A Study on the Relationship between Paradox Cognition, Green Industrial Production, and Corporate Performance

Abstract

1. Introduction

2. Literature Review

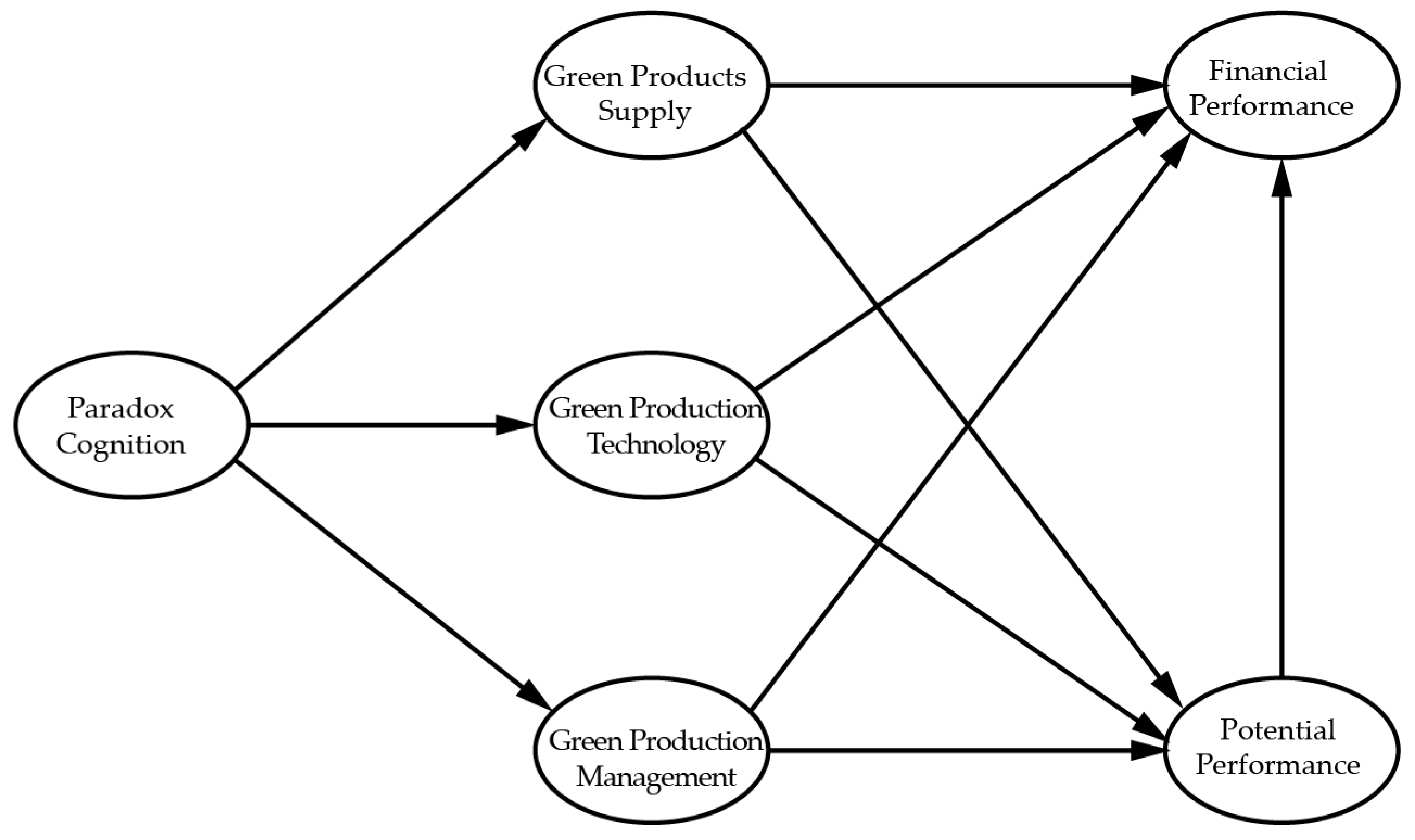

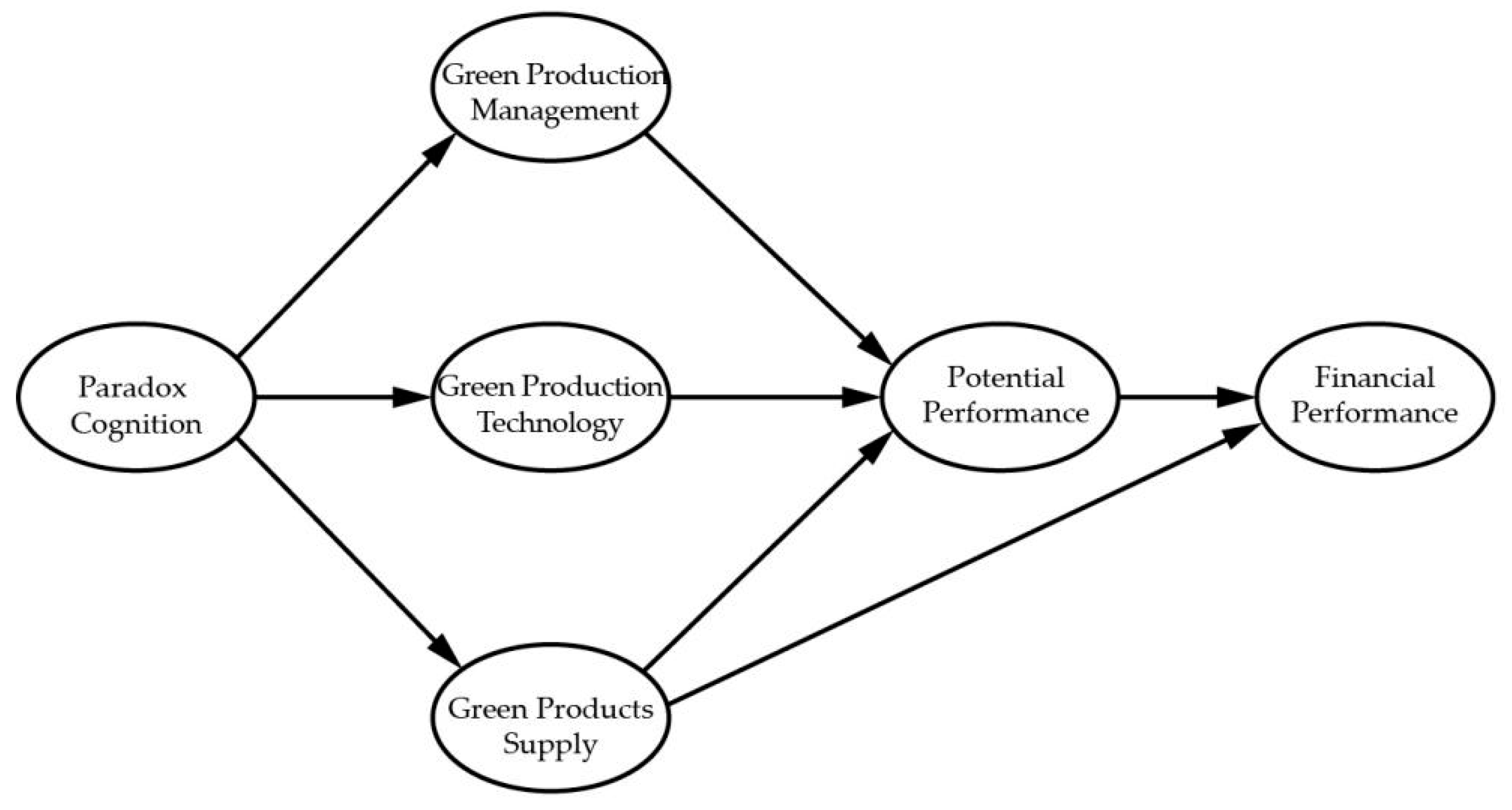

3. Research Model and Hypotheses

4. Methodology

4.1. Questionnaire Design

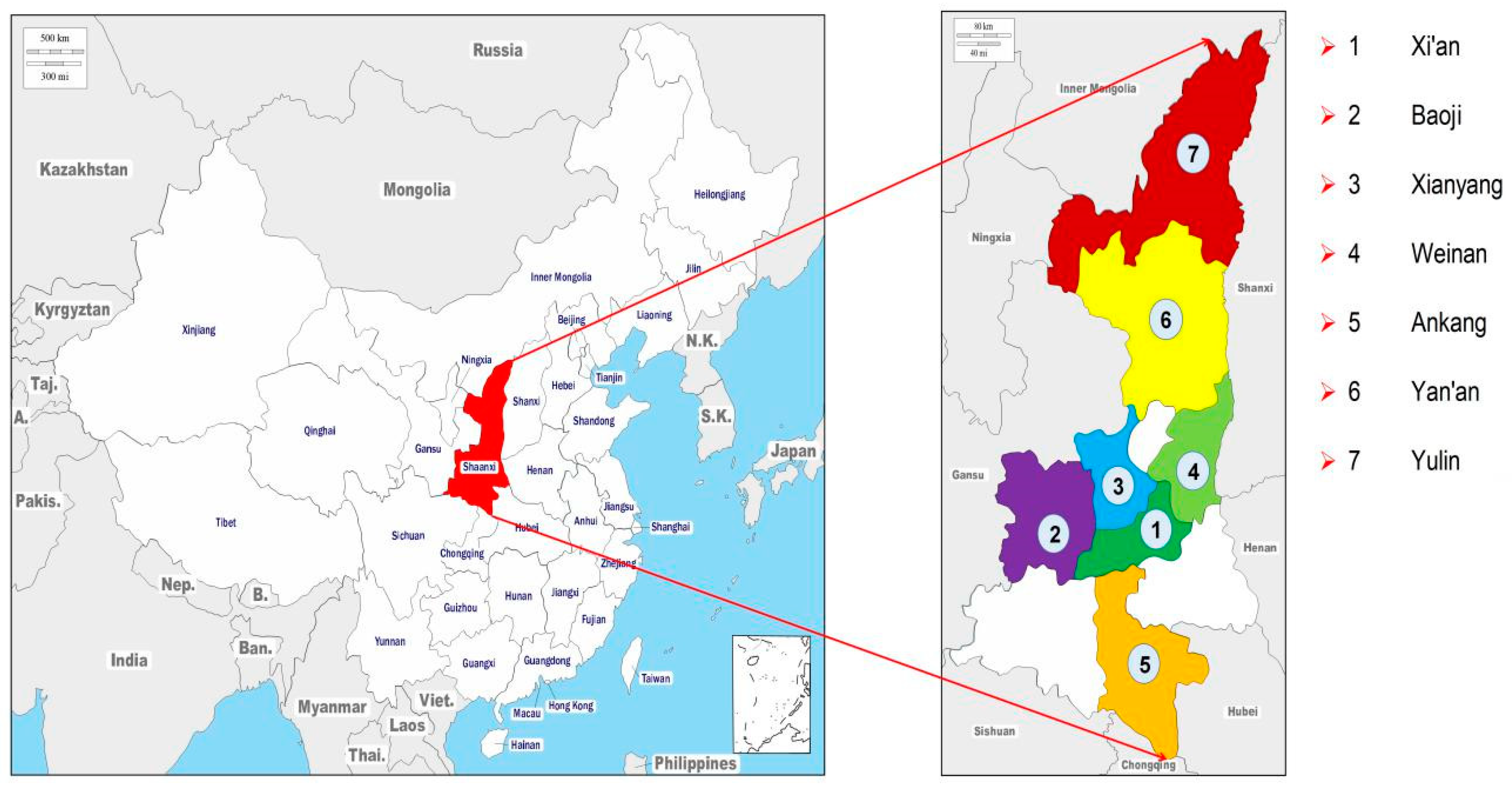

4.2. Data Collection

5. Results

5.1. Measurement Model

5.2. Structural Model

5.3. Hypothesis Testing

5.4. Mediation Effect Analysis

6. Discussion

6.1. Research Conclusion

6.2. Suggestions and Applications

Author Contributions

Funding

Conflicts of Interest

References

- Cadotte, M.W.; Barlow, J.; Nuñez, M.A.; Pettorelli, N.; Stephens, P.A. Solving environmental problems in the Anthropocene: The need to bring novel theoretical advances into the applied ecology fold. J. Appl. Ecol. 2017, 54, 1–6. [Google Scholar] [CrossRef]

- Stavropoulos, S.; Wall, R.; Xu, Y. Environmental regulations and industrial competitiveness: Evidence from China. Appl. Econ. 2017, 50, 1–17. [Google Scholar] [CrossRef]

- Li, C.; Wu, K.; Gao, X. Manufacturing industry agglomeration and spatial clustering: Evidence from Hebei Province, China. Environ. Dev. Sustain. 2019. [Google Scholar] [CrossRef]

- Liu, Z.; Adams, M.; Cote, R.P.; Geng, Y.; Chen, Q.; Liu, W.; Sun, L.; Yu, X. Comprehensive development of industrial symbiosis for the response of greenhouse gases emission mitigation: Challenges and opportunities in China. Energy Policy 2017, 102, 88–95. [Google Scholar] [CrossRef]

- Lin, R.J.; Tan, K.H.; Geng, Y. Market demand, green product innovation, and firm performance: Evidence from Vietnam motorcycle industry. J. Clean. Prod. 2013, 40, 101–107. [Google Scholar] [CrossRef]

- Dangelico, R.M. What drives green product development and how do different antecedents affect market performance? A survey of Italian companies with eco-labels. Bus. Strategy Environ. 2017, 26, 1144–1161. [Google Scholar] [CrossRef]

- Sun, F.R.; Yao, Y.D.; Chen, M.Q.; Li, X.F.; Zhao, L.; Meng, Y.; Sun, Z.; Zhang, T.; Feng, D. Performance analysis of superheated steam injection for heavy oil recovery and modeling of wellbore heat efficiency. Energy 2017, 125, 795–804. [Google Scholar] [CrossRef]

- Yang, A.M.; Li, S.S.; Lin, H.L.; Jin, D.H. Edge Extraction of Mineralogical Phase Based on Fractal Theory. Chaos Solitions Fractals 2018, 117, 215–221. [Google Scholar]

- Szopik-Depczyńska, K.; Cheba, K.; Kiba-Janiak, M.; Dembińska, I.; Ioppolo, G.; Bąk, I.; Saniuk, S. The application of relative taxonomy to the study of disproportions in the area of sustainable development of the European Union. Land Use Policy 2017, 68, 481–491. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, H.M.; Yang, X.H.; Xiong, J.X.; Sun, M.; Li, B. Study on an improved adaptive PSO algorithm for solving multi-objective gate assignment. Appl. Soft Comput. 2017, 59, 288–302. [Google Scholar] [CrossRef]

- Luo, X.; Liu, Y.; Liu, J.; Liu, X. Energy scheduling for a three-level integrated energy system based on energy hub models: A hierarchical Stackelberg game approach. Sustain. Cities Soc. 2020, 52, 101814. [Google Scholar] [CrossRef]

- Pérez-Maqueo, O.; Martínez, M.L.; Cóscatl Nahuacatl, R. Is the protection of beach and dune vegetation compatible with tourism? Tour. Manag. 2017, 58, 175–183. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, Q.; Ma, C.; Hu, Y.; Luo, K.; Li, W. Economic evaluation of environmental externalities in China’s coal-fired power generation. Energy Policy 2017, 102, 307–317. [Google Scholar] [CrossRef]

- Liu, T.; Liu, H.; Chen, Z.; Lesgold, A.M. Fast blind instrument function estimation method for industrial infrared spectrometers. IEEE Trans. Ind. Inform. 2018, 14, 5268–5277. [Google Scholar]

- Roxas, B.; Coetzer, A. Institutional environment, managerial attitudes and environmental sustainability orientation of small firms. J. Bus. Ethics 2012, 111, 461–476. [Google Scholar] [CrossRef]

- Snell, D.; Schmitt, D. ‘It’s not easy being green’: Electricity corporations and the transition to a low-carbon economy. Compet. Chang. 2012, 16, 1–19. [Google Scholar] [CrossRef]

- Maas, S.; Schuster, T.; Hartmann, E. Stakeholder pressures, environmental practice adoption and economic performance in the German third-party logistics industry—A contingency perspective. J. Bus. Econ. 2018, 88, 167–201. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Yang, L.; Liu, T.; Zhang, C.; Dong, H. Climatic and seasonal suitability of phase change materials coupled with night ventilation for office buildings in Western China. Renew. Energ. 2020, 147, 356–373. [Google Scholar] [CrossRef]

- Bai, X.; Chang, J. Corporate social responsibility and firm performance: The mediating role of marketing competence and the moderating role of market environment. Asia Pac. J. Manag. 2015, 32, 505–530. [Google Scholar] [CrossRef]

- Hahn, T.; Preuss, L.; Pinkse, J.; Figge, F. Cognitive frames in corporate sustainability: Managerial sensemaking with paradoxical and business case frames. Acad. Manag. Rev. 2014, 39, 463–487. [Google Scholar] [CrossRef]

- Shah, K.U.; Arjoon, S.; Rambocas, M. Aligning corporate social responsibility with green economy development pathways in developing countries. Sustain. Dev. 2016, 24, 237–253. [Google Scholar] [CrossRef]

- Smith, W.K. Dynamic decision making: A model of senior leaders managing strategic paradoxes. Acad. Manag. J. 2014, 1015, 58–89. [Google Scholar] [CrossRef]

- Rawangphai, M.; Maneeintr, K. Potential of carbon dioxide storage from petroleum industries in the Gulf of Thailand for green production. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012025. [Google Scholar] [CrossRef]

- Sharma, S.; Vredenburg, H. Proactive corporate environmental strategy and the development of competitively valuable organizational capabilities. Strateg. Manag. J. 2015, 19, 729–753. [Google Scholar] [CrossRef]

- Llach, J.; Perramon, J.; Alonso-Almeida, M.d.M.; Bagur-Femenías, L. Joint impact of quality and environmental practices on firm performance in small service businesses: An empirical study of restaurants. J. Clean. Prod. 2013, 44, 96–104. [Google Scholar] [CrossRef]

- Schad, J.; Lewis, M.W.; Raisch, S.; Smith, W.K. Paradox research in management science: Looking back to move forward. Acad. Manag. Ann. 2016, 10, 5–64. [Google Scholar] [CrossRef]

- Li, C.; Gao, X.; He, B.-J.; Wu, J.; Wu, K. Coupling Coordination Relationships between Urban-industrial Land Use Efficiency and Accessibility of Highway Networks: Evidence from Beijing-Tianjin-Hebei Urban Agglomeration, China. Sustainability 2019, 11, 1446. [Google Scholar] [CrossRef]

- Keegan, A.; Bitterling, I.; Sylva, H.; Hoeksema, L. Organizing the HRM function: Responses to paradoxes, variety, and dynamism. Hum. Resour. Manag. 2018, 57, 1111–1126. [Google Scholar] [CrossRef]

- Fu, H.; Manogaran, G.; Wu, K.; Cao, M.; Jiang, S.; Yang, A. Intelligent Decision-making of Online Shopping Behavior Based on Internet of Things. Int. J. Inf. Manag. 2019. [Google Scholar] [CrossRef]

- Leung, A.K.; Liou, S.; Miron-Spektor, E.; Koh, B.; Chan, D.; Eisenberg, R.; Schneider, I. Middle ground approach to paradox: Within- and between-culture examination of the creative benefits of paradoxical frames. J. Personal. Soc. Psychol. 2017, 114. [Google Scholar] [CrossRef]

- Chiou, T.Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Zhao, X.; Yue, Z.; Zeng, S.; Zhang, S. Corporate behavior and competitiveness: Impact of environmental regulation on Chinese firms. J. Clean. Prod. 2015, 86, 311–322. [Google Scholar] [CrossRef]

- Fu, H.; Wang, M.; Li, P.; Jiang, S.; Hu, W.; Guo, X.; Cao, M. Tracing Knowledge Development Trajectories of the Internet of Things Domain: A main path analysis. IEEE Trans. Ind. Inform. 2019. [Google Scholar] [CrossRef]

- Hasson, D.; Arnetz, B.B. Validation and findings comparing VAS vs Likert scales for psychosocial measurements. Int. Electron. J. Health Educ. 2005, 8, 178–192. [Google Scholar]

- Hair, J.F.; Anderson, R.E.; Tatham, R.L.; Black, W. Multivariate Data Analysis, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1998; pp. 677–679. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Rucker, D.D.; Preacher, K.J.; Tormala, Z.L.; Petty, R.E. Mediation analysis in social psychology: Current practices and new recommendations. Soc. Personal. Psychol. Compass 2011, 5, 359–371. [Google Scholar] [CrossRef]

- Edwards, J.R.; Lambert, L.S. Methods for integrating moderation and mediation: A general analytical framework using moderated path analysis. Psychol. Methods 2007, 12, 1–22. [Google Scholar] [CrossRef]

- Spencer, S.J.; Zanna, M.P.; Fong, G.T. Establishing a causal chain: Why experiments are often more effective than mediational analyses in examining psychological processes. J. Personal. Soc. Psychol. 2006, 89, 845–851. [Google Scholar] [CrossRef]

- Zhao, X.; Lynch, J.G.; Chen, Q. Reconsidering Baron and Kenny: Myths and truths about mediation analysis. J. Consum. Res. 2010, 37, 197–206. [Google Scholar] [CrossRef]

| Latent Variable | Question No. | Question Item |

|---|---|---|

| Paradox cognition | PC 1 | We believe that the economic benefits for enterprises are as important as environmental benefits. |

| PC 2 | We also pay attention to environmental benefits while paying attention to corporate performance. | |

| PC 3 | We believe that there is no conflict between corporate performance and environmental benefits. | |

| PC4 | We believe that corporate environmental sensitivities can improve the market performance of enterprises. |

| Latent Variable | Question No. | Question Item |

|---|---|---|

| Green product supply | GPS 1 | The materials used in our products are low-pollution materials. |

| GPS 2 | We use relatively environmentally friendly product packaging methods. | |

| GPS 3 | We realize more environmentally friendly products through innovation and improvement of products. | |

| GPS 4 | We use ecological labels for our products. |

| Latent Variable | Question No. | Question Item |

|---|---|---|

| Green Production Technology | GPT 1 | The company is able to introduce environmentally friendly and energy-saving equipment. |

| GPT 2 | The company spends a lot of money on transforming existing technologies to maximize energy conservation and emission reduction. | |

| GPT 3 | The company’s green technology capabilities have changed dramatically. | |

| GPT 4 | Production technologies adopted by the company have relatively smaller impacts on the environment. |

| Latent Variable | Question No. | Question Item |

|---|---|---|

| Green Production Management | GPM 1 | The company attaches great importance to the environmental performance of the company in its management. |

| GPM 2 | The company has clear regulations on the energy consumption of the product throughout its life cycle. | |

| GPM 3 | The corporate culture has a clear concept of sustainability. | |

| GPM 4 | The company has carried out mass education regarding sustainable development for its employees. | |

| GPM 5 | The company incorporates environmental performance into its performance appraisal system. |

| Latent Variable | Question No. | Question Item |

|---|---|---|

| Potential Performance | PP 1 | The corporate image has been greatly improved in the past two years. |

| PP 2 | Customer satisfaction with the company has increased significantly in the past two years. | |

| PP 3 | The company’s ability to innovate has significantly improved in the past two years. | |

| PP 4 | The market reputation of the company has increased year by year in the past two years. |

| Latent Variable | Question No. | Question Item |

|---|---|---|

| Financial Performance | FP 1 | In the past two years, the company’s sales revenue has significantly increased. |

| FP 2 | In the past two years, the company’s after-tax profit has increased. | |

| FP 3 | In the past two years, the profitability of the company has been greatly improved. | |

| FP 4 | In the past two years, the company’s ability to resist risks has been greatly improved. |

| Item | Type | Quantity | Proportion | Item | Type | Quantity | Proportion |

|---|---|---|---|---|---|---|---|

| State-owned | State-owned | 125 | 41% | Respondent | Male | 216 | 71% |

| /Private | Private | 180 | 59% | Gender | Female | 89 | 29% |

| Industry | Metallurgy | 33 | 11% | Region | Xi’an | 67 | 22% |

| Textile | 47 | 16% | Baoji | 53 | 17% | ||

| Chemical | 41 | 13% | Xianyang | 44 | 14% | ||

| Pharmaceutical | 28 | 9% | Weinan | 29 | 9% | ||

| Construction | 36 | 12% | Ankang | 26 | 8% | ||

| Manufacturing | 67 | 22% | Yan’an | 35 | 11% | ||

| Electronics | 53 | 17% | Yulin | 51 | 17% | ||

| Corporate Scale (Operating Revenue) | Large | 34 | 11% | Respondent Age | Over 50 | 52 | 17% |

| Medium | 123 | 40% | 45–50 | 68 | 22% | ||

| Small | 87 | 29% | 40–45 | 89 | 29% | ||

| Micro | 61 | 20% | 30–40 | 74 | 24% | ||

| Below 30 | 22 | 7% |

| Latent Variable | Estimation of Parameter Significance | Factor Loading | Question Reliability | Composite Reliability | Convergent Validity | Cronbach’s Alpha | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Unstd. | S.E. | t-Value | p | Std. | SMC | CR | Average Variance Extraction (AVE) | α | ||

| Paradox Cognition | 1 | 1.000 | 0.699 | 0.489 | 0.768 | 0.455 | 0.767 | |||

| 2 | 1.012 | 0.109 | 9.307 | *** | 0.699 | 0.489 | ||||

| 3 | 1.053 | 0.114 | 9.266 | *** | 0.693 | 0.480 | ||||

| 4 | 0.843 | 0.100 | 8.397 | *** | 0.600 | 0.360 | ||||

| Green Production Management | 1 | 1.000 | 0.748 | 0.560 | 0.843 | 0.519 | 0.843 | |||

| 2 | 0.966 | 0.079 | 12.167 | *** | 0.759 | 0.576 | ||||

| 3 | 0.969 | 0.087 | 11.098 | *** | 0.688 | 0.473 | ||||

| 4 | 0.898 | 0.081 | 11.027 | *** | 0.683 | 0.466 | ||||

| 5 | 0.930 | 0.080 | 11.617 | *** | 0.721 | 0.520 | ||||

| Green product Supply | 1 | 1.000 | 0.685 | 0.469 | 0.807 | 0.512 | 0.805 | |||

| 2 | 1.230 | 0.123 | 10.029 | *** | 0.709 | 0.503 | ||||

| 3 | 1.044 | 0.104 | 10.014 | *** | 0.708 | 0.501 | ||||

| 4 | 1.243 | 0.119 | 10.431 | *** | 0.757 | 0.573 | ||||

| Green Production Technology | 1 | 1.000 | 0.757 | 0.573 | 0.852 | 0.594 | 0.847 | |||

| 2 | 0.914 | 0.071 | 12.806 | *** | 0.745 | 0.555 | ||||

| 3 | 1.132 | 0.078 | 14.595 | *** | 0.901 | 0.812 | ||||

| 4 | 0.879 | 0.078 | 11.225 | *** | 0.659 | 0.434 | ||||

| Financial Performance | 1 | 1.000 | 0.749 | 0.561 | 0.904 | 0.703 | 0.902 | |||

| 2 | 1.196 | 0.073 | 16.385 | *** | 0.915 | 0.837 | ||||

| 3 | 1.202 | 0.075 | 16.008 | *** | 0.890 | 0.792 | ||||

| 4 | 1.022 | 0.073 | 14.012 | *** | 0.788 | 0.621 | ||||

| Potential Performance | 1 | 1.000 | 0.774 | 0.599 | 0.846 | 0.578 | 0.845 | |||

| 2 | 1.021 | 0.078 | 13.133 | *** | 0.798 | 0.637 | ||||

| 3 | 0.969 | 0.077 | 12.607 | *** | 0.759 | 0.576 | ||||

| 4 | 0.820 | 0.070 | 11.773 | *** | 0.708 | 0.501 | ||||

| AVE | PP | GPT | FP | GPS | GPM | PC | |

|---|---|---|---|---|---|---|---|

| PP | 0.578 | 0.760 | |||||

| GPT | 0.594 | 0.501 | 0.771 | ||||

| FP | 0.703 | 0.701 | 0.411 | 0.838 | |||

| GPS | 0.512 | 0.794 | 0.418 | 0.663 | 0.716 | ||

| GPM | 0.519 | 0.508 | 0.255 | 0.386 | 0.526 | 0.720 | |

| PC | 0.455 | 0.616 | 0.368 | 0.591 | 0.654 | 0.544 | 0.675 |

| Fitness Index | Measured Fit | Ideal Fit |

|---|---|---|

| Chi-square | 448.315 | |

| Df | 265 | |

| Chi-square/df | 1.692 | ≤3 |

| RMSEA | 0.048 | <0.08 |

| GFI | 0.897 | >0.80 |

| AGFI | 0.874 | >0.80 |

| NFI | 0.890 | >0.90 |

| TLI | 0.945 | >0.90 |

| CFI | 0.952 | >0.90 |

| Path Name | Standardized Estimated Value | Non-Standardized Estimated Value | Standard Error | p | Significance |

|---|---|---|---|---|---|

| PC → GPM | 0.587 | 0.503 | 0.068 | *** | Significant |

| PC → GPT | 0.417 | 0.461 | 0.083 | *** | Significant |

| PC → GPS | 0.728 | 0.738 | 0.089 | *** | Significant |

| GPM → PP | 0.136 | 0.163 | 0.068 | 0.017 | Significant |

| GPT → PP | 0.226 | 0.209 | 0.050 | *** | Significant |

| GPS → PP | 0.653 | 0.659 | 0.079 | *** | Significant |

| GPM → FP | 0.008 | 0.010 | 0.067 | 0.884 | Not Significant |

| GPT → FP | 0.093 | 0.083 | 0.051 | 0.107 | Not Significant |

| GPS → FP | 0.331 | 0.323 | 0.100 | 0.001 | Significant |

| PP → FP | 0.390 | 0.377 | 0.108 | *** | Significant |

| Research Hypothesis | Hypothesis Test |

|---|---|

| Hypothesis 1.The paradox cognition of industrial units has a positive and significant impact on green production management. | Valid |

| Hypothesis 2.The paradox cognition of industrial units has a positive and significant impact on green production technology. | Valid |

| Hypothesis 3.The paradox cognition of industrial units has a positive and significant impact on green product supply. | Valid |

| Mediation Path |

|---|

| Path 1: Paradox Cognition → Green Production Management → Corporate Financial Performance |

| Path 2: Paradox Cognition → Green Production Management → Corporate Potential Performance → Corporate Financial Performance |

| Path 3: Paradox Cognition → Green Production Technology → Corporate Financial Performance |

| Path 4: Paradox Cognition → Green Production Technology → Corporate Potential Performance → Corporate Financial Performance |

| Path 5: Paradox Cognition → Green Product Supply → Corporate Financial Performance |

| Path 6: Paradox Cognition → Green Product Supply → Corporate Potential Performance → Corporate Financial Performance |

| SIE— Specific Indirect Effects | Point Estimate | Product of Coefficients | Bias-Corrected 95% CI | Percentile 95% CI | |||

|---|---|---|---|---|---|---|---|

| Standard Error | Z Value | Lower | Upper | Lower | Upper | ||

| Path 1 | 0.005 | 0.036 | 0.139 | −0.063 | 0.076 | −0.058 | 0.083 |

| Path 2 | 0.031 | 0.019 | 1.632 | 0.003 | 0.083 | 0 | 0.077 |

| Path 3 | 0.038 | 0.037 | 1.027 | −0.011 | 0.147 | −0.017 | 0.13 |

| Path 4 | 0.036 | 0.022 | 1.636 | 0.008 | 0.092 | 0.008 | 0.091 |

| Path 5 | 0.238 | 0.095 | 2.505 | 0.059 | 0.429 | 0.047 | 0.424 |

| Path 6 | 0.183 | 0.072 | 2.542 | 0.062 | 0.362 | 0.056 | 0.334 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Li, Z.; Khan, K. A Study on the Relationship between Paradox Cognition, Green Industrial Production, and Corporate Performance. Sustainability 2019, 11, 6588. https://doi.org/10.3390/su11236588

Gao Y, Li Z, Khan K. A Study on the Relationship between Paradox Cognition, Green Industrial Production, and Corporate Performance. Sustainability. 2019; 11(23):6588. https://doi.org/10.3390/su11236588

Chicago/Turabian StyleGao, Yi, Zhiguo Li, and Kashif Khan. 2019. "A Study on the Relationship between Paradox Cognition, Green Industrial Production, and Corporate Performance" Sustainability 11, no. 23: 6588. https://doi.org/10.3390/su11236588

APA StyleGao, Y., Li, Z., & Khan, K. (2019). A Study on the Relationship between Paradox Cognition, Green Industrial Production, and Corporate Performance. Sustainability, 11(23), 6588. https://doi.org/10.3390/su11236588