Embodied Energy Flow Patterns of the Internal and External Industries of Manufacturing in China

Abstract

:1. Introduction

2. Model Construction

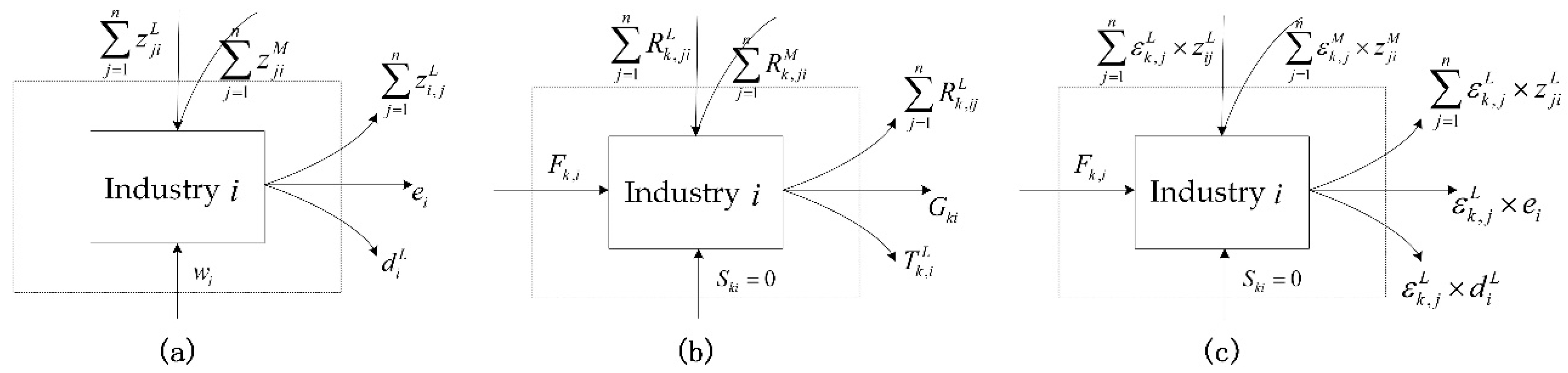

2.1. Embodied Energy Flow Model

2.2. Embodied Energy Flow Network

3. Samples and Data

4. Results and Discussion

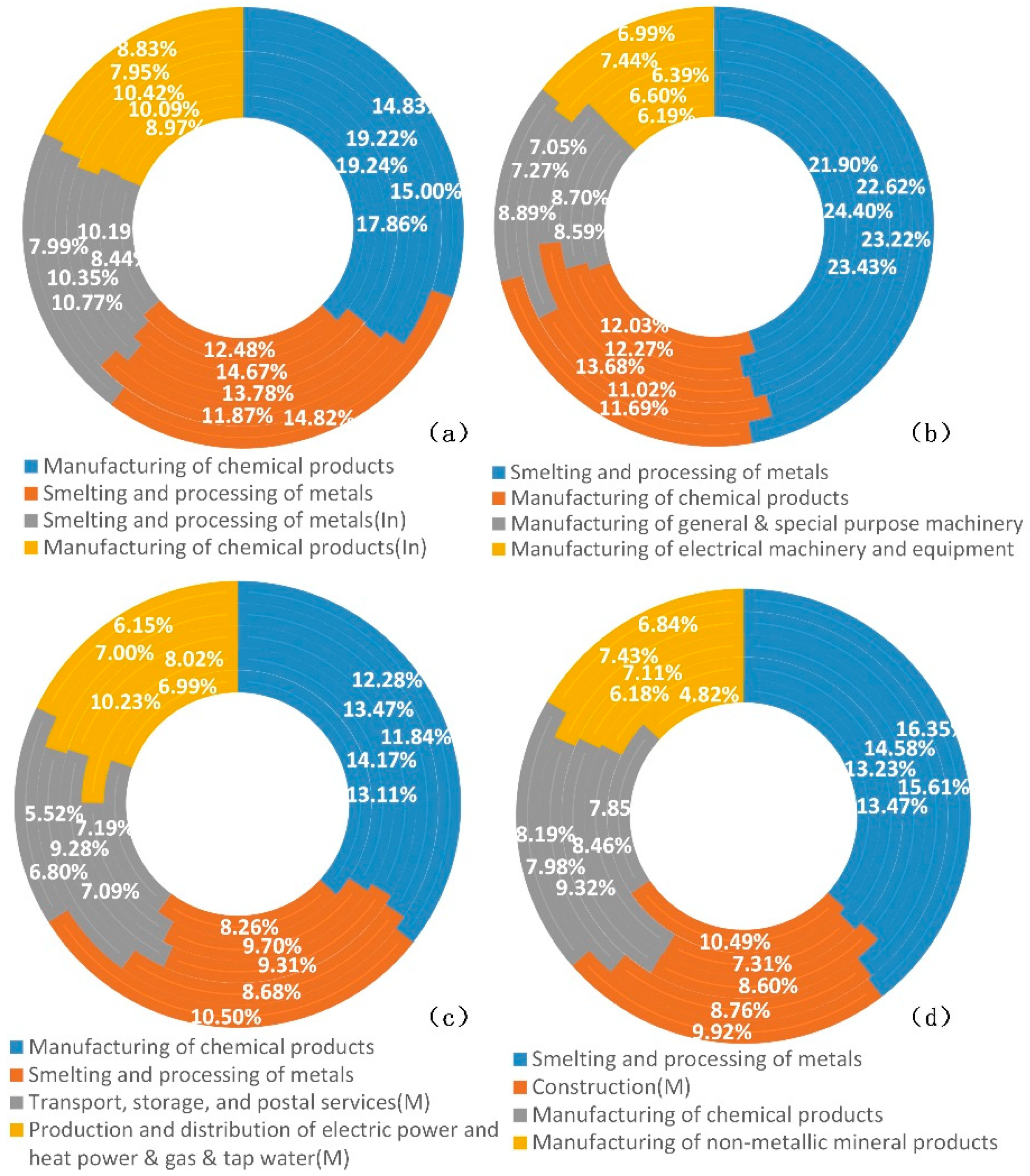

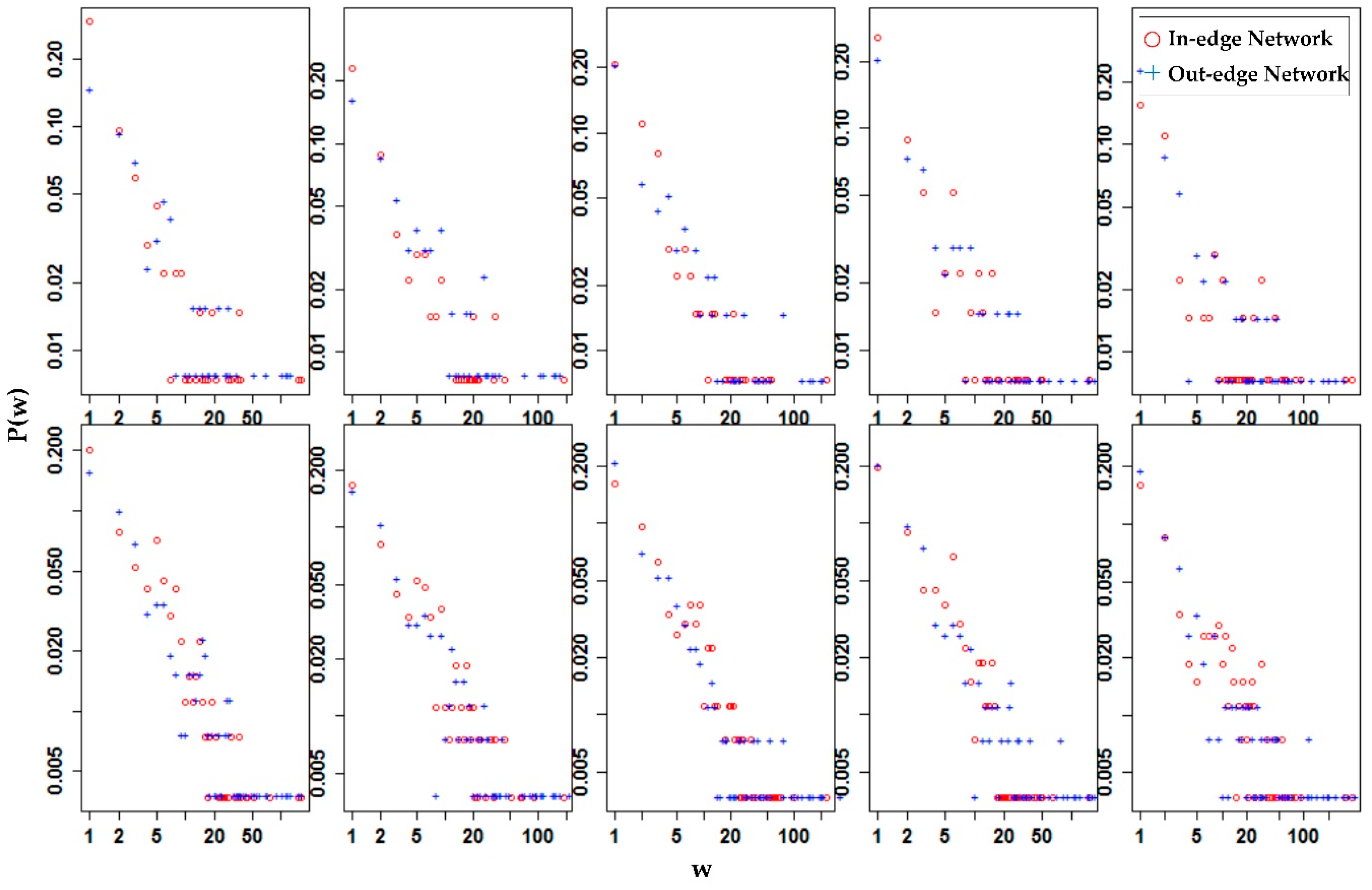

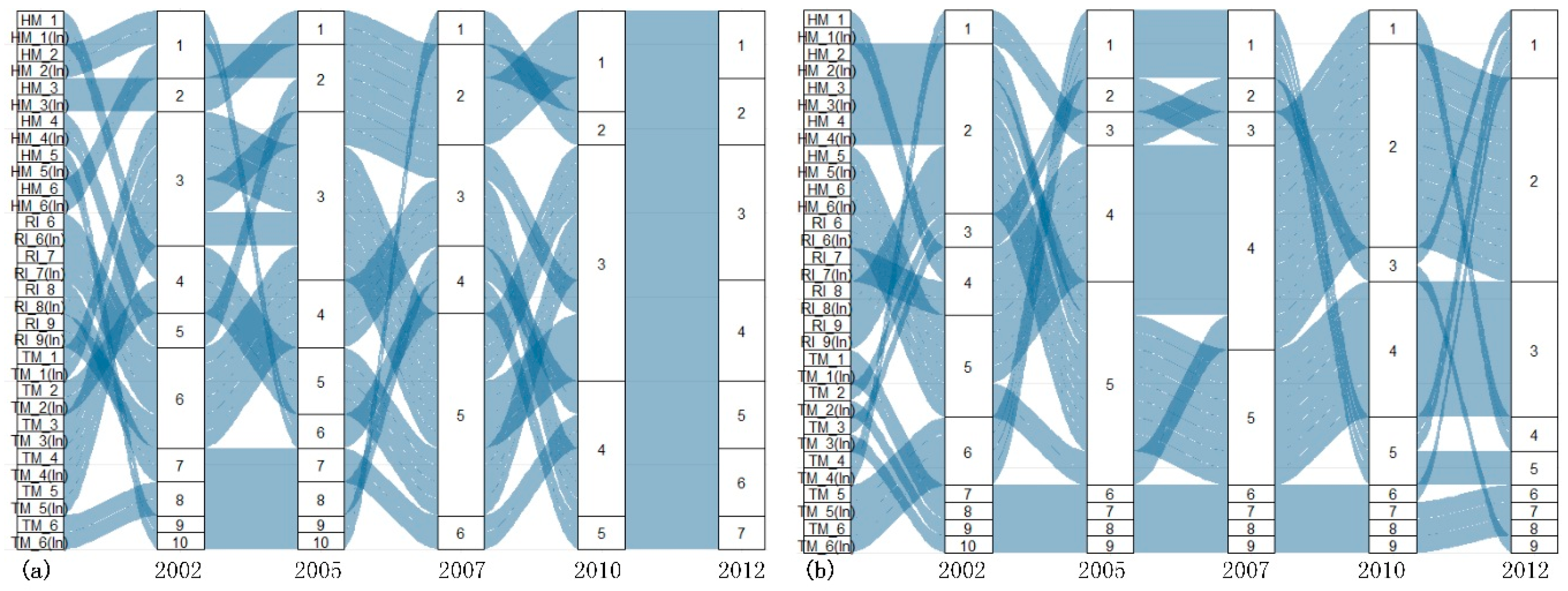

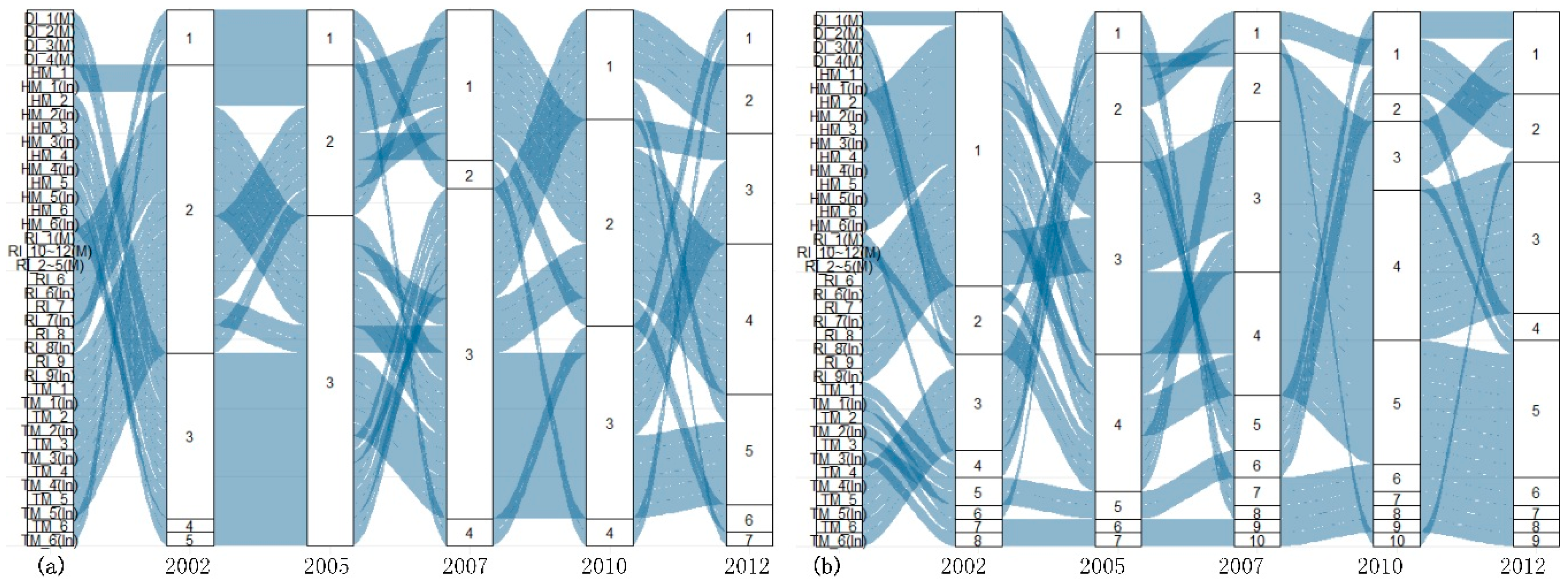

4.1. Structural Features of Embodied Energy Flow Network of China’s Manufacturing Industry

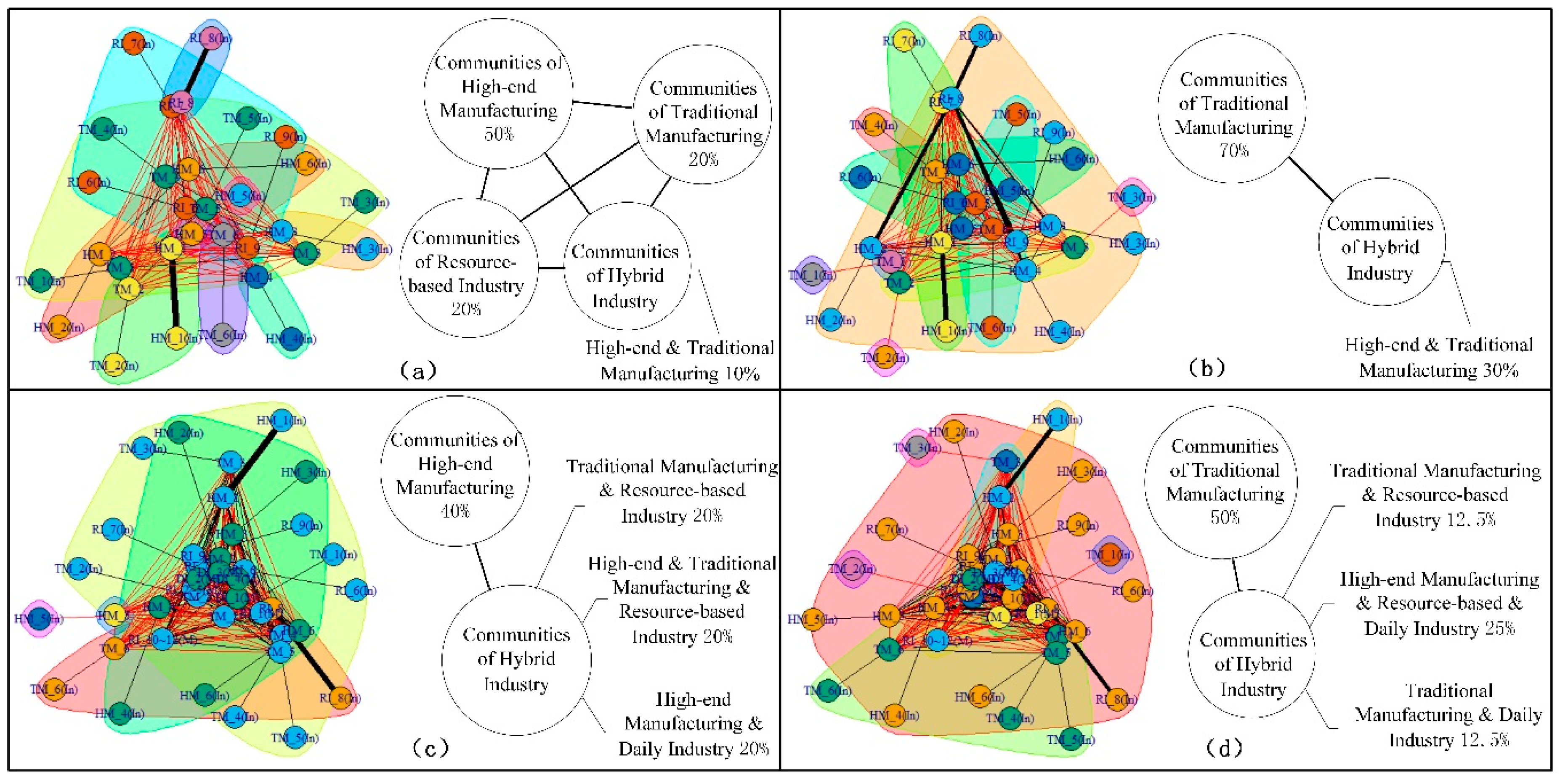

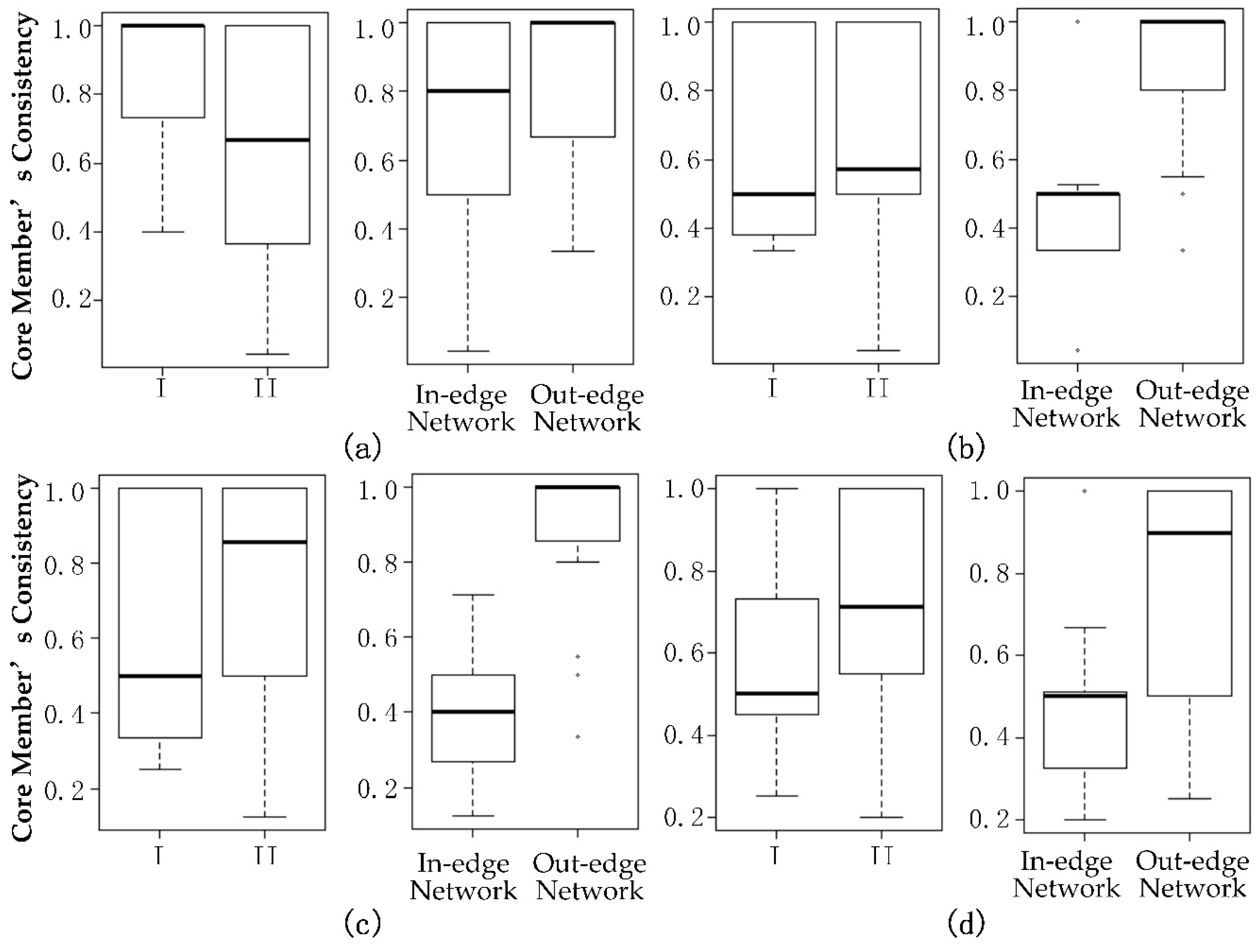

4.2. Evolution of Embodied Energy Flow Patterns in China’s Manufacturing Industry

5. Conclusions and Policy Recommendations

5.1. Conclusions

5.2. Policy Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zeng, B.; Duan, H.; Bai, Y.; Meng, W. Forecasting the output of shale gas in China using an unbiased grey model and weakening buffer operator. Energy 2018, 151, 238–249. [Google Scholar] [CrossRef]

- Tian, Y.; Xiong, S.; Ma, X.; Ji, J. Structural path decomposition of carbon emission: A study of China’s manufacturing industry. J. Clean. Prod. 2018, 193, 563–574. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Statistical Yearbook; National Bureau of Statistics of China: Beijing, China, 2017.

- Zeng, B.; Zhou, M.; Zhang, J. Forecasting the Energy Consumption of China’s Manufacturing Using a Homologous Grey Prediction Model. Sustainability 2017, 9, 1975. [Google Scholar] [CrossRef]

- Hou, J.; Chen, H.; Xu, J. External Knowledge Sourcing and Green Innovation Growth with Environmental and Energy Regulations: Evidence from Manufacturing in China. Sustainability 2017, 9, 342. [Google Scholar] [CrossRef]

- Chen, X.; Gong, Z. DEA Efficiency of Energy Consumption in China’s Manufacturing Sectors with Environmental Regulation Policy Constraints. Sustainability 2017, 9, 210. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, G. Can Industrial Restructuring Significantly Reduce Energy Consumption? Evidence from China. Emerg. Mark. Financ. Trade 2018, 5, 1082–1095. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, H.; Liu, G.; Zeng, W. A Study on The Contribution of Industrial Restructuring to Reduction of Carbon Emissions in China During the Five Five-Year Plan Periods. J. Clean. Prod. 2018, 176, 629–635. [Google Scholar] [CrossRef]

- An, Q.; An, H.; Wang, L.; Gao, X.; Lv, N. Analysis of Embodied Exergy Flow between Chinese Industries Based on Network Theory. Ecol. Model. 2015, 318, 26–35. [Google Scholar] [CrossRef]

- Chen, B.; Li, J.; Wu, X.; Han, M.; Zeng, L.; Li, Z.; Chen, G. Global Energy Flows Embodied in International Trade: A Combination of Environmentally Extended Input-Output Analysis and Complex Network Analysis. Appl. Energy 2018, 210, 98–107. [Google Scholar] [CrossRef]

- Sun, X.; An, H.; Gao, X.; Jia, X.; Liu, X. Indirect Energy Flow between Industrial Sectors in China: A Complex Network Approach. Energy 2016, 94, 195–205. [Google Scholar] [CrossRef]

- Liu, H.; Xi, Y.; Guo, J.E.; Li, X. Energy Embodied in the International Trade of China: An Energy Input–Output Analysis. Energy Policy 2010, 38, 3957–3964. [Google Scholar] [CrossRef]

- Tao, F.; Xu, Z.; Duncan, A.A.; Xia, X.; Wu, X.; Li, J. Driving Forces of Energy Embodied in China-EU Manufacturing Trade from 1995 to 2011. Resour. Conserv. Recyl. 2018, 136, 324–334. [Google Scholar] [CrossRef]

- Yang, R.; Long, R.; Yue, T.; Shi, H. Calculation of Embodied Energy in Sino-USA Trade: 1997–2011. Energy Policy 2014, 72, 110–119. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Chen, M. Inter-Industry Transmission Network and Coordinated Emission Reduction of Industrial CO2 Emissions in China. China Pop. Resour. Environ. 2016, 4, 90–99. [Google Scholar]

- Shi, J.; Li, H.; Guan, J.; Sun, X.; Guan, Q.; Liu, X. Evolutionary Features of Global Embodied Energy Flow between Sectors: A Complex Network Approach. Energy 2017, 140, 395–405. [Google Scholar] [CrossRef]

- Chen, G.Q.; Wu, X.F. Energy Overview for Globalized World Economy: Source, Supply Chain and Sink. Renew. Sustain. Energy Rev. 2017, 69, 735–749. [Google Scholar] [CrossRef]

- Chen, Z.M.; Chen, G.Q. Demand-Driven Energy Requirement of World Economy 2007: A Multi-Region Input–Output Network Simulation. Commun. Nonlinear Sci. 2013, 18, 1757–1774. [Google Scholar] [CrossRef]

- Gao, C.; Su, B.; Sun, M.; Zhang, X.; Zhang, Z. Interprovincial Transfer of Embodied Primary Energy in China: A Complex Network Approach. Appl. Energy 2018, 215, 792–807. [Google Scholar] [CrossRef]

- Hao, X.; An, H.; Qi, H.; Gao, X. Evolution of the Exergy Flow Network Embodied in the Global Fossil Energy Trade: Based on Complex Network. Appl. Energy 2016, 162, 1515–1522. [Google Scholar] [CrossRef]

- Rocco, M.V.; Di Lucchio, A.; Colombo, E. Exergy Life Cycle Assessment of Electricity Production from Waste-To-Energy Technology: A Hybrid Input-Output Approach. Appl. Energy 2017, 194, 832–844. [Google Scholar] [CrossRef]

- Miller, J.; Foxon, T.J.; Sorrell, S. Exergy Accounting: A Quantitative Comparison of Methods and Implications for Energy-Economy Analysis. Energies 2016, 9, 947. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M.; Kiritsis, D. Energy Management in Manufacturing: From Literature Review to A Conceptual Framework. J. Clean. Prod. 2017, 167, 1464–1489. [Google Scholar] [CrossRef]

- Jovanović, B.; Filipović, J.; Bakić, V. Energy Management System Implementation in Serbian Manufacturing–Plan-Do-Check-Act Cycle Approach. J. Clean. Prod. 2017, 162, 1144–1156. [Google Scholar] [CrossRef]

- Kara, S.; Manmek, S.; Herrmann, C. Global Manufacturing and the Embodied Energy of Products. CIRP Ann. 2010, 59, 29–32. [Google Scholar] [CrossRef]

- Kara, S.; Ibbotson, S. Embodied Energy of Manufacturing Supply Chains. CIRP J. Manuf. Sci. Technol. 2011, 4, 317–323. [Google Scholar] [CrossRef]

- Andersen, J.P.; Hyman, B. Energy and Material Flow Models for the US Steel Industry. Energy 2001, 26, 137–159. [Google Scholar] [CrossRef]

- Zeng, B.; Liu, S. A self-adaptive intelligence gray prediction model with the optimal fractional order accumulating operator and its application. Math. Method Appl. Sci. 2017, 23, 1–15. [Google Scholar] [CrossRef]

- Zeng, B.; Li, C. Improved multi-variable grey forecasting model with a dynamic background-value coefficient and its application. Comput. Ind. Eng. 2018, 118, 278–290. [Google Scholar] [CrossRef]

- Zeng, B.; Tan, Y.; Xu, H.; Quan, J.; Wang, L.; Zhou, X. Forecasting the Electricity Consumption of CommercialSector in Hong Kong Using a Novel Grey Dynamic Prediction Model. J. Grey Syst. 2018, 30, 157–172. [Google Scholar]

- An, Q.; An, H.; Wang, L. Analysis of Embodied Energy Flow Network between Chinese Industries. J. Syst. Eng. 2014, 6, 754–762. [Google Scholar]

- Wang, X.; Li, X.; Chen, G. Introduction to Network Science; Higher Education Press: Beijing, China, 2012. [Google Scholar]

- National Bureau of Statistics of China. China Input-Output Table; National Bureau of Statistics of China: Beijing, China, 2018.

- National Bureau of Statistics of China. China Energy Statistics Yearbook; National Bureau of Statistics of China: Beijing, China, 2013.

- National Bureau of Statistics of China. China Energy Statistics Yearbook; National Bureau of Statistics of China: Beijing, China, 2005.

- Zhu, Q.; Sun, H.; Wang, S. The Relationship between China’s Resource-Based Industries and Manufacturing Carbon Emissions and Industrial Economic Development. China Pop. Resour. Environ. 2014, 11, 112–119. [Google Scholar]

- Kolaczyk, E.D.; Csardi, G. Statistical Analysis of Network Data with R; Springer: New York, NY, USA, 2014. [Google Scholar]

- Newman, M.E.J.; Girvan, M. Finding and Evaluating Community Structure in Networks. Phys. Rev. E 2004, 69, 026113. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yin, Y.; Zhu, C. Research on Industry Importance Algorithm in Industrial Correlation Network: Based on Complex Network Centrality. J. Econ. Manag. 2014, 3, 96–102. [Google Scholar]

- Wilson, J.D.; Palowitch, J.; Bhamidi, S.; Nobel, A.B. Community Extraction in Multilayer Networks with Heterogeneous Community Structure. J. Mach. Learn. Res. 2017, 18, 5458–5506. [Google Scholar]

- Gauvin, L.; Panisson, A.; Cattuto, C. Detecting the Community Structure and Activity Patterns of Temporal Networks: A Non-Negative Tensor Factorization Approach. PLoS ONE 2014, 9, e86028. [Google Scholar] [CrossRef] [PubMed]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy Management in Industry–A Systematic Review of Previous Findings and An Integrative Conceptual Framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef]

| Type of Industry | Name of Industry | Abbrev. |

|---|---|---|

| High-end manufacturing | Manufacturing of chemical products | HM_1 |

| Manufacturing of general and special purpose machinery | HM_2 | |

| Manufacturing of transportation equipment | HM_3 | |

| Manufacturing of electrical machinery and equipment | HM_4 | |

| Manufacturing of communication equipment, computers, and other electronic equipment | HM_5 | |

| Manufacturing of measuring instruments and repair of metal products, machinery, and equipment | HM_6 | |

| Traditional manufacturing | Food and tobacco processing | TM_1 |

| Textile industry | TM_2 | |

| Manufacturing of leather, fur, and related products | TM_3 | |

| Processing of timber and furniture | TM_4 | |

| Manufacturing of paper, printing, and articles for cultural, educational, and sports activities | TM_5 | |

| Other manufacturing and comprehensive use of waste resources | TM_6 | |

| Resource-based industry | Agriculture, forestry, animal husbandry and fishery | RI_1 |

| Mining and washing of coal | RI_2 | |

| Extraction of petroleum and natural gas | RI_3 | |

| Mining and processing of metal ores | RI_4 | |

| Mining and processing of nonmetals and other ores | RI_5 | |

| Processing of petroleum, coking, and processing of nuclear fuel | RI_6 | |

| Manufacturing of non-metallic mineral products | RI_7 | |

| Smelting and processing of metals | RI_8 | |

| Manufacturing of metal products | RI_9 | |

| Production and distribution of electric power and heat power | RI_10 | |

| Production and distribution of gas | RI_11 | |

| Production and distribution of tap water | RI_12 | |

| Daily industry | Construction | DI_1 |

| Wholesale and retail trades and accommodation and catering | DI_2 | |

| Transport, storage, and postal services | DI_3 | |

| Others | DI_4 |

| Internal Network of Manufacturing | External Network of Manufacturing | |||

|---|---|---|---|---|

| In-Edge Network | Out-Edge Network | In-Edge Network | Out-Edge Network | |

| Node count | 32 | 32 | 39 | 39 |

| Edge count | 136 | 129 | 269 | 261 |

| Network density | 0.274 | 0.269 | 0.363 | 0.358 |

| Degree centrality | 0.242 | 0.248 | 0.242 | 0.248 |

| Closeness centrality | 0.033 | 0.036 | 0.032 | 0.033 |

| Betweenness centrality | 0.279 | 0.292 | 0.257 | 0.269 |

| Eigenvector centrality | 0.498 | 0.507 | 0.413 | 0.421 |

| 2002 | 2005 | 2007 | 2010 | 2012 | ||

|---|---|---|---|---|---|---|

| Internal network of manufacturing | In-edge network | TM_5-HM_6 | TM_4-HM_6 | RI_6-HM_5 | RI_6-HM_5 | TM_2-HM_5 |

| Betweenness | 60 | 108 | 136 | 144 | 152 | |

| Out-edge network | TM_1-HM_6 | TM_1-HM_6 | HM_6-TM_6 | TM_2-RI_6 | HM_6-TM_6 | |

| Betweenness | 220 | 220 | 148 | 148 | 144 | |

| External network of manufacturing | In-edge network | HM_6-DI_1(M) | HM_6-DI_1(M) | TM_4-HM_5 | TM_4-HM_5 | TM_2-HM_5 |

| Betweenness | 148 | 129 | 203 | 228 | 232 | |

| Out-edge network | HM_6-RI_1(M) | HM_6-RI_1(M) | RI_6-RI_1(M) | RI_6-RI_1(M) | RI_1(M)-RI_10~12(M) | |

| Betweenness | 380 | 361 | 312 | 332 | 243 |

| df | QS | MSE | F-Statistic | p-Value | ||

|---|---|---|---|---|---|---|

| Comparison between time periods 2005 and 2002 | Network type | 1 | 0.458 | 0.458 | 6.422 | 0.017 * |

| In-edge and out-edge network | 1 | 0.156 | 0.156 | 2.181 | 0.151 | |

| Network type: In-edge and Out-edge network | 1 | 0.165 | 0.165 | 2.312 | 0.139 | |

| Residuals | 29 | 2.068 | 0.071 | —— | —— | |

| Comparison between time periods 2007 and 2002 | Network type | 1 | 0.000 | 0.000 | 0.000 | 0.984 |

| In-edge and out-edge network | 1 | 1.682 | 1.682 | 33.426 | 2.9 × 10−6 *** | |

| Network type: In-edge and out-edge network | 1 | 0.063 | 0.063 | 1.249 | 0.273 | |

| Residuals | 29 | 1.459 | 0.050 | —— | —— | |

| Comparison between time periods 2010 and 2002 | Network type | 1 | 0.060 | 0.060 | 1.576 | 0.219 |

| In-edge and out-edge network | 1 | 2.020 | 2.020 | 52.719 | 5.38 × 10−8 *** | |

| Network type: In-edge and out-edge network | 1 | 0.011 | 0.011 | 0.290 | 0.594 | |

| Residuals | 29 | 1.111 | 0.038 | —— | —— | |

| Comparison between time periods 2012 and 2002 | Network type | 1 | 0.184 | 0.184 | 3.085 | 0.090 |

| In-edge and out-edge network | 1 | 0.596 | 0.596 | 10.015 | 0.004 ** | |

| Network type: In-edge and out-edge network | 1 | 0.021 | 0.021 | 0.351 | 0.558 | |

| Residuals | 29 | 1.725 | 0.060 | —— | —— | |

| df | F-Statistic | p-Value | ||

|---|---|---|---|---|

| Comparison between time periods 2005 and 2002 | Network type | 1/31 | 4.153 | 0.050 # |

| In-edge and out-edge network | 1/31 | 1.406 | 0.245 | |

| Comparison between time periods 2007 and 2002 | Network type | 1/31 | 0.215 | 0.646 |

| In-edge and out-edge network | 1/31 | 0.081 | 0.777 | |

| Comparison between time periods 2010 and 2002 | Network type | 1/31 | 0.036 | 0.852 |

| In-edge and out-edge network | 1/31 | 0.188 | 0.668 | |

| Comparison between time periods 2012 and 2002 | Network type | 1/31 | 1.501 | 0.230 |

| In-edge and out-edge network | 1/31 | 2.828 | 0.103 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Z.; Zhou, W.; Ming, Q. Embodied Energy Flow Patterns of the Internal and External Industries of Manufacturing in China. Sustainability 2019, 11, 438. https://doi.org/10.3390/su11020438

Feng Z, Zhou W, Ming Q. Embodied Energy Flow Patterns of the Internal and External Industries of Manufacturing in China. Sustainability. 2019; 11(2):438. https://doi.org/10.3390/su11020438

Chicago/Turabian StyleFeng, Zhijun, Wen Zhou, and Qian Ming. 2019. "Embodied Energy Flow Patterns of the Internal and External Industries of Manufacturing in China" Sustainability 11, no. 2: 438. https://doi.org/10.3390/su11020438

APA StyleFeng, Z., Zhou, W., & Ming, Q. (2019). Embodied Energy Flow Patterns of the Internal and External Industries of Manufacturing in China. Sustainability, 11(2), 438. https://doi.org/10.3390/su11020438