Selection of Favourable Concept of Energy Retrofitting Solution for Social Housing in the Czech Republic Based on Economic Parameters, Greenhouse Gases, and Primary Energy Consumption

Abstract

:1. Introduction

2. Methods and Input Data

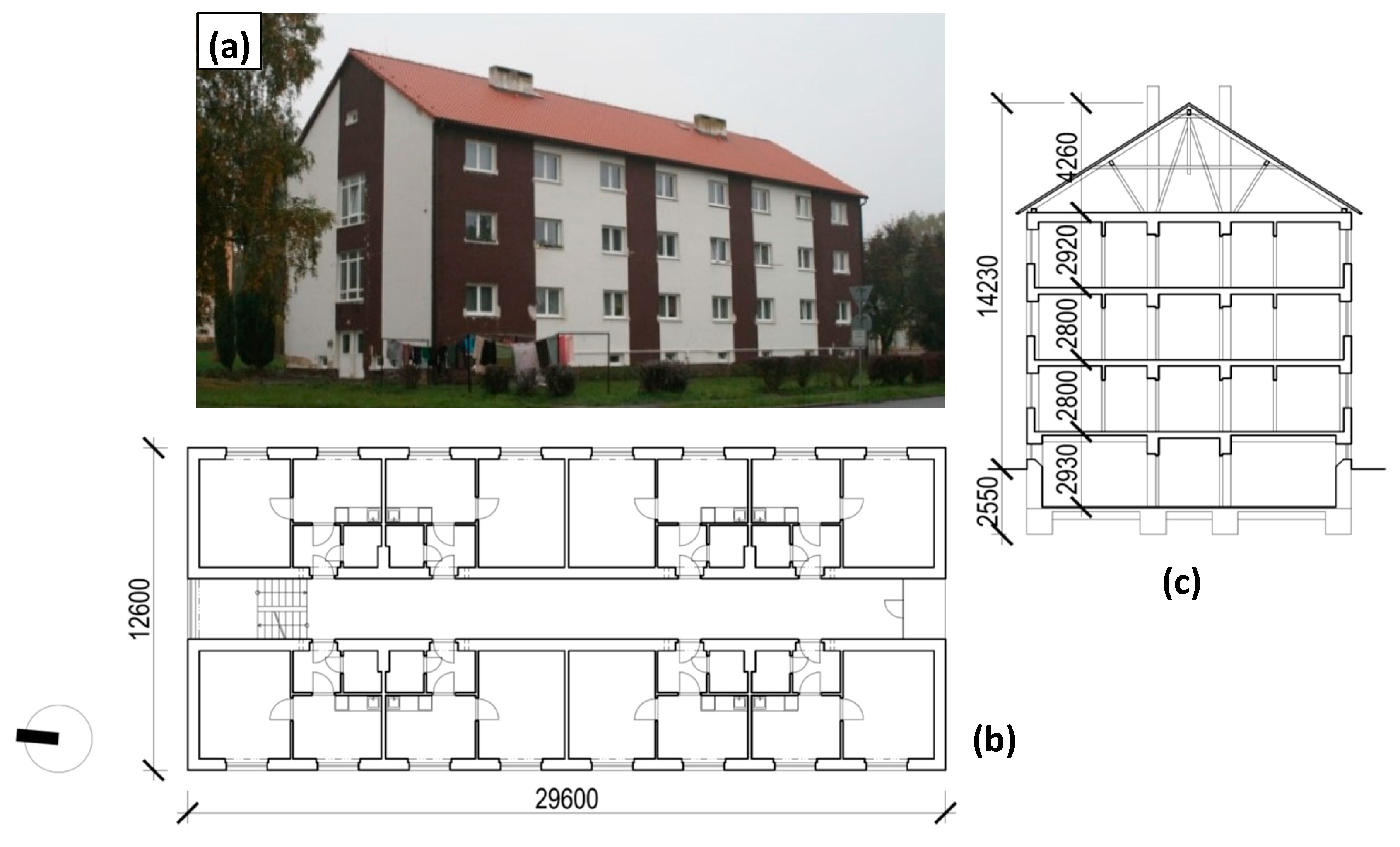

2.1. Reference Building

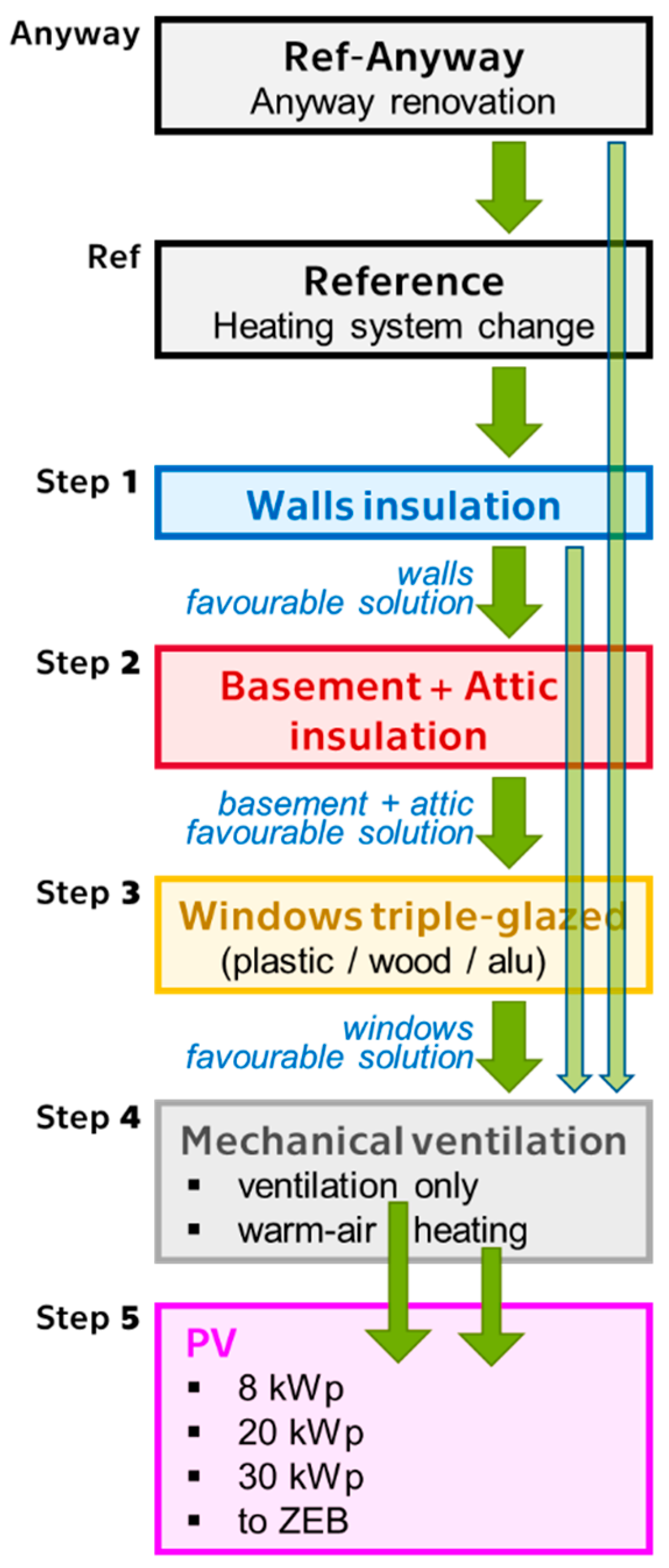

2.2. Investigated Retrofitting Packages and Favourable Package Selection Method

2.2.1. Retrofitting Packages

- district heating (current heating system),

- heat pump,

- natural gas, and

- wooden pellets.

2.2.2. Favourable Package Selection

- First, “anyway” renovation was considered as the basic case. It comprised the restoration of the functionality of the renovated building elements (plasters, leakages, etc.), but without improvement of their energy performance.

- Second, a change of heating system was considered. No other improvement was supposed. This case served as a reference for further retrofitting steps.

- Step 1: External walls were improved considering their thermal insulation and possibly also window replacement.

- Step 2: Attic floor and basement ceiling were provided with thermal insulation.

- Step 3: Triple-pane glazing windows were used.

- Step 4: A mechanical ventilation system with heat recovery was used (considering either only mechanical ventilation or warm-air heating system).

- Step 5: Photovoltaic (PV) panels of various sizes were added (applied to both variants from Step 4).

2.2.3. MORE-CONNECT solution

2.3. Multi-Criteria Assessment—Method and Data

2.3.1. Embodied Environmental Data

2.3.2. Operational Environmental Impact

2.3.3. Costs

3. Results and Discussion

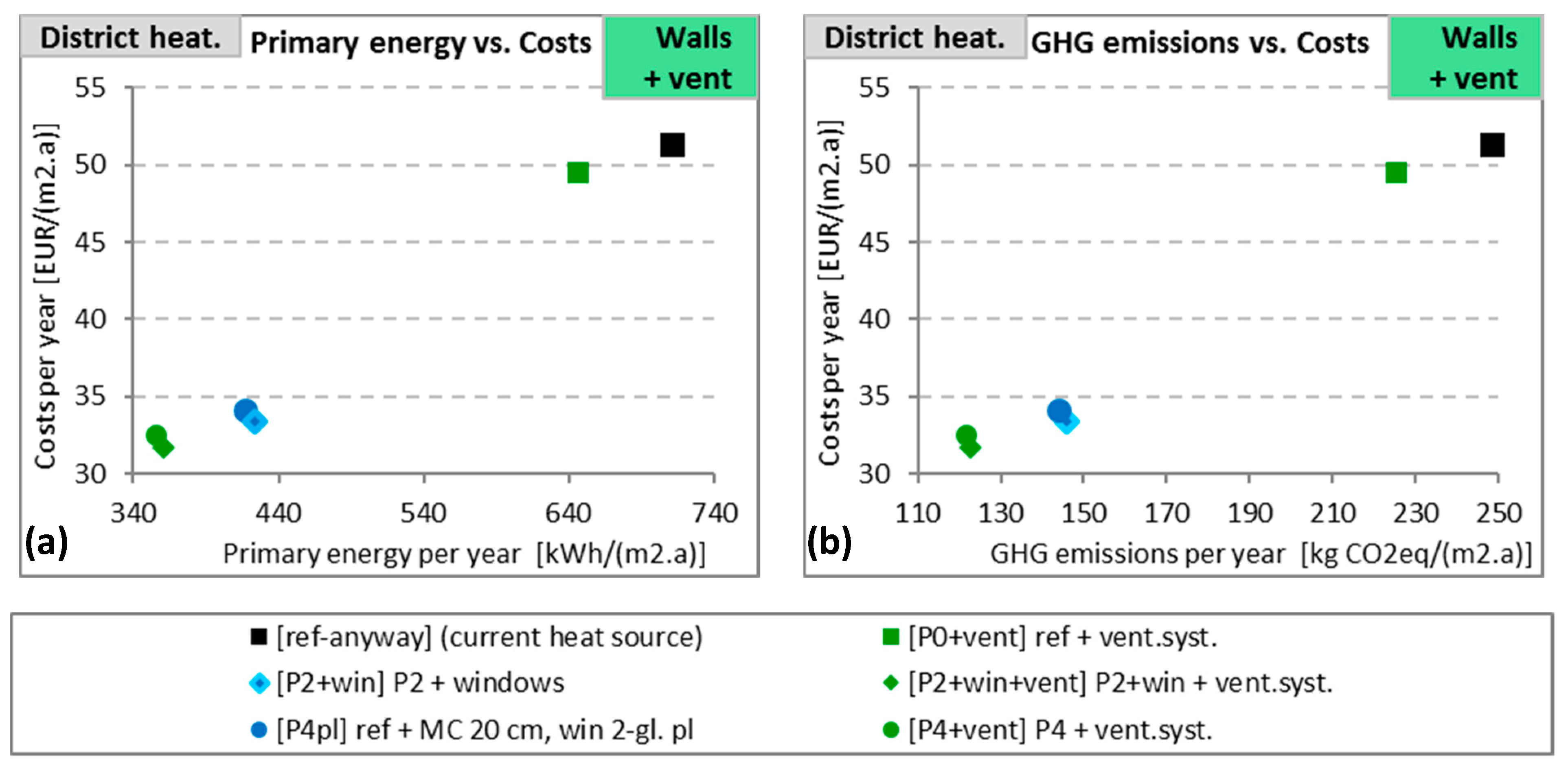

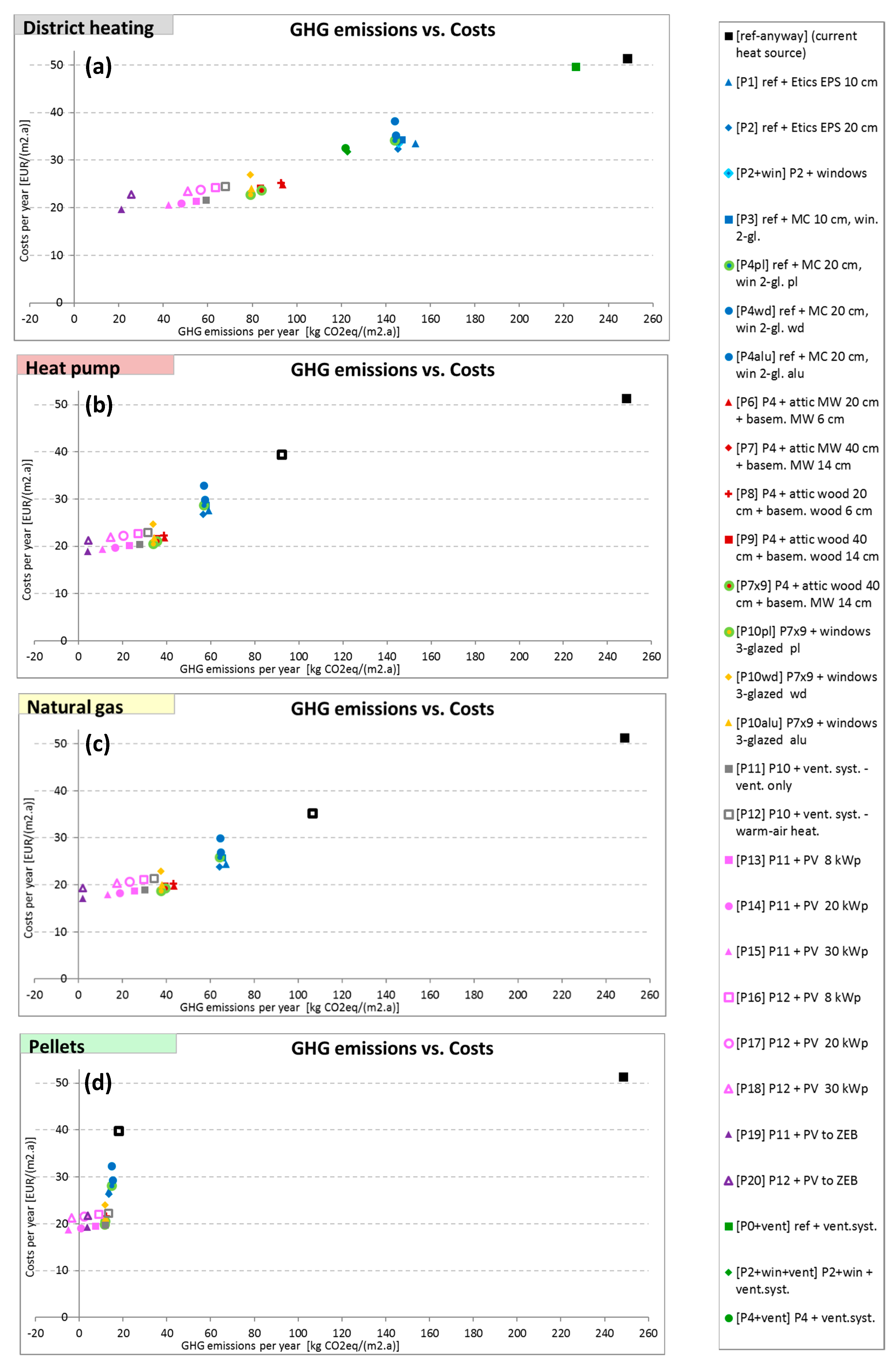

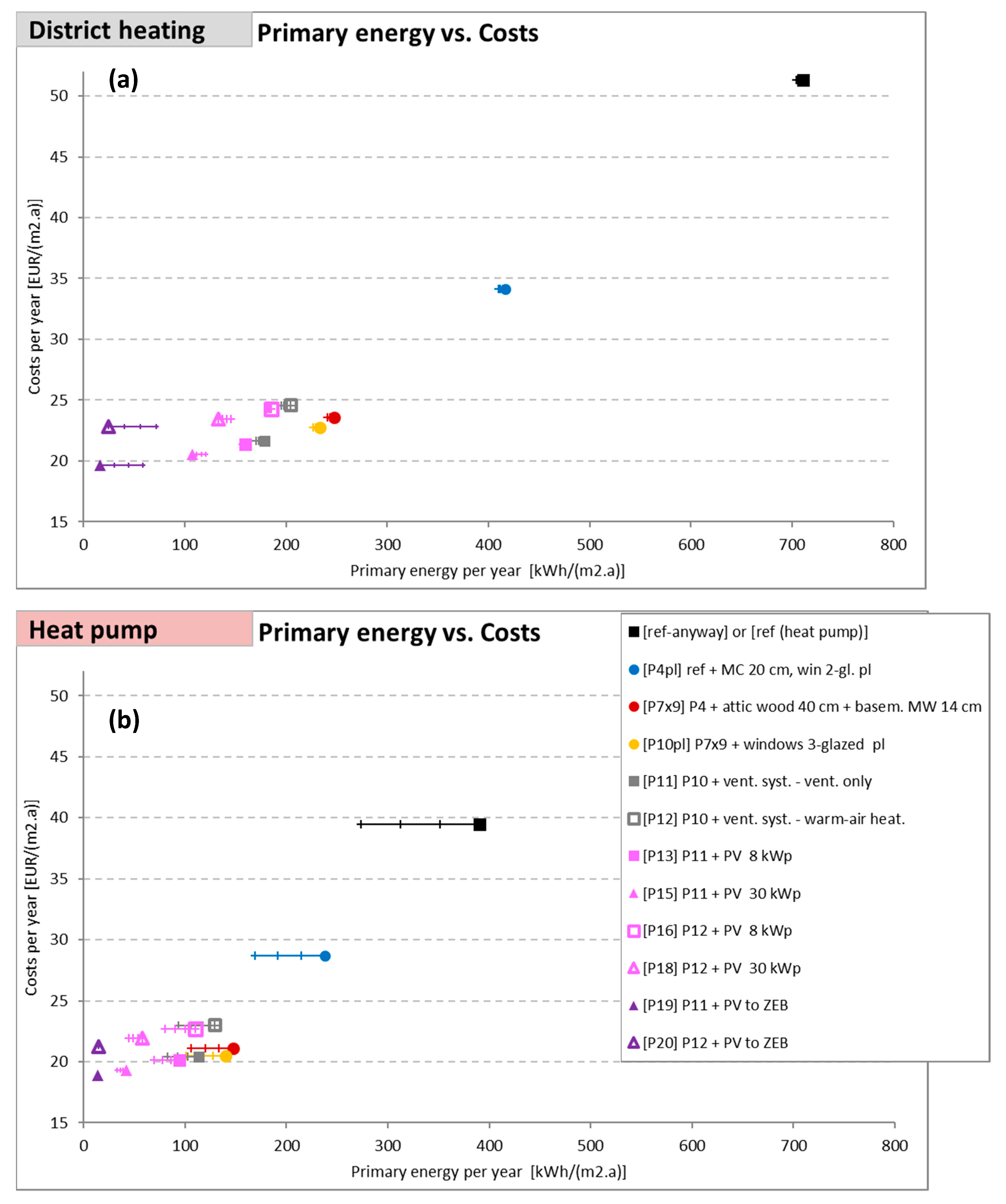

3.1. Consecutive Evaluation and Selection of Favourable Package per Each Step

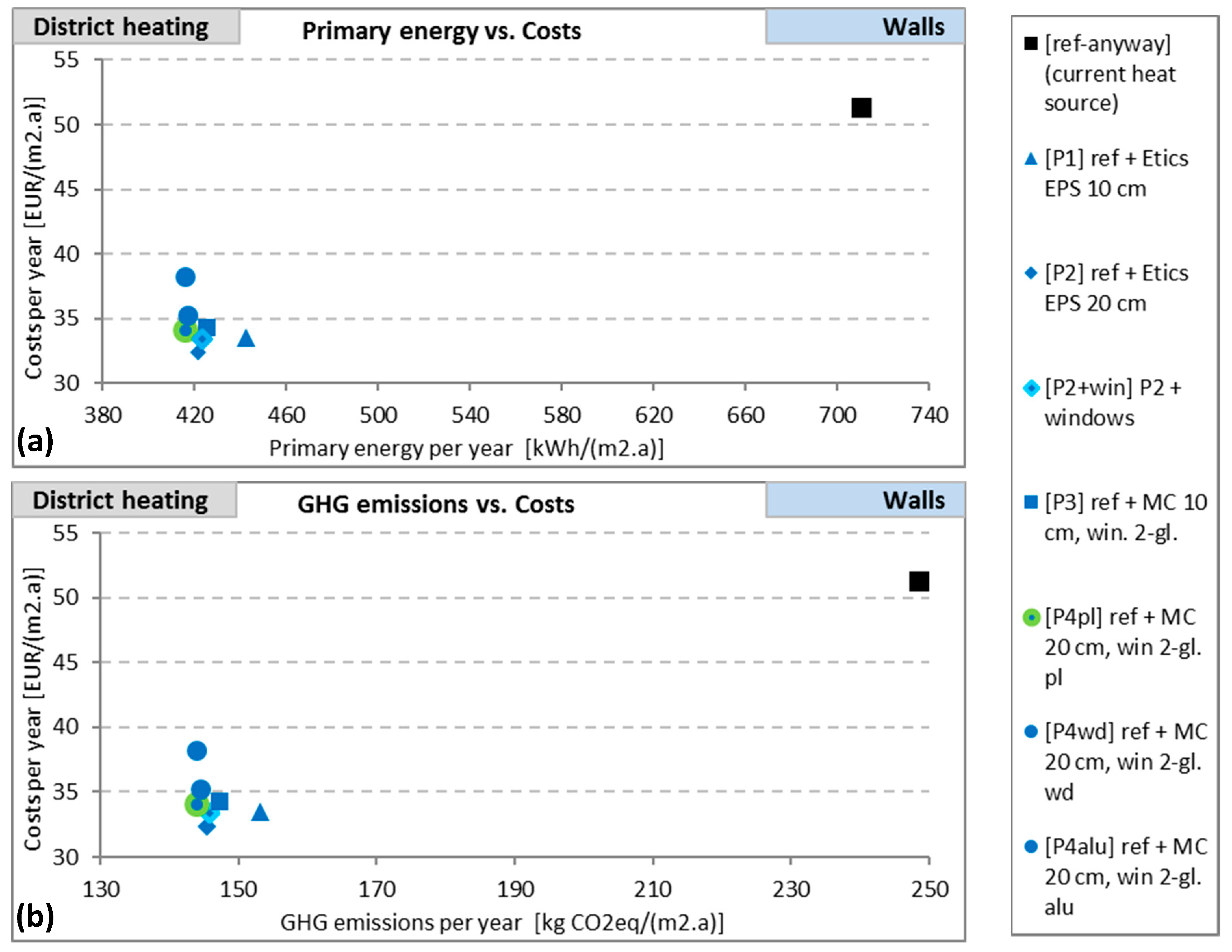

3.1.1. Step 1: External Wall Insulation

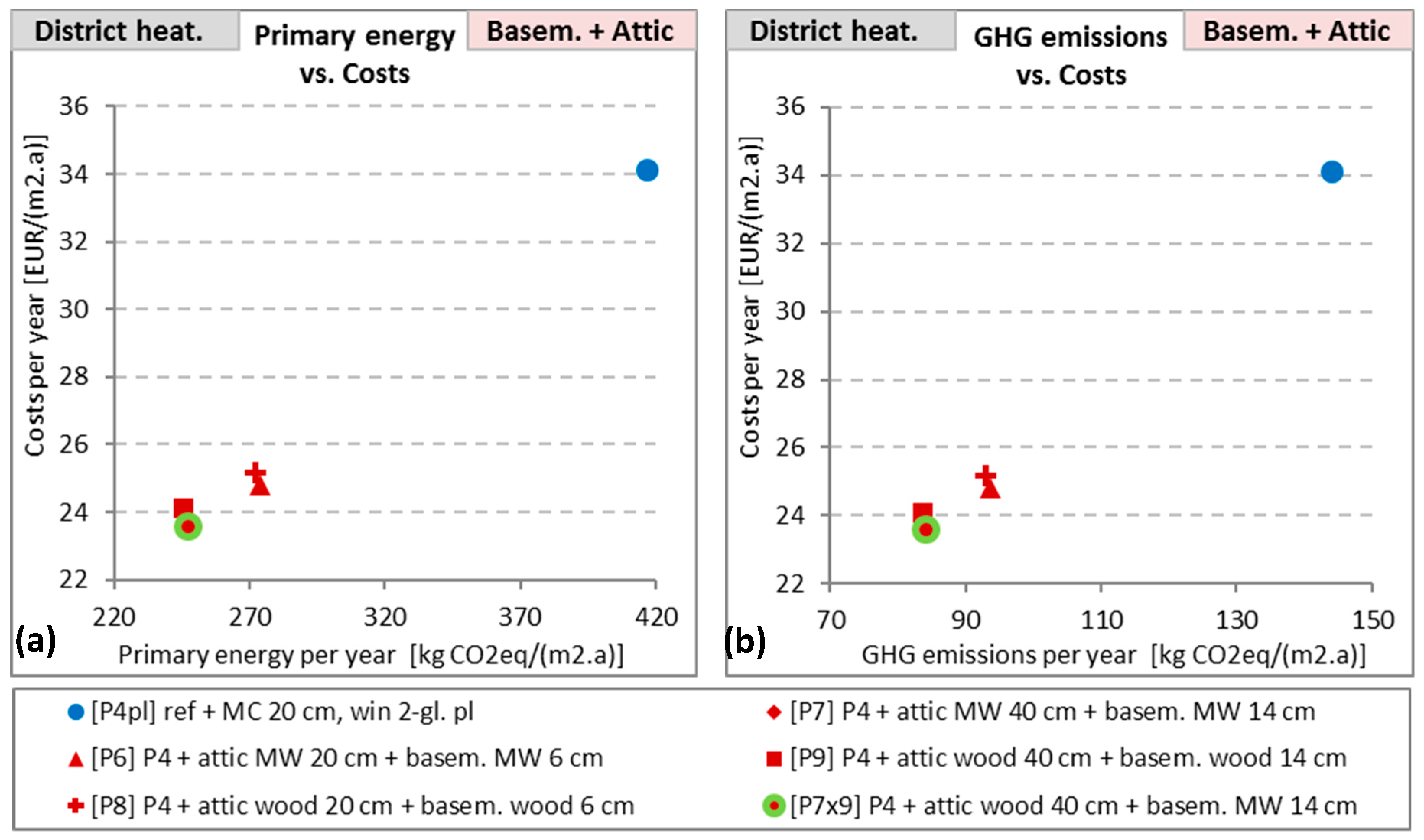

3.1.2. Step 2: Attic and Basement Insulation

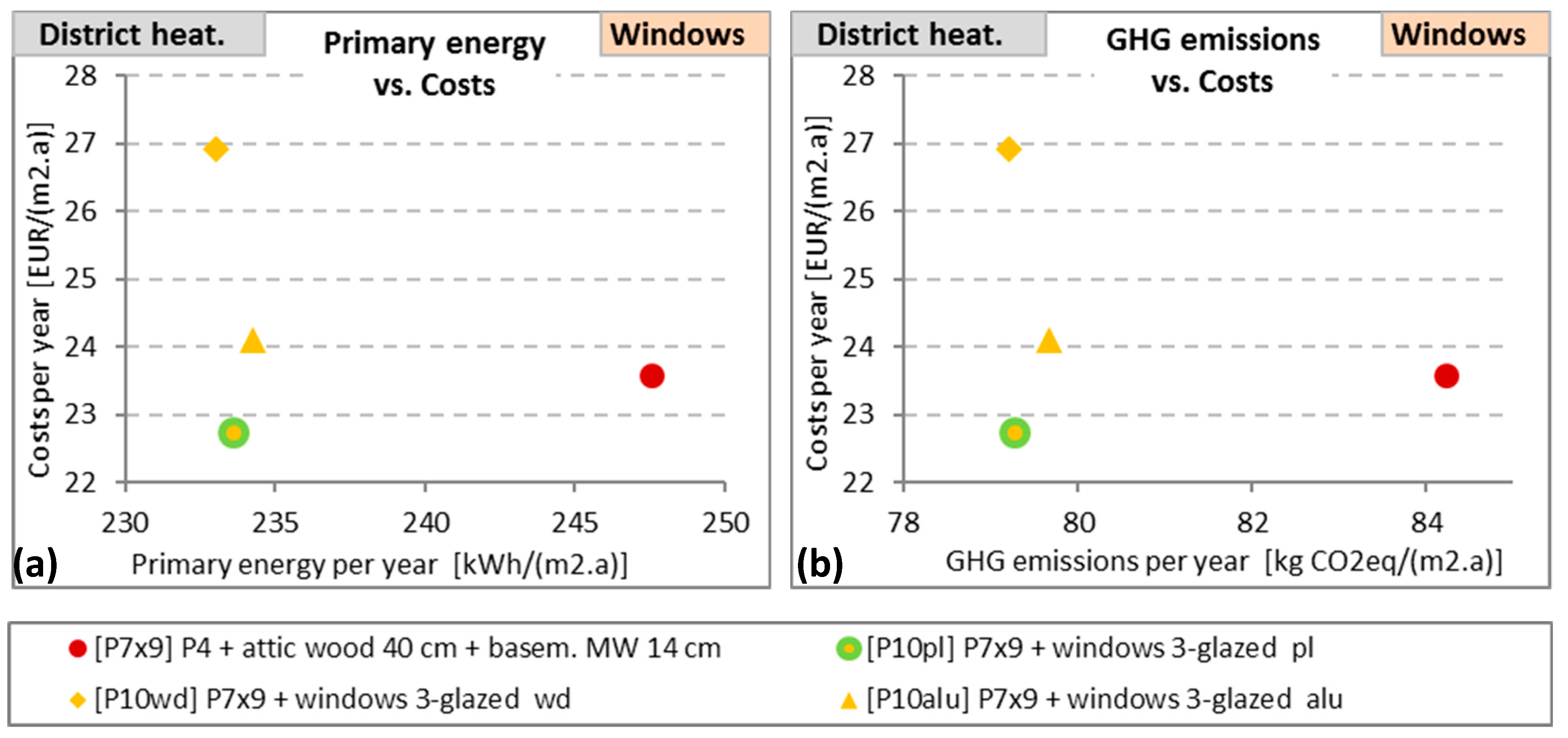

3.1.3. Step 3: Triple-Pane Glazing Windows

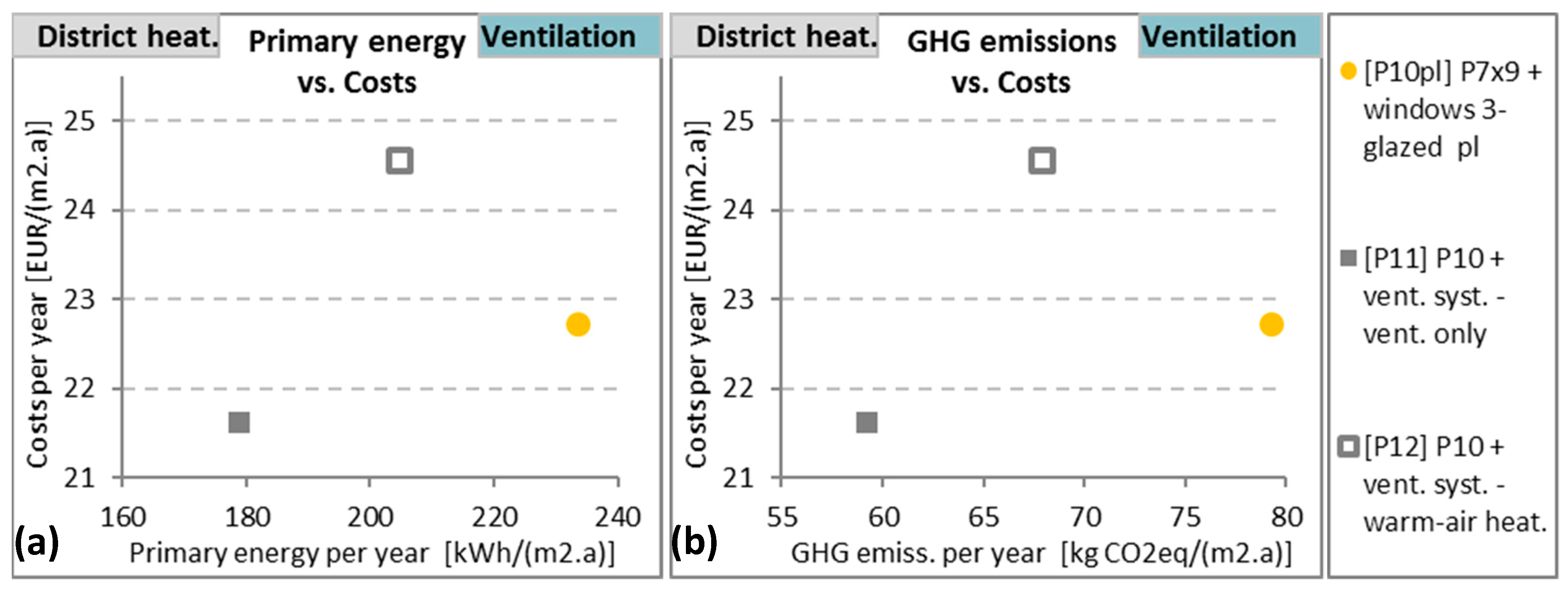

3.1.4. Step 4: Mechanical Ventilation

3.1.5. Step 5: PV Panel Installation

- pitched roof—east and west orientation, slope 33°, 180 + 180 m2;

- south gable wall—90 m2; and

- west and east façades—80 + 80 m2.

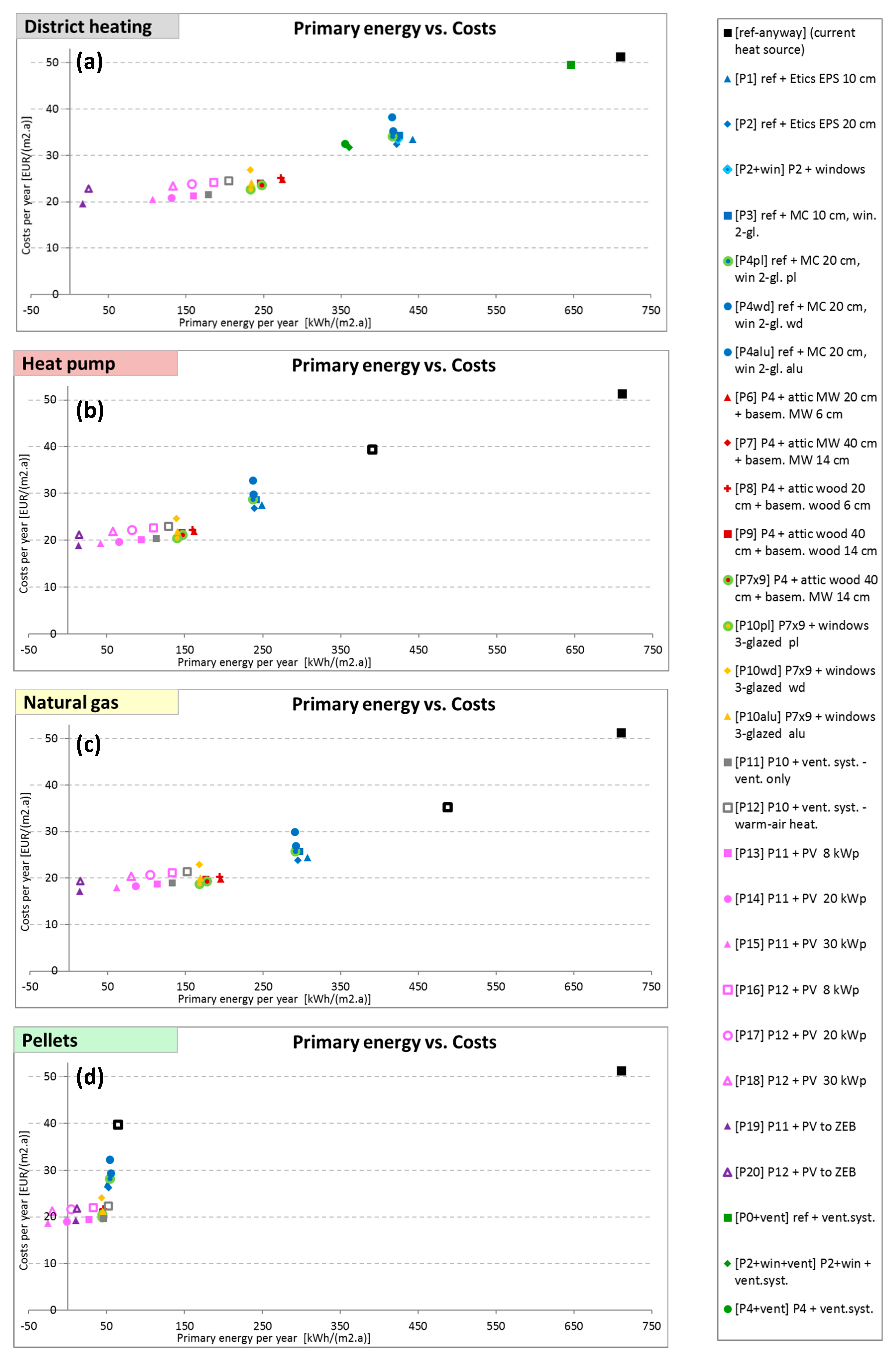

3.2. Overview Results and Heat Source Comparison

- District heating

- P19: 81 kWp; fully covered roof and gable wall (i.e., 180 + 180 m2 on roof, 90 m2 on gable wall) and 15 + 15 m2 on façades.

- P20: did not reach net zero primary energy even with fully utilized available area for PV (i.e., 180 + 180 m2 on roof, 90 m2 on south gable wall, and 80 + 80 m2 on west and east façades), producing 103 kWp in total.

- Heat pump (COP = 2.6 was considered)

- P19: 42 kWp; 124 + 124 m2 on roof.

- P20: 48 kWp; 143 + 143 m2 on roof.

- Natural gas

- P19: 50 kWp; 148 + 148 m2 on roof.

- P20: 58 kWp; 171 + 171 m2 on roof.

- Pellets

- P19: 15 kWp; 44 + 44 m2 on roof.

- P20: 17 kWp; 50 + 50 m2 on roof.

3.2.1. Result Sensitivity on Electricity Conversion and Emission Factor Changes

3.3. General Discussion

3.4. Limitations and Strengths

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Inputs Used for Cost and Environmental Impact Calculation

| Building Envelope | Costs | Lifetime | Embodied Primary Energy (non-renew.) | Embodied Greenhouse Gas Emissions | U-Value (incl. orig. struct.) | Maintenance Costs |

|---|---|---|---|---|---|---|

| [EUR/m2] | [years] | [MJ/m2] | [kg CO2eq/m2] | [W/m2K] | [EUR/m2 /year] | |

| Wall insulation | ||||||

| ETICS – EPS 10 cm | 40.15 | 30 | 373.4 | 15.9 | 0.26 | |

| ETICS – EPS 20 cm | 52.52 | 30 | 742.7 | 31.6 | 0.15 | |

| MORE-CONNECT – mineral wool (10 + 4 cm) | 72.01 | 30 | 686.0 | 57.7 | 0.16 | |

| MORE-CONNECT – mineral wool (20 + 4 cm) | 85.08 | 30 | 878.8 | 73.0 | 0.12 | |

| Attic insulation | ||||||

| Mineral wool 20 cm | 9.70 | 25 | 101.1 | 8.1 | 0.21 | |

| Mineral wool 40 cm | 19.41 | 25 | 202.2 | 16.1 | 0.11 | |

| Wood blown insulation 20 cm | 10.44 | 25 | 10.0 | 0.6 | 0.21 | |

| Wood blown insulation 40 cm | 20.89 | 25 | 20.0 | 1.2 | 0.11 | |

| Basement insulation | ||||||

| Mineral wool 6 cm | 19.96 | 35 | 97.1 | 7.7 | 0.54 | |

| Mineral wool 14 cm | 39.30 | 35 | 226.5 | 18.0 | 0.27 | |

| Wood fibres 6 cm | 31.55 | 20 | 17.2 | 1.0 | 0.51 | |

| Wood fibres 14 cm | 52.41 | 20 | 40.2 | 2.4 | 0.25 | |

| Windows | ||||||

| Double-glazed window – wood | 203.70 | 30 | 743.42 | 58.73 | 1.2 | 34.07 |

| Double-glazed window – alum. | 337.04 | 30 | 1 764.33 | 163.81 | 1.2 | 5.93 |

| Double-glazed window – plastic | 159.26 | 30 | 1 194.24 | 71.77 | 1.2 | 5.93 |

| Triple-glazed window – wood | 225.93 | 30 | 1 011.34 | 80.19 | 0.7 | 34.07 |

| Triple-glazed window – alum. | 385.19 | 30 | 2 032.25 | 185.28 | 0.7 | 5.93 |

| Triple-glazed window – plastic | 177.78 | 30 | 1 462.16 | 93.23 | 0.7 | 5.93 |

| New Heating System | Costs | Lifetime | Embodied Primary Energy (non-renewable) | Embodied Greenhouse Gas Emissions |

|---|---|---|---|---|

| [EUR/m2] | [years] | [MJ/m2] | [kg CO2eq/m2] | |

| New natural gas heating system | 5 500 | 10 | 5 400.37 | 464.03 |

| New air/water heat pump | 10 000 | 10 | 22 167.01 | 5 291.7 |

| New wood pellet heating system | 6 000 | 15 | 25200 | 2 116 |

| On-site Renewable Electricity Production | Costs | Lifetime | Embodied Primary Energy (non-renewable) | Embodied Greenhouse Gas Emissions | Installed Power | Annual Electricity Production | PV Area | |

|---|---|---|---|---|---|---|---|---|

| [EUR/full system] | [years] | [MJ/m2] | [kg CO2eq/m2] | [kWp] | [kWh/a] | [m2] | ||

| 8 kWp | 11 000 | 51 | 2749 | 203.7 | 8 | 6 200 | 48 | |

| 20 kWp | 26 000 | 51 | 2749 | 203.7 | 20 | 15 500 | 118 | |

| 30 kWp | 39 000 | 51 | 2749 | 203.7 | 30 | 23 250 | 178 | |

| ZEB solutions | ||||||||

| District heating | pack 19 | 104 223 | 51 | 2749 | 203.7 | 81 | 62 775 | 480 |

| pack 20 | 132 381 | 51 | 2749 | 203.7 | 103 | 79 825 | 610 | |

| Heat pump | pack 19 | 54 307 | 51 | 2749 | 203.7 | 42 | 32 550 | 248 |

| pack 20 | 61 986 | 51 | 2749 | 203.7 | 48 | 37 200 | 286 | |

| Natural gas | pack 19 | 64 546 | 51 | 2749 | 203.7 | 50 | 38 750 | 296 |

| pack 20 | 74 785 | 51 | 2749 | 203.7 | 58 | 44 950 | 342 | |

| Pellets | pack 19 | 19 750 | 51 | 2749 | 203.7 | 15 | 11 625 | 88 |

| pack 20 | 22 310 | 51 | 2749 | 203.7 | 17 | 13 175 | 100 | |

References

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. United Nations Sustainable Knowledge Platform, 2015. Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld (accessed on 23 September 2019).

- European Commission 2018 Buildings. Available online: https://ec.europa.eu/energy/en/topics/energy-efficiency/energy-performance-of-buildings/overview (accessed on 23 September 2019).

- United Nations. Buildings and Climate Change: Summary for Decision Makers. 2009. Available online: https://europa.eu/capacity4dev/unep/document/buildings-and-climate-change-summary-decision-makers (accessed on 23 September 2019).

- Lupíšek, A. Carbon Dioxide Emissions from Operation of Czech Building Stock and Potential for Their Reduction. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012101. [Google Scholar]

- Šance pro budovy. Strategie Renovace Budov, Aktualizace Prosinec 2016. 2016. Available online: https://sanceprobudovy.cz/wp-content/uploads/2018/04/strategie-renovace-a-adaptace-budov.pdf (accessed on 23 September 2019).

- Aranda, J.; Zabalza, I.; Conserva, A.; Millán, G. Analysis of Energy Efficiency Measures and Retrofitting Solutions for Social Housing Buildings in Spain as a Way to Mitigate Energy Poverty. Sustainability 2017, 9, 1869. [Google Scholar] [CrossRef]

- Antonín, J. Housing Stock and Energy Savings Possibilities Survey; Czech Green Building Council: Praha, Czech Republic, 2014. [Google Scholar]

- STÚ-K 2012 TABULA: Typology Approach for Building Stock Energy Assessment—National Scientific Report. Available online: http://episcope.eu/fileadmin/tabula/public/docs/scientific/CZ_TABULA_ScientificReport_STU-K.pdf (accessed on 31 May 2019).

- Lupíšek, A.; Sojková, K.; Volf, M.; Hejtmánek, P. Potential for energy savings in Czech residential building stock by application of a prefabricated mass retrofitting system. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012173. [Google Scholar]

- Buratti, C.; Barbanera, M.; Palladino, D. An original tool for checking energy performance and certification of buildings by means of Artificial Neural Networks. Appl. Energy 2014, 120, 125–132. [Google Scholar] [CrossRef]

- Escandón, R.; Ascione, F.; Bianco, N.; Mauro, G.M.; Suárez, R.; Sendra, J.J. Thermal comfort prediction in a building category: Artificial neural network generation from calibrated models for a social housing stock in southern Europe. Appl. Therm. Eng. 2019, 150, 492–505. [Google Scholar] [CrossRef]

- Marvuglia, A.; Messineo, A.; Nicolosi, G. Coupling a neural network temperature predictor and a fuzzy logic controller to perform thermal comfort regulation in an office building. Build. Environ. 2014, 72, 287–299. [Google Scholar] [CrossRef]

- Penna, P.; Prada, A.; Cappelletti, F.; Gasparella, A. Multi-objectives optimization of Energy Efficiency Measures in existing buildings. Energy Build. 2015, 95, 57–69. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelakder, M. A hybrid fuzzy-optimization method for modeling construction emissions. Decis. Sci. Lett. 2020, 9, 1–20. [Google Scholar] [CrossRef]

- Xie, Y.; Hu, P.; Zhu, N.; Lei, F.; Xing, L.; Xu, L. Collaborative optimization of ground source heat pump-radiant ceiling air conditioning system based on response surface method and NSGA-II. Renew. Energy 2020, 147, 249–264. [Google Scholar] [CrossRef]

- Ferrara, M.; Fabrizio, E.; Virgone, J.; Filippi, M. A simulation-based optimization method for cost-optimal analysis of nearly Zero Energy Buildings. Energy Build. 2014, 84, 442–457. [Google Scholar] [CrossRef]

- Jedrzejuk, H.; Marks, W. Optimization of shape and functional structure of buildings as well as heat source utilisation example. Build. Environ. 2002, 37, 1249–1253. [Google Scholar] [CrossRef]

- Alanne, K. Selection of renovation actions using multi-criteria “knapsack” model. Autom. Construct. 2004, 13, 377–391. [Google Scholar] [CrossRef]

- Asadi, E.; da Silva, M.G.; Antunes, C.H.; Dias, L. A multi-objective optimization model for building retrofit strategies using TRNSYS simulations, GenOpt and MATLAB. Build. Environ. 2012, 56, 370–378. [Google Scholar] [CrossRef]

- Kaklauskas, A.; Zavadskas, E.K.; Raslanas, S. Multivariant design and multiple criteria analysis of building refurbishments. Energy Build. 2005, 37, 361–372. [Google Scholar] [CrossRef]

- Karmellos, M.; Kiprakis, A.; Mavrotas, G. A multi-objective approach for optimal prioritization of energy efficiency measures in buildings: Model, software and case studies. Appl. Energy 2015, 139, 131–150. [Google Scholar] [CrossRef]

- Martinaitis, V.; Kazakevičius, E.; Vitkauskas, A. A two-factor method for appraising building renovation and energy efficiency improvement projects. Energy Policy 2007, 35, 192–201. [Google Scholar] [CrossRef]

- Chantrelle, F.P.; Lahmidi, H.; Keilholz, W.; Mankibi, M.E.; Michel, P. Development of a multicriteria tool for optimizing the renovation of buildings. Appl. Energy 2011, 88, 1386–1394. [Google Scholar] [CrossRef]

- Jaggs, M.; Palmer, J. Energy performance indoor environmental quality retrofit—A European diagnosis and decision making method for building refurbishment. Energy Build. 2000, 31, 97–101. [Google Scholar] [CrossRef]

- MORE-CONNECT Project. Available online: http://www.more-connect.eu/ (accessed on 29 January 2017).

- Hejtmánek, P.; Volf, M.; Sojková, K.; Brandejs, R.; Kabrhel, M.; Bejček, M.; Novák, E.; Lupíšek, A. First stepping stones of alternative refurbishment modular system leading to zero energy buildings. Energy Procedia 2017, 111, 121–130. [Google Scholar] [CrossRef]

- Almeida, M.; Ferreira, M. IEA EBC Annex56 Vision for Cost Effective Energy and Carbon Emissions Optimization in Building Renovation. Energy Procedia 2015, 78, 2409–2414. [Google Scholar] [CrossRef]

- IEA EBC. Energy in Buildings and Communities Programme, Methodology for Cost-Effective Energy and Carbon Emissions Optimization in Building Renovation (Annex 56). 2017. Available online: http://www.iea-annex56.org/Groups/GroupItemID6/Methodology%20for%20Cost-Effective%20Energy%20and%20Carbon%20Emissions%20Optimization%20in%20Building%20Renovation%20(Annex%2056).pdf (accessed on 3 September 2019).

- Lattke, F.; Cronhjort, Y. (Eds.) smartTES: Introduction to a New Retrofit Method; TUM Faculty of Architecture: München, Germany, 2014. [Google Scholar]

- Professur für Entwerfen und Holzbau: TES Energy Facade. Available online: http://www.holz.ar.tum.de/en/research/tesenergyfacade/ (accessed on 24 July 2017).

- Ott, S.; Technische Universität München (Eds.) Multifunctional TES: Book 3; TUM Faculty of Architecture: München, Germany, 2014. [Google Scholar]

- Project description—E2VENT. Available online: http://www.e2vent.eu/project-description (accessed on 25 July 2017).

- Eekhout, M.; van Swieten, P. The Delft Prototype Laboratory; IOS Press: Amsterdam, The Netherlands, 2016. [Google Scholar]

- 2nd SKIN: Systemic deep retrofit for social housing. Climate-KIC. Available online: https://www.climate-kic.org/success-stories/2nd-skin/ (accessed on 30 October 2019).

- MeeFS. Available online: http://www.meefs-retrofitting.eu (accessed on 24 July 2017).

- Pihelo, P.; Kalamees, T.; Kuusk, K. nZEB Renovation with Prefabricated Modular Panels. Energy Procedia 2017, 132, 1006–1011. [Google Scholar] [CrossRef]

- Mørck, O.C. Energy saving concept development for the MORE-CONNECT pilot energy renovation of apartment blocks in Denmark. Energy Procedia 2017, 140, 240–251. [Google Scholar] [CrossRef]

- Sojková, K.; Volf, M.; Lupíšek, A.; Novák, E.; Vácha, T. MORE-CONNECT Project, Deliverable 6.2 Final Selection of Favourable Concept Based on LCA; Czech Republic, 2018. Available online: https://www.more-connect.eu/deliverables/ (accessed on 11 September 2019).

- Antonín, J. Průzkum Fondu Rezidenčních Budov v České Republice a Možností Úspor v Nich, Aktualizovaná Verze Prosinec 2016. Available online: https://sanceprobudovy.cz/predstavujeme-aktualizovane-verze-pruzkumu-fondu-budov-v-cr (accessed on 19 September 2019).

- European Committee for Standardization. Energy Performance of Buildings—Calculation of Energy Use for Space Heating and Cooling; EN ISO 13790; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- Volf, M.; Hejtmánek, P.; Lupíšek, A.; Kalamees, T.; Christensen, F.; StephanOlesen; van Oorschot, J.A.W.H.; Mørck, O.C.; Borodinecs, A.; Šenfeldr, P. MORE-CONNECT Project, Deliverable 2.2 A Set of Basic Modular Facade and Roof Elements Including Renewable Energy Production and Integration of HP Insulation. 2019. Available online: https://www.more-connect.eu/wp-content/uploads/2019/07/MORE-CONNECT_WP2_D2.2-I-Set-of-modular-facade-elements-II-Integration-of-RES-III-Super-Insulation.pdf (accessed on 19 September 2019).

- European Committee for Standardization. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; EN 15804; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; EN 15978; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Ecoinvent Association. Ecoinvent. Available online: http://www.ecoinvent.org (accessed on 9 March 2018).

- SBToolCZ. Available online: https://www.sbtool.cz/cs (accessed on 14 March 2018).

- Czech Standardization Agency. Energetická Náročnost Budov—Typické Hodnoty pro Výpočet—Část 1: Obecná Část a Měsíční Výpočtová Data (Energy Performance of Buildings—Typical Values for Calculation—Part 1: General and Calculation Data per Month); ČSN 73 0331-1; Czech Standardization Agency: Prague, Czech Republic, 2018. [Google Scholar]

- Vonka, M.; Hájek, P.; Hodková, J.; Lupíšek, A.; Mančík, Š.; Růžička, J. Czech Gemis Database. In Metodika SBToolCZ—Manuál hodnocení bytových staveb ve fázi návrhu; Faculty of Civil Engineering, Czech Technical University in Prague, and CIDEAS: Prague, Czech Republic, 2009. [Google Scholar]

- Reports and Documents on GEMIS—IINAS. Available online: http://iinas.org/gemis-documents.html (accessed on 8 August 2017).

- Bolliger, R.; Ott, W. Methodological Framework and Instructions for the Selection of Favourable Concepts for the Pilot Projects (Task 6.1 Part 1). developed within the MORE-CONNECT project. 2016. Available online: www.more-connect.eu/wp-content/uploads/2019/07/MORE-CONNECT_WP6_D6.1_Pre-selection-of-favourable-concepts.zip (accessed on 19 September 2019).

- Földváry, V.; Bukovianska, H.P.; Petráš, D. Analysis of Energy Performance and Indoor Climate Conditions of the Slovak Housing Stock before and after its Renovation. Energy Procedia 2015, 78, 2184–2189. [Google Scholar] [CrossRef]

- Li, X.; Wen, J. Net-zero energy building clusters emulator for energy planning and operation evaluation. Comput. Environ. Urban Syst. 2017, 62, 168–181. [Google Scholar] [CrossRef]

- Femenías, P.; Mjörnell, K.; Thuvander, L. Rethinking deep renovation: The perspective of rental housing in Sweden. J. Clean. Prod. 2018, 195, 1457–1467. [Google Scholar] [CrossRef]

- Jensen, P.A.; Maslesa, E.; Berg, J.B.; Thuesen, C. 10 questions concerning sustainable building renovation. Build. Environ. 2018, 143, 130–137. [Google Scholar] [CrossRef]

- Ástmarsson, B.; Jensen, P.A.; Maslesa, E. Sustainable renovation of residential buildings and the landlord/tenant dilemma. Energy Policy 2013, 63, 355–362. [Google Scholar] [CrossRef]

- Bolliger, R.; Ott, W.; von Grünigen, S. Finding the balance between energy efficiency measures and renewable energy measures in building renovation: An assessment based on generic calculations in 8 European countries. Energy Procedia 2015, 78, 2372–2377. [Google Scholar] [CrossRef]

- Kopecký, P.; Sojková, K. Analysis of Possible Impacts of Change in Climatic Boundary Conditions on Residential Buildings in the Czech Republic (Analýza možných dopadů změny klimatických okrajových podmínek na obytné budovy v České republice). Vytápění Větrání Instalace 2019, 1, 36–46. (In Czech) [Google Scholar]

- Khoury, J.; Alameddine, Z.; Hollmuller, P. Understanding and bridging the energy performance gap in building retrofit. Energy Procedia 2017, 122, 217–222. [Google Scholar] [CrossRef]

- Zou, P.X.; Xu, X.; Sanjayan, J.; Wang, J. Review of 10 years research on building energy performance gap: Life-cycle and stakeholder perspectives. Energy Build. 2018, 178, 165–181. [Google Scholar] [CrossRef]

- Torgal, F.P.; Granqvist, C.-G.; Jelle, B.P.; Vanoli, G.P.; Bianco, N.; Kurnitski, J. (Eds.) Cost-Effective Energy-Efficient Building Retrofitting: Materials, Technologies, Optimization and Case Studies; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar]

- Konstantinou, T.; Santin, O.; Azcarate-Aguerre, J.F.; Klein, T.; Silvester, S. A zero-energy refurbishment solution for residential apartment buildings by applying an integrated, prefabricated façade module. In Proceedings of the PowerSkin Conference, Munich, Germany, 19 January 2017; pp. 231–240, ISBN 978-94-92516-29-9. [Google Scholar]

- Kalema, T.; Jóhannesson, G.; Pylsy, P.; Hagengran, P. Accuracy of Energy Analysis of Buildings: A Comparison of a Monthly Energy Balance Method and Simulation Methods in Calculating the Energy Consumption and the Effect of Thermal Mass. J. Build. Phys. 2008, 32, 101–130. [Google Scholar] [CrossRef]

- Nielsen, A.N.; Jensen, R.L.; Larsen, T.S.; Nissen, S.B. Early stage decision support for sustainable building renovation—A review. Build. Environ. 2016, 103, 165–181. [Google Scholar] [CrossRef]

- Hejtmánek, P.; Sojková, K.; Volf, M.; Lupíšek, A. Development of a Modular Retrofitting System for Residential Buildings and Experience from Pilot Installation. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012132. [Google Scholar] [CrossRef]

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 30 October 2019).

| Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|

| Building period | 1946–1960 | Typical indoor temperature | °C | 20 | |

| Upper storeys | - | 3 | Average electricity consumption (excluding heating, cooling, ventilation and user (plug-in) electricity) | kWh/(m2 a) | 8.8 |

| Basement storeys | - | 1 | |||

| Building dimensions (length × width) | m | 29.6 × 12.6 | |||

| Gross heated volume | m3 | 3567.9 | |||

| Gross heated floor area | m2 | 993.3 | U-value wall | W/(m2 K) | 1.4 |

| Wall area (excl. windows) | m2 | 776.9 | U-value attic floor | W/(m2 K) | 0.9 |

| Attic floor area (unheated) | m2 | 410.4 | U-value ceiling of cellar | W/(m2 K) | 2.2 |

| Area of basement ceiling | m2 | 369.1 | U-value windows | W/(m2 K) | 1.2 |

| Area of windows to north | m2 | 11.1 | g-value windows | - | 0.67 |

| Area of windows to east | m2 | 51.8 | Airflow rate (estimated) | h-1 | 0.3 |

| Area of windows to south | m2 | 17.7 | Internal heat gains | W/m2 | 4.8 |

| Area of windows to west | m2 | 51.8 | Energy need for hot water preparation (calculated*) | kWh/(m2 a) | 35.2 |

| Average heated gross floor area per person | m2/person | 20.7 | Energy need for heating (calculated*) | kWh/(m2 a) | 186.6 |

| Step | Renov. Pack. | Description |

|---|---|---|

| Step 1 | Ref-anyway | In the reference case (“anyway” renovation), façade plasters were renovated and repainted, and water-proofing failures in the basement and the attics were renovated. These measures did not improve the energy performance of the building. |

| Ref | In addition to Ref-anyway, considered change of heating system. | |

| P1 | In addition to Ref, walls were supplemented with external thermal insulation composite system (ETICS) with 10 cm of expanded polystyrene (EPS), U-value = 0.26 W/(m2 K); existing windows retained since they had already recently been replaced by plastic ones with double glazing. | |

| P2 | In addition to Ref, walls were supplemented with ETICS with 20 cm of EPS, U-value = 0.15 W/(m2 K); existing windows retained since they had already been replaced by plastic ones with double glazing recently | |

| P2+win | Ditto P2, but windows assumed to have been replaced (to assess the potential for buildings where windows have not yet been renovated); entire window Uw = 1.2 W/(m2 K). | |

| P3 | In addition to Ref, walls were supplemented with a MORE-CONNECT panel containing 10 cm of mineral wool within the main insulation layer; new double-glazed windows with plastic frames as a part of the panel; wall U-value = 0.16 W/(m2 K); window Uw = 1.2 W/(m2 K) | |

| P4 | In addition to Ref, walls were supplemented with a MORE-CONNECT panel including 20 cm of mineral wool within the main insulation layer, new double-glazed windows as a part of the panel; wall U-value = 0.12 W/(m2 K); window Uw = 1.2 W/(m2 K); window frame material impact was investigated for plastic, wooden, and aluminium frames). | |

| Step 2 | P6 | In addition to Step 1 optimum, ceiling of last storey (attic floor) was supplemented with 20 cm of mineral wool (U-value = 0.21 W/(m2 K)), basement with 6 cm of mineral wool (U-value = 0.54 W/(m2 K)) |

| P7 | In addition to Step 1 optimum, ceiling of last storey (attic floor) was supplemented with 40 cm of mineral wool (U-value = 0.11 W/(m2 K)), basement with 14 cm of mineral wool (U-value = 0.27 W/(m2 K)) | |

| P7x9 | In addition to Step 1 optimum, ceiling of last storey (attic floor) was reinforced with 40 cm of wood blown insulation (U-value = 0.11 W/(m2 K)), basement with 14 cm of mineral wool (U-value = 0.27 W/(m2 K)) | |

| P8 | In addition to Step 1 optimum, ceiling of last storey (attic floor) was supplemented with 20 cm of wood blown insulation (U-value = 0.21 W/(m2 K)), basement with 6 cm of wood-fibres insulation (U-value = 0.51 W/(m2 K)) | |

| P9 | In addition to Step 1 optimum, ceiling of last storey (attic floor) was supplemented with 40 cm of wood blown insulation (U-value = 0.11 W/(m2 K)), basement with 14 cm of wood-fibres insulation (U-value = 0.25 W/(m2 K)) | |

| Step 3 | P10 | In addition to Step 2 optimum, windows were replaced with new triple-glazed windows; U-value for entire window of 0.7 W/(m2 K); plastic, wooden, and aluminium frames were considered. |

| Step 4 | P11 | In addition to Step 3 optimum, mechanical ventilation system with heat recovery was installed for ventilation (airflow rate 860 m3/h) |

| P12 | In addition to Step 3 optimum, mechanical ventilation system with heat recovery was installed for both ventilation and warm air heating (airflow rate 2400 m3/h). | |

| P0+vent | In addition to Ref-anyway, mechanical ventilation system with heat recovery was installed for ventilation. | |

| P2+win+vent | In addition to P2+win, mechanical ventilation system with heat recovery was installed for ventilation. | |

| P4 +vent | In addition to P4, mechanical ventilation system with heat recovery was installed for ventilation. | |

| Step 5 | P13 | In addition to P11, photovoltaic (PV) panels of 8 kWp were installed. |

| P14 | In addition to P11, PV panels of 20 kWp were installed. | |

| P15 | In addition to P11, PV panels of 30 kWp* were installed. | |

| P16 | In addition to P12, PV panels of 8 kWp were installed. | |

| P17 | In addition to P12, PV panels of 20 kWp were installed. | |

| P18 | In addition to P12, PV panels of 30 kWp* were installed. | |

| P19 | In addition to P11, PV panels of such power to reach net zero primary energy on annual basis. | |

| P20 | In addition to P12, PV panels of such power to reach net zero primary energy on annual basis. |

| Energy Carrier | Primary Energy [kWh/kWh] | CO2,equiv. [kg CO2, equiv./kWh] | Energy Price [EUR/MWh] |

|---|---|---|---|

| District heating | 2.23 | 0.79 | 75.0 |

| Electricity from the grid | 3.16 (2.84, 2.53, 2.21)* | 0.75 (0.67, 0.60, 0.52)* | 149.3 |

| Natural gas | 1.46 | 0.32 | 48.2 |

| Pellets | 0.11 | 0.03 | 46.4 |

| Electricity produced (PV) | −3.16 (−2.84, −2.53, −2.21)* | −0.75 (−0.67, −0.60, −0.52)* | 16.1 (0–21.4)** |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sojkova, K.; Volf, M.; Lupisek, A.; Bolliger, R.; Vachal, T. Selection of Favourable Concept of Energy Retrofitting Solution for Social Housing in the Czech Republic Based on Economic Parameters, Greenhouse Gases, and Primary Energy Consumption. Sustainability 2019, 11, 6482. https://doi.org/10.3390/su11226482

Sojkova K, Volf M, Lupisek A, Bolliger R, Vachal T. Selection of Favourable Concept of Energy Retrofitting Solution for Social Housing in the Czech Republic Based on Economic Parameters, Greenhouse Gases, and Primary Energy Consumption. Sustainability. 2019; 11(22):6482. https://doi.org/10.3390/su11226482

Chicago/Turabian StyleSojkova, Katerina, Martin Volf, Antonin Lupisek, Roman Bolliger, and Tomas Vachal. 2019. "Selection of Favourable Concept of Energy Retrofitting Solution for Social Housing in the Czech Republic Based on Economic Parameters, Greenhouse Gases, and Primary Energy Consumption" Sustainability 11, no. 22: 6482. https://doi.org/10.3390/su11226482

APA StyleSojkova, K., Volf, M., Lupisek, A., Bolliger, R., & Vachal, T. (2019). Selection of Favourable Concept of Energy Retrofitting Solution for Social Housing in the Czech Republic Based on Economic Parameters, Greenhouse Gases, and Primary Energy Consumption. Sustainability, 11(22), 6482. https://doi.org/10.3390/su11226482