Abstract

The objective of this study is to identify Mexican nontoxic ecotypes of Jatropha curcas with potential for a sustainable agriculture practice to produce biodiesel and food products through a methodology and criteria of sustainability. In a rural region of Morelos state in central México, nine Mexican ecotypes of Jatropha curcas were evaluated in an experimental plantation with minimal water resources and fertilization. The experimental trial was assessed in terms of (1) toxicity, (2) growth and survival of the plants, (3) yield of seed, (4) residual biomass production, (5) oil characteristics for biodiesel production, (6) nutrimental properties of the seeds, and (7) changes in the chemical properties of the soil. Finally, two outstanding nontoxic ecotypes were identified as the most suitable for the establishment of Jatropha curcas crops to produce biodiesel and, at the same time, for food products using the de-oiled endosperm cake, for energy production from the residual biomass and for improvement of soil properties in marginal lands of rural regions of Morelos state.

1. Introduction

The use of Jatropha curcas as a raw material to produce biodiesel has been extensively studied in the last decade [1,2]. The reason why Jatropha plants have attracted attention as energy crop is because it is a fast-growing, easy-to-spread, drought-resistant shrub that grows in arid lands [3,4]. These characteristics are beneficial because they avoid competition for land and/or resources for food crops [5], can rehabilitate degraded lands by fixing carbon and improving physical-chemical properties in the soil [6], prevention of erosion [7], as well as providing diverse ecosystem services [8].

However, successful production of Jatropha curcas crops has been limited due to low seed production, making commercial plantations unfeasible [9,10,11]. This is despite that most of the production systems show a positive balance of emissions and energy [12,13].

In order to obtain an added value of the Jatropha curcas crops, in addition to the production of biodiesel, the use of the biomass of the plant for energy production purposes has been explored, where the de-oiled seed cake, that is, the pericarp (fruit husks), the tegument (seed husk), and endosperm (core of the seeds) are used for combustion, pyrolysis, gasification and biogas processes [14,15,16,17].

On the other hand, the endosperm can be used for food purposes, providing additional value to Jatropha curcas crops. Some studies [18,19,20] reported that the chemical composition of the endosperm has high levels of crude protein content (40–60%) and essential amino acids; in this way, the alimentary use in humans and/or animals may be appropriate.

It should be noted that these food benefits have been limited since the plantations of Jatropha curcas have been based on seed varieties with high levels of phorbol esters. These varieties are called “toxic” because phorbol esters are found in concentration ranges of 0.35–2.34 mg g−1 of oil [21] and 0.60–5.15 mg g−1 of seed weight [22,23]. Indeed, several studies have demonstrated that phorbol esters are toxic organic compounds due to their strong activity promoting different illness in humans or animals. Although the presence of another substances also influence in the negative nutritional features of the Jatropha curcas cakes, the authors consider that phorbol esters are the main toxic compounds [24,25,26].

For this reason, the toxic seed varieties cannot be used for human and animal consumption; unless the seeds are subjected to a detoxification treatment to remove or inactivate phorbol esters. However, these treatments are currently under development and their scaling, in some cases, is difficult to control [27,28] and fail to reduce the levels of phorbol esters in the seed to acceptable levels for consumption [29,30]. In addition, it has been reported that even at very low concentration levels of phorbol esters in the seed, from 0.4–0.09 mg g−1, negative effects in animals have been detected [27].

Mexico is considered the center of origin of Jatropha curcas according to Pecina-Qintero et al. [31], Mexican seed varieties have been classified as” nontoxic” because they do not contain phorbol esters or they are present at a very low concentration (i.e., not detectable at –0.02 mg g−1 of seed) [21,22,32]. These varieties are located in the states of Veracruz, Hidalgo, Puebla, Yucatán and Quintana Roo where domestication took place by the Mayan and Olmec pre-Hispanic cultures [31]. In some provinces of Quintana Roo and Veracruz the seeds are used in the preparation of traditional dishes [32].

Likewise, the existence of nontoxic varieties has been reported in the state of Morelos in Cuautla and Yautepec municipalities [23,33]. However, these varieties are also distributed in other areas of the state that have not been studied.

Nontoxic Jatropha curcas can be consumed by humans and/or animals [18,34], in this way, nontoxic varieties would allow the possibility to obtain food products from de-oiled endosperm in addition to obtaining the oil to produce biodiesel, as well as, to obtain energy from residual biomass and benefits from others sustainable properties of the Jatropha curcas crop, such as, soil rehabilitation and the use of marginal lands that not compete with food production. It is important to point out that nontoxic varieties have not been used in commercial plantations nor have been the object of breeding programs, these varieties are only found in natural populations.

Currently, the yield of seed and oil are mainly the most important characteristics that are taken into account to develop strategies to improve Jatropha curcas [35,36,37]. Nevertheless, as discussed in this article, the selection of nontoxic varieties of Jatropha curcas could be another important aspect for the formulation of improvement programs and the development of production technology packages, so that Jatropha curcas crops can be more comprehensive and sustainable.

According to this vision, the main objective of this study is to identify Mexican nontoxic ecotypes of Jatropha curcas with the best potential to establish crops in marginal lands to produce biodiesel and food products in a more integral and sustainable way.

Nine Jatropha curcas ecotypes were evaluated in an experimental plantation in marginal soils and a scenario of minimum resources to know the development of these plants in lands that are no used for growing food. These ecotypes were analyzed to determine the phorbol ester content in their seeds in order to determine their toxicity and thus be able to select nontoxic ecotypes (see Nontoxicity Test section).

The aspects evaluated in the selected nontoxic ecotypes were the following: (1) morphological growth and survival plants, (2) yield of seed production, (3) yield of residual biomass and (4) oil content. The physicochemical properties of the oil of those ecotypes that showed better growth characteristics and a higher yield in seed and oil were analyzed to determine if its quality was suitable for the biodiesel production.

Moreover, these ecotypes were subjected to a bromatological analysis of the endosperm of the seed to know if the nutritional value was suitable for food purposes. Finally, changes in the soil were analyzed in order to know if there was an improvement of the soil chemical properties where the selected ecotypes were grown.

2. Materials and Methods

2.1. Study Site and Plant Material

An experimental Jatropha curcas plantation was established in Miacatlan, a rural municipality from Morelos state, Mexico (latitude 18° 47′43.3″ N, longitude 99° 21′0.40″ W) at 1000 m a.s.l., as shown in the map in Figure 1.

Figure 1.

Location of the Jatropha curcas experimental plot in Morelos, Mexico.

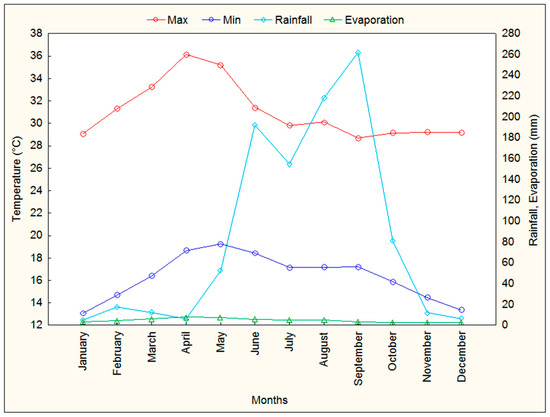

The climate of the site is hot-humid with rainy season in summer. For a period of nine years (2009–2018), an average temperature of 23.7 °C was recorded, reaching the maximum temperature of 36.2 °C in May and minimum temperature of 13.1 °C in January. The annual average rainfall was 1020.8 mm, with the highest value between the months of June–October with 908.9 mm and the regime with the highest amount of evaporation in the March–May period, as shown in Figure 2.

Figure 2.

Monthly averages of climatic parameters at the experimental plot for period of study (2009–2018).

The plantation was developed on a marginal land that was previously used for agricultural activities. The soil properties, prior to the planting of the ecotypes, showed a medium level of organic matter and low levels of nutrients availability with slightly alkaline clay soil texture with pH = 7.6.

In the experimental plot, 569 plants of nine Jatropha curcas ecotypes distributed in nine microparcels were planted, having at least 60 plants for each ecotype.

The field methodology involved a selection of seeds from the Mexican states of Michoacán, Morelos and Oaxaca to obtain germplasm of Jatropha curcas by generative propagation, direct seeding.

Seed germination was carried out under controlled laboratory conditions and the obtained seedlings remained in the nursery for three months. Subsequently, transplanting of the seedlings was made at the experimental plot in pits of 0.4 m × 0.4 m × 0.4 m and spacing of 2 m × 2.8 m, keeping the spacing between plant to plant constant, resulting in a crop density of 1250 plants per hectare.

Each ecotype was identified with an alphanumeric ID code for recognizing the location at the experimental plot—E1M, E2M, E3M, E4M, E5M, E6O, E7O, E8O and E9C—.

The cultivation system established was of minimum resources with low intensity of management. Fertilizers were used only once during the transplant process by adding a compost mix to each pit. The irrigation of the plantation was carried out though natural rain. The auxiliary irrigation was used only for three months, after having performed the transplant, pouring 20 L of water per plant every fortnight. For the control of pests and diseases, no insecticides or fungicides were used.

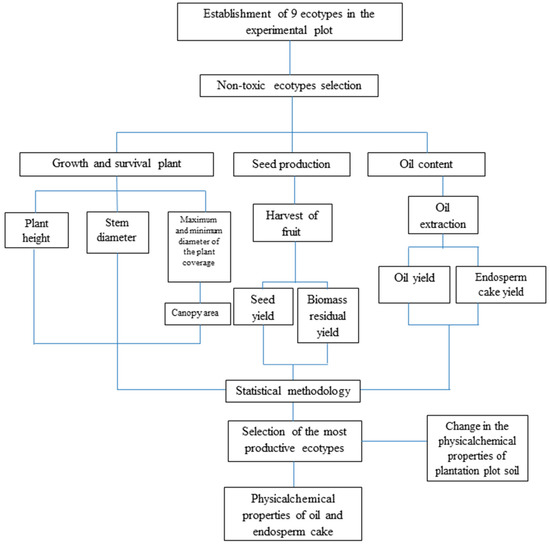

Under the described conditions, the selection of ecotypes was carried out following the methodology in Figure 3.

Figure 3.

Methodology evaluation of nine ecotypes of Jatropha curcas in the experimental plot.

2.2. Nontoxicity Test

The identification of toxic and nontoxic ecotypes was accomplished by estimating the concentration of phorbol esters in the oil.

HPLC analysis was carried out—LC/MS instrument 1100, Agilent—based on the modified method of Haas et al. [38]. For each ecotype of Jatropha curcas, 1.5 g of oil was weighted on an electronic balance and diluted with 5 mL of ether. Samples were treated with a solid phase extraction device. The silica column was activated and conditioned with ether. The samples were poured and washed with 5 mL of ether and 3.5 mL of acetone, to eliminate the column interferences or contaminants. The final step was the phorbol esters elution performed with 5 mL of methanol and 5 mL of ethanol. Methanol and ethanol were evaporated and the sample was diluted with 2 mL of acetonitrile for HPLC analysis. The quantitative analysis was performed following the same method, but with the addition of 40 μL of phorbol 12-myristate 13-acetate (SIGMA) of known concentration—0.005 mg μL−1 as the reference standard.

The samples were collected from the reverse phase column Agilent Eclipse XDB C18 (5 μm × 4.6 mm). The separation conditions were: flow rate of 1 mL min−1, mobile phase 75/25 acetonitrile–water, and isocratic mode.

The ecotypes in which the presence of phorbol esters was not detected were selected to evaluate their performance according to the data obtained from the experimental plantation.

2.3. Growth and Plants Survival

Once the plantation was established, the growth parameters of the Jatropha curcas ecotype were permanently monitored. The measurements of basic biophysical parameters included the plant height or vertical distance from the ground level to the highest green plant, the stem base diameter (the cross-section of the stem at the apex height), and the maximum and minimum diameter of the plant coverage. With these parameters, the canopy area was calculated assuming an ellipsoidal shape as the best approximation to the shape of the plants.

Measurements were collected at the experimental plantation on an annual basis starting in July 2009 through July 2013 and the last measurement was carried out in July 2018, when the plants were nine years old. All data were recorded systematically in a database [39] for its subsequent processing.

Finally, the plant account was registered and the plant survival rate under the site environmental conditions was calculated using the number of plants surviving at the end of July for the years of 2009, 2011, 2012, 2013 and 2018.

2.4. Seed, Biomass and Oil Production

The yield in seed production of the nontoxic ecotypes was analyzed in the 8th and 9th years of age of the plants.

The fruits in mature state were collected individually of each plant in the months of August and September for the years 2017 and 2018. The weight of the fruits collected was registered to estimate the yield of fruit production.

Afterwards, the fruits were driedutdoors and cleaned manually by separating the pericarp and the seeds at a humidity of 14.1% for the pericarp and 8.1% in the seeds. The percentage of composition of the seeds and the pericarp with respect to the weight of the fruit was calculated to estimate the yield per hectare of seed and biomass of the pericarp.

Finally, ten samples of 100 g of seed were prepared by ecotype. The tegument and the endosperm were manually separated from the seed. The composition percentage of the endosperm and tegument with respect to the weight of the seeds was calculated to estimate first the yield of endosperm later the tegument biomass per hectare. In this way, the yields of the pericarp and tegument biomass were added to obtain the total yield of residual biomass per hectare.

In addition to the above, the oils were extracted directly from endosperm by means of a mechanical cold pressing process, using a hydraulic press specially designed for this study. The oil was extracted from the endosperm samples at a humidity of 6.1%, separated from the solid particles of the oil and subsequently filtered. The yield of oil content was calculated as:

The oil obtained was collected and stored in the laboratory for further analysis. With the percentage of oil extraction and the seed production potential, the potential for oil production per hectare was estimated.

The endosperm cake—the extruded endosperm resulting from oil extraction—was weighed to calculate the endosperm cake yield in the following way:

In the same way as oil, the endosperm cake production potential per hectare was estimated.

2.5. Statistical Analysis

The data was analyzed using a statistical approach. Some statistical tests were applied in order to find patterns, identify similarities or differences among the nontoxic Jatropha curcas ecotypes selected for this study. The methodology involved (i) a comprehensive review of all data collected in the field to avoid data entry mistake; (ii) plotting of histograms to see whether data were normally distributed; (iii) analysis of outliers for identifying discordant outliers, and (iv) application of ANOVA and Tukey HSD (Honestly-significant-difference) significance tests to compare core trend parameters against the set of normal data. The tests for outliers and the significance tests were all applied at 95% confidence level and a 0.05 significance level.

2.6. Endosperm and Oil Characterization

The nontoxic ecotypes with the best results in growth, survival and yield of seed and oil were selected to analyze the physical–chemical properties of oil and endosperm.

Regarding the oil, the physical properties analyzed were: (a) the density of the oil (at 15 °C), determined with an Anton Paar DMA 500 densimeter; (b) the viscosity (at 40 °C), determined with a Brookfield AMETEK MINIVIS II viscometer; and (c) the calorific valued obtained by means of a 6400 Automatic Isoperibol Calorimeter from Parr Instruments Company. The composition of fatty acids was the only chemical property analyzed; this was determined by means of gas chromatography using the AOAC (Association of Official Agricultural Chemists) methodology (2005) for preparation of the fatty acid methyl esters (969.33) and their separation, by gas chromatography (963.22).

As for the endosperm, this was subjected to a bromatological analysis to determine the content of proteins, crude fiber, available carbohydrates, total reducing sugars, ash and energy content, using the methodology of national standards NMX-NORMEX (Mexican Standard of Mexican Society of Standardization and Certification) and NOM (Mexican Official Standards), under the specific AOAC regulations for cereal-seeds-oleaginous.

2.7. Soil Analysis

To monitor changes in soil physical–chemical properties, two measurements of soil fertility of the experimental plot were carried out: (1) prior to the planting of the Jatropha curcas seedling (year 2008); and (2) at nine years of the plants (year 2018).

The soil analysis was performed according to the official Mexican standard NOM-021-SEMARNAT-2000. Soil samples were collected in the cultivation area; each soil sample was obtained from five random points of the cultivation area at 0.3 m depth. The proportional part of organic matter was determined by the Walkley and Black methodology. Inorganic nitrogen was determined by steam drag using the Kejeldahl method; the phosphorus concentration was established by the Olsen method and the potassium concentration was determined by flame emission spectrophotometry.

3. Results and discussion

3.1. Growth and Survival of Non-Toxic Ecotypes

Table 1 shows the names and provenance of the ecotypes, as well as the results of the phorbol ester concentration determination. In the ecotypes E1M, E2M, E3M, E4M and E5M, the presence of phorbol esters was not detected. For this reason, these varieties of Jatropha curcas are identified as nontoxic.

Table 1.

Codes, origin of Jatropha curcas ecotypes provenances and level of phorbol ester in seed oil.

These results agree with previous reports of seeds of genotypes of Jatropha curcas from the southeastern part of the country where phorbol esters are not detected and seeds are consumed by people [22,23].

On the contrary, the remaining ecotypes: E6O, E7O, E8O and E9C are identified as toxic since they presented a concentration of phorbol esters at levels of 0.6–1.6 mg g−1 of oil, typical value of Jatropha curcas genotypes toxicities reported by the authors of [21].

Consequently, these nontoxic ecotypes of Jatropha curcas in addition to obtain the oil, the residual endosperm cake from the extraction of the oil could be a second valuable product that can generate additional economic benefits.

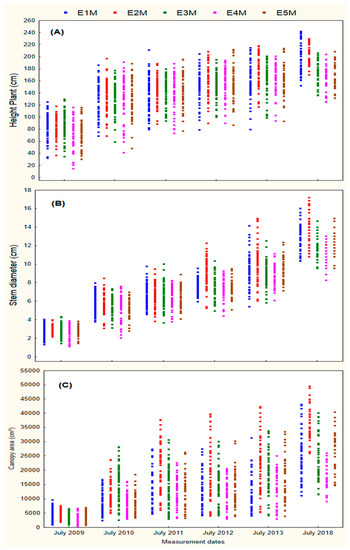

The measurements of biophysical parameters of nontoxic ecotypes E1M, E2M, E3M, E4M and E5M, are presented in Figure 4. All ecotypes showed a similar growth trend throughout the study. The plants of the E1M and E2M ecotypes showed good growth during their first months of life in the experimental plot and continued with this tendency at the end of the study, reaching the plants with the highest growth.

Figure 4.

Measurements of biophysical parameters for plant growth in the study site along nine years (2009–2018). (A) Height of plant, (B) stem diameter, (C) canopy area.

Table S1 displays the measurement of average growth and standard deviation in plant height, stem diameter and canopy area of the nontoxic ecotypes. Likewise, significant statistical differences are present according to the ANOVA test (p ≤ 0.05): (A) the highest growth; (AB) high growth; (B) average growth; (BC) low growth; and (C) the lowest growth.

According to Figure 4 and Table S1, an increase in the height dimensions of the plant is observed during the measurements made in July of the years 2009 and 2010 while the increase was lower in subsequent measurements made in the years 2011, 2012, 2013 and 2018.

In the first measurements made in July 2009, all ecotypes showed significant differences in plant height, the E2M ecotype recorded the highest growth while the E4M and E5M ecotype showed the lowest growth. Subsequently, in the measures recorded in July 2010, 2011 and 2012, all the ecotypes maintained similar plant growth without significant differences between them. In the measurements made in July 2013, the E2M again obtained the highest growth showing significant differences with respect to the remaining ecotypes. In the last measurements made in July 2018, the E1M plants presented an increase in plant height ending at a similar height to the E2M plants. At the end of the study, the E1M and E2M ecotypes showed the greatest growth in plant height.

With respect to stem diameter growth, the dimensions showed a constant increase throughout the monitoring period. The measurements from July 2009–July 2011 showed similar growths in all the ecotypes without presenting significant differences. From the measurements made in July 2012 until 2018 there were significant differences between the ecotypes, the E2M plants were those with the highest average growth followed by the E1M plants.

The differences in the average growth of the ecotypes were more evident in the parameter of canopy area, since throughout the study there were significant differences in all the ecotypes. In the same way as in the parameters of plant height and stem diameter, the dimensions of plant coverage showed marked increases from the measurements of July 2010–July 2018. Throughout the study, E2M also showed the highest growth in this parameter.

At the end of the monitored period, the average value of all the data obtained in plant height was 162.5 ± 16.9–203.5 ± 28.9 cm, stem diameter 11.0 ± 1.2–14.3 ± 2.3 cm and canopy area at 18,804.7 ± 5526.6–39,072.9 ± 10,521.0 cm2.

In summary, the plant height growth by ecotype in ascending order was: E4M > E5M > E3M > E2M > E1M; for stem diameter is: E4M > E3M > E5M > E1M > E2M; and for the canopy area is: E4M > E3M > E5M > E1M > E2M. As can be seen, the E1M ecotype presented the highest growth in plant height and the E2M presented the highest growth in stem diameter and canopy area.

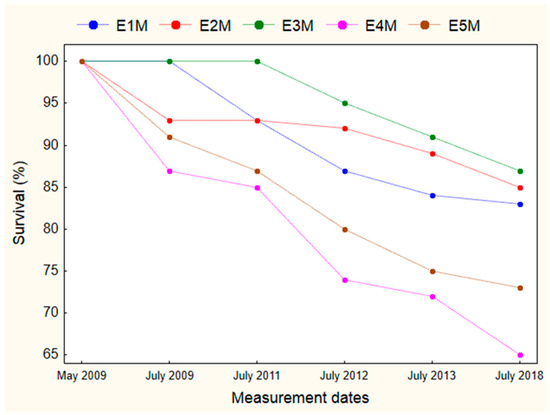

Regarding the survival of the plants, Figure 5 shows the survival tendency of the ecotypes.

Figure 5.

Plant survival rate by ecotype in the studied site.

All the ecotypes maintained 100% survival of plants in the first months after the plants were planted until the first measurements made in May 2009, indicating a good adaptation to the conditions of the experimental plantation. However, in the second measurement carried out in July 2009, at four months of age of the plants in the experimental site, the loss of plants was almost 10% for the E2M and E5M ecotypes and 13% for the E4M ecotype.

In the measurements made in July 2012, at the third year of age of the plants, the greatest loss of plant occurred due to the presence of the borer pest (Diatraea saccharalis), mainly affecting the EM4 and E5M ecotypes.

Finally, among the measurements made in July 2013 and 2018, the loss of plants was minimal for the E1M, E2M and E5M ecotypes, while the E3M and E4M ecotypes showed a higher percentage of plant loss. However, in the last monitoring year, July 2018, the E3M ecotype showed the highest survival percentage with 87% followed by the E2M and E1M ecotypes with 85% and 83%, respectively, while the E4M and E5M ecotypes presented the lowest percentage of 65% and 73%, respectively.

3.2. Yield in the Production of Seeds, Biomass and Oil Content

Table 2 presents the production of seeds and biomass; two harvests of Jatropha curcas fruits were analyzed to estimate seed production. The first harvest of ripe fruit was made at 8 years of age of the plants, in the months of August and September in the year 2017. The highest fruit production was presented in the ecotypes E1M and E2M, for this reason the second harvest of fruit of the year 2018 was made only in these ecotypes.

Table 2.

Seed yield and biomass of nontoxic Jatropha curcas ecotypes. Same letters mean there are not significant differences according to ANOVA and Tukey test (p ≤ 0.05).

The production of ripe fruits was varied. According to the ANOVA and Tukey test (p ≤ 0.05), two groups with significant differences were shown. In the first group, the E2M and E1M ecotypes with the highest fruit production per plant were identified, the E2M ecotype with a yield of 0.81-kg plant and the E1M ecotype with 0.75-kg plant (see Table 2, column 2, letter A). In the second group, the ecotypes with the lowest productions were shown, E5M with 0.37-kg plant, E3M with 0.24-kg plant and E4M with 0.10-kg plant (see Table 2, column 2, letter B).

Consequently, the E2M and E1M ecotypes showed the highest fruit production per hectare with a potential of 1021 kg ha−1 for the E2M ecotype 946 kg ha−1 for the E1M ecotype considering the cultivation density of 1250 plants per hectare as is shown in Table 2, column 2.

It is important to mention that the amount of seeds contained in the fruit of Jatropha curcas varies between 3 and 4 units. The weight of the seeds represented between 64.1% and 70.3%, while the weight of the pericarp (fruit husk) represented between 29.7% and 35.9%, of the total weight of the fruits (see Table 2, columns 3 and 40.

In this way, the yield of seeds per plant in the ecotypes with the highest fruit production was 0.56 kg for the E2M ecotype and 0.49 kg for the E1M ecotype with a seed yield per hectare of 700 kg and 618 kg, respectively. The E5M, E3M and E4M ecotype presented the lowest yield of seeds per plant with yield of 0.25 kg, 0.17 kg and 0.06 kg, as well as the production potential per hectare of 318 kg, 213 kg and 74 kg, respectively (see Table 2 column 5).

Under a production scenario without irrigation and without the application of fertilizer and in conditions of precipitation and temperature similar to those presented in this study, the authors of [40] reported an elite variety of Jatropha curcas native to India that recorded yields of between 858.3 kg ha−1 and 922 kg ha−1, in the city of Bhavnagar, and between 69.4 kg ha−1 and 58.6 kg ha−1, in the city of Hyderabad, both plantations with a spacing of 2.5 m × 2.5 m.

The seed production per plant of the ecotypes identified as the most productive, E2M and E1M, is higher than the production reported Naresh et al. [41] in the city of Hyderabad, where its four best varieties produced between 0.24-kg plant and 0.39-kg plant.

So, if the nontoxic property is taken into account in terms of the seed yields of E1M and E2M ecotypes, these are attractive to promote programs of crop improvement in order to increase their seed production to produce biodiesel and benefit of the nontoxicity of these ecotypes to have the possibility to produce food products.

Regarding other features of the Jatropha curcas production, the endosperm represents 55.8–60.5% of the weight of the seed, as is shown in Table 2, column 7. According to the ANOVA and Tukey tests (p ≤ 0.05), there are significant differences between the ecotypes with higher and lower percentage of endosperm. The weight percentage of the endosperm is higher in the E1M with 60.5% of the weight of the seed than for the E2M with 58.8% of the weight of the seed and its potential for endosperm production per hectare is 411 kg ha−1 for E2M and 376 kg ha−1 for the E1M.

The pericarp and tegument are biomass that covers the seed and the endosperm, respectively; they are not considered a relevant product. However, the weight of both biomasses represents 60% of the weight of fruit production so this percentage suggests that it is important to consider this biomass as another valuable product of Jatropha curcas crops. According to the authors of [2], the pericarp and tegument biomass could be appropriate supply for pyrolysis and gasification to generate heat and/or power.

In the most productive ecotypes, E2M and E1M, they present a pericarp and tegument biomass yield of 612 kg ha−1 and 570 kg ha−1 respectively (see Table 2, column 9).

The Table 3 shows the oil yields obtained by mechanical extraction and the average oil content was 44.8–52.2% with respect to the weight of the endosperm of the seed and from 26.1–31.5% with respect to the total weight of the seed (weight of tegument and endosperm).

Table 3.

Oil content and endosperm cake yield of nontoxic Jatropha curcas ecotypes. Same letters mean there are not significant differences according to the ANOVA and Tukey tests (p ≤ 0.05).

According to the ANOVA and Tukey tests (p ≤ 0.05), there were significant differences between the ecotypes with higher and lower percentage of oil extraction. The E1M presented the highest percentage of oil extraction with 52.2% with respect to the weight of the endosperm and 31.5% with respect to the weight of the seed, while E2M presented a low yield of 46.5% with respect to the weight of the endosperm and 27.3% with respect to the weight of the seed, as is shown in Table 3, column 2.

This way, the oil extraction yields obtained in these ecotypes are in the range of the percentages reported for different varies of Jatropha curcas; from 45–70% by weight of oil with respect to the weight of the endosperm and 20–50% as a function of the seed weight [2]. In the same way as in the oil extraction yield, the E1M ecotype has the highest oil yield of 196 kg ha−1 followed by the E2M ecotype with 191 kg ha−1.

On the other hand, the residual endosperm cake—the extruded endosperm resulting from the oil extraction—is higher for the E2M ecotype, with 53.5% of the endosperm weight with an endosperm cake yield of 220 kg ha−1; and in the E1M ecotype the endosperm cake represent 47.8% of the weight of the endosperm and a potential of 180 kg ha−1 (see Table 3, column 3). The endosperm cake percentage is similar to the reported by Naresh et al. [41], which is between 49–58%.

As can be seen, the endosperm cake percentage of these ecotypes is a high amount of waste that could be used to produce food products especially in nontoxic Jatropha curcas varieties.

Finally, since the E1M and E2M ecotypes showed the best growth result of biophysical parameters, productivity and seed yield, an analysis of the physicochemical properties of the oil and endosperm of these ecotypes was carried out to determine if they are a suitable raw material to produce biodiesel in the case of oil, and the possible use for food in the case of the endosperm.

3.3. Oil Physicochemical Properties

The physicochemical features of the fatty acids from E1M and E2M ecotypes are presented in Table 4. For the two ecotypes, the density and the specific gravity of the oil, at 15 °C, the value is 0.91 g cm−13. Indeed, the oil should have a low density for the biodiesel production. In case of the oil obtained from E1M and E2M, the density is slightly higher considering the result of 0.90 g cm−13 as reported by Coutinho et al. and Helwani et al. [42,43]. However, our results are similar to those reported by Kamel et al. [44].

Table 4.

Physical properties, fatty acids composition of the oil and chemical composition of endosperm of nontoxic ecotypes E1M and E2M.

Certainly, the viscosity of the oil of the ecotypes E1M and E2M at 40 °C is similar in both samples, 31.88 cst and 31.66 cst, respectively. These results indicate that the oil from these ecotypes has good quality considering the recommendation of 34–42.88 cst by the authors [41,42,44], due to a low oil viscosity is preferable to obtain suitable properties in the biodiesel for it use in engines.

The oil of both ecotypes also shows values of calorific power desirable to produce biodiesel. The calorific power of both ecotypes of 39.4 MJ kg−1, is higher than the values reported in [45,46] of 37.1 MJ kg−1 and 38.5 MJ kg−1.

The composition of the oil is similar among the ecotypes, presenting a high proportion of unsaturated fatty acid, 80.1% and 80.3%, respectively. Oleic acid is the most predominant with 42.1% and 40.1% followed by linoleic acid with 36.7% and 39.3%, respectively.

The composition of saturated fatty acids is 19.7% and 19.4% with a higher proportion of palmitic acid 10.2% and 11.2%, followed by stearic acid 8.9% and 7.4%, respectively. These results are in accordance with the scientific literature where oleic, linoleic, palmitic and stearic fatty acids are the most abundant in Jatropha curcas oil, with oleic acid the highest proportion [47,48]. This composition is also presented in other varieties studied in Mexico by Martínez-Herrera et al. and Sánchez-Arreola et al. [20,33].

Indeed, it is expected that the high content of monounsaturated fatty acids provides quality to biodiesel; according to author of [48] these compounds allows improving the number of cetane in biodiesel and can offer a strong effect on oxidation stability and the shelf life of oil and biodiesel.

3.4. Endosperm Chemical Properties

The chemical composition of the endosperm is presented in Table 4; the crude protein content is higher in the E2M ecotype with 26.0% of crude protein while for the ecotype E1M the crude protein content was 21.7%.

The crude protein composition of the E2M ecotype is within the range of 23.7–27.2%, reported for varieties from different parts of the world [49], as well as, that reported for Mexican varieties, from 23.2–31.9% [23,32,50].

Although the crude protein content of the E2M and E1M ecotypes is lower than that reported for the Morelos state varieties; 32.1% for the municipality of Yautepec and 29.7% for the municipality of Cuautla [23,33], it is comparable with the crude protein content of other food such as rapeseed (19%), karanja (22%), sesame (25.2%), squash (26.5%), sunflower (23%) and peanut (26%).

Regarding total fats the percentage for the ecotypes E2M is 63.3% and for the ecotype E1M it is 60.9%; these percentages are higher than those of other varieties in different parts of the world that are between 42.9–59.0% [49] and in relation to the Mexican varieties that are in the range of 51.1–64.5% [23,32,33]. The content of total fats is also higher than the values reported in the varieties of the municipalities of Yautepec (55.3%) and Cuautla (58.7%), in the state of Morelos.

The crude fiber content is higher in E1M with 10.7% and 4% for E2M. The crude fiber content of the E1M is higher than other varieties of the world of 3.8–6.1% [49] and in relation to the Mexican varieties that have percentages of 2.8–5.3% [23,33].

The fiber content of E2M is similar to that reported in the Cuautla, Morelos variety with a value of 4% and higher than the value reported in Yautepec, Morelos variety of 3.1%.

The ecotypes had a high content of dietary fiber; of 34% for the E2M ecotype and 36.2% for the E1M ecotype. These contents have not been reported in other studies.

The ash content was similar for both ecotypes; 2.9% for E2M ecotype and 2.8% for E1M ecotype. These values are below than reported range for varieties from different parts of the world ranging from 3.4–5.0% [49] and from Mexican varieties from 3.6–5.8% [23,32,33].

The gross energy content in the endosperm is greater in the E2M ecotype (28.7 MJ kg−1) than in the E1M ecotype (27.3 MJ kg−1). The energy content provided by these ecotypes is slightly lower than those reported for varieties from different parts of the world that are between 28.9–31.2 MJ kg−1 [49], although they are among the values reported in Mexican varieties from 26.5–31.6 MJ kg−1 [23,33].

In summary, the levels of crude protein, crude fiber, lipids and energy suggest that the endosperm of the seeds of the E1M and E2M ecotypes have adequate characteristics to be a good source of protein for human or animal consumption. In this way, the extruded endosperm from oil extraction can be a product with a significant economic value.

3.5. Changes in the Chemical Properties of the Soil

A poor soil in organic matter cannot support a healthy growth of any plant life. For this reason, increasing the organic matter in the soil composition certainly improves the quality and the availability of plant nutrients. Otherwise, the presence of organic matter in the soil is an important factor for a higher and better productivity of Jatropha curcas.

The changes in the physicochemical properties of the soil of the experimental plot are reported in Table 5. In all the monitored years, the percentage of clay was dominant in the texture of the soil, followed by silt and, in a lower percentage, sand. Being a clay soil, this was beneficial for Jatropha curcas plants, because clay soil can retain water and nutrients.

Table 5.

Soil properties of the experimental plot, before planted the seedling (2008) and nine years after plantation (2018).

In relation to the pH of the soil, initially, the pH was 7.6 and at the end of the study it was 7.9 in such a way that, according to the reference values of NOM-021-SEMARNAT-2000, the pH of the soil maintained slightly alkaline values throughout the study period.

In the same way, the electrical conductivity (CE) maintained values of low salinity; starting at 0.5 ds m−1 and ending at 0.4 ds m−1, so that the decrease of C.E was not substantial.

In the composition of organic matter (OM) an increase was observed in the monitored years. In the first measurement of the year 2008 the value of OM was 2.8%, increasing by 20% for the last year of study, to finish with 3.5% of OM. The increase in the content of organic matter is influenced by plant residues of the leaves of the Jatropha curcas plants that fell to the ground during the dormancy period as well as the grass and grass residues that grew in the experimental plot.

The OM composition of the experimental plot soil was maintained in medium range of %OM, from 1.6–3.5%, according to the reference values of NOM-021-SEMARNAT-2000. However, the percentage of MO at the end of the study was placed at the limit value to move to the high %OM classification, 3.6–6.0%.

The macronutrients showed increases throughout the study, nitrogen (N) and potassium (K) showed a considerable increase between the first and second measurement, going from 6.0 mg kg−1 to 9.1 mg kg−1 of N and 216 mg kg−1 to 364 mg kg−1 of K. According to the reference value of NOM-021-SEMARNAT-2000, the concentration of N remained at the very low level. However, the final concentration is higher than in the first measurement.

The changes in K concentration were from medium to high level between the first and the second measurement. In the case of phosphorus (P), it presented an increase of 7.0 mg kg−1 to 10.7 mg kg−1 but remained at medium level to the reference values.

The aforementioned increases in the content of organic matter and nutrients may be related to the interaction of Jatropha curcas plant with fauna, such as insects, pollinators, rodents and birds, flora and various organisms that came to be established along the years in which the plantation has been maintained. In this way, these results coincide with the study carried out by the authors of [8] that identified that Jatropha plantations provide eco-systemic services that support the soil nutrient cycle.

The results obtained suggest that the cultivation of the E1M and E2M ecotypes of Jatropha curcas can maintain and increase the organic matter of the soil as well as favor the reserve of nutritious elements promoting soil improvement. All these results are relevant in terms of rehabilitation of rural marginal soils as is the case of our experimental plantation in Morelos.

The features of nontoxic Jatropha curcas could be used as an additional benefit to the use of oil, endosperm cake and residual biomass.

4. Conclusions

According to the results of this study, two nontoxic ecotypes of Jatropha curcas (E1M and E2M) were identified as the best sustainable raw materials with the highest potential for the production of biodiesel in the Mexican Morelos state. The secondary products from the seed residues, after oil extraction, increase the value of the crops: the production of energy from residual biomass (pericarp and tegument) is an added value; the production of food products from the endosperm cake; and the improvement of the chemical properties of the soil during the cultivation process in marginal soils that have been abandoned in Morelos state.

Future studies of concerning life cycle assessment are required to establish the environmental impact of Jatropha curcas farming, oil extraction processes, and biomass residue usages. Additionally, the whole production process should be evaluated for developing a comprehensive technological and economic package of sustainable feasibility for the cultivation of the selected ecotypes.

Supplementary Materials

The following are available online at https://www.mdpi.com/2071-1050/11/20/5823/s1, Table S1: Growth evaluation of nontoxic ecotypes of Jatropha curcas by means of biophysical parameters at different plant ages in plantation.

Author Contributions

Conceptualization, J.I.; Data curation, G.P. and M.G.; Formal analysis, G.P., J.I. and M.G.; Investigation, G.P. and J.I.; Methodology, G.P. and J.I.; Supervision, J.I., M.G. and R.S.; Validation, M.G. and R.S.; Writing—original draft, G.P.; Writing—review & editing, G.P., J.I., M.G. and R.S.

Funding

This research was funded by the Project Program for Technological Research and Innovation of the National Autonomous University of Mexico through the projects PAPIIT-IT110911, PAPIIT-IT101214 and PAPIIT IN102216, and the Mexican National Council of Science and Technology (CONACYT) for granting scholarship CVU No. 490087 for the first author.

Acknowledgments

The authors would like to thanks to María de Jesús Pérez Orozco and Jorge Ramírez Guerrero, (IER-UNAM), for the technical support in building database and to Rogelio Morán Elvira for the technical support in oil analysis. A special acknowledgment to Ivonne Toledo García from Center for Genomic Sciences-UNAM for supporting us to propagate the germplasm, and to M. Javier Cruz Gómez and Fernando de Jesús Rosas Ramírez from the Faculty of Chemistry-UNAM for the use of HPLC facilities.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lim, B.Y.; Shamsudin, R.; Baharudin, B.T.; Yunus, R. A Review of Processing and Machinery for Jatropha curcas L. Fruits and Seeds in Biodiesel Production: Harvesting, Shelling, Pretreatment and Storage. Renew. Sustain. Energy Rev. 2015, 52, 991–1002. [Google Scholar] [CrossRef]

- Navarro-Pineda, F.S.; Baz-Rodríguez, S.A.; Handler, R.; Sacramento-Rivero, J.C. Advances on the Processing of Jatropha curcas towards a Whole-Crop Biorefinery. Renew. Sustain. Energy Rev. 2016, 54, 247–269. [Google Scholar] [CrossRef]

- Achten, W.M.; Verchot, L.; Franken, Y.J.; Mathijs, E.; Singh, V.P.; Aerts, R.; Muys, B. Jatropha Bio-Diesel Production and Use. Biomass Bioenergy 2008, 32, 1063–1084. [Google Scholar] [CrossRef]

- Fini, A.; Bellasio, C.; Pollastri, S.; Tattini, M.; Ferrini, F. Water Relations, Growth, and Leaf Gas Exchange as Affected by Water Stress in Jatropha curcas. J. Arid Environ. 2013, 89, 21–29. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.; Masjuki, H.H.; Norhasyima, R.S. Comparison of Palm Oil, Jatropha curcas and Calophyllum inophyllum for Biodiesel: A Review. Renew. Sustain. Energy Rev. 2011, 15, 3501–3515. [Google Scholar] [CrossRef]

- Wani, S.P.; Chander, G.; Sahrawat, K.L.; Srinivasa, R.C.; Raghvendra, G.; Susanna, P.; Pavani, M. Carbon Sequestration and Land Rehabilitation through Jatropha curcas (L.) Plantation in Degraded Lands. Agric. Ecosyst. Environ. 2012, 161, 112–120. [Google Scholar] [CrossRef]

- Reubens, B.; Achten, W.M.; Maes, W.H.; Danjon, F.; Aerts, R.; Poesen, J.; Muys, B. More than Biofuel? Jatropha Curcas Root System Symmetry and Potential for Soil Erosion Control. J. Arid Environ. 2011, 75, 201–205. [Google Scholar] [CrossRef]

- Mantri, V.A.; Parmar, D.R.; Rao, P.N.; Ghosh, A. Observations on Ecosystem Services in Jatropha curcas Plantations Established in Degraded Lands in India. Int. J. Environ. Stud. 2014, 71, 209–214. [Google Scholar] [CrossRef]

- Borman, G.D.; Von Maltitz, G.P.; Tiwari, S.; Scholes, M.C. Modelling the Economic Returns to Labour for Jatropha Cultivation in Southern Africa and India at Different Local Fuel Prices. Biomass Bioenergy 2013, 59, 70–83. [Google Scholar] [CrossRef]

- Dawa, A.; Klemola, T.; Saloniemi, I.; Niemelä, P.; Vuorisalo, T. Energy for Sustainable Development Factors Affecting Genetic and Seed Yield Variability of Jatropha curcas (L.) across the Globe: A Review. Energy Sustain. Dev. 2017, 42, 170–182. [Google Scholar] [CrossRef]

- Singh, K.; Singh, B.; Verma, S.K.; Patra, D.D. Jatropha curcas: A Ten Year Story from Hope to Despair. Renew. Sustain. Energy Rev. 2014, 35, 356–360. [Google Scholar] [CrossRef]

- Rivero, J.C.; Eastmond-Spencer, A.; García, J.B.; Navarro-Pineda, F.S. A Three-Dimensional Sustainability Evaluation of Jatropha Plantations in Yucatan, Mexico. Sustainablity 2016, 8, 1316. [Google Scholar] [CrossRef]

- Wang, Z.; Calderon, M.M.; Lu, Y. Lifecycle Assessment of the Economic, Environmental and Energy Performance of Jatropha curcas L. Biodiesel in China. Biomass Bioenergy 2011, 35, 2893–2902. [Google Scholar] [CrossRef]

- Jabłoński, S.J.; Kułażyński, M.; Sikora, I.; Łukaszewicz, M. The Influence of Different Pretreatment Methods on Biogas Production from Jatropha curcas Oil Cake. J. Environ. Manag. 2017, 203, 714–719. [Google Scholar] [CrossRef] [PubMed]

- Manurung, R.; Wever, D.Z.; Wildschut, J.; Venderbosch, R.H.; Hidayat, H.; van Dam, J.E.; Leijenhorst, E.J.; Broekhuis, A.A.; Heeres, H.J. Valorisation of Jatropha curcas L. Plant Parts: Nut Shell Conversion to Fast Pyrolysis Oil. Food Bioprod. Process. 2009, 87, 187–196. [Google Scholar] [CrossRef]

- Naik, D.V.; Kumar, R.; Tripathi, D.; Singh, R.; Kanaujia, P.K. Co-Pyrolysis of Jatropha Curcas Seed Cake and Bituminous Coal: Product Pattern Analysis. J. Anal. Appl. Pyrolysis 2016, 121, 360–368. [Google Scholar] [CrossRef]

- Wever, D.A.; Heeres, H.J.; Broekhuis, A.A. Characterization of Physic Nut (Jatropha curcas L.) Shells. Biomass Bioenergy 2012, 37, 177–187. [Google Scholar] [CrossRef]

- León-Villanueva, A.; Huerta-Ocampo, J.A.; Barrera-Pacheco, A.; Medina-Godoy, S.; Barba de la Rosa, A.P. Proteomic Analysis of Non-Toxic Jatropha curcas Byproduct Cake: Fractionation and Identification of the Major Components. Ind. Crops Prod. 2018, 111, 694–704. [Google Scholar] [CrossRef]

- Makkar, H.P.; Becker, K. Jatropha Curcas, a Promising Crop for the Generation of Biodiesel and Value-Added Coproducts. Eur. J. Lipid Sci. Technol. 2009, 111, 773–787. [Google Scholar] [CrossRef]

- Sánchez-Arreola, E.; Martin-Torres, G.; Lozada-Ramírez, J.D.; Hernández, L.R.; Bandala-González, E.R.; Bach, H. Biodiesel Production and de-Oiled Seed Cake Nutritional Values of a Mexican Edible Jatropha Curcas. Renew. Energy 2015, 76, 143–147. [Google Scholar] [CrossRef]

- Martínez-Díaz, Y.; González-Rodríguez, A.; Delgado-Lamas, G.; Espinosa-García, F.J. Geographic Structure of Chemical Variation in Wild Populations of the Fuel Crop Jatropha curcas L. in Mexico. Ind. Crops Prod. 2015, 74, 63–68. [Google Scholar] [CrossRef]

- He, W.; King, A.J.; Khan, M.A.; Cuevas, J.A.; Ramiaramanana, D.; Graham, I.A. Analysis of Seed Phorbol-Ester and Curcin Content Together with Genetic Diversity in Multiple Provenances of Jatropha curcas L. from Madagascar and Mexico. Plant Physiol. Biochem. 2011, 49, 1183–1190. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Herrera, J.; Martíne Ayala, A.; Makkar, H.; Francis, G.; Becker, K. Agroclimatic Conditions, Chemical and Nutritional Characterization of Different Provenances of Jatropha curcas L. from Mexico. Eur. J. Sci. Res. 2010, 39, 396–407. [Google Scholar]

- Aregheore, E.M.; Makkar, H.P.; Becker, K. Assessment of Lectin Activit Y in a Toxic and a Non-Toxic Variety of Jatropha curcas Using Latex Agglutination and Haemagglutination Methods and Inactivation of Lectin by Heat Treatments. J. Sci. Food Agric. 1998, 77, 349–352. [Google Scholar] [CrossRef]

- Goel, G.; Makkar, H.P.; Francis, G.; Becker, K. Phorbol Esters: Structure, Biological Activity, and Toxicity in Animals. Int. J. Toxicol. 2007, 26, 279–288. [Google Scholar] [CrossRef]

- Saetae, D.; Suntornsuk, W. Toxic Compound, Anti-Nutritional Factors and Functional Properties of Protein Isolated from Detoxified Jatropha curcas Seed Cake. Int. J. Mol. Sci. 2011, 12, 66–77. [Google Scholar] [CrossRef]

- Kumar, V.; Makkar, H.P.; Amselgruber, W.; Becker, K. Physiological, Haematological and Histopathological Responses in Common Carp (Cyprinus carpio L.) Fingerlings Fed with Differently Detoxified Jatropha curcas Kernel Meal. Food Chem. Toxicol. 2010, 48, 2063–2072. [Google Scholar] [CrossRef]

- Makkar, H.P. State-of-the-Art on Detoxification of Jatropha curcas Products Aimed for Use as Animal and Fish Feed: A Review. Anim. Feed Sci. Technol. 2016, 222, 87–99. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H. Comparative Evaluation of Jatropha curcas L. Seed Meals Obtained by Different Methods of Defatting on Toxic, Antinutritional and Nutritive Factors. J. Food Sci. Technol. 2014, 51, 1126–1132. [Google Scholar] [CrossRef][Green Version]

- Xiao, J.; Zhang, H.; Niu, L.; Wang, X.; Lu, X. Evaluation of Detoxification Methods on Toxic and Antinutritional Composition and Nutritional Quality of Proteins in Jatropha curcas Meal. J. Agric. Food Chem. 2011, 59, 4040–4044. [Google Scholar] [CrossRef]

- Pecina-Quintero, V.; Anaya-López, J.L.; Zamarripa-Colmenero, A.; Núñez-Colín, C.A.; Montes-García, N.; Solís-Bonilla, J.L.; Jiménez-Becerril, M.F. Genetic Structure of Jatropha curcas L. in Mexico and Probable Centre of Origin. Biomass Bioenergy 2014, 60, 147–155. [Google Scholar] [CrossRef]

- Makkar, H.P.; Becker, K.; Schmook, B. Edible Provenances of Jatropha curcas from Quintana Roo State of Mexico and Effect of Roasting on Antinutrient and Toxic Factors in Seeds. Plant Foods Hum. Nutr. 1998, 52, 31–36. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Herrera, J.; Siddhuraju, P.; Francis, G.; Dávila-Ortíz, G.; Becker, K. Chemical Composition, Toxic/antimetabolic Constituents, and Effects of Different Treatments on Their Levels, in Four Provenances of Jatropha curcas L. from Mexico. Food Chem. 2006, 96, 80–89. [Google Scholar] [CrossRef]

- Oliveira, P.B.; Lima, P.M.; Campeche, A.; Mendonça, S.; Laviola, B.G.; McManus, C.; Louvandini, H. Growth and Carcass Characteristics of Santa Inês Lambs Fed Diet Supplemented with Physic Nut Meal Free of Phorbol Ester. Small Rumin. Res. 2013, 114, 20–25. [Google Scholar] [CrossRef]

- Kumar, N.; Singh, A.S.; Kumari, S.; Reddy, M.P. Biotechnological Approaches for the Genetic Improvement of Jatropha curcas L.: A Biodiesel Plant. Ind. Crops Prod. 2015, 76, 817–828. [Google Scholar] [CrossRef]

- Laviola, B.G.; Rodrigues, E.V.; Teodoro, P.E.; Peixoto, L.A.; Bhering, L.L. Biometric and Biotechnology Strategies in Jatropha Genetic Breeding for Biodiesel Production. Renew. Sustain. Energy Rev. 2017, 76, 894–904. [Google Scholar] [CrossRef]

- Senger, E.; Martin, M.; Dongmeza, E.; Montes, J.M. Genetic Variation and Genotype by Environment Interaction in Jatropha curcas L. Germplasm Evaluated in Different Environments of Cameroon. Biomass Bioenergy 2016, 91, 12–18. [Google Scholar] [CrossRef]

- Haas, W.; Sterk, H.; Mittelbach, M. Novel 12-Deoxy-16-Hydroxyphorbol Diesters Isolated from the Seed Oil of Jatropha curcas. J. Nat. Prod. 2002, 65, 1434–1440. [Google Scholar] [CrossRef]

- Islas, J.M.; Manzini, F.L.; Martinez, E.; Pérez, M.J.; Toledo, I.I. Base de Datos de Parametros Biofísicos de 15 Ecotipos de Jatropha Curcas de la Plantación Experimental de Miacatlán, Morelos; Número de Registro de la Base de Datos: 03-2013-020113160600-01; Registro Público Del Derecho de Autor: Puebla, México, 2013.

- Singh, B.; Singh, K.; Rejeshwar Rao, G.; Chikara, J.; Kumar, D.; Mishra, D.K.; Saikia, S.P.; Pathre, U.V.; Raghuvanshi, N.; Rahi, T.S.; et al. Agro-Technology of Jatropha curcas for Diverse Environmental Conditions in India. Biomass Bioenergy 2013, 48, 191–202. [Google Scholar] [CrossRef]

- Naresh, B.; Reddy, M.S.; Vijayalakshmi, P.; Reddy, V.; Devi, P. Physico-Chemical Screening of Accessions of Jatropha curcas for Biodiesel Production. Biomass Bioenergy 2012, 40, 155–161. [Google Scholar] [CrossRef]

- Coutinho, D.J.; Barbosa, M.O.; de Souza, R.J.; da Silva, A.S.; da Silva, S.I.; de Oliveira, A.F. Biodiesel Potential of the Seed Oils from Some Brazilian Native Euphorbiaceae Species. Renew. Energy 2016, 91, 275–281. [Google Scholar] [CrossRef]

- Helwani, Z.; Aziz, N.; Kim, J.; Othman, M.R. Improving the Yield of Jatropha Curcas’s FAME through Sol-Gel Derived Meso-Porous Hydrotalcites. Renew. Energy 2016, 86, 68–74. [Google Scholar] [CrossRef]

- Kamel, D.A.; Farag, H.A.; Amin, N.K.; Zatout, A.A.; Ali, R.M. Smart Utilization of Jatropha (Jatropha curcas Linnaeus) Seeds for Biodiesel Production: Optimization and Mechanism. Ind. Crops Prod. 2018, 111, 407–413. [Google Scholar] [CrossRef]

- Dharma, S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Silitonga, A.S.; Kusumo, F.; Mahlia, T.M. Optimization of Biodiesel Production Process for Mixed Jatropha curcas-Ceiba Pentandra Biodiesel Using Response Surface Methodology. Energy Convers. Manag. 2016, 115, 178–190. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Kinetics of Acid Base Catalyzed Transesterification of Jatropha curcas Oil. Bioresour. Technol. 2010, 101, 7701–7706. [Google Scholar] [CrossRef]

- Kaushik, N.; Bhardwaj, D. Screening of Jatropha curcas Germplasm for Oil Content and Fatty Acid Composition. Biomass Bioenergy 2013, 58, 210–218. [Google Scholar] [CrossRef]

- Pedro, I.; Andrade, D.S.; Vinícius, M.; Diego, A. Fatty Acid Composition of Jatropha curcas Seeds under Different Agronomical Conditions by Means of 1H HR-MAS NMR. Biomass Bioenergy 2017, 101, 30–34. [Google Scholar] [CrossRef]

- Makkar, H.P.; Becker, K.; Sporer, F.; Wink, M. Studies on Nutritive Potential and Toxic Constituents of Different Provenances of Jatropha curcas. J. Agric. Food Chem. 1997, 45, 3152–3157. [Google Scholar] [CrossRef]

- Marrufo-Estrada, D.M.; Segura-Campos, M.R.; Chel-Guerrero, L.A.; Betancur-Ancona, D.A. Defatted Jatropha curcas Flour and Protein Isolate as Materials for Protein Hydrolysates with Biological Activity. Food Chem. 2013, 138, 77–83. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).