The Numerical Simulation of the Airflow Distribution and Energy Efficiency in Data Centers with Three Types of Aisle Layout

Abstract

1. Introduction

2. Methodology

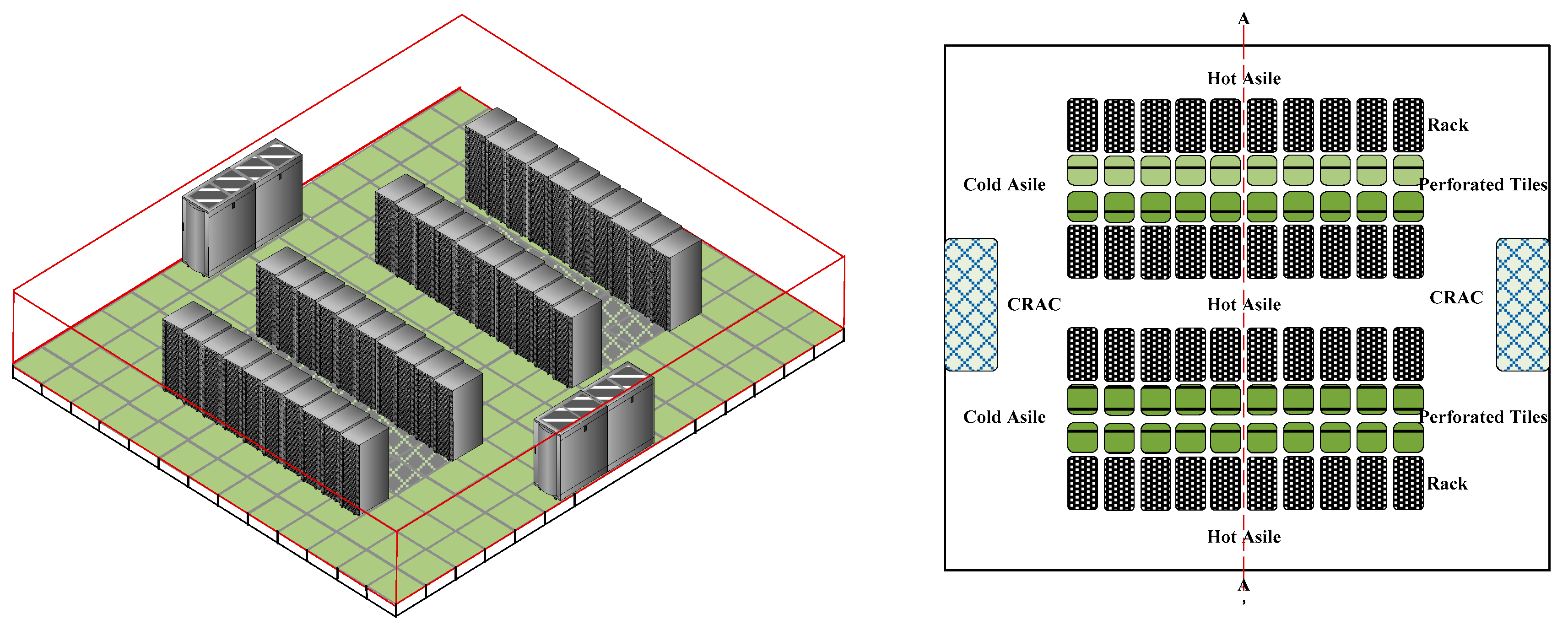

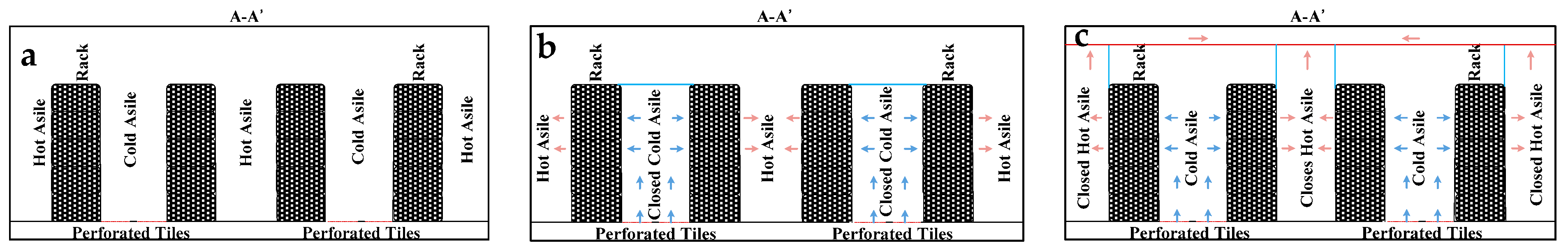

2.1. The Model Framework of Data Center

2.2. Mathematical Model

2.3. Calculation Method

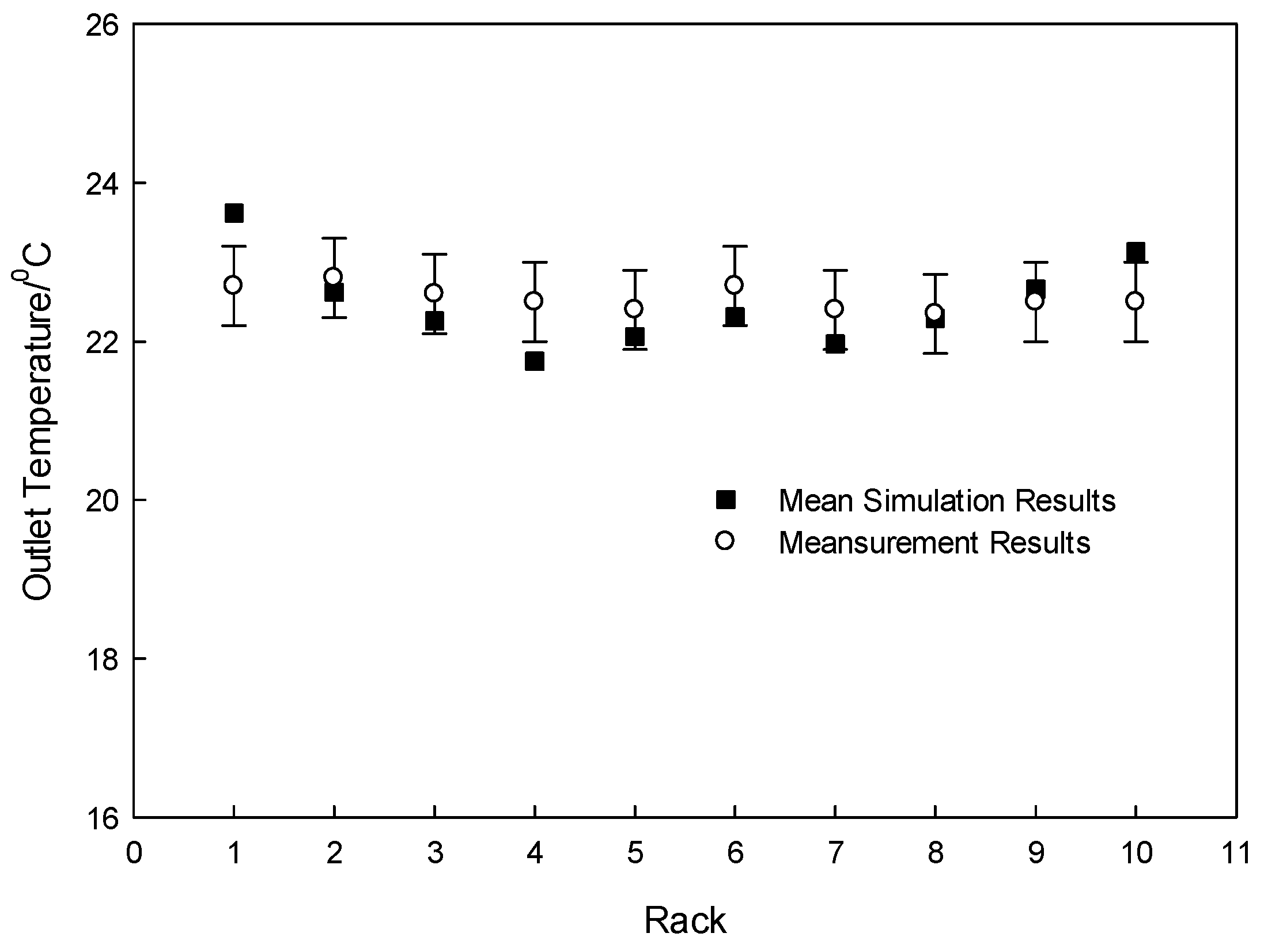

2.4. Grid Independent and Model Validation

3. Results and Discussion

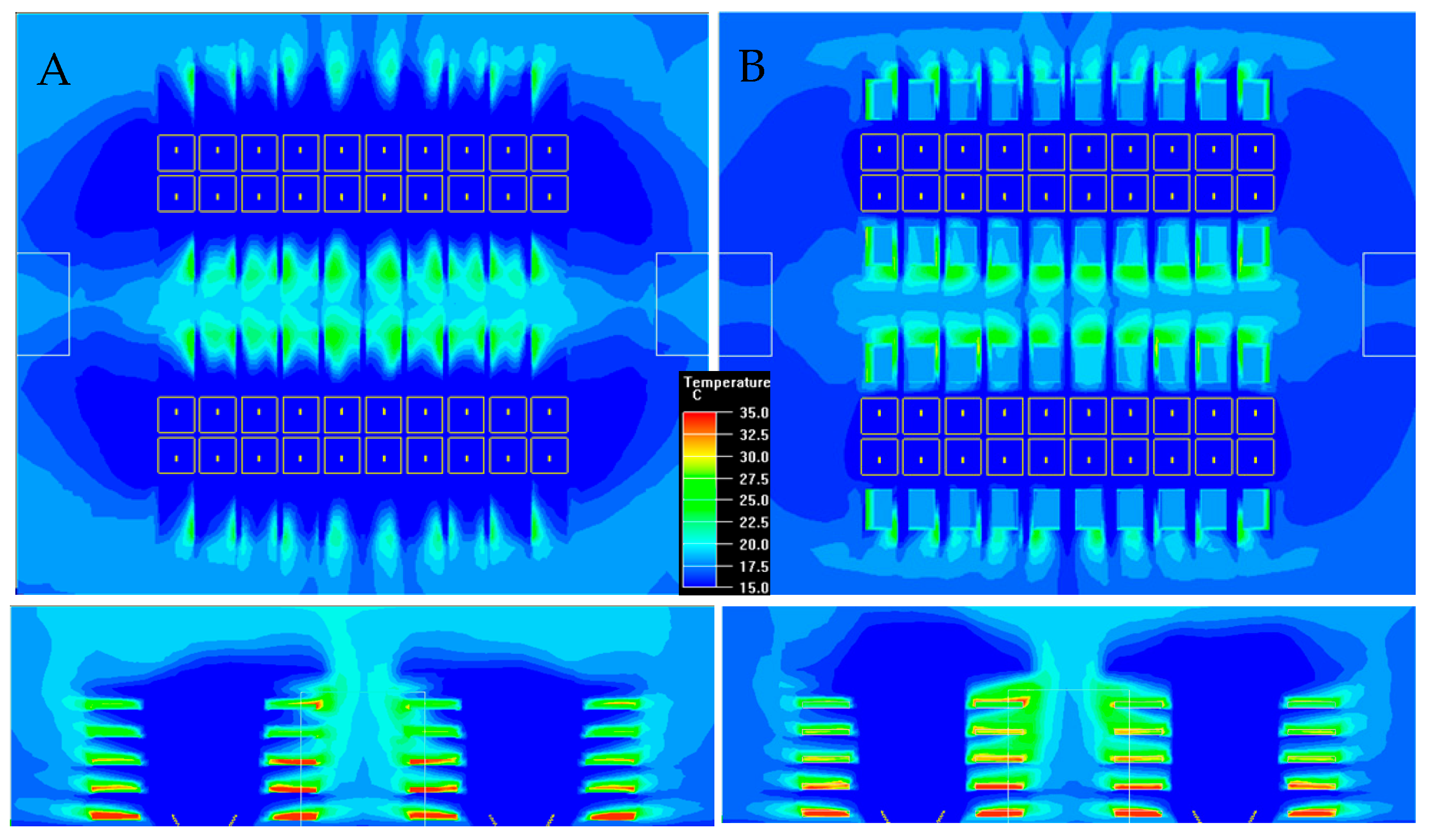

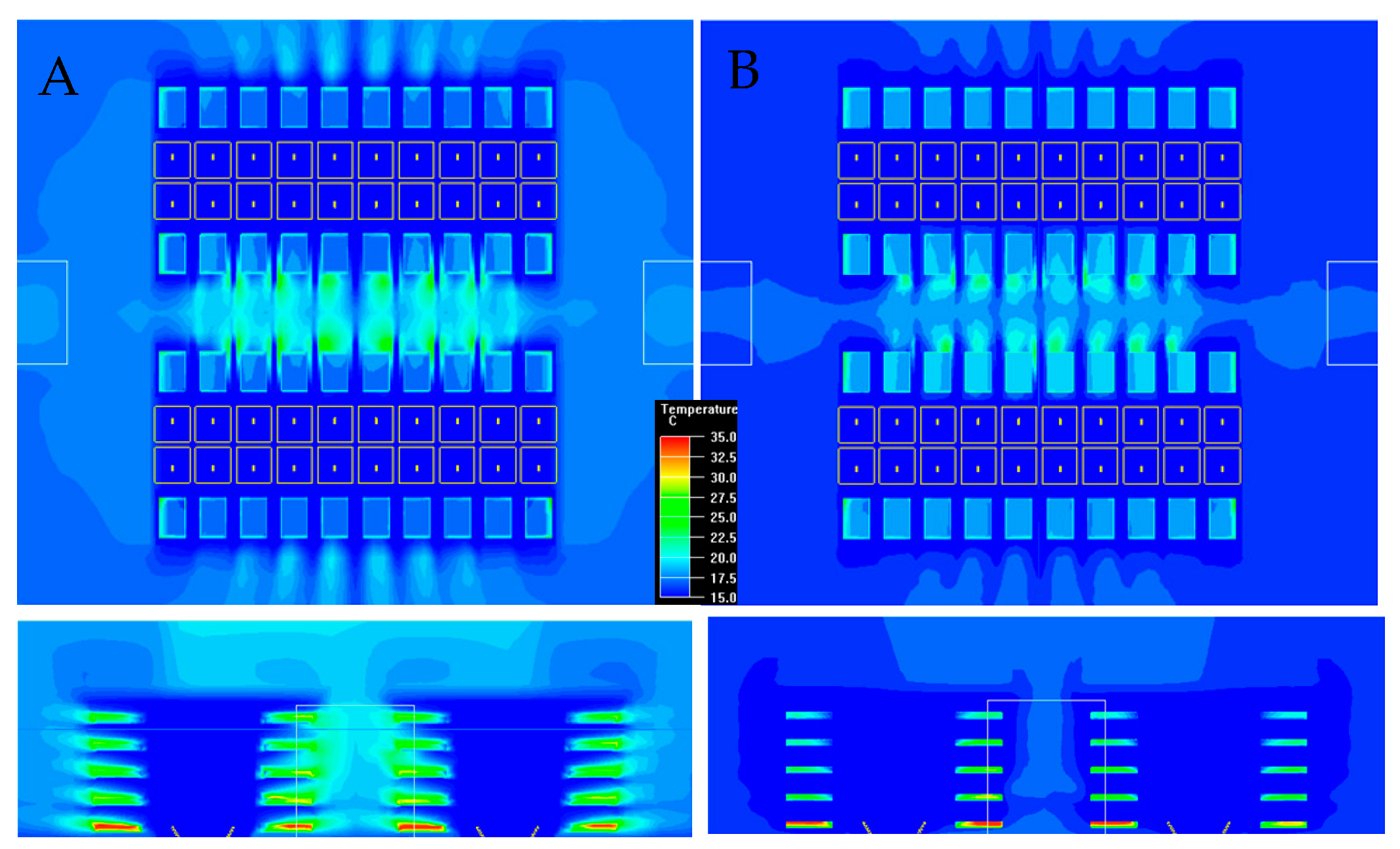

3.1. The Characteristic of Flow and Temperature Distribution

3.2. The Energy Efficiency

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Koomey, J.G. Growth in Data Center Electricity Use 2005 to 2010; Analytics Press: Oakland, CA, USA, 2011. [Google Scholar]

- Data Centers Consume 2% of the Country’s Electricity. How to Surrender the “Electric Tiger” in the Cloud? Available online: http://dy.163.com/v2/article/detail/EBFPE4KA05385JEH.html (accessed on 30 March 2019).

- The Power Consumption of China’s Data Center Has Exceeded that of the Three Gorges Dam. Available online: https://www.sohu.com/a/207358888_531621 (accessed on 29 November 2017).

- Cavanagh, R. A Tectonic Shift in America’s Energy Landscape; Natural Resources Defense Council (NRDC): New York, NY, USA, 2015. [Google Scholar]

- Ni, J.; Jin, B.; Zhang, B.; Wang, X. Simulation of airflow distribution and analysis of energy consumption in data centers with a confined space. Sustainability 2017, 9, 664. [Google Scholar] [CrossRef]

- Ni, J.; Bai, X. A review of air conditioning energy performance in data centers. Renew. Sustain. Energy Rev. 2017, 67, 625–640. [Google Scholar] [CrossRef]

- Wang, W.; Luo, J.; Song, A. Dynamic pricing based energy cost optimization in data center environments. Chin. J. Comput. 2013, 36, 599–612. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, Z.; Yang, L. A review on airflow distribution and management in data center. Energy Build. 2018, 179, 264–277. [Google Scholar] [CrossRef]

- Alkharabsheh, S.; Fernandes, J.; Gebrehiwot, B.; Agonafer, D.; Ghose, K.; Ortega, A.; Joshi, Y.; Sammakia, B. A Brief overview of recent developments in thermal management in data centers. J. Electron. Packag. 2015, 127, 040801. [Google Scholar] [CrossRef]

- Xie, M.X.; Wang, J.; Liu, J.X. Evaluation metrics of thermal management in data centers based on exergy analysis. Appl. Therm. Eng. 2019, 147, 1083–1095. [Google Scholar] [CrossRef]

- Athavale, J.; Yoda, M.; Joshi, Y. Comparison of data driven modeling approaches for temperature prediction in data centers. Int. J. Heat Mass Transf. 2019, 135, 1039–1052. [Google Scholar] [CrossRef]

- Rong, H.; Zhang, H.; Xiao, S.; Li, C.; Hu, C. Optimizing energy consumption for data centers. Renew. Sustain. Energy Rev. 2016, 58, 674–691. [Google Scholar] [CrossRef]

- Sundaralingam, V.; Arghode, V.K.; Joshi, Y.; Phelps, W. Experimental characterization of various cold aisle containment configurations for data Centers. J. Electron. Packag. 2014, 137, 011007. [Google Scholar] [CrossRef]

- Wang, N.; Chen, L.; Cai, F.; Deng, P. Experiment and simulation of cold aisle partition impacting on thermal environment of a computer room. Heat. Vent. Air Cond. 2017, 47, 107–112. [Google Scholar]

- Gondipalli, S.; Sammakia, B.; Bhopte, S.; Schmidt, R.; Iyengar, M.K.; Murray, B. Optimization of cold aisle isolation designs for a data center with roofs and doors using slits. In Proceedings of the ASME 2009 Interpack Conference Collocated with the ASME 2009 Summer Heat Transfer Conference and the ASME 2009 International Conference on Energy Sustainability, San Francisco, CA, USA, 19–23 July 2009; pp. S174–S175. [Google Scholar]

- Muralidharan, B.; Shrivastava, S.K.; Ibrahim, M.; Alkharabsheh, S.A.; Sammakia, B.G. Impact of cold aisle containment on thermal performance of data center. InterPACK 2013, v2. In Proceedings of the ASME 2013 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, Burlingame, CA, USA, 16–18 July 2013. [Google Scholar]

- Nada, S.A.; Elfeky, K.E. Experimental investigations of thermal managements solutions in data centers buildings for different arrangements of cold aisles containments. J. Build. Eng. 2016, 5, 41–49. [Google Scholar] [CrossRef]

- Nada, S.A.; Said, M.A.; Rady, M.A. CFD investigations of data centers’ thermal performance for different configurations of CRACs units and aisles separation. Alex. Eng. J. 2016, 55, 959–971. [Google Scholar] [CrossRef]

- Nada, S.A.; Said, M.A.; Rady, M.A. Numerical investigation and parametric study for thermal and energy management enhancements in data centers’ buildings. Appl. Therm. Eng. 2016, 98, 110–128. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, J.; Yang, Y.; Wang, Y.; Yuan, X. Investigation and improvement of air distribution system’s airflow performance in data centers. Procedia Eng. 2017, 205, 2895–2902. [Google Scholar] [CrossRef]

- Wang, C.H.; Tsui, Y.Y.; Wang, C.C. On cold-aisle containment of a container data center. Appl. Therm. Eng. 2016, 112, 133–142. [Google Scholar] [CrossRef]

- Wang, I.; Tsui, Y.; Wang, C. Improvements of Airflow Distribution in a Container Data Center. Energy Procedia 2015, 75, 1819–1824. [Google Scholar] [CrossRef]

- Niemann, J.; Brown, K.; Avelar, V. Impact of Hot and Cold Aisle Containment on Data Center Temperature and Efficiency; White Paper 135; Schneider Electric Data Center Science Center: Omaha, NE, USA, 2011. [Google Scholar]

- Pervila, M.; Kangasharju, J. Cold Air Containment. In Proceedings of the 2nd ACM SIGCOMM Workshop on Green Networking (GreenNets ’11), Toronto, ON, Canada, 15–19 August 2011; pp. 7–12. [Google Scholar]

- Gao, T.Y.; David, M.; Geer, J.; Schmidt, R.; Sammakia, B. Experimental and numerical dynamic investigation of an energy efficient liquid cooled chiller-less data center test facility. Energy Build. 2015, 91, 83–96. [Google Scholar] [CrossRef]

- Cho, J.; Lim, T.; Kim, B.S. Measurements and predictions of the air distribution systems in high compute density (internet) data centers. Energy Build. 2009, 41, 1107–1115. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, C.; Wang, C.; Zhang, X. Numerical simulation on a thermal management system for a small data center. Int. J. Heat Mass Transf. 2018, 124, 677–692. [Google Scholar] [CrossRef]

- Huang, Z.L.; Dong, K.J.; Sun, Q.; Su, L.; Liu, T.Q. Numerical Simulation and Comparative Analysis of Different Airflow Distributions in Data Centers. Procedia Eng. 2017, 205, 2378–2385. [Google Scholar] [CrossRef]

- Hassan, N.M.S.; Khan, M.M.K.; Rasul, M.G. Temperature monitoring and CFD Analysis of Data Centre. Procedia Eng. 2013, 56, 551–559. [Google Scholar] [CrossRef]

- Abdelmaksoud, W.A.; Dang, T.Q.; Khalifa, H.E.; Schmidt, R.R. Improved computational fluid dynamics model for open-aisle air-cooled data center simulations. J. Electron. Packag. 2013, 135, 030901-1. [Google Scholar] [CrossRef]

- Fulpagare, Y.; Joshi, Y.; Bhargav, A. Transient characterization of data center racks. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition (IMECE), Phoenix, AZ, USA, 13–17 November 2016. [Google Scholar]

- Ham, S.W.; Jeong, J.W. Impact of aisle containment on energy performance of a data center when using an integrated water-side economizer. Appl. Therm. Eng. 2015, 105, 372–384. [Google Scholar] [CrossRef]

- Lv, C.; Chen, G.; Liu, Y.; Ye, S. Study on computer room layout and air distribution in small scale data center. Cryogenics 2017, 2017, 61–67. (In Chinese) [Google Scholar]

- Schaadt, J.R.H.; Fouladi, K.; Wemhoff, A.P. Load Capacity and thermal efficiency optimization of a research data center using computational modeling. In Proceedings of the ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems Collocated with the ASME 2015, International Conference on Nanochannels, Microchannels, and Minichannels, San Francisco, CA, USA, 6–10 July 2015. [Google Scholar]

- Nada, S.A.; Elfeky, K.E.; Attia, A.M.A. Experimental investigations of air conditioning solutions in high power density data centers using a scaled physical model. Int. J. Refrig. 2016, 63, 87–99. [Google Scholar] [CrossRef]

- Zhang, M.; An, Q.; Long, Z.; Pan, W.; Zhang, H.; Cheng, X. Optimization of airflow organization for a small-scale date center based on the cold aisle closure. Procedia Eng. 2017, 205, 1893–1900. [Google Scholar] [CrossRef]

- Demetriou, D.W.; Khalifa, H.E. Optimization of Enclosed Aisle Data Centers Using Bypass Recirculation. J. Electron. Packag. 2012, 134, 020904-1. [Google Scholar] [CrossRef]

- Ansys Incorported. ANSYS FLUENT-Solver Release 10.0; Ansys Inc.: Canonsbury, PA, USA, 2005; p. 131. [Google Scholar]

- Abanto, J.; Barrero, D.; Reggio, M.; Ozell, B. Airflow modeling in a computer room. Build. Environ. 2004, 39, 1393–1402. [Google Scholar] [CrossRef]

- Song, Z. Thermal performace of a contained data center with fan-assisted perforations. Appl. Therm. Eng. 2016, 102, 1175–1184. [Google Scholar] [CrossRef]

- Dun, Z.; Qin, Y.; Guan, X. Simulation optimization and evaluation analysis of the data center airflow distribution. Build. Energy Effic. 2015, 43, 27–33. [Google Scholar]

- Herrlin, M.K. Rack cooling effectiveness in data centers and telecom central offices: The Rack Cooling Index (RCI). ASHRAE Trans. 2005, 111, 725–731. [Google Scholar]

- Herrlin, M.K. Airflow and cooling performance of DC: Two performance metrics. ASHRAE Trans. 2008, 114, 182–187. [Google Scholar]

- Sorell, V.; Escalante, S.; Yang, J. Comparison of overhead and underfloor air delivery systems in a data center environment using CFD modeling. ASHRAE Trans. 2005, 111, 756–764. [Google Scholar]

- VanGilder, J.; Schmidt, R. Airflow Uniformity through Perforated Tiles in a Raised-Floor Data Center. Paper No. IPACK2005-73375. In Proceedings of the ASME 2005 Pacific Rim Technical Conference and Exhibition on Integration and Packaging of MEMS, NEMS, and Electronic Systems collocated with the ASME 2005 Heat Transfer Summer Conference, San Francisco, CA, USA, 17–22 July 2005. [Google Scholar]

- Arghode, V.K.; Kumar, P.; Joshi, Y.; Weiss, T.; Meyer, G. Rack Level Modeling of Air Flow Through Perforated Tile in a Data Center. J. Electron. Packag. 2013, 135, 030902. [Google Scholar] [CrossRef]

- Xu, Q. Energy Consumption and Air Distribution Simulation of a Substation Data Room. Master’s Thesis, Zhejiang University, Hangzhou, China, 2015. [Google Scholar]

- Seymour, M.J.; Herrlin, M.K. Data center optimization using performance metrics. In Proceedings of the ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, San Francisco, CA, USA, 6–9 July 2015. [Google Scholar]

- Beitelmal, A.H. Numerical investigation of data center raised-floor plenum. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

| Length/m | Width/m | Height/m | |

|---|---|---|---|

| Simulation of data center | 12.0 | 10.00 | 3.20 |

| Chassis | 0.683 | 0.448 | 0.0875 |

| Air conditioner | 0.765 | 0.560 | 1.940 |

| Mesh (Nodes) | Temperature of Wind °C | Rack 1 | Rack 2 | ||

|---|---|---|---|---|---|

| β | ηr | β | ηr | ||

| 110,560 | 17.83 | 0.17 | 1.75 | 0.20 | 1.71 |

| 218,144 | 17.99 | 0.24 | 1.60 | 0.27 | 1.65 |

| 327,424 | 18.01 | 0.30 | 1.61 | 0.30 | 1.64 |

| 430,941 | 17.95 | 0.31 | 1.62 | 0.31 | 1.64 |

| 539,435 | 17.95 | 0.32 | 1.60 | 0.29 | 1.63 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, J.; Jin, B.; Ning, S.; Wang, X. The Numerical Simulation of the Airflow Distribution and Energy Efficiency in Data Centers with Three Types of Aisle Layout. Sustainability 2019, 11, 4937. https://doi.org/10.3390/su11184937

Ni J, Jin B, Ning S, Wang X. The Numerical Simulation of the Airflow Distribution and Energy Efficiency in Data Centers with Three Types of Aisle Layout. Sustainability. 2019; 11(18):4937. https://doi.org/10.3390/su11184937

Chicago/Turabian StyleNi, Jing, Bowen Jin, Shanglei Ning, and Xiaowei Wang. 2019. "The Numerical Simulation of the Airflow Distribution and Energy Efficiency in Data Centers with Three Types of Aisle Layout" Sustainability 11, no. 18: 4937. https://doi.org/10.3390/su11184937

APA StyleNi, J., Jin, B., Ning, S., & Wang, X. (2019). The Numerical Simulation of the Airflow Distribution and Energy Efficiency in Data Centers with Three Types of Aisle Layout. Sustainability, 11(18), 4937. https://doi.org/10.3390/su11184937