A Data-Driven Scheduling Approach for Hydrogen Penetrated Energy System Using LSTM Network

Abstract

:1. Introduction

- (1)

- This paper proposed two LSTM based operational scheduling and control approaches for HPES.

- (2)

- This paper evaluated the performance of the proposed approaches in the intra-day operation of the HPES.

- (3)

- The intra-day operational cost, intra-day equipment operational scheduling and the computational speed of the proposed scheduling and control approaches are analyzed in detail.

2. Materials and Methods

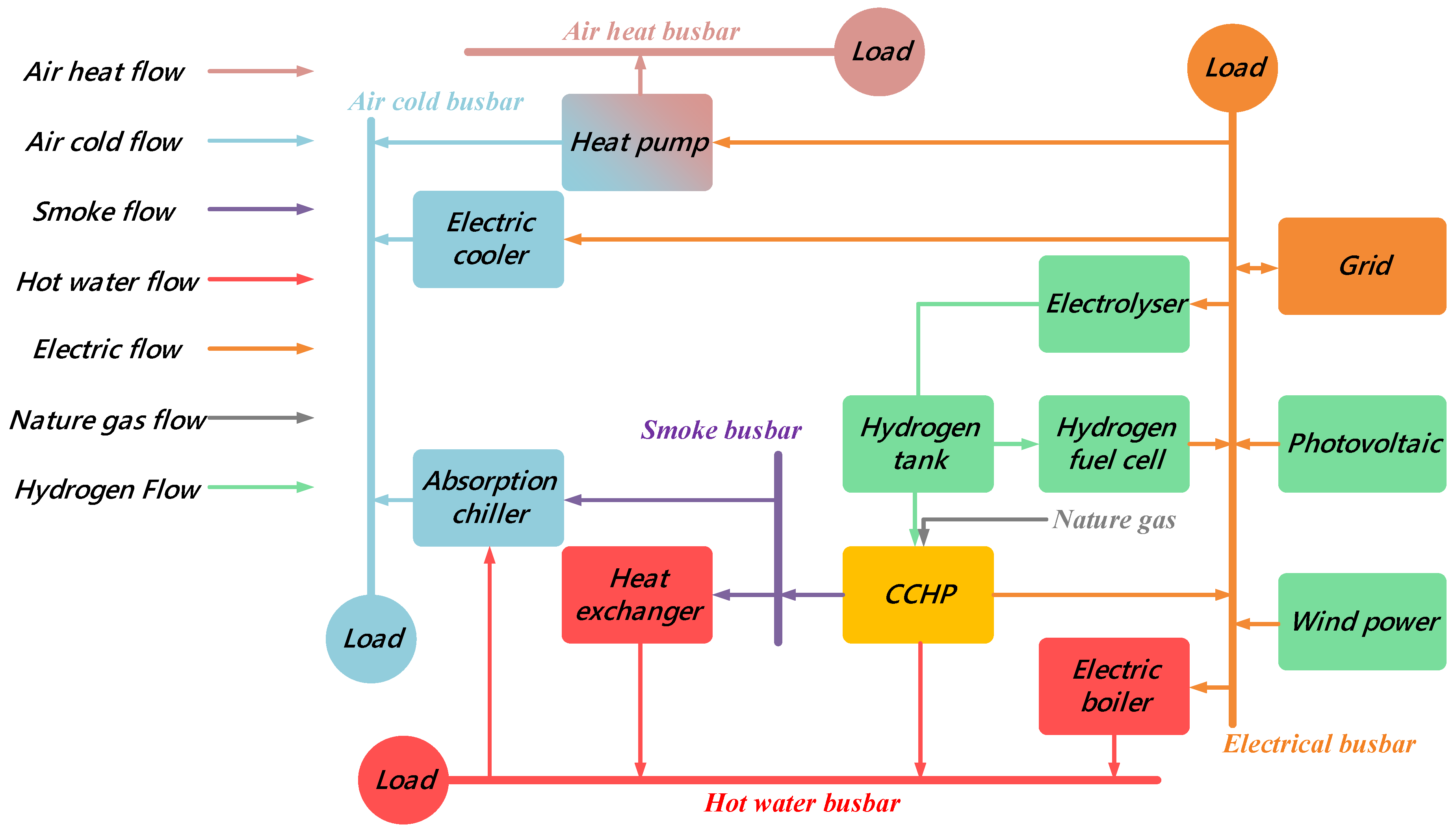

2.1. Hydrogen Penetrated Energy System (HPES)

2.2. HPES Mathematical Modelling

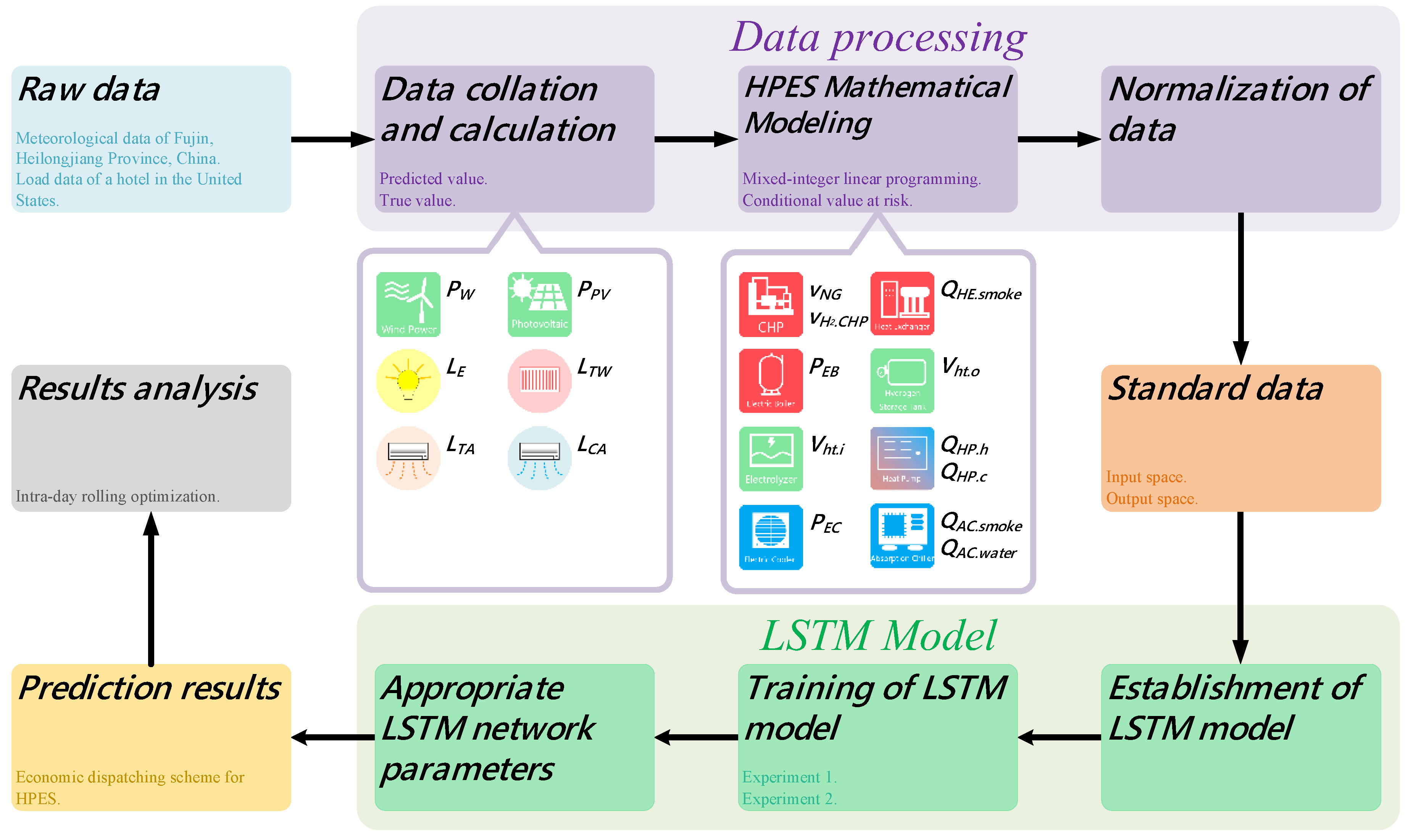

2.3. Data-Driven Approach for HPES Scheduling

2.4. LSTM Based Approach

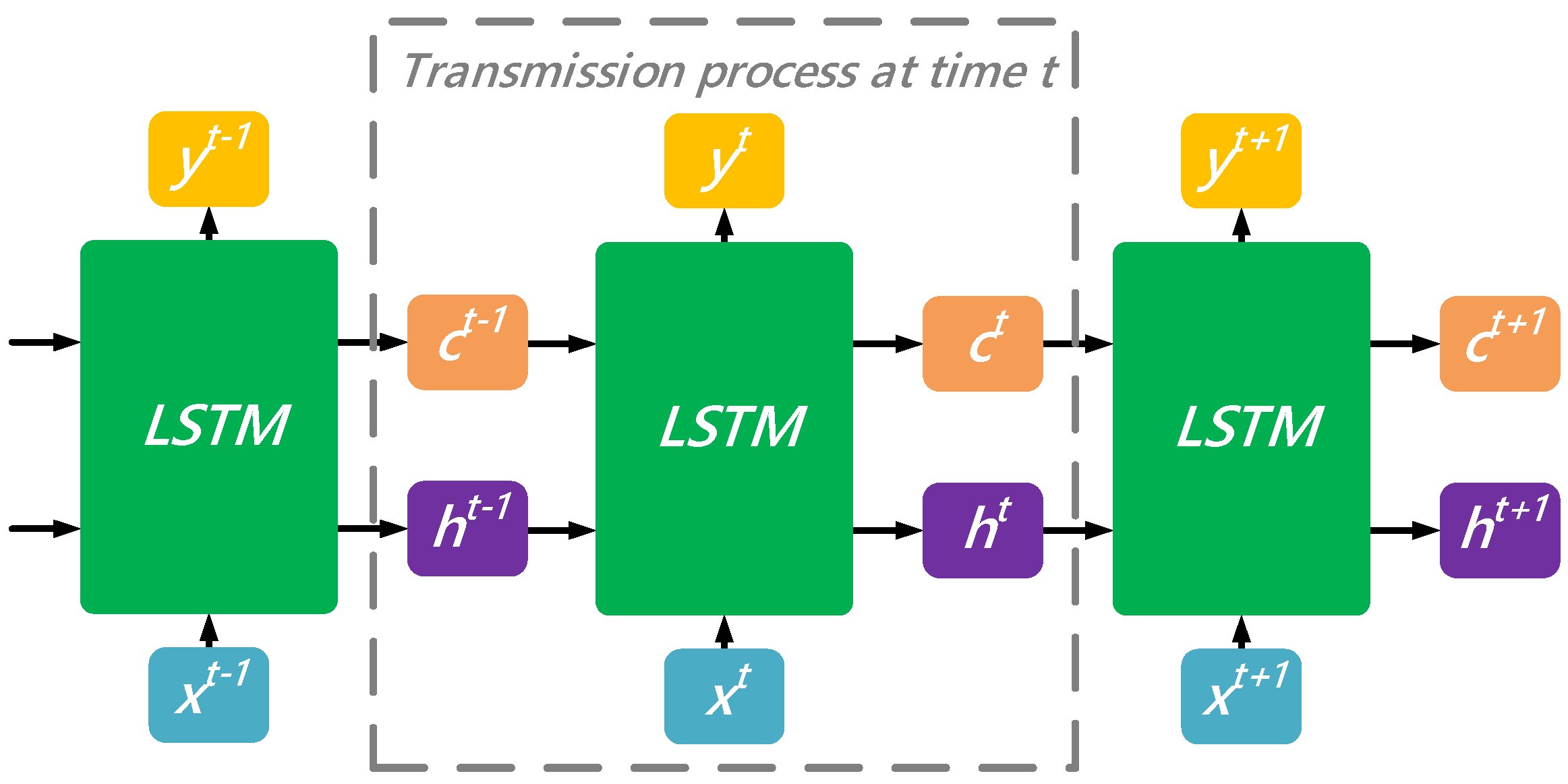

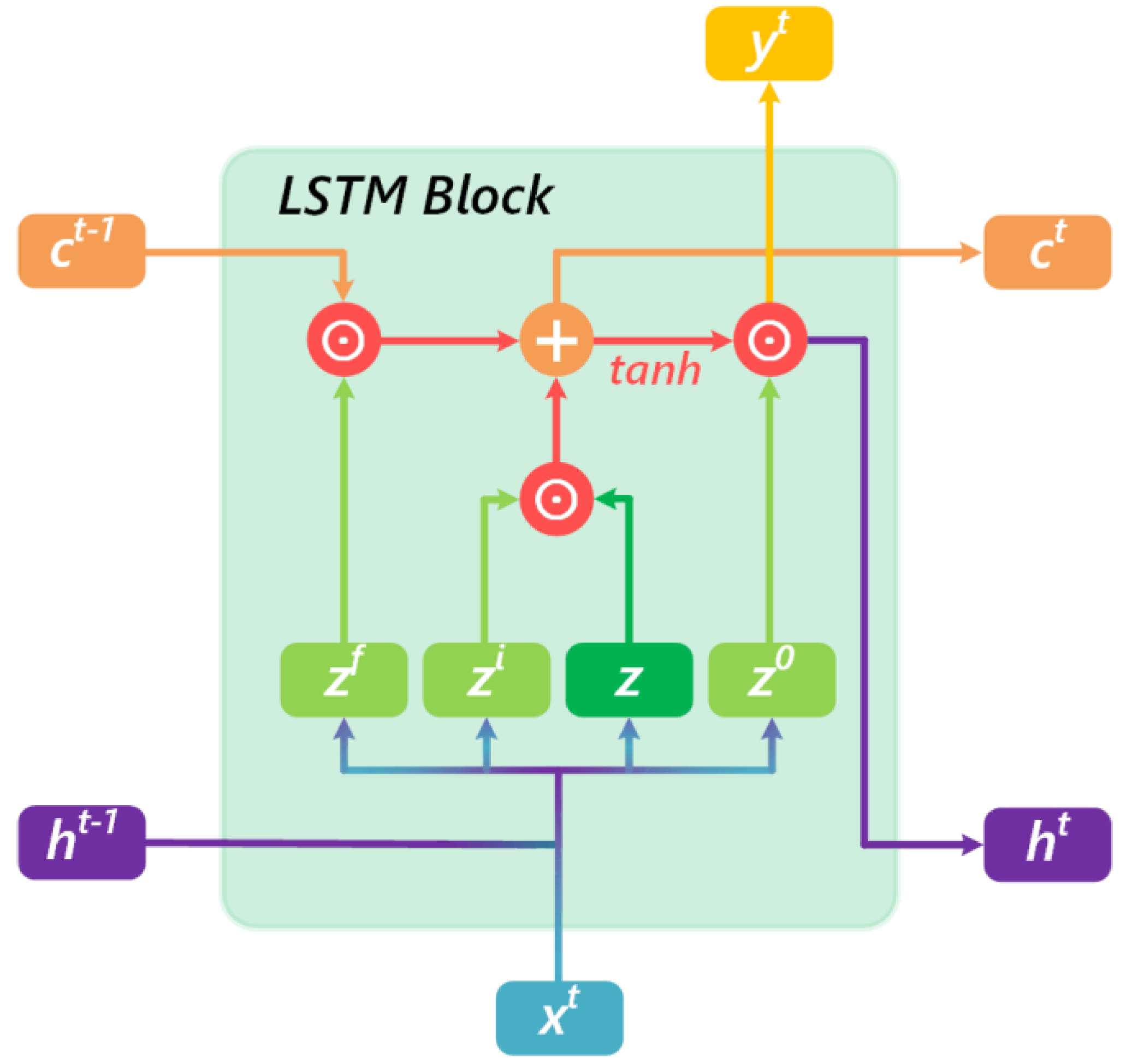

2.4.1. Introduction of LSTM

2.4.2. LSTM based Control Strategy

3. Results and Discussion

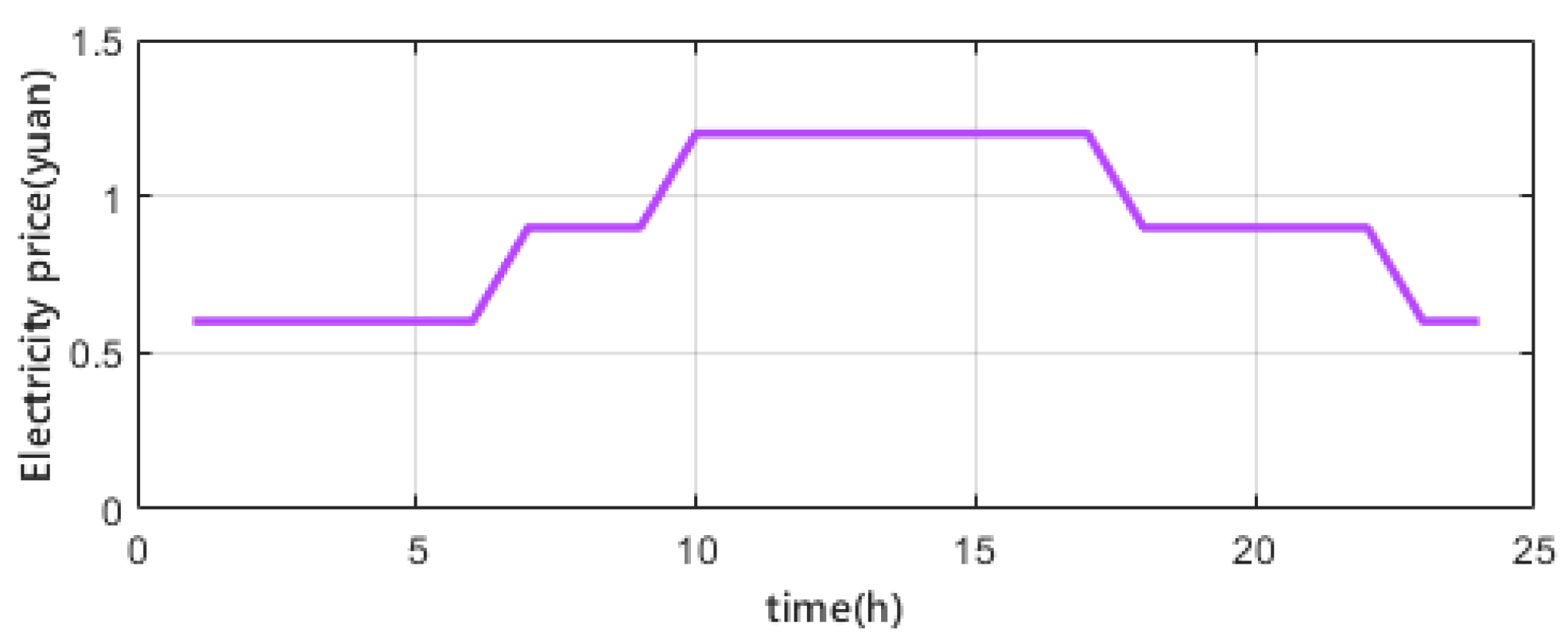

3.1. Data Description and Processing

3.2. LSTM Network Training Process

3.3. Result Analysis

3.3.1. Analysis of Training Results

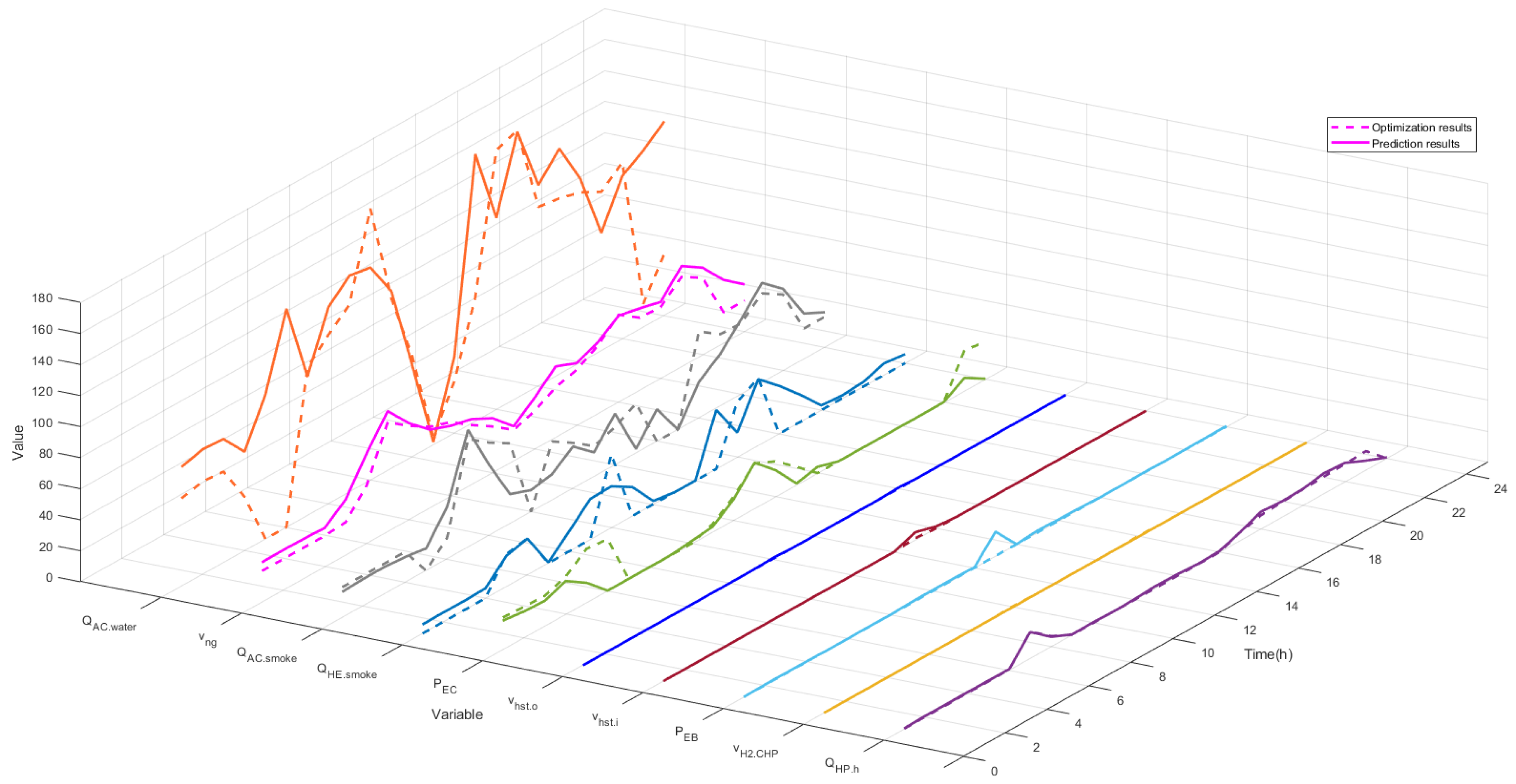

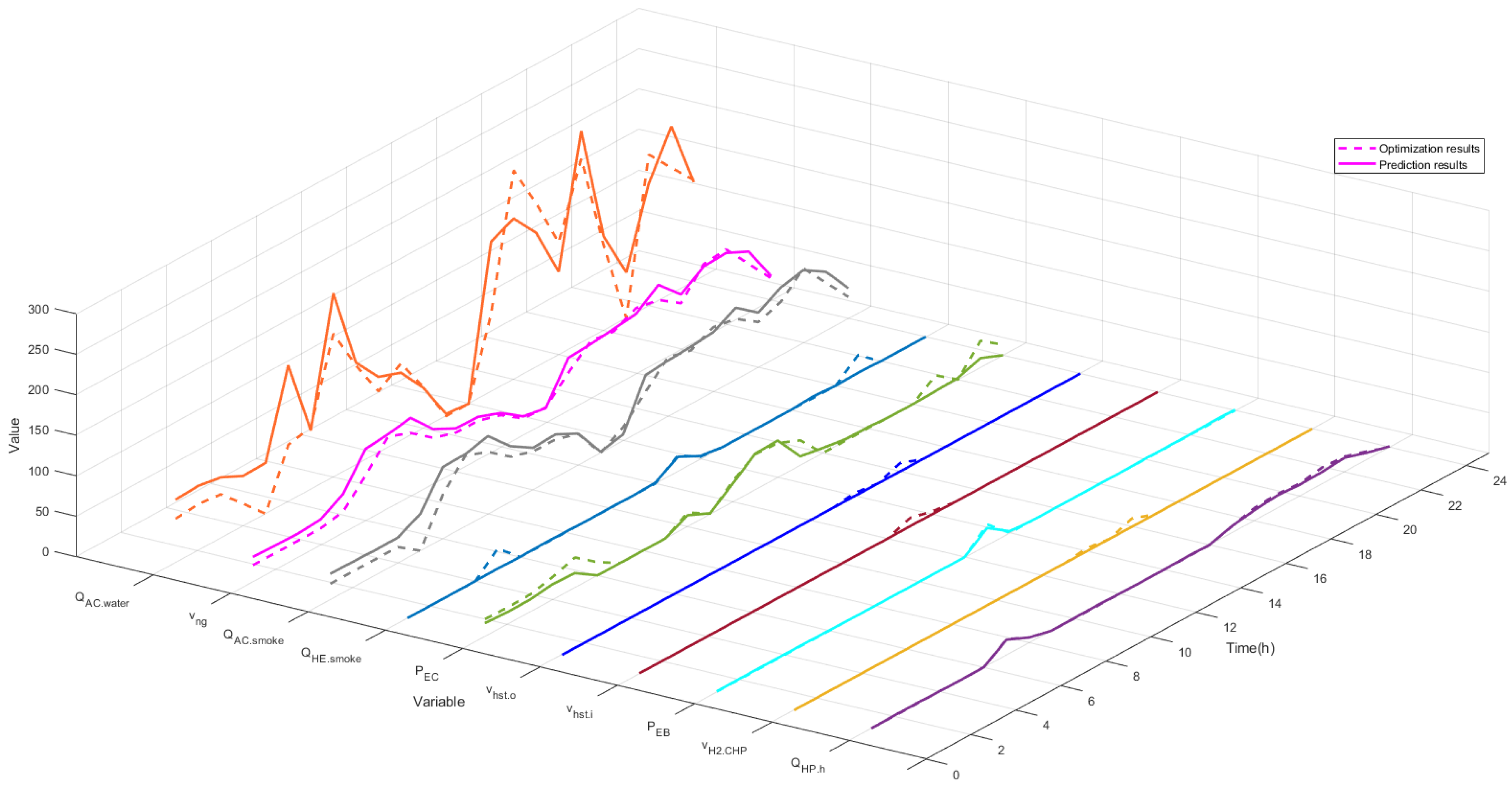

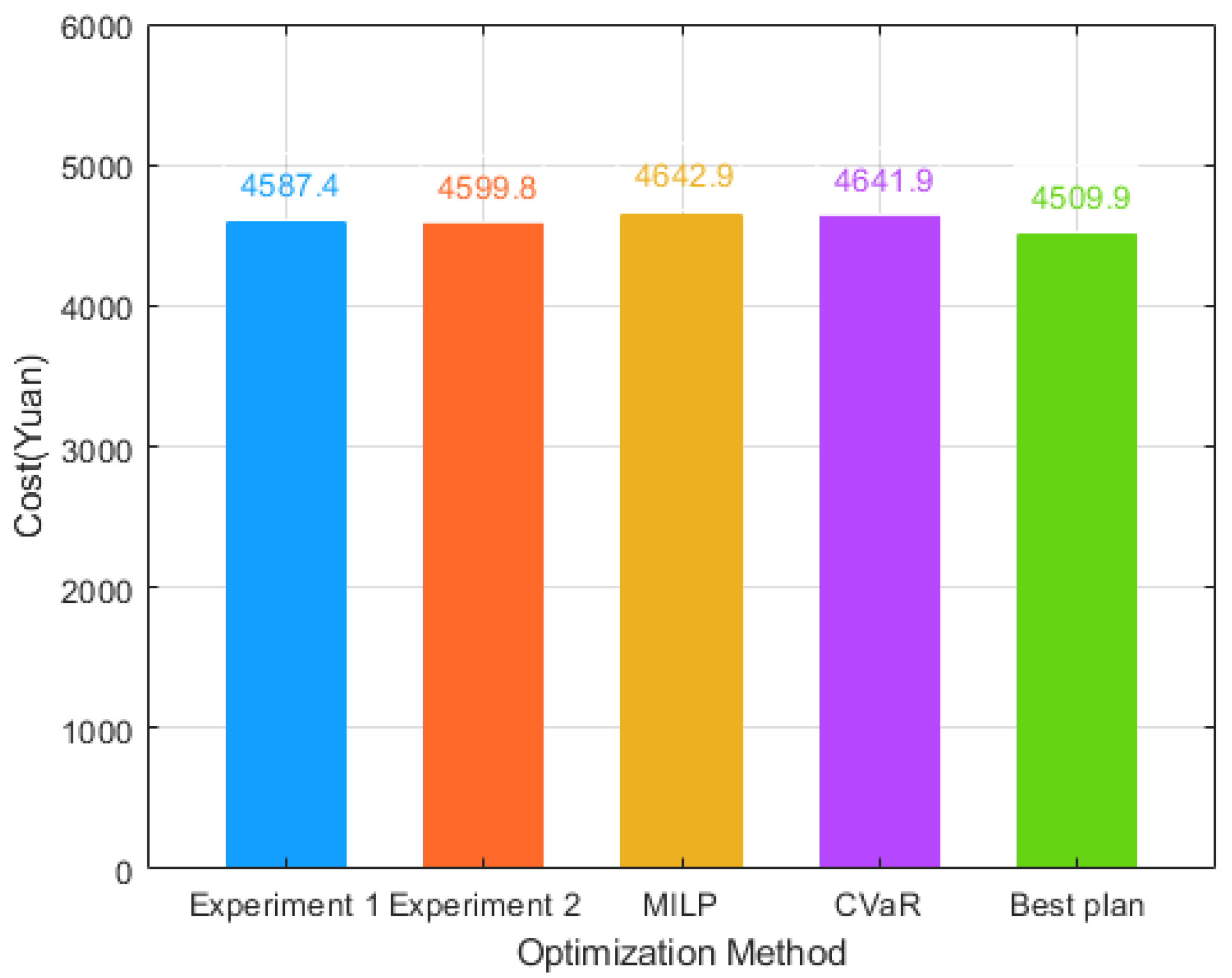

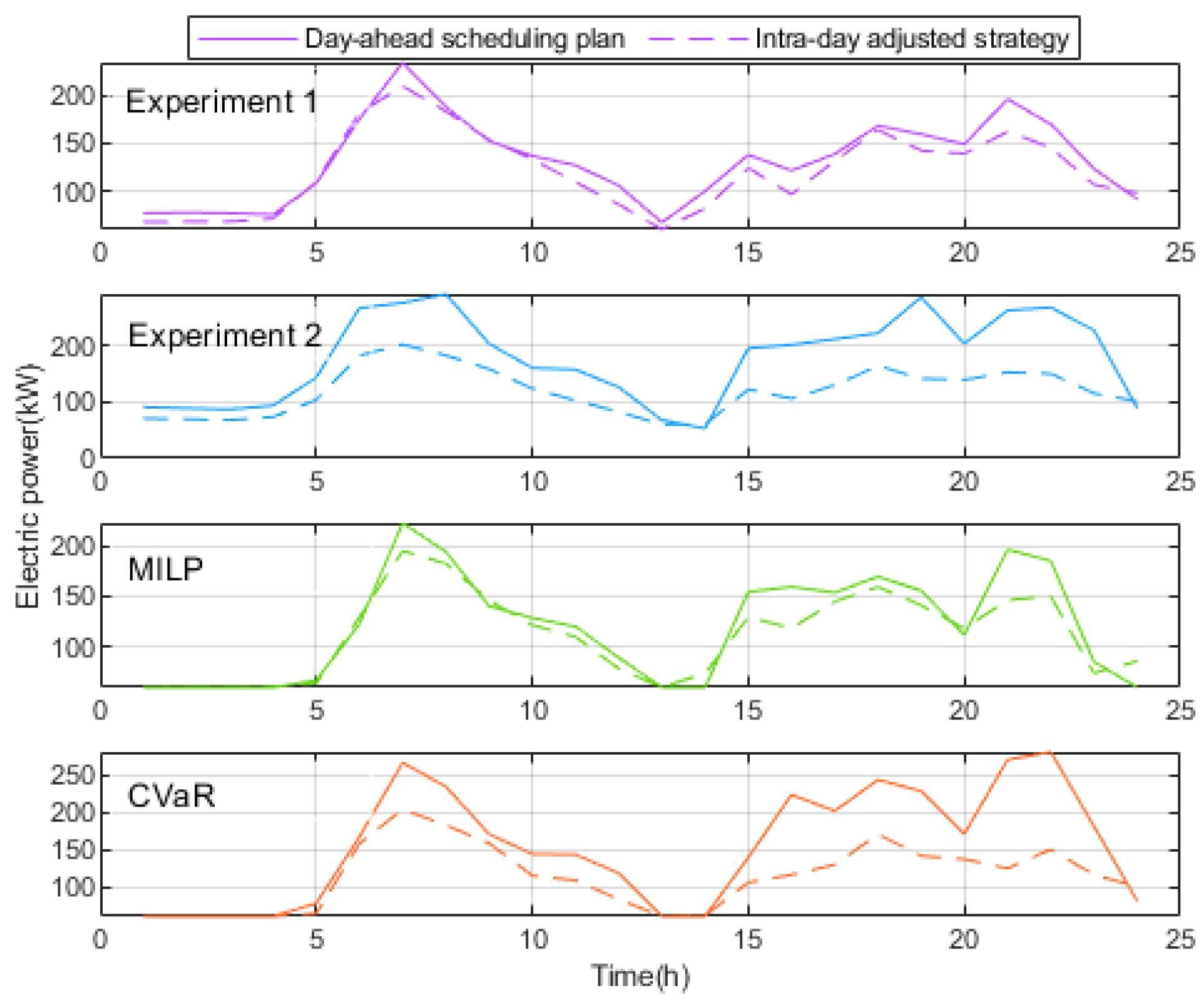

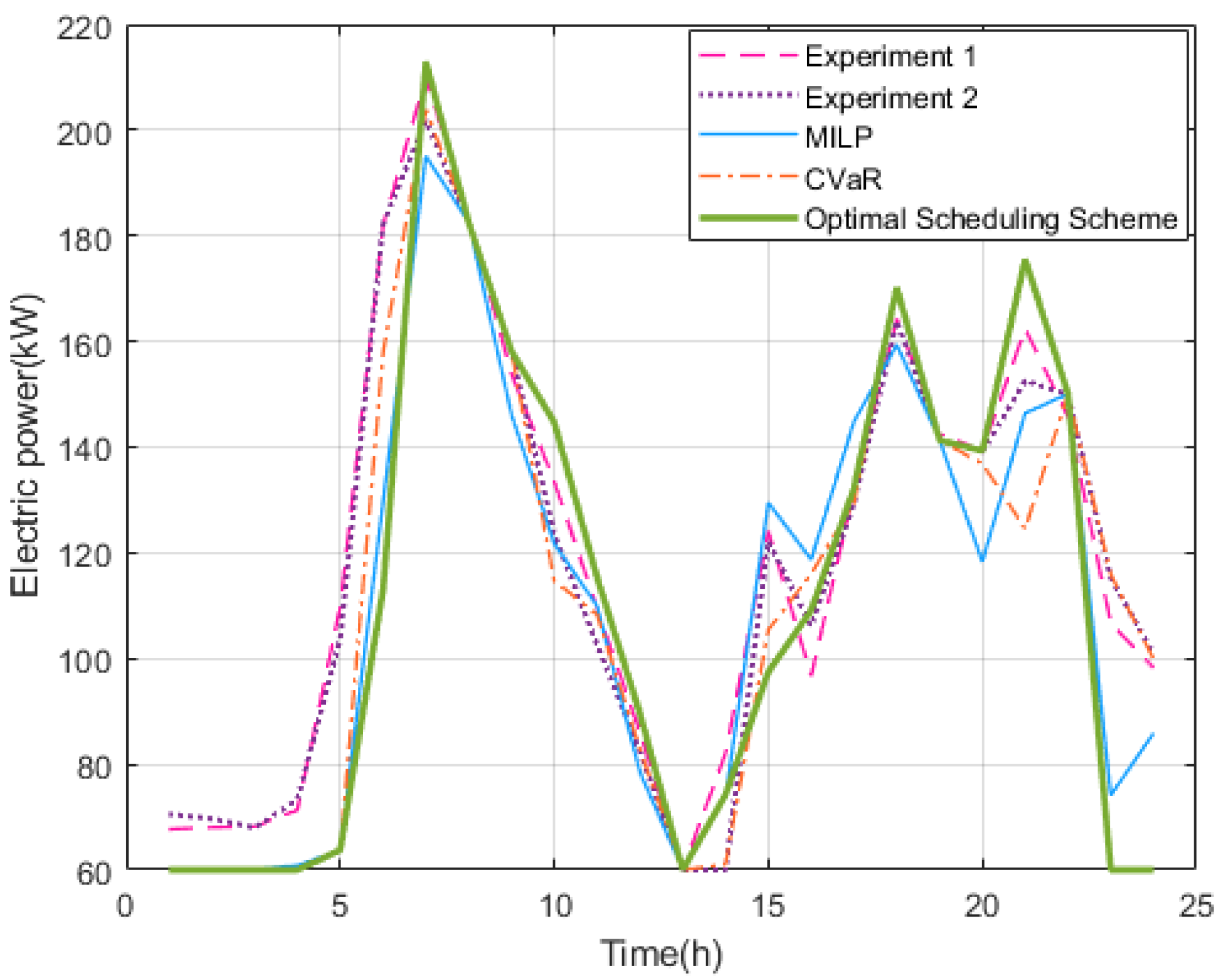

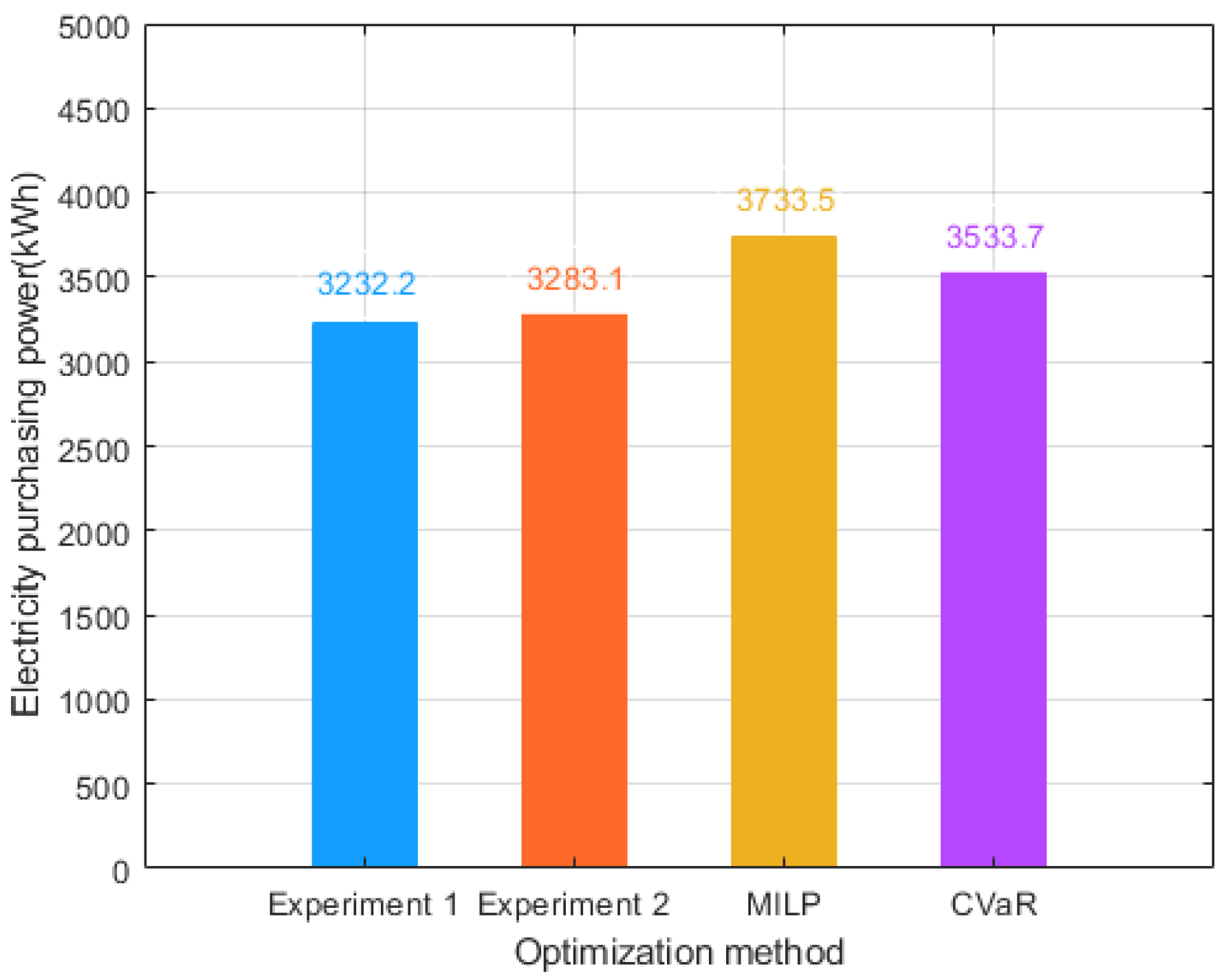

3.3.2. Verification of Training Results on Intra-Day Basis

- Experiment 1: 295.5 kWh

- Experiment 2: 1444.7 kWh

- MILP: 326.5 kWh

- CVaR: 1,019 kWh

3.3.3. Running Time of Optimization Program

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Quantity |

| Time length of the interval () | |

| Confidence level | |

| Factor of the CVaR | |

| Ratio between Electrical Energy and Hydrogen () | |

| Volume Proportion of Hydrogen in the Gas Mixture | |

| Operation Efficiency or Energy Efficiency of Device | |

| Binary Variable | |

| Value at Risk | |

| Air Density () | |

| Intermediate Variable of Calculating CVaR | |

| Difference Matrix of Scheduling Scheme | |

| Cost (¥) | |

| Unit Cost (¥) | |

| Long Term Memory of LSTM | |

| Directional Irradiation () | |

| Short Term Memory of LSTM | |

| PV Efficiency | |

| Cooling load () | |

| Electrical Load (kW) | |

| Heating Load () | |

| Hot water load () | |

| Lower Heating Value of Gas Mixture () | |

| Number of Intraday Rolling Optimization | |

| Number of Monte Carlo Simulation | |

| Matrix of Scheduling Scheme | |

| Electrical Power (kW) | |

| Electricity generation power of CHP () | |

| Power consumed by electric boiler () | |

| Power consumed by electric refrigerator () | |

| Power consumed by electrolyzer () | |

| Power bought from grid () | |

| Power sold to grid () | |

| Fuel cell generation power () | |

| Power consumed by heat pump () | |

| PV generation power () | |

| Wind generation power () | |

| Heating/Cooling Power (kW) | |

| Output power of absorption chiller () | |

| Smoke power consumed by absorption chiller () | |

| Hot water power consumed by absorption chiller () | |

| Smoke power generated by CHP () | |

| Hot water power generated by CHP (kW) | |

| Hot water power generated by electric boiler (kW) | |

| Cooling power generated by electric cooler (kW) | |

| Smoke power consumed by heat exchanger (kW) | |

| Hot water power generated by heat exchanger () | |

| Hot water power generated by fuel cell(SOFC only) () | |

| Cooling power generated by heat pump () | |

| Heating power generated by heat pump () | |

| Electrical Power Ramping Constraint of CHP (kW/h) | |

| Cross Sectional Area of Wind Turbine Blade () | |

| Time | |

| Rolling Period (h) | |

| Gas Volume () | |

| Gas Flow Rate () | |

| Input to LSTM | |

| Output from LSTM | |

| Network Input of LSTM | |

| Gate Controller of LSTM |

References

- Mancarella, P. MES (multi-energy systems): An overview of concepts and evaluation models. Energy 2014, 65, 1–17. [Google Scholar] [CrossRef]

- Bitar, E.; Khargonekar, P.P.; Poolla, K. Systems and control opportunities in the integration of renewable energy into the smart grid. IFAC Proc. Vol. 2011, 44, 4927–4932. [Google Scholar] [CrossRef]

- Korpås, M.; Greiner, C.J. Opportunities for hydrogen production in connection with wind power in weak grids. Renew. Energy 2008, 33, 1199–1208. [Google Scholar] [CrossRef]

- Hajimiragha, A.; Canizares, C.; Fowler, M.; Geidl, M.; Andersson, G. Optimal energy flow of integrated energy systems with hydrogen economy considerations. In Proceedings of the 2007 iREP Symposium-Bulk Power System Dynamics and Control-VII. Revitalizing Operational Reliability, Charleston, SC, USA, 19–24 August 2007; pp. 1–11. [Google Scholar]

- Winter, C.-J.; Nitsch, J. Hydrogen as an Energy Carrier: Technologies, Systems, Economy; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Zhou, S.; He, D.; Gu, W.; Wu, Z.; Abbas, G.; Hong, Q.; Booth, C. Design and evaluation of operational scheduling approaches for HCNG penetrated integrated energy system. IEEE Access 2019, 7, 87792–87807. [Google Scholar] [CrossRef]

- De Santoli, L.; Basso, G.L.; Bruschi, D. Energy characterization of CHP (combined heat and power) fuelled with hydrogen enriched natural gas blends. Energy 2013, 60, 13–22. [Google Scholar] [CrossRef]

- Wu, Q.; Zheng, J.; Jing, Z. Coordinated scheduling of energy resources for distributed DHCs in an integrated energy grid. CSEE J. Power Energy Syst. 2015, 1, 95–103. [Google Scholar] [CrossRef]

- Sugihara, H.; Komoto, J.; Tsuji, K. A multi-objective optimization model for determining urban energy systems under integrated energy service in a specific area. Electr. Eng. Jpn. 2004, 147, 20–31. [Google Scholar] [CrossRef]

- Geidl, M. Integrated Modeling and Optimization of Multi-Carrier Energy Systems; ETH Zurich: Zurich, Switzerland, 2007. [Google Scholar]

- Sanjari, M.; Karami, H.; Gooi, H. Micro-generation dispatch in a smart residential multi-carrier energy system considering demand forecast error. Energy Convers. Manag. 2016, 120, 90–99. [Google Scholar] [CrossRef]

- Ma, H.; Wang, B.; Gao, W.; Liu, D.; Sun, Y.; Liu, Z. Optimal scheduling of a regional integrated energy system with energy storage systems for service regulation. Energies 2018, 11, 195. [Google Scholar] [CrossRef]

- Tan, Z.; Ju, L.; Li, H.; Qin, C.; Peng, D. Multiobjective CVaR optimization model and solving method for hydrothermal system considering uncertain load demand. Math. Probl. Eng. 2015, 2015, 741379. [Google Scholar] [CrossRef]

- Li, G.; Zhang, R.; Jiang, T.; Chen, H.; Bai, L.; Li, X. Security-constrained bi-level economic dispatch model for integrated natural gas and electricity systems considering wind power and power-to-gas process. Appl. Energy 2017, 194, 696–704. [Google Scholar] [CrossRef]

- Ahmadi, P.; Dincer, I.; Rosen, M.A. Thermoeconomic multi-objective optimization of a novel biomass-based integrated energy system. Energy 2014, 68, 958–970. [Google Scholar] [CrossRef]

- Jiang, X.; Jing, Z.; Li, Y.; Wu, Q.; Tang, W. Modelling and operation optimization of an integrated energy based direct district water-heating system. Energy 2014, 64, 375–388. [Google Scholar] [CrossRef]

- Firestone, R.; Stadler, M.; Marnay, C. Integrated energy system dispatch optimization. In Proceedings of the 2006 4th IEEE International Conference on Industrial Informatics, Singapore, 16–18 August 2006; pp. 357–362. [Google Scholar]

- Martinez-Mares, A.; Fuerte-Esquivel, C.R. A robust optimization approach for the interdependency analysis of integrated energy systems considering wind power uncertainty. IEEE Trans. Power Syst. 2013, 28, 3964–3976. [Google Scholar] [CrossRef]

- Costanzo, G.T.; Iacovella, S.; Ruelens, F.; Leurs, T.; Claessens, B.J. Experimental analysis of data-driven control for a building heating system. Sustain. Energy Grids Netw. 2016, 6, 81–90. [Google Scholar] [CrossRef]

- Smarra, F.; Jain, A.; de Rubeis, T.; Ambrosini, D.; D’Innocenzo, A.; Mangharam, R. Data-driven model predictive control using random forests for building energy optimization and climate control. Appl. Energy 2018, 226, 1252–1272. [Google Scholar] [CrossRef]

- Darivianakis, G.; Georghiou, A.; Smith, R.S.; Lygeros, J. The power of diversity: Data-driven robust predictive control for energy-efficient buildings and districts. IEEE Trans. Control Syst. Technol. 2017, 27, 132–145. [Google Scholar] [CrossRef]

- Zhou, S.; Wu, Z.; Gu, W. Potential of Model-Free Control for Demand-Side Management Considering Real-Time Pricing. Energies 2019, 12, 2587. [Google Scholar] [CrossRef]

- Zhou, S.; Hu, Z.; Gu, W.; Jiang, M.; Zhang, X.-P. Artificial intelligence based smart energy community management: A reinforcement learning approach. CSEE J. Power Energy Syst. 2019, 5, 1–10. [Google Scholar] [CrossRef]

- Qin, Z.; Xifan, W. Hedge contract characterization and risk-constrained electricity procurement. IEEE Trans. Power Syst. 2009, 24, 1547–1558. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

| Device | Quantity | Parameter | Value |

|---|---|---|---|

| Grid | / | 1000 | |

| 1000 | |||

| Electric Boiler | 2 | 0.95 | |

| 240 | |||

| Absorption Chiller | 12 | 0.8 | |

| 50 | |||

| Hydrogen Storage Tank | 5 | 200 | |

| 20 | |||

| 20 | |||

| Heat Pump | 14 | 3.85 | |

| 4 | |||

| 38 | |||

| 38 | |||

| Fuel Cell | 1 | 1 | |

| 35 | |||

| Heat Exchanger | 1 | 0.85 | |

| 150 | |||

| Electric Refrigerator | 6 | 4 | |

| 20 | |||

| CCHP | 1 | 200 | |

| 80 | |||

| 600 | |||

| 60 | |||

| 100 | |||

| Electrolyser | 3 | 5 | |

| 50 |

| Parameter | Experiment 1 | Experiment 2 |

|---|---|---|

| Dimension of LSTM Layer Output | 100 | 100 |

| Loss Function | MAE | MAE |

| Number of Iteration | 600 | 450 |

| Dimension of Output Layer | 11 | 11 |

| Data Set | 365 | 365 |

| Learning Rate | 0.001 | 0.001 |

| Solver | adam | adam |

| Optimization Method | Experiment 1 | Experiment 2 | MILP | CVaR |

|---|---|---|---|---|

| Time(s) | 0.16 | 0.23 | 0.98 | 586.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; He, D.; Zhang, Z.; Wu, Z.; Gu, W.; Li, J.; Li, Z.; Wu, G. A Data-Driven Scheduling Approach for Hydrogen Penetrated Energy System Using LSTM Network. Sustainability 2019, 11, 6784. https://doi.org/10.3390/su11236784

Zhou S, He D, Zhang Z, Wu Z, Gu W, Li J, Li Z, Wu G. A Data-Driven Scheduling Approach for Hydrogen Penetrated Energy System Using LSTM Network. Sustainability. 2019; 11(23):6784. https://doi.org/10.3390/su11236784

Chicago/Turabian StyleZhou, Suyang, Di He, Zhiyang Zhang, Zhi Wu, Wei Gu, Junjie Li, Zhe Li, and Gaoxiang Wu. 2019. "A Data-Driven Scheduling Approach for Hydrogen Penetrated Energy System Using LSTM Network" Sustainability 11, no. 23: 6784. https://doi.org/10.3390/su11236784

APA StyleZhou, S., He, D., Zhang, Z., Wu, Z., Gu, W., Li, J., Li, Z., & Wu, G. (2019). A Data-Driven Scheduling Approach for Hydrogen Penetrated Energy System Using LSTM Network. Sustainability, 11(23), 6784. https://doi.org/10.3390/su11236784