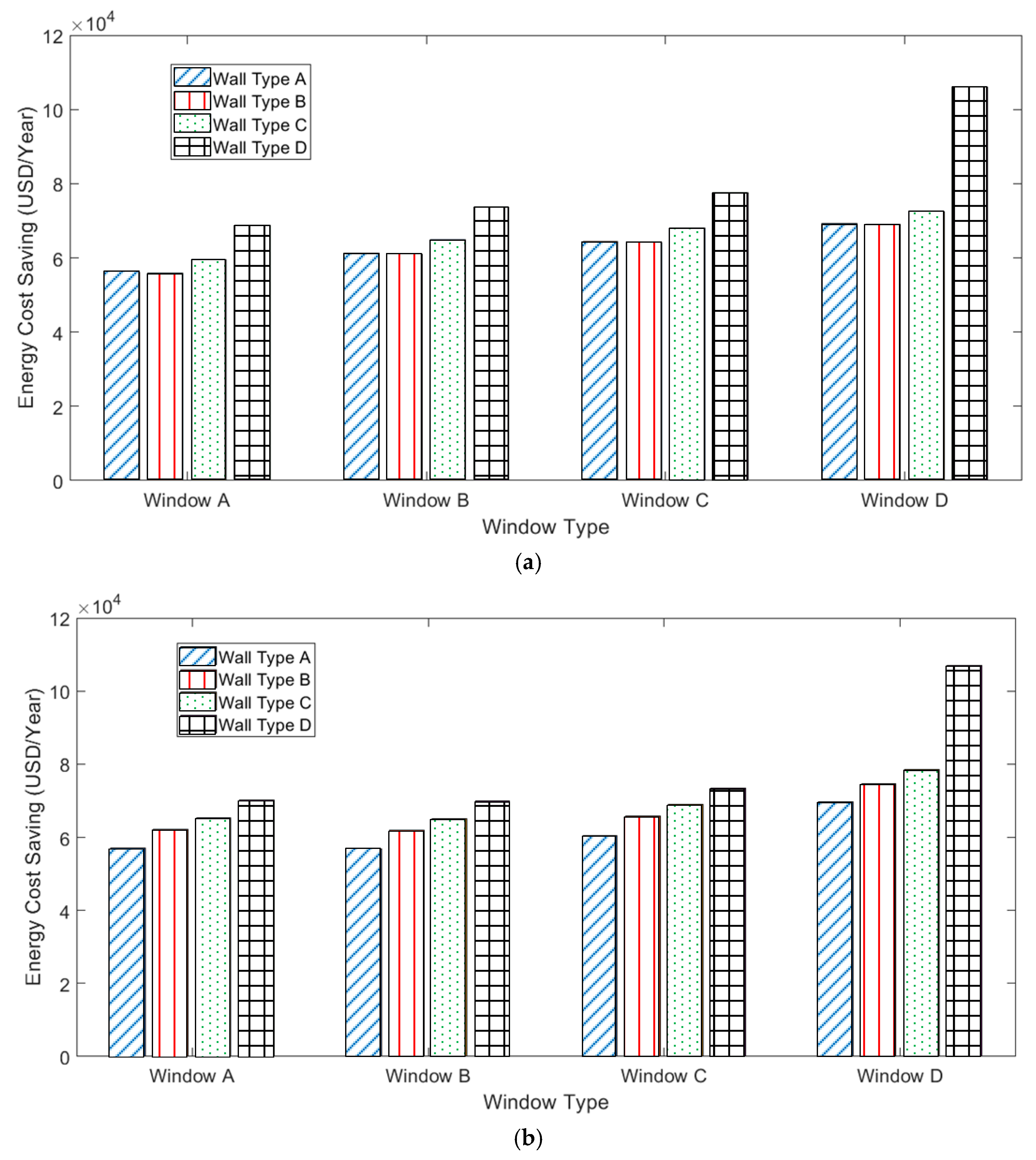

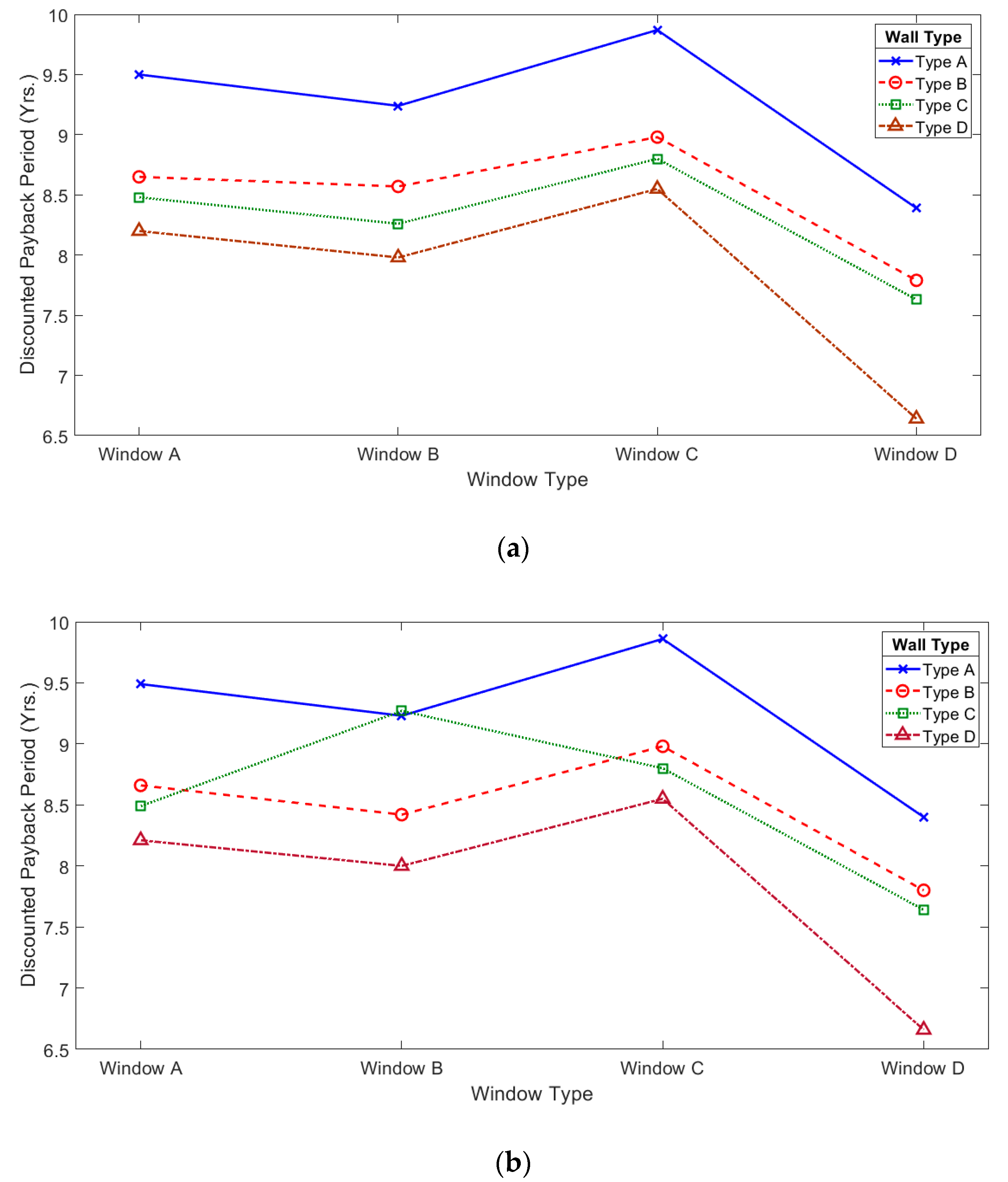

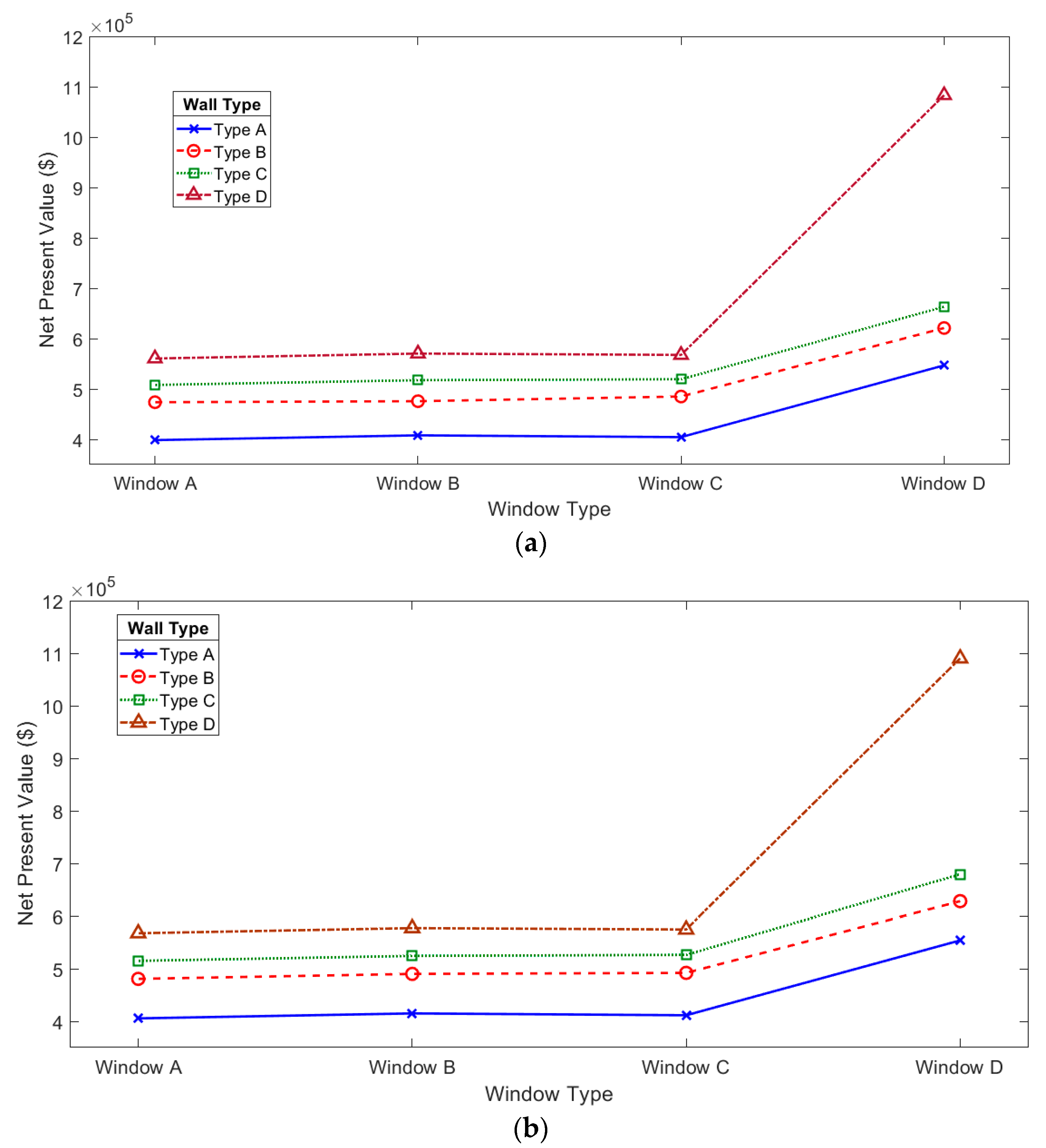

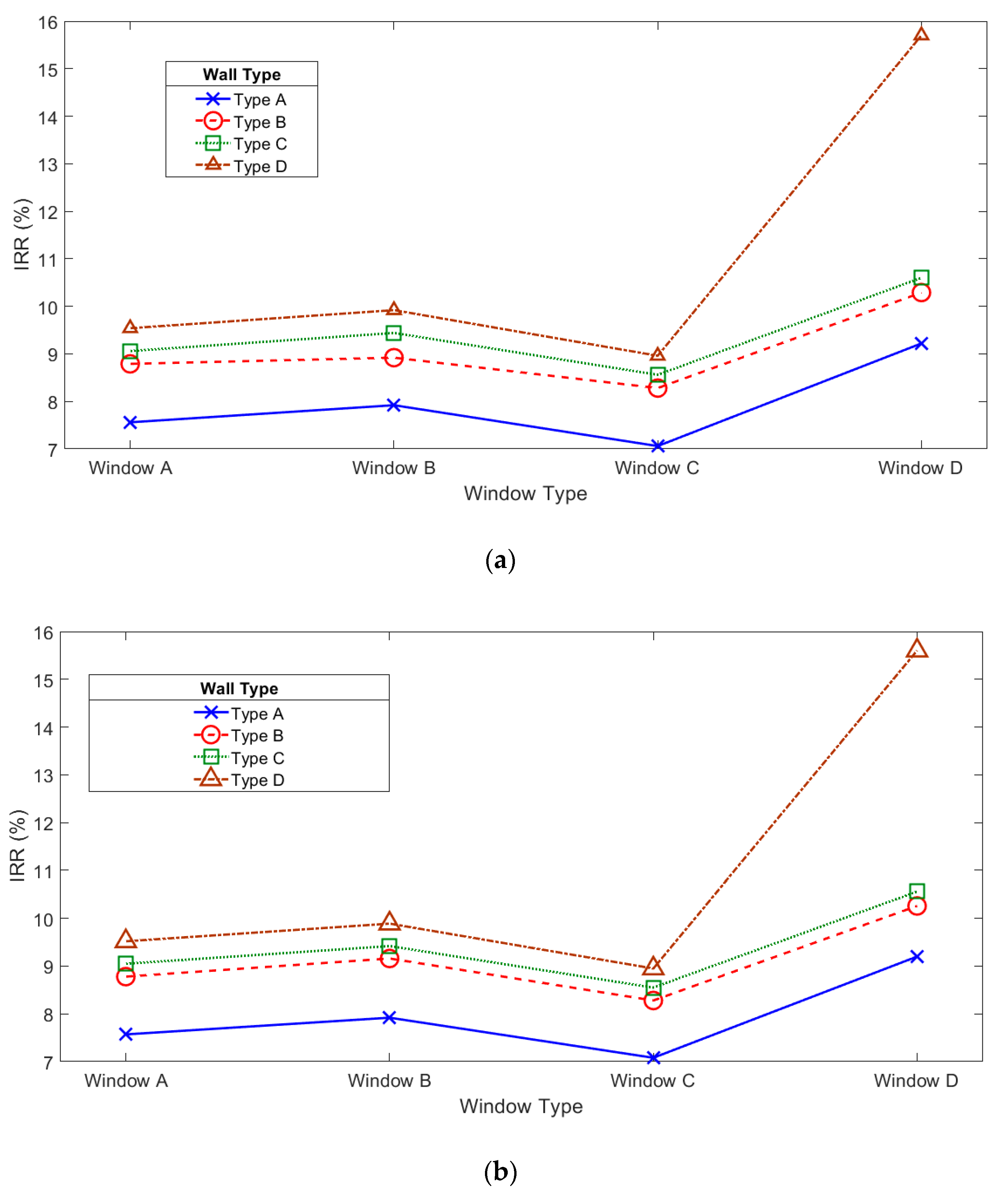

5.3. Economic Result

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Energy Agency. Technology Roadmap—Energy Efficient Building Envelopes; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Commercial Buildings Energy Consumption Survey: Energy Usage Summary. 2012. Available online: https://www.eia.gov/consumption/commercial/reports/2012/energyusage/index.php (accessed on 15 July 2019).

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Ministry of Energy. 20-Year Energy Efficiency Development Plan (2011–2030); Ministry of Energy: Bangkok, Thailand, 2011. [Google Scholar]

- Government Gazette. Energy Conservation Promotion Act, B.E. 2535. 1992, Volume 1. Part 33, 2 April 1992. Available online: https://www.eppo.go.th/images/law/ENG/nation2 (accessed on 17 July 2019).

- Chirarattananon, S.; Chaiwiwatworakul, P.; Hien, V.D.; Rakkwamsuk, P.; Kubaha, K. Assessment of energy savings from the revised building energy code of Thailand. Energy 2010, 35, 1741–1753. [Google Scholar] [CrossRef]

- Climate-Data.org, Bangkok Climate. Available online: https://en.climate-data.org/asia/thailand/bangkok/bangkok-6313/ (accessed on 15 November 2019).

- Pezeshki, Z.; Soleimani, A.; Darabi, A.; Mazinani, S.M. Thermal transport in: Building materials. Constr. Build. Mater. 2018, 181, 238–252. [Google Scholar] [CrossRef]

- Trgala, K.; Pavelek, M.; Wimmer, R. Energy performance of five different building envelope structures using a modified Guarded Hot Box apparatus—Comparative analysis. Energy Build. 2019, 195, 116–125. [Google Scholar] [CrossRef]

- Balaji, N.C.; Mani, M.; Reddy, B.V.V. Dynamic thermal performance of conventional and alternative building wall envelopes. J. Build. Eng. 2019, 21, 373–395. [Google Scholar] [CrossRef]

- Cao, X.; Liu, J.; Cao, X.; Li, Q.; Hu, E.; Fan, F. Study of the thermal insulation properties of the glass fiber board used for interior building envelope. Energy Build. 2015, 107, 49–58. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, H. Heat transfer pattern judgment and thermal performance enhancement of insulation air layers in building envelopes. Appl. Energy 2019, 250, 834–845. [Google Scholar] [CrossRef]

- Favoino, F.; Jin, Q.; Overend, M. Design and control optimisation of adaptive insulation systems for office buildings. Part 1: Adaptive technologies and simulation framework. Energy 2017, 127, 301–309. [Google Scholar] [CrossRef]

- Jin, Q.; Favoino, F.; Overend, M. Design and control optimisation of adaptive insulation systems for office buildings. Part 2: A parametric study for a temperate climate. Energy 2017, 127, 634–649. [Google Scholar] [CrossRef]

- Cui, H.; Overend, M. A review of heat transfer characteristics of switchable insulation technologies for thermally adaptive building envelopes. Energy Build. 2019, 199, 427–444. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. Vacuum glazing for highly insulating windows: Recent developments and future prospects. Renew. Sustain. Energy Rev. 2016, 54, 1345–1357. [Google Scholar] [CrossRef]

- Fang, Y.; Arya, F. Evacuated glazing with tempered glass. Sol. Energy 2019, 183, 240–247. [Google Scholar] [CrossRef]

- Sun, Y.; Wilson, R.; Wu, Y. A Review of Transparent Insulation Material (TIM) for building energy saving and daylight comfort. Appl. Energy 2018, 226, 713–729. [Google Scholar] [CrossRef]

- Shahin, H.S.M. Adaptive building envelopes of multistory buildings as an example of high performance building skins. Alex. Eng. J. 2019, 58, 345–352. [Google Scholar] [CrossRef]

- Mirrahimi, S.; Mohamed, M.F.; Haw, L.C.; Lukman, N.; Ibrahim, N.; Yusoff, W.F.M.; Aflaki, A. The effect of building envelope on the thermal comfort and energy saving for high-rise buildings in hot–humid climate. Renew. Sustain. Energy Rev. 2016, 53, 1508–1519. [Google Scholar] [CrossRef]

- Khalil, A.A.; Fikry, M.; Abdeaal, W. High technology or low technology for buildings envelopes in residential buildings in Egypt. Alex. Eng. J. 2018, 57, 3779–3792. [Google Scholar] [CrossRef]

- Yousefi, F.; Gholipour, Y.; Yan, W. A study of the impact of occupant behaviors on energy performance of building envelopes using occupants’ data. Energy Build. 2017, 148, 182–198. [Google Scholar] [CrossRef]

- Belazi, W.; Ouldboukhitine, S.E.; Chateauneuf, A.; Bouchair, A. Uncertainty analysis of occupant behavior and building envelope materials in office building performance simulation. J. Build. Eng. 2018, 19, 434–448. [Google Scholar] [CrossRef]

- Aslani, A.; Bakhtiar, A.; Akbarzadeh, M.H. Energy-efficiency technologies in the building envelope: Life cycle and adaptation assessment. J. Build. Eng. 2019, 21, 55–63. [Google Scholar] [CrossRef]

- Zigart, M.; Lukman, R.K.; Premrov, M.; Leskovar, V.Z. Environmental impact assessment of building envelope components for low-rise buildings. Energy 2018, 163, 501–512. [Google Scholar] [CrossRef]

- Výskala, M. Investment Costs of the Building Envelope Reconstructions. J. Built Environ. 2014, 2, 17–25. [Google Scholar] [CrossRef]

- Darwish, I.E.; Gomaa, M. Retrofitting strategy for building envelopes to achieve energy efficiency. Alex. Eng. J. 2017, 56, 579–589. [Google Scholar] [CrossRef]

- Rodrigues, E.; Fernandes, S.; Gaspar, A.R.; Gomes, A.; Costa, J.J. Thermal transmittance effect on energy consumption of Mediterranean buildings with different thermal mass. Appl. Energy 2019, 252, 1134–1137. [Google Scholar] [CrossRef]

- Bano, F.; Sehgal, V. Evaluation of energy-efficient design strategies: Comparison of the thermal performance of energy-efficient office buildings in composite climate, India. Sol. Energy 2018, 176, 506–519. [Google Scholar] [CrossRef]

- Modrego, N.C.; Modrego, M.G. Energy retrofit of an existing affordable building envelope in Spain, case study. Sustain. Cities Soc. 2019, 44, 395–405. [Google Scholar] [CrossRef]

- Ali, H.; Hashlamun, R. Envelope retrofitting strategies for public school buildings in Jordan. J. Build. Eng. 2019, 25, 1008–1019. [Google Scholar] [CrossRef]

- Tummu, P.; Chirarattananon, S.; Hien, V.D.; Chaiwiwatworakul, P.; Rakkwamsuk, P. Formulation of an OTTV for walls of bedroom in Thailand. Appl. Therm. Eng. 2017, 113, 334–344. [Google Scholar] [CrossRef]

- Chirarattananon, S.; Limmeechokchai, B. A new building energy-efficiency law in Thailand: Impact on new buildings. Energy 1994, 19, 269–278. [Google Scholar] [CrossRef]

- Chirarattananon, S.; Taveekun, J. An OTTV-based energy estimation model for commercial buildings in Thailand. Energy Build. 2004, 36, 680–689. [Google Scholar] [CrossRef]

- Assawamartbunlue, K. An Investigation of Cooling and Heating Degree-Hours in Thailand. J. Clean Energy Technol. 2013, 1, 87–90. [Google Scholar] [CrossRef][Green Version]

- Goel, S. Capital Budgeting Appraisal Methods. In Capital Budgeting, 1st ed.; Business Expert Press, LLC.: New York, NY, USA, 2015; pp. 63–88. [Google Scholar]

- Peterson, P.P.; Fabozzi, F.J. Net Present Value Technique. In Capital Budgeting: Theory and Practice; John Wiley & Sons, Inc.: New York, NY, USA, 2002; pp. 72–78. [Google Scholar]

- Comptroller General’s Department. Material and Labour Cost for Fiscal Year 2562 B.E; Comptroller General’s Department: Bangkok, Thailand, 2018. [Google Scholar]

- Electricity Tariffs Large General Service. Available online: https://www.mea.or.th/en/profile/109/114 (accessed on 15 July 2019).

- Interest Rates in Financial Market (2005-Present). Available online: https://www.bot.or.th/App/BTWS_STAT/statistics/BOTWEBSTAT.aspx?reportID=223&language=ENG (accessed on 15 July 2019).

| Building Type | OTTV (watt/sq. mm.) | RTTV (watt/sq. mm.) |

|---|---|---|

| Office and Educational Institution | ≤50 | ≤15 |

| Department Store, Conference Centre | ≤40 | ≤12 |

| Hotel, Hospital and Apartment | ≤30 | ≤10 |

| Envelope Direction | Type | Area (m2) | Window-to-Wall Ratio |

|---|---|---|---|

| South | Wall | 724.73 | 0.29 |

| Window | 279.28 | ||

| North | Wall | 608.59 | 0.01 |

| Window | 48.04 | ||

| West | Wall | 807.09 | 0.28 |

| Window | 310.71 | ||

| East | Wall | 421.23 | 0.09 |

| Window | 78.23 | ||

| Roof | 907.28 | - | |

| Material | Thermal Conductivity (W/m·K) | Density (kg/m3) | Specific Heat (kJ/kg·K) |

|---|---|---|---|

| Concrete plaster | 0.72 | 1860 | 0.84 |

| Autoclaved aerated concrete | 0.476 | 1280 | 0.84 |

| Gypsum plates | 0.282 | 800 | 1.09 |

| Fiberglass insulation | 0.033 | 32 | 0.96 |

| Reinforced concrete | 1.442 | 2400 | 0.92 |

| Types | Thickness (m) | Air Gap Resistance (m2·C/W) | |

|---|---|---|---|

| Air gap (wall) | High radiation level | 0.1 | 0.16 |

| Low radiation level | 0.1 | 0.606 | |

| Air gap (roof) | High radiation level | 0.1 | 0.174 |

| Low radiation level | 0.1 | 1.423 |

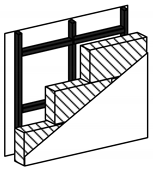

| Diagram | Detail | Thickness (m) | U-Value (W/m2·K) | Total Thickness (m) | |

|---|---|---|---|---|---|

| Base case |  | Concrete plaster | 0.01 | 1.634 | 0.22 |

| Autoclaved aerated concrete | 0.2 | ||||

| Concrete plaster | 0.01 | ||||

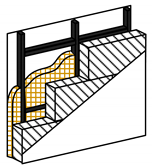

| Type A |  | Gypsum plates | 0.015 | 0.99 | 0.325 |

| Air gap | 0.1 | ||||

| Autoclaved aerated concrete | 0.2 | ||||

| Concrete plaster | 0.01 | ||||

| Type B |  | Concrete plaster | 0.01 | 1.03 | 0.32 |

| Autoclaved aerated concrete | 0.1 | ||||

| Air gap | 0.1 | ||||

| Autoclaved aerated concrete | 0.1 | ||||

| Concrete plaster | 0.01 | ||||

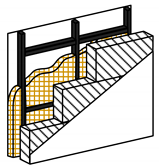

| Type C |  | Gypsum plates | 0.015 | 0.462 | 0.325 |

| Fiberglass insulation | 0.1 | ||||

| Autoclaved aerated concrete | 0.2 | ||||

| Concrete plaster | 0.01 | ||||

| Type D |  | Gypsum plates | 0.015 | 0.396 | 0.425 |

| Fiberglass insulation | 0.1 | ||||

| Air gap | 0.1 | ||||

| Autoclaved aerated concrete | 0.2 | ||||

| Concrete plaster | 0.01 |

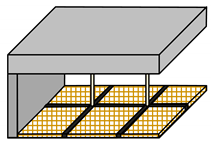

| Diagram | Detail | Thickness (m) | U-Value (W/m2·K) | Total Thickness (m) | |

|---|---|---|---|---|---|

| Base case |  | Reinforced concrete | 0.15 | 1.368 | 0.265 |

| Air gap | 0.1 | ||||

| Gypsum plates | 0.015 | ||||

| Roof A |  | Reinforced concrete | 0.15 | 0.445 | 0.315 |

| Air gap | 0.1 | ||||

| Fiberglass insulation | 0.05 | ||||

| Gypsum plates | 0.015 | ||||

| Roof B |  | Reinforced concrete | 0.15 | 0.266 | 0.365 |

| Air gap | 0.1 | ||||

| Fiberglass insulation | 0.1 | ||||

| Gypsum plates | 0.015 |

| Material | Composition | Thickness (m) | U-Value (W/m2·K) | SHGC | |

|---|---|---|---|---|---|

| Base case | Clear float glass |  | 0.06 | 5.74 | 0.82 |

| Window A | Ocean green float glass |  | 0.06 | 5.74 | 0.6 |

| Window B | Heat reflective glass |  | 0.06 | 5.16 | 0.54 |

| Window C | Clear float glass and tinted ocean green float glass for outer glass |  | 0.06-0.06-0.06 * | 3.47 | 0.5 |

| Window D | Clear colour single silver low-e coat on ocean green |  | 0.06-0.06-0.06 * | 2.73 | 0.4 |

| OTTV (W/m2) | Base Case | Window A | Window B | Window C | Window D |

|---|---|---|---|---|---|

| Base case | 130.459 | 101.456 | 93.546 | 88.273 | 75.09 |

| Type A | 92.210 | 71.987 | 66.471 | 62.794 | 57.559 |

| Type B | 92.499 | 72.275 | 66.759 | 63.082 | 57.825 |

| Type C | 73.504 | 68.358 | 62.447 | 58.770 | 53.846 |

| Type D | 72.947 | 58.011 | 52.577 | 48.324 | 31.445 |

| Material Name | Cost per Unit (USD/m2) * | Labour Cost per Unit (USD/m2) * | Total Cost (USD/m2) * |

|---|---|---|---|

| Autoclaved aerated concrete (20 cm) | 12.47 | 2.60 | 15.07 |

| Autoclaved aerated concrete (10 cm) | 6.23 | 1.87 | 8.10 |

| Concrete plaster | 4.00 | 2.67 | 6.67 |

| Reinforced concrete | 326.27 | 67.10 | 393.37 |

| Gypsum plates | 10.63 | 2.50 | 13.13 |

| Fiberglass insulator (5 mm) | 8.33 | 0.83 | 9.16 |

| Fiberglass insulator (10 mm) | 16.67 | 0.83 | 17.50 |

| Clear float glass | 6.45 | 0.37 | 6.82 |

| Ocean green float glass | 7.53 | 0.37 | 7.90 |

| Heat reflective glass | 8.60 | 0.37 | 8.97 |

| Clear float glass and tinted ocean green float glass for outer glass | 28.20 | 4.00 | 32.20 |

| Clear colour single silver low-e coat on ocean green | 56.00 | 4.00 | 60.00 |

| Retrofitted Case | Cost per Unit (USD/m2) * | Labour Cost per Unit (USD/m2) * | Total Cost (USD/m2) * |

|---|---|---|---|

| Wall | |||

| Base case | 20.47 | 7.94 | 28.41 |

| Type A | 27.10 | 7.77 | 34.87 |

| Type B | 20.46 | 9.08 | 29.54 |

| Type C | 43.77 | 8.6 | 52.37 |

| Type D | 43.77 | 8.6 | 52.37 |

| Roof | |||

| Base case | 336.90 | 69.6 | 406.50 |

| Roof A | 345.23 | 70.43 | 415.66 |

| Roof B | 353.57 | 70.43 | 424.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiradeja, P.; Ngaopitakkul, A. Energy and Economic Analysis of Tropical Building Envelope Material in Compliance with Thailand’s Building Energy Code. Sustainability 2019, 11, 6872. https://doi.org/10.3390/su11236872

Chiradeja P, Ngaopitakkul A. Energy and Economic Analysis of Tropical Building Envelope Material in Compliance with Thailand’s Building Energy Code. Sustainability. 2019; 11(23):6872. https://doi.org/10.3390/su11236872

Chicago/Turabian StyleChiradeja, Pathomthat, and Atthapol Ngaopitakkul. 2019. "Energy and Economic Analysis of Tropical Building Envelope Material in Compliance with Thailand’s Building Energy Code" Sustainability 11, no. 23: 6872. https://doi.org/10.3390/su11236872

APA StyleChiradeja, P., & Ngaopitakkul, A. (2019). Energy and Economic Analysis of Tropical Building Envelope Material in Compliance with Thailand’s Building Energy Code. Sustainability, 11(23), 6872. https://doi.org/10.3390/su11236872