Abstract

Energy use in agricultural production has been increasing faster than in many other sectors of the world economy. Owing to high energy consumption during the production of agricultural inputs, with mineral nitrogen fertilizers in particular, it is often questioned as to whether agricultural production is still energy efficient. The objective of this research was to evaluate the energy efficiency of different intensity systems for the production of semi-dwarf winter triticale cultivar ”Twingo”. Cultivar “Twingo” entered the Polish National List in 2012 as one of the best yielding. For this reason, it was used in this experiment to examine its response to basic agrotechnical factors. The field experiment was conducted in the Agricultural Experiment Station in Tomaszkowo in 2013–2015. Low-input, medium-input and high-input production systems were evaluated. The compared systems differed in nitrogen fertilization rates and the level of fungicide protection. The highest output/input ratio was noticed growing winter triticale in low-input production system. The most energy-consuming operation during winter triticale production in the compared systems was mineral fertilization. The high-input production system was significantly lower energy efficiency than the other systems (6.21, medium-input 5.95, low-input 8.19). The energy return on investment (EROI) ratio was low, but above 1, in all the analyzed technologies (low-input 1.30, medium-input 1.14, high-input 1.15). The energy value of the bioethanol produced was higher than the energy inputs into the production of raw material and its processing. The conversion of winter triticale grain to bioethanol proved that the EROI reached the most favorable value for the low-input production system.

1. Introduction

Triticale is an increasingly popular cereal species which acreage continues to grow steadily in Poland. Triticale ranks second after wheat in terms of cropped area, and this highly versatile crop has a wide range of end use possibilities. The area sown with triticale in Poland constitutes about 34% of the area of this species in the world. European agriculture has also appreciated this species. In the last decade, the area sown with triticale increased by 30%. This undoubtedly confirms the growing position of this species [1].

The energy consumption in agriculture has been increasing due to the decreasing arable land, the growing population, the growing machine number, and the pursuit of higher living standards [2]. The Integrated Farming System, the key to which is an attempt at reconciliation of seemingly contradictory economic (assumption of high farming effectiveness), environmental, and social goals, represents one of the concepts of sustainable agriculture development. Sustainable development results from assuming the principle of integrated order seen as consistent and simultaneous perception of the economic, social, and natural order. Agriculture is the sector of the economy in which the most favorable conditions for implementation of the principles of sustainable development exist because, on the one hand, resources of the natural environment are used there, and on the other, farmers, through their activities, shape that environment [3]. In modern farming systems, profitability is closely associated with a reduction in agricultural inputs. One of the methods for evaluating agricultural production relies on the concept of energy consumption. According to Pawlak [4], growing prices of energy contribute to the effective use of agricultural inputs. There is a growing need for new solutions that would improve energy efficiency in agricultural production, increase the competitive advantage of economies, and contribute to environmental protection. The changes in energy efficiency should be regularly monitored. Previous research showed that the assessment of energy consumption and its efficiency has an influence on improving the efficiency of energy use when receiving similar crop productivity [5]. According to OECD (The Organisation for Economic Co-operation and Development) [6], improving energy efficiency in agriculture will reduce GHG (greenhouse gases) emissions nitrous, especially Oxide (N2O) and methane (CH4).

In agriculture, energy efficiency depends on the type and production intensity, mechanization, and the applied production technology. Agricultural inputs and expenditures can be minimized by selecting the most appropriate means of production and optimizing agricultural technologies [4].

Depending on the purpose of the analysis, the energy efficiency of plant production is determined using various methods. No standard methods for calculating the energy balance have been defined yet. Methods found in the literature often differ significantly, especially in terms of energy equivalents. Energy equivalents are not static values and must be adapted to local conditions. [7]. It is necessary to undertake systemic research on the harmonization of contractual conversion factors for energy units of individual agricultural raw materials intended for caloric food products or for biofuels (RES) with a specific heat value. The conversion of agricultural products into conventional cereal units should also be updated.

Currently, the search for alternative energy sources has become an urgent need. Fuels from plant sources are used in huge amounts. Biofuels are considered safe for the environment, improve energy security, and do not negatively affect the food market [8]. The need to acquire energy from other alternative sources arises from the fact that fossil fuels are limited in amount. First generation biofuels (biodiesel, bioethanol) and gas fuels are still the basic sources of renewable energy. They are either obtained from food and fodder raw materials by fermentation or transesterification processes. One of the most important biofuels used in transport is bioethanol [9], which is recognized as environmentally safe, renewable fuel [10,11].

A very important factor shaping the demand for agricultural products is growing purchases from entities operating outside the agri-food sector. Among them, fuel and energy concerns that use agricultural products in the biofuel production process are of particular importance. It is assumed that competition in the use of agricultural raw materials for biofuels negatively affects food prices and therefore contributes to the deepening of world hunger. In recent years, there have also been analyses attributing biofuels a role smaller than before in the negative influence on agricultural market prices [12,13]. The use of a part of soil resources for biomass production limits the potential of food production, which may result in an increase in its price. Agriculture is expected to continue to increase productivity to meet the food needs of the growing world population [14].

In recent years, the production of bioethanol grew dynamically, exceeding 8.2 billion liters in the EU (2016), while global production reached 119.7 billion liters. About 6.1% of cereal production in the world (wheat, fodder grains) and 5.0% of harvest in the EU was used for this purpose. In 2005, cereal grains were used much less in the production of bioethanol, 2.7% in the world, and 1.0% in the EU [15].

The most important reasons justifying biofuel development policy are the growing demand for energy and the increase of its prices, diversification of energy sources, and improvement of energy security toward energy self-sufficiency, environmental aspects, and the use of surplus agricultural production, as well as diversification of agricultural producers’ income. The production of biofuels is usually perceived as a desirable and beneficial phenomenon that fits into the stream of activities for the creation of alternative, renewable energy sources, and at the same time are often recognized as environmentally friendly and favorable to environmental protection [16].

Winter triticale was selected for this study as an annual energy crops, and therefore, with its short rotation cycle, can become a source of raw material in a relatively short time, depending on the demand [17]. Many authors analyzing the results of triticale and wheat state that these cereals seem to be the most suitable raw material for the production of bioethanol, because they provide more bioethanol than rye [18]. According to Kučerová [19], triticale is considered to be one of the best types of biomass for the production of bioethanol, owing to its high amylolytic activity and, consequently, a low falling number. As a result, the hydrolysis of starch is more rapid, and the fermentation proceeds in a relatively short time, even though triticale has a lower content of low-molecular nitrogen compounds than rye. An economic factor plays an important role as well, as the use of triticale entails a lower demand for enzymes hydrolyzing starch to glucose.

Meanwhile, there exists an equally valid environmental factor: an opportunity to allocate worse soils to growing crops for bioethanol production. On the one hand, more jobs can be created; on the other hand, an increase in food prices can be stimulated. Bioethanol production ensures biodegradability and reproducibility of fuels, as well as diversification in the fuel sector. The future of biofuels depends on the achievable rate of return, which in turn rests on a series of mutually connected factors, including the taxation policy of a state or the European Union. A negative influence on the profitability of agricultural production is exerted by the increasing costs of plant production on farms, in addition to which the current taxes on fuels reduce the profits. Economically speaking, production of biofuels requires maintaining low costs of input raw materials. This, however, is difficult to achieve unless an adequate crop production technology is chosen. An important element in the evaluation of biofuel production, apart from costs, is the calculation of energy efficiency. This calculation shows what energy inputs must be spent on the production of a unit of energy in biofuels. An advantage of energy calculation is its independence from price relations, which facilitates any comparison of the results [20].

According to Kučerová [19], triticale is considered to be one of the best types of biomass for the production of bioethanol. Triticale can provide both starch and cellulose, and therefore it is important to assess its suitability as a raw material for biofuel production [21,22]. Triticale is particularly considered a promising source of biomass in Europe and is increasingly used in the production of bioethanol [23,24]. In addition, triticale is cheaper than wheat and used mainly for fodder purposes.

Triticale is an important crop and can contribute to cropping system sustainability and grain supply [25]. Conventional agriculture prefers intensive production systems that consume large quantities of inputs, such as fertilizers and plant protection products. The effect of increasing the intensity of production is its adverse impact on the environment [26]. An alternative to the intensive system is integrated technology, which skillfully combines the entire agrotechnics with limited consumption of industrial means of production, which results in an increase of the efficiency of outlays and minimization of the negative impact of agriculture on the natural environment [27]. In integrated production, the use of chemical plant protection products is limited to the necessary minimum, and doses of mineral fertilizers are determined based on the soil’s nutrient content and assessment of plant nutritional status [28,29]. Bujak, et al. [30], and Mohammadi and Amri [31] divided the varieties into static ones, which tend to maintain a constant crop regardless of environmental conditions. Varieties with this type of stability can be grown under extensive agricultural conditions. Varieties with dynamic stability have high average yields and clearly react to the level of production system; they are useful for cultivation in intensive agriculture.

Precision farming is becoming increasingly popular in Poland as a key crop management system to achieve agricultural sustainability through the use of new information technologies.

Obtaining yields close to the variety’s possibility is conceivable under the conditions of meeting its agrotechnical requirements, so therefore it is necessary to determine the response of varieties to basic agrotechnical factors [32].

The aim of this study has been to conduct an energy analysis and assessment of three different technologies in the production of winter triticale and processing of harvested yields to biofuels. Another objective has been to calculate the energy efficiency of the bioethanol production from winter triticale grain.

2. Materials and Methods

The energy efficiency analysis was carried out based on the results of a three-year field experiment involving the semi-dwarf cultivar “Twingo” of winter triticale. “Twingo” is a recently developed and high yielding cultivar of triticale. The experiment was conducted in the 2013 to 2015 period in the Agricultural Experiment Station in Tomaszkowo (53.71 °N, 20.41 °E), Poland. The experiment had a split-plot factorial design with four replications, and it was established on soils characterized in Table 1.

Table 1.

Chemical soil properties.

Triticale was cultivated according to classical plough cultivation. Soil tillage methods were identical in all plots, involving cultivator tillage after the harvest of the preceding crop, pre-sowing ploughing, and harrowing. Oats were the preceding crops in all three years of the experiment. The energy efficiency of winter triticale grain was evaluated in low-input, medium, and high-input production systems. Energy efficiency was calculated based on average grain yields for the 3-year experimental period. The production system was selected based on quartiles as statistical tools. The upper quartile (Q3) covers 25% of the highest yields in the experiment and was adopted as a criterion for determining a subset of the largest yields. In the subset of the largest yields, the largest number of analyzed combinations factors was selected and considered the most favorable (nitrogen fertilization: 150 kg ha−1 and chemical diseases control: seed treatment + two foliar spraying as high-input production system). Similarly, to determine a subset of the smallest yields, the lower quartile (Q1) was taken, which determines 25% of the lowest crops. The least favorable yields were obtained where nitrogen fertilization was applied: 30 kg ha−1 and chemical disease control: only seed treatment as a low-input production system. Analogically, a medium-input production system was chosen. The differences in the analyzed production systems are presented in Table 2.

Table 2.

Differences between winter triticale production systems.

The yield of winter triticale grain was converted to dry matter yield. The energy inputs of successive agricultural operations were calculated in each system. In this paper, the energy inputs due to the materials consumed was expressed in mega joules (MJ) according to unit energy consumption factors (Table 3) [33].

Table 3.

Energy equivalence of inputs associated with winter triticale production.

Energy consumption was determined by measuring the consumption of diesel oil, labor inputs, and the efficiency of standard agricultural machines and equipment used during the experiment: U1224 + U103/1 Atlas 4H (ploughing), U1224 + U774/2 (cultivation unit), U4512 + U212/2 (harrowing), U4512 + N035 RNW-3 (application of potassium and phosphorus fertilizers before sowing), U1224 + S052/C Mazur 5 (sowing), U1224 + N039 RNZ-3 (nitrogen top-dressing), U4512 + Pilmet 612 (chemical control).

The energy consumption of agricultural materials was determined in MJ based on their specific energy consumption. Agricultural inputs (Etech) were analyzed in four energy flows in tractors, machines, agricultural vehicles, spare parts (Eagr), fuel (Epal), materials (Emat), and labor (Er). The energy consumption of agricultural operations was calculated by using the following formula:

Etech = Eagr + Epol + Emat + Er (MJ ha−1)

Energy efficiency was calculated based on specific energy consumption. The energy efficiency coefficient (Eee) was calculated as the ratio of the energy value of crops (Pe in GJ ha−1) to energy inputs (Ne in GJ ha−1) based on the following formula:

Eee = Pe/Ne

The main yield of winter triticale (grain) was expressed per dry matter yield. It was assumed that the calorific value of 1 kg of dry matter was 18.4 MJ. It was also assumed that the calorific value of straw was 15.2 MJ kg−1. The efficiency of a biomass furnace was presupposed to be around 80%.

Having ground the grain in a laboratory mill, the content of starch was determined with the method developed by Clendenning, according to ICC Standard No. 122/1. The theoretical efficiency of ethanol production from starch was calculated from the formula [34]:

where Et is the theoretical ethanol yield, g, C–a dose of starch, g, 1.11–the starch to glucose conversion factor, 2–a stoichiometric factor for the total of the equation of the glucose to ethanol conversion reaction, 46–the molar mass of ethanol, 180.16–the molar mass of glucose.

The actual yield of bioethanol was assumed to be around 94% of the theoretical yield [35]. All production stages (pre-treatment of raw material, mashing, fermentation, rectification) were included in the calculations, and the amount of energy needed to produce 1 dm3 of bioethanol per 100% spirit was assumed to be 12.74 MJ [36]. The calorific value of bioethanol was presumed to equal 25.8 MJ kg−1. The calculations did not include the energy inputs into the process of ethanol dewatering or the preparation of a fuel mixture and its distribution. Likewise, the energy value of waste from spirits distillation (waste code 02 07 02), which in the course of gradual thickening becomes completely dried in the final stage of the processing and turns into DDGS (dried distillers grain with solubles), was excluded from the calculations.

The research results and calculations allowed us to assess the energy efficiency of the production of biomass from winter triticale. Most often, the energy efficiency of biofuels is expressed by the EROI (energy return on investment) ratio. The EROI expresses the ratio of energy contained in a unit of the fuel to the energy needed for its production, and is derived from the following formula [37]:

where rE denotes the efficiency ratio (non-nominal), Eout is energy contained in the biofuel, Ein is energy provided from non-renewable resources to produce this biofuel.

Mean values in treatments were compared by Duncan’s test at the probability level of 0.05 in the Statistica® 13 program (TIBCO Software Inc.). The values of grain yield, starch, bioethanol production, bioethanol yield, and energy balance indicators were processed by analysis of variance (ANOVA).

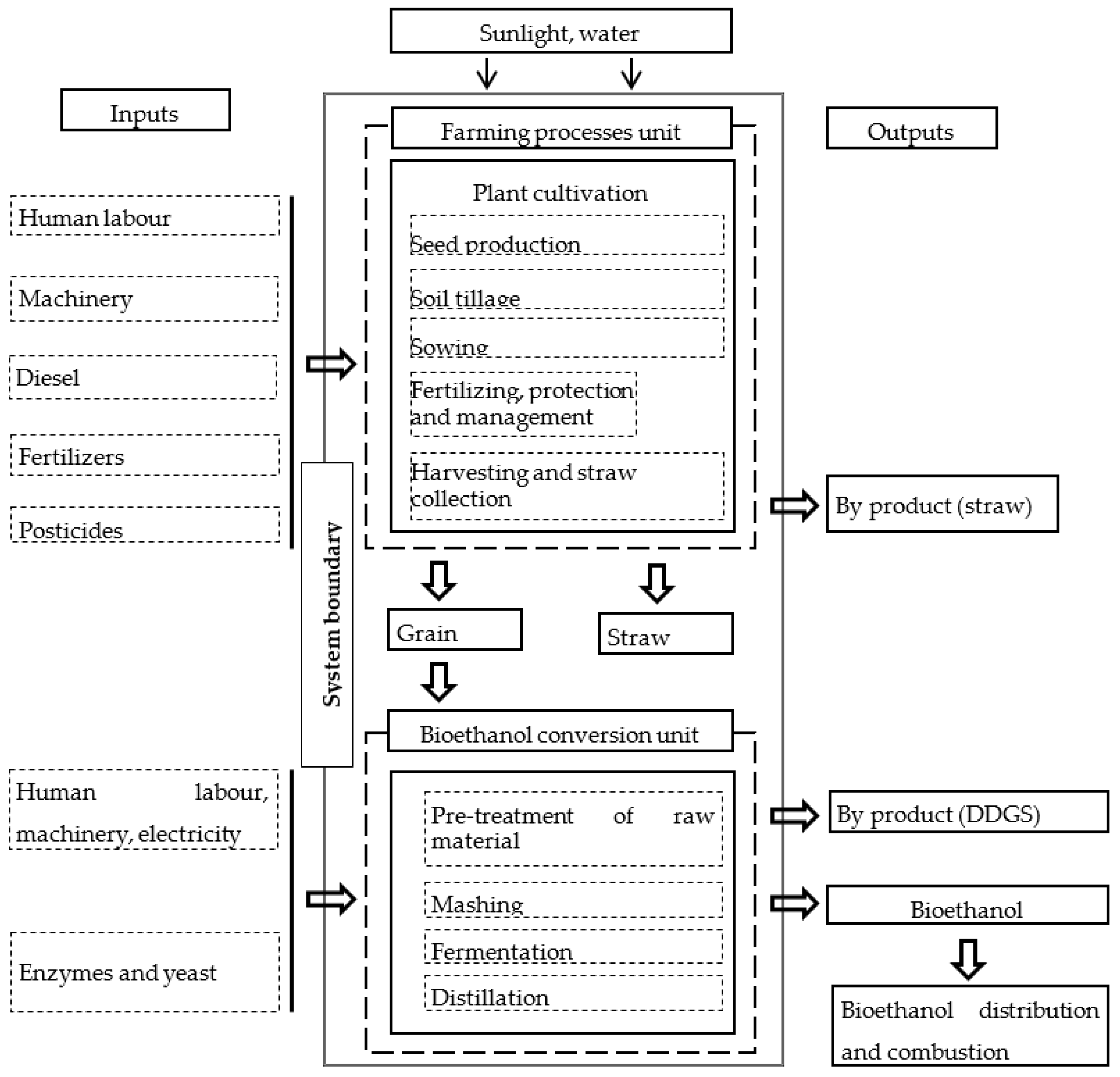

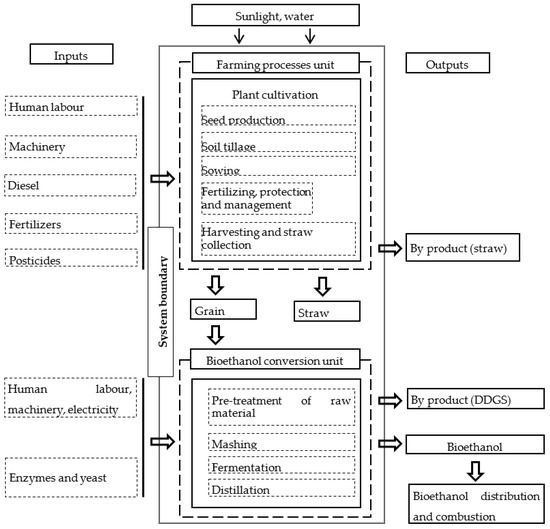

In this research, the system boundary was designed to include the main unit operations in the production systems (Figure 1). In this context we have paid attention particularly to feedstock production and its conversion to bioethanol. The system boundary considered in the evaluation involves cultivation winter triticale and conversion of grain to energy. The production factors consumed over the production process such as human labor, machineries, fuels, fertilizers, and pesticides were included. Sunlight, water, and byproducts were excluded from the system boundary. Solar energy is free and the triticale experiment was not irrigated. Feedstock transport units from field to storage and to alcohol factory were excluded because the aim of the study was only to compare selected triticale production systems. The distance between the field production and the storage room or the distillery is practically different in every farm and therefore difficult to compare.

Figure 1.

System boundary with inputs and outputs triticale production for biofuels.

3. Results and Discussion

In this experiment, averaged across years and production systems, the energy input to winter triticale was ranging from 12.06 to 22.16 GJ ha−1 (Table 4). In the high-input system with the highest rates of nitrogen fertilization and full fungicide control, the total energy inputs spent on the production of 7.50 t ha−1 of triticale grain were nearly twice higher at 22.15 GJ ha−1. Similar amounts of energy in the production of spring triticale were reported by Raczkowski [38]. In contrast, Vigovskis, et al. [39] observed significantly higher energy inputs (30 GJ ha−1) in the production of winter triticale. Mineral fertilization was the most energy-consuming agricultural treatment, responsible for 37.1% to 62.3% of total energy consumption in the cultivation of winter triticale. The values of energy inputs associated with fertilization were similar in the experiments conducted by Gozubuyuk, et al. [40].

Table 4.

Energy outlays to differ production systems 1 ha winter triticale.

Our findings are also consistent with the results reported by Kazemi [41], where fertilizers and pesticides accounted for up to 60% of energy in total energy inputs. In most production systems, mineral fertilizers, in particular nitrogen fertilizers, have the highest share of total energy inputs [42]. In our experiment, considerable amounts of energy were also consumed by sowing and seeds (14.1% in the high-input system to 26.0% in the low-input system) and pre-sowing tillage (11.4% to 6.2%) in both systems. Weed control accounted for only 3.2–5.9% of total energy consumption. In research conducted by Gozubuyuk, et al. [40], pesticide treatments accounted only for 1.5% of total energy consumption. In the present study, harvesting operations represented 2.7–5.0% of the overall energy cost of triticale production. In a study by Alluvione, et al. [5], soil tillage consumed 24.5%. In this experiment, the lowest energy expenditure was associated with fungicide application, which accounted for 0.1–1.8% of total energy inputs.

An analysis of the energy structure based on energy flows revealed the highest share of agricultural materials, which ranged from 84.2% to 73.9% (Table 5). The above can be attributed mainly to the energy cost of mineral fertilizers and seeds. A significantly lower share of agricultural materials (63.8%) in energy expenditures associated with the production of winter triticale was also reported by Gozubuyuk, et al. [40] and 58% with the production of spring triticale [43]. In our experiment, energy carriers were also a significant item in agricultural inputs (9.3–15.5%), whereas in a study by Raczkowski [38], the share of energy carriers in overall energy expenditures was much higher at 17.2% to 21.5% and Gozubuyuk, et al. [40] at 27.9% of the total energy input. The participation of tractors and agricultural machines in total energy consumption ranged from 4.3% to 7.1%, while Gozubuyuk, et al. [40] were recorded at 8.1%.

Table 5.

Energy expenditure and it’s structure to grow 1 ha winter triticale.

Labor was the least energy-intensive item that accounted for only 2.2% to 3.5% of total energy inputs. According to Gozubuyuk, et al. [40] human labor is less than 0.3% of total energy consumption in most modern production systems. Hülsbergen, et al. [7] observed that the energy flows associated with labor are generally disregarded in calculations of the energy balance in agricultural production.

The lowest energy input occurred at the low-input production system when it was applied at 30 kg ha−1 N and seeds were dressed. The highest value of energy input was obtained when winter triticale received 150 kg ha−1 N, and protection against diseases included seed treatment and two foliar treatment (Table 6). The lowest net energy output (86.7 G J ha−1), energy output from grain yield, was observed in the low-input production system. The energy output increased to 115.54 GJ ha−1 for winter triticale in the high-input production system, but maximum output/input ratio (8.19) was recorded in the low-input production system. The analyzed production systems and their outputs can be compared with the use of the energy efficiency coefficient. The value of the above coefficient is determined mainly by yield and energy inputs associated with yield. High values of the energy efficiency coefficient were noted in the present experiment.

Table 6.

Energy balance indexes for winter triticale production systems.

Bielski [42] in previous research with winter triticale cultivar “Gniewko” also achieved high energy efficiency coefficient ranging from 7.44 to 9.86. In our experiment, an increase in the nitrogen fertilization rate by 120 kg ha−1 and two foliar fungicide treatments decreased energy efficiency by 32%. In Klikocka, et al. [43] research, the average energy efficiency ratio was 6.81. Vigovskis, et al. [39] investigated the energy efficiency of various cereals (spring barley, spring wheat, triticale) and reported significantly lower values of the energy efficiency coefficient (1.5–1.8). The very high coefficient (10.5) was also recorded by Gozubuyuk, et al. [40] in a study of winter triticale. This parameter indicates the optimum intensity of the production system [7]. Additionally, Hirel, et al. [44] found out that the utilization of nitrogen from mineral fertilizers is higher at lower production levels, and nitrogen fertilizer is used in small quantities.

Fertilization experiments are conducted all over the compared with untreated control. The tested fertilizers have world aim at establishing the optimal rate for optimum production. The optimization of fertilization should be done according to the purpose of production. It was found that the conditions of the year and the level of fertilization are decisive factors for the formation of the yield in new varieties of triticale [45]. Proper nitrogen fertilization is one of the most important factors in triticale production to achieve optimal performance. Providing this knowledge will enable farmers to make better decisions regarding economic and environmental benefits, and will improve decision making concerning management and triticale production.

Agriculture is a branch of the economy that significantly contributes to the high level of chemicals in fertilizers and pesticides, as well as the use of large amounts of hydrocarbon fuels. Energy efficiency measurement is crucial when planning energy reduction policies [46]. By referring to the idea of the lowest level of energy to produce output, this measurement should highlight their potential in energy savings in order to reduce the energy dependence of agriculture. The obligation to increase the efficiency of energy use, and thus the need to save it, also results from the adopted energy and climate policy. The reduction of energy consumption through simple policies is not an easy matter. In order to be acceptable, energy policies must economically satisfy the producers who undertake them. Farmers cannot afford to jeopardize their year’s income in an attempt to refine the energy efficiency of their practices. A comparison between cost minimization and energy consumption minimization should also be made by policy-makers in order to check the cost of the policies to be implemented. In the energy analysis process, the measurement of efficiency is the first step. The next step consists of highlighting the factors which explain efficiency.

One of the basic principles of sustainable agriculture is reducing dependence on non-renewable resources, such as fuel, mineral fertilizers and pesticides, and providing a more profitable farm income [47]. The idea of sustainable agriculture is based on a balance of maximizing crop efficiency and economic stability, while minimizing the utilization of limited natural resources and harmful effects on the environment.

Agriculture is a very energy-intensive sector of economy, but at the same time it is a potential producer of biomass and components for the production of biofuels. Intensification and concentration of agricultural production creates environmental threats resulting from the use of agrochemicals. There is no doubt that agriculture makes extensive use of natural resources. The efficient use of energy in a farm aims mainly to save it, and this is an economic and environmental benefit. The future improvement of energy consumption and energy efficiency indicators for agriculture will be significantly influenced by the introduction of energy-saving agricultural production technologies, the increase in the use of renewable energy resources (RES), the introduction of multi-functional tools and machines, as well as new generation energy resources. It is necessary to undertake further interdisciplinary basic and development research on the respect of energy and the shaped environment, among others, in setting real production standards.

This study helps to identify wasteful consumption of energy and to suggest reasonable savings in energy consumption. The results of this study may be a recommendation of choosing the most energy-efficient system for farmers involved in triticale production.

The grain yield of winter triticale cultivar “Twingo”, under controlled experiment conditions ranged from 5.38 to 5.50 t ha−1 of dry matter. The grain yield, starch content in triticale grain, bioethanol production, and bioethanol yield were significantly different between production systems (Table 7). The grain yield obtained in the medium-input production system was significantly higher than the yield obtained in the low-input production system. Similarly, the grain yield in the high-input production system was significantly higher than the grain yield in the medium-input production system. While the starch content in grain and bioethanol production differed significantly between the low-input and high-input production system, as well as the medium-input and high-input production systems. The bioethanol yield per unit area also differed between the low-input and medium-input, and medium-input and high-input production systems.

Table 7.

Grain yields and ethanol of winter triticale grain (mean for the study years).

According to Obuchowski, et al. [48], the starch content in grain is an important, but not solitary factor used to assess the suitability of triticale for bioethanol production. Another significant consideration is the grain yield per cropped field unit [48,49], which largely depends on the weather conditions and the dose of mineral nitrogen fertilization [50,51]. Therefore, despite a significantly lower content of starch in grain, the high-input production system supplied bioethanol yield per unit of the cropped fields higher by 25.0% than the low-input production system. According to McKenzie, et al. [52] the influence of nitrogen dose on starch content and yield of spring triticale was very significant. The opposite research results were obtained in the study Jansone, et al. [49] where no significant effect of nitrogen on starch content and bioethanol yield was noted. The yield of grain, starch, and bioethanol in triticale cultivation is highly variable and highly dependent on weather conditions during the growing season. This variability may be particularly limited by appropriate crop management, especially mineral fertilization [49,50]. Thiemt and Oettler [53] claim that the high genetic variability of grain traits affecting the yield of ethanol that occurs within elite triticale breeding material, implicating high potential for breeding and selecting triticale toward higher ethanol productivity.

The energy expended to make the raw material obtained corresponded to 23.6% to 34.0% of the energy value of bioethanol (Table 8). Based on the studies and analyses performed, it was concluded that the energy inputs in the processing of winter triticale grain in the production of bioethanol are very high, constituting around 37% of total inputs.

Table 8.

Energy inputs for the production and processing of winter triticale raw material for biofuel and its energy value (mean for the study years), (GJ ha−1).

In the production of winter triticale for energy purposes a greater amount of energy was obtained in the form of biofuel than was spent to produce it. This is suggested by the energy efficiency ratio of bioethanol production higher than one (EROI > 1) (Table 9). The EROI reached the best value (1.30:1) in the low-input technology, distinguished by the lowest demand for energy. The author noted similar results in earlier research on winter triticale [54]. Also, Klikocka, et al. [43] recorded the best value above ratio (1.44:1) when nitrogen fertilization was used at the lowest dose (40 kg ha−1).

Table 9.

The energy efficiency indexes of the conversion winter triticale biomass into biofuel.

According to Lewandowski and Kauter [55], there is a need to rationalize the use of nitrogen, as the highest inputs into the raw material production process are incurred by nitrogen fertilization. Optimization of nitrogen fertilization on energy crop plantations must resolve the conflict between productivity and aspects related to energy use. The EROI obtained in our study are far from satisfactory. Hall, et al. [56] state that the minimum value of the EROI should be no less than 3.0, as this ensures the economic viability of biofuel production. The relevant literature references present different values of this ratio. The research conducted in Poland has demonstrated quite unsatisfactory values of the EROI computed for winter wheat grain processed to bioethanol. In a study by Dobek [20] and Dobek, et al. [57], for example, the EROI ratio ranged between 0.68 and 0.92. Reports published across the world regarding the same ratio show quite divergent results. The processing of maize grain is often characterized by the EROI below 1:0.74 [58], 0.80 [37], 0.92 [59], although in a number of studies it exceeds 1:1.20 [60], 1.25 [61], 1.20–1.70 [62], and even 5.40–5.90 depends on intensity production systems [63] or 6.85 [64].

Much better energy efficiency ratio values were obtained for winter triticale when its grain and straw biomass was used as solid fuel. The highest efficiency was obtained by the low-input production system. By investing 1 MJ of energy to produce solid biomass, an amount of 12.73 MJ of energy contained in the grain and straw was obtained (the amount of energy was lowered by 20% to consider the efficiency of solid fuel furnaces). Some authors [57] state that triticale deserves special attention because this species produces high yields with relatively low energy inputs for production.

Triticale tends to sprout during the grain ripening and harvest stages if the weather conditions are unsuitable. Often, due to severe sprouting, some batches of grain are completely discarded as raw material for feeds or even ethanol production. Such triticale grain is then considered material to be burned for heating purposes. The USA and Canada, as well as Sweden [65], have much experience in using grain for energy purposes. The process of grain incineration must be carried out in specially designed burners with an adequate supply of air, where the incineration temperature maintained is different from the temperatures at which other types of biomass are burnt.

4. Conclusions

Agriculture requires energy as an important input to production. The steady increase in production inputs puts pressure on the environment and depletes natural resources. Effective production systems and rational resource management strategies are required to maximize efficiency of resource use.

Many analyses of crop production systems are limited to financial criteria. However, the most rational and sustainable production system should be selected based on an analysis of its energy balance. The effects of economic analyses are short-lived due to frequent changes in the prices of resources and agricultural commodities. For this reason, energy efficiency analyses provide more objective and reliable results.

In this experiment, the total energy inputs in the production of winter triticale ranged from 12.06 GJ h−1 to 22.15 GJ h−1. The highest energy efficiency coefficient (8.19) was noted in the low-input system. Agricultural materials had the highest share of energy expenditure, which ranged from 73.9% in the low-input system to 84.2% in the high-input system. The energy efficiency coefficient significantly decreased with an increase in agricultural inputs. There were no significant differences between the medium-input and high-input system. The increase in energy inputs was not compensated by an increase in the amount of energy accumulated in triticale grain.

The highest yield of energy accumulated in bioethanol was obtained from the grain of triticale cultivated in the highest yield technology. However, this outcome resulted from the unit productivity of grain (higher by 10% compared to the medium yield technology and by as much as 34% compared to the lowest yield technology). Regardless of the above, the energy efficiency ratios calculated for the production of winter triticale biomass scored the highest yield technology as the least favorable among the analyzed variants. The reason for this was the inclusion of high doses with nitrogen fertilizer, a component which incurs high energy inputs during its production. The EROI ratio was low, but above 1, in all the analyzed technologies. The energy value of the bioethanol produced was higher than the energy inputs into the production of raw material and its processing.

The tested conversion of winter triticale grain to fuel bioethanol proved that the EROI reached its most favorable value for the lowest yield technology. A much better solution, however, in terms of energy recovery, is to use triticale biomass in the solid form (grain and straw). In Poland, it is not very common to use grain for energy purposes. There is a mental barrier to burning grain, arising from the high respect Polish farmers have for cereal grains. Using triticale grain to make energy seems more easily acceptable than using bread cereal grains, such as wheat. It is possible to use worse quality grain, unsuitable for human or animal consumption. Another source of grains could be cereal fields infested by fungal diseases. Triticale tends to sprout pre-harvest, under adverse weather conditions during the grain ripening and harvest stage. Often, due to severe sprouting, whole batches of grain are discarded as potential raw material for feed even for bioethanol production. Such triticale grain is then considered to be material for burning in order to generate heat.

Author Contributions

Conceptualization, S.B. and K.R.; methodology, S.B.; formal analysis, A.N. and E.Š.; investigation, S.B.; data curation, S.B., K.R., A.N. and E.Š.; writing—original draft preparation, S.B. and K.R.; writing—review and editing S.B., A.N.; supervision, S.B.; project administration, K.R.

Funding

This research was funded by Department of Agrotechnology, Agricultural Production Management and Agribusiness, Faculty of Environmental Development and Agriculture, University of Warmia and Mazury in Olsztyn.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- FAOSTAT. Food and Agriculture Organization of the United Nations; FAO: Rome, Italy, 2018. [Google Scholar]

- Hatirli, S.A.; Ozkan, B.; Fert, C. Energy inputs and crop yield relationship in greenhouse tomato production. Renew. Energy 2006, 31, 427–438. [Google Scholar] [CrossRef]

- Marks-Bielska, R.; Bielski, S.; Novikova, A.; Romaneckas, K. Straw stocks as a source of renewable energy. A case study of a district in Poland. Sustainability 2019, 11, 4714. [Google Scholar] [CrossRef]

- Pawlak, J. Efficiency of energy inputs in polish agriculture. Rocz. Nauk Roln. 2012, 1, 121–128. (In Polish) [Google Scholar]

- Alluvione, F.; Moretti, B.; Sacco, D.; Grignani, C. EUE (energy use efficiency) of cropping systems for a sustainable agriculture. Energy 2011, 36, 4468–4481. [Google Scholar] [CrossRef]

- OECD. Improving Energy Efficiency in The Agro-Food Chain, OECD Green Growth Studies; OECD Publishing: Paris, France, 2017. [Google Scholar] [CrossRef]

- Hülsbergen, K.J.; Feil, B.; Biermann, S.; Rathke, G.W.; Kalk, W.D.; Diepenbrock, W. A method of energy balancing in crop production and its application in a long-term fertilizer trial. Agric. Ecosyst. Environ. 2001, 86, 303–321. [Google Scholar] [CrossRef]

- Shahare, V.V.; Kumar, B.; Singh, P. Biofuels for sustainable development: A global perspective. In Green Technologies and Environmental Sustainability; Singh, R., Kumar, S., Eds.; Springer: Cham, Switzerland, 2017; pp. 67–89. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H. Recent trends in global production and utilization of bioethanol fuel. Appl. Energy 2009, 86, 2273–2282. [Google Scholar] [CrossRef]

- Marina, O.S.D.; Tassia, L.J.; Carlos, E.V.R.; Rubens, M.F.; Antonio, B. Evaluation of process configurations for second generation integrated with first generation bioethanol production from sugarcane. Fuel Process. Technol. 2013, 109, 84–89. [Google Scholar] [CrossRef]

- Baeyens, J.; Kang, Q.; Appels, L.; Dewil, R.; Lv, Y.; Tan, T. Challenges and opportunities in improving the production of bio-ethanol. Prog. Energy Combust. 2015, 547, 60–88. [Google Scholar] [CrossRef]

- Oladosu, G.; Msangi, S. Biofuel-Food market interactions: A review of modeling approaches and findings. Agriculture 2013, 3, 53–71. [Google Scholar] [CrossRef]

- Gomiero, T. Are biofuels an effective and viable energy strategy for industrialized societies? A reasoned overview of potentials and limits. Sustainability 2015, 7, 8491–8521. [Google Scholar] [CrossRef]

- Godfray, C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food Security: The challenge of feeding 9 billion people. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- OECD-FAO Agricultural Outlook 2018. In OECD-FAO Agricultural Outlook 1990–2028; OECD/Food and Agriculture Organization of United Nations, OECD Publishing: Paris, France, 2018.

- Bielski, S. Conditions of biomass production for energy generation purposes in Poland. Folia Oeconomica Stenensia 2011, 10, 238–249. [Google Scholar] [CrossRef][Green Version]

- Nonhebel, S. Energy yields in intensive and extensive biomass production systems. Biomass Bioenerg. 2002, 22, 159–167. [Google Scholar] [CrossRef]

- Rosenberger, A.; Kaul, H.P.; Senn, T.; Aufhammer, W. Costs of bioethanol production from winter cereals: The effect of growing conditions and crop production intensity levels. Ind. Crop. Prod. 2002, 15, 91–102. [Google Scholar] [CrossRef]

- Kučerová, J. The effect of year, site and variety on the quality characteristics and bioethanol yield of winter triticale. J. I Brew. 2007, 113, 142–146. [Google Scholar] [CrossRef]

- Dobek, T. Evaluation of economic effectiveness and power consumption for farming of winter rape seed and winter wheat utilized for biofuel production. Inżynieria Rol. 2007, 6, 41–48. (In Polish) [Google Scholar]

- Mojović, L.; Pejin, D.; Grujić, O.; Markov, S.; Pejin, J.; Rakin, M.; Vukasinovic, M.; Nikolić, S.; Savic, D. Progress in the production of bioethanol on starch-based feedstock. Chem. Ind. Chem. Eng. Q. 2009, 15, 211–226. [Google Scholar] [CrossRef]

- Mupondwa, E.; Li, X.; Tabil, L. Integrated bioethanol production from triticale grain and lignocellulosic straw in Western Canada. Ind. Crop. Prod. 2018, 117, 75–87. [Google Scholar] [CrossRef]

- García-Aparicio, M.; Trollope, K.; Tyhoda, L.; Diedericks, D.; Görgens, J. Evaluation of triticale bran as raw material for bioethanol production. Fuel 2010, 90, 1638–1644. [Google Scholar] [CrossRef]

- Cantale, C.; Petrazzuolo, F.; Correnti, A.; Farneti, A.; Felici, F.; Latini, A.; Galeffi, P. Triticale for bioenergy production. Agric. Agric. Sci. Procedia 2016, 8, 609–616. [Google Scholar] [CrossRef]

- McGoverin, C.M.; Snyders, F.; Muller, N.; Botes, W.; Fox, G.; Manley, M. A review of triticale uses and the effect of growth environment on grain quality. J. Sci. Food Agric. 2011, 91, 1155–1165. [Google Scholar] [CrossRef] [PubMed]

- Jaśkiewicz, B. The impact of production technology on yields of winter triticale under varied percentages of cereals to total cropped area. Pol. J. Agron. 2015, 23, 11–17. (In Polish) [Google Scholar]

- Kuś, J.; Jończyk, K. Production and environmental consequence of the ecological and conventional crop production systems. J. Res. Appl. Agric. Eng. 2009, 54, 183–187. (In Polish) [Google Scholar]

- Jaśkiewicz, B. The influence of integrated and intensive production technologies on yield of two winter triticale cultivars in cereals monoculture. Fragm. Agronom. 2014, 4, 28–36. (In Polish) [Google Scholar]

- Korbas, M.; Mrówczyński, M. (Eds.) Metodyka integrowanej ochrony pszenżyta ozimego i jarego; Inst. Ochr. Roślin—PIB: Poznań, Poland, 2011; pp. 1–189. (In Polish) [Google Scholar]

- Bujak, H.; Tratwal, A.; Walczak, F. Winter triticale yielding and value traits variability in Winna Góra. Ann. UMCS Sect. E Agric. 2012, 67, 1–11. (In Polish) [Google Scholar]

- Mohammadi, R.; Amri, A. Comparison of parametric and non-parametric methods for selecting stable and adapted durum wheat genotypes in variable environments. Euphytica 2008, 159, 419–432. [Google Scholar] [CrossRef]

- Jaśkiewicz, B. The reaction of new winter triticale varieties on agrotechnical factors. Folia Pomer. Univ. Technol. Stetin. Agric., Aliment. Pisc. Zootech. 2009, 274, 11–18. (In Polish) [Google Scholar]

- Wójcicki, Z. Technical Equipment, Material and Energy Inputs in the Development of Agricultural Holdings; IBMER: Warszawa, Poland, 2000. (In Polish) [Google Scholar]

- Clarke, S.; Kindred, D.; Weightman, R.; Dyer, C.; Sylvester-Bradley, R. Growing Wheat for Alcohol and Bioethanol Production in the North East. In The Final Report of ADAS Project XAA1500 Conducted for NEPIC between September 2008 to October 2008. 2008. Available online: www.adas.co.uk (accessed on 10 July 2019).

- Dale, R.T.; Tyner, W.E. Economic and Technical Analysis of Ethanol Dry Milling: Model User’s Manual. Staff Paper # 06-05, Purdue University 2006. Available online: http://purl.umn.edu/28674 (accessed on 10 July 2019).

- Komorowicz, T.; Magiera, J. Indicators effectiveness selected bioethanol production installation. Czas. Tech. 2008, 2, 135–141. (In Polish) [Google Scholar]

- Murphy, D.J.; Hall, C.A.S. Year in review—EROI or energy return on (energy) invested 2010. Ann. N. Y. Acad. Sci. 2010, 1185, 102–118. [Google Scholar] [CrossRef]

- Raczkowski, M. Energy expenditure in triticale cultivation with different microelements fertilization technique. Pol. J. Nat. Sci. 2010, 25, 236–243. [Google Scholar] [CrossRef]

- Vigovskis, J.; Sarkanbarde, D.; Svarta, A.; Jermuss, A.; Agafonova, L. The Estimation of Energy Efficiency of Crop Rotation in Long–Term Trials. In Proceedings of the International Scientific Conference Renewable Energy and Energy Efficiency, Jelgava, Latvia, 28–30 May 2012. [Google Scholar]

- Gozubuyuk, Z.; Demir, O.; Kucukozdemir, A. Some operating parameters, energy efficiency, carbon dioxide emission and economic analysis of triticale and wheat grown in high altitude semi-arid climate conditions. J. Crop. Breed. Genet. 2019, 5, 42–53. [Google Scholar]

- Kazemi, H.; Kamkar, B.; Lakzaei, S.; Badsar, M.; Shahbyki, M. Energy flow analysis for rice production in different geographical regions of Iran. Energy 2015, 84, 390–396. [Google Scholar] [CrossRef]

- Bielski, S. Energy balance evaluation of winter triticale production. In Proceedings of the 14th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 20–22 May 2015; Volume 4, pp. 552–557. [Google Scholar]

- Klikocka, H.; Kasztelan, A.; Zakrzewska, A.; Wyłupek, T.; Szostak, B.; Skwaryło-Bednarz, B. The energy efficiency of the production and conversion of spring triticale grain into bioethanol. Agronomy 2019, 9, 423. [Google Scholar] [CrossRef]

- Hirel, B.; Tétu, T.; Lea, P.; Dubois, F. Improving nitrogen use efficiency in crops for sustainable agriculture. Sustainability 2011, 3, 1452–1485. [Google Scholar] [CrossRef]

- Ivanova, A.; Tsenov, N. Production potencial of new triticale varieties grown in the region of Dobrudzha. Agric. Sci. Technol. 2014, 6, 243–246. [Google Scholar]

- Chel, A.; Kaushik, G. Renewable Energy for Sustainable Agriculture. Agronomy for Sustainable Development; Springer: Berlin, Germany, 2011; pp. 91–118.

- Lichtfouse, E.; Navarrete, M.; Debaeke, P.; Souchère, V.; Alberola, C.; Ménassieu, J. Agronomy for sustainable agriculture. A review. Agron. Sustain. Dev. 2009, 29, 1–6. [Google Scholar] [CrossRef]

- Obuchowski, W.; Banaszak, Z.; Makowska, A.; Łuczak, M. Factors affecting usefulness of triticale grain for bioethanol production. J. Sci. Food. Agric. 2010, 90, 2506–2511. [Google Scholar] [CrossRef]

- Jansone, I.; Malecka, S.; Miglane, V. Suitability of winter triticale varieties for bioethanol production in Latvia. Agron. Res. 2010, 8, 573–582. [Google Scholar]

- Janušauskaitė, D. Analysis of grain yield and its components in spring triticale under different N fertilization regimes. Zemdirb. Agric. 2014, 101, 381–388. [Google Scholar] [CrossRef][Green Version]

- Janušauskaitė, D.; Feiziene, D.; Feiza, V. Comparative response of spring and winter triticale productivity and bioethanol yield to fertilisation intensity. Acta Agr. Scand. B-S P 2019, 69, 95–104. [Google Scholar] [CrossRef]

- McKenzie, R.H.; Bremer, E.; Middelton, A.B.; Beres, B.; Yoder, C.; Hietamaa, C.; Pfiffner, P.; Kereliu, G.; Pauly, D.; Henriquez, B. Agronomic practices for bioethanol production from spring triticale in Alberta. Can. J. Plant. Sci. 2013, 94, 15–22. [Google Scholar] [CrossRef]

- Thiemt, E.M.; Oettler, G. Agronomic performance of anther-derived doubled haploid and single seed descent lines in crosses between primary and secondary winter triticale. Plant. Breed. 2008, 127, 476–479. [Google Scholar] [CrossRef]

- Bielski, S.; Dubis, B.; Jankowski, K. Energy efficiency of production and conversion of winter triticale biomass for biofuels. Przem. Chem. 2015, 94, 1798–1801. (In Polish) [Google Scholar] [CrossRef]

- Lewandowski, I.; Kauter, D. The influence of nitrogen fertilizer on the yield and combustion quality of whole grain crops for solid fuel use. Ind Crop. Prod. 2003, 17, 103–117. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Lambert, J.G.; Balogh, S.B. EROI of different fuels and the implications for society. Energy Policy 2014, 64, 141–152. [Google Scholar] [CrossRef]

- Dobek, T.; Dobek, M.; Šarec, O. Assessment of economic and energy efficiency for the production of winter wheat and winter rape used to manufacture biofuels. Inżynieria Rol. 2010, 1, 161–168. (In Polish) [Google Scholar]

- Pimentel, D.; Patzek, T. Ethanol production using corn, switchgrass and wood; biodiesel production using soybean and sunflower. Nat. Resour. Res. 2005, 14, 65–76. [Google Scholar] [CrossRef]

- Patzek, T. Thermodynamics of the corn-ethanol biofuel cycle. Crit. Rev. Plant. Sci. 2004, 23, 519–567. [Google Scholar] [CrossRef]

- Farrell, A.E.; Plevin, R.J.; Turner, B.T.; Jones, A.D.; O’Hare, M.; Kammen, D.M. Ethanol can contribute to energy and environmental goals. Science 2006, 311, 506–508. [Google Scholar] [CrossRef]

- Hill, J.; Nelson, E.; Tilman, D.; Polasky, S.; Tiffany, D. Environmental, economic and energetic costs and benefits of biodiesel and ethanol biofuels. Proc. Natl. Acad. Sci. USA 2006, 103, 11206–11210. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Balogh, S.; Murphy, D.J.R. What is the minimum EROI that a sustainable society must have? Energies 2009, 2, 25–47. [Google Scholar] [CrossRef]

- Arodudu, O.; Helming, K.; Wiggering, H.; Voinov, A. Bioenergy from low-intensity agricultural systems: An energy efficiency analysis. Energies 2017, 10, 29. [Google Scholar] [CrossRef]

- Donke, A.; Nogueira, A.; Matai, P.; Kulay, L. Environmental and energy performance of ethanol production from the integration of sugarcane, corn, and grain sorghum in a multipurpose plant. Resources 2016, 6, 1. [Google Scholar] [CrossRef]

- Lynd, L.R.; Wang, M.Q. A product-nonspecific framework for evaluating the potential of biomass-based products to displace fossil fuels. J. Ind. Ecol. 2004, 7, 17–32. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).